Page 1

OPERATING INSTRUCTIONS

For

TRI-PHASE™

True Three-Phase Transformer Turns-Ratio Tester

Vanguard Instruments Co., Inc.

TEL: 909-923-9390 October 2008

FAX: 909-923-9391 REV. 01

.

1520 S. Hellman Ave.

Ontario, California 91761, USA

Page 2

TRI-PHASE OPERATING™ INSTRUCTIONS

SAFETY WARNINGS AND CAUTIONS

Only trained operators shall use this device.

All transformers under test shall be off line and fully isolated.

Always ground the TRI-PHASE™ to a substation ground before connecting the test cables to

a transformer

Do Not Modify Test Equipment

Because of the risk of introducing unknown hazards, do not install substitute parts or perform any

unauthorized modifications to any TRI-PHASE™ test device. To ensure that all designed safety

features are maintained it is recommended that repairs be performed only by Vanguard Instruments

Co. factory personnel or by an authorized repair service. Unauthorized modifications will cause

serious safety hazards and will nullify the manufacturer's warranty.

Follow Exact Operating Procedures

Any deviation from the procedures described in this operator’s manual may create safety hazards,

damage the TRI-PHASE™ test device or cause errors in the test results. Vanguard Instruments Co.,

Inc. assumes no liability for unsafe or improper use of the TRI-PHASE™.

2

Page 3

TRI-PHASE OPERATING™ INSTRUCTIONS

Table of Contents

1.0 Introduction...........................................................................................................................10

1.1 Applicability.......................................................................................................................10

2.0 General Description...............................................................................................................10

3.0 Functional Description..........................................................................................................11

4.0 Principles of Operation..........................................................................................................12

5.0 Specifications ........................................................................................................................13

6.0 Supplied Cables.....................................................................................................................14

6.1 Cable Marking and Identification ......................................................................................15

7.0 TRI-PHASE™ Front Panel Descriptions..............................................................................16

7.1 TRI-PHASE™ Operating Controls, Indicators and Connectors........................................16

8.0 TRI-PHASE™ Printer and Printer Paper..............................................................................18

9.0 Memory Storage Capabilities................................................................................................18

9.1 Test Record Memory Storage Capabilities ........................................................................18

9.2 Transformer Test Plan Memory Storage Capabilities........................................................18

10.0 Operating Voltages................................................................................................................18

10.1 Operating Voltages.............................................................................................................18

11.0 Special Features.....................................................................................................................19

11.1 LCD Contrast Control........................................................................................................19

11.2 Test Voltages......................................................................................................................19

11.3 Computer Control And TTRA Software Application........................................................19

11.4 USB FLASH Memory Thumb Drive.................................................................................19

12.0 Typical Cable Hook Up Configurations................................................................................20

12.1 Typical Cable Connections to a Delta-Wye Transformer..................................................20

12.3 Single Phase Transformer Typical Connections................................................................22

12.4 Voltage Regulator Typical Connections ............................................................................23

12.5 Donut Type (un-mounted) Current Transformer (CT) Typical Connections ....................24

12.6 Multi-tap CT Typical Connections ....................................................................................25

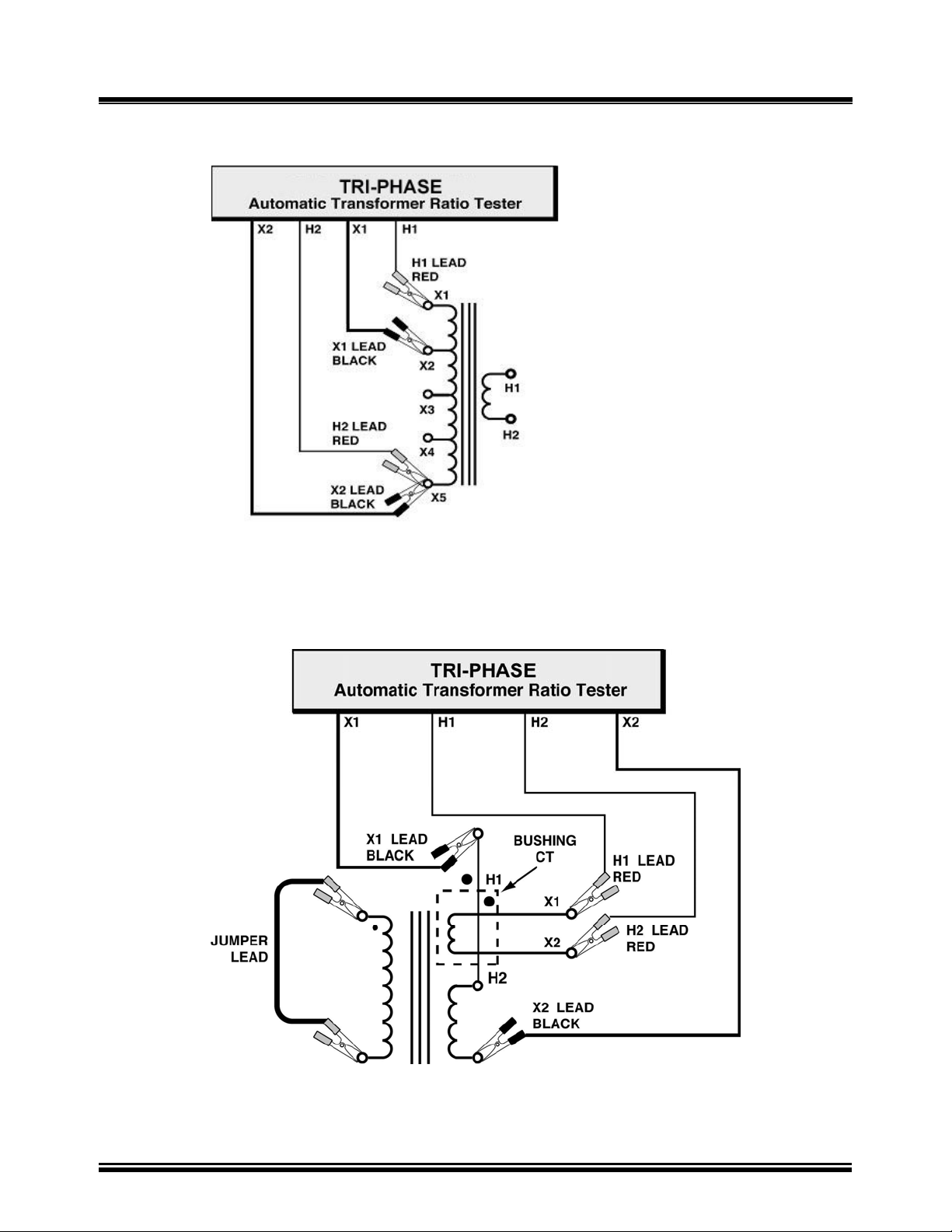

12.7 Bushing-Mount-CT on A Single Phase Transformer Typical Connections ......................25

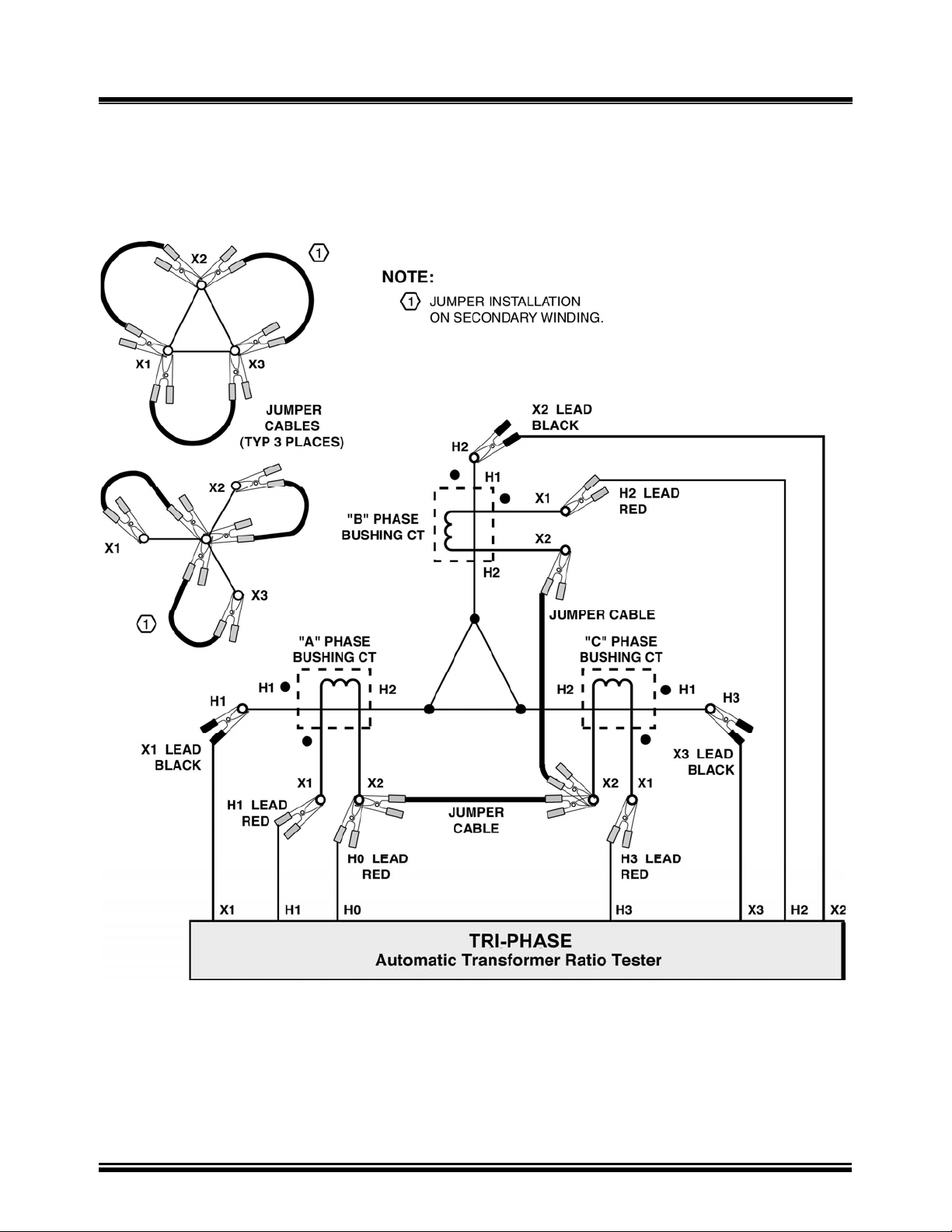

12.8 Bushing Mount CT’s on Delta Transformer Typical Connections....................................26

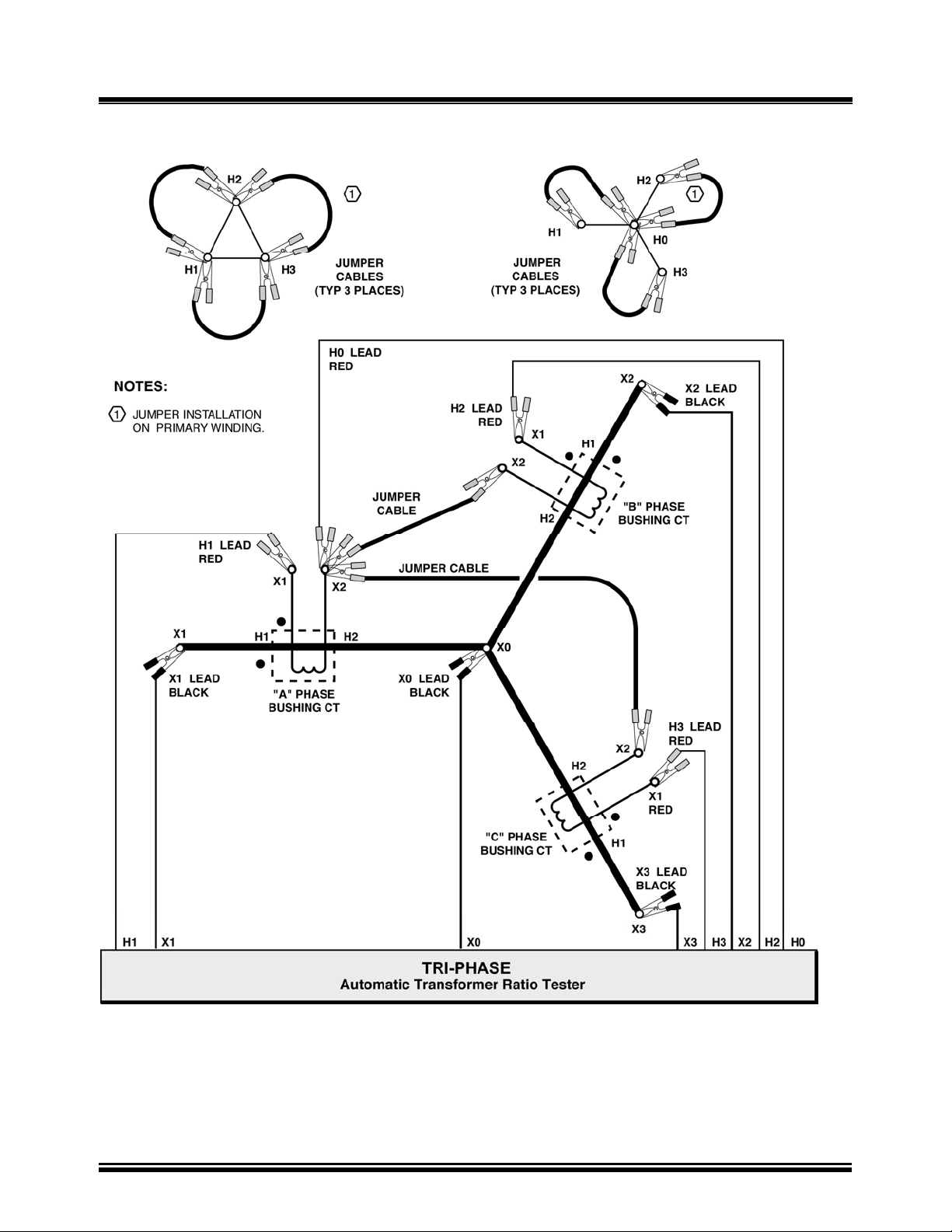

12.9 Bushing Mount CT’s on Wye Transformer Typical Connection.......................................27

13.0 Single-Phase Transformer Test Procedure............................................................................28

13.1 Main Menu.........................................................................................................................31

13.2 Transformer Configuration Selection Menu ......................................................................32

13.3 Transformer Name Plate Voltage Menu ............................................................................33

13.4 Transformer Voltage Data Entry Status Displays..............................................................34

13.5 Start/Stop Test Status Display............................................................................................35

