Page 1

r

USER'S GUIDE

Vaisala Ultrasonic Wind Senso

WS425 F/G

M210713EN-C

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Contents of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

General Safety Considerations . . . . . . . . . . . . . . . . . . . . .10

Product Related Safety Precautions . . . . . . . . . . . . . . . . .11

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Product History - ASOS Program . . . . . . . . . . . . . . . . . . . .15

Introduction to Ultrasonic Wind Sensor

WS425 F/G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ultrasonic Wind Sensor WS425 F/G Components . . . . . . .17

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

CHAPTER 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Installation of Mounting Arm and Sensor Cable . . . . . . . .25

Installation of Wind Sensor . . . . . . . . . . . . . . . . . . . . . . . . .26

Installation of Power Supply . . . . . . . . . . . . . . . . . . . . . . . .26

Installation of Power Supply on Pole Mast . . . . . . . . . . . . .26

Connecting Lightning Ground . . . . . . . . . . . . . . . . . . . . . .27

Connecting Fiber Optic Cable . . . . . . . . . . . . . . . . . . . . . .28

Connecting Fiber Optic Modem FOM111 . . . . . . . . . . . . .28

Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Connecting Sensor Interface Cable . . . . . . . . . . . . . . . . . .29

Power Supply Terminal Blocks . . . . . . . . . . . . . . . . . . . . .31

Conducting Off-Line Test . . . . . . . . . . . . . . . . . . . . . . . . . .31

Aligning the Wind Sensor . . . . . . . . . . . . . . . . . . . . . . . . . .32

Magnetic Declination Correction . . . . . . . . . . . . . . . . . . . .32

Compass Alignment with Mast Adapter . . . . . . . . . . . . . . .33

VAISALA________________________________________________________________________ 1

Page 4

________________________________________________________________________________

CHAPTER 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Power On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Diagnostic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

RS-232 Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

WB Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

VFIRMWARE Command . . . . . . . . . . . . . . . . . . . . . . . . . .40

WA Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Example of the WA Command Message. . . . . . . . . . . 42

WL Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

WM Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

WN Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

WS Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

WJ Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

WD Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

WF Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Example of the WF Command Message . . . . . . . . . . . 48

WR Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

WATE Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

WCAL Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

WH Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

WT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

WSST Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

WSTK Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

WCDV Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

CHAPTER 5

OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Wind Measurement Principle . . . . . . . . . . . . . . . . . . . . . . . .59

Power Supply Operating Principle . . . . . . . . . . . . . . . . . . .61

Verifier Associated Operations . . . . . . . . . . . . . . . . . . . . . .63

CHAPTER 6

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Visual Inspection of Ultrasonic Wind Sensor WS425 F/G .65

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Wind Sensor Removal and Installation . . . . . . . . . . . . . . .74

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 74

Power Supply Removal and Installation . . . . . . . . . . . . . . .75

Power Supply Module Removal and Installation . . . . . . . .77

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 78

FOM Assembly Removal and Installation . . . . . . . . . . . . .78

Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 79

2 _______________________________________________________________________________

Page 5

________________________________________________________________________________

Sensor Interface Cable Removal and Installation . . . . . . .80

Firmware Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Download Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Recovery Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Vaisala Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

CHAPTER 7

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

VAISALA________________________________________________________________________ 3

Page 6

________________________________________________________________________________

4 _______________________________________________________________________________

Page 7

________________________________________________________________________________

List of Figures

Figure 1 Ultrasonic Wind Sensor WS425 F/G . . . . . . . . . . . . . . . . . . . .16

Figure 2 Components Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 3 Schematic of Ultrasonic Wind Sensor WS425 F/G . . . . . . . . .18

Figure 4 Ultrasonic Wind Sensor Power Supply . . . . . . . . . . . . . . . . . .19

Figure 5 Power Supply and FOM Module Assembly . . . . . . . . . . . . . . .20

Figure 6 Cable Assembly, Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 7 Fiber Optic Modem FOM111 . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 8 WS425 F/G Tower Assembly. . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 9 Sensor Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 10 Power Supply and Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 11 Power Supply Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 12 Sketch of Magnetic Declination . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 13 Correctly AlignedWS425 F/G Sensor. . . . . . . . . . . . . . . . . . . .34

Figure 14 Adjusting the N-S Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 15 Ultrasonic Wind Sensor Block Diagram. . . . . . . . . . . . . . . . . .60

Figure 16 Power Supply Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . .62

Figure 17 Solder Spot and Sensor Handling . . . . . . . . . . . . . . . . . . . . . .67

Figure 18 Field Verifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 19 Field Verifier with Cloth Bag. . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 20 Fault Isolation Flow Chart: Sensor Not Responding Part 1 . . .70

Figure 21 Fault Isolation Flow Chart: Sensor Not Responding Part 2 . . .71

Figure 22 Fault Isolation Flow Chart: Sensor Responds with F Status . .72

Figure 23 Fault Isolation Flow Chart: Sensor Responds with H Status . .73

Figure 24 Sensor Cable Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . .88

VAISALA________________________________________________________________________ 5

Page 8

________________________________________________________________________________

6 _______________________________________________________________________________

Page 9

________________________________________________________________________________

List of Tables

Table 1 Terminal Block 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 2 Terminal Block 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 3 Ultrasonic Wind Interrogation Requests. . . . . . . . . . . . . . . . . . . .39

Table 4 Explanation of the WA Command Message . . . . . . . . . . . . . . . .42

Table 5 Explanation of the WF Command Message. . . . . . . . . . . . . . . . .48

Table 6 Field Replaceable Units of Ultrasonic Wind Sensor WS425 F/G.86

Table 7 Wind Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Table 8 Wind Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Table 11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 9 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Table 10 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

VAISALA________________________________________________________________________ 7

Page 10

________________________________________________________________________________

8 _______________________________________________________________________________

Page 11

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the product.

About This Manual

This manual provides information for installing, operating, and

maintaining the product.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information: This chapter provides general

notes for the product.

- Chapter 2, Product Overview: This chapter introduces the features

and advantages of Vaisala Ultrasonic Wind Sensor WS425 F/G.

- Chapter 3, Installation: This chapter provides you with information

on the installation and alignment procedures, and connections of

the power supply and fiber optic modem.

- Chapter 4, Operation: This chapter contains information needed to

operate Vaisala Ultrasonic Wind Sensor WS425 F/G.

- Chapter 5, Operating Principle: This chapter provides you with a

brief explanation of the operating principles of Vaisala Ultrasonic

Wind Sensor WS425 F/G and its power supply.

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

- Chapter 6, Maintenance: This chapter contains instructions for the

basic maintenance, fault isolation and installation and removal of

the field replaceable units of the Vaisala Ultrasonic Wind Sensor

WS425 F/G.

- Chapter 7, Technical Data: This chapter provides the technical data

of the product and lists the field replaceable units, and the

accessories.

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com

.

Safety

WARNING

CAUTION

NOTE

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

10 ______________________________________________________________________________

Page 13

Chapter 1 ________________________________________________________ General Information

Product Related Safety Precautions

The Vaisala Ultrasonic Wind Sensor WS425 F/G delivered to you has

been tested for safety and approved as shipped from the factory. Note

the following precautions:

WARNING

CAUTION

Ground the product, and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself with a wrist strap and a resistive connection cord to the

equipment chassis before touching the boards. When neither of the

above is possible, at least touch a conductive part of the equipment

chassis with your other hand before touching the boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

Recycling

Recycle all applicable material.

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is

provided by the applicable supply contract or Software License

Agreement.

Warranty

Vaisala hereby represents and warrants all Products manufactured by

Vaisala and sold hereunder to be free from defects in workmanship or

material during a period of twelve (12) months from the date of delivery

save for products for which a special warranty is given. If any Product

proves however to be defective in workmanship or material within the

period herein provided Vaisala undertakes to the exclusion of any other

remedy to repair or at its own option replace the defective Product or

part thereof free of charge and otherwise on the same conditions as for

the original Product or part without extension to original warranty time.

Defective parts replaced in accordance with this clause shall be placed

at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and service works

performed by its employees to products sold by it. In case the repair or

service works should appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the service was

performed Vaisala shall at its free option either repair or have repaired

or replace the product in question. The working hours used by

employees of Vaisala for such repair or replacement shall be free of

charge to the client. This service warranty shall be valid for a period of

six (6) months from the date the service measures were completed.

This warranty is however subject to following conditions:

a)A substantiated written claim as to any alleged defects shall have been

received by Vaisala within thirty (30) days after the defect or fault

became known or occurred, and

12 ______________________________________________________________________________

Page 15

Chapter 1 ________________________________________________________ General Information

b)The allegedly defective Product or part shall, should Vaisala so

require, be sent to the works of Vaisala or to such other place as Vaisala

may indicate in writing, freight and insurance prepaid and properly

packed and labelled, unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty does not however apply when the defect has been caused

through

a)normal wear and tear or accident;

b)misuse or other unsuitable or unauthorized use of the Product or

negligence or error in storing, maintaining or in handling the Product or

any equipment thereof;

c)wrong installation or assembly or failure to service the Product or

otherwise follow Vaisala's service instructions including any repairs or

installation or assembly or service made by unauthorized personnel not

approved by Vaisala or replacements with parts not manufactured or

supplied by Vaisala;

d)modifications or changes of the Product as well as any adding to it

without Vaisala's prior authorization;

e)other factors depending on the Customer or a third party.

