USER'S GUIDE

Vaisala BAROCAP® Barometer

Module

PMB100

M010035EN-A

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

CHAPTER 1_______________________________________________________ GENERAL INFORMATION

Table of contents

CHAPTER 1

GENERAL INFORMATION ............................................................................4

Safety.........................................................................................4

Warranty ....................................................................................4

CHAPTER 2

PRODUCT DESCRIPTION.............................................................................5

BAROCAP® pressure sensor..................................................5

CHAPTER 3

OPERATION...................................................................................................7

Connections..............................................................................7

Dimensions in mm (in inches).................................................9

Pressure calculations...............................................................9

Offset/Gain corrections..........................................................10

CHAPTER 4

TECHNICAL DATA.......................................................................................11

Specifications .........................................................................11

Operating range..............................................................11

Accuracy.........................................................................11

General...........................................................................11

APPENDIX A

READING COEFFICIENTS FROM THE EEPROM......................................13

VAISALA __________________________________________________________________________ 3

USER'S GUIDE_______________________________________________________________________

CHAPTER 1

GENERAL INFORMATION

Safety

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

CAUTION

NOTE

Warranty

Warning denotes a serious hazard. It calls attention to a procedure,

practice, condition or the like, which, if not correctly performed or

adhered to, could result in injury to or death of personnel.

Caution denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to,

could result in damage to or destruction of part or all of the product.

Note highlights important information. It calls attention to an

essential procedure, practice, condition or the like.

Vaisala issues a guarantee for the material and workmanship of this

product under normal operating conditions for one (1) year from the

date of delivery. Exceptional operating conditions, damage due to

careless handling and misapplication will void the guarantee.

4 ____________________________________________________________________ M010035EN-A

CHAPTER 2_______________________________________________________ PRODUCT DESCRIPTION

CHAPTER 2

PRODUCT DESCRIPTION

The PMB100 for OEM applications is a new circuit board mountable

barometric pressure transducer that is designed to interface with an

AD converter and a microprocessor.

The PMB100 module is characterized over 800 to 1100 hPa (mbar)

pressure range and over –5 to +45C temperature range. It ouputs

pressure dependant voltage within 0 and 2.5 VDC along with a

reference voltage of 2.5 VDC. All pressure and temperature related

coefficients are given in a module specific certificate and also stored

in an incorporated EEPROM, which uses the I2C interface. All the user

needs to do is to measure the temperature of the module and the two

voltage outputs and then calculate the compensated pressure reading

using the coefficients. A final offset correction against a high-class

pressure standard is recommended as a final touch.

