Varec 4000 User Manual

4000 Tank Gauge Transmitter

Advanced Technology Transmitter for transmission of level and

temperature data from the tankside to inventory management

systems.

Installation and

Operations Manual

IOM003GVAE1007

www.varec.com

5834 Peachtree Corners East, Norcross (Atlanta), GA 30092 USA

Tel: +1 (770) 447-9202 Fax: +1 (770) 662-8939

Varec, Inc.

4000

Copyright

All rights reserved. Printed in the United States of America. Except as permitted under

the United States Copyright Act of 1976, no part of this publication may be reproduced,

stored in a retrieval system or transmitted in any form or by any means- electronic,

mechanical, photocopying, recording or otherwise- without the prior written permission

of the Publisher:

Varec, Inc.

5834 Peachtree Corners East

Norcross (Atlanta) GA 30096

USA

Trademarks acknowledged

Varec, Inc. recognizes all other trademarks. Trademarks of other products mentioned in

this document are held by the companies producing them.

Varec® is a registered trademark of Varec, Inc. Copyright 2003

FuelsManager® is a registered trademark of Varec, Inc. Copyright 2004

MODBUS® is a registered trademark of Modicon, Inc.

TIWAY® is a registered trademark of Texas Instruments Corporation.

HART® interface is a registered trademark of HART communications foundation.

Rosemount® and Smart Family® are registered trademarks, and HART is a

trademark of Rosemount Inc.

i

Tank Gauge Transmitter

Disclaimer of Warranties

The contract between the Seller and the Buyer states the entire obligation of the Seller.

The contents of this document shall not become part of or modify any prior or existing

agreement, commitment or relationship between the Seller and Buyer. There are no

express or implied warranties set out in this document. The only warranties that apply

are those in the existing contract between the Seller and Buyer.

Varec, Inc. products have not been tested by Varec, Inc. under all possible operational

conditions, and Varec, Inc. may not have all the data relative to your application. The

information in this document is not all inclusive and does not and cannot take into

account all unique situations. Consequently, the user should review this product

literature in view of his/her application. If you have any further questions, please contact

Varec, Inc. for assistance.

Limitations of Seller's Liability

In the event that a court holds that this document created some new warranties, Seller's

liability shall be limited to repair or replacement under the standard warranty clause. In

no case shall the Seller's liability exceed that stated as Limitations of Remedy in the

contract between the Seller and Buyer.

Terms of Use

The information provided in this document is provided “as is” without warranty of any

kind. Varec, Inc. disclaim all warranties, either express or implied, including the

warranties of merchantability and fitness for a particular purpose. In no event shall

Varec, Inc. or its suppliers be liable for any damages whatsoever including direct,

indirect, incidental, consequential, loss of business profits or special damages, even if

Varec, Inc. or its suppliers have been advised of the possibility of such damages.

Use of parts that are not manufactured or supplied by Varec, Inc. voids any Varec, Inc.

warranty and relieves Varec, Inc. of any obligation to service the product under warranty.

Varec, Inc. recommends the use of only Varec, Inc. manufactured or supplied parts to

maintain or service Varec, Inc. products.

ii Installation and Operations Manual

4000

Safety Precaution Definitions

Caution! Damage to equipment may result if this precaution is disregarded.

Warning! Direct injury to personnel or damage to equipment which can cause injury to

personnel may result if this precaution is not followed.

Safety Precautions

READ AND UNDERSTAND THIS INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING

OR PERFORMING MAINTENANCE ON VAREC 4000 SERIES TANK GAUGE TRANSMITTER.

FOLLOW ALL PRECAUTIONS AND WARNINGS NOTED HEREIN WHEN INSTALLING,

OPERATING OR PERFORMING MAINTENANCE ON THIS EQUIPMENT.

iii

Tank Gauge Transmitter

iv Installation and Operations Manual

4000

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Getting Acquainted with the Advanced Technology Transmitter (ATT) . . . . .1

1.4 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.5 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1.2 Storage Prior to Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1.3 Becoming Familiar with the ATT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1.4 Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3 Grounding the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.1 ATT Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.2 Wiring Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.3 Connecting Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4.4 Connecting Host Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.5.1 Connecting the Handheld Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5.2 Wiring Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5.3 Installation Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5.4 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Configuration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 1200 Hand Held Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Terminal Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4.5 Notes on Menu Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5.6 Imperial Decimal 1800 Series Transmitter Quick Setup . . . . . . . . . . . . . . .24

3.5.7 0-20 Meters 1800 Series Transmitter Quick Setup. . . . . . . . . . . . . . . . . . .24

3.5.8 0-30 Meters 1800 Series Transmitter Quick Setup. . . . . . . . . . . . . . . . . . .24

4 Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .27

4.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.2 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.3.1 ATT Error Status Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.5 ATT Configuration Error Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.7 Host Communication Loopback Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.1 Specifications and Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 31

v

5.1.1 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.2 Physical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.3 Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1.4 Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.1 Explosion Proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.2 Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Order Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 CPU Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3 Status Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.4 ATTI Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.5 Host Communications Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.6 Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tank Gauge Transmitter

7.6.1 Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.6.2 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.7 Encoder Battery Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.8 Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.9 Host Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.10 Mark/Space Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.11 Modbus Support over Mark/Space Host Interface. . . . . . . . . . . . . . . . . . . . 41

7.12 Compatibility with Varec Tank Polling Unit . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 ATT Family of Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1 Model 4040 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Model 4050 Digital Input/Output Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.2.1 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.2.2 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.2.3 Relay Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9 Modbus Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.5 Integer Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.5.1 Integer Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.5.3 Character Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.5.5 Packed Bit Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.6.1 Floating-Point Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.6.2 The Two 16-bit Registers Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

vi Installation and Operations Manual

4000

9.6.3 Floating Point Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.6.5 Floating Point Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6.6 Floating Point Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.7.1 Status Bit Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.8 Exception Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.10 Loopback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

9.11 Hardware Implementation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

9.12 Integer Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.14 Status Bit Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

10 Optional Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.1 4000TIFMO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.2 4000GEFMO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.3 4000LJFMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.4 4000MXFMO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

10.6 4000GMFMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

vii

Tank Gauge Transmitter

viii Installation and Operations Manual

4000 Introduction

g

1 Introduction

1.1 Using This Manual

This manual is designed to assist the user with the installation, configuration, operation, maintenance, and

troubleshooting of the Varec Model 4000 Advanced Technology Transmitter (ATT).