Notwithstanding the aforesaid Vaisala's liability under this clause shall

not apply to any defects arising out of materials, designs or instructions

provided by the Customer.

This warranty is expressly in lieu of and excludes all other conditions,

warranties and liabilities, express or implied, whether under law, statute

or otherwise, including without limitation any implied warranties of

merchantability or fitness for a particular purpose and all other

obligations and liabilities of Vaisala or its representatives with respect

to any defect or deficiency applicable to or resulting directly or

indirectly from the Products supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and waived. Vaisala's liability

shall under no circumstances exceed the invoice price of any Product

for which a warranty claim is made, nor shall Vaisala in any

circumstances be liable for lost profits or other consequential loss

whether direct or indirect or for special damages.

VAISALA_______________________________________________________________________ 13

Page 16

User's Guide ______________________________________________________________________

14 ______________________________________________________________________________

Page 17

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features and advantages of Vaisala

Ultrasonic Wind Sensor WS425 F/G.

Product History - ASOS Program

Vaisala Ultrasonic Wind Sensor WS425 F/G was originally developed

for the Automated Surface Observing Systems (ASOS) program, and

due to this fact this document contains references to the ASOS.

The ASOS program is a joint effort of the US National Weather Service

(NWS), the Federal Aviation Administration (FAA), and the

Department of Defense (DOD). The ASOS serves as the primary

weather observing network of the United States. It is designed to

support weather forecast activities and aviation operations and, at the

same time, support the needs of the meteorological, hydrological, and

climatological research communities.

Introduction to Ultrasonic Wind Sensor

WS425 F/G

Thank you for choosing Vaisala Ultrasonic Wind Sensor WS425 F/G.

It measures wind speed and direction from the smallest breeze to

hurricane force gales, including gusts.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

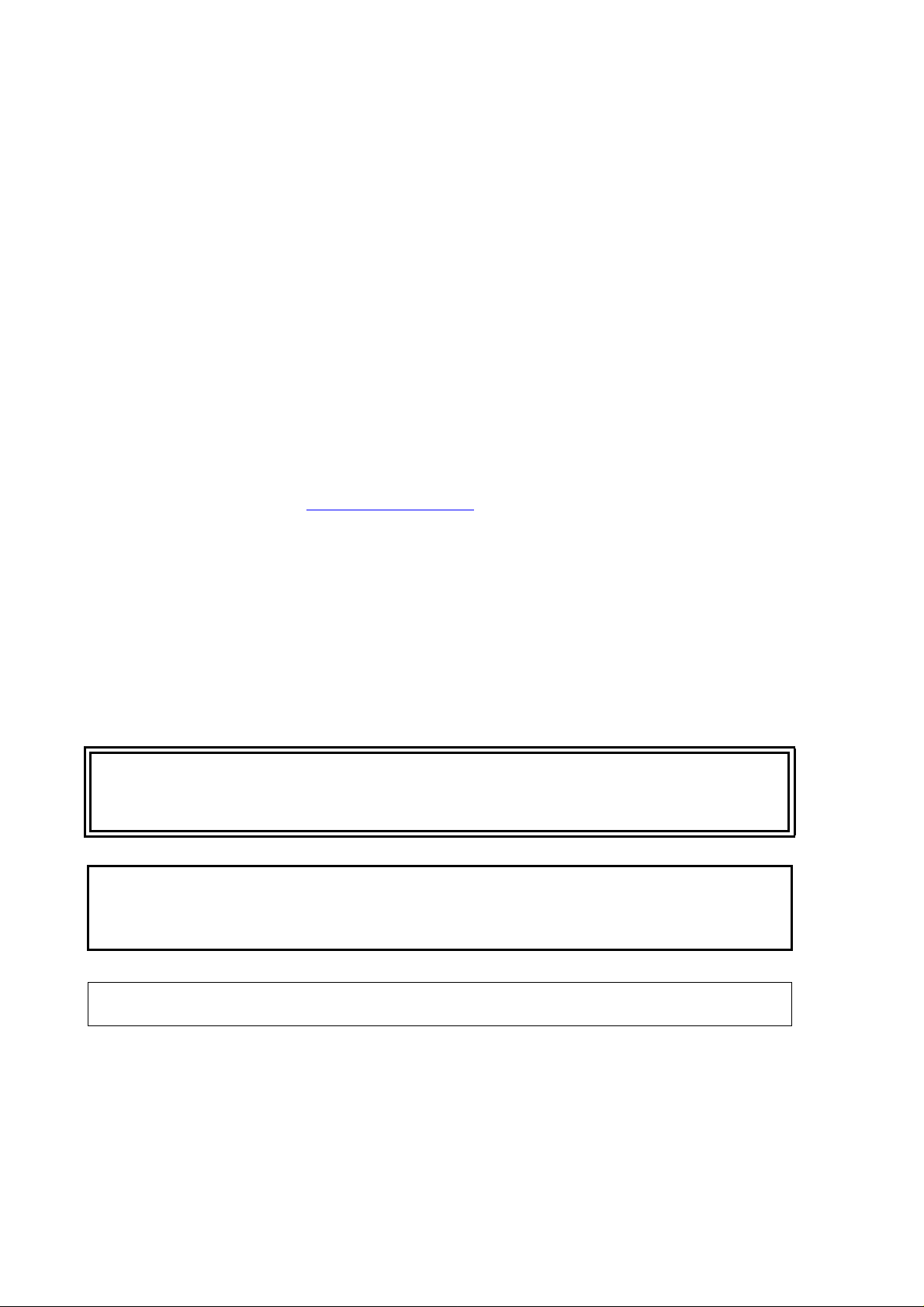

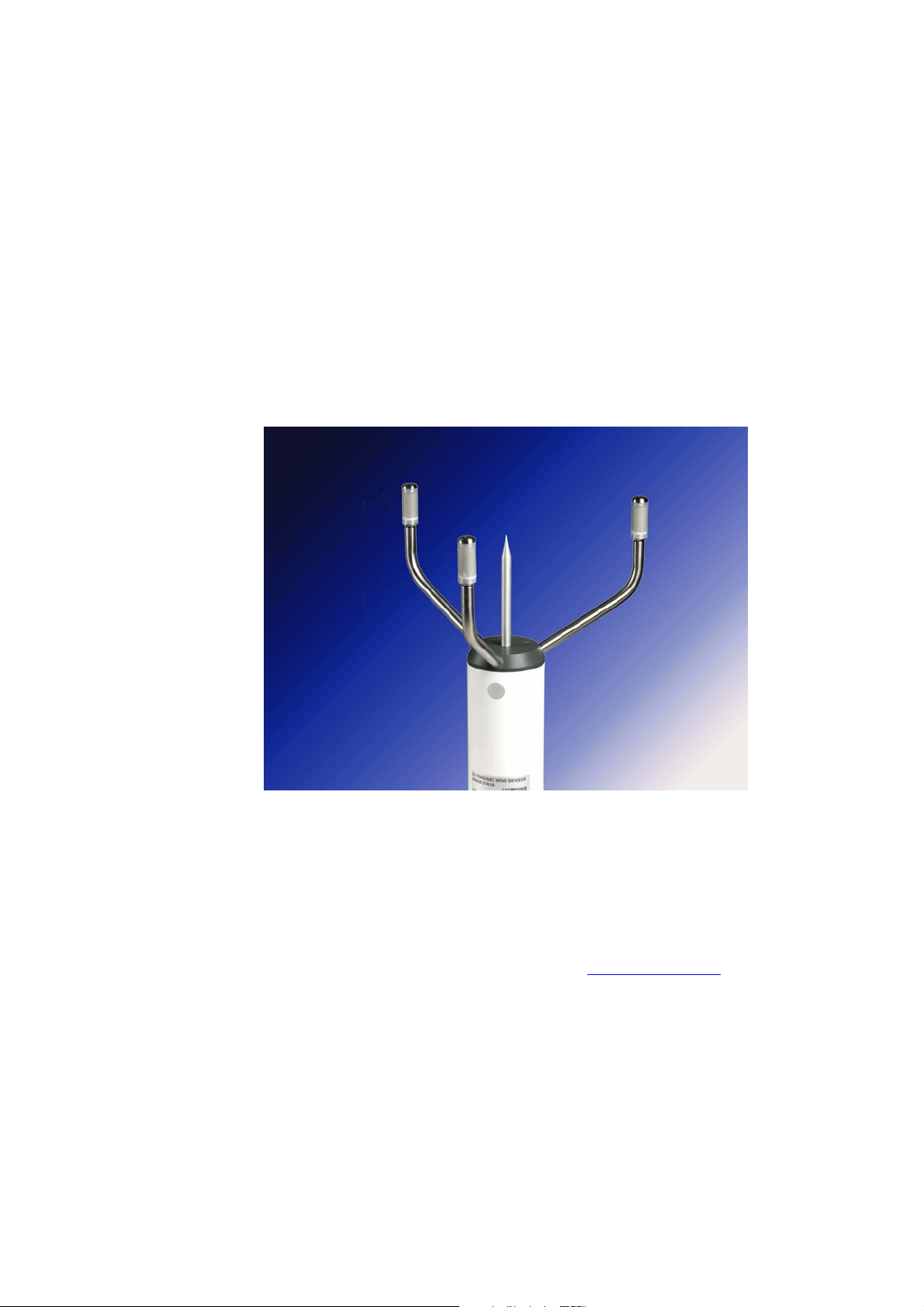

The patented three transducer layout provides superior data availability

and accuracy in all wind directions. The effects of temperature,

humidity, and pressure are fully compensated. The sensor

communicates to the system or data logger via an fiber optic

connection. The message format is ASOS compatible.

