Page 1

M212438EN-C

User Guide

Sanitary Process Refractometer

PR-43-AC/AP

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala Oyj 2020

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

Page 3

Table of contents

Table of contents

1. About this document.....................................................................................5

1.1 Version information..........................................................................................5

1.2 Related manuals................................................................................................5

1.3 Documentation conventions........................................................................... 5

1.4 Trademarks........................................................................................................6

2. Product overview............................................................................................ 7

2.1 Vaisala Sanitary Process Refractometers PR‑43‑AC and PR‑43‑AP...........7

2.2 Safety..................................................................................................................7

3. Installation..........................................................................................................9

3.1 Choosing mounting location........................................................................... 9

3.2 Checklist for pipe mounting............................................................................ 9

3.3 Checklist for mounting in tank, vessel or large pipe...................................10

3.4 Mounting guide.................................................................................................11

3.5 Electrical connections.....................................................................................12

4. Prism wash........................................................................................................16

4.1 Prism coating...................................................................................................16

4.2 Prism wash.......................................................................................................16

4.2.1 Recommended wash pressures and times............................................17

4.2.2 Prism wash systems.................................................................................18

4.2.3 Prism wash nozzles................................................................................. 22

5. Technical data................................................................................................ 25

5.1 Compatibility...................................................................................................25

5.2 Refractometer rangeability........................................................................... 25

5.3 Sanitary process refractometer PR-43-AC..................................................25

5.3.1 PR-43-AC model code............................................................................26

5.3.2 PR-43-AC mounting hardware model code.........................................28

5.3.3 PR-43-AC specifications.........................................................................32

5.3.4 PR-43-AC parts list................................................................................. 34

5.3.5 PR-43-AC mounting specifics................................................................37

5.3.6 Mounting specifics for EHEDG certified PR-43-AC configuration....44

5.3.7 3-A Sanitary Standard compliance.......................................................44

5.4 Sanitary process refractometer PR-43-AP................................................. 46

5.4.1 PR-43-AP model code............................................................................ 47

5.4.2 PR-43-AP mounting hardware model code........................................ 49

5.4.3 PR-43-AP specifications........................................................................ 50

5.4.4 PR-43-AP parts lists................................................................................52

5.4.5 PR-43-AP mounting specifics................................................................55

5.4.6 Mounting specifics for EHEDG certified PR-43-AP configuration.... 58

5.4.7 3-A Sanitary Standard compliance.......................................................59

Appendix A:

Refractometer verification.................................................. 60

1

Page 4

PR-43-AC/AP User Guide M212438EN-C

Appendix B: PR-43 refractometer verification form..............................62

Appendix C: EU declaration of conformity..............................................63

Warranty............................................................................................................65

Technical support............................................................................................65

Recycling...........................................................................................................65

2

Page 5

List of figures

Figure 1 Refractometer models..................................................................................... 7

Figure 2 PR-43-AC and PR-43-AP mounting guide.................................................11

Figure 3 The M12 connector...........................................................................................12

Figure 4 Connecting refractometer cable to refractometer.................................13

Figure 5 Wiring with analogue output only.............................................................. 13

Figure 6 Wiring options with both analogue and digital outputs...................... 14

Figure 7 Wiring options with both analogue and digital outputs

and RJ45 ethernet connector.......................................................................14

Figure 8 Connections in M12 and RJ-45 connectors...............................................15

Figure 9 Prism wash system for steam.......................................................................19

Figure 10 Wiring for prism wash system for steam................................................. 20

Figure 11 Prism wash system for high pressure water.............................................21

Figure 12 Wiring for prism wash system for high pressure water........................22

Figure 13 Wash nozzles for flowcell AFC-HSS-XXX-XX-NC................................... 22

Figure 14 Process connection of wash nozzle in flowcell.......................................24

Figure 15 PR-43-AC rangeability...................................................................................25

Figure 16 PR-43-AC dimensions....................................................................................26

Figure 17 Refractometer cover assembly................................................................... 34

Figure 18 PR-43-AC assembly....................................................................................... 36

Figure 19 Mounting with sanitary ferrule, pipe diameter 80 mm

(3 in) or more....................................................................................................37

Figure 20 Flow cell AFC-HSS-H10 for pipe diameter 25 mm (1 in)

and H15 for pipe diameter 40 mm (1.5 in)................................................38

Figure 21 Flow cell AFC-HSS- with wash nozzle connection (-NC)

H10 for pipe diameter 25 mm (1 in) and H15 for pipe

diameter 40 mm (1.5 in)................................................................................39

Figure 22 Flow cell AFC-HSS-H20 for pipe diameter 50 mm (2 in)

and H25 for pipe diameter 65 mm (2.5 in)..............................................40

Figure 23 Flow cell AFC-HSS- with wash nozzle connection (-NC)

H20 for pipe diameter 50 mm (2 in) and H25 for pipe

diameter 65 mm (2.5 in)................................................................................ 41

Figure 24 Side flow cells.................................................................................................. 42

Figure 25 I-Line fitting for PR-43-AC........................................................................... 43

Figure 26 Mounting with sanitary ferrule, pipe diameter 80 mm

(3 in) or more EHEDG certified configuration........................................ 45

Figure 27 Dimensions of an inserted refractometer PR-43-AP-H25-L170........ 46

Figure 28 Flush mounted refractometer PR-43-AP-T10-L00................................47

Figure 29 Refractometer cover assembly....................................................................52

Figure 30 PR-43-AP assembly....................................................................................... 54

Figure 31 Insertion of probe refractometer PR-43-AP-H25.................................. 56

Figure 32 Flush mounting probe refractometer PR-43-AP-T10-L100.................57

Figure 33 I-Line fitting for PR-43-AP............................................................................58

Figure 34 EHEDG certified PR-43-AP...........................................................................59

Figure 35 Universal sample holder PR-1012............................................................... 60

List of figures

3

Page 6

PR-43-AC/AP User Guide M212438EN-C

List of tables

Table 1 Document versions (English)...........................................................................5

Table 2 Related manuals.................................................................................................. 5

Table 3 Wash medium parameters for integral wash nozzles in PR-43-AP......17

Table 4 Wash medium parameters for flowcell wash nozzle AFC.......................17

Table 5 Flowcell -H10 or -H15........................................................................................23

Table 6 Flowcell -H20 or -H25......................................................................................23

Table 7 Flowcell -H30......................................................................................................23

Table 8 Flowcell -H40..................................................................................................... 23

Table 9 Prism wash nozzle selection.......................................................................... 24

Table 10 Sanitary compact refractometer for pipelines..........................................27

Table 11 Mounting hardware without wash nozzles................................................28

Table 12 EHEDG certified mounting hardware..........................................................28

Table 13 Mounting hardware with wash nozzles.......................................................29

Table 14 Mounting hardware, mini flow cell............................................................... 30

Table 15 Mounting hardware, Varivent DN65 connection......................................30

Table 16 Mounting hardware........................................................................................... 31

Table 17 PR-43-AC specifications..................................................................................32

Table 18 Refractometer cover assembly parts list....................................................34

Table 19 PR-43-AC assembly parts list........................................................................36

Table 20 I-Line fitting for PR-43-AC............................................................................. 43

Table 21 Mounting materials...........................................................................................45

Table 22 SANITARY PROBE REFRACTOMETER for large pipelines

and vessels..........................................................................................................47

Table 23 SANITARY PROBE REFRACTOMETER with prism wash

for large pipelines and vessels......................................................................49

Table 24 Mounting hardware for PR-43-AP refractometer....................................50

Table 25 PR-43-AP specifications.................................................................................50

Table 26 Refractometer cover assembly parts list....................................................52

Table 27 PR-43-AP assembly parts list........................................................................54

Table 28 Verification results display..............................................................................62

4

Page 7

Chapter 1 – About this document

1. About this document

1.1 Version information

This document provides instructions for installing and using the Vaisala K‑PATENTS® Sanitary

Process Refractometers PR‑43‑AC and PR‑43‑AP.

This product manual is delivered to the end user with a Vaisala K‑PATENTS® product.

Information in this manual is subject to change without notice. When the manual is changed, a

revised copy is published at www.kpatents.com.

Table 1 Document versions (English)

Document Code Date Description

M212438EN-C April 2020 Manual updated to new format, template, and document

IM‑EN‑PR43ACAP

2.00

IM‑EN‑PR43ACAP

1.12

September

2019

June 2018 IP rating updated.

1.2 Related manuals

code. Minor changes to content.

Changed K-Patents to Vaisala.

Table 2 Related manuals

Document Code Name

M212455EN Sanitary Process Refractometer PR-43 Series User Guide

IM-EN-MI Multichannel User Interface MI Instruction Manual

IM-EN-CI Compact User Interface CI Instruction Manual

IM-EN-PR43IAAX Process Refractometer PR-43-…-IA/AX/CU Instruction Manual

1.3 Documentation conventions

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

Warning alerts you to a serious hazard. If you do not read and

5

Page 8

PR-43-AC/AP User Guide M212438EN-C

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Indicates that you need to take some notes during the task.