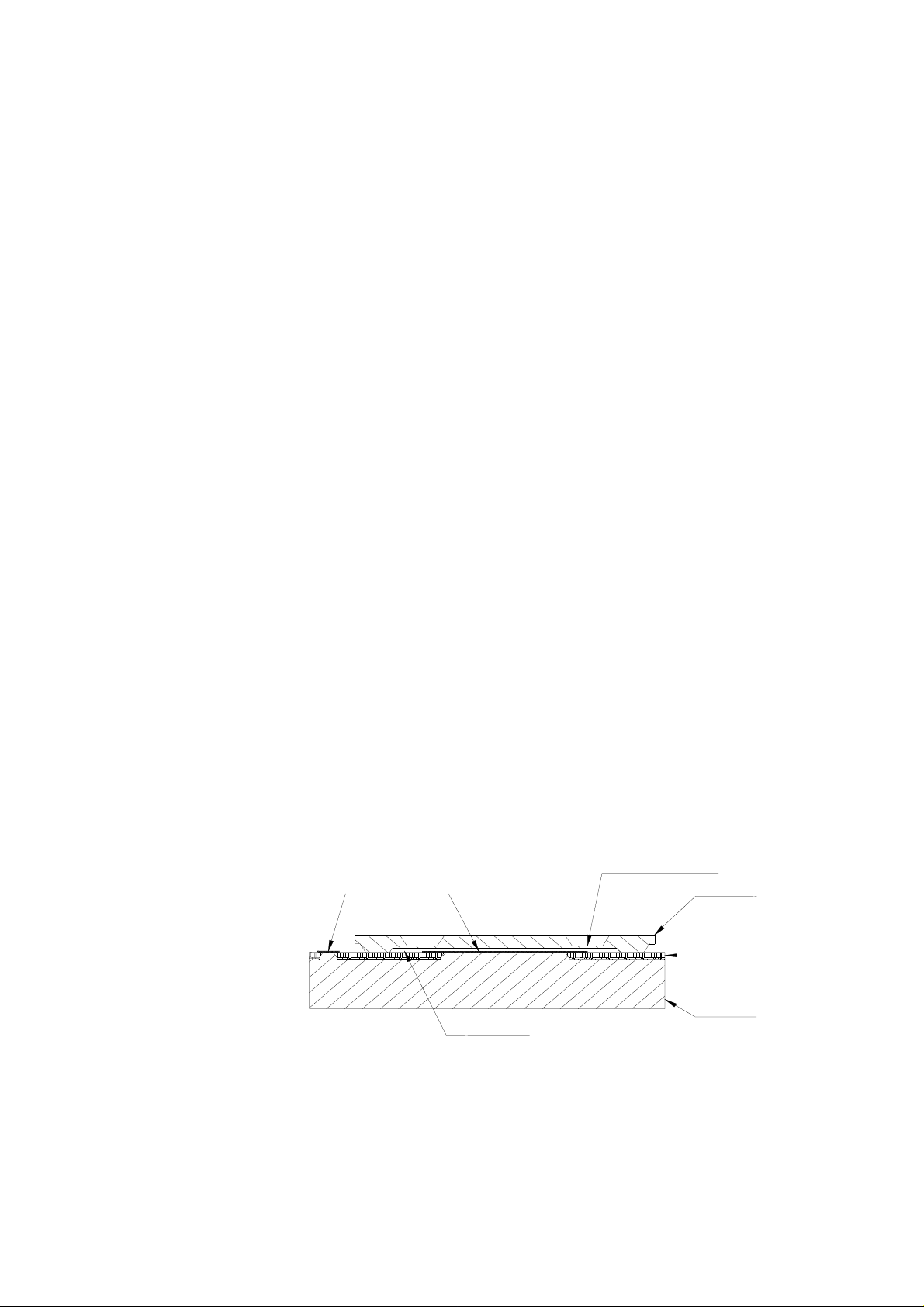

BAROCAP® pressure sensor

The PMB100 barometer modules use the BAROCAP® silicon

capacitive absolute pressure sensor. The BAROCAP® sensor has

excellent hysteresis and repeatability characteristics, low temperature

dependence and a very good long-term stability. The ruggedness of

the BAROCAP® sensor is outstanding and the sensor is resistant to

mechanical and thermal shocks.

Thin film metallization

Vacuum gap

Figure 1 The BAROCAP® pressure sensor

The BAROCAP® pressure sensor consists of two layers of single

crystal silicon having a layer of glass between them. The thinner

silicon layer is etched on both sides to create an integrated vacuum

Silicon diaphragm

Silicon

Glass

Silicon

VAISALA __________________________________________________________________________ 5

USER'S GUIDE_______________________________________________________________________

reference chamber for the absolute pressure sensor and to form a

pressure sensitive silicon diaphragm. The thicker silicon layer is the

rigid base plate of the sensor and it is clad with a glass dielectric. The

thinner piece of silicon is electrostatically bonded to the glass surface

to form a strong and hermetic bond. Thin film metallization has been

deposited to form a capacitor electrode inside the vacuum reference

chamber; the other electrode is the pressure sensitive silicon

diaphragm.

The coefficients of thermal expansion of silicon and glass materials

used in the BAROCAP® pressure sensor are carefully matched

together in order to minimize the temperature dependence and to

maximize the long-term stability. The BAROCAP® pressure sensor is

designed to achieve zero temperature dependence at 1000 hPa and its

long-term stability has been maximized by thermal ageing at an

elevated temperature.

The BAROCAP® capacitive pressure sensor features a wide dynamic

range and no self-heating effect. The excellent hysteresis and

repeatability characteristics are based on the ideal spring

characteristics of single crystal silicon. In the BAROCAP® pressure

sensor, the silicon material is exerted to only few percent of its whole

elastic range.

6 ____________________________________________________________________ M010035EN-A

CHAPTER 3________________________________________________________________ OPERATION

CHAPTER 3

OPERATION

Connections

The pin assignments of the PMB100 module are according to Figure

2. Connect 8...16 VDC supply voltage (typically 2 mA) to the pin VDC

and the ground plane directly to the pin GND. The output signal (0...2.5

VDC) is measured from the pin OUT and the reference signal (2.5 VDC

± 2%) from the pin REF.

