Page 1

IM-EN-PR23-E

User Guide

Process Refractometer

PR-23 Series

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala 2021

No part of this document may be reproduced,

published or publicly displayed in any form or by

any means, electronic or mechanical (including

photocopying), nor may its contents be modified,

translated, adapted, sold or disclosed to a third

party without prior written permission of the

copyright holder. Translated documents and

translated portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject to

change without prior notice.

Local rules and regulations may vary and they

shall take precedence over the information

contained in this document. Vaisala makes no

representations on this document’s compliance

with the local rules and regulations applicable at

any given time, and hereby disclaims any and all

responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards customers

or end users. All legally binding obligations and

agreements are included exclusively in the

applicable supply contract or the General

Conditions of Sale and General Conditions of

Service of Vaisala.

This product contains software developed by

Vaisala or third parties. Use of the software is

governed by license terms and conditions

included in the applicable supply contract or, in

the absence of separate license terms and

conditions, by the General License Conditions of

Vaisala Group.

This product may contain open source software

(OSS) components. In the event this product

contains OSS components, then such OSS is

governed by the terms and conditions of the

applicable OSS licenses, and you are bound by the

terms and conditions of such licenses in

connection with your use and distribution of the

OSS in this product. Applicable OSS licenses are

included in the product itself or provided to you

on any other applicable media, depending on

each individual product and the product items

delivered to you.

Page 3

Table of contents

1. About this document...................................................................................... 11

1.1 Version information............................................................................................ 11

1.2 Documentation conventions..............................................................................11

1.3 Trademarks..........................................................................................................12

1.4 Patent notice.......................................................................................................12

2. Product overview.............................................................................................13

2.1 Safety...................................................................................................................13

2.2 Storage conditions, packaging and transportation....................................... 15

2.3 PR-23 refractometer models............................................................................ 15

2.4 Refractometer sensor........................................................................................15

3. Mounting sensor...............................................................................................17

3.1 Choosing sensor mounting location................................................................17

3.2 PR-23 mounting guide...................................................................................... 19

3.3 Pipe mounting checklist...................................................................................20

3.4 Checklist for mounting in tank, vessel or large pipe.................................... 20

4. Indicating transmitter DTR...........................................................................21

4.1 Mounting indicating transmitter..................................................................... 23

4.2 Electrical connections...................................................................................... 24

4.2.1 Interconnecting cable................................................................................ 24

4.2.2 Connecting sensor......................................................................................25

4.2.3 Connecting indicating transmitter............................................................27

4.2.4 Power terminals for AC power..................................................................33

4.2.5 Power terminals for 24 VDC power..........................................................33

4.2.6 Relay connections...................................................................................... 34

4.2.7 Reset button................................................................................................36

Table of contents

5. Prism wash systems....................................................................................... 37

5.1 Prism coating.....................................................................................................37

5.2 Prism wash......................................................................................................... 37

5.2.1 Recommended wash pressures and times..............................................37

5.2.2 Prism wash systems................................................................................... 39

5.2.3 Prism wash nozzles.................................................................................... 46

6. Startup and use...............................................................................................50

6.1 Startup............................................................................................................... 50

6.1.1 Initial check................................................................................................. 50

6.1.2 Calibration check......................................................................................... 51

6.1.3 Testing prism wash...................................................................................... 51

6.2 Using indicating transmitter............................................................................. 51

6.2.1 Keyboard functions.................................................................................... 52

6.2.2 Display setup...............................................................................................53

6.3 Viewing system information............................................................................ 55

6.4 Viewing sensor status.......................................................................................55

6.4.1 Optical image with IDS.............................................................................. 55

6.4.2 Optical image with VD............................................................................... 57

6.4.3 Diagnostic values........................................................................................57

6.4.4 Temperature measurement.......................................................................58

6.4.5 Sensor head humidity................................................................................ 58

6.5 Sensor verification............................................................................................ 58

1

Page 4

PR-23 Series User Guide

7. Configuration and calibration....................................................................59

7.1 Configuring

output signal damping............................................................... 59

7.1.1 Exponential damping.................................................................................59

7.1.2 Linear damping.......................................................................................... 60

7.1.3 Slew rate limit...............................................................................................61

7.2 Configuring output signal hold functionality................................................ 62

7.2.1 External hold............................................................................................... 63

7.2.2 Hold during wash........................................................................................63

7.2.3 Tolerance time.............................................................................................63

7.2.4 QF threshold............................................................................................... 64

7.2.5 Hold source interactions............................................................................64

7.2.6 Hold and signal damping...........................................................................65

7.2.7 Hold functions with DD‑23........................................................................ 65

7.3 Configuring refractometer system................................................................. 66

7.3.1 Configuring relays...................................................................................... 66

7.3.2 Configuring input switches....................................................................... 68

7.3.3 Configuring mA outputs............................................................................70

7.4 Calibrating concentration measurement........................................................72

7.4.1 Chemical curve............................................................................................74

7.4.2 Selecting display units and display decimals..........................................74

7.4.3 Field calibration...........................................................................................75

7.4.4 Entering field calibration parameters...................................................... 76

7.4.5 Direct BIAS adjustment..............................................................................76

7.5 Configuring prism wash................................................................................... 77

7.5.1 Wash cycle...................................................................................................77

7.5.2 Setting prism wash parameters................................................................82

IM-EN-PR23-E

8. Regular maintenance....................................................................................84

8.1 Checking sensor humidity level...................................................................... 84

8.2 Checking prism and prism gaskets.................................................................84

9. Troubleshooting.............................................................................................. 85

9.1 Hardware............................................................................................................85

9.1.1 Blank display............................................................................................... 88

9.1.2 Diagnostic LEDs..........................................................................................89

9.1.3 Display unreadable......................................................................................91

9.1.4 Troubleshooting messages

........................................................................92

9.1.5 Diagnostic message priorities...................................................................97

10. Sensor specifications

.................................................................................... 99

10.1 Sensor compatibility.........................................................................................99

10.2 Sensor rangeability...........................................................................................99

10.3 Sanitary process refractometer PR‑23‑AC...................................................100

10.3.1 PR‑23‑AC sensor model code.................................................................100

10.3.2 PR

‑23‑AC mounting hardware model code...........................................102

10.3.3 PR‑23‑AC specifications.......................................................................... 106

10.3.4 PR‑23‑AC parts list....................................................................................107

10.3.5 PR‑23‑AC mounting specifics..................................................................107

10.3.6 Mounting specifics for EHEDG‑certified PR‑23‑AC configuration....... 112

10.3.7 3‑A Sanitary Standard compliance.......................................................... 112

10.4 Sanitary probe refractometer PR‑23‑AP....................................................... 113

10.4.1 PR‑23‑AP model code............................................................................... 113

10.4.2 PR‑23‑AP mounting hardware model code............................................116

10.4.3 PR‑23‑AP specifications............................................................................118

2

Page 5

10.4.4 PR‑23‑AP parts list..................................................................................... 119

10.4.5 PR‑23‑AP mounting specifics...................................................................119

10.4.6 Mounting specifics for EHEDG‑certified PR‑23‑AP configuration....... 121

10.4.7 3‑A Sanitary Standard compliance.......................................................... 121

10.5 Compact process refractometer PR‑23‑GC..................................................122

10.5.1 PR‑23‑GC sensor model code..................................................................122

10.5.2 PR‑23‑GC specifications...........................................................................124

10.5.3 PR‑23‑GC parts list....................................................................................126

10.5.4 PR‑23‑GC mounting specifications.........................................................126

10.6 Probe process refractometer PR‑23‑GP........................................................ 131

10.6.1 PR‑23‑GP sensor model code..................................................................132

10.6.2 PR‑23‑GP specifications...........................................................................133

10.6.3 PR‑23‑GP thermal cover PR‑7062.......................................................... 134

10.6.4 PR‑23‑GP parts list....................................................................................136

10.6.5 PR‑23‑GP mounting specifications......................................................... 137

10.7 Process refractometer PR‑23‑RP...................................................................138

10.7.1 PR‑23‑RP sensor model code..................................................................139

10.7.2 PR‑23‑RP specifications...........................................................................140

10.7.3 PR‑23‑RP parts list.....................................................................................141

10.7.4 PR‑23‑RP head parts list..........................................................................142

10.7.5 PR‑23‑RP dimensions...............................................................................143

10.7.6 PR‑23‑RP mounting specifications.........................................................144

10.7.7 PR‑23‑RP prism wash system..................................................................145

10.8 Teflon body refractometer PR‑23‑M/MS......................................................146

10.8.1 PR‑23‑M sensor model code....................................................................147

10.8.2 PR‑23‑M specifications.............................................................................149

10.8.3 PR‑23‑M parts list......................................................................................150

10.8.4 PR‑23‑MS sensor model code.................................................................150

10.8.5 PR‑23‑MS specifications...........................................................................152

10.8.6 PR‑23‑MS parts list....................................................................................153

10.8.7 PR‑23‑M/MS mounting specifications....................................................154

10.9 Saundersâ body refractometer PR‑23‑W....................................................154

10.9.1 PR‑23‑W sensor model code...................................................................155

10.9.2 PR‑23‑W specifications............................................................................ 157

10.9.3 PR‑23‑W parts list.....................................................................................159

10.9.4 PR‑23‑W mounting specifications..........................................................159

10.10 Intrinsically safe refractometers PR‑23‑…‑IA, PR‑23‑…‑IF and

PR‑23‑…‑CI.........................................................................................................161

10.10.1 Intrinsically safe refractometer equipment.............................................161

10.10.2 Intrinsically safe mounting.......................................................................165

10.10.3 Isolator/barriers........................................................................................ 168

Table of contents

11. Safe-Drive.........................................................................................................170

