Page 1

OPERATING INSTRUCTIONS

for the

VBT-80P

Vacuum Bottle Tester

Vanguard Instruments Company

1520 S. Hellman Ave.

Ontario, California 91761

TEL: (909) 923-9390 July 2006

FAX: (909) 923-9391 Rev. 1

Page 2

Operating Procedures VBT-80P

SAFETY SUMMARY

Follow Exact Operating Procedures

Any deviation from the procedures described in this operator’s manual may create one or more

safety hazards, damage the VBT-80P, or cause errors in the test results. Vanguard Instruments

Co., Inc. assumes no liability for unsafe or improper use of the VBT.

The following safety precautions must be observed during all phases of test set up, test hookups,

testing, and test-lead disconnects.

SAFETY WARNINGS AND CAUTIONS

This device shall be used only by trained operators.

All circuit breakers under test shall be off line and fully isolated.

Do Not Modify Test Equipment

Because of the risk of introducing unknown hazards, do not install substitute parts or perform

any unauthorized modification to any Model VBT-80P Test unit. To ensure that all designed

safety features are maintained, it is recommended that repairs be performed only by Vanguard

Instruments Co. factory personnel or by an authorized repair service. Unauthorized

modifications can cause serious safety hazards and will nullify the manufacturer's warranty.

1

Page 3

Operating Procedures VBT-80P

Table of Contents

1.0 INTRODUCTION ................................................................................................................... 4

1.2 General Description.............................................................................................................. 4

1.3 Functional Description.......................................................................................................... 4

1.4 Furnished Test Accessories................................................................................................... 4

2.0 VBT 80P SPECIFICATIONS.................................................................................................. 6

3.0 CONTROL AND DISPLAY................................................................................................... 7

3.1 VBT-80P Front Panel ........................................................................................................... 7

4.0 VBT-80P Special Features....................................................................................................... 9

4.1 VBT-80P LCD Contrast Control.......................................................................................... 9

4.2 Printer Paper Control ............................................................................................................ 9

4.3 Printer Paper.......................................................................................................................... 9

5.0 VBT-80P CABLE Connection .............................................................................................. 10

6.0 OPERATING PROCEDURES..............................................................................................11

6.1 Run Test Procedure............................................................................................................. 11

6.2. Enter Test Record ID Procedure........................................................................................ 15

6.3 Restore Record Procedure................................................................................................... 17

6.4 Review Record Procedure................................................................................................... 18

6.5 Print/View Test Record Directory Procedure..................................................................... 19

6.6 Erase Test Record Procedure.............................................................................................. 21

6.7 Set VBT-80P Real Time Clock........................................................................................... 22

2

Page 4

Operating Procedures VBT-80P

List of Figures

Figure 1 High voltage cable...........................................................................................................5

Figure 2 High Voltage return cable ............................................................................................... 5

Figure 3 VBT-80P Control-Panel Controls and Display............................................................... 7

Figure 4 Typical VBT-80P Connection.......................................................................................10

Figure 5 Typical VBT-80P Test Report....................................................................................... 14

Figure 6 Typical VBT-80P Directory Print Out .......................................................................... 20

List of Tables

Table 1.0 VBT-80P Specifications ................................................................................................ 6

Table 2.0 Functional Description of VBT-80P Controls and Display........................................... 8

Table 3 Run Test Procedure......................................................................................................... 11

Table 3 Run Test Procedure (Continued) .................................................................................... 12

Table 3 Run Test Procedure (Continued) .................................................................................... 13

Table 4 Enter Test Record ID Procedure.....................................................................................15

Table 4 Enter Test Record ID Procedure (continued) ................................................................. 16

Table 5 Restore Test Record Procedure....................................................................................... 17

Table 6 Print Record Procedures ................................................................................................. 18

Table 7 Print Test Record Directory............................................................................................19

Table 7 Print Test Record Directory (Continued)........................................................................ 20

Table 8 Erase Test Record Procedure..........................................................................................21

Table 9 Set Time Procedure......................................................................................................... 22

3

Page 5

Operating Procedures VBT-80P

1.0 INTRODUCTION

1.2 General Description

The VBT-80P is a lightweight DC vacuum bottle tester made by Vanguard Instruments

Company. The VBT-80P tests a vacuum bottle’s integrity by applying a DC voltage across the

bottle under test. A simple “PASS” or “FAIL” message indicates the condition of the bottle after

each test.

