Page 1

OPERATING INSTRUCTIONS

for the

ACCU-TRANS™

TRANSFORMER-WINDING

RESISTANCE METER

Series II

Part Number VIC-8000-S2

Vanguard Instruments Company

1710 Grevillea Court

Ontario, California 91761

TEL: (909) 923-9390 July 2001

FAX: (909) 923-9391 Rev 0

Page 2

Page 3

Accu-Trans Operating Procedures

SAFETY SUMMARY

The following safety precautions must be

observed during all phases of test set-up, test

hookups, testing, and test-lead disconnects.

Do Not Service or Test Alone

Do not perform test procedures or service

unless another person is also present who is

capable of rendering aid and resuscitation.

Avoid Contact with High Voltage

Because electric utility station environments

contain high voltages and currents, there’s

always the possibility of personal contact with

an unexpected lethal voltages generated by

magnetically induced and/or electrostatic

leakage from nearby live circuitry. When test

units are connected to de-energized ("dead")

lines, regardless of how short these lines may

be, always discharge the lines before

attaching test lead. Because of the possibly

deadly consequences of physical contact with

such lines, engineers and technicians must

always treat electrical equipment and hookups

as though a lethal condition will eventually

occur. Therefore, no matter how unlikely it

may be, never assume anything about the

safety of any test setup.

Ensure the safety of personal by checking

first-hand to eliminate every possible hazard!

Avoid Contact With High-Voltage “Kicks”

Any transformer with many windings turns

and an iron core supports induced magnetic

fields, such that even low-level test currents

produce a magnetic field that, if interrupted,

can produce a high-voltage spike capable of

causing severe injury or death. Accordingly,

its important for personnel safety that test

leads be securely attached to the transformer

terminals to prevent their being accidentally

disconnected during testing. All personnel

are warned to stand clear of the transformer

during all testing. Test technicians should

always ensure that all non-technical personnel

(who may not understand the hazards) be

required to stand clear of all transformers and

equipment during all phases of transformer

testing.

Do Not Modify Test Equipment

Because of the added risk of introducing

additional or unknown hazards, do not install

substitute parts or perform any unauthorized

modification to the Accu-Trans. To ensure all

designed safety features are maintained, it is

recommended that all Accu-Trans repairs be

performed at Vanguard Instruments Co. or by

an authorized repair-service. Unauthorized

equipment modifications can create safety

hazards and will void the Accu-Trans

warranty.

Follow Exact Operating Procedures

Any deviation from the operating

procedures described in this manual may

create one or more safety hazards, damage

the unit or cause test result errors; Vanguard

Instruments Co. assumes no liability for

unsafe or improper use of the Accu-Trans.

i

Page 4

Page 5

Accu-Trans Operating Procedures

1

Table of Contents

SAFETY SUMMARY................................................................................................................. I

1.0 INTRODUCTION...................................................................................................................3

1.1 APPLICABILITY................................................................................................................3

1.2 SUPERSEDURE NOTICE..................................................................................................3

1.3 GENERAL DESCRIPTION................................................................................................3

1.4 FUNCTIONAL DES CRIPTION.........................................................................................3

1.5 FURNISHED ACCESSORIES ...........................................................................................3

2.0 ACCU-TRANS SPECIFICATIONS.......................................................................................4

3.0 CONTROLS and INDICATORS ............................................................................................5

4.0 PRETEST SETUP ...................................................................................................................7

4.1 OPERATING VOLTAGES.................................................................................................7

4.2 ACCU-TRANS LCD CONTRAST CONTROL.................................................................8

4.3 ACCU-TRANS PRINTER PAPER CONTROL.................................................................8

5.0 ACCU-TRANS PRINTER PAPER.........................................................................................8

6.0 OPERATING PROCEDURES................................................................................................8

6.1 GENERAL PROCEDURES................................................................................................8

6.2 STEP-BY-STEP PROCEDURES AT START-UP MENU..............................................10

6.2.1 START-UP MENU:.......................................................................................................10

6.2.2 TEST TRANSFORM ER PROCEDURE.......................................................................10

6.3 SETUP MENU:..................................................................................................................11

6.3.1 TRANSFORMER ID ENTRIES:..................................................................................12

6.3.2 REVIEW TEST RECORDS PROCEDURE .................................................................13

6.3.3 RESTORE RECORDING PROCEDURES ..................................................................14

6.3.4 PRINTING TEST-RECORD DIRECTORY.................................................................15

6.3.5. ERASE RECORDING PROCEDURE..........................................................................17

6.3.6 ENABLING COMPUTER INTERFACE.....................................................................18

6.3.7 SETTING DATE AND TIME.......................................................................................18

6.3.8 ENABLE PASSIVE TEST MODE ...............................................................................19

6.3.9 VOLTAGE REGULATOR TEST.................................................................................19

Page 6

Accu-Trans Operating Procedures

2

Table of Figure

Figure 1.0 Accu-Trans Controls and Indicators............................................................................5

Figure 2.0 90 to 130Vac Jumper Setting.......................................................................................7

Figure 3.0 210 to 240Vac Jumper Setting.....................................................................................7

Figure 4.0 Summary of Step-by-Step Accu-Trans Operat ion.......................................................9

Figure 5.0 Typical Test Report Printout......................................................................................12

Figure 6.0 Typical Record Directory Printout .............................................................................17

Page 7

Accu-Trans Operating Procedures

3

1.0 INTRODUCTION

1.1 Applicability

This manual applies to a second-generation

Accu-Trans™ (Series II, henceforth, called

the Accu-Trans), part number VIC-80000S2 manufactured by the Vanguard

Instruments Co. A prior manual supports a

first generation Accu-Trans (i.e., a Series I

configuration).