The device has no moving parts, so it is virtually maintenance free. The

stainless steel construction makes it resistant to contamination and

corrosion. The sensor heating function of the ice-free model prevents

freezing rain and snow build-ups and thus guarantees uninterrupted

operations throughout the year.

0506-047

Figure 1 Ultrasonic Wind Sensor WS425 F/G

Wind measurement and wind data is important in meteorology,

aviation, transport safety, in ships and harbors, and also in many

industrial applications. Vaisala manufactures wind sensors for all these

needs, from low cost combined units to sophisticated totally heated

sensors for extreme weather conditions. For more information, please

contact your Vaisala representative or visit www.vaisala.com.

16 ______________________________________________________________________________

Page 19

Chapter 2 __________________________________________________________ Product Overview

Ultrasonic Wind Sensor WS425 F/G

Components

0506-067

Figure 2 Components Overview

The following numbers refer to Figure 2 on page 17:

1 = Wind sensor

2 = Power supply

3 = Module assembly, power supply

4 = Fiber optic modem (FOM) assembly

The device consists of the following field replaceable units (FRU):

- Wind sensor, model WS425 F/G (item 1 in Figure 2 on page 17)

- Power supply,WS425PowerUS or WS425PowerEU (item 2)

- Module assembly, power supply (item 3)

- Fiber optic modem assembly (item 4)

- Cable assembly, sensor WS425 F/G (Figure 6 on page 21)

The FRUs are represented individually in Figures 3-6.

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

0506-010

Figure 3 Schematic of Ultrasonic Wind Sensor WS425 F/G

The following numbers refer to Figure 3 on page 18:

1 = Sensor body

2=Bird spike

3 = Transducer (3 pcs)

18 ______________________________________________________________________________

Page 21

Chapter 2 __________________________________________________________ Product Overview

0506-011

Figure 4 Ultrasonic Wind Sensor Power Supply

NOTE

Figure 4 on page 19 represents the WS425PowerUS power supply

made for 115 VAC - the European model WS425PowerEU has

different primary (internal) wiring and is made for 240 VAC. The

customer must check local regulations concerning the correct and safe

wiring of the power supply.

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

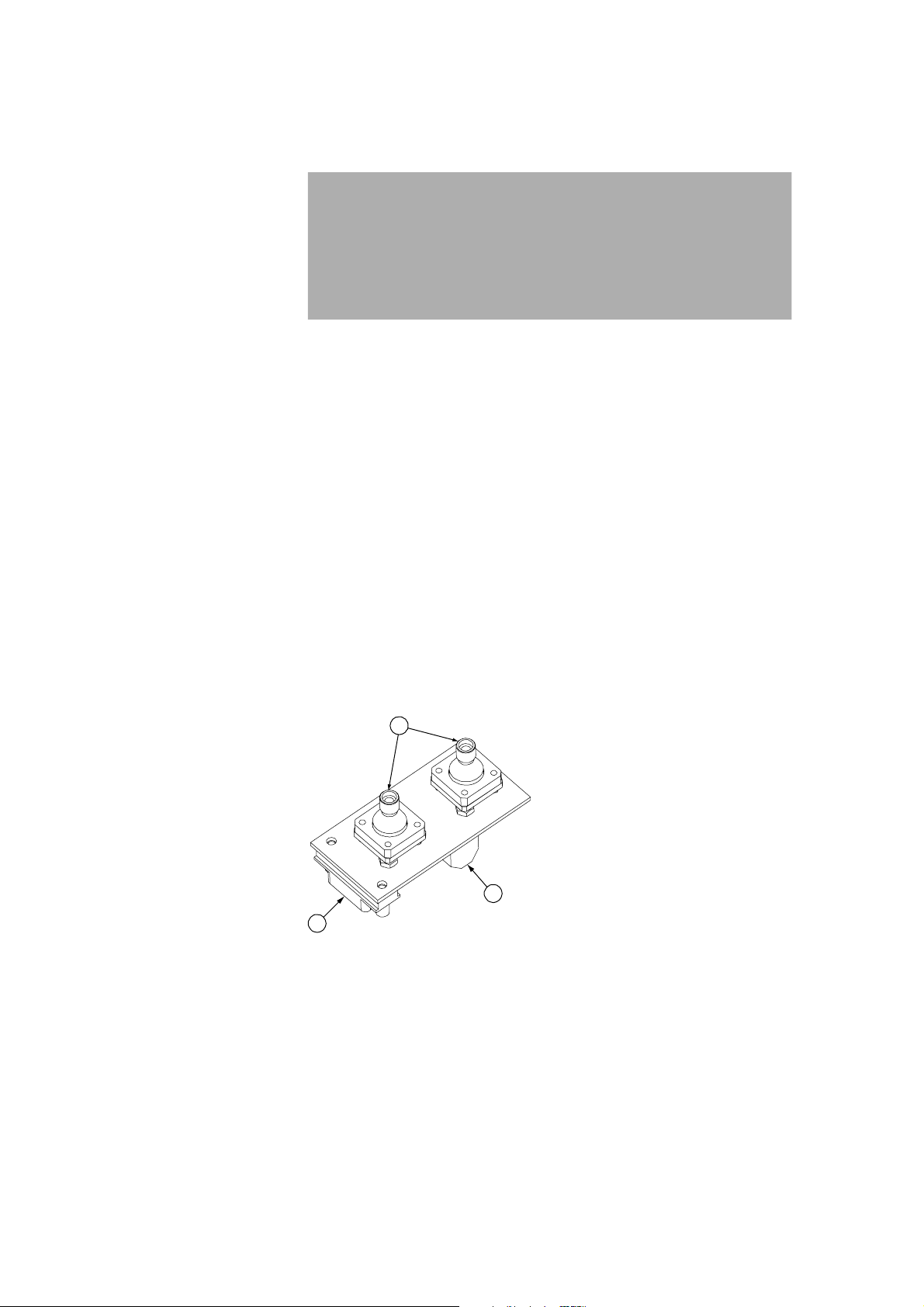

0506-012

Figure 5 Power Supply and FOM Module Assembly

The following numbers refer to Figure 5 on page 20:

1 = Fiber optic connector TX

2 = Fiber optic connector RX

3 = 12-position terminal block (TB2, see also Figure 11 on page

30 and Table 2 on page 31)

20 ______________________________________________________________________________

Page 23

Chapter 2 __________________________________________________________ Product Overview

0506-014

Figure 6 Cable Assembly, Sensor

The sensor interface cable assembly is 11.2 m in length. The 12 ring

lugs (indicated by the arrow in Figure 6 on page 21) of the sensor

interface cable are each numbered 1-12. Connect them to the

correspondingly numbered terminal positions in the power supply

assembly terminal block 2; see Figure 5 on page 20, Figure 11 on page

30 and Table 2 on page 31.

Accessories

Ultrasonic Wind Sensor WS425 F/G also has the following optional

accessories:

- Fiber optic modem, FOM111

1

3

2

0506-055

Figure 7 Fiber Optic Modem FOM111

The following numbers refer to Figure 7 on page 21:

1 = Fiber optic connectors

2 = RS-232 connector for PC cable

3 = Screw wire terminals for operating voltage

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

When using the fiber optic connection between the Ultrasonic Wind

sensor and a personal computer, two fiber optic modems are needed.

One is supplied as standard with the Ultrasonic Wind sensor enclosed

in the power supply module housing. The other is available from

Vaisala as an optional accessory. Please note that FOM111 is supplied

without a housing. If needed, the customer must source a proper

housing locally.

