Page 1

M211857EN-A

Installation

Guide

Vaisala Optimus™ DGA Monitor f

or Transformers

OPT100

DRAFT

24 May 2017

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at w

© Vaisala 2017

No part of this manual may be reproduced,

published or publicly displa

or by any means, electronic or mechanical

(including photocopying), nor may its

contents be modified, translated, adapted,

sold or disclosed to a third party without

prior written permission of the copyright

holder. Translated manuals and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this manual are subject to

change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this manual.

Vaisala makes no representations on this

manual’s compliance with the local rules

and regulations applicable at any given

time, and hereby disclaims any and all

responsibilities related thereto.

This manual does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

ww.vaisala.com.

yed in any form

exclusively in the applicable supply

c

ontract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

This product may contain open source

software (OSS) components. In the event

this product contains OSS components,

then such OSS is governed by the terms

and conditions of the applicable OSS

licenses, and you are bound by the terms

and conditions of such licenses in

connection with your use and distribution

of the OSS in this product. Applicable OSS

licenses are included in the product itself

or provided to you on any other applicable

media, depending on each individual

product and the product items delivered

to you.

Page 3

Table of Contents

1. About This Document........................................................................................ 5

1.1 Version Information............................................................................................... 5

2. Planning The Installation...................................................................................7

2.1 Installation Safety...................................................................................................7

2.2 Installation Phases................................................................................................. 8

2.3 Required Personnel................................................................................................8

2.4 Required Materials................................................................................................. 9

2.5 Recommended Tools........................................................................................... 10

2.6 Storing and Transporting the DGA Monitor....................................................... 11

2.7 Preparations for Reinstalling a DGA Monitor..................................................... 11

2.8 Installation Site Requirements............................................................................. 11

2.8.1 Installation Location of DGA monitor...........................................................11

2.8.2 Recommended Locations of Oil Connections............................................ 13

3. Mechanical Installation.....................................................................................15

3.1 Unpacking DGA Monitor......................................................................................15

3.2 Mounting with Ground Mounting Set.................................................................15

3.2.1 OPT100 Parts with Ground Mounting Set................................................... 17

3.2.2 OPT100 Dimensions with Ground Mounting Set........................................19

3.3 Mounting with Wall Mounting Set.....................................................................20

3.3.1 OPT100 Parts with Wall Mounting Set........................................................22

3.4 Installing the Oil Lines.........................................................................................23

3.5 Attaching the Power Supply Unit...................................................................... 24

3.6 Attaching the Radiation Shield.......................................................................... 25

Table of Contents

4. Electrical Installation........................................................................................27

4.1 Cable Glands and Connectors............................................................................ 27

4.2 Grounding the DGA Monitor.............................................................................. 28

4.3 Connecting DC Power to DGA Monitor.............................................................29

4.4 Connecting Relay Control to Power Supply Unit..............................................31

4.5 Connecting RS-485............................................................................................. 33

4.6 Connecting Ethernet........................................................................................... 35

4.7 Connecting Relays...............................................................................................36

4.8 Connecting AC (Mains) Power........................................................................... 38

4.9 Verifying Tightness of Cable Glands.................................................................40

5. Commissioning...................................................................................................43

5.1 Turning On the DGA Monitor............................................................................. 43

5.2 Connecting to the User Interface...................................................................... 43

5.3 Initializing the DGA Monitor...............................................................................44

5.4 Starting Measurement Mode..............................................................................45

5.5 Finalizing the Installation....................................................................................45

6. Installation

6.1 Installation Checklist........................................................................................... 47

6.2 Safety Checklist................................................................................................... 48

Technical Support

Warranty......................................................................................................................... 51

Verification...................................................................................47

.......................................................................................................51

Recycling........................................................................................................................51

1

Page 4

OPT100 Installation Guide M211857EN-A

List of Figures

Figure 1 Possible Locations of Oil Connections..........................................................13

Figure 2 Assembly of the Mounting Stand...................................................................16

Figure 3 OPT100 Front Parts with Ground Mounting Set........................................ 17

Figure 4 OPT100 Rear Parts with Ground Mounting Set..........................................18

Figure 5 OPT100 Dimensions with Ground Mounting Set....................................... 19

Figure 6 OPT100 Front Parts with Wall Mounting Set..............................................22

Figure 7 OPT100 Rear Parts with Wall Mounting Set...............................................22