1.2 Supersedure Notice

This Operator’s manual is the basic issue for

the Accu-Trans and does not supersede any

previously published manual.

1.3 General Description

Vanguard Instruments Company produces

the Accu-Trans, a microprocessor-controlled

winding resistance meter that measures low

resistances of a transformer’s inductive

windings, in a range from 1 micro-ohm to

200 ohms with very high accuracy. This

instrument can also measure any low

milliohm resistance (e.g., the contact

resistance of a circuit breaker).

This Accu-Trans is simple-to-use; it features

keypad controls and an alpha/numeric

display of the measured resistance, test

current, and operator-entered test parameters

and identifying data.

The Accu-Trans uses a 48-volt dc power

supply and a special current-regulator to

quickly measure transformer-winding

resistances. A typical single- phase 400MVA

transformer winding resistance can be

measured in less than 3 minutes. To ensure

operator safety, the Accu-Trans

automatically discharges the energy stored

in the transformer at the end of each test.

A built-in thermal printer prints test results

on 2.5-inch-wide thermal paper. Resistance

and test current display on a 4-line by 20character, back lighted LCD. Up to 63

records (96 readings each) can be stored in

the Accu-Trans FLASH EEPROM. The

user can recall stored reports for printing. A

RS-232C serial interface port is provided for

diagnostic testing and down loading test

records.

The Accu-Trans is field-portable, rugged; it

features simple, easy operation by first-time

users with little training.

1.4 Functional Description

The Accu-Trans’s operation is based on the

electrical relationships described by Ohm’s

law: R=V/I, where I is a known current and

V is the dc voltage measured across the

unknown resistance (typically, a circuitbreaker’s contacts). The value of the

unknown resistance under test is the direct

function of the measured voltage divided by

the current and being calculated by the

microprocessor. Resistance reading is then

displayed on a back-lighted 4 line by 20

character LCD.

The Accu-Trans’ 48V dc power supply

applies up to 2 amperes test current to the

device under test. Accu-Trans voltmeter test

leads are run separately from the currentbearing test leads to the resistive load; thus,

voltages are measured at the terminals of the

resistance being measured, eliminating error

from the I•R voltage drop in the test current

cables. The Accu-Trans makes precise

micro-ohm measurements possible without

calculating compensation for test-currentlead resistance errors.

A built-in discharge circuit automatically

discharges the energy stored in the

transformer at the end of each test.

1.5 Furnished Accessories

The Accu-Trans is shipped with two 45-foot

test cables with “quick disconnect” type test

plugs on the unit end and battery-type

clamps at the test load end. One power cord,

one ground cable, and a cable-carrying bag.

Page 8

Accu-Trans Operating Procedures

4

2.0 ACCU-TRANS SPECIFICATIONS

Table 1. ACCU-TRANS SPECIFICATIONS

TYPE Special-purpose test equipment, portable, micro-ohmmeter

SIZE (inches) 16.8 wide by 12.6 high by 10.6 deep

WEIGHT Less than 21 pounds

RESISTANCE 1 micro-ohm to 200 ohms

TEST CURRENT 2 amperes max

DISPLAY LCD, back-lighted, 4-line by 20-character

PRINTER 2.5-inch wide thermal printer

ACCURACY ± 1 % reading, ± 1 count

POWER 2 amps, 90-120 / 200-240 V ac (selectable), 50/60 Hz

SERIAL INTERFACE RS-232C connector port

ENVIRONMENT Operating: 0°C to 55°C; Storage: -40°C to 65°C

WARRANTY One-year parts & labor (post warranty service is available)

NOTE:

THE ABOVE SPECIFICATIONS ARE VALID AT NOMINAL OPERATING VOLTAGE AND AT A TEMPERATURE OF 25 °C (77°F)

?ACCU-TRANS SPECIFICATIONS MAY BE UPGRADED AND CHANGED WITHOUT PRIOR NOTICE.