1.2 Getting Acquainted with the Advanced Technology Transmitter (ATT)

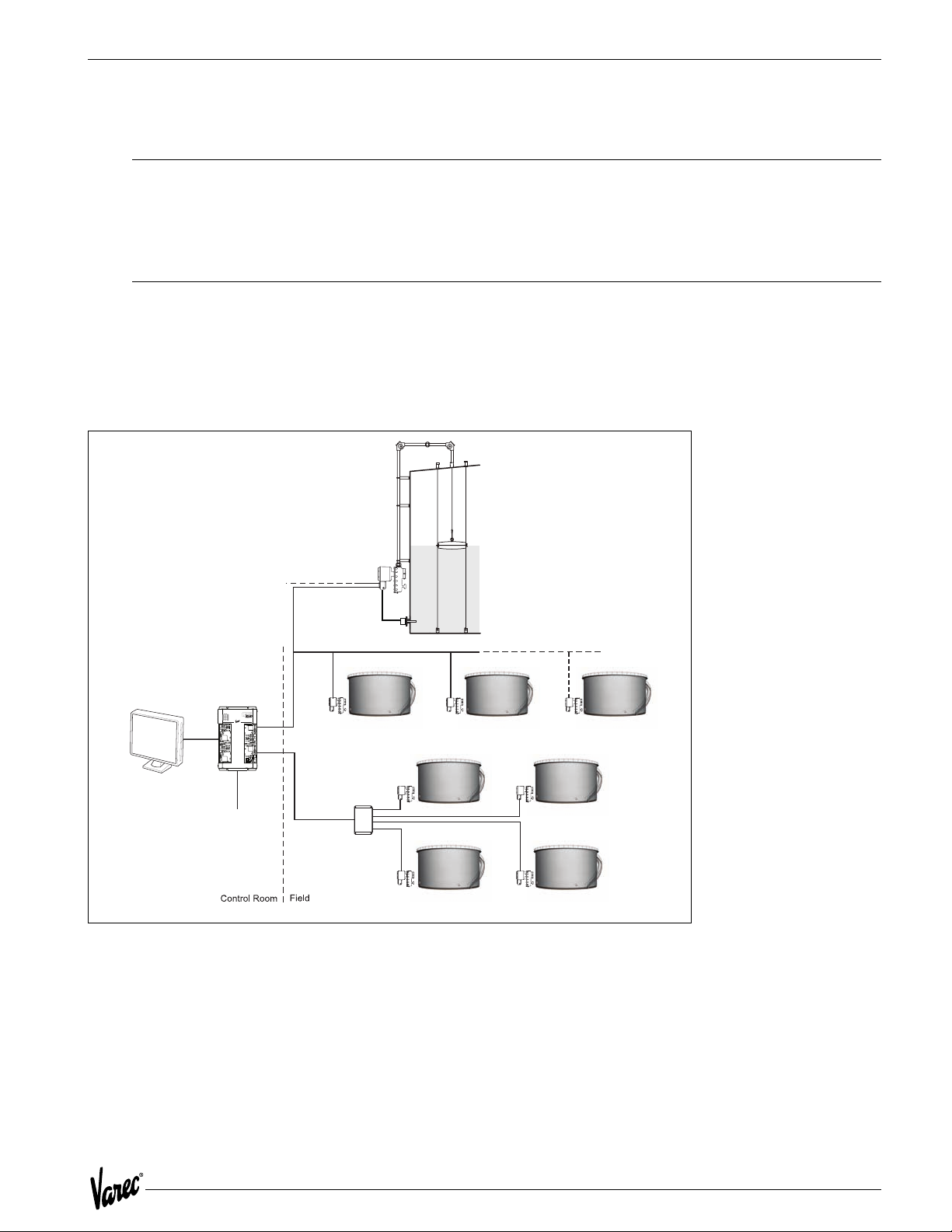

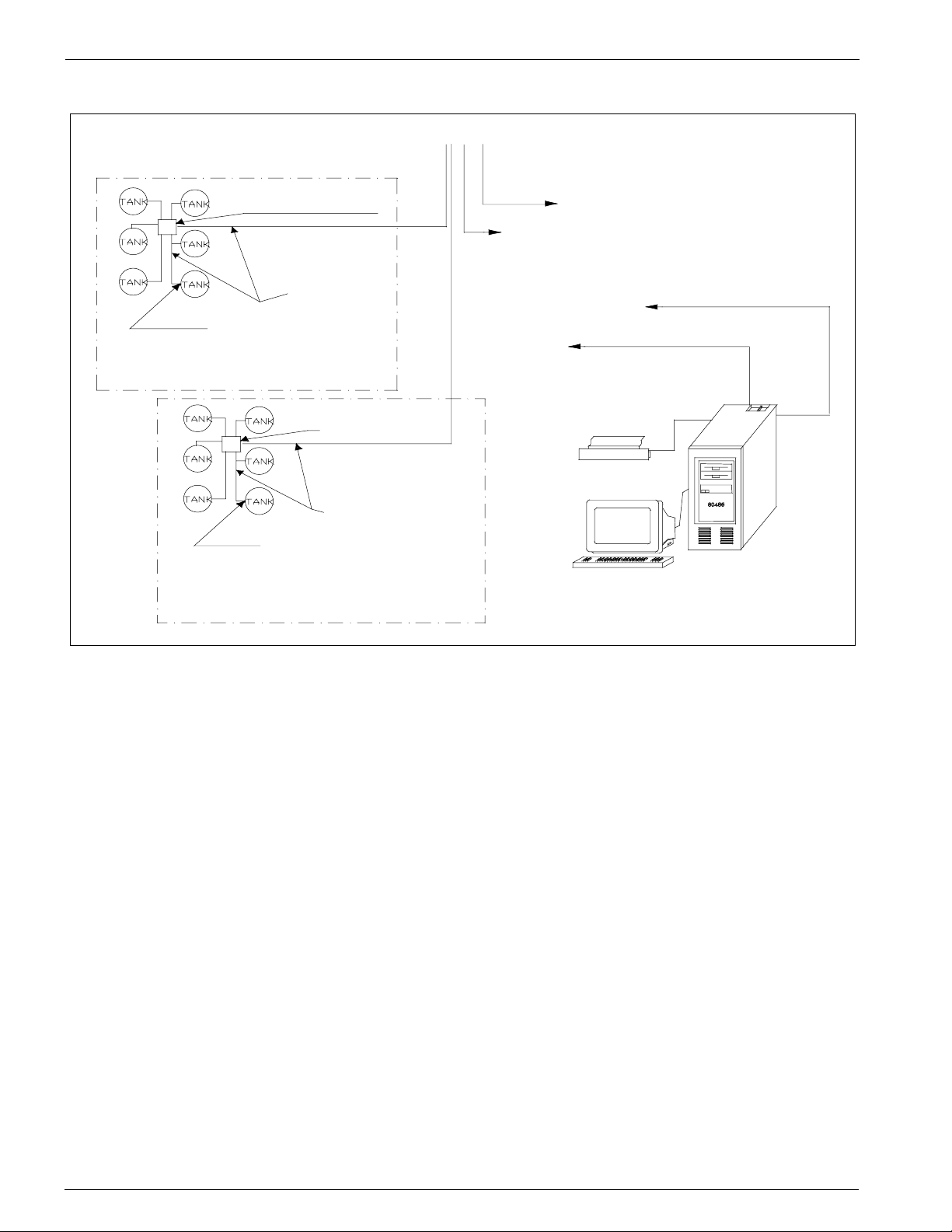

The Varec Model 4000 Advanced Technology Transmitter (ATT), in conjunction with a host, represents a data

acquisition and communications system for use in liquid level measurement and/or other measurement applications.