Caution warns you of a potential hazard. If you do not read and

1.4 Trademarks

Vaisalaâ and K-PATENTS® are registered trademarks of Vaisala Oyj.

Linuxâ is a registered trademark of Linus Torvalds.

Windowsâ is either a registered trademark or trademark of Microsoft Corporation in the

United States and other countries.

Varivent® is a registered trademark of GEA Tuchenhagen GMBH.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

6

Page 9

Chapter 2 – Product overview

2. Product overview

2.1 Vaisala Sanitary Process Refractometers

PR‑43‑AC and PR‑43‑AP

The sanitary refractometers PR‑43‑AC and PR‑43‑AP provide a digital interface detection

system for alimentary industry.

The PR‑43‑AC/AP measures the refractive index nD and the temperature of the process

medium. The concentration of the process liquid is calculated from these values when the

composition of the process medium is known.

The output values of the refractometer are transmitted through mA output and digitally

through an Ethernet connection by using a UDP/IP protocol (for specification see PR-43

general manual). mA output is available with mA output cable (mA only) or with a split cable

(mA and Ethernet).

Figure 1 Refractometer models

2.2

Safety

This product has been tested for safety. Note the following precautions:

WARNING!

must adhere to local and state legislation and regulations.

Only licensed experts may install electrical components. They

7

Page 10

PR-43-AC/AP User Guide M212438EN-C

The process medium may be hot or otherwise hazardous. Use shields and protective clothing

adequate for the process medium. Do not rely on avoidance of contact with the process

medium.

Wear protective eyewear.

Wear protective gloves.

Precautions when removing a sensor from the process line :

• Check that the process line is depressurized and drained

• Loosen the flowcell screws cautiously; be prepared to tighten again

• Ensure you are clear of any possible spillage and you have a clear emergency escape path

8

Page 11

Chapter 3 – Installation

3. Installation

3.1 Choosing mounting location

The refractometer mounting location should be chosen with care to ensure reliable readings

from the process.

The mounting location needs to be such that sediments or gas bubbles cannot accumulate by

the refractometer. Good flow velocity is essential in keeping the prism clean.

CAUTION!

might damage the inline refractometer mounted on it.

A Vaisala K‑PATENTSâ inline refractometer can be located either indoors or outdoors in most

climates. However, when a refractometer is located outdoors, some basic protection against

direct exposure to sunlight and rain should be provided. Special care should be taken if the

pipe wall is translucent (e.g. of fiberglass), as light from outside reaching the prism through the

pipe wall may disturb the measurement.

The refractometer cover should not be exposed to high temperature radiation. In most cases,

draft and natural convection provide sucient air cooling if the air gets to flow freely around

the refractometer head.

Additional cooling is necessary when the ambient temperature is higher than 45 °C (113 °F) or

when the process temperature is above 110 °C (230 °F) and the ambient temperature is above

35 °C (95 °F). The air cooling is improved by blowing pressurized air against the refractometer

cover. The pressurized air can be supplied by the ventilation system. It is also possible to

mount a PR‑14038 cooling cover for cooling with water.

CAUTION!

points downwards from the refractometer head.

If the process pipe vibrates, support the pipe. A vibrating pipe

Always mount the refractometer so that the interconnecting cable

3.2 Checklist for pipe mounting

The PR‑43‑AC and PR‑43‑AP are mounted in a pipe. Vaisala recommends a flow velocity

between 1 and 3 m/s (3–10 ft/s). If the flow velocity exceeds 6 m/s (20 ft/s), there is a risk of

cavitation. Cavitation may damage the refractometer and the piping. Too slow a flow velocity

may cause erraneous measurement readings due to coating of stratification (layering) of the

sample on the prism.

The diameter and form of the pipe and the process temperature all aect the measurement

and need to be taken into account.

• If the process pipe diameter varies, select the position with the smallest diameter(and

accordingly highest velocity). Then the prism stays clean better.

9

Page 12

PR-43-AC/AP User Guide M212438EN-C

• If the refractometer is used in a feed-back control loop, make the time lag short. E.g. when

a dilution valve is controlled, mount the refractometer close to the dilution point.

However, make sure complete mixing has occurred at mounting location.

• If the temperature varies along the process pipe, select the position with the highest

process temperature. That minimizes the risk of coating, because higher temperature

means higher solubility and also lower viscosity.

• Often the position with the highest process pressure (= after pump + before valve) has

favorable flow conditions without sedimentation or air trapping risks.

• The refractometer should be conveniently accessible for service.

3.3 Checklist for mounting in tank, vessel or large pipe

A probe refractometer PR‑43‑AP can be inserted with a flange or clamp into tanks and vessels

which either don’t have a scraper or where the mixer doesn’t touch the vessel wall. A probe

refractometer can also be flush mounted in a cooker where the scraper touches the wall.

• The inserted probe refractometer is mounted close to a stirrer to ensure representative

sample of the process liquid and to keep the prism clean.

• The refractometer should be conveniently accessible for service.

10

Page 13

3.4 Mounting guide

Prevent outside light

Easy access

Easy access

High pressure

High temperature

High pressure

Small diameter

High temperature

High velocity >1.5m/s

(>5ft/s)

Upper pipe bend

Ambient air

cooling

Chapter 3 – Installation

Figure 2 PR-43-AC and PR-43-AP mounting guide

11

Page 14

PR-43-AC/AP User Guide M212438EN-C

3.5 Electrical connections

The refractometer has an M12 connector in the refractometer for power supply, mA output and

Ethernet connections.

Figure 3 The M12 connector

PR-43 refractometers are powered with 24 VDC. For connecting the refractometer to

Multichannel user interface MI, see the Instruction manual for Multichannel User Interface MI.

For connecting the refractometer to Compact user interface CI, see the Instruction manual for

Compact User Interface CI. See the following figure for instruction how to connect the M12

refractometer cable.

12

Page 15

Turn to tighten

Align groove and

guide

P4-031

Connector screw thread

PR-43 REFRACTOMETER

M-12-8 pin, A-code, M

non-Ex

max. 200m (656ft)

PR-8680

M12-8 pin, A-code, F

Field plug

PR-8432

Power supply and

mA output cable

F

Chapter 3 – Installation

Figure 4 Connecting refractometer cable to refractometer

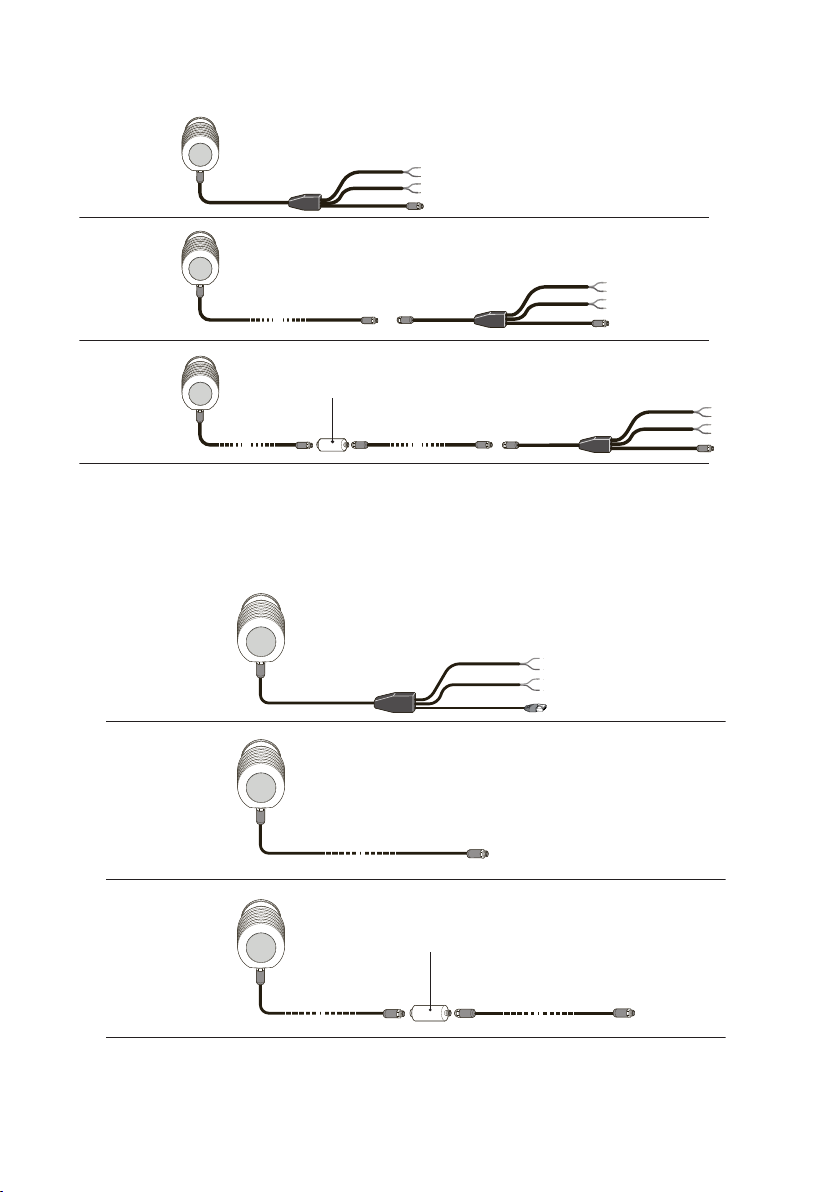

The PR-43 refractometer provides both analog (mA) and digital output signals. See the

following figure for the wiring when only analog output is used.