13.6 Test In Progress Status Display..........................................................................................36

13.7 Test Results Status Display................................................................................................37

13.8 Print Test Results Menu.....................................................................................................38

13.9 Print Format Menu.............................................................................................................38

13.10 Test Result Column Format Printout .................................................................................40

13.11 Test Result Detail Format Printout.....................................................................................41

13.12 Keep This Reading Menu...................................................................................................43

13.13 Previous Data In Buf. Menu...............................................................................................44

13.14 Run Another Test Menu.....................................................................................................45

13.15 Save This Record Menu.....................................................................................................46

13.16 Record Saved Confirmation Status....................................................................................47

3

Page 4

TRI-PHASE OPERATING™ INSTRUCTIONS

13.17 Transformer Name Plate Voltage Menu For Another Test................................................48

13.18 Test Record Not Saved Menu ............................................................................................49

14.0 Dyn1 Transformer Test Procedure........................................................................................50

14.1 Delta-To-Wye (Dyn) Transformer Test Column Format Printout.....................................53

14.2 Delta-To-Wye Transformer Test Detail Format Printout...................................................55

15.0 Auto Detect Transformer Configuration Capability .............................................................58

16.0 Test Record Options..............................................................................................................59

16.1 Restore A Test Record To Print Procedure........................................................................59

16.2 Setup Menu ........................................................................................................................61

16.3 Save/Restore Record Menu................................................................................................62

16.4 Restore Record Menu.........................................................................................................63

16.5 Restore Record Number Status Display.............................................................................64

16.6 Record Restored Menu.......................................................................................................65

16.7 Print Record To LCD Or Printer Menu..............................................................................66

16.8 Print Format Menu.............................................................................................................67

16.9 Test Record Printout Column Format................................................................................68

16.10 Test Record Printout Detailed Format ...............................................................................69

16.11 Save Test Results To A Test Record Procedure ................................................................71

16.12 Print Test Record Directory ...............................................................................................72

16.13 Print Directory Menu .........................................................................................................73

16.14 Record Directory Printout..................................................................................................74

16.15 Restore Test Record To LCD Procedure............................................................................75

16.16 Scroll Test Record Menu....................................................................................................77

16.17 Restored Record Status Display.........................................................................................78

16.18 Record Restored Menu.......................................................................................................79

16.19 Print Record Restored Menu..............................................................................................80

16.20 Restored Record Status Displays .......................................................................................81

16.21 Erase A Test Record Procedure .........................................................................................82

16.22 Erase Record Menu............................................................................................................83

16.23 Erase Record Status Display..............................................................................................84

16.24 Record Number Erased Confirmation Status Display........................................................85

16.25 Erase All Test Records Procedure......................................................................................86

16.26 Erase All Records Status Display.......................................................................................87

16.27 Record Number Erased Confirmation Status Display........................................................88

17.0 Test Plan Options..................................................................................................................89

17.1 Load a Test Plan and Test a Transformer Procedure .........................................................89

17.2 Test Plan Menu...................................................................................................................92

17.3 Load Test Plan Number Status Display .............................................................................93

17.4 Test Plan Loaded Menu......................................................................................................94

17.5 Test Plan Loaded Status Display........................................................................................95

17.6 Test Plan Test Results Status Display................................................................................96

17.7 Print Test Plan Test Results ...............................................................................................97

17.8 Test Plan Test Results Printout ..........................................................................................98

17.9 Unload a Test Plan Procedure............................................................................................99

17.10 Print Test Plan Directory Procedure.................................................................................100

17.11 Test Plan Directory Print Out...........................................................................................101

17.12 Print Test Plan Procedure.................................................................................................102

17.13 Print Test Plan Status Display..........................................................................................103

4

Page 5

TRI-PHASE OPERATING™ INSTRUCTIONS

17.14 Typical Three Phase Dyn1 Test Plan Printout.................................................................104

17.15 Erase A Test Plan Procedure............................................................................................105

17.16 Erase Test Plan Menu.......................................................................................................106

17.17 Erase Test Plan Status Display.........................................................................................107

17.18 Test Plan Number Erased Confirmation Status Display..................................................108

18.0 Entering Test Record Identification Information Procedure...............................................109

19.0 Test Voltage Selection Procedure .......................................................................................111

19.1 Test Voltage Selection .....................................................................................................112

20.0 Test Frequency Selection Procedure...................................................................................113

20.1 Test Frequency Selection .................................................................................................114

21.0 Change Date And Time Procedure......................................................................................115

21.1 Enter Date Status Display ................................................................................................116

21.2 Enter Time Status Display................................................................................................117

22.0 H And X Cable Diagnostic Test Procedure.........................................................................118

23.0 TRI-PHASE™ Verification Test Procedure .......................................................................119

24.0 Load Tap Changer...............................................................................................................120

25.0 USB FLASH Thumb Drive .................................................................................................121

25.1 Save/Restore Record With Thumb Drive Menu..............................................................121

25.2 Copy Record To Thumb Drive Menu..............................................................................122

25.3 Copy Single Record To Thumb Drive Status Displays....................................................123

25.4 Copy All Records To Thumb Drive Status Displays.......................................................124

25.5 Test Plan With Thumb Drive Menu.................................................................................125

25.6 Copy Test Plan To Thumb Drive Status Display.............................................................126

25.7 Test Plan Saved To Thumb Drive Confirmation Status Displays....................................127

25.8 Load Test Plan With Thumb Drive Menu........................................................................128

25.9 Load Thumb Drive Test Plan Status Displays.................................................................129

25.10 Print Test Plan Directory With Thumb Drive Menu........................................................130

25.11 Print Test Plan With Thumb Drive Menu........................................................................131

25.12 Print Thumb Drive Test Plan Status Displays..................................................................132

25.13 Erase Test Plan With Thumb Drive Menu.......................................................................133

25.14 Erase Thumb Drive Test Plan Status Displays.................................................................134

25.15 Save Test Plan With Thumb Drive Menu........................................................................135

26.0 Computer Interface Description..........................................................................................136

26.1 Computer Interface Status Display ..................................................................................136

26.2 Emergency Turn Off Switch............................................................................................137

27.0 TRI-PHASE™ Firmware Programming Notes...................................................................138

5

Page 6

TRI-PHASE OPERATING™ INSTRUCTIONS

List of Tables

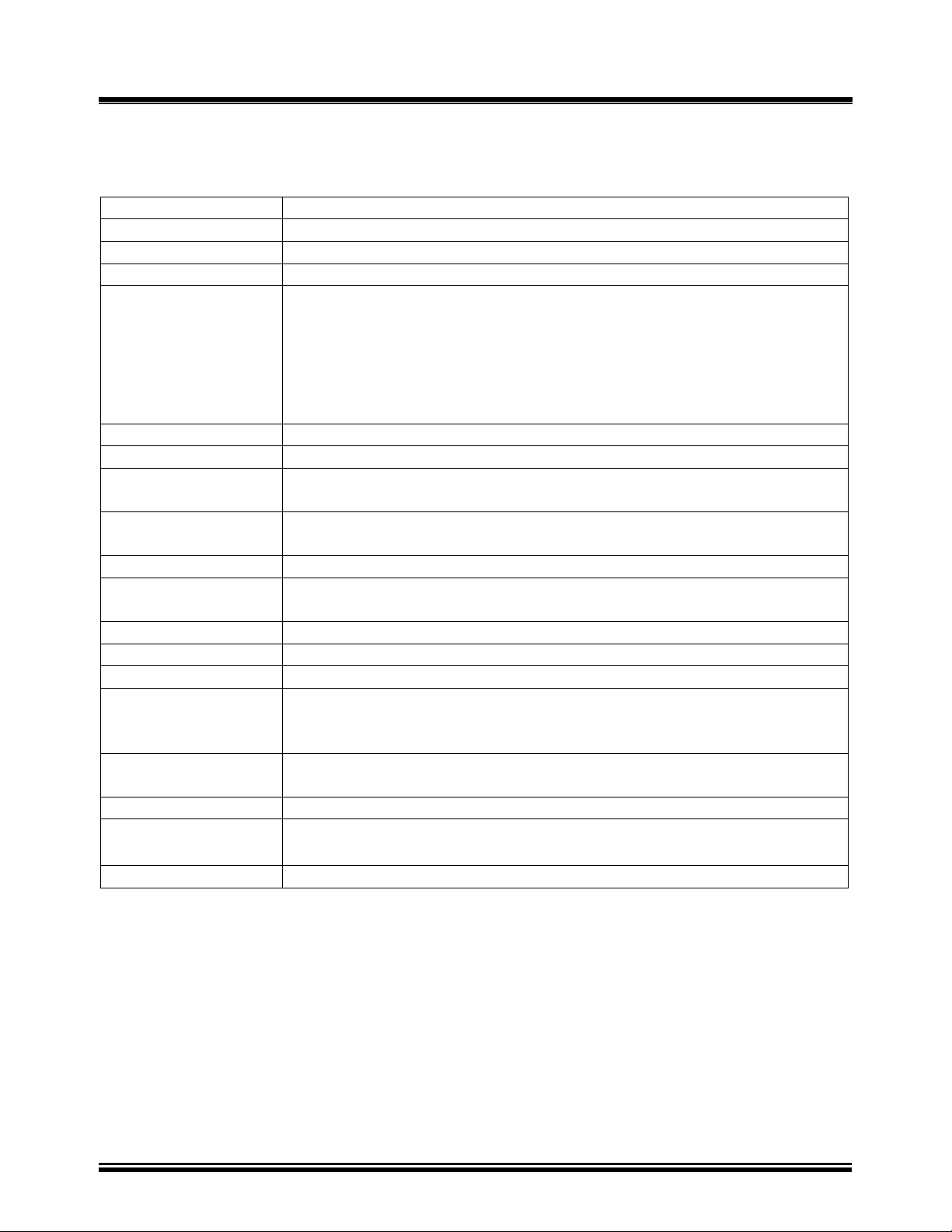

Table 1.0 TRI-PHASE™ Turns-Ratio Meter Specifications.........................................................13

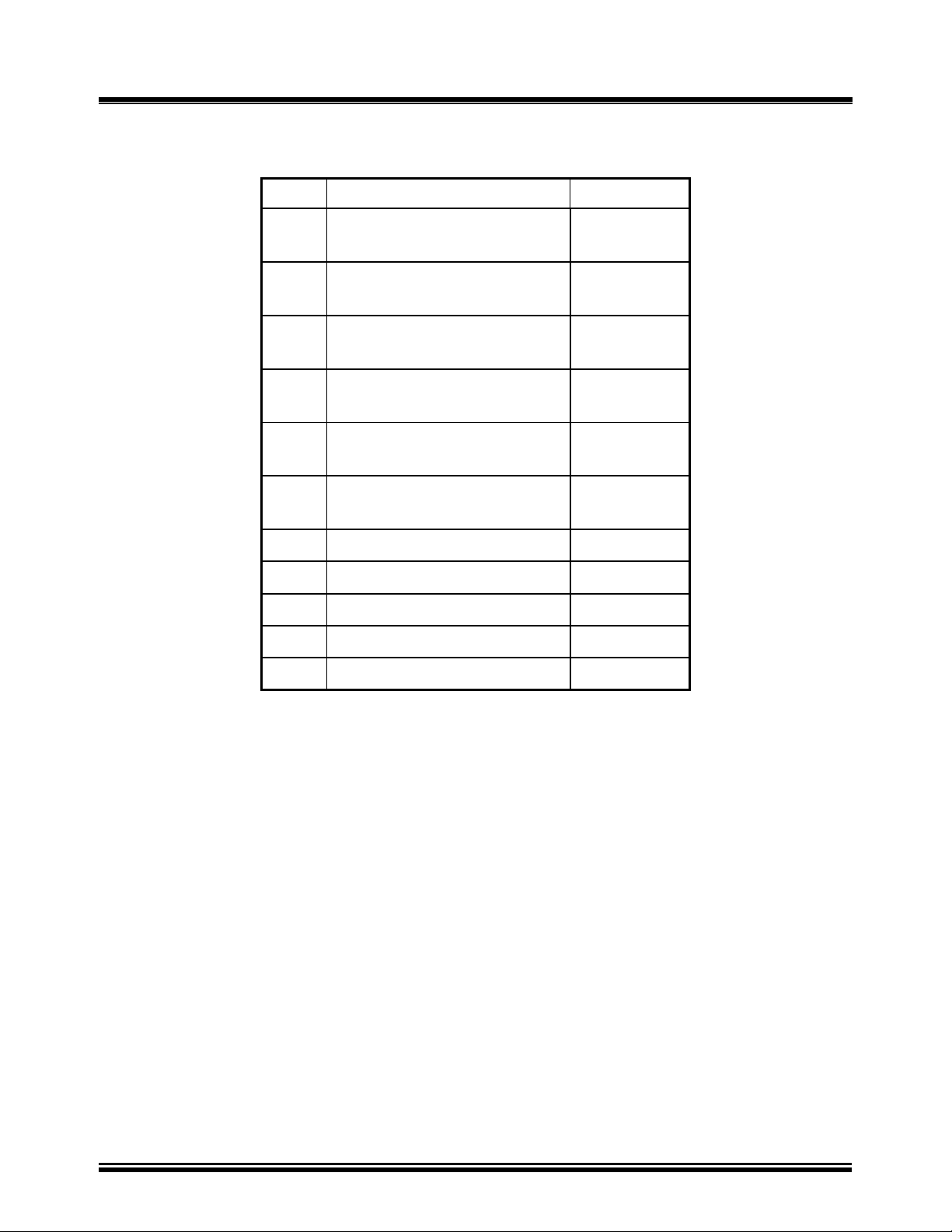

Table 2.0 Supplied Cable Set.........................................................................................................14

Table 3.0 Cable Markings and Identification.................................................................................15

Table 4.0 Model TRI-PHASE™ Front-Panel Controls, Indicators, and Connectors ....................17