11.1 Safe‑Drive system description.......................................................................170

11.2 PR‑23‑SD specifications................................................................................. 170

11.3 Safe‑Drive component parts lists...................................................................172

11.3.1 PR-23-SD sensor....................................................................................... 172

11.3.2 Safe‑Drive isolation valve SDI2‑23..........................................................173

11.3.3 Safe‑Drive steam wash system parts......................................................174

11.3.4 Safe‑Drive retractor SDR2‑23.................................................................. 175

3

Page 6

PR-23 Series User Guide

IM-EN-PR23-E

11.4 Safe‑Drive mounting

....................................................................................... 175

11.4.1 Welding isolation valve to pipe............................................................... 178

11.4.2 PR-23-SD system wiring...........................................................................182

11.4.3 Steam piping for SDI2...............................................................................182

11.4.4 High pressure water piping for SDI2.......................................................185

11.4.5 Water consumption of high pressure wash system..............................186

11.4.6 Non-retractable wash nozzle SDI2‑23‑WPR/WPN‑XS.........................187

11.5 Safe sensor insertion and removal for Safe‑Drive generation 2.1..............189

11.5.1 Inserting Safe‑Drive sensor..................................................................... 190

11.5.2 Removing Safe‑Drive sensor................................................................... 198

11.6 Wash nozzle insertion and removal.............................................................206

11.6.1 Inserting wash nozzle..............................................................................206

11.6.2 Removing wash nozzle........................................................................... 208

11.7 Thermal cover for SDI2‑23...............................................................................211

11.8 Blinding Safe‑Drive system............................................................................ 213

11.9 Identifying your refractometer generation.................................................. 214

12. PR

‑23 process refractometers in potentially explosive

atmosphere......................................................................................................216

12.1 Equipment........................................................................................................216

12.2 Installation........................................................................................................219

13. Indicating transmitter DTR and STR specifications....................... 222

13.1 Compatibility................................................................................................... 222

13.2 Indicating transmitter model codes.............................................................223

13.3 Specifications..................................................................................................223

13.3.1 Indicating transmitter specifications..................................................... 223

13.4 Transmitter parts list...................................................................................... 225

14. Interconnecting cable.................................................................................226

14.1 Interconnecting cable model code...............................................................226

14.2 Interconnecting cable

specifications........................................................... 226

15. Ethernet connection specification........................................................ 227

15.1 Cable requirements and connection............................................................ 227

15.1.1 Ethernet cable specification................................................................... 227

15.1.2 Connecting Ethernet cable..................................................................... 229

15.2 Connection settings.......................................................................................230

15.2.1 IP settings for DTR...................................................................................230

15.2.2 IP settings for stand-alone computer.....................................................231

15.3 Testing Ethernet connection......................................................................... 232

15.3.1 Troubleshooting connection...................................................................233

15.4 Instrument homepage................................................................................... 234

15.4.1 Remote panel............................................................................................235

15.4.2 Sensor verification certificate.................................................................236

15.5 Collecting data using Ethernet..................................................................... 236

15.5.1 Communication protocol........................................................................ 236

15.5.2 Request-response pair specification..................................................... 238

15.5.3 Error message specification...................................................................240

16. Sensor verification

....................................................................................... 242

16.1 Refractive index nD verification.................................................................... 242

16.1.1 Handling R.I. liquids................................................................................. 243

16.2 Verification procedure................................................................................... 243

16.3 Sensor verification certificate.......................................................................246

16.4 Corrective action............................................................................................249

4

Page 7

17. Regulatory compliance and certifications..........................................251

17.1 Declaration of conformity for PR-23 series refractometers....................... 251

17.2 Declaration of conformity for PR-23-...-AX models (ATEX)......................253

17.3 Declaration of conformity for PR-23-...-IA models (ATEX)....................... 255

Appendix A: Glossary and abbreviations................................................257

Appendix B: Principle of measurement...................................................258

Appendix C: PR-23 sensor verification form..........................................260

Appendix D: Field calibration form........................................................... 261

Appendix E: DTR command selection tree............................................. 262

Appendix F: STR/Divert mode command selection tree.................... 263

Index................................................................................................................. 265

Warranty.......................................................................................................... 267

Technical support...........................................................................................267

Recycling..........................................................................................................267

Table of contents

5

Page 8

PR-23 Series User Guide

List of figures

Figure 1 Refractometer equipment.............................................................................13

Figure 2 Sensor structure...............................................................................................16

Figure 3 Indicating transmitter enclosure..................................................................21

Figure 4 Linearized curve.............................................................................................. 22

Figure 5 Indicating transmitter dimensions and mounting feet measures..... 24

Figure 6 Sensor electrical connections......................................................................26

Figure 7 Opening indicating transmitter front panel.............................................29

Figure 8 External power switch...................................................................................30

Figure 9 Motherboard (AC power).............................................................................. 31

Figure 10 Motherboard (24 VDC)..................................................................................32

Figure 11 Location of reset button............................................................................... 36

Figure 12 Prism wash system for steam (non-sanitary)......................................... 39

Figure 13 Sanitary prism wash system for steam.....................................................40

Figure 14 Pressure reducing valve PR‑3341‑J.............................................................41

Figure 15 Install strainer horizontally...........................................................................42

Figure 16 Wiring for a prism wash system for steam..............................................43

Figure 17 Prism wash system for high pressure water............................................44

Figure 18 Wiring for prism wash system for high pressure water....................... 45

Figure 19 Wash nozzles for flow cell AFC‑HSS‑XXX‑XX‑NC................................. 46

Figure 20 Process connection of wash nozzle in flow cell......................................47

Figure 21 Mounting of wash nozzle for sanitary probe

refractometer PR‑23

Figure 22 Mounting of wash nozzle for process refractometer PR‑23‑GP........ 49

Figure 23 Main display alternatives.............................................................................. 50

Figure 24 DTR keyboard and Main menu for sensor B............................................ 52

Figure 25 Display setup menu........................................................................................ 53

Figure 26 Main display format selection..................................................................... 54

Figure 27 System description.........................................................................................55

Figure 28 Optical images with IDS................................................................................56

Figure 29 Slope graph with IDS..................................................................................... 56

Figure 30 Optical images with VD................................................................................. 57

Figure 31 Exponential damping.................................................................................... 60

Figure 32 Linear damping................................................................................................ 61

Figure 33 Slew rate damping..........................................................................................62

Figure 34 Eect of tolerance time on output............................................................ 64

Figure 35 Damping stops during hold......................................................................... 65

Figure 36 Relay menu for relay 1....................................................................................66

Figure 37 Output menu for mA Output 1......................................................................71

Figure 38 Default mA output values.............................................................................72

Figure 39 Concentration calibration layers................................................................. 73

Figure 40 Using FIELD SAMPLE soft key.....................................................................76

Figure 41 Automatic prism wash cycle........................................................................77

Figure 42 Wash logic.........................................................................................................79

Figure 43 Wash cycle.........................................................................................................81

Figure 44 Transmitter card positions............................................................................86

Figure 45 Motherboard PR‑10600 and H1 interface card PR‑10701..................... 87

Figure 46 Troubleshooting blank display....................................................................88

Figure 47 Checking power supply.................................................................................89

Figure 48 Diagnostic LED functions.............................................................................. 91

Figure 49 Sensor nameplates.........................................................................................99

Figure 50 PR‑23 rangeability........................................................................................ 100

‑AP............................................................................... 48

IM-EN-PR23-E

6

Page 9

Figure 51 PR‑23‑M/MS/W rangeability with a sapphire prism (74)

and with a standard prism (73).................................................................100

Figure 52 PR‑23‑AC parts list........................................................................................107

Figure 53 Mounting with sanitary ferrule pipe diameter 3 in

(80 mm) or more...........................................................................................108

Figure 54 Flow cell AFC‑HSS‑ H10 for pipe diameter 1 in (25 mm)

and H15 for pipe diameter 1.5 in (40 mm)..............................................109

Figure 55 Flow cell AFC‑HSS‑ with wash nozzle connection (‑NC)

H10 for pipe diameter 1 in (25 mm) and H15 for pipe

diameter 1.5 in (40 mm)...............................................................................110

Figure 56 Flow cell AFC‑HSS‑ H20 for pipe diameter 2 in (50 mm)

and H25 for pipe diameter 2.5 in (65 mm)...............................................111

Figure 57 Flow cell AFC‑HSS‑ with wash nozzle connection (‑NC)

H20 for pipe diameter 2 in (50 mm) and H25 for pipe

diameter 2.5 in (65 mm)...............................................................................112