Figure 5 Wiring with analogue output only

The following figure shows the options for connecting the refractometer with both analog and

digital outputs. Both Compact user interface CI and Multichannel user interface MI use the

digital output signal.

13

Page 16

10m (33ft)

90m (295ft)

180m (590ft)

PR-43 REFRACTOMETER

M-12-8 pin, A-code, M

non-Ex

PR-43 REFRACTOMETER

M-12-8 pin, A-code, M

non-Ex

PR-43 REFRACTOMETER

M-12-8 pin, A-code, M

non-Ex

max. 90m (295ft) max. 90m (295ft)

max. 90m (295ft)

10m (33ft)

PR-8430

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8430

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8430

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8660

Platform 4 cable extender

M12-8 pin, A-code, F+M

PR-8431

Split cable M12

M12-8 pin, A-code, F

Ethernet (M12-4 pin, D-code,M)

mA, 24V

PR-8431

Split cable M12

M12-8 pin, A-code, F

Ethernet (M12-4 pin, D-code,M)

mA, 24V

1m (3ft)

PR-8431

Split cable M12

M12-8 pin, A-code, F

Ethernet (M12-4 pin, D-code,M)

mA, 24V

1m (3ft)

M

M M

M MM

F

F

F

F

F F

10m (33ft)

90m (295ft)

180m (590ft)

PR-43

REFRACTOMETER

M-12-8 pin, A code, M

Unclassied area

max. 90m (295ft) max. 90m (295ft)

max. 90m (295ft)

PR-8430-___

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8430-___

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8430-___

Platform 4 cable

M12-8 pin, A-code, F+M

Ethernet, mA, 24V

PR-8660

Platform 4 cable extender

M12-8 pin, A-code, F+M

PR-8444-001/010

Split cable M12

M12-8 pin, A-code, F

Ethernet (RJ 45)

mA, 24V

1m (3ft) or 10m (33ft)

M

MM

F

F

F

F

PR-43

REFRACTOMETER

M-12-8 pin, A code, M

Unclassied area

PR-43

REFRACTOMETER

M-12-8 pin, A code, M

Unclassied area

PR-43-AC/AP User Guide M212438EN-C

Figure 6 Wiring options with both analogue and digital outputs

The following figure shows the wiring options when both analogue and digital outputs are

used, with RJ45 ethernet connector.

Figure 7 Wiring options with both analogue and digital outputs and RJ45 ethernet connector

14

Page 17

Chapter 3 – Installation

Figure 8 Connections in M12 and RJ-45 connectors

In split cables the power cable and the mA output cable are marked near the end of the cable.

Power cable:

• White: +24DC

• Brown: GND

mA output cable:

• White: mA+

• Brown: mA-

15

Page 18

PR-43-AC/AP User Guide M212438EN-C

4. Prism wash

Prism wash requires a system for wash control and diagnostics. This can be achieved with

Multichannel user interface (MI) with a relay module.

4.1 Prism coating

Deposit build-up on the prism surface disturbs the measurement. Anabnormally high

concentration reading, an upward concentration (CONC) drift, decreased QF value or increased

LED value may indicate coating.

In most applications the prism will keep clean due to the self-cleaning eect. If coating occurs,

check the following:

• Sucient flow velocity

• A temperature dierence between the process fluid and refractometer probe may cause

coating. This may happen with small flows if the thermal insulation is inadequate. In some

cases it helps to also insulate the clamp connector.

In case of a coating problem, the preferred solution is to try to increase the flow velocity, for

example, by installing a pipe portion with smaller diameter.

Installing a wash nozzle can be considered, if increasing the velocity does not provide a

solution. For more information, see Prism wash (page 16).

4.2

Prism wash

Three alternative wash media can be used for prism wash:

• Steam

• Water

• High pressure water

Relay modules in a Multichannel user interface MI can be configured to control the prism wash

cycle, see MI manual, Chapter 6, "Module cards" and Chapter 7, "Prism wash".

CAUTION!

culinary steam or safe water. Shut-o valve and check valve must meet 3-A

sanitary standards.

Culinary steam: Means steam produced using a system meeting criteria in the 3-A Accepted

Practices for a Method of Producing Steam of a Culinary Quality, Number 609.

Safe Water: Means water from a supply properly located, protected, and operated, and shall be

of safe, sanitary quality. The water shall meet the standards prescribed in the National Primary

Drinking Water Regulation of the Environmental Protection Agency (EPA) as referenced in The

Code of Federal Regulations (CFR), Title 40, Parts 141, 142, and 143.

16

Important: In food industry applications, wash medium must be

Page 19

4.2.1 Recommended wash pressures and times

The following tables provide the recommended wash pressures and times.

Table 3 Wash medium parameters for integral wash nozzles in PR-43-AP

Chapter 4 – Prism wash

Minimum above

process pressure

Maximum above

process pressure

Wash

time

RecoveryInterval

Steam (SN) 2 bar (30 psi) 4 bar (60 psi) 3 s 20 ‑ 30 s 20 ‑ 30

min

Water (WN) 2 bar (30 psi) 4 bar (60 psi) 10 s 20 ‑ 30 s 10 ‑ 20 m

in

High pressure water

(WP)

15 bar (220 psi) 40 bar (600 psi) 10 s 20 ‑ 30 s 10 ‑ 20 m

in

Table 4 Wash medium parameters for flowcell wash nozzle AFC

Minimum above

process pressure

Maximum above

process pressure

Wash

time

RecoveryInterval

Steam (SN) 3 bar (45 psi) 6 bar (90 psi) 3 ‑ 5 s 20 ‑ 30 s 20 ‑ 30

min

Water (WN) 3 bar (45 psi) 6 bar (90 psi) 10 ‑ 15 s 20 ‑ 30 s 10 ‑ 20 m

in

High pressure water

(WP)

CAUTION!

25 bar (350 psi) 35 bar (500 psi) 10 ‑ 15 s 20 ‑ 30 s 10 ‑ 20 m

in

In steam wash, do not exceed the recommended wash times,

because some process media may burn to the prism surface if steamed for

longer time. In case of coating, shorten the wash interval.

In water wash, water temperature should be above the process temperature.

The check valve pressure drop is 0.7 bar (10 psi).

17

Page 20

PR-43-AC/AP User Guide M212438EN-C

4.2.2 Prism wash systems

WARNING!

closed pipe section when the high pressure pump is operated. It is

recommended to mount a pressure relief valve in the pipe section. Relief

pressure should be according to pipe pressure rating.

The following figures describe the prism wash system for steam.

In high pressure wash systems, pressure increase can occur in a

18

Page 21

Chapter 4 – Prism wash

Figure 9 Prism wash system for steam

19

Page 22

PR-43 REFRACTOMETER

(1-4 pcs.)

1 2 3 4 5

6 7

8

SAFETY SWITCH

PR-7060

MULTI CHANNEL USER INTERFACE MI

RELAY OUTPUT

MODULE PR-50023

mA-OUTPUT MODULE

PR-50021

2122 2324

RELAY1RELAY

2

mA

+ 2 -

11

mA

+ 1 -

1512 16

SOLENOID VALVE FOR

PNEUMATICALLY OPERATED

SHUT-OFF VALVE ASSEMBLY:

PR-3340-24/110/240

INSTRUMENTS

M12 CONNECTORS

L N N L L L

NL

POWER SUPPLY VOLTAGE

110VAC/230VAC/24VDC

FUSE 10A

L N

MAINS POWER

SWITCH PR-10900

L

N

+

-

mA Output 1

4-20mA

POWER SUPPLY

100-240VAC/50-60Hz

3894

9

PR-8430

Platform 4 cable

L

N

+

-+

OPTIONAL 24V POWER

SUPPLY FOR MI

24VDC

ETHERNET M12

ETHERNET

M12-8pin, D-code, M

PR-8440 Ethernet cable for interfaces

MAINS POWER

SWITCH PR-10900

PR-43-AC/AP User Guide M212438EN-C

Figure 10 Wiring for prism wash system for steam

The following figures describe the prism wash system for high pressure water.

20

Page 23

1

7

3

4

8

9

10

11

5

12

6

2

7

Water supply min 10l/min( 2.5gal/min)

Max temp. 60°C (140°F).

Safe water for sanitary use.