Liquid level measurement is provided by the Advanced Technology Transmitter coupled to a Varec Model 2500 or other

level gauge, as shown in Figure 1-1.

Tank Gauge

and

Transmitter

Power

Loop

Communcations

3-wire

RTD

8130 RTU

FuelsManager

Software

or

8300 TGI

CPU

+24V

+5V

COMM

I/O

+15V

ERROR

-15V

Communications

between DCS/PLCs

for control capabilities

Field

Junction Box

Star Communcations e.

Figure 1-1: Tank Installation with Model 4000 ATT

Loop Communcations

. Mark/Space

1

Introduction Tank Gauge Transmitter

1.3 Operation

The ATT uses an incremental counting technique for determining liquid level. An initial level is identified as part of the

calibration procedure. Changes to that level are determined through incremental increases or decreases detected by

the ATT.

The host computer collects measurement information by polling the Advanced Technology Transmitter over a variety

of communication interfaces such as EIA485 and Mark/Space. Several communication protocols are supported. Among

them are Modbus and Mark/Space.

1.4 Configuration

The Varec Model 1200 Handheld Terminal is used to configure the ATT. It connects to the same ATTI bus used to

interconnect other input/output devices to the ATT. There is a special connection located inside the junction box for

the Handheld Terminal.

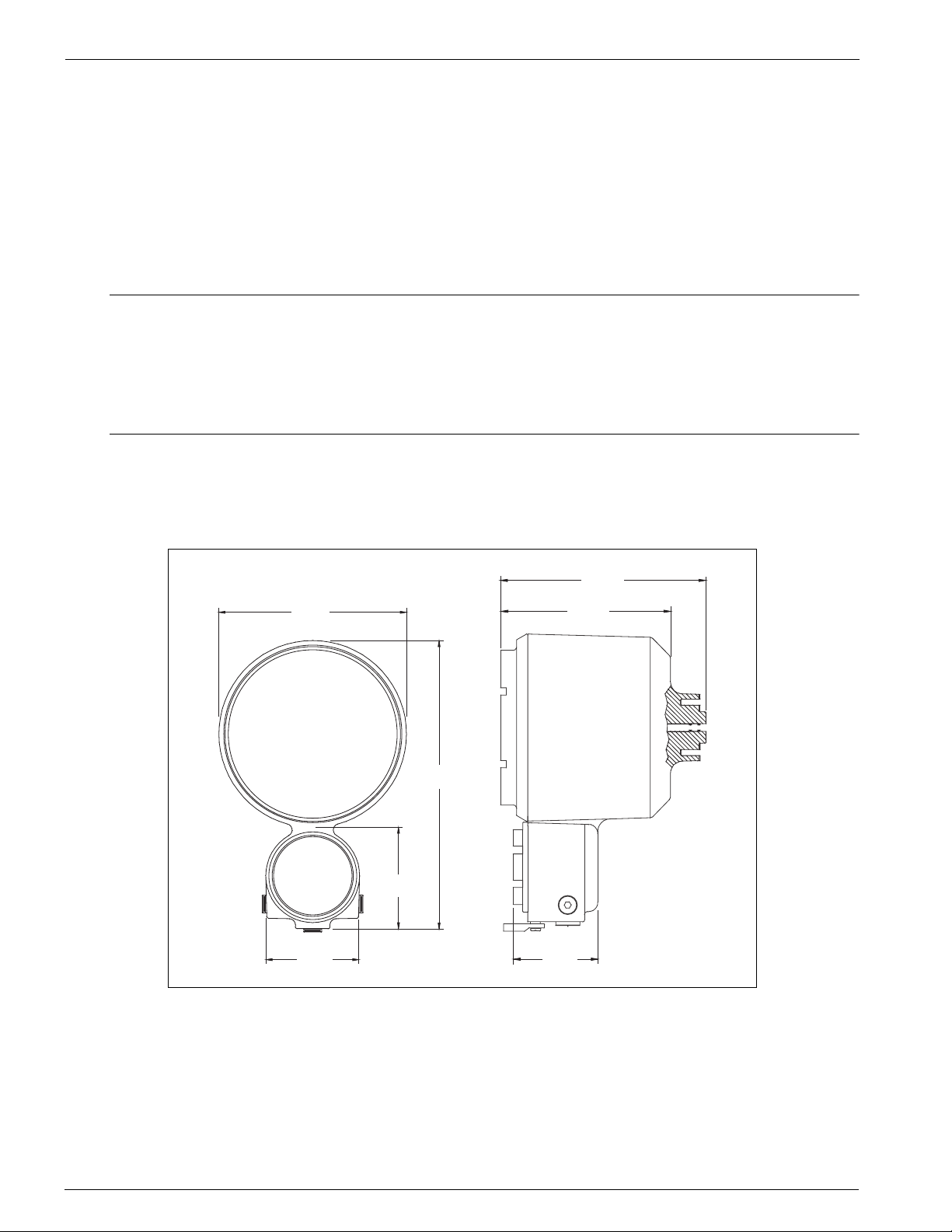

1.5 Construction

The Advanced Technology Transmitter is housed within an aluminum enclosure. The enclosure and assembly meet

explosion proof requirements and are environmentally sealed to prevent internal exposure to contamination.

7.5 "

(190 mm)

12 "

(308 mm)

4 "

(101 mm)

3.7 "

(94 mm)

Figure 1-2: Model 4000 Advanced Technology Transmitter Assembly

3.4 "

(86 mm)

8 "

(203 mm)

6.8 "

(172 mm)

2 Installation and Operations Manual

4000 Installation

2 Installation

2.1 Overview

This section contains instructions for unpacking, mounting, grounding, and wiring the Varec Model 4000 Advanced

Technology Transmitter (ATT) assembly. An installation checklist is also included.

Warning! To avoid electric shock and possible injury, do not perform any service procedures other than those specified in this

manual. These installation instructions are for use by qualified service technicians.