Page 9

Accu-Trans Operating Procedures

5

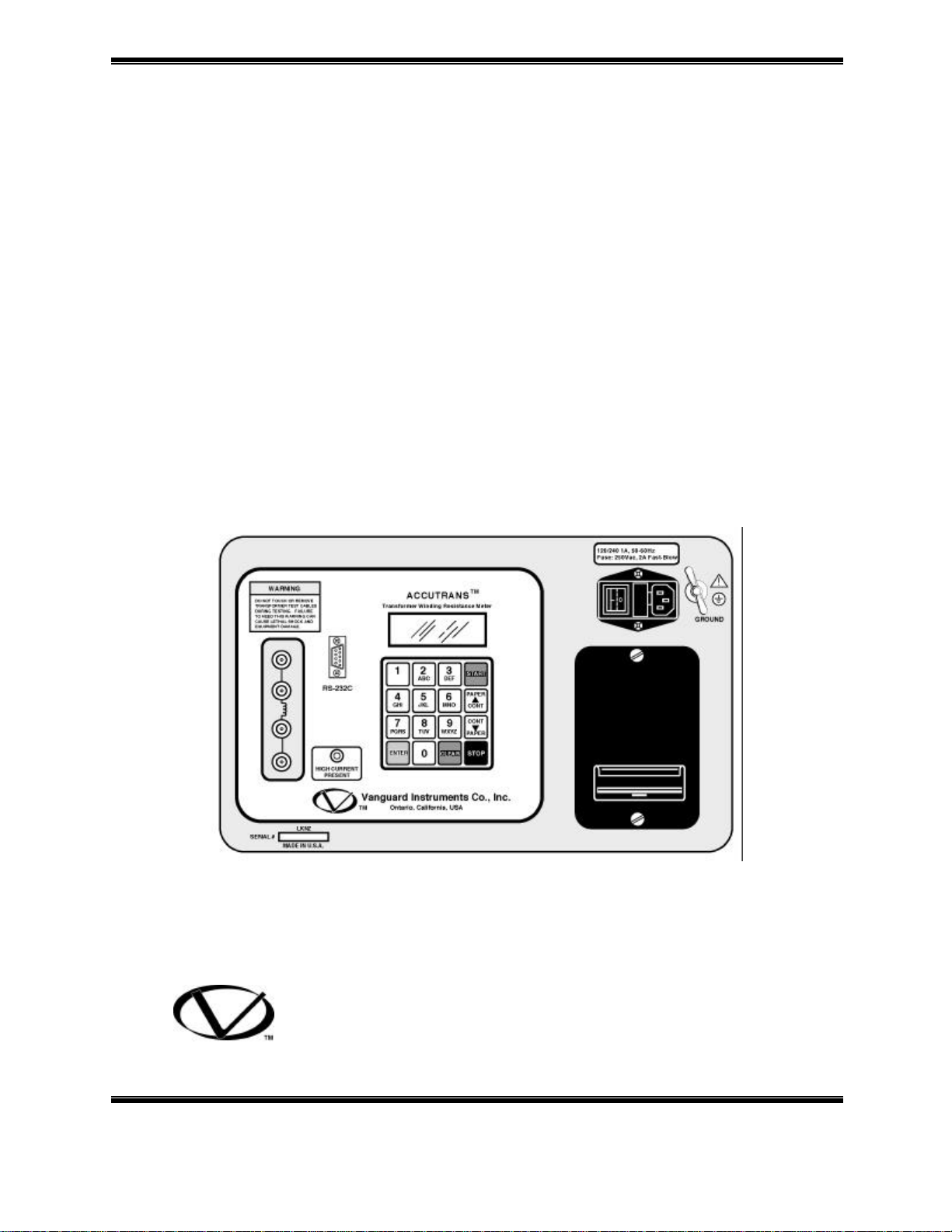

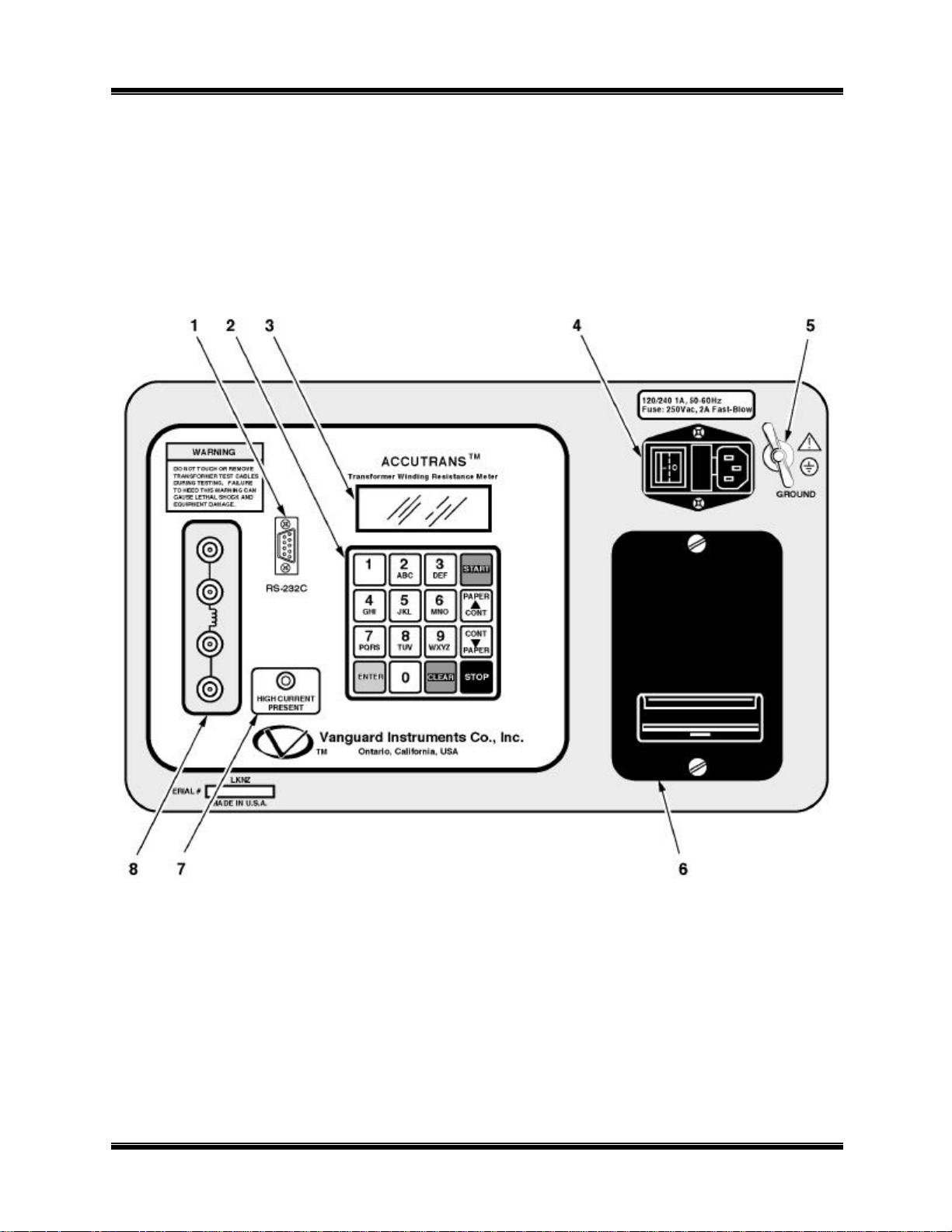

3.0 CONTROLS AND INDICATORS

(See Figure 1 and refer to Table 1.)

Accu-Trans controls and indicators are

shown in Figure 1.0. A leader line with an

index number points to each control and

indicator, which is cross-referenced to a

functional description in Table 2. This table

describes the function of each item on the

control-panel. The purpose of the controls

and indicators may seem obvious, but users

should become familiar with them before

using the Accu-Trans. Accidental misuse of

the controls will usually cause no serious

harm. Users should also be familiar with the

Safety Summary found on the front page of

this operator’s manual.

Figure 1.0 Accu-Trans Controls and Indicators

Page 10

Accu-Trans Operating Procedures

6

Table 1.0 Functional Descriptions of Accu-Trans Controls and Indicators

Fig. 1

Index Panel Markings Functional Descriptions

1

RS-232C

2 (Not titled; 16-key pad) Pushbutton operating controls; 10 key pad, plus

3 (Not titled; LCD) Liquid-Crystal Display, 4-line by 20 character;

4 120/240 2A, 50-60 Hz

Fuse: 250 Vac, 3A Slow Blow

5 GROUND Stud, 5/16-18 thread, with hand-turned wing

6 (Not titled; thermal printer) Built in thermal printer; prints test results in the

7

HIGH CURRENT

PRESENT

8 (Not titled; test lead jacks) Test connector jacks, female; for connecting

Computer interface port; 9-pin connector;

female DB type.The data are set to 19,200

baud, 1 start bit, 2 stop bits, 8 data bits, and no

parity bit.

PIN SIGNAL

2 Rx

3 Tx

5 Signal Gnd

START, STOP, ENTER, CLEAR, two paperdrive buttons; number keys 2 thru 9 have dual

functions as letter entries (a la telephone dialer

key pad).

back lighted and readable in sunlight; Displays

menus, user selections, status readouts, and test