13

14

3892

No. Descrip�on Supplied by Qty

1 PR-43 refractometer K-Patents 1

2 Mulchannel user interface K-Patents 1

3 Power relay unit PR_3603-300-U/M-230/110 K-Patents 1

4 Plaorm 4 cable PR-8430 K-Patents 1

5 Relay cable 3x1 (AWG 17) Customer 1

6 Power supply for MI Customer 1

6.1 Power supply 100-240 VAC/50-60 Hz

6.2 Power supply 24V DC

7 Water supply line min. 12 mm (1/2") C ustomer 1

8 High pressure pump PR-3602-XXX K-Patents 1

9 Solenoid cable 3x1 (AWG 17) Customer 1

10 Power cable 4x2.5 (AWG 12) Customer 1

11 Power supply 400-575 VAC/50-60

Hz Customer 1

12 Mains power switchy PR-10900 K-Patents 1

13 mA output cable Customer 1

14 Ethernet cable for interface PR-8840 Customer 1

Chapter 4 – Prism wash

Figure 11 Prism wash system for high pressure water

21

Page 24

PR-43 REFRACTOMETER

(1-4 pcs.)

SUPPLY VOLTAGE

110VAC FUSE 10A

230VAC FUSE 10A

L N

LL

L

N

NL

SOLENOID VALVE

FOR WATER INLET

POWER RELAY UNIT

PR-3603-____

11

10987654

12

31N2

T1T2T3

T3T1T2

MAINS

SWITCH

THERMAL

OVERLOAD

RELAY

L1

L2L3

N

L3

L1

L2

SUPPLY VOLTAGE

400/550VAC FUSE 10A

HIGH PRESSURE PUMP

L

MAINS POWER

SWITCH PR-10900

PR-8440 Ethernet cable for interfaces

ETHERNET

M12-8pin, D-code, M

ETHERNET M12

24VDC

OPTIONAL

24V POWER

SUPPLY FOR MI

+ -

+

-

N

3894

POWER SUPPLY

100-240VAC/50-60Hz

mA Output 1

4-20mA

-

+

N

L

MAINS POWER

SWITCH PR-10900

NL

INSTRUMENTS

M12 CONNECTORS

1612 15

mA

+ 1 -

11

mA

+ 2 -

RELAY

2

RELAY

1

24232221

mA-OUTPUT MODULE

PR-50021

RELAY MODULE

PR-50023

MULTI CHANNEL USER INTERFACE MI

PR-8430 Platform 4 cable

A

PR-43-AC/AP User Guide M212438EN-C

Figure 12 Wiring for prism wash system for high pressure water

4.2.3 Prism wash nozzles

When selecting a wash nozzle for PR-43-AP, take into account both the wash medium and the

flowcell model: flowcells with larger pipe diameters need longer wash nozzles. The figure

below shows a wash nozzle for a flowcell and gives the measurements and the tables provide

part numbers for each nozzle type.

Figure 13 Wash nozzles for flowcell AFC-HSS-XXX-XX-NC

22

Page 25

Chapter 4 – Prism wash

Table 5 Flowcell -H10 or -H15

A B Part number

Steam 64.75 4.0 PR-3365

Water 75 2.5 PR-3369

Pressurized water 75 1.5 PR-3368

Table 6 Flowcell -H20 or -H25

A B Part number

Steam 72.15 4.0 PR-3375

Water 97 2.5 PR-3379

Pressurized water 97 1.5 PR-3378

Table 7 Flowcell -H30

A B Part number

Steam 103 4.0 PR-3393

Water 113 2.5 PR-3394

Pressurized water 113 1.5 PR-3395

Table 8 Flowcell -H40

A B Part number

Steam 133 4.0 PR-3390

Water 143 2.5 PR-3391

Pressurized water 143 1.5 PR-3392

The following figure shows how the nozzle is mounted in a flowcell (-NC with stud for a wash

nozzle).

23

Page 26

PR-43-AC/AP User Guide M212438EN-C

Figure 14 Process connection of wash nozzle in flowcell

For PR-43-AP, select the wash nozzle according to wash medium, see the following table.

Table 9 Prism wash nozzle selection

PR-43-AP

Steam nozzle PR-9321

Water nozzle PR-9320

Pressurized water nozzle PR-9322

24

Page 27

PR-43-AC-73

PR-43-AC-74

1.30

1.25

1.35 1.40 1.45 1.50 1.55

n

D

Chapter 5 – Technical data

5. Technical data

5.1 Compatibility

Electrically: The PR-43 refractometers are not interchangeable with any other refractometer

model. All PR-43-AC/AP refractometers are however interchangeable with each other as long

as they have the same prism. The PR-43-AC/AP refractometers are not compatible with the

indicating transmitters DTR, STR or IT-R.

Mechanically: The sanitary process refractometer PR-43-AC/AP fits the same sanitary process

connections as PR-23-AC/AP.

5.2 Refractometer rangeability

The refractive index standard range of a PR-43-AC/AP is 1.320-1.530 (corresponds to 0-100

Brix) with a Sapphire prism. A PR-43-AC can also be equipped with a Sapphire prism with a

refractive index range 1.260-1.470.

Figure 15 PR-43-AC rangeability

5.3

Sanitary process refractometer PR-43-AC

The refractometer PR-43-AC is a 3-A and EHEDG certified sanitary process refractometer for

measuring concentrations in a pipeline. It is easy to install in any pipe size directly or using a

flow cell. The Sanitary process refractometer is suitable for all food and beverage processing

applications where real-time monitoring and control can help to improve product quality and

reduce costs.

25

Page 28

PR-43-AC/AP User Guide M212438EN-C

Figure 16 PR-43-AC dimensions

5.3.1 PR-43-AC model code

The following table lists the model codes for the sanitary compact refractometer for pipelines.

26

Page 29

Chapter 5 – Technical data

Table 10 Sanitary compact refractometer for pipelines

Model and description Model

PR-43 = Refractometer PR-43

Refractometer model

-AC = Compact sanitary certified process refractometer, insertion length 14 mm -AC

Prism material and Refractive Index range limit

-73 = R.I. 1.320-1.530 nD (0-100 Brix) Sapphire prism -73

-74 = R.I. 1.260-1.470 nD Sapphire prism -74

Connection type and size

-E25-P15 = Varivent DN65, 15 bar

-H25-P15 = Sanitary 3A-clamp, 63.5 mm (2.5 in), 15 bar

-H25-P40 = Sanitary 3A-clamp, 63.5 mm (2.5 in), High Pressure, 40 bar @

1)

20 °C

-Z25-P15 = 63.5 mm (2.5 in) I-clamp, 15 bar

1)

1)

2)

-E25-P15

-H25-P15

-H25-P40

-Z25-P15

Wetted parts material

-SS = AISI 316 L -SS

-HC = Alloy C276 -HC

Electrical classification

-UN = Unclassified area, general purpose, ordinary location -UN

-AX = EX and IECEx certified Ex II 3G, Ex nA IIC T4 Gc (up to zone 2) (T

amb

-AX

-40 … +65 °C)

-IA = ATEX and IECEx certified Ex II 1G, Ex ia IIC T4 Ga (up to zone 0) (T

amb

-IA

-40 … +65 °C)

High accuracy option

-HAC = High accuracy version in range 0-30 Brix 4 … 30 °C -HAC

EHEDG option

-EH = EHEDG Type EL class I Certified Model -EH

Polishing option

-EP = Electropolished refractometer wetted parts (Ra 0.4 µm, 15 µ inch) -EP

1) EHEDG certified version available

2) Sanitary 3-A certified

27

Page 30

PR-43-AC/AP User Guide M212438EN-C

5.3.2 PR-43-AC mounting hardware model code

The following tables list the model codes for the sanitary compact refractometer mounting

hardware.

Table 11 Mounting hardware without wash nozzles

Model and description Model

AFC = Elbow flow cell AFC

Refractometer connection

-H = Sanitary 3A clamp, 2 1/2 in -H

Construction material

SS = AISI 316 SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

• 10 = 25 mm (1 in)

1)

• 15 = 40 mm (1 1/2 in)

• 20 = 50 mm (2 in)

• 25 = 65 mm (2.5 in)

• 30 = 80 mm (3 in)

• 40 = 100 mm (4 in)

1)

1)

1)

• 10

• 15

• 20

• 25

• 30

• 20

1) With -SI option only

Table 12 EHEDG certified mounting hardware

Model and description Model

AFC = Elbow flow cell AFC

Refractometer connection

-H = Sanitary 3A clamp, 2.5 in -H

Construction material

SS = AISI 316 SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

20 = 50 mm (2 in) 20

Flow cell inlet type

28

Page 31

Chapter 5 – Technical data

Model and description Model

-SI = Straight pipe -SI

EHEDG

-EH = EHEDG Type EL Class I Certified model -EH

Polishing option

-EP = Electropolished process wetted parts (Ra 0.4 µm, 15 µ in) -EP

For EHEDG certified refractometers use ISO2852 type EHEDG certified gasket

PR-9202-EH (2½ inch) or PR-9272-EH (4 inch).