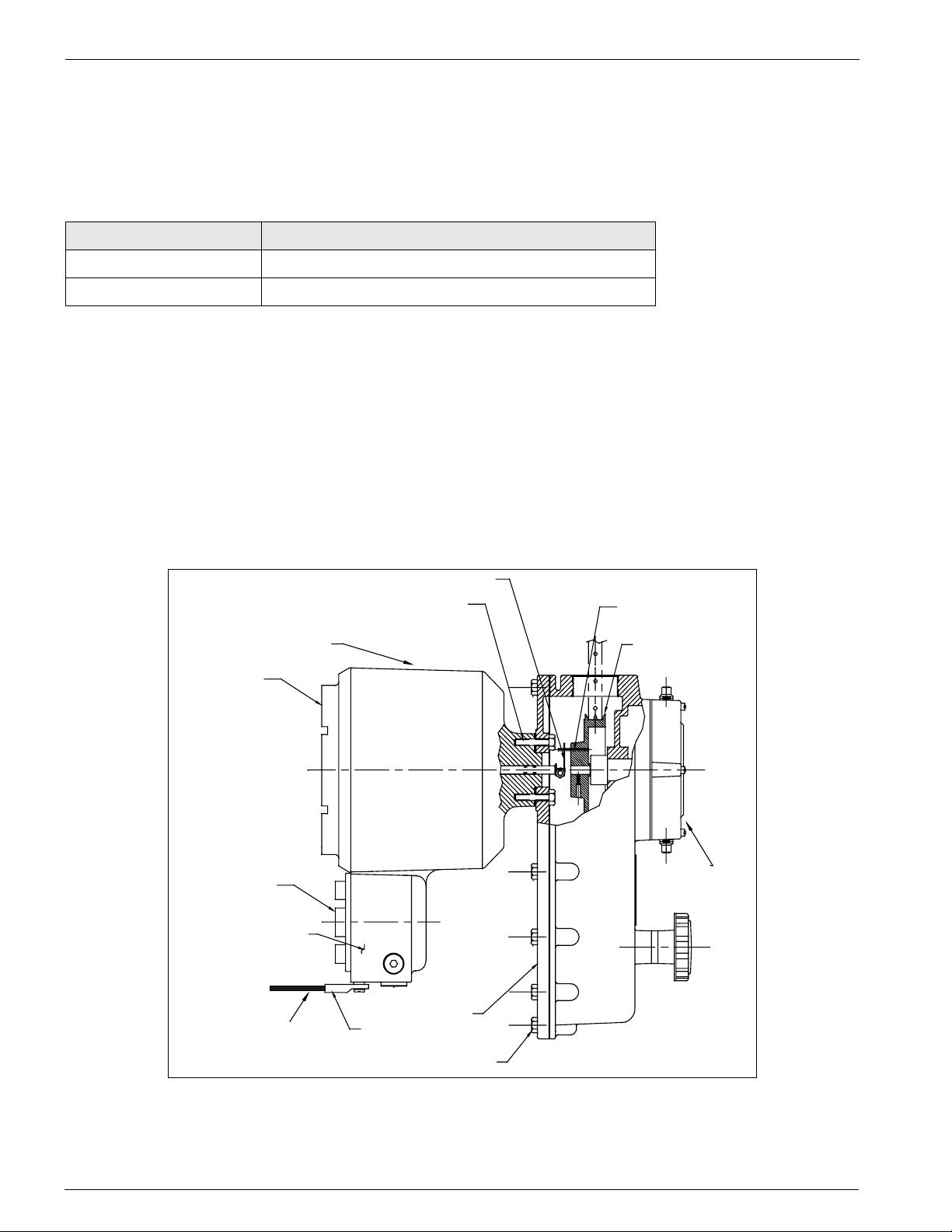

Figure 2-1: Model 4000 ATT mounted on Model 2500 ATG

2.1.1 Unpacking

Remove the ATT from the shipping container and inspect it for evidence of shipping or handling damage. Report any

shipping damage to the carrier. Verify that the contents of the shipping container agrees with the packing list.

2.1.2 Storage Prior to Installation

If the ATT is to be stored prior to installation, it should be repackaged in its shipping container and stored in a

temperature and humidity controlled environment.

2.1.3 Becoming Familiar with the ATT

The ATT is housed within an explosion proof enclosure. A cover is provided to permit access to both the electronics

and backup batteries.

3/4- and 2 1/2-inch NPT plugs are provided for wiring access. Wiring to the ATT consists of connecting power, host

communication, RTD input and an optional ground connection.

2.1.4 Hardware Configuration

All configuration is performed using the Model 1200 Handheld Terminal or a download from a host computer.

However, certain parameters such as communication address and speed must be configured via the Model 1200

Handheld Terminal.

3

Installation Tank Gauge Transmitter

e

E

2.2 Mounting the Equipment

The ATT is bolted to the Model 2500 Automatic Tank Gauge head as illustrated in Figure 2-2. It may also be mounted

to Endress+Hauser, Sakura, Tokyo-Keiso, Shand & Jurs, and Gauging Systems, Inc. float and tape gauges with the

Endress+Hauser adapter shown in the following table.

Part Number Gauge Adapter Kit

13-05956-102 L&J (Shand & Jurs) 92513, 92514, 92020, 92030

13-05956-202 Whessoe 2006, 2026, 2036 and L&J (Shand & Jurs) 92006

Mounting the ATT to the Level Gauge is accomplished in the following manner:

1. Remove the back cover of the Level Gauge.

2. Remove the access cap from the back cover of the Level Gauge.

3. Mount the ATT in place of the access cap, making certain that the word "TOP" cast into the housing lines up with

the top of the Level Gauge back cover.

4. Install the Level Gauge back cover with the transmitter in the Level Gauge. Make certain that the slot in the ATT

drive coupling engages with the pin on the tape sheave of the Level Gauge.

5. Proceed with field wiring.

Back

cover

Junction

box cover

Integral junction

box

Drive coupling

5/16-18 X 1 mounting bolts (4 places)

5/16 split lock washers (4 places)

Transmitter

Pin drive

Sprocket Sheave

2500

Automatic

Tank Gaug

Back Cover

xternal enclosure ground

connection by installer

External Ground Lug

Gauge cover mounting

bolts (15 places)

Figure 2-2: ATT Mounting Diagram

4 Installation and Operations Manual

4000 Installation

2.3 Grounding the Equipment

Warning! The ATT must be grounded before communication and power connections are made.

An external grounding lug is provided on the ATT. A connection from the ground lug to earth ground must be made

before any other wiring connections are made.

Note! For adequate/proper operation of the ATT lightning arrestor, a ground strap must be attached to the ATT. Grounding

through mounting kits or pipe coupling is not adequate.

Note! Properly seal all ports to prevent moisture or other contamination from entering the wiring compartment.

2.4 Wiring

Connections should be made in a conventional manner according to local or plant electric codes.

Warning! Explosion-proof seals must be installed in all wiring entries. Any unused entries must be plugged with pipe plugs and

secured with Loctite®, or equivalent.