results.

Input power connector with third-wire safety

ground, ON (1)/OFF (0) rocker toggle switch;

has built-in fuse protection.

nut; Safety Ground; This must be connected to

station ground before connecting cables to

transformer and begin testing.

field on 2.5-inch-wide paper. NOTE: For best

high-contrast print quality, it is recommended

that only VIC thermal paper be used.

LED indicator light, red; When lighted, this

indicator warns operators that there is a

possibility that lethal high voltage will exist if

any test lead is disconnected while current is

running through an inductive load. Failure to

heed this warning can result in shock and/or

fatal injury to personnel.

heavy gauge current leads and voltage-sensing

test leads. Plug-in voltage plugs are not polarity

sensitive, but must be plugged into the jacks

adjacent to their companion current jacks.

Page 11

Accu-Trans Operating Procedures

7

4.0 PRETEST SETUP

4.1 Operating Vo ltages

The Accu-Trans operating voltages are

selectable between 90-130Vac, 50/60Hz or

200-240, 50/60Hz. Voltage selection is set

Table 2.0 Voltage Selection

VOLTAGE SELECTION TERMINAL BLOCK JUMPERS

90-130Vac Brown to Blue & Yellow to Green

200-240Vac Blue to Yellow

by the placement of jumpers on the power

terminal block as listed in Table 2.0 below

and Figures 2.0 and 3.0.

120Vac Jumper Installation

Figure 2.0 90 to 130Vac Jumper Setting

Figure 3.0 210 to 240Vac Jumper Setting

220Vac Jumper Installation

Page 12

Accu-Trans Operating Procedures

8

4.2 Accu-Trans LCD Contrast Control

To darken the LCD display, press and hold

the “Paper ∧ Contrast” switch for two

seconds; to lighten the LCD display, press

and hold the “Paper ∨ Contrast” switch for

two seconds.

4.3 Accu-Trans Printer Paper Control

To advance the Accu-Trans printer paper,

press and release the “Paper ∧ Contrast”

switch.