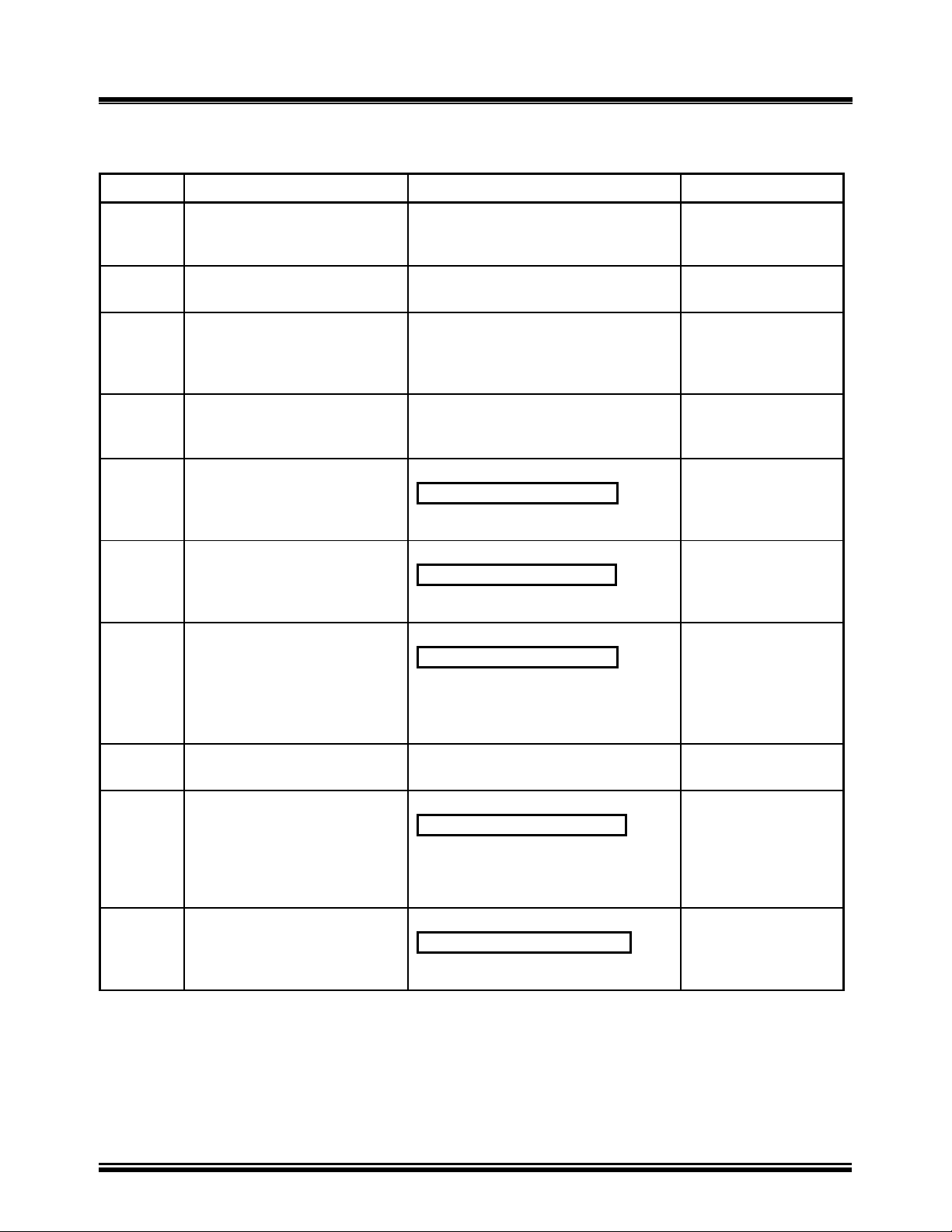

Table 5.0 Single-Phase Transformer Test Procedure.....................................................................28

Table 6.0 Dyn1 Transformer Test Procedure.................................................................................50

Table 7.0 Restore A Test Record To Print Procedure....................................................................59

Table 8.0 Save Test Results To A Test Record Procedure ............................................................71

Table 9.0 Print Test Record Directory Procedure..........................................................................72

Table 10.0 Restore Test Record To LCD Procedure....................................................................75

Table 11.0 Erase A Test Record Procedure .................................................................................82

Table 12.0 Erase All Test Records Procedure..............................................................................86

Table 13.0 Load a Test Plan and Test a Transformer Procedure.................................................89

Table 14.0 Unload A Test Plan Procedure...................................................................................99

Table 15.0 Print Test Plan Directory Procedure.........................................................................100

Table 16.0 Print Test Plan Procedure.........................................................................................102

Table 17.0 Erase A Test Plan Procedure....................................................................................105

Table 18.0 Entering Test Record Identification Information Procedure....................................109

Table 19.0 Transformer Test Voltage Selection Procedure.......................................................111

Table 20.0 Transformer Test Frequency Selection Procedure...................................................113

Table 21.0 Change Date and Time Procedure............................................................................115

Table 22.0 H And X Cable Diagnostic Test Procedure..............................................................118

Table 23.0 TRI-PHASE™ Verification Test Procedure............................................................119

6

Page 7

TRI-PHASE OPERATING™ INSTRUCTIONS

List of Figures

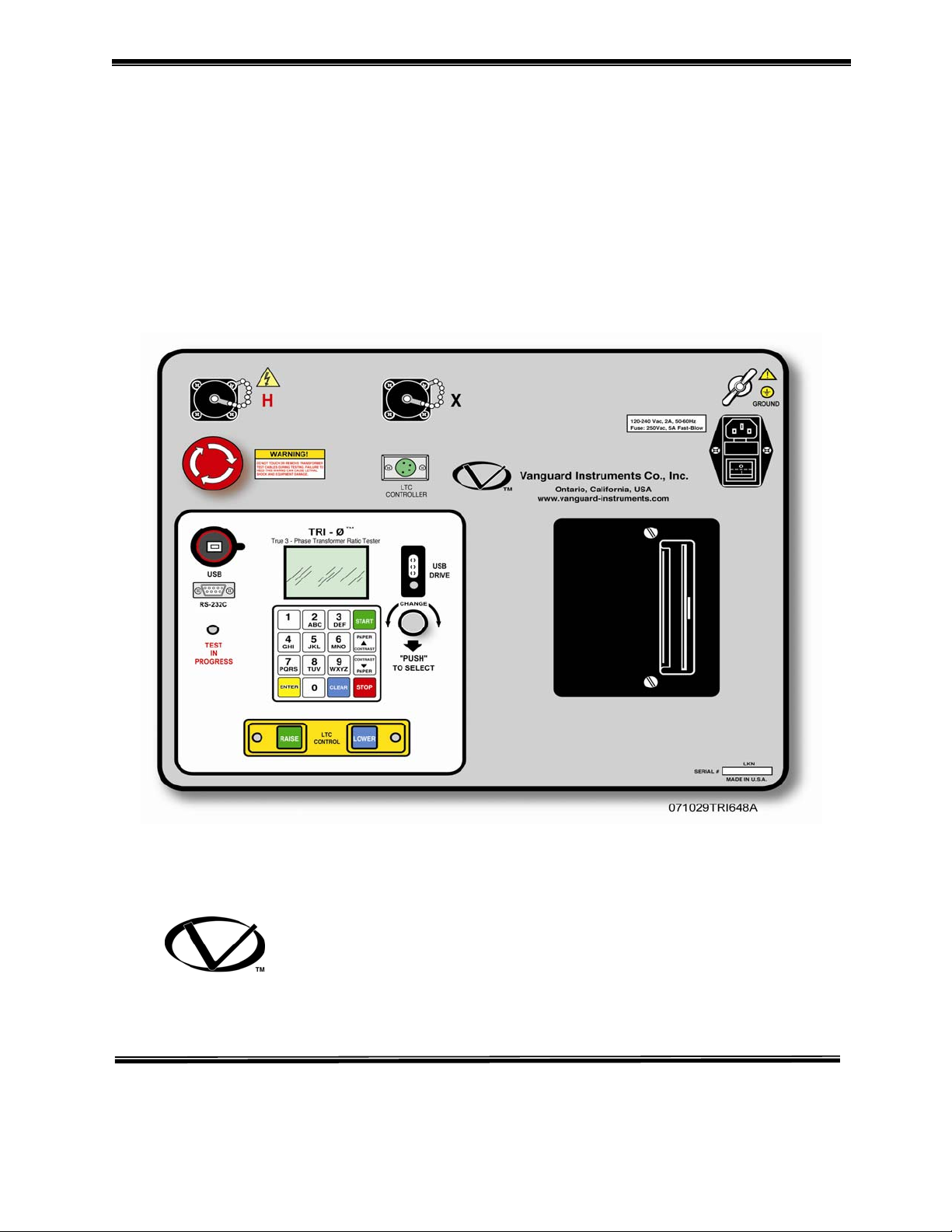

Figure 1.0 Model TRI-PHASE™ Front-Panel Controls, Indicators and Connectors..............................16

Figure 2.0 Typical H & X Cable Connections to a Delta-Wye Transformer ..........................................20

Figure 3.0 Typical Front Panel Cable Connectors...................................................................................21

Figure 4.0 Typical H & X Cable Connections to Delta-Wye Transformer .............................................21

Figure 5.0 Single Phase Transformer Typical Connections ....................................................................22

Figure 6.0 Single Phase Auto Transformer Typical Connections ...........................................................22

Figure 7.0 Type A Voltage Regulator Typical Connections ...................................................................23

Figure 8.0 Type B Voltage Regulator Typical Connections....................................................................23

Figure 9.0 Donut Type (un-mounted) Current Transformer (CT) Typical Connections........................24

Figure 10.0 Multi-tap CT Typical Connections.........................................................................................25

Figure 11.0 Bushing-Mount-CT on A Single Phase Transformer Typical Connections...........................25

Figure 12.0 Bushing Mount CT’s on Delta Transformer Typical Connections ........................................26

Figure 13.0 Bushing Mount CT’s on Wye Transformer Typical Connection ...........................................27

Figure 14.0 Main Menu .............................................................................................................................31

Figure 15.0 Transformer Configuration Selection First Menu ..................................................................32

Figure 16.0 Transformer Configuration Selection Second Menu..............................................................32

Figure 17.0 Transformer Nameplate Voltage Menu..................................................................................33

Figure 18.0 Name Plate Voltage Status Display........................................................................................34

Figure 19.0 Name Plate Voltage Display, H Voltage Keyed In ................................................................34

Figure 20.0 Name Plate Voltage Display, H Voltage Entered...................................................................34

Figure 21.0 Name Plate Voltage Display, X Voltage Keyed In ................................................................34

Figure 22.0 Start/Stop Test Status Display................................................................................................35

Figure 23.0 Test In Progress Status Display..............................................................................................36

Figure 24.0 Test Results Status Display ....................................................................................................37

Figure 25.0 Print Test Results Menu .........................................................................................................38

Figure 26.0 Print Format Menu .................................................................................................................38

Figure 27.0 Single Phase Column Format Printout ...................................................................................40

Figure 28.0 Single Phase Detail Format Printout ......................................................................................41

Figure 29.0 Keep This Reading Menu.......................................................................................................43

Figure 30.0 Previous Data In Buf Menu....................................................................................................44

Figure 31.0 Run Another Test Menu .........................................................................................................45

Figure 32.0 Save This Record Menu .........................................................................................................46

Figure 33.0 Record Saved Confirmation Status Display ...........................................................................47

Figure 34.0 Nameplate Voltage Selection Menu For Another Test...........................................................48

Figure 35.0 Test Record Not Saved Menu......................................................................................... ........49

Figure 36.0 Dyn1 Column Format Printout...............................................................................................53

Figure 37.0 Dyn1 Detail Format Printout..................................................................................................55

Figure 38.0 Setup Menu.............................................................................................................................61

Figure 39.0 Save/Restore Record Menu ....................................................................................................62

Figure 40.0 Restore Record Menu.............................................................................................................63

Figure 41.0 Restore Record Number Status Display .................................................................................64

Figure 42.0 Record Restored Menu...........................................................................................................65

Figure 43.0 Print Record Menu .................................................................................................................66

Figure 44.0 Print Format Menu .................................................................................................................67

Figure 45.0 Test Record Printout Column Format ....................................................................................68

Figure 46.0 Test Record Printout Detailed Format....................................................................................69

Figure 47.0 Print Directory Menu..............................................................................................................73

Figure 48.0 Record Directory Printout ......................................................................................................74

Figure 49.0 Scroll Test Record Menu........................................................................................................77

Figure 50.0 Restored Record Status Display .............................................................................................78

Figure 51.0 Record Restored Menu...........................................................................................................79

7

Page 8

TRI-PHASE OPERATING™ INSTRUCTIONS

Figure 52.0 Print Record Restored Menu ..................................................................................................80

Figure 53.0 Restored Record First Status Display.....................................................................................81

Figure 54.0 Restored Record Second Status Display ................................................................................81

Figure 55.0 Erase Record Menu ................................................................................................................83

Figure 56.0 Erase Record Status Display ..................................................................................................84

Figure 57.0 Record Number Erased Status Display ..................................................................................85

Figure 58.0 Erase All Records Status Display...........................................................................................87

Figure 59.0 Records Erased Status Display...............................................................................................88

Figure 60.0 Test Plan Menu.......................................................................................................................92

Figure 61.0 Load Test Plan Number Status Display..................................................................................93

Figure 62.0 Test Plan Loaded Menu..........................................................................................................94

Figure 63.0 Test Plan Loaded Status Display............................................................................................95

Figure 64.0 Test Plan Test Results Status Display ....................................................................................96

Figure 65.0 Test Plan Test Results Printout Column Format ....................................................................98

Figure 66.0 Test Plan Directory Print Out...............................................................................................101

Figure 67.0 Print Test Plan Status Display ..............................................................................................103

Figure 68.0 Typical Three Phase Dyn1 Test Plan Printout......................................................................104

Figure 69.0 Erase Test Plan Menu...........................................................................................................106

Figure 70.0 Erase Test Plan Status Display.............................................................................................107

Figure 71.0 Test Plan Number Erased Status Display.............................................................................108

Figure 72.0 Test Voltage Selection Menu ...............................................................................................112

Figure 73.0 Test Frequency Selection Menu ...........................................................................................114

Figure 74.0 Enter Date Status Display.....................................................................................................116

Figure 75.0 Enter Time Status Display....................................................................................................117

Figure 76.0 Load Tap Changer Controller...............................................................................................120

Figure 77.0 Save/Restore Record With Thumb Drive Menu...................................................................121

Figure 78.0 Copy Record To Thumb Drive Menu...................................................................................122

Figure 79.0 Copy Single Record To Thumb Drive Status Displays........................................................123

Figure 80.0 Copy All Records To Thumb Drive Status Displays ...........................................................124

Figure 81.0 Test Plan With Thumb Drive Menu ..................................................................................... 125

Figure 82.0 Copy Test Plan To Thumb Drive Status Display .................................................................126

Figure 83.0 Test Plan Saved To Thumb Drive Confirmation Status Displays ........................................127

Figure 84.0 Load Test Plan Number With Thumb Drive Menu..............................................................128

Figure 85.0 Load Thumb Drive Test Plan Status Displays......................................................................129

Figure 86.0 Print Test Plan Directory With Thumb Drive Menu ............................................................130

Figure 87.0 Print Test Plan With Thumb Drive Menu ............................................................................131

Figure 88.0 Print Thumb Drive Test Plan Status Displays......................................................................132

Figure 89.0 Erase Test Plan With Thumb Drive Menu ...........................................................................133

Figure 90.0 Erase Thumb Drive Test Plan Status Displays.....................................................................134

Figure 91.0 Save Test Plan With Thumb Drive Menu ............................................................................135

Figure 92.0 Computer Interface Status Display.......................................................................................136

Figure 93.0 Computer Interface Status Display.......................................................................................137

Figure 94.0 Firmware Revision Menu 1..................................................................................................138

Figure 95.0 Firmware Revision Menu 2..................................................................................................139

Figure 96.0 Firmware Revision Menu 3..................................................................................................139

Figure 97.0 Firmware Revision Menu 3..................................................................................................139

Figure 98.0 Firmware Revision Menu 4..................................................................................................140

Figure 99.0 Firmware Revision Menu 5..................................................................................................140

Figure 100.0 Firmware Revision Menu 6..........................................................................................