Figure 58 PR‑23‑AP parts list......................................................................................... 119

Figure 59 Insertion of probe refractometer PR‑23‑AP‑XX‑TSS...........................120

Figure 60 Flush mounting probe refractometer PR‑23‑AP‑XX‑PSS....................121

Figure 61 PR‑23‑GC parts list........................................................................................126

Figure 62 Mounting sensor in pipe 2.5 in or larger..................................................127

Figure 63 Mounting sensor in 2 in pipe...................................................................... 128

Figure 64 Mounting sensor with PFC flow cell......................................................... 129

Figure 65 Mounting sensor with WFC flow cell....................................................... 129

Figure 66 Mounting wafer flow cell and sensor in vertical pipe..........................130

Figure 67 Mounting wafer flow cell and sensor in horizontal pipe......................131

Figure 68 Mounting thermal cover on PR‑23‑GP.....................................................135

Figure 69 PR‑23‑GP parts list........................................................................................ 136

Figure 70 PR‑23‑GP‑A/D/JSS flow cell....................................................................... 137

Figure 71 PR‑23‑GP‑LSS flow cell................................................................................ 138

Figure 72 PR‑23‑RP parts list......................................................................................... 141

Figure 73 PR‑23‑RP head parts list..............................................................................142

Figure 74 PR‑23‑RP‑73‑M20..........................................................................................143

Figure 75 CFC‑RP‑M20‑SS/HC/HA‑M10‑NC‑PG/SN/WP flow cell ....................144

Figure 76 CFC‑RP‑M20‑SS/HC/HA‑M20‑NC‑PG/SN/WP flow cell....................145

Figure 77 Prism wash system for PR‑23‑RP..............................................................146

Figure 78 PR‑23‑M/MS sensor...................................................................................... 147

Figure 79 PR‑23‑M parts list.......................................................................................... 150

Figure 80 PR‑23‑MS parts list........................................................................................ 153

Figure 81 PR‑23‑M with ½ in G/NPT process connection..................................... 154

Figure 82 PR‑23‑W Saundersâ body sensor............................................................155

Figure 83 PR‑23‑W parts................................................................................................ 159

Figure 84 PR‑23‑W mounting.......................................................................................160

Figure 85 Refractometer system PR‑23‑…‑IA/‑IF/‑CI with STR...........................162

Figure 86 Intrinsically safe sensor nameplates........................................................ 163

Figure 87 Intrinsically safe parts.................................................................................. 164

Figure 88 Warning sticker..............................................................................................164

Figure 89 Intrinsically safe wiring, PR‑23‑…‑IA/‑CI according to WRG‑362....166

Figure 90 Intrinsically safe wiring, PR‑23‑…‑IF with STR according

to WRG‑478.................................................................................................... 167

Figure 91 Isolator unit wiring........................................................................................ 169

Figure 92 Safe‑Drive system: isolation valve, PR‑23‑SD sensor, retractor........170

Figure 93 PR-23-SD sensor parts................................................................................. 172

Figure 94 Safe‑Drive isolation valve parts.................................................................173

Figure 95 Safe‑Drive steam wash system parts....................................................... 174

Figure 96 Safe‑Drive retractor.......................................................................................175

List of figures

7

Page 10

PR-23 Series User Guide

Figure 97 Selecting mounting location...................................................................... 176

Figure 98 Mounting Safe

‑Drive on vertical pipe.......................................................177

Figure 99 Mounting Safe‑Drive on horizontal pipe................................................. 178

Figure 100 Safe-Drive isolation valve installation guide sticker............................ 179

Figure 101 Welding Safe-Drive isolation valve to horizontal pipe....................... 180

Figure 102 Welding Safe-Drive isolation valve to vertical pipe.............................. 181

Figure 103 PR-23-SD system wiring..............................................................................182

Figure 104 Mounting steam wash to isolation valve.................................................183

Figure 105 Pressure-reducing valve PR‑3341‑J..........................................................184

Figure 106 Install strainer horizontally..........................................................................185

Figure 107 Mounting high pressure water wash to isolation valve.......................186

Figure 108 Installing non-retractable wash nozzle................................................... 188

Figure 109 Recommended work zone by side of SD............................................... 190

Figure 110 Mounting thermal cover...............................................................................212

Figure 111 Removing thermal cover............................................................................. 213

Figure 112 SDI mounting flange plug system.............................................................214

Figure 113 Identifying dierent Safe‑Drive generations.........................................215

Figure 114 Refractometer system PR‑23‑…‑AX/FM/CS/CX....................................217

Figure 115 PR‑23‑…‑AX/FM/CS/CX sensor nameplates..........................................218

Figure 116 Safe sensor wiring........................................................................................220

Figure 117 Indicating transmitter DTR serial number label................................... 222

Figure 118 Indicating transmitter STR serial number label....................................222

Figure 119 Indicating transmitter DTR and STR parts (STR-specific

parts in italics)............................................................................................... 225

Figure 120 Connecting DTR to computer....................................................................227

Figure 121 Connecting DTR to LAN..............................................................................228

Figure 122 Connecting DTR to hub or switch............................................................228

Figure 123 Connecting DTR to WLAN......................................................................... 228

Figure 124 Using fiber optics Ethernet........................................................................229

Figure 125 Ethernet connector on underside of front panel.................................230

Figure 126 Typical IP configuration for stand-alone laptop when

connected to DTR; laptop wireless (WLAN) turned o......................231

Figure 127 Ping OK............................................................................................................233

Figure 128 Ping error message...................................................................................... 233

Figure 129 Instrument homepage open in browser.................................................235

Figure 130 DTR remote panel.........................................................................................236

Figure 131 Universal sample holder PR‑1012..............................................................242

Figure 132 Verification, pre-verificaton checks.........................................................243

Figure 133 Verification display...................................................................................... 244

Figure 134 Typical optical images.................................................................................244

Figure 135 Verification in progress...............................................................................245

Figure 136 Verification completed successfully (here only with one

RI liquid)..........................................................................................................245

Figure 137 Instrument verification page open in browser.....................................246

Figure 138 Instrument verification certificate........................................................... 248

Figure 139 Verification failed..........................................................................................249

Figure 140 Finding verification information for sensor verification form..........250

Figure 141 Refractometer principle..............................................................................258

Figure 142 Optical images...............................................................................................259

Figure 143 Optical image detection............................................................................. 259

IM-EN-PR23-E

8

Page 11

List of tables

Table 1 Document versions (English)............................................................................11

Table 2 PR-23 patents....................................................................................................... 12

Table 3 Wash medium parameters for integral wash nozzles in

PR‑23‑AP/GP........................................................................................................38

Table 4 Wash medium parameters for flow cell wash nozzle AFC...................... 38

Table 5 Wash medium parameters for Safe‑Drive isolation valve

nozzle SDI............................................................................................................. 38

Table 6 Prism wash nozzle selection............................................................................47

Table 7 Chemical curve parameters............................................................................. 74

Table 8 Diagnostic LEDs..................................................................................................90

Table 9 Hardware troubleshooting...............................................................................92

Table 10 Measurement troubleshooting....................................................................... 94

Table 11 Wash troubleshooting.......................................................................................96

Table 12 Sanitary compact refractometer for pipelines.........................................100

Table 13 Elbow flow cells for PR‑23‑AC‑xx‑HSS sensor..........................................102

Table 14 EHEDG certified elbow flow cells, connection sanitary clamp 2.5 in..103

Table 15 Elbow flow cells with prism wash nozzle for PR‑23‑AC‑xx‑HSS.......... 103

Table 16 Mounting hardware for PR-23-AC-xx-HSS sensor...................................104

Table 17 Mounting hardware for PR‑23‑AC‑xx‑ESS sensor................................... 104

Table 18 Side flow cells, connection sanitary clamp 2.5 in.....................................105

Table 19 General specifications..................................................................................... 106

Table 20 Sensor PR-23-AC specifications...................................................................106

Table 21 Sanitary probe refractometer for large pipelines and vessels...............113

Table 22 Sanitary probe refractometer PR‑23‑AP with prism wash

for large pipelines and vessels....................................................................... 114

Table 23 Mounting hardware for PR‑23‑AP sensor....................................................116

Table 24 Side flow cells, connection sanitary clamp 2.5 in......................................117

Table 25 Aseptic steam valve for PR‑23‑AP‑ISS.........................................................117

Table 26 General specifications.......................................................................................118

Table 27 Sensor PR‑23‑AP specifications.....................................................................118

Table 28 PR‑23‑GC sensor model code........................................................................122

Table 29 Wafer flow cell model code............................................................................123

Table 30 Pipe flow cell model code...............................................................................124

Table 31 General specifications......................................................................................124

Table 32 Sensor PR‑23‑GC specifications....................................................................125

Table 33 PR‑23‑GP sensor model code........................................................................ 132

Table 34 General specifications......................................................................................133

Table 35 Sensor PR‑23‑GP specifications....................................................................134

Table 36 PR‑23‑RP sensor model code........................................................................ 139

Table 37 General specifications..................................................................................... 140

Table 38 Sensor PR‑23‑RP specifications................................................................... 140

Table 39 PR‑23‑M sensor model code.......................................................................... 147