The VBT-80P is rugged and field-portable. It is easy to operate and requires little training for

first-time users. Operating the VBT-80P only requires connecting the test leads to the vacuum

bottle, selecting the desired test voltage, current threshold, and test time duration, then initiating

the test. A keypad with 16 alphanumeric keys allows the user to control and enter circuit breaker

test data. A built-in thermal printer produces test results on 2.5-inch-wide thermal paper. The

VBT-80P test records can be stored in its FLASH EEPROM memory. Up to 84 records (of 16

readings each) can be stored in the VBT-80P’s memory.

1.3 Functional Description

Using a voltage multiplier, the VBT-80P generates a programmable test voltage from 10,000Vdc

to 80,000Vdc in 1,000Vdc steps.

The test voltage can be applied for different time durations: 5 seconds, 10 seconds, 30 seconds, 1

minute, or 2 minutes. The current through the bottle is monitored by the VBT-80P’s circuitry

during a test. If this test current exceeds a preset threshold, the test is terminated and a test

“FAIL” message will be displayed on the LCD. The “TEST FAIL” indicator will also be

illuminated on the front panel.

The over current threshold can be programmed for 100 micro-amps, 200 micro-amps, or 300

micro-amps.

A test is considered successful if the selected test voltage was applied for the entire test time and

the test current did not exceed the preset threshold.

The VBT-80P’s LCD displays a “PASS” message along with the test voltage and test duration if

a test is successful. The “PASS” and “FAIL”” message can be printed on the built-in thermal

printer.

1.4 Furnished Test Accessories

The VBT-80P is supplied with one 10-foot long high-voltage test cable, one 10 foot long

voltage-return lead with alligator clamps. A Ground cable, power cord, and a shipping case are

also included with each VBT-80P.

Note

The VBT-80P high voltage cable can be replaced in the field. Do not remove this HV cable from

the connector except for cable replacement.

4

Page 6

Operating Procedures VBT-80P

Figure 1 High voltage cable

Figure 2 High Voltage return cable

5

Page 7

Operating Procedures VBT-80P

2.0 VBT-80P SPECIFICATIONS

VBT-80P specifications and leading particulars are listed in Table 1.0

Table 1.0 VBT-80P Specifications

MODEL.......................VBT-80P

TYPE.............................Special-Purpose Test Equipment, portable 80 kV vacuum bottle tester

SIZE............................... 16.8” W by 3.5” H by 10.6” D (42.7 cm by 8.9 cm by 26.9 cm)

WEIGHT ....................... 10 pounds (4.53 Kg)

INPUT POWER ........... 2 amps, 90-240 Vac, 50/60 Hz

OUTPUT VOLTAGE... 10kV to 80kV dc in 1,000 volt steps

OUTPUT RIPPLE

VOLTAGE.................... 3% max

DISCHARGE TIME..... Maximum discharge time for internal high voltage is 0.3 seconds

DISPLAY...................... Back-lighted LCD, 4-lines by 16 characters

INDICATORS.............Test Failure Indicator: LED is turned on if test current exceeds

the preset current threshold (100A, 200A or 300A).

High Voltage Enable Indicator: LED is turned on when high voltage

is present on the high voltage cable.

PRINTER...................... 2.5” wide Thermal Printer

ENVIRONMENT.......... Operating: -10°C to 55°C (15F to +122F)

Storage: -30°C to 70°C (-22F to +158F)

FURNISHED ITEMS... One power cord, one ground cable, one 10-ft. high-voltage cable,

one 10-ft. high-voltage return cable.

OPTIONS ...................Transportation case included

WARRANTY................ One-Year Parts & Labor (Post-Warranty Service Contracts Available)

VBT-80P SPECIFICATIONS ARE SUBJECT TO UPGRADES AND MAY BE CHANGED WITHOUT PRIOR NOTICE.