Table 13 Mounting hardware with wash nozzles

Model and description Model

AFC = Elbow flow cell AFC

Refractometer connection

-H = Sanitary 3A clamp, 2.5 in -H

Construction material

SS = AISI 316 SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

• 10 = 25 mm (1 in)

• 15 = 40 mm (1.5 in)

• 20 = 50 mm (2 in)

• 25 = 65 mm (2.5 in)

• 30 = 80 mm (3 in)

• 40 = 100 mm (4 in)

1)

1)

1)

• 10

• 15

• 20

• 25

• 30

• 40

Flow cell inlet type

-SI = Straight pipe -SI

-RI = Reduced pipe (cone) -RI

Wash nozzle connection

-NC = Nozzleconnection -NC

Wash nozzles for 10/15 flow cells

-SN = Steam nozzle, threads G ¼ in female -SN

29

Page 32

PR-43-AC/AP User Guide M212438EN-C

Model and description Model

-WN = Water nozzle, threads G ¼ in female -WN

-WP = Pressurized water nozzle, threads G ¼ in female -WP

-PG = Plug for nozzle connection -PG

1) With -SI option only

Example:

• Refractometer: PR-43-AC-73-H25-P15

• Flowcell: AFC-HSS-H20-SI

Prism wash control and diagnostics require the use of a Multichannel user

interface MI (or customer’s own control system).

Table 14 Mounting hardware, mini flow cell

Model and description Model

MFC = Mini flow cell MFC

Refractometer connection

-H = Sanitary 3A clamp, 2.5 in -H

Construction material

SS = AISI 316 SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

05 = 15 mm (½ in) 05

Table 15 Mounting hardware, Varivent DN65 connection

Model and description Model

TDN = Varivent®in-line access unit clamp DN65 Type N

1)

TDN

Pipe section diameter

30

Page 33

Chapter 5 – Technical data

Model and description Model

• 40 = 100 mm (4 in)

• 50 = 50 mm (2 in)

• 65 = 65 mm (2.5 in)

• 80 = 80 mm (3 in)

• 100 = 100 mm (4 in)

• 125 = 125 mm (5 in)

• 150 = 150 mm (6 in)

• -40

• -50

• -65

• -80

• -100

• -125

• -150

Counter flange options

-SN = Steam nozzle, threads G ¼ in female -SN

-WN = Water nozzle, threads G ¼ in female -WN

-WP = Pressurized water nozzle, threads G ¼ in female -WP

-PG = Varivent blind flange type N -PG

1) Includes one 2.5 in Type N blind flange with 2.5 in EPDM gasket and 2.5 in Varivent clamp

Type N

Table 16 Mounting hardware

Model and description Model

SFC = Side flow cell

1)

SFC

Refractometer connection

-HH = Sanitary 3A clamp, 2.5 in -HH

Construction material

SS = AISI 316 SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

• 10 = 25 mm (1 in)

• 15 = 40 mm (1.5 in)

• 20 = 50 mm (2 in)

• 25 = 65 mm (2.5 in)

1)

• 10

• 15

• 20

• 25

Flow cell inlet and outlet orientation

-090 = Elbow, 90 degree bend -090

-180 = Straight pipe, 180 degree -180

1) Includes one 2.5 in blind flange with 2.5 in EPDM gasket and 2.5 in sanitary clamp is included

31

Page 34

PR-43-AC/AP User Guide M212438EN-C

5.3.3 PR-43-AC specifications

The following table lists the standard and optional specifications for the PR-43-AC

refractometer.

Table 17 PR-43-AC specifications

Standard Optional

REFRACTOMETER PR-43-A

Models

Refractive Index range Full range, nD = 1.3200 … 1.5300

Accuracy Across the full range of 0-100

Repeatability Across the full range of 0-100 Brix: nD ±0.00004 (corresponds

Speed of response 1 s undamped, damping time selectable up to 5 min

Calibration With NIST traceable Cargille standard R.I. liquids over full range

Patented CORE-Optics No mechanical adjustments and digital measurement with 3648

Temperature compensation Automatic, digital compensation.

Instrument verification With NIST traceable Cargille standard R.I. liquids and guided

Process connection Sanitary 3A-clamp 2.5 in; Varivent in-line access unit clamp DN65

Hygienic design certification 3-A Sanitary Standard 46-04 certified and EHEDG (European

Process pressure Sanitary 3A and I-clamp max. 15 bar (200 psi) at 20 °C (70 °F)/

Process temperature -40 °C … 130 °C (-40 °F … 266 °F)

Ambient temperature Min. -40 °C (-40 °F), max. 45 °C (113 °F)

PR-43-AC Compact model for small pipelines.

nD 1.2600 … 1.4700.

corresponds to hot water…100

Brix or % by weight.

Brix: Refractive Index n

±0.0002 corresponds typically

to ±0.1 Brix or % by weight

typically to ±0.02 Brix or % by weight).

pixel CCD element, sodium D-line light emitting diode (LED)

built-in Pt-1000 temperature sensor (linearization according to

IEC 751).

procedure, including a printable verification report.

or via elbow flow cell (for line sizes of 2.5 in and smaller); 2.5 in Iclamp.

Hygienic Engineering & Design Group) Type EL Class I certified.

9 bar (125 psi) at 120 °C (250 °F). High pressure Sanitary 3A

clamp HP 40 bar.

D

High accuracy version -HAC in

the range of 0-30 Brix and

4-30 °C:

• ±0.05 Brix or % by weight.

• ±0.02 Brix or % by weight (in

set-point applications).

32

Page 35

Chapter 5 – Technical data

Standard Optional

Process wetted parts AISI 316L stainless steel, prism

Alloy C276

sapphire, prism gasket

modified PTFE (Teflon), gasket

EPDM for Sanitary 3‑A and

ISO2852 type EHEDG certified

gasket for EHEDG certified

refractometers.

Refractometer protection

IP67, Type 4X

class

Refractometer weight 1.6 kg (3.5 lbs)

Current output Isolated 4-20 mA, max. load 1000 Ohm, galvanic isolation

1000 VDC or AC (peak), hold function during prism wash.

Remote and Ethernet

connections

10/100 BaseT Ethernet, web server for configuration and

diagnostics, UDP/IP Protocol connection for data acquisition.

Power supply +24 VDC ±10 %, max. 2 VA

INTERCONNECTING CABLES Standard length 10 m. Single cable maximum length 90 m, with

cable extender PR-8660 maximum length 90 + 90 m.

33

Page 36

PR-43-AC/AP User Guide M212438EN-C

5.3.4 PR-43-AC parts list

Figure 17 Refractometer cover assembly

Table 18 Refractometer cover assembly parts list

Item Description Part number Quantity

1 Screw M4x10 DIN7380 Torx

tamper proof

2 PR-43 end plate PR-14001 1

3 Dryer pack PR-9108 1

4 PR-43 sensor interface card 1

4.1 PR-43 interface card (Ex ia) PR-50011

4.2 mA-output card (general

purpose, Ex nA)

5 O-ring for PR-43 end plate FPM PR-14002-FPM 2

6 Screw M3x6 DIN7985 TX A2 3

34

PR-14003 2

PR-50033

Page 37

Chapter 5 – Technical data

Item Description Part number Quantity

7 PR-43 sensor processor card 1

7.1 Ex processor card (Ex ia) PR-50012

7.2 General purpose and Ex nA PR-50038

8 Screw M3x10 DIN965 TX A2 3

9 PR-33/PR-43-A card holder PR-14050 1

10 PR-33/PR-43-A disk spring ring 1

11 Screw M5x10 ISO 14583 TX A2 6

12 Nord-Lock washer NL5ss 6

13 PR-43 connector & cable set 1

13.1 P4 connector & cable set

PR-14101

(general purpose, Ex nA)

13.2 P4 connector & cable set (Ex

PR-14101-EX

ia)

14 PR-43 sensor cover PR-14000 1

15 O-ring 68x3 FPM PR-10048 1

16 O-ring 14x1,78 FPM PR-14102-FPM 1

17 Disk spring 1

35

Page 38

4

3

2

1

PR-43-AC/AP User Guide M212438EN-C

Figure 18 PR-43-AC assembly

Table 19 PR-43-AC assembly parts list

Item Description Part number Quantity

1 PR-43-AC nameplate PR-14404 1

2 PR-43 base assembly 1

3 PR-43 compact core 1

3.1 H73 Optics module PR-14020

3.2 H74 Optics module PR-14022

4 Sensor head 1

4.1 PR-43-AC-H25-SS head PR-10001

4.2 PR-43-AC-E25-SS head PR-10028 1

4.3 PR-43-AC-H25-HC head PR-10001-HC 1

4.4 PR-43-AC-E25-HC head PR-10028-HC

4.5 PR-43-Z25-SS head

36

Page 39

Chapter 5 – Technical data

5.3.5 PR-43-AC mounting specifics

Sanitary process refractometer PR-43-AC is connected to the process by a 2 1/2" 3A sanitary

clamp. The recommended mounting is in a pipe bend, with a vertical flow upwardsbefore the

refractometer, and a horizontal pipe after. This mounting ensures

1. Self-cleaning of the prism due to the flow directed against itssurface.

2. Ecient drainage when the pipe isemptied.

Forpipe diameters of 80 mm (3 in) or above, a ferrule is welded directly to the pipe wall, see

the following figure (a ferrule, length 21.5 mm, is delivered with standard refractometer

delivery).