....140

8

Page 9

TRI-PHASE OPERATING™ INSTRUCTIONS

List of Appendicies

APPENDIX A .................................................................................................................................141

APPENDIX B .................................................................................................................................142

9

Page 10

TRI-PHASE OPERATING™ INSTRUCTIONS

1.0 Introduction

1.1 Applicability

This manual is applicable to the True Three-Phase Transformer Turns-Ratio (TRI-PHASE™)

Tester model made by Vanguard Instruments Company, Inc.

2.0 General Description

The TRI-PHASE™ is a true three-phase, field-portable, automatic transformer turns-ratio test

instrument designed to conform to IEEE C57.12.90 measurement method. The TRI-PHASE™ is

designed for on-site measurement of turns-ratios, winding polarity, phase angles, and no-load

excitation currents of single phase and three-phase utility transformers, potential transformers

(PT's), and primary current transformers (CT's)

Since the TRI-PHASE™ is capable of outputting a true three-phase excitation test voltage (for

testing three-phase transformers), it can easily measure turns-ratios and phase angles of Zig-Zag, T

type, special configuration, and phase shifting transformers.

A built-in Load Tap Changer (LTC) controller provides the capability to raise or lower the LTC tap

position from the TRI-PHASE™ front panel.

The TRI-PHASE™ can be controlled from the front panel keypad (Stand Alone Mode) or in

Computer Control Mode with an IBM compatible Personal Computer (PC) via the Universal Serial

Bus (USB) port or RS-232C port.

The TRI-PHASE™ is supplied with single phase and three-phase hook-up cables, LTC control

cables, an RS232 serial cable, a USB cable, and a Microsoft Windows™ based PC Transformer

Turns Ratio Analyzer (TTRA) software application.

The TTRA software is provided on a compact disk along with the unit. New released TTRA

software and TRI-PHASE™ firmware are available to all users on the Vanguard Instruments web

site (www.vanguard-instruments.com).

10

Page 11

TRI-PHASE OPERATING™ INSTRUCTIONS

3.0 Functional Description

The TRI-PHASE™ measures a transformer turns-ratio from its windings by applying a 3-phase test

voltage across the primary (H) winding and sensing the induced voltage on the secondary (X)

winding. The measured voltage ratio between H and X is virtually the same as the turns-ratio of the

windings because of no load on the windings during testing. The TRI-PHASE™ is capable of

testing either single phase or three phase transformers. The need to change test leads to test each

phase on three phase transformers is eliminated using the three-phase cables. The TRI-PHASE™

will automatically test each phase of the transformer. The TRI-PHASE™ also has the following

features:

• Capable of testing with 3 test voltages; 8Vac, 40Vac, and 100Vac.

• Capable of testing three-phase transformers in Delta, Wye, Zig-Zag, and T type

configurations.

• Capable of displaying transformer phase angle relationships between primary and secondary

windings.

• Capable of automatically detecting and testing 130 three-phase transformer types defined by

ANSI, CEI/IEC and Australian standards. Refer to appendix B for the different transformer

configurations.

• Capable of testing phase-shifting transformer turns-ratios and displaying phase shift angles.

• Capable of performing test cable hook-up error checks before each test and automatically

aborting the test when there is an error.

• Capable of calculating the transformer turns-ratio based on the operator data entry of the

transformer nameplate voltages.

• Capable of calculating the percentage error based on the difference between the calculated

and measured turns-ratio values.

• Capable of saving transformer test result(s) in the on-board FLASH EEPROM. The test

result data consists of H and X nameplate voltages, phase A/B/C turns-ratios, excitation

current and phase angle measurements.

• Capable of storing a total of 112 test records in the on-board FLASH EEPROM. A test

record may contain up to 33 tests. Stored test records may be recalled, printed or transferred

to an IBM compatible PC with the built-in RS-232C port or USB interface port.

• Capable of storing up to 128 test plans in the on-board FLASH EEPROM. A test plan

provides the capability to store transformer nameplate voltages.

• Capable of printing “PASS” or “FAIL” test results of each of the transformer tests.

• Capable of storing test records and transformer test plans to an external FLASH memory

drive via the built-in USB FLASH memory thumb drive interface.

• Capable of printing test reports with a built-in 4.5-inch wide thermal printer.

• Capable of alpha-numeric input with the 16-key, alpha-numeric keypad.

• Capable of menu and submenu selection with either the alpha-numeric input or with a rotary

switch knob control.

• Capable of displaying data entry, menus, test results, and status readouts with the Liquid

Crystal Display (LCD) 64 by 128 dot graphic, back-lighted, sunlight readable display.

• Users can retrieve test records, review test records, and create test plans. Under computer

control operation with the supplied Transformer Turns-Ratio Analyzer (TTRA) software

application, the TTRA software application allows the user to perform a transformer turns

ratio test and saves the test results directly to a compatible IBM PC. The test data is stored in

ASCII format for database compatibility.

11

Page 12

TRI-PHASE OPERATING™ INSTRUCTIONS

3.0 Functional Description (continued)

• The TTRA software application is compatible with Microsoft Windows XP, and Microsoft

Windows Vista (see section

11.3 for more details).

• Capable of raising or lowering the Load Tap Changer (LTC) tap position from the TRI-

PHASE™ front panel with the built-in LTC controller (see section

24.0 for more details).

4.0 Principles of Operation

The TRI-PHASE™ measures transformer turns-ratios (using the ANSI/IEEE C57.12.90 method) by

applying a test voltage across the primary (H) winding and sensing the induced voltage on the

secondary (X) side. For safety, testing is always done in a step-down transfer, regardless of the

transformer’s actual use. Since there is no load on the windings during testing, the measured voltage

ratio is virtually the same as the winding turns-ratio.

The TRI-PHASE™ checks for test cable hook-up errors before each test. It applies a low-level test

voltage (300 mV) across the winding being tested and senses the induced secondary voltage. If the

induced voltage is greater than the applied excitation voltage, a hookup error is assumed. If a

connection error is detected, the TRI-PHASE™ aborts the test and displays “Hook-Up Error” on the

LCD. If no hookup error is detected, the TRI-PHASE™ applies a full test voltage to the transformer

winding being tested and the turns-ratio (or voltage ratio) is displayed on the LCD.

The winding polarity and phase-angle are determined by comparing the induced voltage waveform

to the test voltage waveform (which is used as the reference). In-phase waveforms (+) measure a

phase angle centered about 0 degrees. Out-of-phase waveforms (−) measure a phase angle centered

about 180 degrees.

The TRI-PHASE™ measures turns-ratios in the range from 0.8 to 15,000. Excitation current

(flowing in the H leads) is measured for reference and ranges from 0 to 2,000mA. Winding polarity

is displayed as a “+” or “−”sign in front of the measured ratio. The phase angle is measured in

degrees with a resolution of ±0.2 degrees.

NOTE:

The phase angle measurement is not displayed on the LCD.

The phase angle measurement will be printed when the detail print format is selected

and displayed with a PC running the TTRA software application.

12

Page 13

TRI-PHASE OPERATING™ INSTRUCTIONS

5.0 Specifications

TRI-PHASE™ specifications are listed in Table 1.0.

Table 1.0 TRI-PHASE™ Turns-Ratio Meter Specifications

Type Portable, True Three-Phase Transformer Turns-Ratio Meter

Size 17” (43.2cm) L by 21” (53.3cm) W by 9” (22.9cm) H

Weight 35lbs/15.9Kg

Input Voltage 3 A, 100-240Vac 50/60Hz

Turns-ratio

Measuring Ranges

0.8-999: ±0.1%, 1,000-1,599: ±0.2%, 1,600-9,999: ±1% @ 8Vac

10,000-15,000: ±1.5% @ 8Vac

0.8-999: ±0.1%, 1,000-1,599: ±0.2%, 1,600-9,999: ±1% @ 40Vac

10,000-15,000: ±1.5% @ 40Vac

0.8-999: ±0.1%, 1,000-1,599: ±0.2%, 1,600-9,999: ±1% @ 100Vac

10,000-15,000: ±1.5% @ 100Vac

Excitation Voltages Three-phase, 8Vac, 40Vac, 100Vac (Selectable)

Excitation Current 1A @ 8Vac, 0.2A @ 40Vac, 0.1A @ 100Vac

Current Reading

0 to 2,000mA

Range

Current Reading

±0.1mA, ±2% of reading (±1mA)

Accuracy

Phase Angle Reading 0 to 360 degrees

Phase Angle Reading

±0.2 degrees of Reading (±1 Digit)

Accuracy

Winding Polarity Displayed on LCD screen

Display Back-lit LCD screen, 64 x 128 dot graphic display, Viewable in sun light

Computer Interface One RS-232C port and one USB port

FLASH Memory

One USB FLASH memory thumb drive interface port

Thumb Drive

Interface

Memory Storage

Capabilities

Store 112 test records. A test record may contain up to 99 test results.

Store 128 test plans. A test plan may contain up to 33 tests.

LTC Contacts Rating 240Vac, 2A

Temperature

Operating: −10°C to 55°C (15°F to 122°F)

Storage: −30°C to 70° C(−22°F to 158°F)

Warranty One Year on Parts and Labor

NOTE:

All Specifications herein are valid at nominal voltage and ambient temperature of +25º C (+77º F).

Specifications are subject to change without notice.

13

Page 14

6.0 Supplied Cables

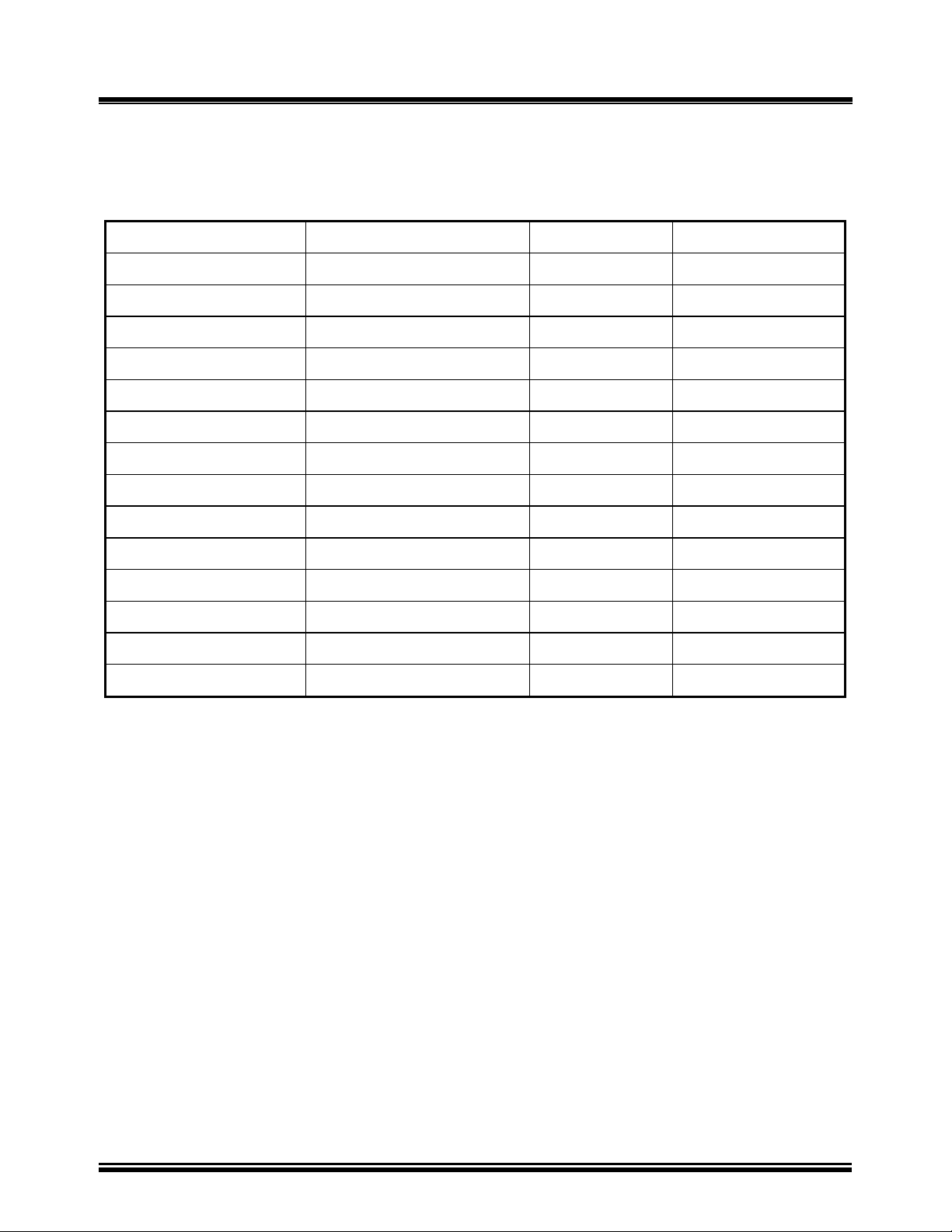

Item Description Qty

TRI-PHASE OPERATING™ INSTRUCTIONS

Table 2.0 Supplied Cable Set

1 H Test-Lead Cable, 15-foot

1

Single-Phase Cables

2 X Test-Lead Cable, 15-foot

1

Single-Phase Cables

3 H Test-Lead Cable, 15-foot

1

Three-Phase Cables

4 X Test-Lead Cable, 15-foot

1

Three-Phase Cables

5 H Extension Cable, 20-foot

1

Three-Phase Cables

6 X Extension Cable, 20-foot

1

Three-Phase Cables

7 LTC Control Cable, 15-foot 1

8 RS-232C Cable 1

9 USB Cable 1

9 Power cord 1

10 Ground Cable 1

NOTE:

A canvas cable-carrying bag is included with the cable set.