6

Page 8

Operating Procedures VBT-80P

3.0 CONTROL AND DISPLAY

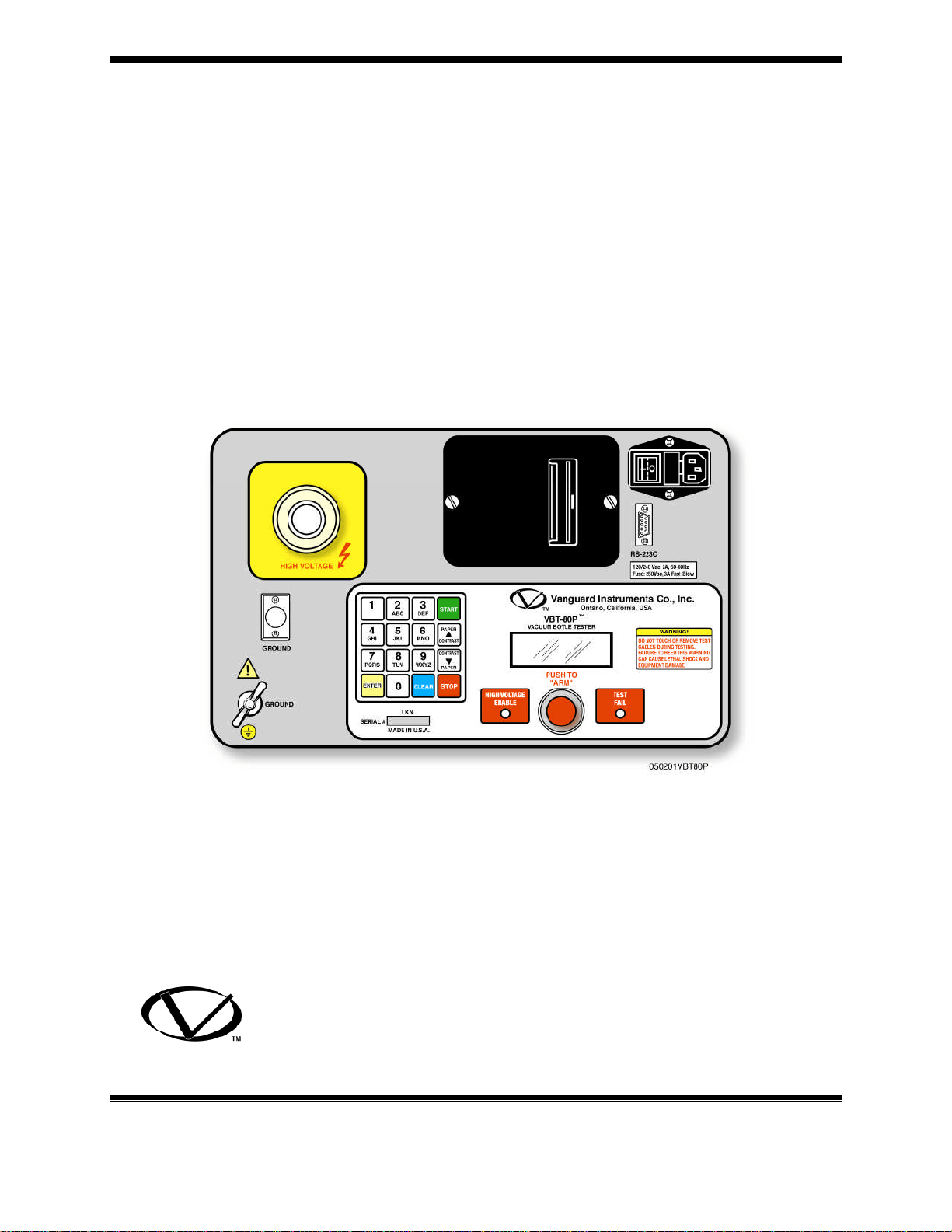

3.1 VBT-80P Front Panel

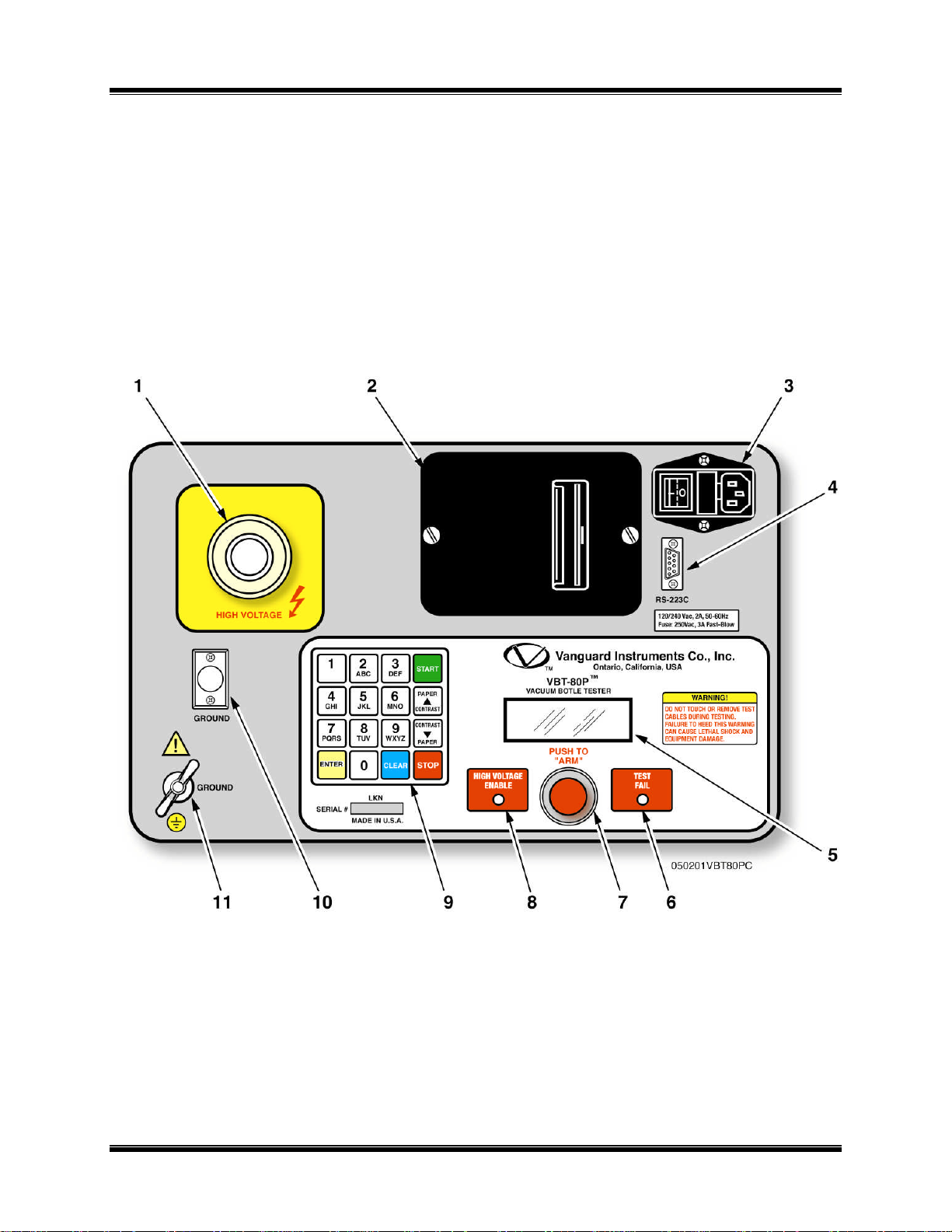

The VBT-80P controls and displays are shown in Figure 3. Pointing leader lines reference each

item with an index number. Each index number is cross-referenced to a functional description in

Table 2, which describes the function and purpose of each item on the control panel. Although

the purpose of these controls and the display may seem obvious and intuitive, users should

become familiar with them before attempting to use the VBT-80P. First-time users should also

review and become familiar with the Safety Summary on the front page.

Figure 3 VBT-80P Control-Panel Controls and Display

7

Page 9

Operating Procedures VBT-80P

Table 2.0 Functional Description of VBT-80P Controls and Display

Figure 1

Index #

1

2

3

4

5

Adjacent Panel Marking Functional Description

(Connector) High voltage cable connector

No marking

No marking Input power connector with built-in fuse

RS-232C

No marking

2.5” wide thermal printer

holder and power switch.

RS-232C interface port, 9-pin connector,

female DB type. The port is set to 19,200

baud, 1 start bit, 8 data bits, and no parity bit

PIN ................SIGNAL

2 Rx

3 Tx

5 Signal Gnd

This serial port is for factory calibration and

firmware updates

LCD, 4-line by 20-character, back-lighted:

displays menus of selections, operator entries,

and test measurement results.