The fiber optic cable is connected to the connectors of the fiber optic

modem located in the power supply module assembly and at the other

end to the connectors of the optional FOM111 fiber optic modem. The

FOM111 in turn is connected to the host system personal computer/data

logger via an RS-232 cable. Note that the RS-232 cable between the PC/

data logger and the fiber optic modem is different than the one used

between the PC and the TEST connector in the power supply module

(see Figure 5 on page 20).

A DC power supply for the fiber optic modem is also required. See

Connecting Fiber Optic Cable on page 28 and Connecting Fiber Optic

Modem FOM111 on page 28 for further instructions on how to make the

fiber optic connections.

22 ______________________________________________________________________________

Page 25

Chapter 3 _______________________________________________________________ Installation

CHAPTER 3

INSTALLATION

This chapter provides you with information on the installation and

alignment procedures, and connections of the power supply and fiber

optic modem.

Required Tools

- 3-millimeter Allen wrench

- 9/16-inch crescent wrench (2 each)

- Flat blade screwdriver for #6 screw

- Phillips screwdriver for ¼-inch x 20 flathead screw

- Electrical tape

- Verifier

- Laptop with a Diagnostics Program

- RS-232 cable

- Tape measure

NOTE

Packaging materials

The WS425 F/G sensors and power supplies are shipped in cardboard

containers with custom foam pieces to support these items during the

shipment. It is very important to keep all the original packing materials

in case the items need to be returned for repair service in the future.

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

0506-015

Figure 8 WS425 F/G Tower Assembly

The following numbers refer to Figure 8 on page 24:

1 = WS425 F/G

2 = Cable assembly

3 = Adapter for F/G models

4 = Mounting tube

5 = Lightning rod (not provided by Vaisala)

24 ______________________________________________________________________________

Page 27

Chapter 3 _______________________________________________________________ Installation

Installation of Mounting Arm and Sensor Cable

1. Tilt the tower to a horizontal position.

2. Remove the mounting tube from the shipping container.

3. Find the end of the mounting tube with the two cross holes.

4. Insert this end of the mounting tube on the pole.

5. Rotate the mounting arm in its hole until the two cross-holes in the

pole are aligned with the two cross-holes in the mounting tube.

6. Insert the bolts into the cross-holes and tighten them

7. Remove the adapter from the sensor shipping box and place it over

the mounting tube.

8. Tighten the three set screws of the clamp at the bottom of the

adapter only lightly (these will be tightened during the sensor

alignment procedure).

9. Remove the sensor cable from the shipping box.

10. At the end of the sensor cable with ring lugs, take about half of the

individual wire and fold it back. See Figure 9 on page 25.

11. Feed the cable through the adapter, mounting arm, tower, tower

pivot, and the conduit going to the power supply, starting with the

wrapped end of the cable into the open end of the adapter at the end

of the mounting arm.

0506-016

Figure 9 Sensor Cable Installation

Wrap electrical tape around the wires tightly so that later it can be easily

threaded through the ½" conduit.

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

Installation of Wind Sensor

1. Open the sensor shipping box and remove the sensor.

2. Take the wind sensor and connect the cable connector to it. Then

insert the sensor over the end of the adapter. The sensor needs to be

rotated until its alignment pin slides into the slot of the adapter.

Tighten the single set screw that secures the sensor to the adapter.

CAUTION

After removing the sensor from the box, do not impact the three

transducers against hard objects or damage to the sensor might result.

Installation of Power Supply

Installation of Power Supply on Pole

Mast

1. Take the mounting plate out of the mounting kit assembly

container.

2. Take the power supply out of its shipping container.

3. Attach the power supply to the mounting plate with four flathead

screws and four each flat washers, lock washers and ¼-20 nuts

found in the mounting kit assembly container.

4. After these four screws are tightened, mount the entire assembly on

the pole mast, using the four hex-head screws as shown in Figure

10 on page 27. The customer must provide the pole mast and the

pole mast installation plate.

26 ______________________________________________________________________________

Page 29

Chapter 3 _______________________________________________________________ Installation

0506-017

Figure 10 Power Supply and Mount

The following numbers refer to Figure 10 on page 27:

1 = WS425PowerUS or WS425PowerEU power supply

2 = Power supply mounting plate

3 = Pole mast installation plate (not provided by Vaisala)

4 = Pole mast (not provided by Vaisala)

Connecting Lightning Ground

Connect the existing ground wire to the threaded ground stud at the

bottom left of the power supply with the provided lock washer and nut

found in the mounting kit assembly.

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

Connecting Fiber Optic Cable

WARNING

The fiber optic cable and the power cable share the same conduit.

Before proceeding make absolutely sure that the AC power is turned

off at the host system power distribution system. Then take an AC

voltmeter and measure the AC voltage between the black wire and

each of the green white and yellow wires; and between the red wire and

each of the green white and yellow wires. All the readings must be zero

before proceeding.

1. Thread the two fiber optic cables and the five power wires through

the conduit hole at the bottom right of the power supply.

2. Use the conduit nut to secure the conduit at the bottom of the power

supply.

3. After removing the protective covers, connect the fiber cable

marked TX to the fiber optic connector on the left.

4. Connect the fiber optic cable marked RX to the fiber optic

connector on the right.

Connecting Fiber Optic Modem

FOM111

1. Remove the protective covers from the optic fiber cables.

2. Connect the fiber optic cable marked TX to the correspondingly

marked connector in the modem.

3. Connect the fiber optic cable marked RX to the correspondingly

marked connector in the modem.

4. Connect the DC power wires to the modem screw terminals.

5. Connect the modem to a PC using the RS-232 cable. The modem

is now ready for use.

28 ______________________________________________________________________________

Page 31

Chapter 3 _______________________________________________________________ Installation

Connecting AC Power

CAUTION

Make sure you have correct mains voltage power supply

(WS425PowerUS or WS425PowerEU).

1. Remove the protective cover plate over the AC power terminal

block.

2. Connect the AC power wires to the AC power terminal block as

shown in Figure 11 on page 30, starting with the green wire.

Double-check that each wire is connected as shown in Figure 11 on

page 30.

3. Restore the protective cover plate over the AC power terminal

block.

Connecting Sensor Interface Cable

1. Feed the sensor interface cable through the left hole at the bottom

of the power supply.

2. Use the conduit-nut to secure the conduit at the bottom wall of the

power supply box.

3. Connect the 12 ring lugs of the sensor interface cable to the 12position terminal block (see Figure 11 on page 30). Follow the

numbering scheme next to the terminal block and on the labels of

the individual wires.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

0506-071

Figure 11 Power Supply Terminal Blocks

The following numbers refer to Figure 11 on page 30:

1 = AC power terminal block

2 = Terminal block 1 (TB1)

3 = Terminal block 2 (TB2)

30 ______________________________________________________________________________

Page 33

Chapter 3 _______________________________________________________________ Installation