2.4.1 ATT Wiring

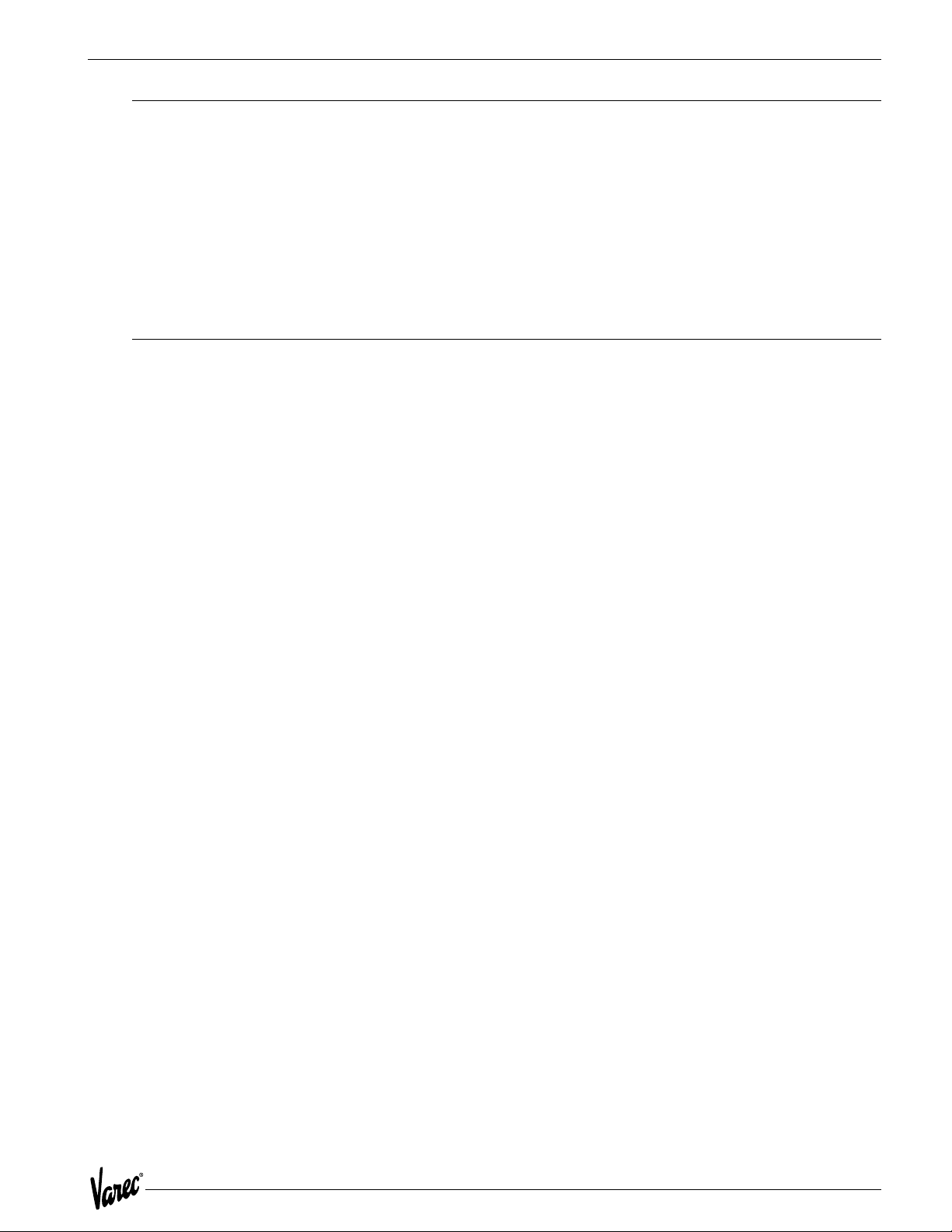

Wiring the ATT is described in the following paragraphs. The wiring diagram provided in Figure 2-3 on page 6 should

be used in conjunction with these wiring instructions.

2.4.2 Wiring Preparation

Remove the two thread protectors from the 1/2-inch NPT conduit entries at the top and bottom of the ATT. Remove

the rear cover from the ATT housing.

2.4.3 Connecting Input Power

Warning! When connecting DC power leads to the ATT, make certain that power is OFF.

The ATT operates on a 24-48 volts DC power source. The input power connection to the ATT is accomplished in the

following manner.

Connect the positive side of the power supply to terminal 10, B+, and the negative side to terminal 9, B-, of the

terminal block assembly. See Figure 2-3 on page 6.

5

Installation Tank Gauge Transmitter

Figure 2-3: ATT Field Terminal Block Wiring

Terminal Block One TB1 Terminal Block Two TB2

1 L+ = ATTI expansion Bus +

power

2 HPORT = ATTI bus HART Signal 11 M = Mark or EIA485 -

3 L- = ATTI expansion Bus -

power

4 C = RTD C lead 9 B - = ATT - power

5 B = RTD B lead 8 -- = Reserved

6 A = RTD A lead 7 -- = Reserved

12 S = Space or EIA485 +

10 B + = ATT + power

2.4.4 Connecting Host Communication

The procedure used to wire the ATT to the host computer depends on the type of host interface option ordered with

the ATT.

6 Installation and Operations Manual

4000 Installation

2.4.5 ATT EIA485 Wiring

The ATT uses a 2-wire EIA485 hardware interface to communicate with the Modbus master. EIA485 is a high speed

differential communications network which allows up to 32 devices to operate on one network. The ATT and Modbus

master share a twisted pair of wires to communicate. Figure 2-4 illustrates the typical EIA485 wiring.

The communication distance that EIA485 can reliably travel is dependent on baud rate (communication speed), wire

quality, environmental noise, wiring configuration, and the number of multi-dropped ATTs. The recommended wire

for EIA485 systems is 18-gauge or larger, shielded, twisted pairs. The shield should be earth grounded at the Modbus

master (control system or computer end). The shield at the ATT should be open. The ATT B- power line acts as a

common reference tie to the Modbus master. Figure 2-5 on page 8 illustrates the EIA485 Modbus system.

TB2

TB2

Power Supply

6

5

4

+48

VDC Common

Figure 2-4: Typical EIA485 Wiring

RTU 8130 with 8230 expansion module

7

Installation Tank Gauge Transmitter

Field Junction Box

Model 4000 ATT

Transmitters*

Model 4000 ATT

* Up to 31 units with

5000 ft. max. wiring distance

using good quality wire.

Two 18 AWG

twisted pair

cables

Field Junction Box

EIA85 comm.

with MODBUS to FIC

Two 18 AWG

twisted pair cables

Transmitters*

Area 0

Area 1

RTU 8130

Model 8130 with optional

48 VDC power supply.

110/220 VAC 50/60 Hz.