6

7

8

9

10

11

TEST FAIL

PUSH TO

“ARM”

HIGH VOLTAGE

ENABLE

No marking 16-key keypad.

GROUND

GROUND

(Wing Nut)

Test Fail Indicator. This indicator is turned on

if the test current exceeds the preset current

threshold (100, 200, or 300 A).

Arm switch: Press and hold during a test

LED indicator, red: Lights when high voltage

is on the high voltage cable.

High-voltage-return cable connector.

VBT-80P ground stud. Connect ground stud

to substation ground using the provided cable.

8

Page 10

Operating Procedures VBT-80P

4.0 VBT-80P SPECIAL FEATURES

4.1 VBT-80P LCD Contrast Control

The VBT-80P LCD is back-lighted for viewing in low light conditions. To increase the LCD

display contrast, press and hold the “ Contrast” key for more than two seconds. To lighten the

LCD display contrast, press and hold the “ Contrast” key for more than two seconds.

4.2 Printer Paper Control

To advance paper, press and release the “ Paper” key.

To retract paper, press and release the “ Paper” key.

4.3 Printer Paper

The VBT-80P built-in thermal printer uses 2.5-inch wide thermal paper for printing test results.

In order to maintain the highest quality printing and to avoid paper jams we recommend using

the paper supplied by our factory. Paper can be ordered from the following two sources:

Vanguard Instruments Co, Inc.

1520 S. Hellman Ave.

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: TP-3 Paper

OR

BG Instrument Co.

13607 E. Trent Ave.

Spokane, WA 99216

Tel: 888-244-4004

Fax: 509-893-9803

Part Number: TP-3 paper

9

Page 11

Operating Procedures VBT-80P

5.0 VBT-80P CABLE CONNECTION

Always ground the VBT-80P before connecting any cables. Use the ground cable provided with

the cable set. A typical VBT-80P connection to a vacuum bottle is shown in figure 4.

Figure 4 Typical VBT-80P Connection

10

Page 12

Operating Procedures VBT-80P

1.RUN

TEST 07/06/06

1.

5 SEC. 2. 10 SEC

ENTER TEST VOLTAGE:

0

KV

ENTER TEST VOLTAGE:

61

KV

1. 300uA

3. 100uA

TEST PARAMETERS:

6.0 OPERATING PROCEDURES

(Refer to tables 3 through 8)

WARNING

Always connect the VBT-80P ground to the substation ground first.

6.1 Run Test Procedure

The following test procedure describes the steps required to run a test

Table 3 Run Test Procedure

STEP

3-1

3-2

3-3

3-4

ACTION DISPLAY

None. VBT-80P Main menu.

To begin the RUN TEST procedure, press

key # 1 (RUN TEST) on the MAIN

MENU. The “Test Duration” menu

appears.

Select a test time duration. Press key # 1

to select 5 seconds for this example.The

“Test Voltage” menu appears.

Note

Test voltage can be selected in the 1KV

steps.

Key in the test voltage using the the 0-9

keys.

2.SETUP 16:22:01

3. 30 SEC 4. 60 SEC

5. 2 MIN

(10 to 80)

(10 to 80)

3-5

3-6

Press the “Enter” key to confirm the entry.

The “Current Threshold” menu appears.

Select a current threshold. Press key # 1 to

select 300uA for this example.

The “Test parameters” display appears.

2. 200uA

61KV 5 SEC 300uA

“CLEAR” TO CHANGE OR

“ENTER” TO CONTINUE

11

Page 13

Operating Procedures VBT-80P

PRESS “ARM” SWITCH

TEST IN PROGRESS

TEST COMPLETED

PRINT TEST RESULTS?

SAVE THIS RECORD?

KEEP THIS READING?

RUN ANOTHER TEST?

TEST SAVED

TEST COMPLETED

Table 3 Run Test Procedure (Continued)

STEP

3-7

3-8

3-9

ACTION DISPLAY

Press the “ENTER” key to continue.

Press and hold the “ARM” Switch to run

the test.

A “TEST FAIL” message will appear if

the test current exceed the preset value

(300uA in this example) and the test will

terminate immediately. The “TEST FAIL”

LED will also be lit on the front panel.