Power Supply Terminal Blocks

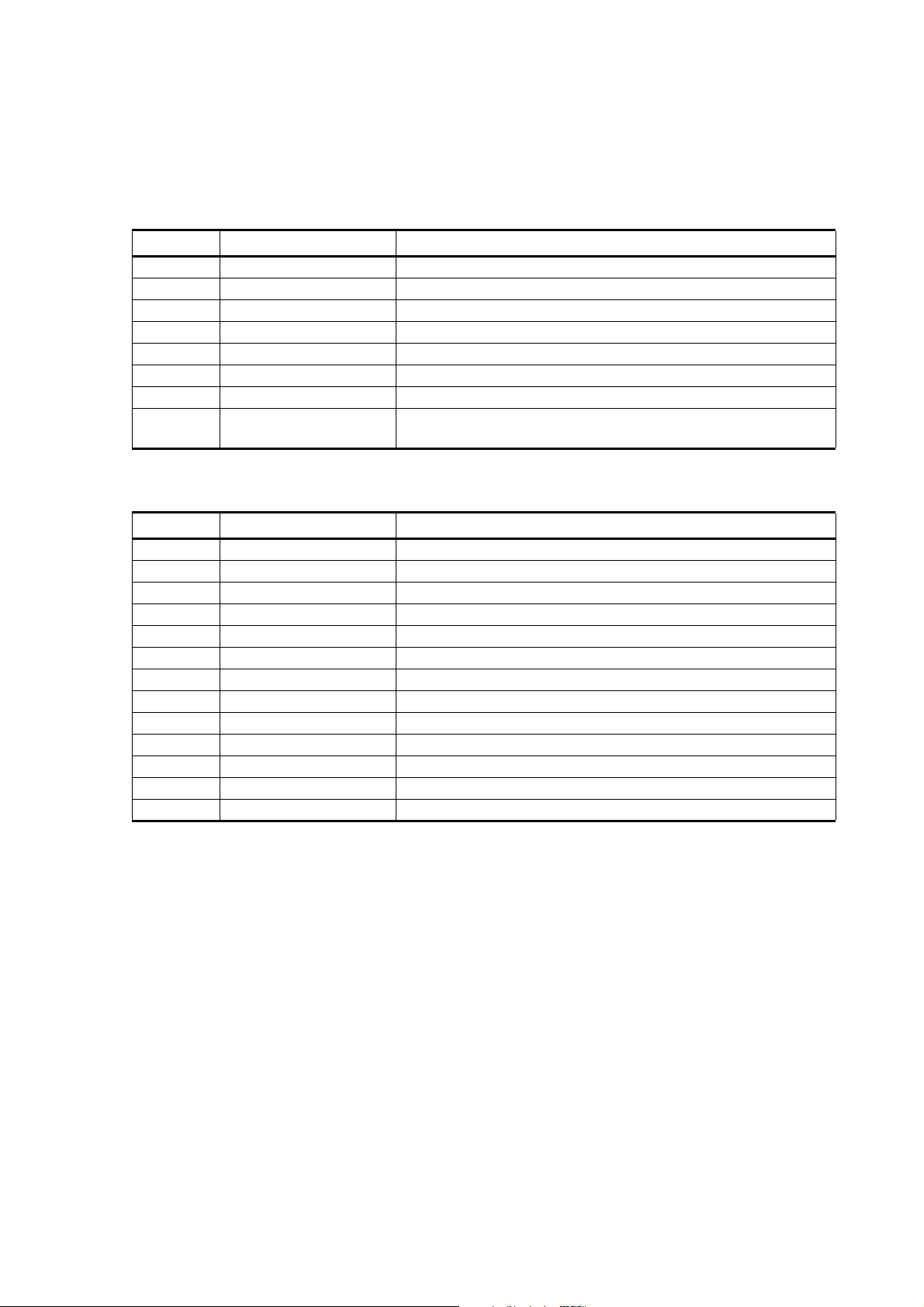

Table 1 Terminal Block 1

TB1

Terminal Name Description

1 12.6 V_H1 12.6 VAC transformer, line 1

2 12.6 V_CT 12.6 VAC transformer, center tap

3 12.6 V_H2 12.6 VAC transformer, line 2

4 36 V_H1A 24 VAC transformer, line A

5 36 V_H2A 24 VAC transformer, return A

6 36 V_H1B 24 VAC transformer, line B (internally connected to 36 V_H1A)

7 36 V_H2B 24 VAC t ansformer, return B (internally connected to 36

V_H2A)

Table 2 Terminal Block 2

TB2

Terminal Name Description

1 TOP_HEAT Top heater line, switched 24 VAC

2 ENCLOSUREHEATB Two of two enclosure heater lines, switched 24 VAC

3 ENCLOSUREHEATA One of two enclosure heater lines, switched 24 VAC

4 RETURN_36VAC_B Heater return, ground at sensor

5 RETURN_36VAC_A Heater return, ground at sensor

6 TOP_CTRL To heater control, >+3 V = ON

7 ENLOSURE_CTRL Enclosure heater control, >+3 V = ON

8 SENSOR+12V +12 VDC to sensor

9 SENSOR_TXD Connect to sensor TX data line

10 SENSOR_RXD Connect to sensor RX data line

11 GND (12V Common) Ground return from sensor

12 GND (RS232 Common) Connect to sensor cable shield

Conducting Off-Line Test

1. Turn on the AC power to the wind sensor in your system (system

power distribution).

2. Turn on the power switch in the power supply.

3. Connect a laptop to the TEST connector in the power supply with

an RS-232 cable. Run the Diagnostics Program on the laptop.

Choose the option that connects the sensor to the laptop with the

system disconnected.

4. Issue the WA command. The sensor must respond with a P status.

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

5. Place the verifier over the sensor and completely cover it with the

included bag. Pull the bag drawstrings to close it off at the sensor

alignment adapter.

6. Issue five WA commands spaced at least five seconds apart. All

five responses must have P status.

7. Turn off the power through the switch in the power supply before

performing the alignment procedure.

Aligning the Wind Sensor

Magnetic Declination Correction

One transducer arm is permanently marked with an N for north and

another with an S for south.

NOTE

Aligning might be easier if you mark the sensor body, for example,

with paint or colored tape, to indicate north and south so that it can be

seen from the ground.

Wind direction can be referenced to either the true north, which uses the

earth's geographic meridians, or to the magnetic north, which is read

with a magnetic compass. The magnetic declination is the difference in

degrees between the true north and magnetic north. See Figure 12 on

page 33.

32 ______________________________________________________________________________

Page 35

Chapter 3 _______________________________________________________________ Installation

NOTE

0003-011

Figure 12 Sketch of Magnetic Declination

The source for the magnetic declination must be current as the

declination changes over time.

Compass Alignment with Mast

Adapter

The following steps aim the wind sensor when using the 1-inch adapter

for mounting:

1. Use a compass to determine that the N-S transducer heads of the

ultrasonic wind sensor are exactly in line with the compass. Adjust

the heads by moving them to the left or right. For the correct

ground position of the installer, see Figure 14 on page 35.

2. If the alignment is not correct, lower the wind mast or tower.

3. Loosen the three set screws of the clamp at the bottom of the sensor

alignment adapter and rotate the sensor so that the heads marked

with the N and with the S are exactly aligned to north and south

when the tower is set up. Tighten the clamp screws.

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

4. Raise the tower to the vertical position. Figure 13 on page 34 shows

the correct alignment.

0506-072

Figure 13 Correctly AlignedWS425 F/G Sensor

34 ______________________________________________________________________________

Page 37

Chapter 3 _______________________________________________________________ Installation

0208-024

Figure 14 Adjusting the N-S Heads

The following letters refer to Figure 14 on page 35:

A = The installer is too far to the left.

B = The installer is in line with the sensor.

C = The appearance of the sensor is shown when the installer is in

the correct position. The sensor, however, is not correctly

aligned.

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

36 ______________________________________________________________________________

Page 39

Chapter 4 ________________________________________________________________ Operation

CHAPTER 4

OPERATION

This chapter contains information needed to operate Vaisala Ultrasonic

Wind Sensor WS425 F/G.

Power On/Off

The power switch is located in the power supply enclosure at the top

left. When turned on, the two LEDs labeled +5 V and +12 V will be

turned off if their respective supply is operational. If neither is turned

on, check the 0.25 A fuse and make sure that AC power is present.

System Operation

In normal system operation, the sensor communicates with the host

system system via two fiber optic cables. This normal state exists when

no cable is plugged into the RS-232 DB-9 connector labeled TEST in

the power supply.

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

Diagnostic Operation

When a laptop computer is plugged into the TEST connector via the

DB-9 connection in the power supply, the following states exist:

RTS DTR Description of States

LO LO Normal host system operation (TEST, connector

unplugged).

HI LO PC talks to the sensor, host system is disconnected

LO HI PC talks to the host system, Sensor is disconnected

HI HI Host system is connected to the Sensor with the PC

listening to both the transmit and receive lines

A special Diagnostics Program for the laptop PC is provided that allows

RS-232 communications and sets the RTS and DTR lines to the desired

states.

RS-232 Data Format

Ultrasonic Wind Sensor WS425 F/G communicates via an RS-232

serial interface. The host system sends American Standard Code for

Information Interchange (ASCII) characters to the Ultrasonic Wind

sensor and waits for the appropriate response. The sensor transmits an

ASCII response to various interrogation commands within 250

milliseconds at 2400 bits per second. The sensor is programmable to

operate at data rates 2400, 4800, or 9600 bits per second (bps). The

communication link is via an RS-232 serial port interfaced to a fiber

optic modem utilizing separate cables for transmitting and receiving

data. Control characters and control procedures are compatible with

ANSI x 3.28 and ANSI x 3.66 respectively. The data format consists of

the following:

- 1 start bit

- 8 data bits

- 1 stop bit

- No parity

- 2400 bits per second, programmable to 9600 bps

- Full duplex

- Serial asynchronous

- Configures as Data Terminal Equipment (DTE)

38 ______________________________________________________________________________

Page 41

Chapter 4 ________________________________________________________________ Operation

All user configuration parameters are stored in the non-volatile

memory.

Command Set

There are 18 interrogation requests that the host system and/or operator

can send to the Ultrasonic Wind sensor. They are listed below. The

sensor response to each command consists of a fixed-length message.

In each of the command descriptions below, CR is an ASCII carriage

return control character and LF is an ASCII line feed control character.

NOTE

The Ultrasonic Wind sensor only responds to upper case characters.