14

Page 15

TRI-PHASE OPERATING™ INSTRUCTIONS

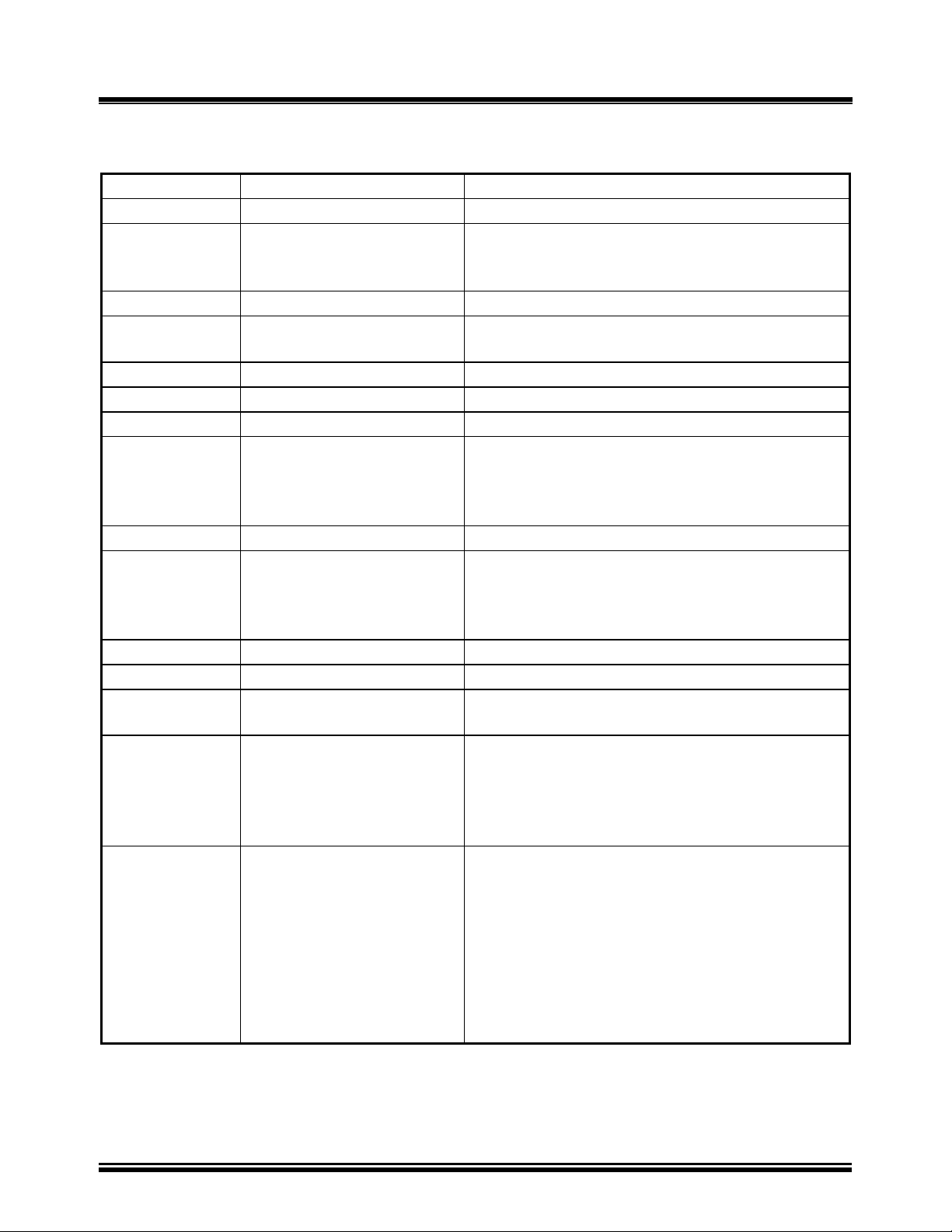

6.1 Cable Marking and Identification

Both the H and X cable test leads are terminated with heavy-duty battery clips. Test cable leads are

identified as follows.

Table 3.0 Cable Markings and Identification

Test Cable Name Transformer Terminals Clip Color Identification

Single Phase H Cables H1 Red H1/1U/A

Single Phase H Cables H2 Red H2/1V/B

Single Phase X Cables X1 Black X1/2U/a

Single Phase X Cables X2 Black X2/2V/b

Three Phase H Cables H0 Red H0/1N/n

Three Phase H Cables H1 Red H1/1U/A

Three Phase H Cables H2 Red H2/1V/B

Three Phase H Cables H3 Red H3/1W/C

Three Phase X Cables X0 Black X0/2N/n

Three Phase X Cables X1 Black X1/2U/a

Three Phase X Cables X2 Black X2/2V/b

Three Phase X Cables X3 Black X3/2W/c

LTC Cable RAISE (two connections) Green RAISE

LTC Cable LOWER (two connections) White LOWER

15

Page 16

TRI-PHASE OPERATING™ INSTRUCTIONS

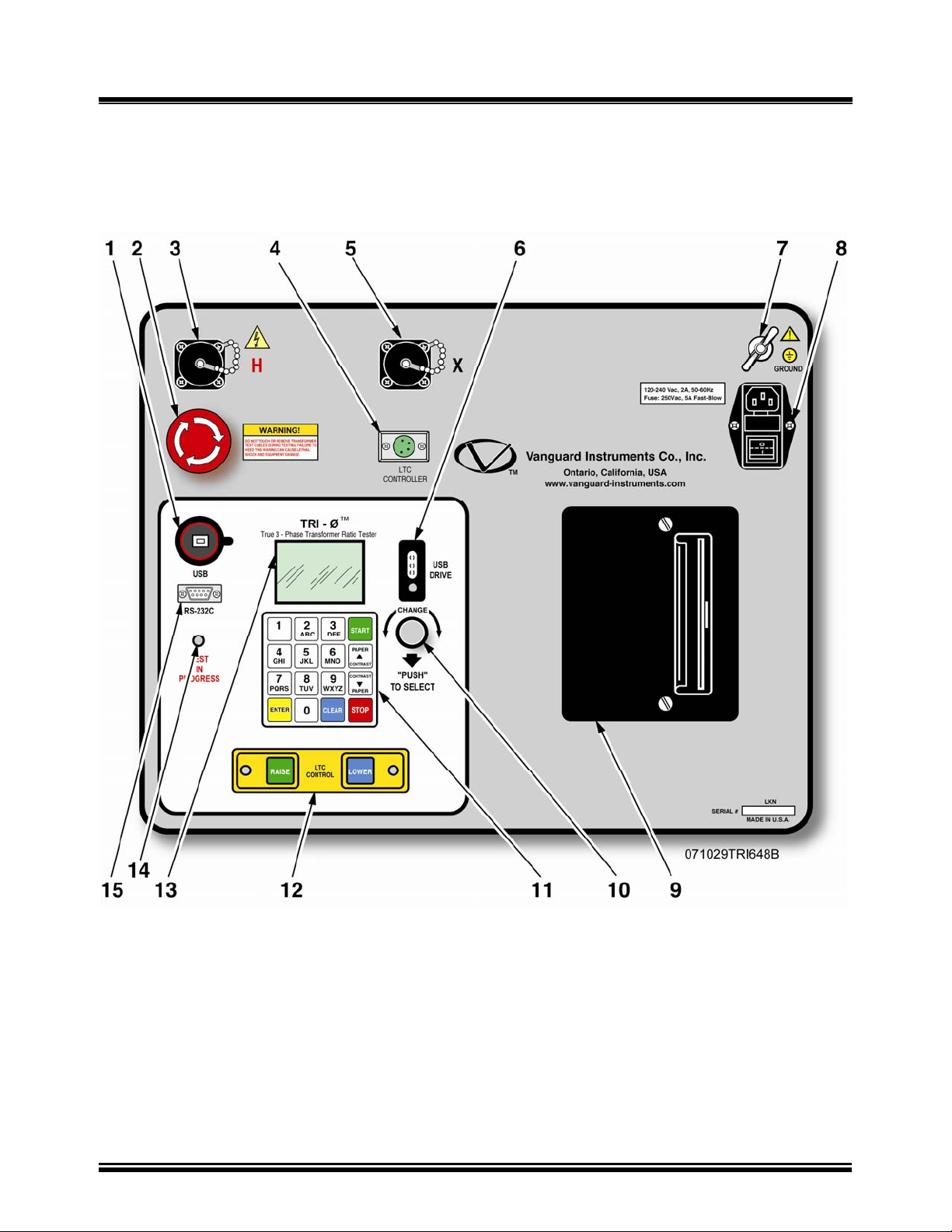

7.0 TRI-PHASE™ Front Panel Descriptions

7.1 TRI-PHASE™ Operating Controls, Indicators and Connectors

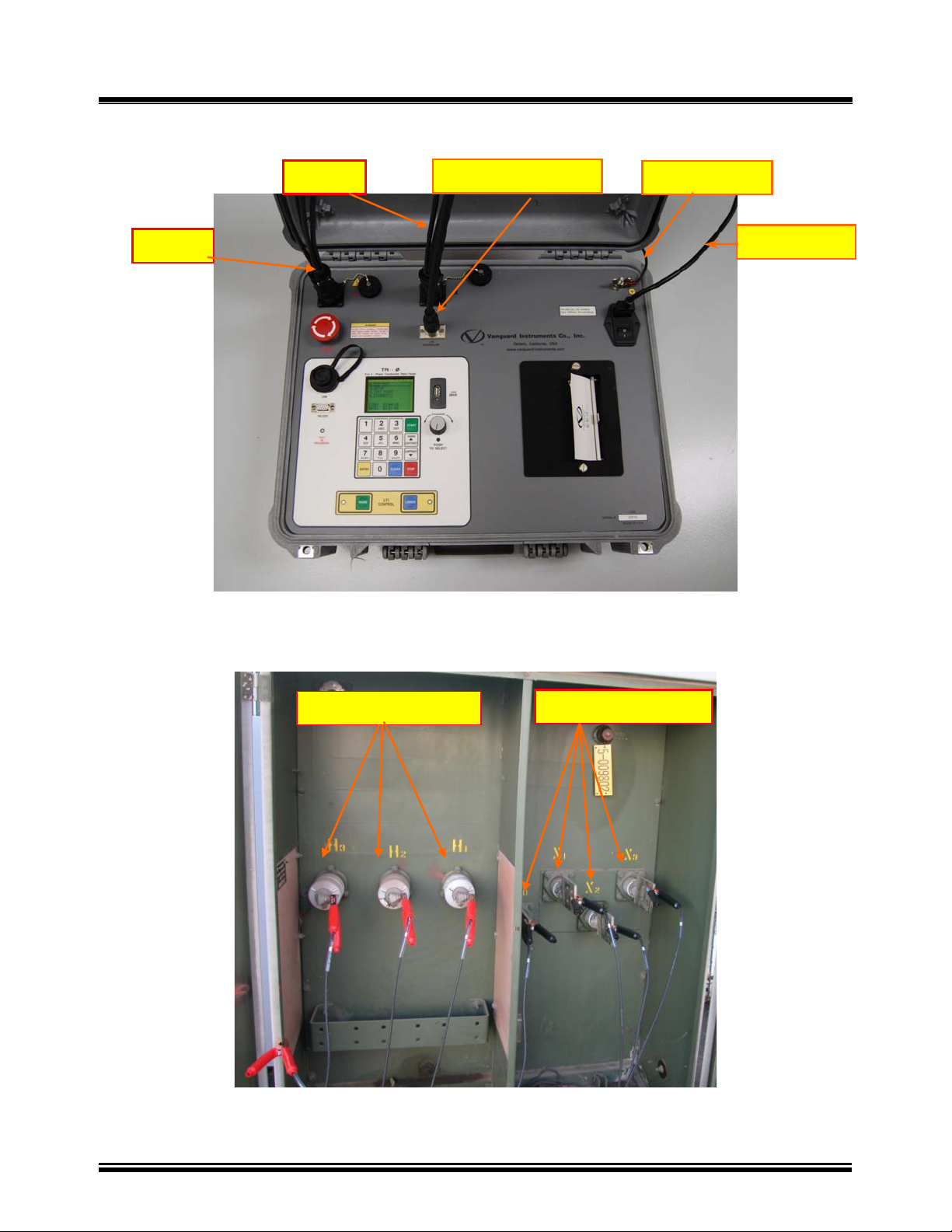

Figure 1.0 Model TRI-PHASE™ Front-Panel Controls, Indicators and Connectors

16

Page 17

TRI-PHASE OPERATING™ INSTRUCTIONS

7.1

TRI-PHASE™ Operating Controls, Indicators and Connectors (continued)

Table 4.0 Model TRI-PHASE™ Front-Panel Controls, Indicators, and Connectors

Fig. 2.0 Index Panel Markings Functional Description

1

2

USB

EMERGENCY

USB interface port to PC

Emergency turn off test voltage switch

TURN OFF

“PUSH”

3

4

H

LTC

H voltage test connector

Load Tap Changer controller connector

CONTROLER

5

6

7

8

X

USB DRIVE

None (wing nut)

120-240Vac, 2 A,

50/ 60Hz

X voltage test connector

USB FLASH memory thumb drive interface port

Ground stud connected to substation ground

Input power connector and fused power switch

with third-wire safety ground

Fuse: 250Vac, 5 A,

Fast Blow

9

10

None (printer)

CHANGE

“PUSH”

TO SELECT

Thermal printer, 4.5-inch wide printout

Control Knob: Turning this Control Knob

scrolls through different menu options (shown

on LCD). Select the displayed menu option by

pushing the knob.

11

12

13

None (keypad)

LTC CONTROL

None (LCD display)

pushbutton operating controls, 16-keys

Load Tap Changer Control push button switches

LCD display 64 by 128 dot graphic, back-

lighted, sunlight readable display

14

TEST IN PROGRESS

This red LED flashes in response to a command

or when a test voltage is applied to the test

transformer. The red LED flashes with a

corresponding beeping sound at a 1 second rate

during test.

15

RS-232C

RS-232C connector for interface to an IBM

compatible computer. A 9-pin, female DB type

connector. Data rate is set to 115,000 baud, 1

start bit, 8 data bits, 2 stop bits, and no parity bit.

Connector pin functions are:

PIN SIGNAL

2 Rx

3 Tx

5 Gnd

17

Page 18

TRI-PHASE OPERATING™ INSTRUCTIONS

8.0 TRI-PHASE™ Printer and Printer Paper

The TRI-PHASE™ built-in thermal printer uses 4.5-inch wide thermal paper for printing test

results. In order to maintain the highest quality printing and to avoid paper jams we recommend

using the paper supplied by our factory. Paper can be ordered from the following sources.

Vanguard Instruments Co, Inc.

1520 S. Hellman Ave.

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: TP-4 Paper

OR

BG Instrument Co.