A “TEST PASS” message will appear if

the test current did not exceed the current

threshold during the duration of the test.

TO START TEST

61KV 0.20uA

TIME 00:05

61KV 5 SEC 300uA

>>> FAIL <<<

61KV 5 SEC 300uA

>>> PASS <<<

3-10

3-11

3-12

3-13

3-14

Press the “ENTER” key to go to the print

menu

Press key #1 to print a test report. A

typical test report is shown in figure 5.

Press key #2 to skip printing.

Press key #1 to keep this reading.

Press key #2 to not store this reading in

working memory, go to step 3-14.

Press the “ENTER” key to advance to the

next menu.

Press key #1 to run another test, go to step

3-6.

Press key #2 to end the test.

1.YES

2.NO

1.YES

2.NO

1.YES

2.NO

1.YES

2.NO

12

Page 14

Operating Procedures VBT-80P

1.RUN

TEST 07/06/06

RECORD NUMBER 1

ARE YOU SURE?

Table 3 Run Test Procedure (Continued)

STEP

3-15

3-16

3-17

ACTION DISPLAY

Press key #1 to save the test record. The

test record is saved in the VBT-80P’s

Flash EEPROM. A test record number

will be assigned. Press the “ENTER” key

to return to the main menu.

Press key # 2 to skip saving the test

record. Go to step 3-16.

None. The user selected not to save the

test record; a reminder message is

displayed

Press key #2 to save the record. Go to step

3-15.

Press key #1 to abort saving the record.

The VBT-80P will return to the MAIN

MENU.

HAS BEEN SAVED!

DATA WILL BE LOST!

1.DO NOT SAVE RECORD

2.SAVE RECORD

2.SETUP 16:22:10

Note

1. A “FAIL” message will be displayed on the LCD and the “TEST FAIL” indicator will be

illuminated on the front panel.

2. The VBT-80P’s LCD displays a “PASS” message along with the test voltage and test duration

if a test is successful.

13

Page 15

Operating Procedures VBT-80P

Figure 5 Typical VBT-80P Test Report

14

Page 16

Operating Procedures VBT-80P

1.RECORD ID

COMPANY:

STATION:

CIRCUIT:

MANUFACTURER:

“ENTER” TO ACCEPT

MODEL:

1.RUN

TEST 07/06/06

6.2. Enter Test Record ID Procedure

This procedure allows the user to enter the equipment identification information to be used with

the test record. Each ID field can contain up to 20 characters. Always enter the test record ID

before starting a test.

Table 4 Enter Test Record ID Procedure

STEP ACTION DISPLAY

4-1

None. VBT-80P Main menu.

2.SETUP 16:22:01

4-2

4-3

4-4

4-5

On the MAIN MENU, press key # 2

(SETUP) to go to the Setup menu options

(shown at right).

Press key #1 (RECORD ID) to begin

entering identification information. The

“COMPANY:” input screen is displayed.

Enter the utility COMPANY name using

the alpha-numeric keypad. When finished,

press ENTER to store the data and go to

the “STATION:” input screen.

Enter the utility STATION name using the

alpha-numeric keypad. When finished,

press ENTER to store the data and go to

the “CIRCUIT:” input screen.

2.REVIEW RECORD

3.RESTORE RECORD

4.NEXT PAGE

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

4-6

4-7

Enter the utility CIRCUIT name using the

alpha-numeric keypad. When finished,

press ENTER to store the data and go to

the “MANUFACTURER:” input screen.

Enter the utility MANUFACTURER name

using the alpha-numeric keypad. When

finished, press ENTER to store the data

and go to the “MODEL:” input screen.

15

UP/DOWN TO POSITION

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

Page 17

Operating Procedures VBT-80P

OPERATOR:

1.RUN

TEST 07/06/06

SERIAL NUMBER:

KVA RATING:

“ENTER” TO ACCEPT

Table 4 Enter Test Record ID Procedure (continued)

STEP ACTION DISPLAY

4-8

Enter the utility MODEL name using the

alpha-numeric keypad. When finished,

press ENTER to store the data and go to the

“SERIAL NUMBER:” input screen.

UP/DOWN TO POSITION

“ENTER” TO ACCEPT

4-9

4-10

4-11

This completes the ENTER ID procedure.