Figure 8 OPT100 DGA Monitor Cable Glands and Connectors..............................27

Figure 9 OPTPSU1 Power Supply Unit Cable Glands and Connectors.................28

Figure 10 Terminal Block Y3 Wiring................................................................................ 29

Figure 11 Terminal Block X5 Wiring................................................................................ 30

Figure 12 Terminal Block Y2 Wiring................................................................................ 32

Figure 13 Terminal Block X4 Wiring................................................................................ 33

Figure 14 Terminal Block Y1 Wiring Example................................................................35

Figure 15 Terminal Block X3 Wiring for Normally Open (NO) Relay

Connection...........................................................................................................37

Figure 16 Terminal Block X1 Wiring.................................................................................40

2

Page 5

List of Tables

Table 1 Document Versions.................................................................................................5

Table 2 Terminal Block Y3 Wiring....................................................................................29

Table 3 Terminal Block X5 Wiring....................................................................................30

Table 4 Terminal Block Y2 Wiring.................................................................................... 32

Table 5 Terminal Block X4 Wiring....................................................................................33

Table 6 Terminal Block Y1 Wiring..................................................................................... 35

Table 7 Terminal Block X3 Wiring.................................................................................... 37

Table 8 Terminal Block X1 Wiring....................................................................................40

List of Tables

3

Page 6

OPT100 Installation Guide M211857EN-A

4

Page 7

1. About This Document

1.1 Version Information

Table 1 Document Versions

Document Code Date Description

M211857EN-A - First version.

Chapter 1 – About This Document

5

Page 8

OPT100 Installation Guide M211857EN-A

6

Page 9

Chapter 2 – Planning The Installation

2. Planning The Installation

2.1 Installation Safety

WARNING!

you encounter the following marking during installation, consult product

documentation to

have to be taken to avoid them:

WARNING!

adhere to local and state legislation and regulations.

WARNING!

regulations at all times.

Read the installation instructions carefully before installing the product. If

find out the nature of the potential hazards and any actions which

Only licensed experts may install electrical components. They must

Make sure that you prepare only de-energized wires.WARNING!

Keep away from live circuits. Operating personnel must observe safety

WARNING!

Verify the grounding before and after performing maintenance on the unit.

CAUTION!

documentation.

perform according to specification, or decreased equipment lifetime.

Ground the DGA monitor chassis as instructed in the wiring instructions.

Do not modify the DGA monitor or use it in ways not described in the

Modifications may lead to safety hazards, equipment damage, failure to

7

Page 10

OPT100 Installation Guide M211857EN-A

CAUTION!

heat up during normal operation. Avoid touching the hot surfaces and wear protective

gloves when working inside the enclosure. Whenever possible, allow the device to cool

down before starting the work.

Follow the safety regulations of the installation site.

The safety of any system incorporating this equipment is the responsibility of the

assembler.

Surfaces inside the DGA monitor that are marked with the symbol below

Wear protective eyewear and gloves.

2.2 Installation Phases

Perform the installation of the DGA monitor in the following phases:

• Planning

• Mechanical installation

• Electrical installation

• Commisioning

• Installation

These phases correspond to chapters of the Installation Guide. As part of the final

installation verification phase, use the provided installation checklists to make sure you have

done all of the required installation steps.

2.3

Installation of the DGA monitor requires two persons. While most of the installation and

commissioning tasks can be done by a single person, safe carrying and lifting of the DGA

monitor requires two persons.

Installers must have the necessary training to legally perform all required tasks. For example,

connecting the DGA monitor to mains power must be done by a licensed electrician.

Required Personnel

verification

8

Page 11

Applicable legislation and site safety guidelines may require additional personnel to be

present in the installation.

2.4 Required Materials

In addition to the items delivered by Vaisala, installation of the DGA monitor requires

various materials that you must supply yourself.