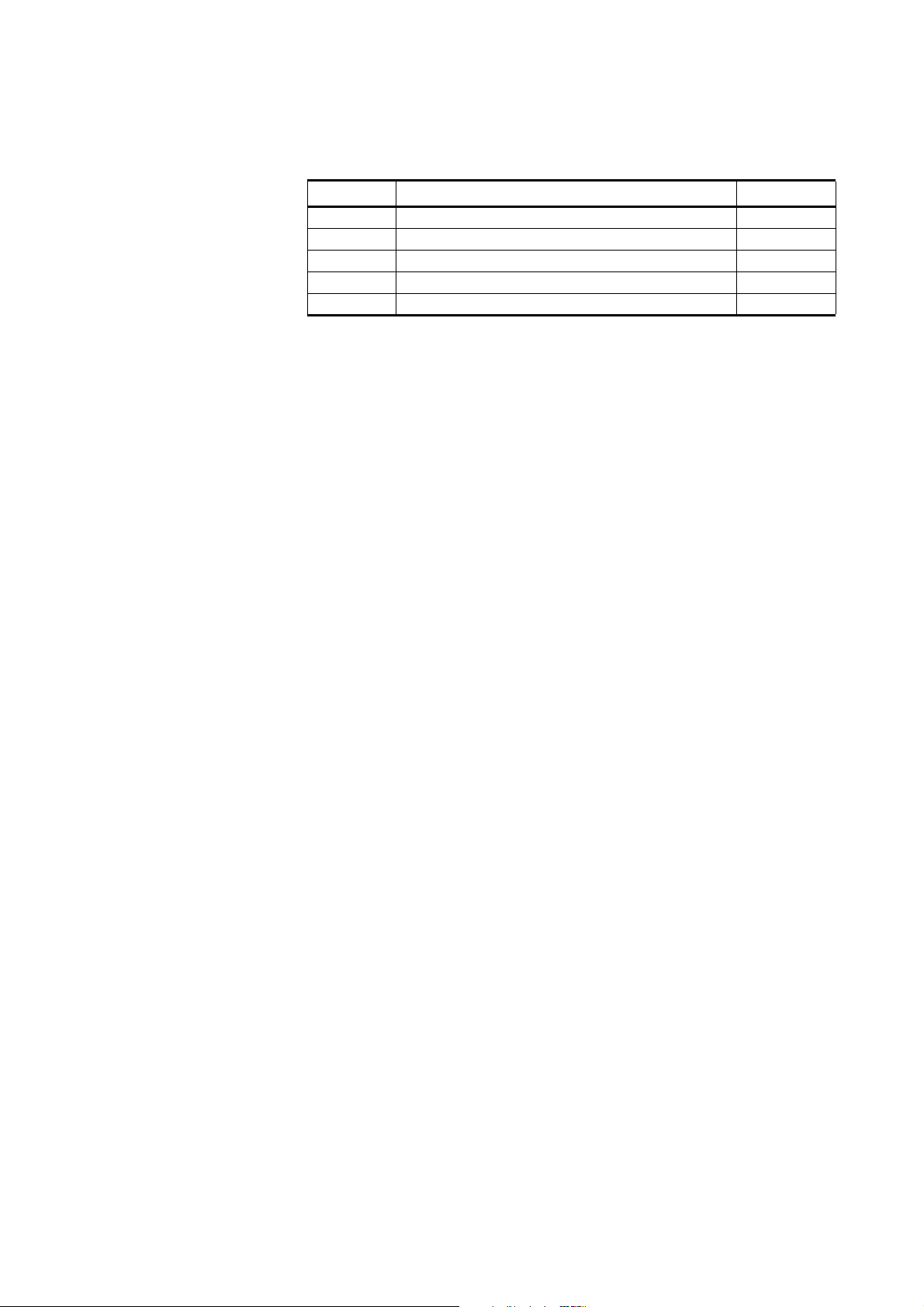

Table 3 Ultrasonic Wind Interrogation Requests

ASCII Request Description

WB Baud rate control

WFIRMWARE Downloading firmware

WA Average wind speed and direction message

WL Heater function automatically controlled by sensor

WM Heaters locked on

WN Heaters locked off

WS Verbose BIT results and status

WJ Set sp ee d an d dire ctio n av er ag in g tim e

WD Report BIT status

WF Send test data message

WR Execute system reset

WCAL Sensor self calibration

WH Display sensor command Help menu

WT Short response BIT results and status

WSST Return static speed of sound and sonic

temperature

WSTK Calibrate static speed of sound and sonic

temperature from ambient temperature

WCDV Return sensor self calibration data

WATE Return sensor measurement with reduced signal

amplitude

The WA command is executed by the ASOS at an interval of between

one and thirty seconds. For the WA command, the sensor responds to

the ASOS interrogation poll within 250 milliseconds of receiving the

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

request. The WD, WT, WF, and WR commands are executed by the

ASOS periodically to perform diagnostic checks.

The WH, WS, WSST, WSTK, WCDV, and WATE commands are

primarily initiated by an operator accessing the sensor via an external

laptop through the sensor's RS-232 port.

WB Command

This command is used to control the baud rate. The command format is:

WB9600 CR LF

where

9600 = In this case, represents 9600 bps, and would be replaced

with 2400 bps or 4800 bps as required to select those

values for a baud rate.

CR = Carriage return (ASCII control character)

LF = Line feed (ASCII control character)

When the command is received, the sensor will terminate

measurements and will respond with the following:

BAUD RATE 9600 after re-initialization CR LF

Please wait for the completion of configuration change save CR LF or

another value instead of 9600 as chosen.

The sensor will then resume normal operations after performing a

complete power up self-test. The next command character must be at the

new baud rate. The character framing will remain 8 data bits, no parity,

one start and stop bit. The new operating state will be maintained

through power cycles in the non-volatile memory.

VFIRMWARE Command

This command is used to invoke firmware downloads. The command

format is:

WFIRMWARE CR LF

40 ______________________________________________________________________________

Page 43

Chapter 4 ________________________________________________________________ Operation

The sensor will stop the current measurement activity when it receives

this command, and will respond with

PASSWORD? CR LF

At this time, the sensor will expect the password in capital letters and

CR LF in caps to be typed. If the password is not correct, the command

will be terminated unsuccessfully with the response string:

INVALID PASSWORD CR LF

and normal operation will resume.

If the password is entered correctly, the sensor will respond with:

READY FOR FIRMWARE CR LF

At this time, the host computer must send the firmware to the sensor in

a standard Intel hex format. Flow control must be accomplished by the

host holding off the next record until the echo of the current record is

completely and successfully received. The host may send complete

records without waiting character by character for the echo check. The

host will perform error recovery by checking each character in the

record echo against what was sent. The host must repeat records with

errors. The sensor will perform the power on a initialization sequence

once the firmware download completes.

For firmware v2.04 and above, downloading new firmware will not

modify any calibration information already saved in the sensor if this

calibration information is still meaningful to the new firmware. Observe

the power on initialization message following the firmware download.

If the new firmware requires the calibration operations to be repeated,

the following message will be displayed:

WARNING, SENSOR IS UNCALIBRATED. PERFORM CALIBRATION

BEFORE USE.

If this message does not appear prior to the ready indication, you may

assume the sensor calibration remains intact.

WA Command

This command requests the averaged wind speed and direction message

with peak winds. The command format is:

WA CR LF

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

The sensor response to the WA command consists of the averaged wind

speed and direction data, peak wind speed, and associated direction.

The average wind speed is a scalar running average of the fundamental

one second interval wind speed measurement made by the sensor. The

average direction is a unit vector running average over the same run

length set with the WJ command. The peak wind speed is the largest

scalar running average wind speed during the number of seconds before

the command set by the WJ command for average wind. The peak wind

run interval is also set in the WJ command. The peak wind direction is

the running unit vector average direction calculated at the same time the

peak speed was found.

The command also indicates the sensor status, the averaging time for

average and peak wind speed and wind direction and signal quality,

which shall be a numeric value from 0 to 99 representing the data

quality of processed data samples during the averaging interval. For

example, a value of 99 would signify that all data samples were

determined to be valid and were processed during the averaging

interval. If some samples were determined to be "missing", these

samples would not be processed and the reported signal quality would

be a proportional value less than 99.

Example of the WA Command Message

The following is an example of the message from the wind sensor for

the WA command:

WAP2131870503012.6014.7K99xx

Table 4 Explanation of the WA Command Message

Byte Description Value

1 Start of text STX

2 Sensor ID W

3 Command identifier A

4 Sensor status (notes b, c) P/F/H

5-7 Averaged wind direction (degrees) 213

8-10 Wind direction (degrees) @ peak wind speed 187

11-12 Averaging time for wind speed an d direction

(seconds)

13-14 Averaging time for peak wind speed and

direction (seconds)

15-19 Averaged wind speed 012.6

20-24 Peak wind speed since last WA command 014.7

25 Wind speed units (knots) K

05

03

42 ______________________________________________________________________________

Page 45

Chapter 4 ________________________________________________________________ Operation

Table 4 Explanation of the WA Command Message

Byte Description Value

26-27 Signal quality 99

28-29 Hex checksum (note a) xx

30 End of text ETX

31 Carriage return CR

32 Line feed LF

Notes:

1. Bytes 28-29 are the modulo 256 hexadecimal checksum of the

ASCII values calculated for bytes 2 through 27.