If the coefficients are read from the EEPROM, the pin +5 V, SCL and

SDA are also connected. The +5 V-pin is used for supply voltage of the

EEPROM. The pins SCL and SDA are for data transfer between the

EEPROM and a microprocessor.

Temperature of the module is measured with an external T sensor,

which should be placed as close to the module as possible.

The module can also be switched to shut down mode by using a TTL

level trigger on the pin SH. A signal 0.7 V or lower activates and a

signal higher than 2 V switches the module off.

REF

SH

Out

VDC

GND

+ 5V

SCL

SDA

Figure 2 Pin assignments

VAISALA __________________________________________________________________________ 7

USER'S GUIDE_______________________________________________________________________

In applications where adverse electromagnetic fields exist, an

additional EMI protection may be necessary. In Figure 3, there is an

example of an electromagnetic interference protection of the PMB100

module. The EMI filters should be placed as close to the pins as

possible.

GND directly connected

to ground plane

Power

regulator

+

-

V

out

V

out

VDC

GND

V

ref

filter

filter

PMB100 module

GND

VDC

OUT

Copper pour connected to ground.

REF

filter

V

ref

Figure 3 Electromagnetic interference protection of the

PMB100. Filters, for example, T-type EMI

suppression filters with capacitance of 47pF (like

Murata, DSS310-55Y5S470M100). This connection

setup fulfills the RF field immunity standard

EN61000-4-3.

8 ____________________________________________________________________ M010035EN-A

CHAPTER 3________________________________________________________________ OPERATION

Dimensions in mm (in inches)

Pressure calculations

Measure the following parameters of the PMB100 barometer module:

- output voltage V

- reference voltage V

- module temperature Tm (°C)

NOTE

VAISALA __________________________________________________________________________ 9

External T-sensor is required for temperature compensation purpose

with minimum ±1°C accuracy.

1°C error in temperature measurement causes 0.14 hPa error in

pressure value.

out

ref

USER'S GUIDE_______________________________________________________________________

In pressure calculation, normalized voltage (Vn) and temperature (Tn)

are required. The normalization of the parameters is performed by

using the equations 1 and 2.

out

V

æ

n

V (1)

ç

è

T

T (2)

n

128

ö

⋅=

ref

V

m

0 −∈−=

TT

n

[]

V

n

[]

1...1,12 −∈−

1...1,

Constant T0 is found in the list of coefficient or in the EEPROM.

Normalized pressure Pn is calculated according to the equation 3. All

the module specific coefficients are available in the list of coefficients

supplied with each module or in the EEPROM.

é

ê

⋅=

kP

ê

n

0201

ê

ê

ë

Compensated pressure P is then calculated by using the equation 4.

950150 +⋅=

PP hPa (4)

n

Offset/Gain corrections

A final offset/gain correction against a high-class pressure standard is

recommended as a final touch. The offset and gain adjustments are

done after the pressure calculation by the user's host system.

2

201000

2

⋅+⋅+

TaTa

nn

1211

2

3

⋅+⋅+⋅+

VaVaVaa

30

nnn

2

21

31

ù

[]

1...1,

−∈

P

n

3

⋅⋅+⋅⋅+⋅⋅+⋅⋅+

TVaTVaTVaTVa

nnnnnnnn

(3)

10 ___________________________________________________________________ M010035EN-A

CHAPTER 4____________________________________________________________ TECHNICAL DATA

CHAPTER 4

TECHNICAL DATA

Specifications

Operating range

Pressure range (1 hPa = 1 mbar) 800 ... 1100 hPa

Temperature range -5°C ... +45°C

Humidity range < 80%RH

Accuracy

Linearity ±0.25 hPa

Pressure hysteresis ±0.05 hPa

Repeatability ±0.05 hPa

Accuracy at +20°C ±0.3 hPa

Temperature hysteresis ±0.3 hPa

Accuracy (-5°C ... 45°C) ±0.5 hPa

Total accuracy after the OFFSET correction (+20 °C, 1000 hPa)

performed by the user is obtained by using the following equation:

Total accuracy = hPan

where n is the calibration uncertainty

Without the OFFSET correction performed by the user:

Total accuracy (-5 ... +45 °C)±1.00 hPa

Long-term stability ±0.20 hPa/year (typical)

Effect of thermal or mechanical

shocks <0.20 hPa

An error of 1 °C in temperature measurement causes an error of 0.14

hPa in pressure.