The VBT-80P will retain the test record ID in memory until it is changed by the operator.

Enter the utility SERIAL NUMBER using

the alpha-numeric keypad. When finished,

press ENTER to store the data and go to the

“COMMENTS:” input screen.

Enter test COMMENTS using the alphanumeric keypad. When finished, press

ENTER to store the data and go to the

“OPERATOR:” input screen.

Enter the test OPERATOR name, using the

alpha- numeric keypad When finished, press

ENTER to store the data and return to the

MAIN MENU display.

NOTE

UP/DOWN TO POSITION

UP/DOWN TO POSITION

2.SETUP 16:27:00

16

Page 18

Operating Procedures VBT-80P

1.ENTER ID

1.RESTORE RECORD

RESTORE RECORD

RESTORE RECORD

REVIEW RECORD?

2.PRINT TEST RECORD

PRINT REPORT

6.3 Restore Record Procedure

This procedure describes how to restore a test record stored in VBT-80P’s Flash EEPROM to

working memory. The user can then print the test record with the thermal printer.

NOTE

The VBT-80P can store up to 84 test records in the FLASH EEPROM.

Table 5 Restore Test Record Procedure

STEP ACTION DISPLAY

5-1

On the MAIN MENU, press key #2

(SETUP) to display the SETUP MENU

options (shown at right).

2.REVIEW RECORD

3 RESTORE RECORD

4.NEXT PAGE

5-2

5-3

5-4

5-5

5-6

Press key #3 to select “RESTORE

RECORD”

Press key #1 to restore a record.

Press key #1 to enter the record number.

Enter the record number using the number

keys. Then press the ENTER key to confirm.

Press the“ENTER” key to display the

“REVIEW RECORD?” menu options.

2.DIRECTORY

3.ERASE RECORD

1.ENTER RECORD NUMBR

2.SCROLL TO SELECT

NUMBER:

RECORD RESTORED!

1.SCROLL TEST RECORD

5-7

This completes the Restore Record Procedure. A typical test result is shown in figure 5.

Press key #1 to scroll through the test record.

Press key #2 to print the test record on the

thermal printer.

Press “STOP” to return to the MAIN MENU.

PLEASE WAIT ………..

17

Page 19

Operating Procedures VBT-80P

1.ENTER ID

REVIEW RECORD

RECORD ID INFO

2 TESTS

TEST NUMBER: 1

TEST NUMBER: 2

1.RUN

TEST 07/06/06

6.4 Review Record Procedure

This procedure allows the user to view or print a test report residing in the VBT-80P’s working

memory

Table 6 Print Record Procedures

STEP ACTION DISPLAY

6-1

On the MAIN MENU, press key #2

(SETUP) to select the SETUP MENU

options (shown at right).

2.REVIEW RECORD

3.RESTORE RECORD

4.NEXT PAGE

6-2

6-3

6-4

6-5

Press key #2 to select the “REVIEW

RECORD” menu options.

1.SCROLL TEST RECORD

2.PRINT TEST RECORD

Press key #1 to Scroll through the test record

(see next menu).

Press key #2 to print the test record, return to

step 5-6 of the previous table.

Press “” key to view the next field.

07/06/06 16:20:01

Press “” key to view the next field.

10KV 5 Sec 100uA

0.00uA AT 10.0KV

TEST PASSED!

6-6

6-7

This completes Review Record Procedure.

Press “” key to view the next field.

10KV 5 Sec 100uA

0.00uA AT 10.0KV

TEST PASSED!

Press the “STOP” key to return to the MAIN

MENU display.

2.SETUP 16:27:00

18

Page 20

Operating Procedures VBT-80P

1.PRINT DIRECTORY

1.ENTER ID

1.RESTORE RECORD

PRINT DIRECTORY

RECORDS IN DIRECTORY

6.5 Print/View Test Record Directory Procedure

This procedure describes the steps to print or view the test record directory.

Table 7 Print Test Record Directory

STEP ACTION DISPLAY

7-1

On the MAIN MENU, press key #2

(SETUP) to select the SETUP MENU

options (shown at right).

2.REVIEW RECORD

3.RESTORE RECORD

4.NEXT PAGE

7-2

7-3

7-4

7-5

Press key#3 (RESTORE RECORD)

Press key #2 (DIRECTORY)

Press key #1 to select “Print Directory” (see

next menu).