13607 E. Trent Ave.

Spokane, WA 99216

Tel: 888-244-4004

Fax: 509-893-9803

Part Number: TP4 paper

9.0 Memory Storage Capabilities

9.1 Test Record Memory Storage Capabilities

The TRI-PHASE™ is capable of storing up to 112 transformer test records in the on-board FLASH

EEPROM. The TRI-PHASE™ is capable of restoring test records from the on-board FLASH

EEPROM. After a test record is restored it may be viewed on the TRI-PHASE™ LCD screen

and/or transferred to a USB FLASH memory thumb drive, to a PC, or printed using the built-in

thermal printer. Storing more than 112 transformer test records requires a USB FLASH memory

thumb drive. A USB FLASH thumb drive is capable of storing 999 transformer test records.

9.2 Transformer Test Plan Memory Storage Capabilities

Each TRI-PHASE™ is capable of storing up to 128 Transformer Test Plans in the FLASH

EEPROM. Test plans allow the operator to perform a complete transformer test and obtain

PASS/FAIL results.

10.0 Operating Voltages

10.1 Operating Voltages

The TRI-PHASE™ operating voltage is 100-240Vac, 50/60Hz.

The TRI-PHASE™ has built-in ground fault isolation detection and will only operate with

operating voltages that are ground-fault isolated.

18

Page 19

TRI-PHASE OPERATING™ INSTRUCTIONS

11.0 Special Features

11.1 LCD Contrast Control

To darken the LCD display, press and hold the “V Contrast” switch for more than two seconds. To

lighten the LCD display, press and hold the “W Contrast” switch for more than two seconds.

11.2 Test Voltages

The TRI-PHASE™ has three selectable test voltages: 8Vac, 40Vac, and 100Vac. The TRIPHASE™ has two selectable test frequencies, 50 Hz and 60 Hz. Refer to Table

19.0 for test voltage

selection.

11.3 Computer Control And TTRA Software Application

The TRI-PHASE™ may be controlled by an IBM compatible PC via the RS-232 interface port or

USB interface port. Cables for the RS-232C and USB connections are supplied with each TRIPHASE™. The operator connects the appropriate PC interface cable to the TRI-PHASE™. A

Microsoft Windows

™

Based PC TTRA software application is delivered with each TRI-PHASE™.

The TRI-PHASE™ test result data is stored in ASCII format making it possible to export the data

into any database desired. Microsoft Windows XP™, and Microsoft Windows Vista™ support the

TTRA software application. Using this software application, the operator has the ability to:

• Perform transformer test(s) under control of the PC

• Save transformer test results directly to the PC

• Transfer test records stored in the TRI-PHASE™ FLASH EEPROM to the PC

• Transfer transformer test plans generated by the TTRA to the TRI-PHASE™ FLASH

EEPROM memory

• Transfer test records from the TRI-PHASE™ FLASH EEPROM to the thumb drive

• Transfer test plans generated by the TTRA into the thumb drive

11.4 USB FLASH Memory Thumb Drive

The USB FLASH memory thumb drive is capable of storing test records and test plans. This device

will be referred to from now on as the “thumb drive”. Many of the operational menus described in

this manual will contain an extra option to select the thumb drive. When this option is selected, the

submenus will allow for selection of the internal FLASH EEPROM memory or the thumb drive

FLASH memory. Refer to section

25.0 for further details of the menus which have this option.

19

Page 20

TRI-PHASE OPERATING™ INSTRUCTIONS

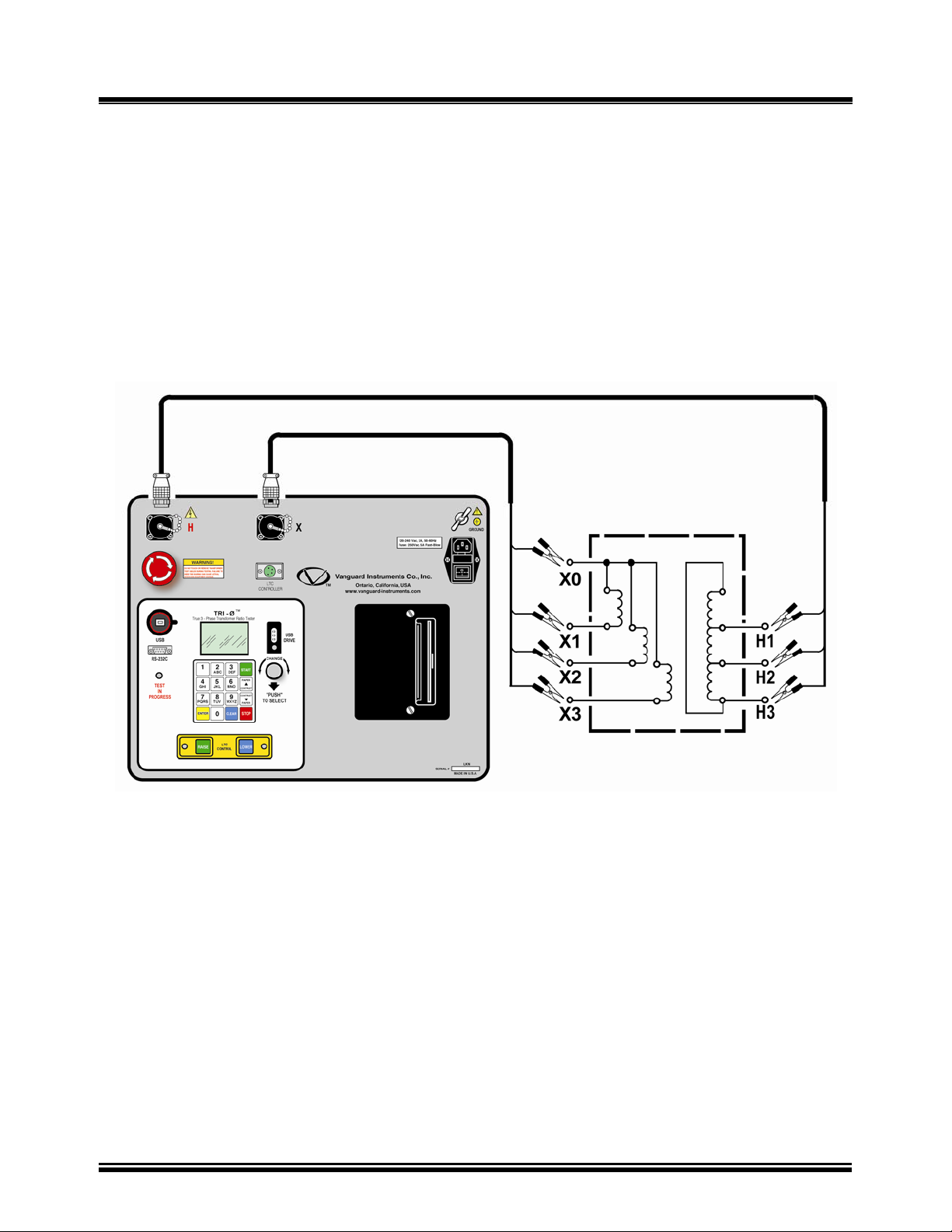

12.0 Typical Cable Hook Up Configurations

Always ground the TRI-PHASE™ with the provided ground cable contained in the cable set

before connecting H and X cables. Ground the transformer bushings before connecting test leads to

transformer. This procedure prevents inducing any voltages into the TRI-PHASE™. All transformer

buss connections must be removed and transformer isolated before performing testing of

transformer. Typical TRI-PHASE™ cable connections to different transformers are illustrated in

Figure 2.0 to Figure 13.0.

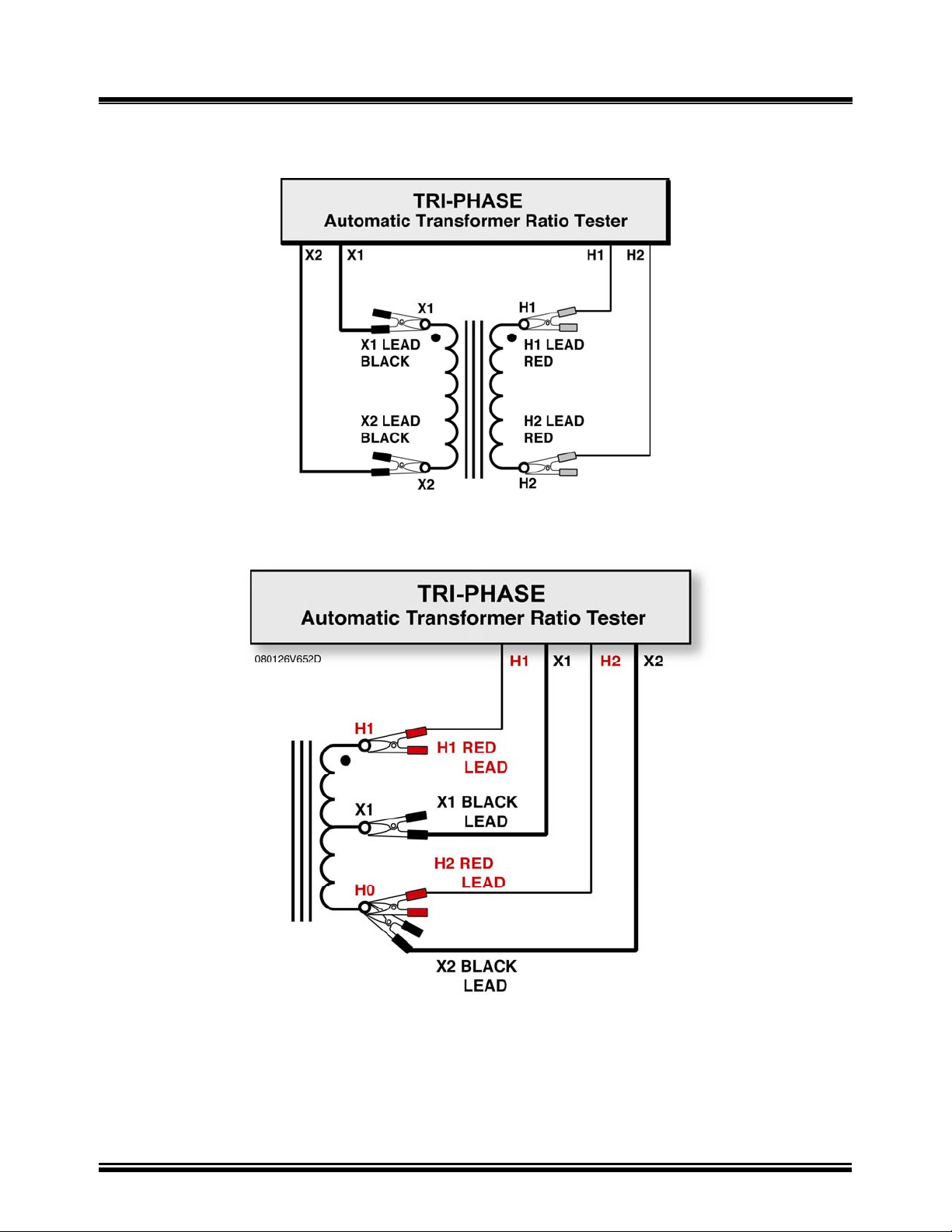

12.1 Typical Cable Connections to a Delta-Wye Transformer

Typical cable connections to a Delta to Wye transformer are shown in

Figure 2.0 and Figure 4.0.