5.0 +± (5)

22

General

Supply voltage range 9...16 VDC

Shutdown control with TTL level trigger

<0.7 V module ON

>2.0 V module OFF

Supply voltage sensitivity less than 0.1 hPa

VAISALA _________________________________________________________________________ 11

USER'S GUIDE_______________________________________________________________________

Current consumption

operation mode 2 mA (typical)

shutdown mode 150 µA (typical)

Output voltage

output 0...2.5 V

reference 2.5 V ±2% (type LM4431M3)

Resolution 0.1 hPa

Load resistance 10 kΩ minimum

Load capacitance 100 nF maximun

Settling time at power-up 200 ms

Response time 100 ms

Warm-up shift less than 0.05 hPa

Pressure hose 1/16'' id 1/8'' OD, vinyl hose

300mm

Maximum pressure limit 2000 hPa

Electrical connectors two 6-pin pin headers, 2.54 mm

grid

Weight 70 g

12 ___________________________________________________________________ M010035EN-A

APPENDIX A _______________________________________ READING COEFFICIENTS FROM THE EEPROM

APPENDIX A

READING COEFFICIENTS FROM THE EEPROM

The PMB100 module has a Xicor's EEPROM memory, type X24C02,

which uses the I2C interface. All the pressure and temperature related

coefficients are stored in the memory in form of 32 bit, and can be

read by a microprocessor (see Table 1). The pin assignments are as

shown in Figure 2 on page 7. Detailed instructions of the EEPROM are

found on Xicor's web pages (http://www.xicor.com/).

NOTE

EEPROM can not be read if the shut down is active (ON).

Table 1 EEPROM memory ma p

Name Symbol Type Length Memory

address

[Bit] [Byte]

Product code

Serial number

Calibration date

Scaling factor

Normalized room

PCode

Sno

Date

k

T

0

8-bit int 8 0 [0...256]

32 1 - 4

24 5 - 7

8-bit int 8 8 [0...256]

32-bit int 32 10 - 13 [-1...1]

temperature

Normalized coefficients

a

00

a

10

a

20

a

30

a

01

a

02

a

11

a

21

a

31

a

12

32-bit int 32 14 - 17 [-1...1]

32-bit int 32 18 21 [-1...1]

32-bit int 32 22 25 [-1...1]

32-bit int 32 26 29 [-1...1]

32-bit int 32 30 33 [-1...1]

32-bit int 32 34 37 [-1...1]

32-bit int 32 38 41 [-1...1]

32-bit int 32 42 45 [-1...1]

32-bit int 32 46 49 [-1...1]

32-bit int 32 50 53 [-1...1]

Range

VAISALA _________________________________________________________________________ 13

USER'S GUIDE_______________________________________________________________________

The form of coefficients (32-bit signed integer) in the eeprom:

eeprom: byte_0 xxxxxxxx byte_1 xxxxxxxx byte_2 xxxxxxxx byte_3 xxxxxxxx

long_int: bit_31 xxxxxxxx bit_23 xxxxxxxx bit_15 xxxxxxxx bit_7 xxxxxxxx bit_0

MSB LSB

MSB LSB MSB LSB MSB LSB MSB LSB

32-bit signed integer → FLOAT (1.0...-1.0)

float=signed_long_int/2^31

In following there is an example of C-program to convert the 32 bit

coefficients to floating point numbers.

unsigned char read_eeprom(addr)

{

/* eeprom read routine */

return(read_data);

}

/*------------------------------------------------------

-------------------- -------------------*/

void read_long_int( char addr, long int *coef )

{

unsigned char *pointer=(char*)coef;

*pointer++=read_eeprom(addr++);

*pointer++=read_eeprom(addr++);

*pointer++=read_eeprom(addr++);

*pointer=read_eeprom(addr);

}

/*------------------------------------------------------

-------------------- -------------------*/

void main(void)

{

long int long_coef=0; /* signed long integer

(32 bit) */

float float_coef=0.;

read_long_int(14,&long_coef);

float_coef=(float)long_coef/0x80000000;

printf("Float is %e\r\n",float_coef);

}

14 ___________________________________________________________________ M010035EN-A

*M010035

EN

*

www.vaisala.com

Loading...

Loading...