RS232 To FuelsManager

or other MODBUS master

RS232 serial port

50 feet max to FIC

Office Printer

Host Computer Interface

certified by Honeywell

FuelsManager

MODBUS interface is

Figure 2-5: Typical EIA485 System Wiring

8 Installation and Operations Manual

4000 Installation

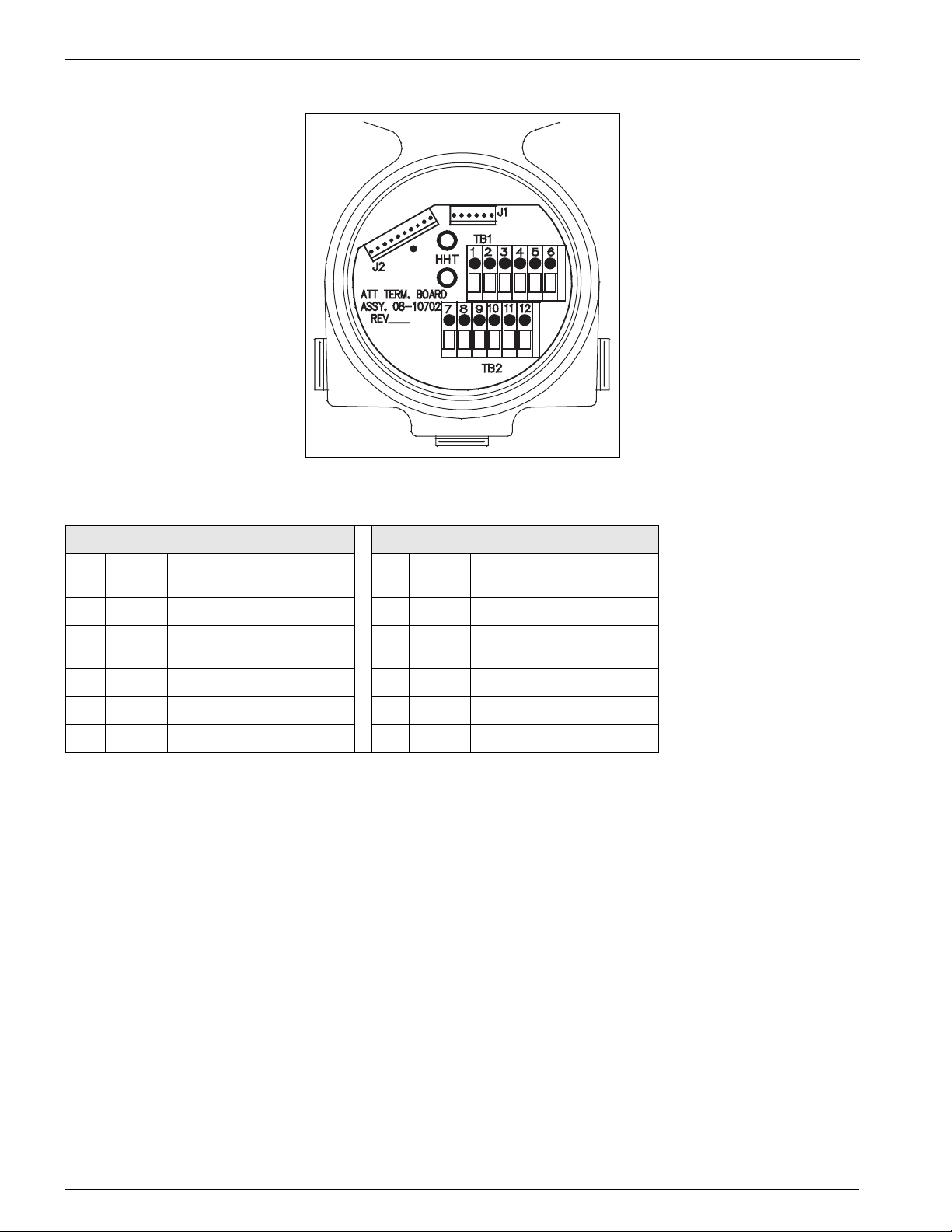

2.4.6 ATT Mark/Space Wiring

For an ATT using the Mark/Space field communications option, the following additional wiring connections must be

made. (Refer to Input Power Wiring in Section 6 to determine the minimum wire size required.). See Figure 2-6.

• Run two twisted pairs of 18 AWG wire (Mark/Space wires) into the ATT through the conduit entry along with the

48 VDC power wiring.

• Connect the Mark line to terminal 11, M/485-, and the Space line to terminal 12,

S/485+, on the terminal block assembly.

8203 With 8210

expansion module

Field Junction Box

4 Conductor

Cable

18 AWG

Shielded

To Other

4-Wire

Transmitters

in Area 0

Ground shield at RTU8130 ONLY!

Do NOT ground shield at transmitter.

Details of RTU8130 with 8210 expansion

module and ATT termination board wiring

External

Power Supply

Varec

Model 4000

ATT

Figure 2-6: Typical Mark/Space Field Wiring

9

Installation Tank Gauge Transmitter

2.5 Connecting the RTD

The following list shows how the ATT is wired to an RTD device. The ATT’s temperature circuit is designed to work

with a platinum or copper 3-wire RTD.

2.5.1 Connecting the Handheld Terminal

Figure 2-3 on page 6 shows how the 1200 Hand Held Terminal is connected to the ATTI bus on the ATT. The Model

268 can also be used to configure the ATT.

Warning! The 1200 Hand Held Terminal on the ATT is not Intrinsically Safe. Care must be taken to only use in a non-hazardous

environment

Wire as follows:

• Connect the RTD's A terminal to the ATT's terminal 6, A.

• Connect the RTD's B terminal to the ATT's terminal 5, C.

• Connect the RTD's C terminal to the ATT's terminal 4, C.

2.5.2 Wiring Completion

Caution! Do not overtighten metal plugs used to seal wiring compartment ports. Overtightening may damage the housing.

Properly seal the 1/2-inch NPT conduit entry. Install cover and tighten to ensure that the O-ring seal is adequately

compressed. Proper sealing of all ports is necessary to prevent moisture or other contamination from entering the

wiring compartment.

2.5.3 Installation Checkout

After a thorough check that all connections are correctly made and that all covers and plugs are installed, turn on

power to the ATT. Proceed to Chapter 3, Configuration.

2.5.4 Installation Checklist

The steps required in the installation process are summarized in the following checklist. Since each step is detailed

specifically with accompanying notes, cautions, and warnings, be sure to refer to the sub-sections indicated for further

information.

Step Sub-Section(s) Reference

Unpack the ATT and check the packing list. Unpacking

Verify that the required input power is available. Mounting the ATT, Wiring

Mount the ATT. Mounting the Equipment

Ground the ATT. Grounding the Equipment

Route the conduit between the ATT and other

devices and seal all ports.

Wire the host communications. Connecting Host Communication

Wire the RTD Connecting the RTD

Wire the input power connections. Connecting Input Power

Apply power to the ATT. Installation Checkout

Wire the Model 1200 Handheld Terminal Connecting Handheld Terminal

Proceed to ATT configuration procedure. ATT Configuration (Section 3)

Wiring Completion

10 Installation and Operations Manual

4000 Configuration

3 Configuration

The Varec Model 4000 Advanced Technology Transmitter (ATT) must be configured for the specific tank, attached

sensors, and host interface. This section provides detailed information on ATT configuration.