Table 40 Flow cell for sensor PR‑23‑M......................................................................... 148

Table 41 General specifications......................................................................................149

Table 42 Sensor PR‑23‑M specifications......................................................................149

Table 43 Flow cell for PR‑23‑M specifications............................................................149

Table 44 PR‑23‑MS sensor model code....................................................................... 150

Table 45 Flow cell for sensor PR‑23‑MS........................................................................151

Table 46 General specifications......................................................................................152

Table 47 Sensor PR-23-MS specifications................................................................... 152

Table 48 Flow cell for PR‑23‑MS specifications..........................................................153

Table 49 PR‑23‑W sensor model code......................................................................... 155

List of tables

9

Page 12

PR-23 Series User Guide

IM-EN-PR23-E

Table 50 Saunders

Table 51 General

â valve body flow cell for sensor PR‑23‑W.............................156

specifications......................................................................................157

Table 52 Sensor PR‑23‑W specifications..................................................................... 157

Table 53 Saundersâ valve body specifications.........................................................158

Table 54 PR

‑23‑SD specifications..................................................................................170

Table 55 PR-23-SD and isolation valve SDI-23 specifications................................ 171

Table 56 Safe‑Drive retractor SDR-23 specifications................................................ 171

Table 57 Nozzle flow at various pressures with 2 mm (0.080 in)

nozzle orifice diameter....................................................................................186

Table 58 Indicating transmitter DTR and STR model codes.................................. 223

Table 59 Indicating transmitter specifications.......................................................... 223

Table 60 Interconnecting cable model code..............................................................226

Table 61 Interconnecting cable specifications..........................................................226

Table 62 Request-response pair specification.......................................................... 238

Table 63 Verification results display............................................................................ 260

10

Page 13

Chapter 1 – About this document

1. About this document

1.1 Version information

This document provides instructions for installing, using and maintaining Vaisala KPATENTSâ Process Refractometer PR-23.

Table 1 Document versions (English)

Document code Date Description

IM-EN-PR23, E February 2021 Structure and style updates, updates to sensor specifications.

IM-EN-PR23, D January 2021 Minor updates.

IM-EN-PR23, C November 2019 New AX certificate

1.2 Documentation conventions

WARNING!

instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

instructions carefully at this point, the product could be damaged or important data

could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Warning alerts you to a serious hazard. If you do not read and follow

Caution warns you of a potential hazard. If you do not read and follow

Lists tools needed to perform the task.

11

Page 14

PR-23 Series User Guide

Indicates that you need to take some notes during the task.

1.3 Trademarks

IM-EN-PR23-E

Vaisalaâ and K

-PATENTS® are registered trademarks of Vaisala Oyj.

Linuxâ is a registered trademark of Linus Torvalds.

Windowsâ is either a registered trademark or trademark of Microsoft Corporation in the

United States and other countries.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

1.4 Patent notice

This product is protected by the following patents and patent applications and their

c

orresponding national rights:

Table 2 PR-23 patents

Product Applicable patent

Process Refractometer PR-03/23/33 US 9063020 23.2.2032

Process Refractometer PR-03M/23M/MS/W US 6760098 1.8.2021

US 9028140 19.1.2032

SAFE-DRIVE™ Refractometer PR-23-SD FI 118442 17.6.2026

US 7631569 9.12.2027

Process Refractometer PR-23/33 also has the following additional patent applications

pending:

• FI 20106065

• DE 102011084387.6

• US 13/273,907

• FI 20106066

• DE 102011094386.8

• US 13/274,000

12

Page 15

PROCESSINSTRUMENTS

POWE R

1 2

3

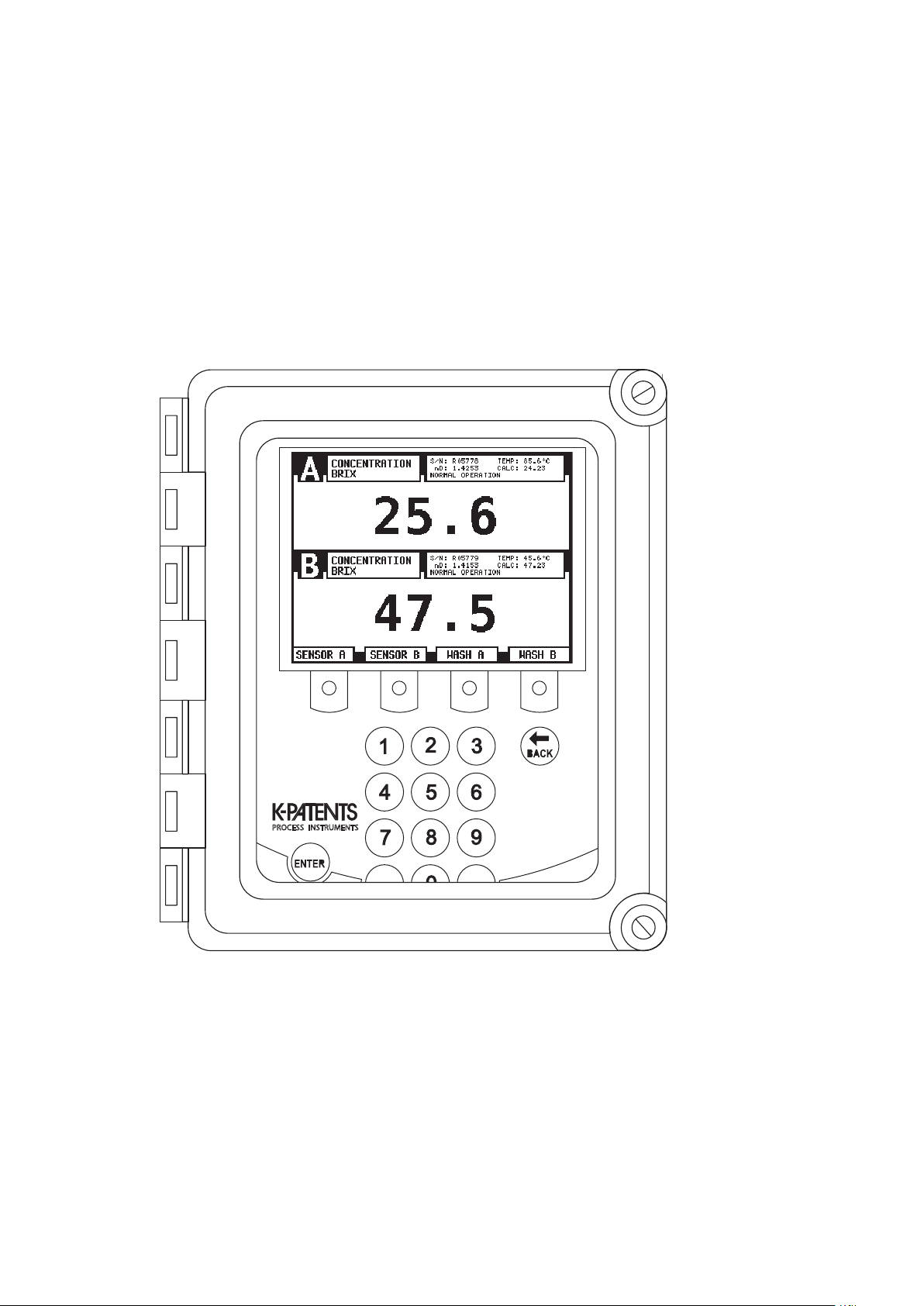

Chapter 2 – Product overview

2. Product overview

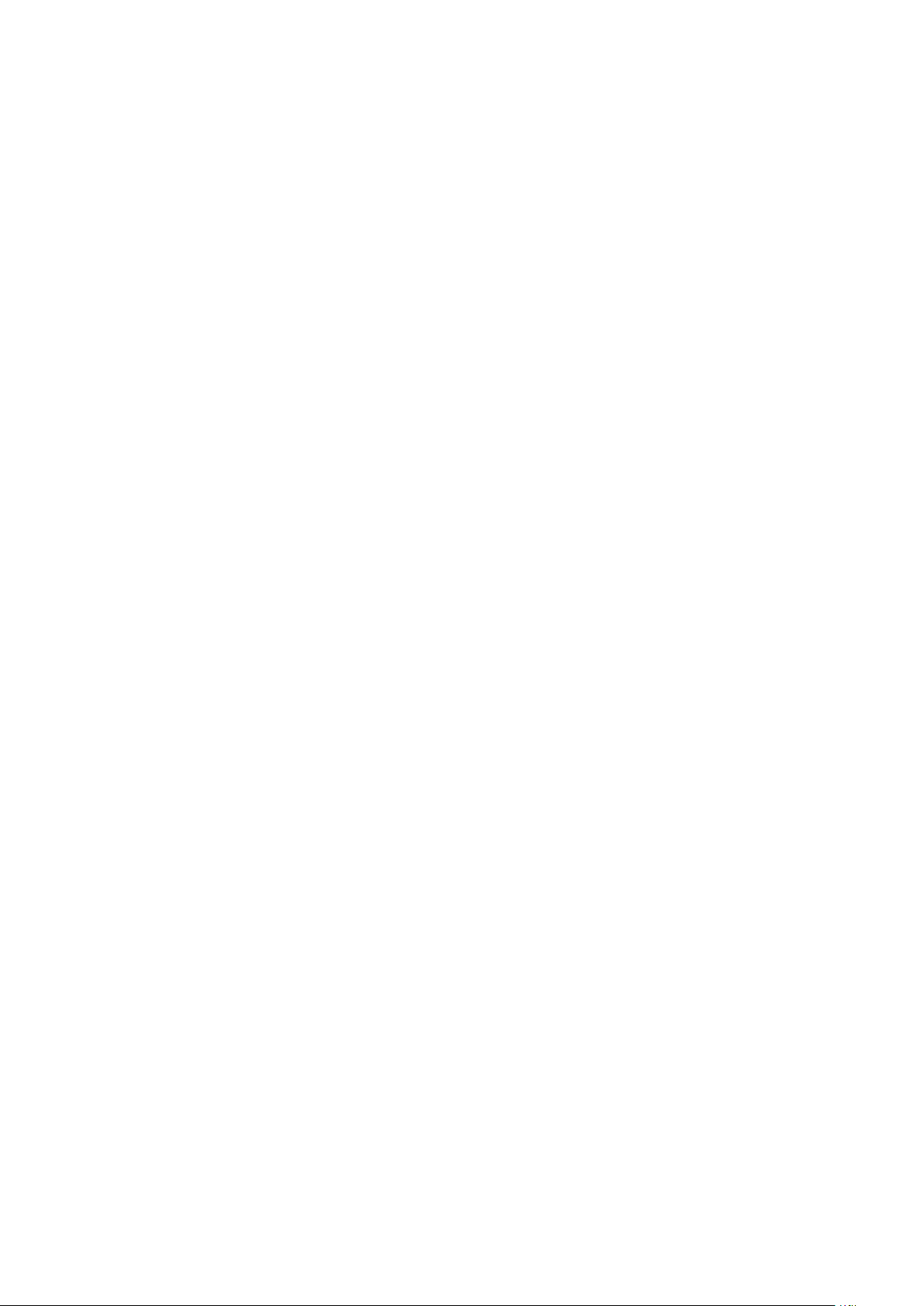

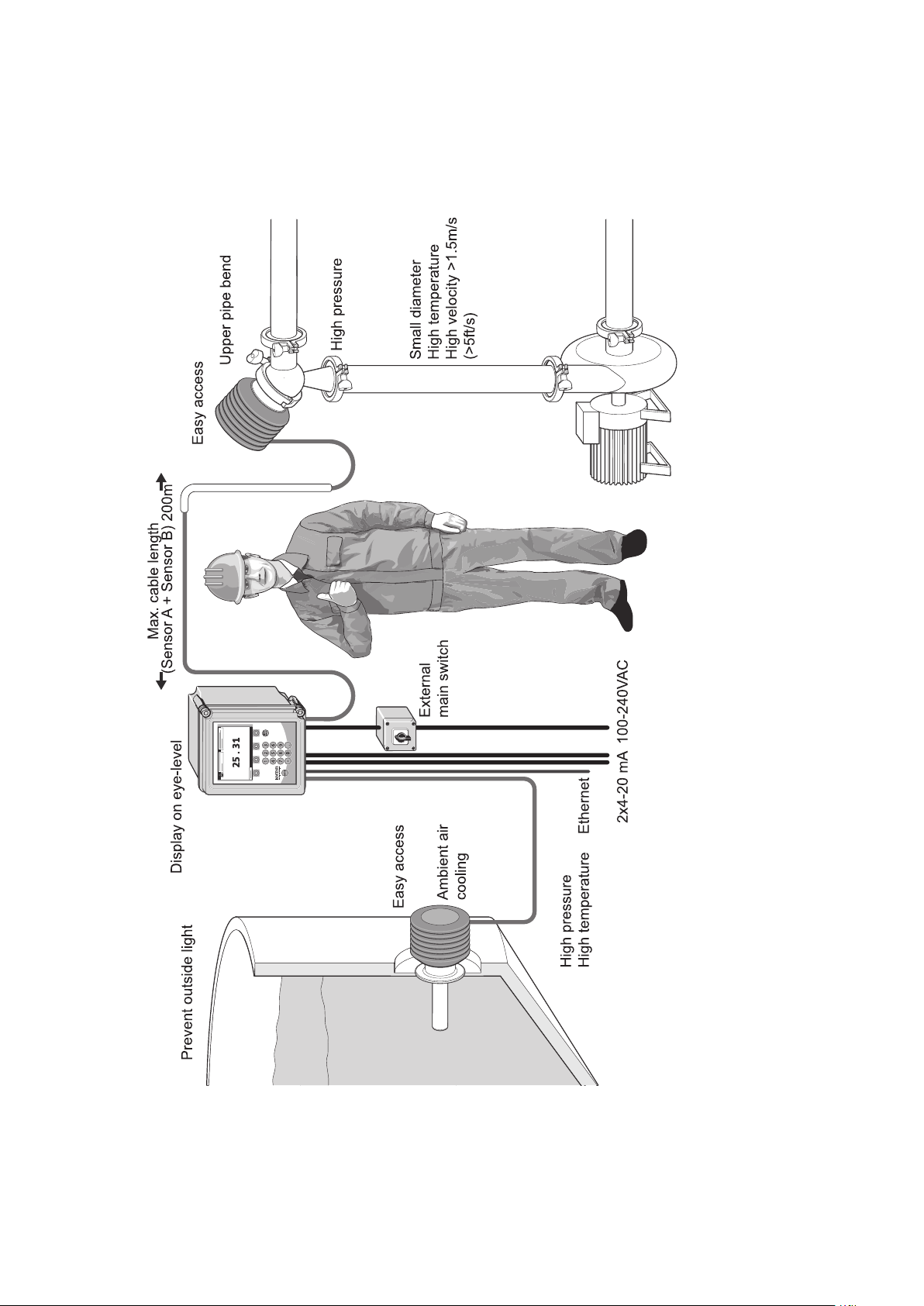

The PR‑23 in‑line refractometer is an instrument for measuring liquid concentration in the

process line. The measurement is based on the refraction of light in the process medium, an

accurate and safe way of measuring liquid concentration.

Figure 1 Refractometer equipment

1 Sensors

2 Interconnecting cables

3 Indicating transmitter

The in‑line refractometer sensor (1) measures the refractive index nD and the temperature of

the process medium. This information is sent through the interconnecting cable (2) to the

indicating transmitter (3). The indicating transmitter DTR calculates the concentration of the

process liquid based on the refractive index and temperature, taking predefined process

conditions into account. The output of the DTR is a 4 to 20 mA DC output signal

proportional to process solution concentration. Process data can also be downloaded to a

computer through an Ethernet cable.

The password for PR‑23 is:

7 8 4 5 1 2

2.1 Safety

This product has been tested for safety. Note the following precautions:

13

Page 16

PR-23 Series User Guide

IM-EN-PR23-E

WARNING!

e to local and state legislation and regulations.

adher

Only licensed experts may install electrical components. They must

Precautions when removing the sensor from the process line:

Make positively sure that the process line is not under pressure. Open a vent valve to

•

the atmosphere.

• For a prism wash system, close a hand valve for the wash medium and disable the wash

valve.

• Loosen the flange or clamp cautiously, be prepared to tighten again.

• Be out of the way of any possible splash and ensure the possibility of escape.

• Use shields and protective clothing adequate for the process medium, do not rely on

avoidance of contact with the process medium.

• After removal of the sensor, it may be necessary to mount a blind cover for security

reasons.

For the Safe-Drive system safety rules, see S

Safe‑Drive generation 2.1 (page 189) and for additional precautions required by explosive

atmosphere, see PR‑23 process refractometers in potentially explosive atmosphere

(page 216).

afe sensor insertion and removal for

Wear protective eyewear.

Wear protective gloves.

It is the user’s responsibility to follow manufacturer’s safety and operating instructions. The

client’s organization has the responsibility to develop and maintain occupational safety and

create a safety culture where individuals are expected to follow safety instructions at all

times. Any negligence towards safety instructions or failure to comply with safe practices

should not be tolerated. It is the manufacturer’s responsibility to produce goods that are

safe to use when instructions are followed.

The process medium may be hot or otherwise hazardous. Use shields and protective

clothing adequate for the process medium. Do not rely on avoidance of contact with the

process medium.

14

Page 17

Chapter 2 – Product overview

2.2 Storage conditions, packaging and transportation

Soft shell packaging prevents damage to the refractometer. Transport the device in its

original packaging.

Before storing, remove any dirt and grease from the refractometer and make sure that it is

dry.

Storage conditions:

• Temperature: −40 °С…+40 °С (−40 °F… +104 °F)

• Humidity: No condensation

The product's shelf life is six months.

2.3 PR-23 refractometer models

The basic system of one or two sensors connected to an indicating transmitter (DTR) is the

same for all PR‑23 in-line refractometer models. However, there are dierent sensor models,

each model is adapted for dierent process requirements.