2. Sensor response message status byte in all applicable messages

reporting a sensor status, the status byte (byte 4) indicates the

following: P (Pass) indicates that all diagnostic tests have passed

and the sensor is functioning normally. F (Fail) indicates that one

or more of the diagnostic tests have failed. The user can then

request diagnostics and extended tests (WD) to further isolate the

problem. H (Heater failure) indicates that the wind reading is valid

but one or more built-in heater diagnostic tests have failed.

3. When the status byte is F, the wind direction fields are set to 999

and the wind speed fields are set to 999.9 in the applicable sensor

response messages. This does not apply to the WF command

response.

WL Command

This command sets the heater function to be automatically controlled by

the sensor. The command format is:

WL CR LF

The sensor response to the WL command indicates the status of heater

control after execution. In this mode the sensor automatically controls

the operation of the transducer heaters, based on an internal sensor

algorithm.

The response to this command is the following:

Heaters on automatic control CR LF

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

WM Command

This command locks the heater function ON. The command format is:

WM CR LF

The sensor response to the WM command indicates the state of the

transducer heaters after execution. In this mode the heater has been

energized by the external command.

The response to this command is the following:

Heater control locked ON CR LF

The command will energize the array heater circuit. The heaters will

remain on until the power supply watch dog circuit disables them (three

seconds later) to prevent damage to the sensor from overheating. The

normal operation is reset by either the WM or WL command, or cycling

sensor power. Note that the watch dog circuit will lock the heaters off if

the command is not undone.

WN Command

This command locks the heater function OFF. The command format is:

WN CR LF

The sensor response to the WN command indicates the state of the

transducer heaters after execution. In this mode the heater has been deenergized by the external command.

Notes:

1. The WL, WM, or WN commands override the previously

executed heater control command.

2. On sensor power-up and after the WR command, the heater control

function is initialized in the automatic mode (WL).

The response to this command is the following:

Heater control locked off CR LF

The command will cause the sensor to turn all heating control circuits

off, disabling heating. This state will remain until either the WR or WM

command is issued, or the sensor power is cycled.

44 ______________________________________________________________________________

Page 47

Chapter 4 ________________________________________________________________ Operation

WS Command

This command requests the verbose Built-In Test (BIT) results. The

command format is:

WS CR LF

The command gives a textual run down of the results of all Built-In

Tests (BITs). In every line except the bad reading counter, the pass/fail

indication is given with the single character P or F. This is followed by

the description of the parameter measured, which is followed by the

actual measured value. The Bad 1 second readings counter is a running

total of the number of fundamental 1 second readings that were flagged

as bad by the sensor. This number rolls over to zero after reaching a

count value of 65535. It is initialized to zero on each power-up or any

other activity that performs a re-initialization of the sensor.

The time measurement quality indices are given for path numbers

defined as follows:

- Path 0 is from south transducer to north transducer

- Path 1 is from north transducer to south transducer

- Path 2 is from north transducer to east transducer

- Path 3 is from east transducer to north transducer

- Path 4 is from east transducer to south transducer

- Path 5 is from south transducer to east transducer

A listing for the command response is given below with representative

values.

CR LF

P Heater voltage 22.3 Volts CR LF

P Array heater resistance 4.9 Ohms CR LF

P Heaters off voltage 0.1 Volts CR LF

P Incoming supply voltage 12.2 Volts CR LF

P 5.0 volt supply 5.05 Volts CR LF

P 10 volt supply 10.2 Volts CR LF

- Bad 1 second reading counter 0 CR LF

P Path 0 signal quality index 99 CR LF

P Path 1 signal quality index 99 CR LF

P Path 2 signal quality index 99 CR LF

P Path 3 signal quality index 99 CR LF

P Path 4 signal quality index 99 CR LF

P Path 5 signal quality index 99 CR LF

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

The test limits for the various tests are as listed below:

- Heater voltage good in range 18.0 to 26.0 V

- Array heater resistance good in range 4.0 to 6.0 Ω

- Heaters off voltage good if below 0.5 V

- Incoming supply voltage good in range 10.5 to 13.5 V

- 5.0 V supply good in range 4.5 to 5.5 V

- 10 V supply good in range 9.0 to 11.0 V

- Signal Quality Index good above 50

WJ Command

This command sets the averaging time for wind speed and direction,

and peak wind speed and direction. The command format is:

WJ CR LF

The sensor prompts for averaging time of one to thirty seconds for wind

speed and direction and then for peak wind speed and direction.

Example:

Wind speed/direction averaging time = ?

At which time user enters selection in seconds followed by CR LF

Peak wind speed/direction averaging time = ?

At which time user enters selection in seconds followed by CR LF

The sensor will then respond with

Changes will start after re-initialization CR LF

Please wait for completion of configuration change save CR

LF

The sensor will perform an automatic re-initialization after saving

changes in non-volatile memory.

Any invalid parameter entry will result in a termination of the command

and resumption of normal operations after the response below is issued.

CR LF Command response error, operation terminated CR LF

46 ______________________________________________________________________________

Page 49

Chapter 4 ________________________________________________________________ Operation

WD Command

This command reports the status of the BITs. The command format is:

WD CR LF

The command is intended to be sent by the host system to get a concise

report on the pass/fail status of all Built-In Tests. The response is the

following:

STX WD PPPPPPPPPPPP CS ETX CR LF

where

STX = ASCII start of test control character (position 1)

WD = command identifier (positions 2,3)

P or F = Pass/Fail for 12 built in tests specified in WS command

above in the order shown in the WS command text

(positions 4-15).

CS modulo 256 hexadecimal checksum of all characters from

position 2 through the last P or F (positions 16,17)

ETX ASCII end of text control character (position 18)

CR ASCII carriage return control character (position 19)

LF ASCII line feed control character (position 20)

For a complete order, description and test limits for each pass/fail status

reported, see section WS Command on page 45.

WF Command

The command format is:

WF CR LF

The WF command returns a fixed pattern of data. This command is

typically used to verify the communications link. The data fields are

fixed at the following values:

Status = F

Wind direction = 678

VAISALA_______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

Peak wind direction = 567

Wind averaging time = 21

Peak wind averaging time = 09

Wind speed = 876.5

Peak wind speed = 432.1

Example of the WF Command Message

The following is an example of the output from the sensor for the WF

command:

WFF6785672109876.5432.1K99xx

Table 5 Explanation of the WF Command Message

Byte Description Value

1 Start to text STX

2 Sensor ID W

3 Command identifier F

4 Sensor status F

5-7 Fixed wind direction 678

8-10 Fixed peak wind direction 567

1 1-12 Averaging time for wind speed and direction 21

13-14 Averaging time for peak wind speed and

direction

15-19 Fixed wind speed 876.5

20-24 Fixed peak wind speed 432.1

25 Wind speed units K

26-27 Signal quality 99

28-29 Hex checksum xx

30 End of text ETX

31 Carriage return CR

32 Line feed LF

09

WR Command

This is the system reset command. The command format is:

WR CR LF

48 ______________________________________________________________________________

Page 51

Chapter 4 ________________________________________________________________ Operation

The WR command initiates a system reinitialization. The processor

executes the initialization routine and returns the initialization message

(firmware revision, sensor status).

The response to the WR command contains the following:

ASOS Ice-Free Wind Sensor CR LF

Manufactured by Vaisala USA Inc. CR LF

Model number WAS 425NWS

Firmware version 2.01 CR LF

Initializing ….CR LF

Ready CR LF

Status = P/F/H CR LF (only the correct status will be

presented)

The sensor performs a system reset and issues the system reset

command message upon sensor power-up.

The user should hold off sending commands until the full response is

received. This may take up to 30 seconds.

WATE Command

This command invokes the sensor test with reduced excitation

amplitude. The command format is:

WATE CR LF

The purpose of the WATE command is to determine the sensor zero

offset and verify that a sufficient signal-to-noise margin exists during

high wind speeds.

The WATE command returns the sensor Signal Quality Index (SQI)

measurement with a reduced signal amplitude. This command exists in

sensor firmware versions v4.00 and above. The command is enhanced

in sensor firmware versions v4.50 and above.

This command is typically used to verify the sensor performance during

the preventive maintenance procedures. The sensor will stop the current

measuring when it receives this command. After this, the transducer

excitation amplitude is reduced followed by a time delay in order to

clear the measurement buffers. The sensor will perform 30 test

measurements in a loop with a reduced amplitude signal. To run

command takes about 5 minutes. At the end of the WATE test, the

sensor will perform a full reset when returning to normal operation.

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

The WATE command is used in conjunction with the zero wind speed

verifier. If the test is performed outdoors, the supplied cloth bag must

be placed over the verifier to eliminate the effect of any ambient wind.

See Figure 18 on page 68. It is extremely important that the WATE

command is performed only when the verifier is installed on the sensor.