Items Delivered by Vaisala

• DGA Monitor (Vaisala item OPT100)

• DGA Monitor enclosure

• Swagelokâ fitting SS-10M0-61-6M (2 pcs)

• Protection shell for Ethernet connector

• Relay control cable (marked RELAY, Vaisala cable CBL210539)

• Enclosure key

• Power Supply Unit (Vaisala item OPT100PSU)

Chapter 2 – Planning The Installation

• Power Supply Unit enclosure

• DC power cable (Vaisala cable CBL210544)

• Enclosure key

Optional items (must have either Wall Mounting Set or Ground Mounting Set):

• Wall Mounting Set (Vaisala item OPTMSET1)

• Installation beam (2 pcs)

• Cradle for Power Supply Unit

• Screws and washers

• Ground Mounting Set (Vaisala item OPTMSET2)

• Mounting stand (delivered in three parts)

• Wedge anchors (6 pcs) for securing the mounting stand to ground

• Screws, washers, and nuts

• Radiation Shield (Vaisala item OPTSHLD1)

• Radiation shield (delivered in three parts)

• Screws and washers

DGA Monitor Installation and Commissioning

• Grounding cable with max 16 mm2 conductor. Enough to reach from the DGA monitor

and the power supply unit to the grounding point(s).

• AC power cable with 2.5 mm2 (AWG10) wires and 9 ... 16 mm external diameter. Must be

compliant with local regulations for mains power cables.

• Relay cable

• RS-485 cable

9

Page 12

OPT100 Installation Guide M211857EN-A

• Shielded outdoor Ethernet cable with a RJ-45 connector for the permanent Ethernet

connection

• Laptop computer with:

• RJ-45 Ethernet connector

• Web browser (Google Chrome, Microsoft Internet Explorer, or Mozilla Firefox)

• Ethernet cable with RJ-45 connectors for temporary use

Oil Pipe Construction

The amount of required oil pipe construction materials depends on the intended pipe

length. Two pipes are needed, one for intake and one for returning the oil. Using the

recommended pipe material, the maximum allowed length of a single pipe is 10 m (33 ft). If

you are using a smaller pipe (minimum inner diameter 4 mm (0.157 in)), the maximum

length is 5 m (16 ft).

• Recommended oil pipe material: stainless steel pipe with 10 mm (0.393 in) outer

diameter, at least 6 mm (0.24 in) inner diameter. Enough to connect the inlet and outlet

valves to the DGA monitor.

• Adapters for connecting the oil pipes to the valves on the transformer

• Adapters for connecting the oil pipes to the DGA monitor (if not using recommended

oil pipe size). For 3/8 inch pipe, use Swagelokâ adapter SS-600-R-10M.

• Pipe

• Pipe supports

• Oil pipe insulation (if necessary)

• Oil absorption material for controlling possible leaks

• Rags for wiping

fittings for joining pipe sections

o oil

Other

• Personal safety equipment as required by installation site and applicable legislation

2.5

Hand Tools

Tools for Oil Pipe Construction

Recommended Tools

• Screwdrivers with slotted and Phillips heads

• Wrenches of various sizes

• Socket wrench and socket set

• Hex keys

• Cutting tools

• Cable stripping tool

• Metal

• Measuring tape

• Impact drill and bits

• Bubble level

• Multimeter

file

• Pipe bending tool

10

Page 13

Chapter 2 – Planning The Installation

• Pipe cutting tool

• Pipe deburring tool

• Pressurized air, either a bottle or a compressor

• Degreasing cleaning spray

• Container for waste oil (at least 5 liter capacity)

2.6 Storing and Transporting the DGA Monitor

Keep the DGA monitor and any installation accessories in their original packaging during

storage and transport. Keep the items dry and in conditions allowed by the storage

specification. Honor any handling instructions marked on the outside of the packaging.

After installation, store the packaging in a dry place. You can reuse it if the DGA monitor is

stored and/or transported again.

2.7 Preparations for Reinstalling a DGA

Monitor

If you want to relocate an already installed DGA monitor, you must prepare it for transport

and reinstallation by following the uninstallation procedure. See OPT100 User Guide for

details.

2.8

DGA monitor can be installed and successfully operated in a wide variety of environments.

Operation in cold environments may require trace heating elements and thermal insulation

to be placed over the exposed sections of the oil pipes. If you have any questions, contact

Vaisala for more information.

2.8.1 Installation Location of DGA monitor

Installation Site Requirements

Performing a site inspection in person is a good idea. Take photographs of the intended

installation location, oil connections, and electrical connections. Measure the amount of

cable and oil pipe needed.

The DGA monitor can be attached to the transformer chassis or to its immediate vicinity. The

location must

• The location must be close to the oil connections to minimize the length of the oil lines.

The maximum length of the lines is 10 m (33 ft) each.

• The location must be safely accessible from the floor without the need to climb or

reach.

fulfill the following requirements:

11

Page 14

OPT100 Installation Guide M211857EN-A

• There must be enough room and suitable supporting structures to install the DGA

monitor in a vertical orientation. The DGA monitor must not be tilted more than 5

degrees.