The ATT can be configured with a 1200 Hand Held Terminal or from a host program such as Varec TankView.

3.1 Configuration Parameters

Configuration parameters associated with ATT operation are entered and modified using the Model 1200 and can be

divided into the following areas:

• General Configuration - includes units of measure, level calibration, temperature type selection, and alarm

setpoints.

• Host Configuration - includes the type of host interface used, baud rate selection, and emulation modes for other

level transmitters.

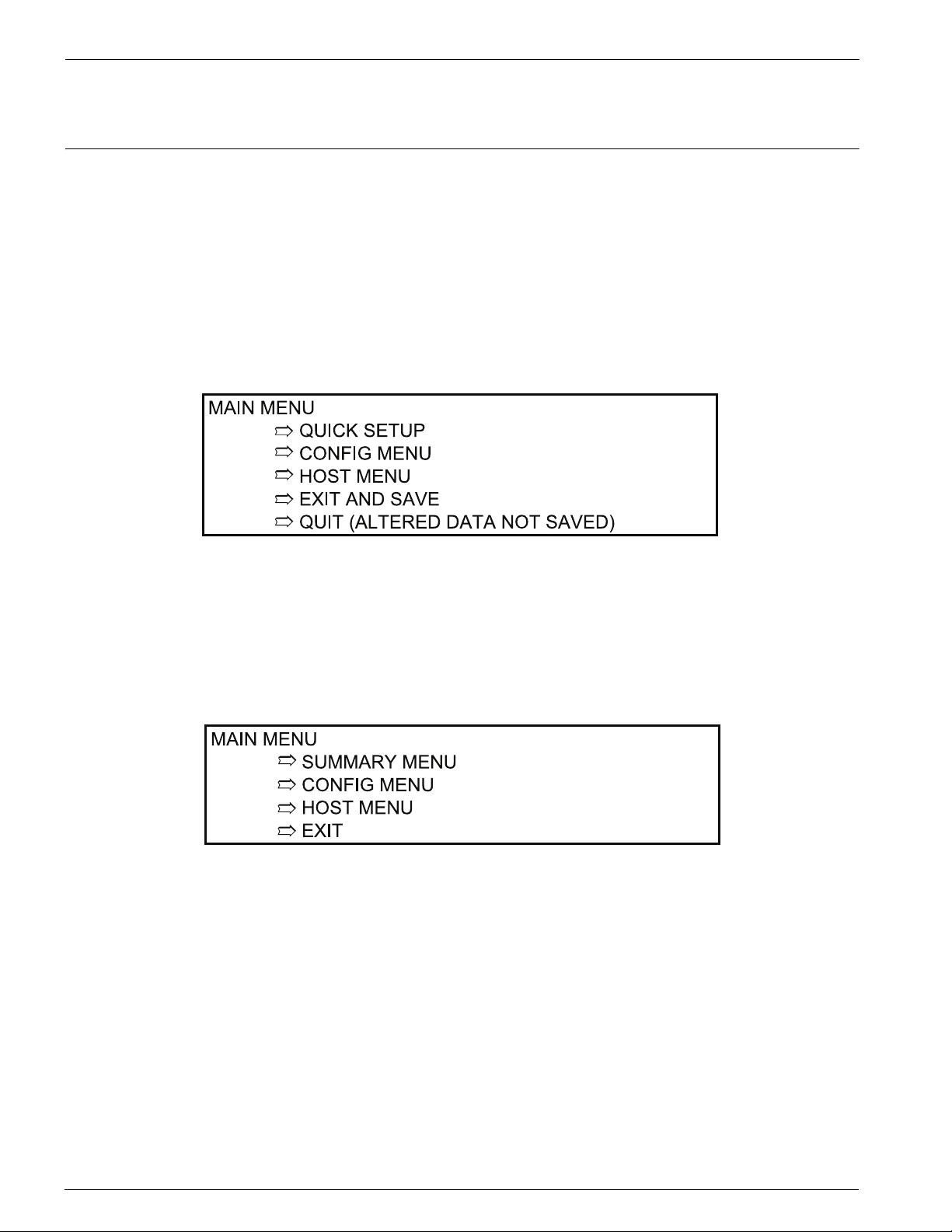

3.2 1200 Hand Held Terminal

The ATT can be used with a 1200 Hand Held Terminal, see Figure 3-3 on page 13. The Model 1200 provides a local

terminal interface to configure the ATT and encoder at tankside. It is connected to the ATTI bus. It can be physically

attached via two banana plugs located inside the terminal block housing.

The ATT uses the Model 1200 in a different mode of operation. Normally, the Model 1200 polls the ATTI BUS device,

recognizes it, and goes into an internal menu system that is specifically tailored to that ATTI Bus device. The ATT

however, uses the Model 1200 in what is called ASCII Terminal mode. In this mode, the Model 1200 sends keyboard

activity to the ATT and displays screen information from the ATT. The ATT can not be configured with the Rosemount

Model 275 Terminal.

Because of the way the ASCII Terminal mode works on the Model 1200, the ATT is unable to poll any ATTI BUS device

while communicating to it. The ATT goes from an operational mode to an off-line mode. The operational mode is

automatically switched to when the Model 1200 is removed from the ATTI BUS bus.

Warning! The 1200 Hand Held Terminal on the ATT is not Intrinsically Safe. Care must be taken to only use in a non-hazardous

environment.

Function keys F1 through F4, defined in Figure 3-1 on page 11, are used for basic scrolling of the ATT menus and

selection of configuration parameters.

Function Key Description

HELP Help Message

F1 Scroll Up

F2 Scroll Down

F3 Alter/Backspace

F4 Enter

Previous Function [Ü] Return to previous menu or abort data entry

Table 3-1: Model 1200 Function Keys

Alpha and numeric information is entered from the keypad directly. Numeric data is entered using a single keystroke,

while alpha information is entered with a two-key combination. The two-key combination for alpha data consists of a

shift key followed by a numeric key to select the desired alpha character.

11

Configuration Tank Gauge Transmitter

For example, to enter the alpha character "N"; first press the shift key, then press the number 4. To enter the alpha

character "R"; first press the shift key, then press the number 1.

Terminal Mode Configuration

When the Model 1200 is connected to the ATTI Bus and turned on, a blank screen will appear on the Model 1200 after

a self test sequence. Pressing any key will cause the following screen to appear on the Model 1200 display:

The version indicated is the software version of the ATT.

Enter a "D" (to select Display Mode entries) or an "A" (to select Alter Mode entries) and press F4 (Enter).