To retract the Accu-Trans printer paper,

press and release the “Paper ∨ Contrast”

switch.

5.0 ACCU-TRANS PRINTER PAPER

The Accu-Trans built-in thermal printer uses

2.5-inch wide thermal paper for printing test

results. To maintain the highest quality testresult printing and to avoid paper jamming,

the use of paper supplied by our factory is

highly recommended. Additional paper can

be ordered from either of the two sources

listed below:

Vanguard Instruments Co, Inc.

1710 Grevillea Court

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: TP-3 Paper

OR

BG Instrument Co.

13607 E. Trent Avenue

Spokane, WA 99216

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: TP-3 paper

6.0 OPERATING PROCEDURES

Before using the Accu-Trans for measuring

any resistance, operators should review the

Summary of Step-by-Step Operation of the

Accu-Trans found in Figure 4.0. Accu-

Trans operations are simple, requiring the

selection of choices from the display menus

and responding to the displayed prompts.

However, first-time operators should review

Figure 1.0 to become familiar with the total

Accu-Trans operation and the logical

branching for various test options. (More

experienced operators may use this figure as

a handy help and reference guide.

WARNING

Do not touch or disconnect any test lead

that is connected to a transformer

terminal while high current is being

conducted during any test. Failure to

heed this warning can result in lethal

electrical shock to personnel and/or

damage to equipment.

6.1 General Procedures

a) Ground Accu-Trans to substation ground

(item 5 in Figure 1.0).

b) Plug Accu-Trans power cable into a

power outlet.

c) Insert current-cable plugs and voltage-

sensing cable plugs into respective control-

panel jacks (index 8 of Figure 1.0). Ensure

that voltage plugs are plugged into jacks that

are adjacent to companion current jacks.

d) Attach test-cable clamps to transformer

terminals of winding that is to be measured

(or if load is not an inductance, simply

attach test leads to opposite terminals of the

resistive load).

e) Turn on Accu-Trans power (item 4 in

Figure 1) by pressing “I” on rocker switch.

f) Observe that after configuration data is

displayed briefly, then the start-up menu

displays (with selection options for “1. RUN

TEST,” “2. SETUP”).

Page 13

Accu-Trans Operating Procedures

9

Figure 4.0 Summary of Step-by-Step Accu-Trans Operation

Page 14

Accu-Trans Operating Procedures

10

TEST IN PROGRESS

MEASURED RESISTANCE

1. TEST

XFMR

04/15/01

6.2 Step-by-Step Procedures at StartUp Menu

6.2.1 START-UP Menu:

Observe that the Start-Up menu displays as

shown below:

2. SETUP 09:28:03

a) Press key #1 to start test. Press #2 to

select other options (i.e. enter recordidentification data, recall test results, etc.)

6.2.2 Test Transformer Procedure

The following procedure shows the steps to

get a resistance reading from a device under

test.

a) To start a test, press key #1 (TEST

XFMR) from main menu. When the test

mode is selected, a “WARNING!” display is

shown below:

This display doesn’t prompt any action; but

simply reminds the user that a test is in

progress. The time for this display depends

on size of the winding’s inductance and the

test mode selected.

The Accu-Trans determines when the

resistance reading is stable and shows

resistance value on LCD as follows:

“STOP” TO ACCEPT

120.0 MICRO-OHM

The Accu-Trans continues to apply the test

voltage on the transformer’s winding and

updates the resistance value on the display.

d) The user presses STOP key to retain this

data and go to the next step. (If the displayed

data is not O.K., press CLEAR to return to

the Start-Up Menu.)

**********WARNING!**********

DANGEROUS FLASH-OVER

MAY OCCUR IF CABLES

ARE DISCONNECTED!

This warning reminds operators that the next

sequence of test steps will run current

through the load, which, if inductive, will

cause lethal voltages to be generated if the

cables are disconnected before the current is

ramped down to zero.

b) Press the ENTER key and proceed to the

next step. The start test display appears:

c) Press the START key to Start test. The

test-in progress display appears below:

PLEASE WAIT………

MEASURED RESISTANCE

FINAL RESISTANCE

120.0 MICRO-OHM

e) Press ENTER key and go to the next

step. The print-option menu is now

displayed.

PRINT TEST RESULTS

1. YES

2. NO

f) Press key #1 to print test results. Typical

Accu-Trans test report is shown in figure 5.

g) Select key #2 to bypass printing results.

* XFMR CHARGING*

Page 15

Accu-Trans Operating Procedures

11

RUN ANOTHER TEST?

1. ENTER

XFMR DATA

1. COMPUTER CONTROL

h) When either option is selected, the next

window displays with the prompt “KEEP

THIS READING? Go to the next step.

KEEP THIS READING

1.YES

2. NO

i) If the KEEP THIS READING prompt is

answered with a YES, the following display

appears.

j) Go to step l. If NO is selected, the next

display is skipped and the second display

following appears.

TEST SAVED

m) At the “RUN ANOTHER TEST?”

Menu, the operator may choose to run

another test, by selecting “YES”. Return to

step 6.2.2.a to run test.

n) If NO is selected (i.e., don’t run another

test) the program returns to the Start-Up.

Menu (section 6.2.1).