Performing the test without the verifier (and bag if required) will

produce anomalous test results and it is not a valid test. After the verifier

is installed on the sensor, it is necessary to wait five minutes before

performing the test. The five-minute waiting period is needed for the

temperature of the verifier interior to equalize without thermal

gradients.

The response to the WATE command is the following:

Performing amplitude test...

Measuring at level 48% (1)

.

.

.

Measuring at level 48% (30)

WAXXXXXX0503XXX.XXXX.XXKXXXX

P Heater voltage XX.X Volts

P Array heater resistance X.X Ohms

P Heaters off voltage X.X Volts

P Incoming supply voltage XX.X Volts

P 5 volt supply X.XX Volts

P +10 volt supply XX.X Volts

- Bad 1 second reading counter = X

P Path 0 signal quality index XX

P Path 1 signal quality index XX

P Path 2 signal quality index XX

P Path 3 signal quality index XX

P Path 4 signal quality index XX

P Path 5 signal quality index XX

Wait for reset...

ASOS Ice-Free Wind Sensor

Manufactured by VAISALA USA INC.

Model number 425 NWS

Firmware version v4.50

Internal version v4.00

Initializing...

Ready

Status=P

To pass the WATE command, the sensor response must meet two

conditions:

50 ______________________________________________________________________________

Page 53

Chapter 4 ________________________________________________________________ Operation

1. The wind speed in this WA message must be equal or smaller than

1.0 knots.

2. The SQI value for each measurement path must be equal or higher

than 90. The average from the individual SQI values must be equal

or higher than 95.

Other parameter test limits are the same as with the WS command.

In typical operation, the WATE command is executed incorporation

with WA command via the WATE test of the Diagnostics Program as

explained in section Preventive Maintenance on page 67.

WCAL Command

This is the sensor self calibration command. The command format is:

WCAL CR LF

This command is to be used in conjunction with the zero wind speed

verifier and in addition, the provided bag if the operation is done

outdoors. It is extremely important that it will only be performed while

the verifier is installed on the sensor. Should it ever be performed

accidentally without the verifier, be sure to redo this command with the

verifier installed prior to the deployment. One of the command

functions is to determine the sensor zero offset and save parameters to

remove it. If the sensor is calibrated in the presence of ambient wind or

even air conditioning flow in the office environment, an invalid zero

offset compensation will result. The verifier by itself is able to keep

indoor air conditioning from affecting the calibration, but not outdoor

airflow. If the sensor is to be calibrated outdoors, you must cover the

verifier completely with the provided bag with drawstrings snug after

placing the verifier over the sensor. This command also performs

measurements that will improve sensor accuracy.

The sensor will stop the current measurement activity when it receives

this command, and will prompt for password. If the password is entered

correctly, the sensor will respond with the following:

CAUTION – Anemometer calibration MUST ONLY be performed

with Vaisala Verifier and bag in place on the anemometer.

Do you wish to proceed? (Y/N)

At this time, the operation may be aborted by responding with N. Do not

respond with Y unless the verifier and bag are already in place. If the

response is Y, the sensor will respond with the following:

VAISALA_______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

Calibration in progress CR LF

When the calibrate function completes successfully, the sensor response

will be the following:

Calibration successful, saving parameters CR LF

The sensor will save the parameters calculated in the non-volatile

memory. After the save completion, the sensor will perform a complete

power on the initialization sequence.

If the sensor returns the following response

Calibration failed CR LF

either the sensor or the zero wind speed verifier is broken. Issue the WS

command to determine if any self tests have detected a sensor failure

after removing the verifier and then waiting for 30 seconds. If the tests

fail, the sensor must be repaired.

WH Command

This command displays the sensor command Help menu. The command

format is:

WH CR LF

The WH command provides a list of all commands available for the

sensor, with a brief description of syntax, arguments (if any), and

description. This message is intended for display to a terminal

connected to the RS-232 sensor port.

Command/Response Summary CR LF

CR LF

WA Return average wind speed and direction CR LF

Response format:

CR LF

Byte 1: STX CR LF

Byte: 2 Sensor ID = W CR LF

Byte: 3 Command identifier CR LF

Byte: 4 Sensor Status: P = PASS, F = Failed,

H = Bad heater CR LF

52 ______________________________________________________________________________

Page 55

Chapter 4 ________________________________________________________________ Operation

Byte 5-7: Average wind direction (degrees) CR

LF

Bytes 8-10: Wind direction at peak wind speed

(degrees) CR LF

Bytes 11-12: Averaging time for wind speed and

direction CR LF

Bytes 13-14: Averaging time for peak wind speed

and direction CR LF

Bytes 15-19: Average wind speed CR LF

Bytes 20-24: Peak wind speed CR LF

Byte 25: Wind speed units (K = knots) CR LF

Byte 26-27: Signal quality CR LF

Bytes 28-29: Hex checksum CR LF

Byte 30: ETX CR LF

Byte 31: Carriage return CR LF

Byte 32 Line feed CR LF

WL Enable automatic heater control CR LF

WM Lock heaters on CR LF

WN Lock heaters off CR LF

WS Description of BIT status CR LF

WJ Set averaging times for wind speed/direction and peak

wind speed/direction CR LF

Enter password when prompted, then selections to the

following prompts CR LF

Wind speed/direction averaging time = ? CR LF

Peak wind speed and direction averaging time = ? CR LF

WD Perform and report extended diagnostic tests CR LF

WF Return fixed data in WA command format CR LF

WR Reset sensor CR LF

WCAL Perform Sensor Self Calibration CR LF

WH Display this help menu CR LF

VAISALA_______________________________________________________________________ 53

Page 56

User's Guide ______________________________________________________________________

WT Command

This command requests the short response BIT results and status. The

command format is:

WT CR LF

This command is an abbreviated version of the verbose BIT results and

status command. Field descriptors are omitted and only pass/fail status

and measured value are reported. The command response is packed in

the standard STX – body – CSUM – ETX format. The response is

shown below.

Byte 1: STX start of text ASCII control character

Byte 2: W sensor ID

Byte 3: T command identifier

Byte 4: P or F for heater voltage pass or fail

Byte 5-8: XX.X format heater voltage (volts RMS)

Byte 9: P or F for array heater resistance pass or fail

Byte 10-12: X.X or XX. (format as required) for array heater

resistance (ohms)

Byte 13: P or F for pass or fail on heater off voltage

Byte 14-16: X.X format heater off voltage (volts RMS)

Byte 17: P or F for pass or fail thermistor temperature

Bytes 18-20: Thermistor temperature (degrees Celsius)

Byte 21: P or F for incoming supply voltage pass or fail

Byte 22-25: XX.X format incoming supply voltage (volts DC)

Byte 26: P or F for 5 volt supply pass or fail

Bytes 26-29: X.XX format 5 volt supply voltage (volts DC)

Byte 30: P or F for 10 volt supply pass or fail

Bytes 31-34: XX.X format 10 volt supply voltage (volts DC)

Byte 35: ASCII hyphen character (-)

Bytes 36-40: XXXXX format bad 1 second reading counter

Byte 41: P or F for path 0 Signal Quality Index pass or fail

Bytes 42-43: XX format path 0 Signal Quality Index

Byte 44: P or F for path 1 Signal Quality Index pass or fail

54 ______________________________________________________________________________

Page 57

Chapter 4 ________________________________________________________________ Operation

Bytes 45-46: XX format path 1 Signal Quality Index

Byte 47: P or F for path 2 Signal Quality Index pass or fail

Bytes 48-49: XX format path 2 Signal Quality Index

Byte 50: P or F for path 3 Signal Quality Index pass or fail

Bytes 51-52: XX format path 3 Signal Quality Index

Byte 53: P or F for path 4 Signal Quality Index pass or fail

Bytes 54-55: XX format path 4 Signal Quality Index

Byte 56: P or F for path 5 Signal Quality Index pass or fail

Bytes 57-58: XX format path 5 Signal Quality Index

Bytes 59-60: XX hexadecimal ASCII for modulo 256 checksum

for

Character positions 2 through 58

Byte 61: ETX end of text ASCII control character

Byte 62: ASCII carriage return control character

Byte 63: ASCII line feed control character

The array heater resistance value will be missing (99.) if either the

heater on voltage is below 10 V RMS or the array heater on current is

below 1 A RMS.

WSST Command

This command returns the static speed of sound and sonic temperature.

The command format is:

WSST CR LF

The command responds with a return string containing the measured

static speed of sound in knots with a tenth of a knot resolution, followed

by an ASCII TAB control character, then the corresponding sonic

temperature in degrees Fahrenheit with a tenth of a degree resolution.

The return string is terminated with an ASCII carriage return and then

line feed character. No descriptive text is included. The sonic

temperature is not compensated for the effects of humidity on the static

speed of sound. The static speed of sound output is a ten second running

average of individual static speed of sound measurements calculated

each second. The sensor calculates a new sonic temperature from this

running average of static speed of sound each second. The sensor

VAISALA_______________________________________________________________________ 55

Page 58