• If the Ground Mounting Set will be used to install the DGA monitor, there must be a

level concrete surface that is at least 100 mm thick.

If you have many suitable locations, prefer the following:

• Locations that are protected from rain and solar radiation.

• Locations where the vibration and heat from the transformer are not directly conducted

to the DGA monitor.

12

Page 15

2

3

4

5

1

Chapter 2 – Planning The Installation

2.8.2 Recommended Locations of Oil Connections

You must build two oil lines between the DGA monitor and the transformer: one for intake of

fresh oil, and an outlet line for returning the measured oil. Make sure you have appropriate

adapters for connecting the oil lines to the valves. The maximum allowed length of an oil line

is 10 m (33 ft). The location of oil connections on the transformer impacts the performance

of the DGA monitor.

Figure 1 Possible Locations of Oil Connections

1 Oil reservoir. Not recommended.

2 Side of the oil tank, top level. Good for returning the measured oil.

3 Side of the oil tank, high enough from the bottom to enable proper oil movement. Good

for oil intake. Moisture response time is moderate depending on the oil volume.

4 Straight section in the radiator’s outlet pipe. Good location if the pipe has guaranteed

oil flow.

Oil flow guarantees that the sampled oil is representative, and the cooling flow carries

the outlet oil from the monitor away from the inlet. Compared to the radiator inlet pipe,

oil in the outlet pipe is cooler, preventing unnecessary heating of the DGA monitor.

5 Drain valve of the oil tank. Not recommended.

Measurement response time is poor due to static oil flow. There is also risk of separated

water (leading to wrong results) and oil sludge (risk of sensor contamination and

clogged filter).

13

Page 16

OPT100 Installation Guide M211857EN-A

DGA monitor needs to pump oil in both directions during initialization and maintenance.

To make sure this is possible, check that:

• Intake and outlet valves are both below oil level in the transformer. There should be

no risk of drawing gas into the pipes even when the flow is reversed.

• There are no flow direction control valves on the oil lines.

14

Page 17

Chapter 3 – Mechanical Installation

3. Mechanical Installation

3.1 Unpacking DGA Monitor

• Wire cutters

Two persons are required to lift the DGA monitor out of the packaging.

1. Cut the packing straps and remove the cover.

2. Remove the top padding from the box.

3. Lift the DGA monitor out of the box and place it on a stable surface with the door

pointing up.

CAUTION!

on the bottom of the enclosure. When unpacking and moving the DGA monitor,

avoid putting the bottom of the DGA monitor on the ground. Putting the weight of

the unit on the cable glands and oil connections may damage them.

The cable glands and oil connections of the DGA monitor are located

3.2 Mounting with Ground Mounting Set

• Ground Mounting Set (Vaisala item OPTMSET2)

• Mounting stand (delivered in three parts)

• Wedge anchors (6 pcs) for securing the mounting stand to ground

• Screws, washers, and nuts

• 6 mm hex key

• 13 mm wrench

• Impact drill and bits

Use the Ground Mounting Set when a free standing installation of the DGA monitor is

needed. The mounting surface must allow the use of wedge anchors to secure the mounting

stand. A concrete surface that is at least 100 mm thick is recommended.

15

Page 18

3

2

1

4

OPT100 Installation Guide M211857EN-A

Figure 2 Assembly of the Mounting Stand

1 Mounting holes on the top are for attaching the DGA monitor.

2 Mounting holes on the side join the parts of the mounting stand together.

3 Holes on the bottom (three on each side) are for anchoring the mounting stand to the

ground.

4 Attach the power supply unit to the middle part using these four holes.

1. Assemble the mounting stand. Tighten the screws to finger tightness at this point, not

all the way.

2. Using the assembled mounting stand as the template, mark the locations of the six

anchors on the mounting surface.

3. Drill holes for the anchors using an impact drill and an 8 mm drill bit. The holes must be

60 mm deep.