6.3 SETUP Menu:

This menu is displayed by again selecting 2

(SETUP) on the Start-UP MENU

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

The TEST SAVED display advises that the

resistance measurement has been saved.

k) Press ENTER and go to the next step.

“RUN ANOTHER TEST?” message will

appears.

l) Select NO from “KEEP THIS

RESULTS” will take the user to the “RUN

ANOTHER TEST?” menu.

1. YES

2. NO

a) Select key 1 to 4. When key #4 (NEXT

PAGE) is selected, More choices for setup

menu are shown (below).

2. SET TIME

3. ENABLE TEST MODE

4. VOLTAGE REG. TEST

Page 16

Accu-Trans Operating Procedures

12

COMPANY:

Figure 5.0 Typical Test Report Printout

6.3.1 Transformer ID Entries:

The operator can enter test data using the

following procedures.

OPERATOR’S NOTE

Test Identification data are entered

with the keypad (item 2 of Figure 1.0).

The keypad has 10 keys that are alphanumerically marked, like pushbuttons

on a telephone. Keys are pressed for

each character position (marked by the

cursor) in the identification area; thus:

If, for example, we consider the key

marked 2/A B C, the first press of the

key selects the number “2,” pressing

the key a second time selects the letter

“A,” pressing the key a third time

selects the letter “B, and pressing the

key a fourth time selects the letter “C.”

Further pressing of the key returns to

the number selection; the cycle repeats

as the key continues to be pressed. The

characters selected are entered at the

position of the cursor. Pressing the up

key (∧ ) advances the cursor by one

space; pressing the down key (∨ )

moves the cursor back one space. If a

character is erroneously entered, select

the new key to get the correct entry.

The first Identification (ID) display is the

COMPANY screen, which is shown below:

a) Enter the characters of the utility

company’s name. When this is done, press

Page 17

Accu-Trans Operating Procedures

13

STATION:

CIRCUIT:

MANUFACTURER:

SERIAL NUMBER:

KVA RATING:

ENTER key and go to the next step. The

STATION screen will then be displayed.

b) Enter characters for naming the station

where the transformer to be tested is located.

When all the characters are selected or

identifying the station, press ENTER key

and go to the next step. The CIRCUIT

screen displays.

c) Enter all characters needed to identify

the circuit name, then press ENTER key and

go to the next step. The manufacturer screen

displays.

go to the next step. The SERIAL NUMBER

screen displays.

f) Enter the alpha-numeric characters

needed to identify the serial number, then

press ENTER key and go to the next step.

The KVA RATING screen displays.

g) Enter the numbers to identify the KVA

rating for the transformer being tested, then

press ENTER key and go to the next step.

The OPERTOR screen displays.

d) Enter all characters needed to identify

the manufacturer of the transformer being

tested, then press ENTER key and go to the

next step. The MODEL screen displays.

MODEL:

e) Enter the characters of the transformer’s

model number, then press ENTER key and

OPERATOR:

h) Enter the characters needed to identify

the operator who is performing the tests.

This completes entries for the transformer

identification data. Press ENTER key to

enter the selected data: the program returns

to the START-UP MENU.

6.3.2 Review Test Records Procedure

This procedure describes steps to review a

test record residing in Accu-Trans

working memory. The user can view the

record on the LCD display or from a thermal

printout.

Page 18

Accu-Trans Operating Procedures

14

1. ENTER

XFMR ID

4. NEXT PAGE

REVIEW RECORD

2 TESTS

TEST NUMBER: 1

press the down (∨ ) key to roll down, through

NOTE

To review a test record stored in Flash

EEPROM, the user must first restore test

record from Flash EEPROM to working

memory (see paragraph 6.3.3).

These procedural steps begin by selecting

SETUP on the Start-Up Menu, which

displays the Set-Up Menu, shown below:

2. REVIEW RECORD

3. RESTORE RECORD

a) In the Set-Up Menu (see above), press 2

to select the REVIEW RECORD procedure.

It starts with the display shown below. Go to

the next step.

the saved test records.

The next menu displays the number of test.

in the record, time and date of the test.

There are 2 tests in the test record below.

06/12/ 01 12:21:34

f) Press the UP (∧ ) key to review the

resistance measured in the first test, which

show in the following display.

ACTIVE TEST

10.88 OHM

AT 0.824 Amps

1. SCROLL TEST RECORD

2. PRINT TEST RECORD

b) Press 1 (SCROLL TEST RECORD) to

view all the test records in memory (see

menu above).

c) Press 2 (PRINT TEST RECORDS) to

output test record to the thermal printer.

See Fig. 5.0 for typical test record printout.

d) Pressing the 1 key (SCROLL TEST

RECORD) produces the RECORD “ID”

INFO display. This menu displays the

information related to the test.

RECORD “ID” INFO:

g) Press the UP (∧ ) key again to display the

second test on the record as shown below:

TEST NUMBER: 2

ACTIVE TEST

122.8 MILLI-OHMs

AT 2.000 Amps

h) When the operator has reviewed the test

measurement for the selected record in the

display above, press STOP to return to the

Start-Up Menu. This ends the steps for

reviewing saved test records.