The models PR‑23‑AC and PR‑23‑AP meet the 3‑A Sanitary Standard requirements. With an

ATEX approved PR‑23‑…‑AX sensor or a FM approved PR‑23‑…‑FM sensor or a CSA

approved PR‑23‑…‑CS sensor or a Nepsi certified PR‑23‑…‑CX sensor a PR‑23 process

refractometer system can be used in potentially explosive atmosphere. Intrinsically safe

process refractometer PR‑23‑…‑IA/‑IF/‑CI can be used in hazardous locations in Zone 0 and

Zone 1. The Safe‑Drive system with a PR‑23‑SD sensor enables safe sensor insertion and

removal also when process line is in full operation.

2.4

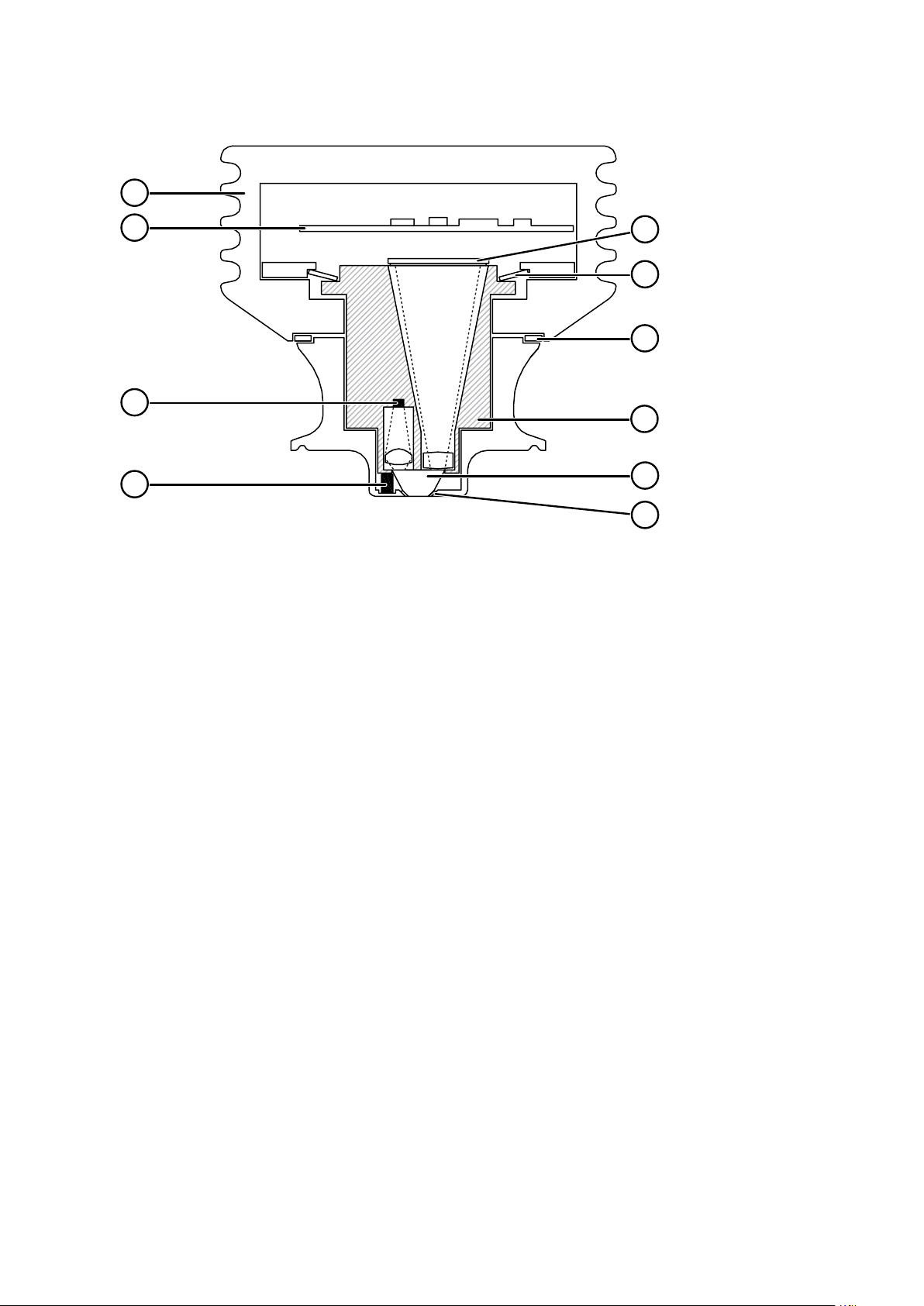

The following figure shows a cutaway picture of a refractometer sensor. The measurement

prism (6) is flush mounted to the surface of the probe tip. The prism (6) and all the other

optical components are fixed to the solid core module (7), which is springloaded (9) against

the prism gasket (5). The light source (3) is a yellow LED, and the receiver is a Charge

Couple Device (CCD) element (10). The electronics is protected against process heat by a

thermal isolator (8) and cooling fins (1). The sensor processor card (2) receives the raw data

from the CCD element (10) and the Pt‑1000 process temperature probe (4), then calculates

the refractive index nD and the process temperature T. This information is transmitted to the

indicating transmitter.

Refractometer sensor

15

Page 18

1

2

3

4

5

6

7

8

9

10

PR-23 Series User Guide

IM-EN-PR23-E

Figure 2 Sensor structure

1 Cooling fins

2 Sensor processor card

3 Light source

4 Temperature probe

5 Gasket

6 Prism

7 Core module

8 Thermal isolator

9 Disc spring

10 CCD element

16

Page 19

Chapter 3 – Mounting sensor

3. Mounting sensor

Choose the sensor mounting location with care to ensure reliable readings from the process.

Some basic rules, described in this section, apply to all sensor models. The model specific

instructions can be found in Sensor specifications (page 99).

• For the Sanitary compact refractometer PR‑23‑AC see Sanitary process refractometer

PR‑23‑AC (page 100)

• For the Probe sanitary refractometer PR‑23‑AP see Sanitary probe refractometer

PR‑23‑AP (page 113)

• For the Process probe refractometer PR‑23‑GP see Probe process refractometer

PR‑23‑GP (page 131)

• For the Teflon body refractometer PR‑23‑M and Teflon body semicon refractometer

PR‑23‑MS see Teflon body refractometer PR‑23‑M/MS (page 146)

• For the Saunders body refractometer PR‑23‑W see Saundersâ body refractometer

PR‑23‑W (page 154)

• For mounting an ATEX/FM/CSA approved sensor in explosive atmosphere, see

Installation (page 219)

• For mounting an intrinsically safe refractometer PR‑23‑…‑IA/‑CI, see Intrinsically safe

refractometers PR‑23‑…‑IA, PR‑23‑…‑IF and PR‑23‑…‑CI (page 161)

• For mounting of the Safe-Drive system with the PR‑23‑SD sensor, see Safe‑Drive

mounting (page 175)

3.1

Choosing sensor mounting location

A PR‑23 refractometer sensor can be located either indoors or outdoors in most climates.

However, when locating a sensor outdoors, make sure to provide some basic protection

against direct exposure to sunlight and rain. Take special care if the pipe wall is translucent

(for example of fiberglass), as light from outside reaching the prism through the pipe wall

may disturb the measurement.

The mounting location needs to be such that sediments or gas bubbles cannot accumulate

by the sensor. Good flow velocity is essential in keeping the prism clean.

CAUTION!

damage the in-line sensor mounted on it.

Always check that the sensor head is kept cool enough; the sensor head should not be too

hot to keep a hand on. The sensor cover should not be exposed to high temperature

radiation. In most cases, draft and natural convection provide sucient air cooling if the air

gets to flow freely around the sensor head.

If the process pipe vibrates, support the pipe. A vibrating pipe might

17

Page 20

PR-23 Series User Guide

IM-EN-PR23-E

Additional cooling is necessary when the ambient temperature is higher than 45 °C (113 °F)

or when the pr

ocess temperature is above 110 °C (230 °F) and the ambient temperature is

above 35 °C (95 °F). The air cooling is improved by blowing pressurized air against the

sensor cover. The pressurized air can be supplied by the ventilation system. If no air is

available it is also possible to install water cooling with PR‑10038 cooling cover (except for

PR‑23‑SD where sensor head needs to be kept in original size for insertion and retraction).

CAUTION!

wnwards from the sensor head.

do

Always mount the sensor so that the interconnecting cable points

18

Page 21

3.2 PR-23 mounting guide

Chapter 3 – Mounting sensor

19

Page 22

PR-23 Series User Guide

IM-EN-PR23-E

3.3 Pipe mounting checklist

Most in-line refractometer models are mounted in a pipe. The recommended minimum flow

velocity is 1.5 m/s (5 ft/s). The diameter and form of the pipe and the process temperature

the measurement and need to be taken into account.

aect

1. If the process pipe diameter varies, select the position with the smallest diameter (and

accordingly highest velocity). Then the prism keeps better clean.

2. If the refractometer is used in a feed-back control loop, make the time lag short. When

a dilution valve is controlled, for example, mount the refractometer close to the dilution

point. However, make sure complete mixing has occurred at mounting location.