Figure 2.0 Typical H & X Cable Connections to a Delta-Wye Transformer

20

Page 21

TRI-PHASE OPERATING™ INSTRUCTIONS

12.2 Typical Cable Connections to a Delta-Wye Transformer (continued)

X Cable

LTC Control Cable

Gnd Cable

H Cable

Power Cable

Figure 3.0 Typical Front Panel Cable Connectors

H Cable Connections

X Cable Connections

Figure 4.0 Typical H & X Cable Connections to Delta-Wye Transformer

21

Page 22

TRI-PHASE OPERATING™ INSTRUCTIONS

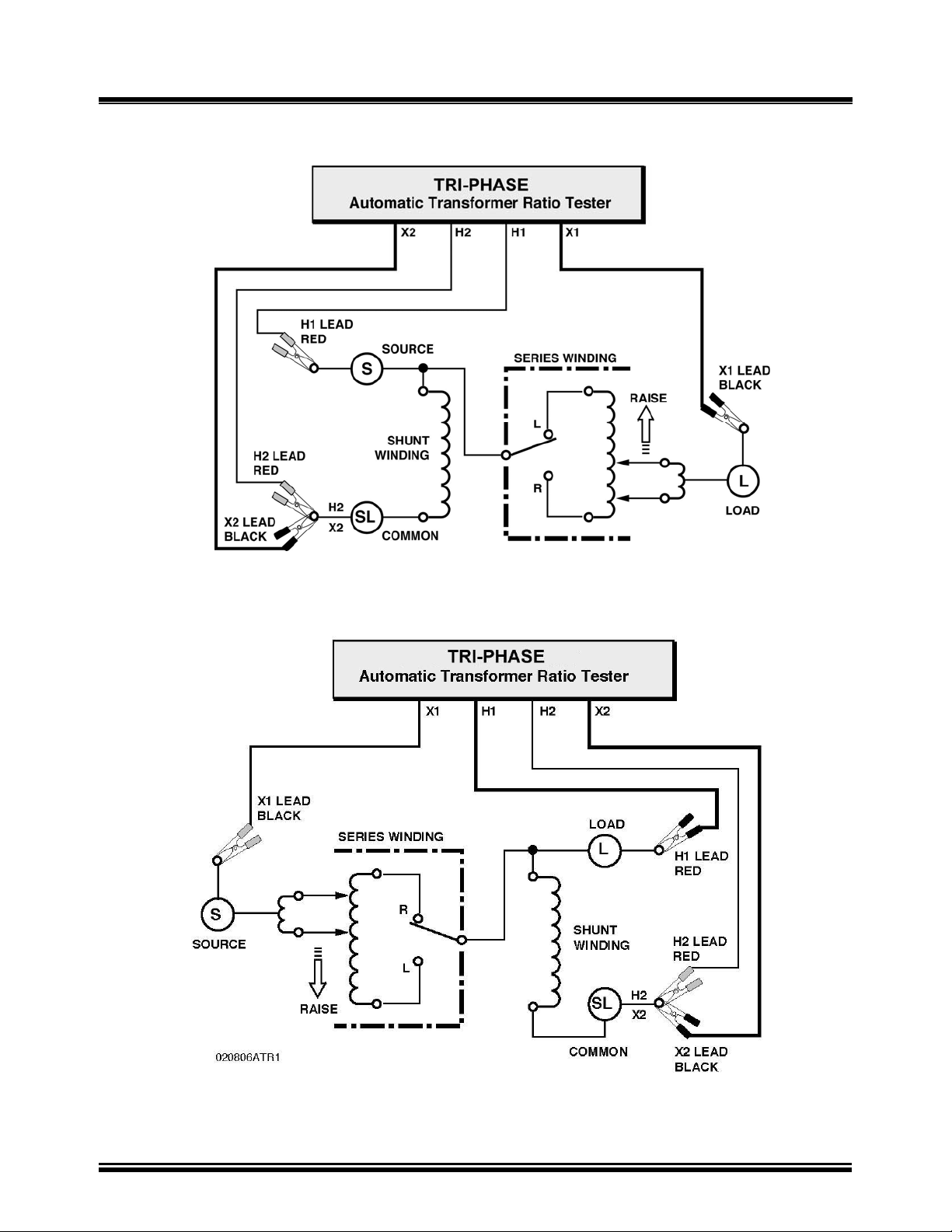

12.3 Single Phase Transformer Typical Connections

Figure 5.0 Single Phase Transformer Typical Connections

Figure 6.0 Single Phase Auto Transformer Typical Connections

22

Page 23

TRI-PHASE OPERATING™ INSTRUCTIONS

12.4 Voltage Regulator Typical Connections

Figure 7.0 Type A Voltage Regulator Typical Connections

Figure 8.0 Type B Voltage Regulator Typical Connections

23

Page 24

TRI-PHASE OPERATING™ INSTRUCTIONS

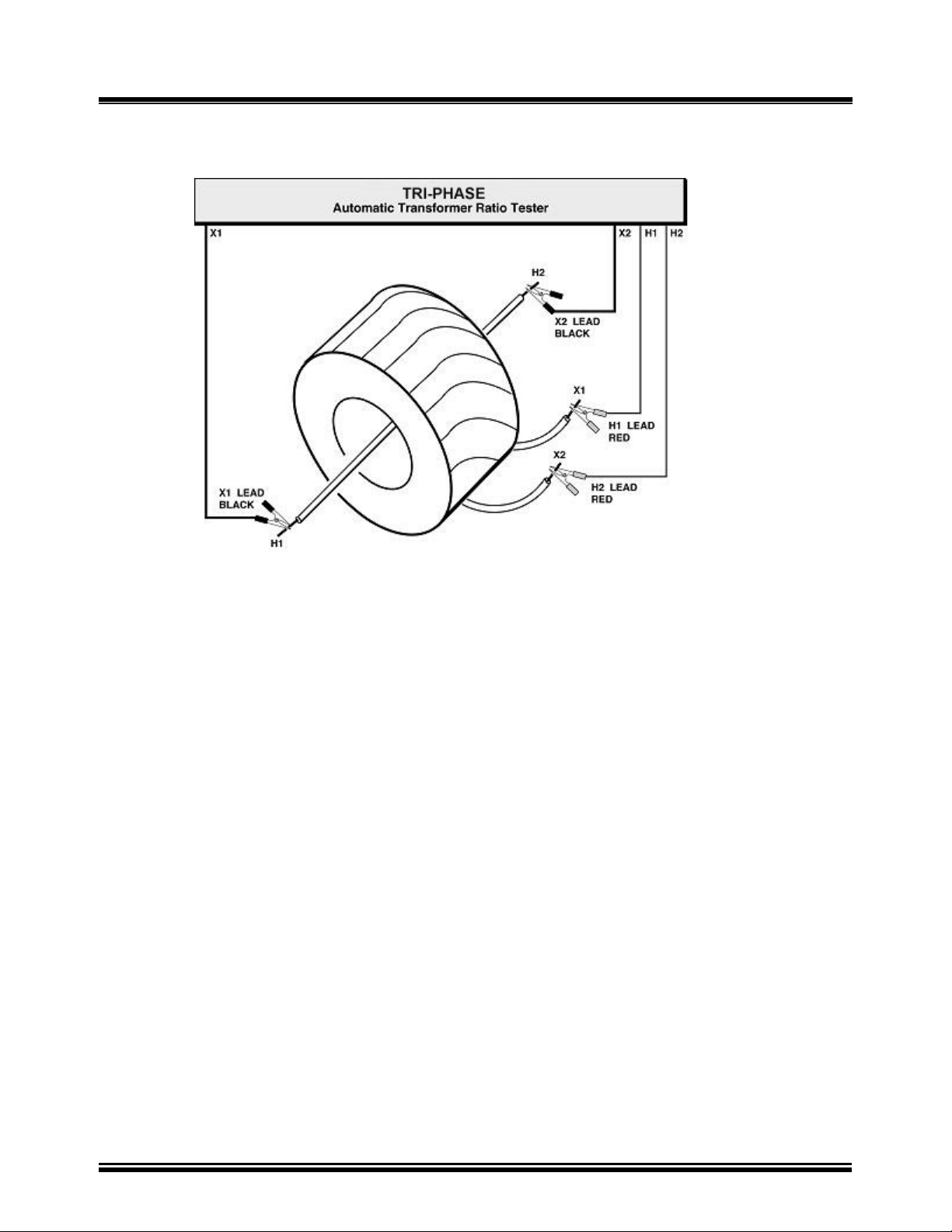

12.5 Donut Type (un-mounted) Current Transformer (CT) Typical Connections

Figure 9.0 Donut Type (un-mounted) Current Transformer (CT)

Typical Connections

NOTE:

H and X test leads are reversed for the CT ratio test shown above.

24

Page 25

12.6 Multi-tap CT Typical Connections

TRI-PHASE OPERATING™ INSTRUCTIONS

Figure 10.0 Multi-tap CT Typical Connections

12.7 Bushing-Mount-CT on A Typical Single Phase Transformer Connections

Figure 11.0 Bushing-Mount-CT on A Typical Single Phase Transformer Connections

25

Page 26

TRI-PHASE OPERATING™ INSTRUCTIONS

12.8 Bushing Mount CT’s on Typical Delta Transformer Connections

NOTE:

Install jumper on the unused winding

Figure 12.0 Bushing Mount CT’s on Typical Delta Transformer Connections

NOTE:

The CT turns-ratio is obtained by performing a YNd test.

Install jumpers on transformer secondary windings

26

.

Page 27

TRI-PHASE OPERATING™ INSTRUCTIONS

12.9 Bushing Mount CT’s on Typical Wye Transformer Connection

Figure 13.0 Bushing Mount CT’s on Typical Wye Transformer Connection

NOTE:

The CT turns-ratio is obtained by performing an YNyn test.

Install jumpers on transformer primary windings.

27

Page 28

TRI-PHASE OPERATING™ INSTRUCTIONS

13.0 Single-Phase Transformer Test Procedure

Table 7.0 shows the procedure to test a single-phase transformer (2,400 V/240 V). Detailed

descriptions of each menu are provided in the following sub-sections. Refer to Figure 1.0 for

location of controls. The precondition for the following test procedure is that no previous singlephase transformer test has been performed (i.e., no stored test results in non-volatile memory), and

there were no previous test records restored to non-volatile memory.

NOTE:

Pressing the “STOP” button aborts all tests and/or submenus

and returns the LCD screen display to the “Main Menu”.

Table 5.0 Single-Phase Transformer Test Procedure

STEP DESCRIPTION DISPLAY ACTION

1 Select “Run Test” from the

“Main Menu”

2 Select “Single Phase” from

“Transformer Configuration

Menu”

3 “Transformer Name Plate

Voltage Status Display”

Select “YES”

4 “Name Plate Voltage Status

Display”

Enter H line voltage from

transformer nameplate

5 “Name Plate Voltage Status

Display”

Confirm H voltage

6 “Name Plate Voltage Status

Display”

Enter X line voltage from

transformer nameplate

7 “Name Plate Voltage Status

Display”

Confirm X voltage

1.RUN TEST

2.SETUP

3.TEST PLAN

4.DIAGNOSTIC

TIME: 20:15:00

DATE: 07/16/08

XFMR CONFIG:

1.SINGLE PHASE

2.Dy

3.Yd

4.Dd

5.Yy

6.Next Page

XFMR NAME PLATE VLTG

1.YES

2.NO

NAME PLATE VOLTAGE:

H : X

0 :

NAME PLATE VOLTAGE:

H : X

2,400 :

NAME PLATE VOLTAGE:

H : X

2,400: 0

NAME PLATE VOLTAGE:

H : X

2,400 : 240

Press key number 1

or push down Control

Knob

Press key number 1

or push down Control

Knob

Press key number 1

or push down Control

Knob

Use keys 0-9 for data

entry of transformer

name plate voltage

Press “ENTER”

or push down Control

Knob

(2400 was keyed for

this test)

Use key numbers 0-9

for data entry

Press “ENTER”

or push down Control

Knob

(240 was keyed for

this test)

28

Page 29

TRI-PHASE OPERATING™ INSTRUCTIONS

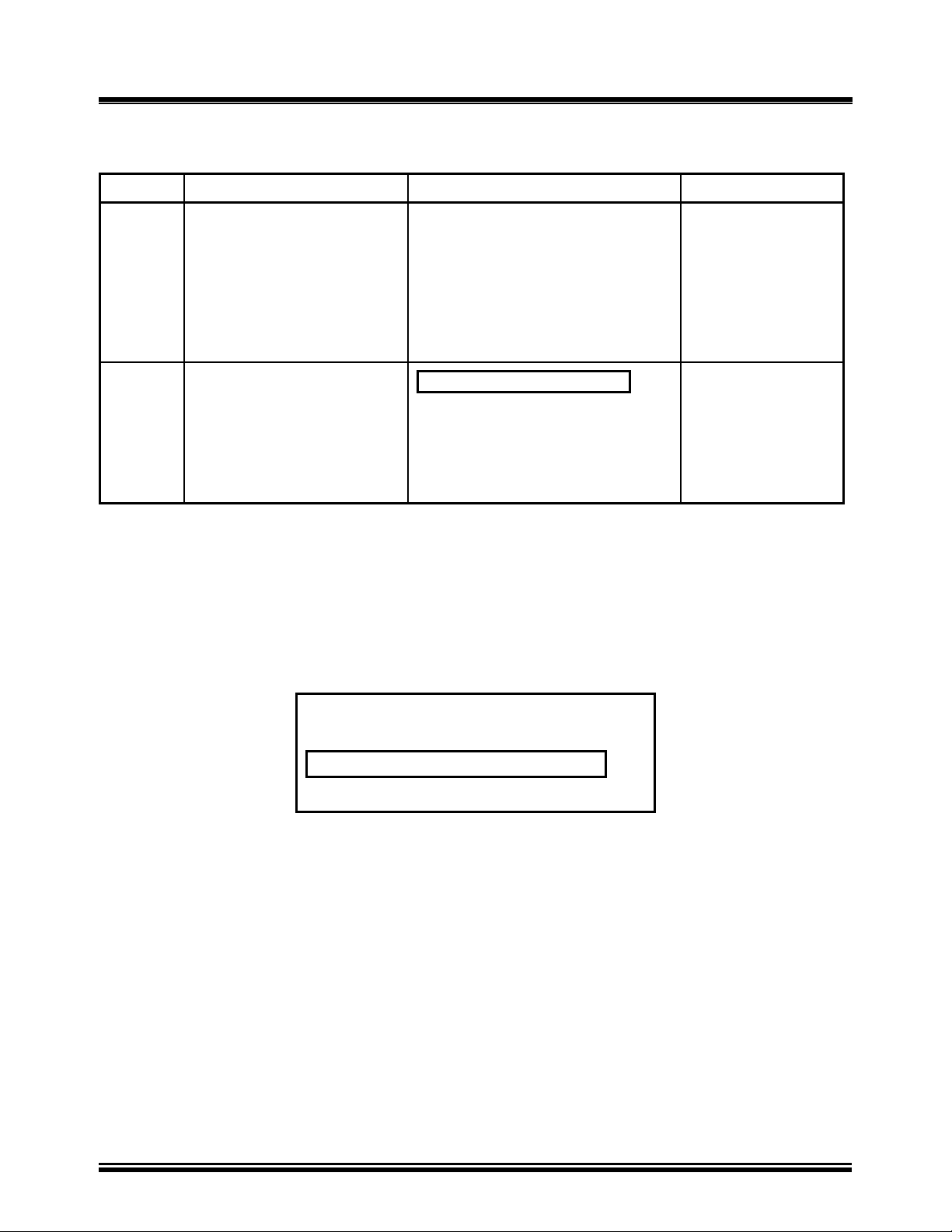

13.0 Single-Phase Transformer Test Procedure (continued)

Table 5.0 Single-Phase Transformer Test Procedure (continued)

STEP DESCRIPTION DISPLAY ACTION

8 “Start/Stop Test Status Display”

9 “Test in Progress” status display

10 “Test Results Status Display”

Observe ratio, excitation current,

and percentage error on LCD

display

11 “Test Results Status Display”

Go to next LCD display

12 Select “YES” from the “Print

Test Results Menu” to print test

result on built-in

printer

13 Select “Column” from the “Print

Format Menu”

14 Select “YES” from the “Keep

This Reading Menu” to store

current test reading (i.e., test

results) in non-volatile memory

NOTE:

Refer to note at end of table

“START” TO TEST

OR

“STOP” TO ABORT

TEST IN PROGRESS

PLEASE WAIT…

RATIO mA %DIFF

+10.005 1.9 0.05

RATIO mA %DIFF

+10.005 1.9 0.05

PRINT TEST RESULTS?

1.YES

2.NO

PRINT FORMAT

1.COLUMN

2.DETAILED

KEEP THIS READING?

1.YES

2.NO

Press START key

None

None

Press any key or push

down Control Knob

Press key number 1

or push down Control

Knob

Press key number 1 or

push down Control

Knob for a column

report.

Press key number 1 or

push down Control

Knob to store reading

15 “Test Saved Status Display”

Current test reading is saved

16 Select “NO” from the “Run

Another Test Menu”

17 Selecting “YES” from the “Save

This Record Menu”

Store test results in FLASH

EEPROM

TEST SAVED

RUN ANOTHER TEST?

1.YES

2.NO

3. REPEAT PREV. TEST

SAVE THIS RECORD?

1.YES

2.NO

29

Press any key or push

down Control Knob

Press key number 2

Selection of 2 may be

made by turning the

Control Knob. Push

down Control Knob

after 2 is selected

Press key number 1

or push down Control

Knob

Page 30

TRI-PHASE OPERATING™ INSTRUCTIONS

13.0 Single-Phase Transformer Test Procedure (continued)

Table 5.0 Single-Phase Transformer Test Procedure (continued)

STEP DESCRIPTION DISPLAY ACTION

18 “Record Saved” confirmation

status display

Test results saved in FLASH

EEPROM as a test record

NOTE:

The next sequential record

number (#) is automatically

generated and displayed

19 Return to “Main Menu”

RECORD NUMBER #

HAS BEEN SAVED

1.RUN TEST

2.SETUP

3.TEST PLAN

4.DIAGNOSTIC

TIME: 20:15:00

DATE: 07/16/08

Press any Key or push

down Control Knob

None

NOTE:

The precondition for the above test procedure was that no previous single-phase transformer test

record was residing in temporary memory. Once a single phase test record has been saved to

FLASH EEPROM, or a single phase test record restored from FLASH EEPROM and another single

phase transformer test is performed, selecting “YES” in response to “Keep This Reading” at step

17 results by displaying the following menu.