6.3.3 Restore Recording Procedures

This procedure allows the user to restore a

test record from the Accu-Trans Flash

EEPROM to working memory. The user can

then review the test record using the

REVIEW RECORD command (6.3.2).

e) To scroll through the test records in

memory, press the UP (∧ ) key to roll up or

The Restore Recording Procedure steps

begin at the Set-Up Menu, shown next:

Page 19

Accu-Trans Operating Procedures

15

1. RESTORE RECORD

RESTORE RECORD

RESTORE RECORD

RECORD RESTORED!

1. ENTER

XFMR ID

REVIEW RECORD

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

a) To begin the Restore Recording steps,

press key # 3 (RESTORE RECORDING),

which shows a menu for three main

procedures, as displayed below. Go to next

step.

2. DIRECTORY

3. ERASE RECORDS

4. NEXT PAGE

b) Press key # 1 (RESTORE RECORD) to

begin the procedure. The next display

appears. Go to the next step.

1. ENTER RECORD NUMBER

2. SCROLL TO SELECT

c) Press # 1 (ENTER RECORD

NUMBER) to produce the Restore Record

display, as shown below. Go to next step.

The above display confirms to the operator

that the selected record has been restored.

e) When the restoration is confirmed, press

ENTER key to select the viewing option as

shown below.

1. SCROLL TEST RECORD

2. PRINT TEST RECORD

f) If the user wants to scroll through the

test record, press key #1 and continue from

step 6.3.2.b.

i) Press key # 2 will produce a test record

print out on the thermal printer. See figure

5.0 for a typical test record printout.

6.3.4 Printing Test-Record Directory

Printing the test record directory begins with

the Set-Up Menu shown below (the same

display from which the Review Records

steps began):

NUMBER:

The above display prompts the operator to

enter the record number.

d) When the record number is displayed,

press ENTER and go to the next step. The

next display will appear.

2. PREVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Page 20

Accu-Trans Operating Procedures

16

1. RESTORE RECORD

PRINT DIRECTORY

a) Press key # 3 to select the Restore

Recording step sequence, and go to the next

step. The following menu displays:

2. DIRECTORY

3. ERASE RECORD

b) Press key # 2 (DIRECTORY) and go to

the next step. The menu below displays:

1. FULL DIRECTORY

2. SHORT DIRECTORY

c) Press key # 1 to print the entire directory

of test records; Press key # 2 to print the

short directory.

A short directory lists the last 20 test records

stored in the Accu-Trans memory.

This ends the print directory sequence.

Page 21

Accu-Trans Operating Procedures

17

1. RESTORE RECORD

ERASE RECORD

Figure 6.0 Typical Record Directory Printout

6.3.5.Erase Recording Procedure

The Erase Recording sequence begins with

the Set-Up Menu, shown below. Go to the

next step.

1. ENTER XFMR ID

2. PREVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

a) Press # 3 (RESTORE RECORD) and go

to the next step. The display below appears.

2. DIRECTORY

3. ERASE RECORD

b) Press # 3 (ERASE RECORD) and go to

next display.

ERASE RECORD

1. ERASE SINGLE REC.

2. ERASE ALL RECORDS

c) To erase a single a record, press key # 1;

to erase all records press key # 2. If a single

recording is selected go to the next step; The

prompt below displays. To erase all

recordings go to step f.

NUMBER:

Page 22

Accu-Trans Operating Procedures

18

RECORD NUMBER

ERASE ALL RECORDS!

RECORD ERASED!

COMPUTER

ITF MODE

1. ENTER

XFMR ID

d) Enter the number of the record that is to

be erased and press ENTER key. Go to the

next step. The confirmation display appears

as shown below:

ERASED

e) When the erased record number is

confirmed, press ENTER key to return to the

start-Up Menu ending the sequence for

erasing a single record.

f) When key # 2 (ERASE ALL

RECORDS) is pressed in the Erase Record

display (back in step c, the following prompt

displays. Go to the next step.

6.3.6 Enabling Computer Interface

The Computer Interface Mode allows the

user to retrieve test records stored in the

Acccu-Trans memory via the RS-232C port

An IBM PC program is provided with each

Accu-Trans allowing the user using his PC

to retrieve these test records.

a) This procedure begins in the Set-Up

Menu, shown below. Go to the next step:

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

b) Pressing key #4 (NEXT PAGE) and the

menu below appears. Go to the next step.

1. COMPUTER CONTROL

2. SET TIME

3. ENABLE TEST MODES

ARE YOU SURE?

“ENTER” TO CONTINUE

g) Press ENTER key to erase all test

records. If ERASE ALL RECORDS was

mistakenly selected, press “STOP” to abort

the erase process and return to the Start-Up

menu. When ENTER key is pressed, the

following confirmation message is

displayed. Press ENTER key to return to the

Start-Up Menue:

This ends the Erase Record(s) sequence.

c) Press key # 1 (COMPUTER

CONTROL) and go to the next step. The

display below appears:

j) Pressing the STOP key terminates the

computer control, at which time the Start-Up

Menu displays, ending this step sequence.

6.3.7 Setting Date and Time

The date and time set begins at the Set-Up

Menu, shown below:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

Page 23

Accu-Trans Operating Procedures

19

a) Begin the date and time set by pressing

key # 4 (NEXT PAGE) and going to the

next step. The menu below appears. Go to

the next step.