3. If the temperature varies along the process pipe, select the position with the highest

process temperature. Then the risk of prism coating is minimized, because higher

temperature means higher solubility and also lower viscosity.

4. Often the position with the highest process pressure (= after pump + before valve) has

favorable flow

5. The sensor is accessible for service.

conditions without sedimentation or air trapping risks.

3.4 Checklist for mounting in tank, vessel or large pipe

A probe sensor PR-23-AP or PR-23-GP can be inserted with a flange or clamp into tanks and

vessels which either do not have a scraper or where the mixer does not touch the vessel

wall. A probe sensor can also be flush mounted in a cooker where the scraper touches the

wall.

1. The inserted probe sensor is mounted close to a stirrer to ensure representative sample

of the process liquid and to keep the prism clean.

2. The sensor is accessible for service.

20

Page 23

PROCESS INSTRUMENTS

P OW E R

Chapter 4 – Indicating transmitter DTR

4. Indicating transmitter DTR

The indicating transmitter DTR is a specialized computer designed to process data received

from one or two sensors. The indicating transmitter enclosure contains a front panel with a

backlit LCD and a keyboard. The front panel swings open to give access for connections and

service. Both of the enclosure’s cover latches include knockout padlock provisions to

prevent unauthorized access.

Figure 3 Indicating transmitter enclosure

The sensors send the values of the refractive index nD and the process temperature T to the

DTR. The microprocessor system then linearizes the concentration reading as shown in the

following example, and performs an automatic temperature compensation.

21

Page 24

10

20

30

40

50

60

70

1.35 1.40 1.45

n

D

BRIX

PR-23 Series User Guide

IM-EN-PR23-E

Figure 4 Linearized curve

22

Page 25

Warning! The DTR does not have a built-in power

switch. The system is always powered on when

connected to a power source. It is recommended to

mount an external power switch to control the DTR’s

power supply.

Varoitus! DTR:ssä ei ole sisäänrakennettua

virtakytkintä. Järjestelmän virta on aina päällä, kun

s

e on kytketty virtalähteeseen. DTR:n virransyötön

ohjaamiseksi on suositeltavaa asentaa ulkoinen

virtakytkin.

Varning! DTR har ingen inbyggd strömbrytare.

Systemet är alltid påslaget när det är anslutet till en

strömkälla. Rekommendationen är att montera en

extern strömbrytare för att styra strömförsörjningen

till DTR:er.

Advarsel! DTR har ikke nogen indbygget afbryder.

Systemet er altid tændt, når det er tilsluttet en

strømkilde. Det anbefales at montere en ekstern

afbryder til styring af DTR'ens strømforsyning.

Hoiatus! DTR-il puudub sisseehitatud toitelüliti.

Süsteem on alati pinge all, kui on toiteallikaga

ühendatud. DTR-i toiteallika juhtimiseks on

soovitatav paigaldada väline toitelüliti.

Внимание! DTR н е имеет встроенного

переключателя питания. Если система

подключена к источнику питания, она всегда

включена. Для управления подачей питания на

DTR рекомендуется установить внешний

переключатель питания.

Įspėjimas! DTR ne turi įmontuoto maitinimo jungiklio.

Sistema visada įjungiama, kai ji yra prijungta prie

maitinimo šaltinio. DTR maitinimo šaltiniui valdyti

rekomenduojama sumontuoti išorinį maitinimo

jungiklį.

Ostrzeżenie! DTR nie zawiera wbudowanego

wyłącznika zasilania. Zasilanie systemu jest włączone

zawsze, gdy jest on podłączony do źródła zasilania.

Wskazane jest wykonanie zewnętrznego wyłącznika

zasilania do sterowania zasilaniem DTR.

Varování! DTR nemá vestavěný vypínač napájení. Po

připojení ke zdroji napájení je systém vždy zapnutý.

Pro ovládání napájení DTR se doporučuje

namontovat externí vypínač.

Figyelmeztetés! A DTR nem rendelkezik beépített

hálózati kapcsolóval. A rendszer mindig be van

kapcsolva, ha áramforráshoz csatlakozik. A DTR

tápellátásának vezérléséhez ajánlott egy külső

tápkapcsolót felszerelni.

Warnung! Der DTR ist nicht mit einem eingebauten

Netzschalter ausgestattet. Das System ist immer

eingeschaltet, wenn es an eine Stromquelle

angeschlossen ist. Es wird empfohlen, einen externen

Netzschalter zu installieren, um die Stromversorgung

des DTR zu steuern.

Waarschuwing! De DTR heeft geen ingebouwde

voedingsschakelaar. Het systeem is altijd

ingeschakeld wanneer het is aangesloten op een

voedingsbron. Het wordt aanbevolen om

een

externe voedingsschakelaar

te monteren om de

voeding van de DTR te regelen.

Avertissement ! Le DTR n’est pas équipé d’un

interrupteur d'alimentation intégré. Le système est

toujours sous tension lorsqu'il est connecté à une

source d'alimentation. Il est recommandé de monter

un interrupteur d'alimentation externe pour

contrôler l'alimentation du DTR.

¡Advertencia! El DTR no tiene un interruptor de

encendido integrado. El sistema siempre está

encendido cuando está conectado a una fuente de

alimentación. Se recomienda montar un interruptor

de encendido externo para controlar la fuente de

alimentación del DTR.

Avvertimento! Il DTR non dispone di un interruttore

di alimentazione integrato. Il sistema è sempre

acceso quando è collegato a una fonte di

alimentazione. Si consiglia di montare un interruttore

di alimentazione esterno per controllare

l'aliment

azione del DTR.

Warning

Chapter 4 – Indicating transmitter DTR

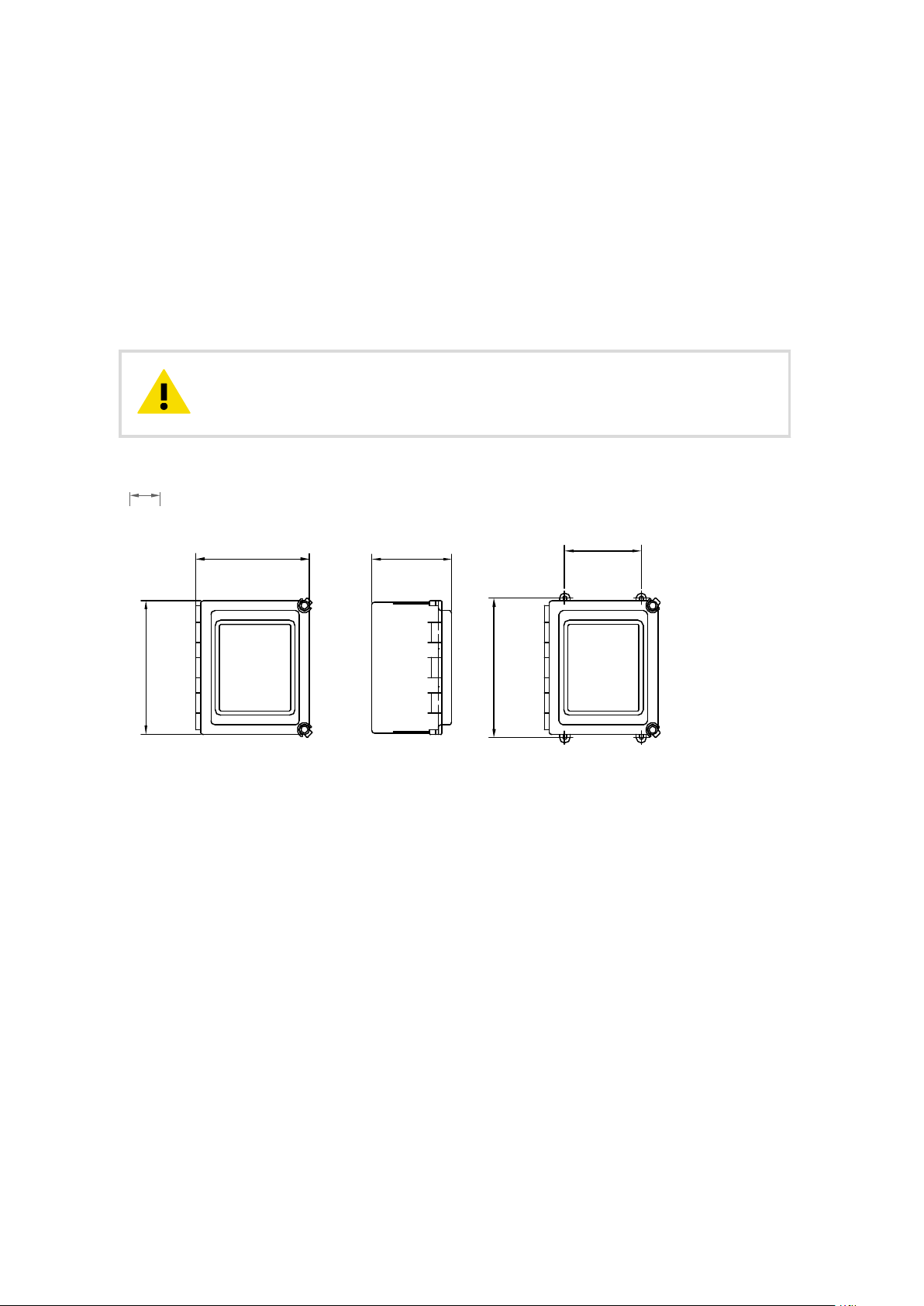

4.1 Mounting indicating transmitter

23

Page 26

mm

[in]

267 [10.5]

226 [8.9] 159 [6.25]

278 [10.94]

152 [6.0]

PR-23 Series User Guide

IM-EN-PR23-E

Mount the indicating transmitter indoors, preferably in an easily accessible, well-lit and dry

ea. Avoid vibration. Take interconnecting cable length into consideration when choosing

ar

the mounting location.