Figure 19 Mounting with sanitary ferrule, pipe diameter 80 mm (3 in) or more

37

Page 40

PR-43-AC/AP User Guide M212438EN-C

For smaller pipe diameters, flow cells are available, see the following figures. The flow cells are

exchangeable with standard 90° bend pieces.

Figure 20 Flow cell AFC-HSS-H10 for pipe diameter 25 mm (1 in) and H15 for pipe diameter 40 mm

(1.5 in)

38

Page 41

'

'

$

%

&

%

%

6(&7,21$ $

6&$/(

6(&7,21%%

6&

$/(

$)&++5,1&

$)&++6,1&

,WHP1R 'HVFULSWLRQ 0DWHULD O 6 XSSOLHGE\ 4W\3FV

6DQLWDU\IHUUXOH $,6,/ &XVWRP HU

6DQLWDU\JDV NHW (3 '0 &XVWRP HU

6DQLWDU\F ODPS $,6, &XVWRPHU

)ORZFHOOW\SH $ % & '

$)&+5,1& >@ >@ >@ >@

$)&+6,1& >@ >@ >@ >@

$)&+5,1& >@ >@ >@ >@

$)&+6,1& >@ >@ >@ >@

,WHP1R 'HVFULSWLRQ 0DWHULD O 6 XSSOLHGE\ 4W\3FV

6DQLWDU\IHUUXOH $,6,/ &XVWRP HU

6DQLWDU\JDV NHW (3 '0 &XVWRP HU

6DQLWDU\F ODPS $,6, &XVWRPHU

)ORZFHOOW\SH $ % & '

$)&+5,1& >@ >@ >@ >@

$)&+6,1& >@ >@ >@ >@

$)&+5,1& >@ >@ >@ >@

$)&+6,1& >@ >@ >@ >@

Chapter 5 – Technical data

Figure 21 Flow cell AFC-HSS- with wash nozzle connection (-NC) H10 for pipe diameter 25 mm

(1 in) and H15 for pipe diameter 40 mm (1.5 in)

39

Page 42

A

A

A

D

45°

B

C

D

SECTION A-A

SCALE 1 : 2

Flow cell type

A

B C D

AFC-HSS-H20-SI

48.6

48.6 51.6 89.0

AFC-HSS-H20-RI

35.6

48.6 51.6 89.0

AFC-HSS-H25-SI

60.3

60.3 64.1 108.0

PR-43-AC/AP User Guide M212438EN-C

Figure 22 Flow cell AFC-HSS-H20 for pipe diameter 50 mm (2 in) and H25 for pipe diameter

65 mm (2.5 in)

40

Page 43

A

A

A

B

C

D

D

45°

B

B

SECTION A-A

SCALE 1 : 2

1

3

2

1

2

3

5

4

45°

SECTION B-B

SCALE 1 : 5

10

6

11

Flow cell type A

B C D

AFC-HSS-H20-SI-NC 48.6

48.6 51.6 89.0

AFC-HSS-H20-RI-NC

35.6

48.6 51.6 89.0

AFC-HSS-H25-SI-NC

60.3

60.3 64.1 108.0

Chapter 5 – Technical data

Figure 23 Flow cell AFC-HSS- with wash nozzle connection (-NC) H20 for pipe diameter 50 mm

(2 in) and H25 for pipe diameter 65 mm (2.5 in)

41

Page 44

PR-43-AC/AP User Guide M212438EN-C

Figure 24 Side flow cells

Sanitary Refractometer PR-43-AC-Z is mounted using 3-A Sanitary certified 2.5 in

CherryBurrell I-Line fittings that are made of interlocking flat face ferrules, a flat gasket and a

clamp. This interlocking, metal-to-metal design eliminates over compression by the clamp not

allowing the gasket to be extruded into the product contact side. The sensor is male part of

the connection.

42

Page 45

Chapter 5 – Technical data

Refractometer wetted parts material is AISI 316L or Alloy C, gaskets EPDM.

Figure 25 I-Line fitting for PR-43-AC

Table 20 I-Line fitting for PR-43-AC

Item Name Material Supplied by Quantity

1 Refactometer PR-43-

AC-Z25

2 65 mm (2.5 in) I-clamp AISI304 Customer 1

3 65 mm (2.5 in) I-clamp

gasket

AISI616L K‑Patents 1

EPDM Customer 1

43

Page 46

PR-43-AC/AP User Guide M212438EN-C

Item Name Material Supplied by Quantity

4 65 mm (2.5 in) I-clamp

ferrule

5 65 mm (2.5 in) pipe or

larger

AISI616L Customer 1

AISI616L Customer 1

5.3.6 Mounting specifics for EHEDG certified PR-43-AC

configuration

Vaisala oers certain PR-43-AC configurations which have been certified to fulfill the sanitary

requirements published by the EHEDG (European Hygienic Engineering & Design Group)

organization. During this certification the hygienic characteristics of both the refractometer

and the process connection were evaluated against the applicable requirements.

To ensure EHEDG compliant installation, follow the mounting specifics provided on the

mounting drawing supplied by Vaisala with each PR-43-AC refractometer ordered with the EH option.

An example of such mounting guideline is shown in 3-A Sanitary Standard compliance

(page 44).

5.3.7 3-A Sanitary Standard compliance

Ensure that the refractometer is not a source of contamination due to damaged or worn

product contact surfaces. Misuse (for example a too-long prism wash time or too high wash

pressure) or mishandling may result in metal scratches or roughened surfaces. Such surfaces

may not stay clean in processing.

Vaisala oers a 3-A Sanitary Standard Accepted repair and maintenance package in which all

wetted parts, prism, gaskets and dryer are replaced.

44

This repair service can be completed by 3-A authorized service center only.

Page 47

TYPE EL

CLASS I

November 2015

Chapter 5 – Technical data

Figure 26 Mounting with sanitary ferrule, pipe diameter 80 mm (3 in) or more EHEDG certified

configuration

The following table lists the parts in the figure above and the materials of the mounting

hardware.

Table 21 Mounting materials

Number Item Material Quantity

1 Sensor PR-43-AC 1

2 Sanitary ferrule 65 mm (2.5 in) ISO

AISI 316L 1

2852

45

Page 48

6,69

170

3,05

77,5

1,48

37,5

3,66

93

11,16

284

2.5" Sanitary clamp

M12-8pin, D-code, male connector

PR-43-AC/AP User Guide M212438EN-C

Number Item Material Quantity

3 Sanitary gasket 65 mm (2.5 in) ISO2852 type EHEDG certified 1

5.4 Sanitary process refractometer PR-43-AP

Sanitary probe refractometer PR-43-AP provides an accurate in-line Brix measurement in

cookers, tanks and large pipelines. The PR-43-APT refractometer version can be installed

through an APV Tank bottom flange. It is flush mounted in the side wall and it allows the use of

scrapers and mixers. It can also be installed through a steam jacket.

Figure 27 Dimensions of an inserted refractometer PR-43-AP-H25-L170

46

Page 49

Chapter 5 – Technical data

Figure 28 Flush mounted refractometer PR-43-AP-T10-L00

5.4.1 PR-43-AP model code

The following table lists the model codes for the sanitary probe refractometer for large

pipelines and vessels.

Table 22 SANITARY PROBE REFRACTOMETER for large pipelines and vessels

Model and description Model

PR-43 = Refractometer PR-43

Refractometer model

-AP = Sanitary process refractometer, probe -AP

Prism material and Refractive Index range limit

-73 = R.I. 1.320-1.530 nD (0-100 Brix) Sapphire prism -73

Connection type and size

-E25-P15 = Varivent DN65, 15 bar -E25-P15

-H25-P15 = Sanitary 3A-clamp, 63.5 mm (2.5 in), 15 bar -H25-P15

-H25-P40 = Sanitary 3A-clamp, 63.5 mm (2.5 in), High Pressure, 40 bar @

20°C

-H40-P15 = Sanitary 3A-clamp, 101.6 mm (4 in), 15 bar - --H40-P15

T10-P15 = MT4 DN25/1T APV tank bottom flange, flush mounted 1" DN10 -T10-P15

-V25-P15 = 63.5 mm (2.5 in), 15 bar with O-ring for refractometer head -V25-P15

-H25-P40

47

Page 50

PR-43-AC/AP User Guide M212438EN-C

Model and description Model

-Z25-P15 = 63.5 mm (2.5 in) I-clamp, 15 bar -Z25-P15

Insertion length, models H25-P15/P40

-L14 = insertion length 14 mm (0.55 in) 1)

2)

-L42 = insertion length 42 mm (1.65 in) 1)

-L140 = insertion length 140 mm (5.5 in)

3)

-L170 = insertion length 170 mm (6.69 in) 1)

2)

2)

-L14

-L42

-L140

-L170

Insertion length, models H40-P15

-L63 = insertion length 63 mm (2.48 in) 1)

-L170 = insertion length 170 mm (6.69 in) 1)

2)

2)

-L63

-L170

Insertion length, models T10-P15

-L00 = flush mount insertion length

2)