1. COMPUTER CONTROL

2. SET TIME

3. ENABLE TEST MODE

b) Press key # 2 (SET TIME) and go to the

next step. The display below appears:

ENTER

MM-DD-YY HH:MM:SS

c) Enter the date and time, which appear in

the dashed-line areas, then press ENTER

key to set the calendar and clock and return

to the Start-UP Menu. This ends the Set

Time step sequence.

6.3.8 Enable Passive Test Mode

Operators have a choice between two test

modes: ACTIVE or PASSIVE. Normally,

the ACTIVE test mode is best suited for

quickly testing transformer resistances. In

this mode, the Accu-Trans automatically

ramps the test current up to its final test

value (when the magnetic field is saturated)

in the shortest possible time. However, in a

very large inductive load, the ACTIVE test

mode reading may appear to be unstable.

In this situation, the user may want to try the

PASSIVE test mode test. In this mode, the

Accu-Trans will take longer to provide a

reading, however, the reading is more stable.

Note

The Accu-Trans always defaults to the

ACTIVE test mode when power is first

applied to the unit. The user needs to enable

the PASSIVE test mode before using it.

a) This procedure begins in the Set-Up

Menu, shown below. Go to the next step:

1. ENTER XFMR ID

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

b) Pressing key #4 (NEXT PAGE) and the

menu below appears:

1. COMPUTER CONTROL

2. SET TIME

3. ENABLE TEST MODES

c) Press key #3 to activate PASSIVE Test

mode.

Note

Once the PASSIVE test mode is

selected, the Accu-Trans will display the

test mode selection menu (shown below)

in step 6.2.2.a after the user presses key

#1 (TEST XFMR).

1. ACTIVE TEST

2. PASSIVE TEST

6.3.9 Voltage Regulator Test

Note

This test verifies that a regulating

switch in a primary-voltage tap

regulator changes contacts through its

selection range with no break in the

circuit (i.e., it checks the tap switch’s

make-before-break). This test is

important because, in actual use, any

breaks in current in a regulating tap

Page 24

Accu-Trans Operating Procedures

20

1. TEST

XFMR

08/14/01

1. ENTER

XFMR ID

1. COMPUTER CONTROL

ARE DISCONNECTED!

VOLTAGE REG. TEST

switch generates large reactive voltage

spikes that are hazardous and exceed

the switch’s voltage ratings, thus

causing irreparable damage.

By connecting the Accu-Trans

continuity test input across the

switching input and running the

regulator switch through all the

contacts in it’s range, any breaks in

continuity caused by faulty tap

switching are detected.

a) To run the Voltage-Regulator test,

perform the following step-by-step

sequence, starting with the STARTUP

MENU (see below):

2. SETUP 12:21:01

b) Press key #2 (SETUP) to produce the

SETUP MENU (see below):

e) Press ENTER key for next display (see

below):

f) Press START key to run the voltage

regulator tap-switch test. The test begins as

the magnetic field in the transformer ramps

up to a stable plateau with the advisory that

the transformer is charging (the red High-

voltage warning indicator lights) When the

transformer current stabilizes, the following

prompt displays (see below):

*****WARNING!*****

DANGEROUS FLASH-OVER

MAY OCCUR IF CABLES

VOLTAGE REG. TEST

“START” TO RUN TEST

or

“STOP” TO ABORT

2. REVIEW RECORD

3. RESTORE RECORD

4. NEXT PAGE

c) Press key #4 (NEXT PAGE) to produce

the next menu of test options (see next

display):

2. SET TIME

3. ENABLE TEST MODES

4. VOLTAGE REG. TEST

d) Connect Accu-Trans input to the

regulating tap-switch input. Press key #4

(VOLTAGE REG. TEST) to start the

regulator test (high-voltage advisory notice

displays—see following):

CURRENT RAMP: xx %

*XFMR CHARGING*

No operator action required; when

transformer current ramps nears a flat

plateau, the run tap switch prompt displays

(see below):

VOLTAGE REG. TEST

RUN TAP CHANGER NOW

“STOP” TO EXIT TEST

XFMR CHARGING

If no transient is detected as taps are

switching, the display above will remain.

Press “STOP” to end the voltage regulator

test.

Page 25

Accu-Trans Operating Procedures

21

If a switch break is detected, an advisory

displays (shown below). Press STOP to end

the voltage-regulator test.

TRANSIENT DETECTED!

.

Page 26

Accu-Trans Operating Procedures

APPENDIX A

ACCU-TRANS Troubleshooting Guide

Item Symptom Possible Problem Solution

1 Reading is incorrect. 1. Poor connection at the

Clips.

2. Broken sensing lead.

2 No Test Current.

(Current % read zero)

and resistance

reading=0

3 Have test current but

resistance reading =

0.

1. No test current going

through DUT.

2. Drive circuit not

working.

1. Broken sense leads.

2. Reverse sense leads.

1.Check connection to make sure

sensing and current teeth are

touching the device under test

(DUT).

2. Inspect sensing cables.

1. Check Connection to DUT.

2. Run Calibration Test.

1. Inspect sense leads.

NOTE: DUT=Device Under Test

Page 27

Page 28

1710 Grevillea Court, Ontario, CA 91761, USA

Phone: 909-923-9390 Fax: 909-923-9391

Website: http//www.vanguard-instruments.com

ACCU-TRANS 09/09/01: OAK

Loading...

Loading...