The enclosure is mounted vertically on an upright surface (wall) using four mounting feet,

see the following figure. The LCD is best viewed when approximately at the eye level of the

user.

In sanitary installations, the recommendation is to use a DTR with stainless steel enclosure. If

standard polycarbonate enclosure is used, install it as remotely as practical from product

areas or connections.

CAUTION!

class of the enclosure and damage the electronics.

Figure 5 Indicating transmitter dimensions and mounting feet measures

Do not drill mounting holes in the enclosure as that aec

t the protection

4.2 Electrical connections

4.2.1 Interconnecting cable

The cable contains a pair of twisted signal wires and a cable shield, see

Standard delivery is 10 m (33 ft) of cable. The maximum length of an interconnecting cable

is 200 m (660 ft). The signal wires are interchangeable (non-polarized). The cable shield is

connected to the protective earth at the indicating transmitter.

The junction box enables the use of customer’s own cable as long as it meets IEC 61158-2

type A standard requirements, see Interconnecting cable specifications (page 226).

More information

‣

Connecting sensor (page 25)

24

Figure 9 (page 31).

Page 27

4.2.2 Connecting sensor

Chapter 4 – Indicating transmitter DTR

CAUTION!

energized. Switch o the power from indicating transmitter DTR external power switch

before disconnecting the sensor cable from the sensor. After connecting the sensor

cable back to the sensor, you can switch power back on.

Do not connect or disconnect the sensor connector when the circuits are

1. Remove the four screws holding the sensor nameplate as shown in the following figure.

The terminal strip is under the nameplate.

2. Connect the signal wires to terminal (1) and (2), and the cable shield to terminal (3).

3. Tighten up the cable gland.

25

Page 28

1

2

3

PR-23 Series User Guide

4. Screw the nameplate back on.

IM-EN-PR23-E

Figure 6 Sensor electrical connections

More information

‣

Interconnecting cable (page 24)

26

Page 29

Warning! Check that the power is off before opening

the front panel. If the green power indicator light is

on, there is still power in the system. To completely

turn the power off, use the external power switch.

Varoitus! Tarkista, että virta on katkaistu, ennen kuin

avaat etupaneelin. Jos vihreä virran merkkivalo

palaa, järjestelmässä on edelleen virtaa. Katkaise

virta kokonaan ulkoisella virtakytkimellä.

Varning! Kontrollera att strömmen är avstängd innan

du öppnar frontpanelen. Om den gröna

indikatorlampan lyser är det fortfarande ström i

systemet. Använd den externa strömbrytaren för att

stänga av strömmen helt.

Advarsel! Kontroller, at strømmen er slukket, før

frontpanelet åbnes. Hvis den grønne

strømindikatorlampe er tændt, er der stadig strøm i

systemet. Brug den eksterne afbryder for at slukke

helt for strømmen.

Hoiatus! Enne esipaneeli avamist kontrollige, et

süsteem poleks pinge all. Kui roheline toitemärgutuli

põleb, on süsteemis endiselt pinge all. Toite

täielikuks väljalülitamiseks kasutage välist toitelülitit.

Внимание! Перед открытием передней панели

убедитесь, что питание отключено. Если горит

зеленый индикатор питания, система находится

под напряжением. Чтобы полностью отключить

питание, используйте внешний переключатель

питания.

Įspėjimas! Prieš atidarydami priekinį skydelį,

patikrinkite, ar maitinimas išjungtas. Jei šviečia žalia

maitinimo indikatoriaus lemputė, sistemoje vis dar

veikia maitinimas. Norėdami visiškai išjungti

maitinimą, naudokite išorinį maitinimo jungiklį.

Ostrzeżenie! Przed otwarciem panelu przedniego

sprawdzić, czy zasilanie jest wyłączone. Dopóki

świeci się zielona kontrolka zasilania, system

znajduje się pod napięciem zasilania. W celu

całkowitego wyłączenia zasilania należy użyć

zewnętrznego wyłącznika zasilania.

Varování! Před otevřením předního panelu

zkontrolujte, zda je napájení vypnuto. Pokud svítí

zelená kontrolka napájení, je v systému stále

přítomno napájení. Chcete-li napájení zcela vypnout,

použijte externí vypínač.

Figyelmeztetés! Az előlap kinyitása előtt ellenőrizze,

hogy a készülék ki van-e kapcsolva. Ha a zöld

tápellátás jelzőfény világít, akkor a rendszer még

áram alatt van. A készülék teljes kikapcsolásához

használja a külső tápkapcsolót.

Warnung! Prüfen Sie, ob das Gerät ausgeschaltet ist,

bevor Sie die Frontblende öffnen. Wenn die grüne

Betriebsanzeige leuchtet, liegt noch Spannung an.

Verwenden Sie den externen Netzschalter, um das

Gerät vollständig auszuschalten.

Waarschuwing! Controleer of de stroom is

uitgeschakeld voordat u het voorpaneel opent. Als

het groene stroomindicatielampje brandt, staat er

nog stroom op het systeem. Gebruik de externe

voedingsschakelaar om de stroom volledig uit te

schakelen.

Avertissement! Vérifiez que l'alimentation est

coupée avant d'ouvrir le panneau avant. Si le voyant

d'alimentation vert est allumé, le système est

toujours sous tension. Pour mettre l'appareil

complètement hors tension, utilisez l'interrupteur

d'alimentation externe.

¡Advertencia! Verifique que la alimentación está

desconectada antes de abrir el panel frontal. Si la luz

indicadora de encendido de color verde está

encendida, aún hay energía en el sistema. Para

apagar completamente la alimentación, use el

interruptor de encendido externo.

Avvertimento! Verificare che l'alimentazione sia

spenta prima di aprire il pannello anteriore. Se la spia

di alimentazione verde è accesa, il sistema è ancora

alimentato. Per spegnere completamente

l'alimentazione, utilizzare l'interruttore di

alimentazione esterno.

Warning

Chapter 4 – Indicating transmitter DTR

4.2.3 Connecting indicating transmitter

27

Page 30

Warning! Hazardous voltage, contact may cause

electric shock or burn. Beware of the live wires in the

lower right-hand corner of the H1 interface card.

Varoitus! Vaarallinen jännite – kosketus voi aiheuttaa

sähköiskun tai palovammoja. Varo jännitteisiä johtoja

H1-liitäntäkortin oikeassa alakulmassa.

Varning! Farlig spänning. Kontakt kan leda till elstöt

eller brännskador. Var försiktig med de strömförande

kablarna i det nedre högra hörnet på H1gränssnittskortet.

Advarsel! Farlig spænding, kontakt kan forårsage

elektrisk stød eller forbrænding. Vær opmærksom på

de strømførende ledninger i nederste højre hjørne af

H1-interfacekortet.

Hoiatus! Ohtlik pinge, kokkupuutel võite saada

elektrilöögi või põletuse. Ettevaatust voolu all

olevate juhtmetega H1-liidesekaardi all paremas

nurgas.

Внимание! Опасное напряжение, при контакте

можно получить удар электрическим током или

ожог. Остерегайтесь проводов под напряжением

в правом нижнем углу интерфейсной платы H1.

Įspėjimas! Pavojinga įtampa, kontaktas gali sukelti

elektros smūgį arba užsidegimą. Saugokitės įtampos

laidų, esančių apatiniame dešiniajame H1 sąsajos

kortelės kampe.

Ostrzeżenie! Niebezpieczne napięcie, dotknięcie

grozi porażeniem prądem lub oparzeniem. Uważać

na przewody pod napięciem w prawym dolnym rogu

karty interfejsu H1.

Varování! Nebezpečné napětí, kontakt může

způsobit úraz elektrickým proudem nebo popálení.

Dejte si pozor na vodiče pod napětím v pravém

dolním rohu karty rozhraní H1.

Figyelmeztetés! Veszélyes feszültség, érintése

áramütést vagy égési sérülést okozhat. Óvakodjon a

feszültség alatt lévő vezetékektől a H1

interfészkártya jobb alsó sarkában.

Warnung! Gefährliche Spannung, Kontakt kann

Stromschlag oder Verbrennungen verursachen.

Halten Sie sich von den stromführenden Kabeln

unten rechts an der H1 Schnittstellenkarte fern.

Waarschuwing! Gevaarlijke spanning, contact kan

elektrische schokken of brandwonden veroorzaken.

Pas op voor de spanningvoerende draden in de

rechterbenedenhoek van de H1-interfacekaart.

Avertissement! Tension dangereuse, un contact peut