-L170 = insertion length 170 mm (6.69 in)

3)

-L100

-L170

Insertion length, models E25-P15

-L170 = insertion length 170 mm (6.69 in) 1)

2)

-L170

Insertion length, models V25-P15

-L170 = insertion length 170 mm (6.69 in)

3)

-L170

Insertion length, models I-clamp Z25-P15

-L178 = insertion length 178 mm (7 in)

2)

-L178

Wetted parts material

-SS = AISI 316 L -SS

Electrical classification

-UN = Unclassified area, general purpose, ordinary location -UN

-AX = EX and IECEx certified Ex II 3G, Ex nA IIC T4 Gc (up to zone 2) (T

amb

-AX

-40 … +65 °C)

-IA = ATEX and IECEx certified Ex II 1G, Ex ia IIC T4 Ga (up to zone 0) (T

amb

-IA

-40 … +65 °C)

EHEDG option

-EH = EHEDG Type EL Class I Certified Model

4)

-EH

1) EHEDG certified versions available

2) Sanitary 3-A certified

3) Design according to Sanitary 3-A

48

Page 51

Chapter 5 – Technical data

4) For models with EHEDG certified versions available

Table 23 SANITARY PROBE REFRACTOMETER with prism wash for large pipelines and vessels

Model and description Model

PR-43 = Refractometer PR-43

Refractometer model

-AP = Sanitary process refractometer, probe -AP

Prism material and Refractive Index range limit

-73 = R.I. 1.320-1.530 nD (0-100 %) Sapphire prism -73

Connection type and size

-H40-P15 = Sanitary 3A-clamp, 101.6 mm (4 in), 15 bar -H40-P15

Insertion length

-L170 = insertion length 170 mm (6.69 in) -L170

Wetted parts material

-SS = AISI 316 L -SS

Electrical classification

-UN = Unclassified area, general purpose, ordinary location -UN

-AX = EX and IECEx certified Ex II 3G, Ex nA IIC T4 Gc (up to zone 2) (T

amb

-AX

-40 … +65 °C)

-IA = ATEX and IECEx certified Ex II 1G, Ex ia IIC T4 Ga (up to zone 0) (T

amb

-IA

-40 … +65 °C)

Prism wash

-NC = integral nozzle connection -NC

-SN = integral steam cleaning nozzle -SN

-WP = integral high pressure water cleaning nozzle -WP

-WN = integral warm water cleaning nozzle -WN

-YC = no integral nozzle connection -YC

Prism wash control and diagnostics require use of Multichannel user interface MI

(or customer’s own control system).

5.4.2 PR-43-AP mounting hardware model code

The following tables list the model codes for the refractometer mounting hardware.

49

Page 52

PR-43-AC/AP User Guide M212438EN-C

Table 24 Mounting hardware for PR-43-AP refractometer

Part number and description Model

VFMA-T10 = MT4 DN25/1T APV tank bottom flange for PR-43-AP T10 VFMA-T10

VFBP-T10 = blind flange for MT4 DN25/1T APV tank bottom flange VFBP-T10

VFME-V25 = mount adaptor for PR-43-AP V25 HEXNUT type VFME-V25

VFMF-V25 = mount adaptor for PR-43-AP V25 HEXNUT extended VFMF-V25

For EHEDG certified refractometers, use EHEDG certified gasket PR-9202-EH

63.5 mm (2.5 in) or PR-9272-EH 101.6 mm (4 in).

5.4.3 PR-43-AP specifications

The following table lists the standard and optional specifications for the PR-43-AP

refractometer.

Table 25 PR-43-AP specifications

REFRACTOMETER PR-43-A

Models

Refractive Index range Full range, nD = 1.3200 … 1.5300 corresponds to hot water…100

Accuracy Across the full range of 0-100 Brix: Refractive Index nD ±0.0002

Repeatability Across the full range of 0-100 Brix: nD ±0.00004 (corresponds

Speed of response 1 s undamped, damping time selectable up to 5 min

Calibration With NIST traceable Cargille standard R.I. liquids over full range

Patented CORE-Optics No mechanical adjustments and digital measurement with 3648

Temperature compensation Automatic, digital compensation.

Instrument verification With NIST traceable Cargille standard R.I. liquids and guided

Process connection Sanitary 3A-clamp 63.5 mm (2.5 in); Varivent in-line access unit

50

PR-43-AP probe model for large pipelines and vessels

Brix or % by weight.

corresponds typically to ±0.1 Brix or % by weight

typically to ±0.02 Brix or % by weight).

pixel CCD element, sodium D-line light emitting diode (LED)

built-in Pt-1000 temperature sensor (linearization according to

IEC 751).

procedure, including a printable verification report.

clamp DN65 or via elbow flow cell (for line sizes of 63.5 mm

(2.5 in) and smaller); 63.5 mm (2.5 in) I-clamp.

Page 53

Chapter 5 – Technical data

REFRACTOMETER PR-43-A

Models

PR-43-AP probe model for large pipelines and vessels

Hygienic design certification 3-A Sanitary Standard 46-04 certified and EHEDG (European

Hygienic Engineering & Design Group) Type EL Class I certified.

Process pressure Sanitary 3A and I-clamp max. 15 bar (200 psi) at 20 °C (70 °F)/

9 bar (125 psi) at 120 °C (250 °F). High pressure Sanitary 3A

clamp HP 40 bar.

Process temperature -40 °C … 130 °C (-40 °F … 266 °F)

Ambient temperature Min. -40 °C (-40 °F), max. 45 °C (113 °F)

Process wetted parts AISI 316L stainless steel, prism sapphire, prism gasket modified

PTFE (Teflon), gasket EPDM for Sanitary 3‑A and ISO2852 type

EHEDG certified gasket for EHEDG certified refractometers.

Refractometer protection

IP67, NEMA 4, 4X, 6, 6P

class

Refractometer weight 2.9 kg (6 lbs)

Current output Isolated 4-20 mA, max. load 1000 Ohm, galvanic isolation

1000 VDC or AC (peak), hold function during prism wash.

Remote and Ethernet

connections

10/100 BaseT Ethernet, web server for configuration and

diagnostics, UDP/IP Protocol connection for data acquisition.

Power supply +24 VDC ±10 %, max. 2 VA

INTERCONNECTING CABLES Standard length 10 m. Single cable maximum length 90 m, with

cable extender PR-8660 maximum length 90 + 90 m.

51

Page 54

PR-43-AC/AP User Guide M212438EN-C

5.4.4 PR-43-AP parts lists

Figure 29 Refractometer cover assembly

Table 26 Refractometer cover assembly parts list

Item Description Part number Quantity

1 Screw M4x10 DIN7380 Torx

tamper proof

2 PR-43 end plate PR-14001 1

3 Dryer pack PR-9108 1

4 PR-43 sensor interface card 1

4.1 PR-43 interface card (Ex ia) PR-50011

4.2 mA-output card (general

purpose, Ex nA)

5 O-ring for PR-43 end plate FPM PR-14002-FPM 2

6 Screw M3x6 DIN7985 TX A2 3

52

PR-14003 2

PR-50033

Page 55

Chapter 5 – Technical data

Item Description Part number Quantity

7 PR-43 sensor processor card 1

7.1 Ex processor card (Ex ia) PR-50012

7.2 General purpose and Ex nA PR-50038

8 Screw M3x10 DIN965 TX A2 3

9 PR-33/PR-43-A card holder PR-14050 1

10 PR-33/PR-43-A disk spring ring 1

11 Screw M5x10 ISO 14583 TX A2 6

12 Nord-Lock washer NL5ss 6

13 PR-43 connector & cable set 1

13.1 P4 connector & cable set

PR-14101

(general purpose, Ex nA)

13.2 P4 connector & cable set (Ex

PR-14101-EX

ia)

14 PR-43 sensor cover PR-14000 1

15 O-ring 68x3 FPM PR-10048 1

16 O-ring 14x1,78 FPM PR-14102-FPM 1

17 Disk spring 1

53

Page 56

PR-43-AC/AP User Guide M212438EN-C

Figure 30 PR-43-AP assembly

Table 27 PR-43-AP assembly parts list

Item Description Part

number

Quantity Product code

1 PR-43-AP name plate 1

2 PR-43-base assembly 1

3 HX3 core assembly PR-14021 1

4 Sensor head 1

4.1 PR-23-AP-PSS head PR-10006 PR-43-AP-T10-P15-L00

4.2 PR-23-AP-RSS head PR-10007 PR-43-AP-H40-L170

4.3 PR-23-AP-TSS head PR-10008 PR-43-AP-H25-L170

4.4 PR-23-AP-RSS-NC head PR-10013 PR-43-AP-H40-L170-NC

4.4.1 Nozzles and plug, contra

nut, O-rings 9.3 and 5.2

4.5 PR-23-AP-VSS head PR-10016 PR-43-AP-V25-P15

4.5.1 O-ring

54

Page 57

Chapter 5 – Technical data

Item Description Part

4.6 PR-23-AP-QSS head PR-10018 PR-43-AP-H25-L140

4.7 PR-23-AP-SSS head PR-10024 PR-43-AP-H40-L63

4.8 PR-23-AP-ISS head PR-10025 PR-43-AP-H25-L42

4.9 PR-23-AP-BSS head PR-10026 PR-43-AP-T10-L170

4.10 PR-23-AP-HSS head PR-10027 PR-43-AP-H25-L14

4.11 PR-23-AP-CSS head

(DN65 Varivent head)

4.12 PR-23-AP-ZP head PR-10046 PR-43-AP-Z25-L178

number

PR-10029 PR-43-AP-E25-L170

Quantity Product code

5.4.5 PR-43-AP mounting specifics

The probe refractometer PR-43-AP is primarily designed for mounting in a tank wall. To ensure

that the measurement is representative and that the prism stays clean, the probe should be

installed close to a stirrer.