PREVIOUS DATA IN BUF.

1.APPEND PREV. DATA

2.CLEAR PREV. DATA

Selecting menu option 1 (“Append Prev. Data”) will result in appending the current test results to

all of the previous test results from the test record stored in temporary memory, assigning this new

record to the next test record number in sequence. Selecting menu option 2, “Clear Prev. Data” will

result in clearing the temporary memory of all previous test results from the test record except the

current test results and assigning this test result to the next sequential test record number. The

temporary memory will be lost when the TRI-PHASE™ is powered-off, but the test records remain

in the TRI-PHASE™ FLASH EEPROM non-volatile internal memory.

30

Page 31

TRI-PHASE OPERATING™ INSTRUCTIONS

13.1 Main Menu

1.RUN TEST

2.SETUP

3.TEST PLAN

4.DIAGNOSTIC

TIME: 20:15:05

DATE: 07/16/08

Figure 14.0 Main Menu

a. Description: The “Main Menu” (i.e., “start-up”) provides selection of the primary

functions of the TRI-PHASE™. These functions consist of one or more sub-menus that

allow the operator to test a transformer, select various settings or options, select test plan

options, or perform diagnostics on the TRI-PHASE™.

b. Origin: The “Main Menu” displays on the LCD after power is applied to the TRI-

PHASE™.

c. Action Options:

Press key number 1 to select “Run Test”

Press key number 2 to select “Setup”

Press key number 3 to select “Test Plan Menu”

Press key number 4 to select “Diagnostic”

Selection may also be made by turning the Control Knob to select a menu option and then

pushing down on the Control Knob once the selection is made.

d. Action To Perform: Select menu option 1 for this example.

NOTES:

Real time and date is displayed at the bottom of LCD screen.

Refer to section

To return to the “Main Menu” at any time press “STOP” on the keypad.

11.1 for LCD contrast control operation.

31

Page 32

TRI-PHASE OPERATING™ INSTRUCTIONS

13.2 Transformer Configuration Selection Menu

XFMR CONFIG:

1.SINGLE PHASE

2.Dy

3.Yd

4.Dd

5.Yy

6.Next Page

Figure 15.0 Transformer Configuration Selection First Menu

XFMR CONFIG:

1.Dz

2.Zd

3.Yz

4.Zy

5.TT

6.Previous Page

Figure 16.0 Transformer Configuration Selection Second Menu

a. Description: Either “Transformer Configuration Selection Menu” above will allow the

operator to select the transformer type to be tested. There are two menus for this selection.

The first menu is shown in Figure 15.0 which is displayed first. When the operator selects

“Next Page” from the first menu, the second menu is displayed as shown in Figure 16.0.

b. Origin: The “Transformer Configuration Selection” first menu displays after selecting

“Run Test” from the “Main Menu” (Figure 14.0).

c. Action Options: Select the type of transformer configuration to be tested by pressing key

numbers that correspond to the numbered menu items on the keypad, or by turning the

Control Knob to the desired menu item, then pushing down on the Control Knob once

selected.

d. Action To Perform: With the first menu displayed, select the menu option 1 for this

example.

NOTE:

The TRI-PHASE™ will support 130 transformer types defined by ASNCI/CEI/ICE standards.

All transformer configurations supported by the TRI-PHASE™ are listed in Appendix B.

32

Page 33

TRI-PHASE OPERATING™ INSTRUCTIONS

13.3 Transformer Name Plate Voltage Menu

XFMR NAME PLATE VLTG

1.YES

2.NO

Figure 17.0 Transformer Nameplate Voltage Menu

a. Description: This menu provides access to the “Name Plate Voltage” status display

(Figure 18.0) for entry of the transformer nameplate voltages which are used to derive a

calculated turns-ratio. The calculated turns-ratio is then used to compare the measured

turns-ratio and calculate a percentage error reading.

b. Origin: The transformer nameplate voltage menu displays after selecting “Single Phase”

from options listed in the “Transformer Configuration Selection Menu” (Figure 15.0). For

other transformer configurations, this menu displays prior to the “Start/Stop Test” status

display.

c. Action Options: Press key number 1 (“YES”) push down the Control Knob to use the

calculated turns-ratio in the test results and advance to the “Name Plate Voltage” status

display (Figure 18.0). Press key number 2 to bypass this option and advance to the

“Start/Stop Test” status display (Figure 22.0). Selection may also be made by turning the

Control Knob to select a menu option, then pushing down on the Control Knob once the

selection is made.

d. Action To Perform: Select menu option 1 for this example.

33

Page 34

TRI-PHASE OPERATING™ INSTRUCTIONS

13.4 Transformer Voltage Data Entry Status Displays

NAME PLATE VOLTAGE:

H : X

0 :

Figure 18.0 Name Plate Voltage Status Display

NAME PLATE VOLTAGE:

H : X

2,400 :

Figure 19.0 Name Plate Voltage Display, H Voltage Keyed In

NAME PLATE VOLTAGE:

H : X

2,400 : 0

Figure 20.0 Name Plate Voltage Display, H Voltage Entered

NAME PLATE VOLTAGE:

H : X

2,400 : 240

Figure 21.0 Name Plate Voltage Display, X Voltage Keyed In

a. Description: Allows for entry of the H and X voltages for the transformer to be tested,

which are used to calculate the turns-ratio. The operator enters the transformer nameplate

voltages.

b. Origin: The name plate voltage status will display on LCD after the operator has selected

menu option 1 on the “Transformer Name Plate Voltage Menu” (Figure 17.0).

c. Action Options: Press key numbers 0 thru 9 to enter transformer voltages. Press the

“ENTER” key to confirm voltage entry. The Control Knob may be pushed down after the

numeric keys are pressed for each entry of H and X voltages. Press the “CLEAR” key to reenter data.

d. Action To Perform: Enter name plate voltages of 2400 for H, and enter 240 for X for this

test example.

34

Page 35

TRI-PHASE OPERATING™ INSTRUCTIONS

13.5 Start/Stop Test Status Display

“START” TO TEST

OR

“STOP” TO ABORT

Figure 22.0 Start/Stop Test Status Display

a. Description: Allows the operator to star t to test or abort a test.

b. Origin: The LCD displays “Start/Stop Test Status Display” after the operator enters the

nameplate voltage for X (Figure 21.0) or selects 2 on the “Transformer Name Plate Voltage

Menu” (Figure 17.0).

c. Action Options: Press the “START” key to start a test and advance to the “Test In

Progress Status Display” (Figure 23.0). Press the “STOP” key to abort a test and return to

the “Main Menu”.

d. Action To Perform: Press the “START” key to start the test for this example.

35

Page 36

TRI-PHASE OPERATING™ INSTRUCTIONS

13.6 Test In Progress Status Display

TEST IN PROGRESS

PLEASE WAIT…

Figure 23.0 Test In Progress Status Display

a. Description: The “Test In Progress Status Display” (Figure 23.0) is displayed when the

turns-ratio test is performed.

b. Origin: The LCD displays the “Test In Progress Status Display” after the operator presses

the “START” key (Figure 22.0).

c. Action Options: None.

d. Action To Perform: Observe status.

36

Page 37

TRI-PHASE OPERATING™ INSTRUCTIONS

13.7 Test Results Status Display

RATIO mA %DIFF

+10.005 1.9 0.05

Figure 24.0 Test Results Status Display

a. Description: Displays the transformer winding polarity, turns-ratio, excitation current (in

milliamps), and turns-ratio percentage error after completion of the transformer test. A

typical turns-ratio test result screen is shown in Figure 24.0. The display result is explained

below:

Ratio displayed: 10.005

Polarity displayed: “+” (in phase)

Excitation current: 1.9mA

Percentage error: 0.05%

b. Origin: The LCD displays “Test Results Status Display” (Figure 24.0) after the “Test In

Progress Status Display” (Figure 23.0).

c. Action Options: Press any key or push down the Control Knob to go to the “Print Test

Results Menu” (Figure 25.0).

d. Action To Perform: Observe the test result status, then press any key or push down the

Control Knob.

NOTE:

“% DIFF” is calculated as the Absolute Value of [(Cal ratio –Measured ratio)/Cal ratio] x 100.

“% DIFF” will only be displayed if nameplate voltages were entered.

37

Page 38

TRI-PHASE OPERATING™ INSTRUCTIONS

13.8 Print Test Results Menu

PRINT TEST RESULTS?

1.YES

2.NO

Figure 25.0 Print Test Results Menu

a. Description: The TRI-PHASE™ has the capability to p rint the current test results

(displayed on the LCD screen) using the built-in thermal printer.

b. Origin: The “Print Test Results Menu” is displayed after operator presses any key or

pushes down on the Control Knob from the “Test Result Status Display” (Figure 24.0).

c. Action Options: Press key number 1 (“YES”) or push down the Control Knob to advance

to the “Print Format Menu” (Figure 26.0). Press key number 2 to advance to “Keep This

Reading Menu” (Figure 29.0). Number 2 may be selected by turning the Control Knob,

then pushing down on the Control Knob after 2 is selected.

d. Action To Perform: Select menu option 1 for this example.

13.9 Print Format Menu

PRINT FORMAT?

1.COLUMN

2.DETAILED

Figure 26.0 Print Format Menu

a. Description: Allows the operator to select which format to use for printing the test results.

Refer to Figure 27.0 for a typical column format printout. Refer to Figure 28.0 for a

detailed format printout.

b. Origin: This menu is displayed after the operator selects 1 (“YES”) from the “Print Test

Results Menu” (

c. Action Options: Press key number 1 or push down on the Control Knob to select the

column format print out of the test results. Press key number 2 to select the detail format

printout of the test results. Number 2 may be selected by turning the Control Knob, then

Figure 25.0).

38

Page 39

TRI-PHASE OPERATING™ INSTRUCTIONS

pushing down on the Control Knob after number 2 is selected.

d. Action To Perform: Select menu option 1 for this example.

e. Results of Action: Once the desired print format is selected the test results are printed and

the LCD displays the “Keep This Reading Menu” (Figure 29.0).

39

Page 40

13.10 Test Result Column Format Printout

TRI-PHASE OPERATING™ INSTRUCTIONS

1

2

3

4

5

6

7

8

12 11 10 9

Figure 27.0 Single Phase Column Format Printout

A typical single-phase transformer test results printout in column format is shown in Figure 27.0.

The test results printout is explained below.

1. Test record time and date is printed at the top of the printout

2. Test voltage is 40 volts at 60 Hz for this test. Refer to section

11.2 for more details about

test voltages and frequencies

3. Type of transformer under test is single phase

4. Transformer configuration diagram

5. H tap voltage is 2,400 volts

6. X tap voltage is 240 volts

7. Calculated turns-ratio is 10.000

8. Percentage error between calculated ratio and measured ratio is 0.05%

9. Measured winding phase angle is 0.02 degrees

10. Excitation current is 1.9mA

11. Measured ratio is 10.005

12. Winding polarity is shown as “+” or “in phase

40

Page 41

13.11 Test Result Detail Format Printout

TRI-PHASE OPERATING™ INSTRUCTIONS

1

2

3

4

5

6

7

8

9

10

11

Figure 28.0 Single Phase Detail Format Printout

41

Page 42

TRI-PHASE OPERATING™ INSTRUCTIONS

13.11 Test Result Detail Format Printout (continued)

The same report is now shown in detailed format printout (Figure 28.0).

The test results detail printout is explained below.

1. Test record time and date is printed at the top of the printout

2. Test voltage is 40 volts at 60 Hz for this test. Refer to paragraph 11.2 for more details

about test voltages and frequencies

3. Type of transformer under test is Single Phase

4. Transformer configuration diagram

5. H tap voltage is 2,400 volts

6. X tap voltage is 240 volts

7. Calculated turns-ratio is 10.000

8. Measured ratio is 10.005

9. Percentage error between calculated ratio and measured ratio is 0.05%

10. Measured winding phase angle is 0.02 degrees

11. Excitation current is 1.9mA

NOTE:

A phase angle printout of 999.9 indicates an unstable phase angle reading.

42

Page 43

TRI-PHASE OPERATING™ INSTRUCTIONS

13.12 Keep This Reading Menu

KEEP THIS READING?

1.YES

2.NO

Figure 29.0 Keep This Reading Menu

a. Description: The operator has the option to store the current test result in non-volatile

memory or disregard the current test results.

b. Origin: After the operator selects 1 (“YES”) or the operator selects 2 (“NO”) from the

“Print Test Results Menu” (Figure 25.0).

c. Action Options: Press key number 1 (“YES”) or push down the Control Knob to store

current transformer test results into non-volatile memory. Press key number 2 (“NO”) to

disregard the current test results. Number 2 may be selected by turning the Control Knob,

then pushing down on Control Knob after 2 is selected.

d. Action To Perform: Select menu option 1 for this example.

e. Results of Action: After selecting menu option 1, the status “TEST SAVED” is displayed

on the LCD. Press any key or push down Control Knob to go to the “Run Another Test

Menu” (Figure 31.0).

43

Page 44

TRI-PHASE OPERATING™ INSTRUCTIONS

13.13 Previous Data In Buf. Menu

PREVIOUS DATA IN BUF.

1. APPEND PREV. DATA

2. CLEAR PREV. DATA

Figure 30.0 Previous Data In Buf Menu

a. Description: This menu is displayed when there is an existing test result in memory of the

same type of transformer which is under test.

The “Append Previous Data” feature allows the operator to stop the testing in order to

perform other duties. The operator will be able to continue testing the transformer at a later

time without having to repeat any of the previous tests. It is important to remember that this

may only be accomplished when all tests are performed on the same transformer. Figure

30.0 will display when another test is performed on an identical transformer configuration

and there is a test record residing in temporary memory (i.e., buf) from an identical

transformer configuration. The previous test record may be a restored test record or the

current test record for an identical transformer configuration.

For example, a previous single phase transformer configuration test record with one or

more test results from a single phase transformer configuration is stored in TRI-PHASE™

FLASH memory. These test results are also still residing in temporary memory. The

operator performs another single phase transformer configuration test. The operator selects

“YES” in response to “Keep This Reading” at step 14 of Table 5.0 resulting in saving the

test results to temporary memory and the display of Figure 30.0.