Press key #2 to scroll through directory (see

7-6).

Press key #1 (FULL DIRECTORY) to

generate a list of all the records stored in

memory

Press key # 2 (SHORT DIRECTORY) to

generate a list of the last 10 records stored

in memory.

When the printout is completed, the display

returns to the MAIN MENU.

2.DIRECTORY

3.ERASE RECORD

2.SCROLL DIRECTORY

1.FULL DIRECTORY

2.SHORT DIRECTORY

PRINTING DIRECTORY

7-6

Continue from 7-4 after presssing key #2

(SCROLL DIRECTORY).

“UP” TO SCROLL FWD

“DWN” TO SCROLL RVS

19

Page 21

Operating Procedures VBT-80P

1.RUN

TEST 07/06/06

# 1 07/06/06 16:20:00

# 2 07/06/06 16:25:00

Table 7 Print Test Record Directory (Continued)

STEP ACTION DISPLAY

7-7

Press the “UP” key to view the first record’s

information.

1 TEST

7-8

7-9

This ends the Print/View Test Record Directory procedure.

Press the “UP” key to view next record’s

information.

Press key the “STOP” key to return to the

main menu.

2 TEST

2.SETUP 16:27:00

Figure 6 Typical VBT-80P Directory Print Out

20

Page 22

Operating Procedures VBT-80P

ERASE RECORD

ERASE RECORD

RECORD NUMBER: XX

ERASE ALL RECORDS!

ERASING RECORDS

PLEASE WAIT

RECORDS ERASED!

1.ENTER ID

4.NEXT PAGE

1.RESTORE RECORD

3.ERASE RECORD

6.6 Erase Test Record Procedure

This procedure describes the steps to delete one or all of the test records stored in the VBT-80P’s

Flash EEPROM.

Table 8 Erase Test Record Procedure

STEP ACTION DISPLAY

8-1

On the MAIN MENU, press key #2

(SETUP) to select the SETUP MENU

options (shown at right).

2.PRINT RECORD

3.RESTORE RECORD

8-2

8-3

8-4

8-5

8-6

Press key #3 (RESTORE RECORD)

Press key #3 (ERASE RECORD) to

display the ERASE RECORD menu

options (shown at right).

On the ERASE RECORD menu display,

press key #1 to erase a single record.

Go to step 8-6 to erase all the test records

stored in Flash EEPROM.

Enter the record number of the record to be

deleted then press the “ENTER” key to

confirm. Press the “ENTER” key again to

return to the Main menu.

NOTE

Press the the “STOP” key to abort.

Press key #2 to erase all records.

NOTE

Press the STOP key to abort.

2.DIRECTORY

1.ERASE SINGLE RECORD

2.ERASE ALL RECORDS

NUMBER: XX

ERASED!

Are you SURE?

“ENTER” TO CONTINUE

8-7

8-8

This ends the Erase Test Record procedure.

Press the “ENTER” key to confirm.

Press the “ENTER” key to return to the

Main menu.

21

Page 23

Operating Procedures VBT-80P

ENTER

ENTER

1.RUN

TEST 07/06/06

1.ENTER ID

4.NEXT PAGE

1.COMPUTER CONTROL

6.7 Set VBT-80P Real Time Clock

This procedure describes the steps to set the VBT-80P real time clock.

Table 9 Set Time Procedure

STEP ACTION DISPLAY

9-1

On the MAIN MENU, press key #2

(SETUP) to select the SETUP MENU

options (shown at right).

2.PRINT RECORD

3.RESTORE RECORD

8-2

8-3

8-4

8-5

This ends the Set Time procedure.

Press key #4 (NEXT PAGE)

Press key #2 (SET TIME)

Use the number keys to enter the current

date and time.

The VBT-80P will return to the main menu

after the date and time are entered.

2.SET TIME

MM-DD-YY HH:MM:SS

MM-DD-YY HH:MM:SS

2.SETUP 16:27:00

22

Page 24

Operating Procedures VBT-80P

1520 S. Hellman Ave., Ontario, CA 91761, USA

Phone 909-923-9390 Fax 909-923-9391

www.vanguard-instruments.com

23

VBT-60/80 August 2006

Loading...

Loading...