Probe refractometer type PR-43-AP-H25 is connected to the process by a 63.5 mm (2.5 in) 3-A

sanitary clamp.

For higher process (or ambient) temperature, use instead a flush mounted

refractometer, where the electronics in the refractometer head are farther away

from the process heat.

55

Page 58

PR-43-AC/AP User Guide M212438EN-C

Figure 31 Insertion of probe refractometer PR-43-AP-H25

The refractometer type PR-43-AP-T10-L00 is flush mounted using a sanitary APV tank

bottomflange. The refractometer can be flush mounted in the side wall, which allows the use of

a scraper. It is also easily installed through a steam jacket.

56

Page 59

Figure 32 Flush mounting probe refractometer PR-43-AP-T10-L100

Chapter 5 – Technical data

Sanitary Refractometer PR-43-AP-Z is mounted using 3-A Sanitary certified 63.5 mm (2.5 in)

CherryBurrell I-Line fittings that are made of interlocking flat face ferrules, a flat gasket and a

clamp. This interlocking, metal-to-metal design eliminates over compression by the clamp not

allowing the gasket to be extruded into the product contact side. The sensor is the male part

of the connection.

Refractometer wetted parts material is AISI 316L or Alloy C, gaskets EPDM.

57

Page 60

PR-43-AC/AP User Guide M212438EN-C

Figure 33 I-Line fitting for PR-43-AP

5.4.6 Mounting specifics for EHEDG certified PR-43-AP

configuration

Vaisala oers certain PR-43-AP configurations which have been certified to fulfill the sanitary

requirements published by EHEDG (European Hygienic Engineering & Design Group)

organization. During this certification the hygienic characteristics of both the refractometer

and the process connection were evaluated against the applicable requirements.

To ensure EHEDG compliant installation, follow the mounting specifics provided on the

mounting drawing supplied by Vaisala with each PR-43-AP refractometer ordered with the EH option.

The following figure shows an example of such mounting guideline.

58

Page 61

3 4

5

1 2

9

3

°

1

,

4

8

3

7

,

5

b

a

Item no. Name Material Suppli ed by Pcs.

1 Refractometer PR-43-AP AISI316L K-P atents 1

2 4" Sanitary clamp AISI304 K-Patents 1

3 EHEDG cer�fied sanitary gasket 4" IS O-2852 K- Patents 1

4 4" Sanitary ferrule AISI316L K-P atents 1

5 Customer pipe/v essel AISI316L Customer 1

TYPE EL

CLASS I

February 2015

Chapter 5 – Technical data

Figure 34 EHEDG certified PR-43-AP

Notes for EHEDG compliant installation:

• The distance a shall be less than the dimeter b per the EHEDG guideline 10

• For other installation specifications see the web address: http://ehedg.org/index.php?

nr=110&lang=en

5.4.7 3-A Sanitary Standard compliance

Ensure that the refractometer is not a source of contamination to product due to damaged or

worn product contact surfaces. Misuse (for example, too long prism wash time or too high

wash pressure) or mishandling may result in metal scratches or roughened surfaces. Such

surfaces may not stay clean in processing.

Vaisala oers a 3-A Sanitary Standard accepted repair and maintenance package in which all

wetted parts, prism, gaskets and dryer are replaced.

This repair service can be completed by 3-A authorized service center only

(Vaisala factory and selected regional oces).

59

Page 62

PR-43-AC/AP User Guide M212438EN-C

Appendix A. Refractometer verification

Each Vaisala K-PATENTS® refractometer is provided with a calibration certificate comparing a

set of standard liquids to the actual refractometer output. Therefore, the calibration and

accuracy can be easily verified on-site with the certified refractive index liquids and menu

guided verification procedure.

For verification you need:

• Universal sample holder PR-1012 (see the figure below). The sample holder keeps the

sample on the prism surface and also keeps the ambient light out.

• A set of standard refractive index liquids.

• Cleaning solution (ethanol) to clean the refractometer prism and the sample holder.

Figure 35 Universal sample holder PR-1012

The verification of the PR-43 refractometer calibration is made using a set of standard

refractive index liquids with the nominal values at 25 °C:

• 1.330

• 1.370

• 1.420

• 1.470

• 1.520

The accuracy of the certified standard refractive index liquids is ± 0.0002 and they can be

traced back to national standards: NIST Standards # 1823 and # 1823II. As the specified

accuracy of PR-43 is ± 0.0002, then the representative level is the sum of the two accuracy

specifications, that is, ± 0.0004.

Vaisala provides a set of standard R.I. liquids, PR-2300, containing these five liquids. The set

can be ordered directly from Vaisala or through your representative.

A verification can be done by connecting to the refractometer over ethernet or by using a

Multichannel user interface MI or Compact user interface CI.

60

Page 63

Appendix A – Refractometer verification

In the web interface, choose Verification on the Main menu and follow the instructions on the

page.

In MI, tap the 54 PR-43-AC/AP instruction manual three dots in the app for the refractometer

to be verified, then choose Verification. Tap the question mark in the Verification display to

get verification instructions.

In CI, choose Verification in the Main menu and follow the instructions on screen.

For a successful verification, the refractometer and the standard refractive index

liquids must be at room temperature (25 ± 5 °C).

To check that the standard liquid is properly wetting the prism, the optical image can be

monitored during the verification procedure. The optical image should show a sharp shadow

edge.

The instrument measures each verification data point ten times and uses the average of these

measurements. Measuring each verification liquid takes a few seconds, during which the

measurement progress display is shown. Please wait until the verification step 2 display

reappears before proceeding to next verification liquid. The limit for acceptance is that all

measurements must be within ± 0.0004 of the nominal values.

If message is VERIFICATION FAILED, first check that the prism and the sample holder are

absolutely clean and the sample holder sits tightly on the refractometer tip before a standard

liquid is applied. Make sure the standard liquids are in good condition and not past their

expiration date. Also, inspect the prism surface, checking that it is flat and glossy without any

scratches. Repeat the verification procedure. If the verification still fails, fill in the PR-43

refractometer verification form, found at the end of this manual. The refractometer serial

number is shown in the upper right corner of each display. The list of CCD and TEMP values are

found on the Verification results display. Send the form to your Vaisala K-PATENTS®

representative or email the collected data to helpdesk@vaisala.com and wait for further

instructions.

61

Page 64

PR-43-AC/AP User Guide M212438EN-C

Appendix B. PR-43 refractometer

verification form

Fill in this form and email it to helpdesk@vaisala.com or to your local service representative.

Refractometer serial no:

Customer:

Address:

Fax:

Email:

Date:

Verification made by:

Table 28 Verification results display

Sample

number

1 1.330

2 1.370

3 1.420

4 1.470

5 1.520

Nominal n

D

Measured n

D

CCD Temp

62

Page 65

Appendix C. EU declaration of conformity

2019-09-01J/JAMO

1 (1)

Vaisala Oyj | PO Box 26, FI-00421 Helsinki, Finland

Phone +358 9 894 91 | Fax +358 9 8949 2227

Email firstname.lastname@vaisala.com | www.vaisala.com

Domicile Vantaa, Finland | VAT FI01244162 | Business ID 0124416-2

EU DECLARATION OF CONFORMITY

Manufacturer: Vaisala Oyj

Mail address: P.O. Box 26, FI-00421 Helsinki, Finland

Street Address: Vanha Nurmijärventie 21, Vantaa, Finland

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Object of the declaration:

K-Patents Process Refractometer PR-43 series

The object of the declaration described above is in conformity with Directives:

RoHS Directive (2011/65/EU)

EMC Directive (2014/30/EU)

The conformity is declared using the following standards:

EN 50581:2012

Technical documentation for the assessment of electrical and

electronic products with respect to the restriction of hazardous s ubstances

EN 61010-1:2010

Safety requirements for el ectrical equipment for measurement,

control and laboratory use – Part 1: General requirements

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory

use – EMC requirements – intended for us

e in industrial locations

Signed for and on behalf of Vaisala Oyj, in Vantaa, on 1

st

September 2019

______________________________________

Jukka Lyömiö

Standards and Approvals Manager

Appendix C – EU declaration of conformity

63

Page 66

Page 67

Warranty

For standard warranty terms and conditions, see www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of damage due to normal wear