If the Display Mode is selected with a "D", current status and configuration data may be examined but cannot be

modified. This mode is useful for verifying ATT configuration. This mode cannot be used to actively monitor ATT

operation, as normal ATT operation is suspended when the Model 1200 is connected.

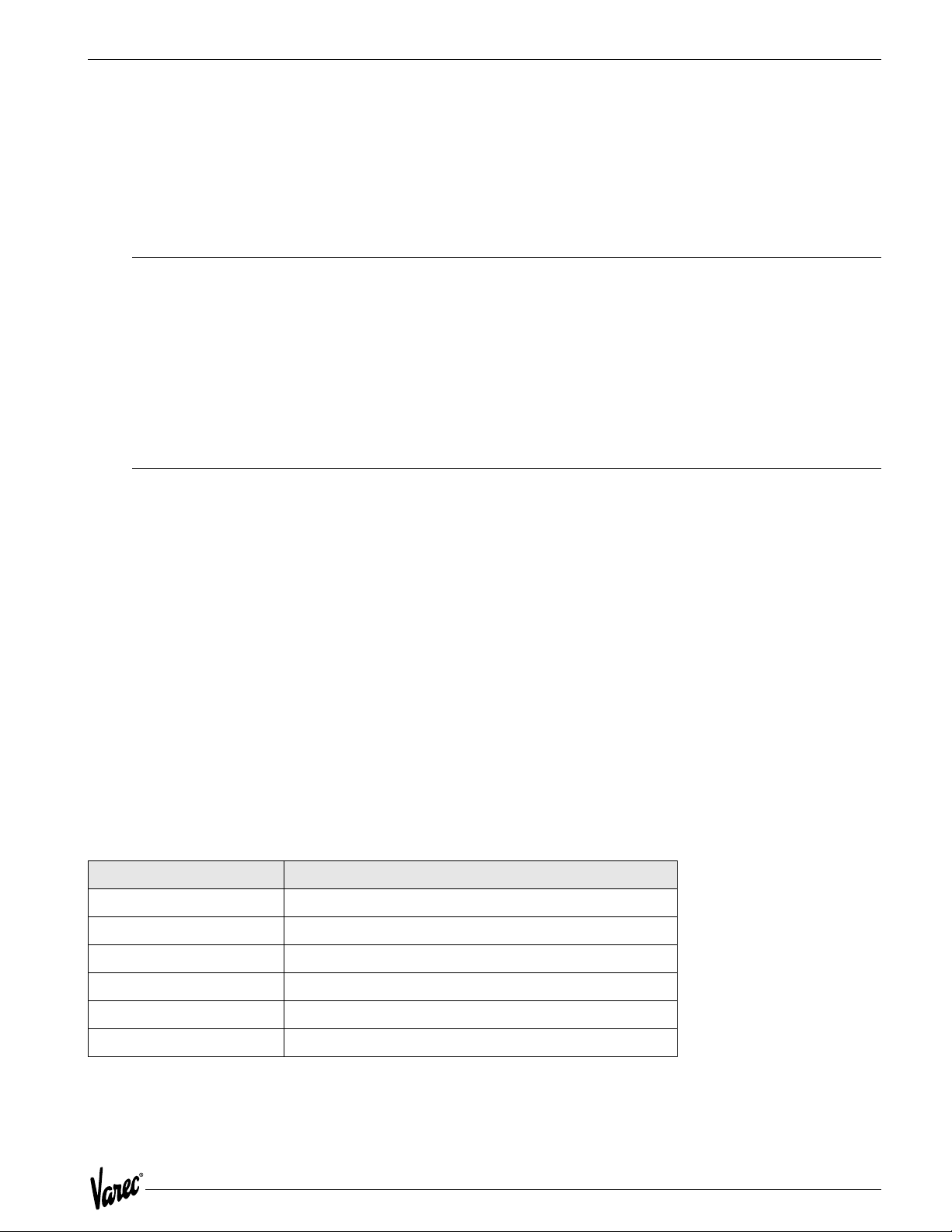

Figure 3-1: ATT Alter Mode Menu Tree

If the Alter Mode is selected with an "A", all applicable configuration parameters can be modified. Figure 3-2 on

page 12 illustrates the display mode menu tree and Figure 3-1 on page 12 illustrates the Alter Mode menu tree. The

menu tree groups related items under separate menus and sub-menus. The menu grouping is provided to permit the

field operator to configure and display items in a related and logical order. Once a menu is selected, the operator can

scroll through related items.

Figure 3-2: ATT Display Mode Menu Tree

12 Installation and Operations Manual

4000 Configuration

ON / OFF

Previous Function

Shift

Figure 3-3: 1200 Hand Held Terminal

3.3 Terminal Mode Operation

The 1200 Hand Held Terminal is used to scroll through the various ATT menus. Basic scroll and selection operations

are performed using the four function keys (F1 through F4) immediately below the display.

Line 1 of the display contains the menu title. Lines 2 and 3 are item display lines. Line 4 is an error message/status line.

If the item displayed on line 2 is preceded with an "M>", the item being displayed is a menu. You can select the menu

by pressing F4 (Enter). If the item is preceded by a "C>" the item being displayed is a command that can be executed

by pressing F4 (Enter).

Where:

F1 = Up

F2 = Down

F3 = Alter

F4 = Enter

13

Configuration Tank Gauge Transmitter

3.4 Menu Operation

For example, when the Main Menu is displayed on the top line, pressing F1 (Up) will scroll up through the possible

main menu selections while pressing F2 (Down) will scroll down through the possible main menu selections.

Pressing F4 (Enter) will cause the selection of the sub-menu displayed on lines two and three (such as Config Menu).

Scrolling through a sub-menu is performed in the same manner as scrolling through the Main Menu using the F1 and

F2 keys.

To return to the Main Menu, press the PREVIOUS FUNCTION key [Ü], as shown in Figure 3-3 on page 13.

When a parameter is encountered which is to be changed, pressing the F3 key (Alter) will cause the display of the

current parameter in a form which permits its modification.

When a specific set of parameters is available, the F1 and F2 keys can be used to scroll through the valid selections.

When the desired selection is displayed, pressing the F4 key (Enter) will cause selection of the new parameter. When

the parameter consists of numeric or free format characters, the Model 1200 keyboard can be used to enter the

parameter. Note that parameter alteration is not final until the session is completed with the EXIT AND SAVE command

from the Main Menu.

To complete parameter alteration, scroll through the Main Menu until the following display is presented, then press

F4 (Enter) to exit and save the altered parameters.

If parameter alteration is to be aborted (new parameters not saved), scroll through the Main Menu until the following

display is presented and press F4 (Enter) to quit without saving alterations. The QUIT or EXIT AND SAVE commands

must be initiated before turning off or disconnecting the 1200 Hand Held Terminal.

14 Installation and Operations Manual

Loading...

Loading...