4. Install the anchors in the holes.

5. Verify that the mounting stand is securely anchored.

6. Attach the mounting stand to the anchors.

16

Page 19

7. Attach the DGA monitor to the top of the mounting stand.

1

2

3

4

5

6

8. Tighten the screws to 20 Nm tightness.

3.2.1 OPT100 Parts with Ground Mounting Set

Figure 3 OPT100 Front Parts with Ground

Mounting Set

1 Status LEDs

2 OPT100 DGA Monitor

3 Door lock (3 pcs)

4 Power Supply Unit

5 Door lock

6 Mounting stand

Chapter 3 – Mechanical Installation

17

Page 20

1

2

3

OPT100 Installation Guide M211857EN-A

Figure 4 OPT100 Rear Parts with Ground

Mounting Set

1 Radiation shield

2 Cable glands and oil connections for DGA

Monitor

3 Cable glands for power supply unit

18

Page 21

675 (26.6)

1630 (62.2)

453 (17.8)

Chapter 3 – Mechanical Installation

3.2.2 OPT100 Dimensions with Ground Mounting Set

Dimensions are in millimeters and inches (in brackets).

Figure 5 OPT100 Dimensions with Ground Mounting Set

19

Page 22

OPT100 Installation Guide M211857EN-A

3.3 Mounting with Wall Mounting Set

• Wall Mounting Set (Vaisala item OPTMSET1)

• Installation beam (2 pcs)

• Cradle for Power Supply Unit

• Screws and washers

• 6 mm hex key

1. Attach one of the installation beams to the mounting location, at a height where you

want the top of the OPT100 enclosure to be. Make sure it is securely attached from at

least two points, and can bear the full weight of the DGA monitor.

2. Attach the second installation beam at the height of the second set of mounting holes.

3. Attach screws with washers to the top mounting holes of each pair on the sides of the

OPT100 enclosure (four screws in total). Tighten them enough to safely bear the weight

of the enclosure but not all the way in. The second hole of each set must remain free at

this point.

4. With two people lifting, lift the OPT100 enclosure up and hang it from installation

beams by the screws. If the lower installation beam is not at the correct height, reattach it at the correct height before attempting this step again.

5. Tighten the four screws to secure the enclosure in place.

20

Page 23

Chapter 3 – Mechanical Installation

6. Add a second screw (with washer) below each of the installed screws, and tighten

them.

The enclosure is now secured to the installation beams by a total of eight screws. The

second set of mounting holes at the ends of the installation beam is used to secure the

radiation shield. They should remain free at this point.

21

Page 24

1

2

3

4

5

1

2

3

4

5

6

OPT100 Installation Guide M211857EN-A

3.3.1 OPT100 Parts with Wall Mounting Set

Figure 6 OPT100 Front Parts with Wall

Mounting Set

1 Status LEDs

2 OPT100 DGA Monitor

3 Door lock (3 pcs)

4 Power supply unit

5 Door lock

Figure 7 OPT100 Rear Parts with Wall

Mounting Set

1 Installation beam (upper)

2 Radiation shield

3 Installation beam

4 Cable glands for DGA Monitor

5 Cradle for Power supply unit

6 Cable glands for power supply unit

22

Page 25

3.4 Installing the Oil Lines

• Adapters for connecting the oil pipes to the valves on the transformer

• Adapters for connecting the oil pipes to the DGA monitor (if not using recommended

oil pipe size). For 3/8 inch pipe, use Swagelokâ adapter SS-600-R-10M.

• Recommended oil pipe material: stainless steel pipe with 10 mm (0.393 in) outer

diameter, at least 6 mm (0.24 in) inner diameter. Enough to connect the inlet and

outlet valves to the DGA monitor.

fittings for joining pipe sections

• Pipe

• Pipe supports

• Pipe bending tool

• Pipe cutting tool

• Pipe deburring tool

• Pressurized air, either a bottle or a compressor

• Degreasing cleaning spray

• Wrenches of various sizes

• Container for waste oil (at least 5 liter capacity)

Chapter 3 – Mechanical Installation

CAUTION!

the ground. Dirty parts may contaminate the transformer oil or cause connections to

leak.

If the DGA monitor is mounted using the wall mounting set, the power supply unit will be

attached by a mounting cradle. Make sure you are not routing the oil lines so that they will

obstruct the power supply unit attachment. See 3.5 Attaching the Power Supply Unit

(page 24).

When working with oil pipes and connectors, keep everything clean and

Wear protective eyewear and gloves.

o

If you are unsure which valves on the transformer to use for oil intake and return, see 2.8.2

Recommended Locations of Oil Connections (page 13).

1. Inspect the selected oil valves on the transformer. If there are any

flow direction control

valves previously installed, remove them. The DGA monitor needs to pump oil in both

directions during initialization, and this will not work if there are flow direction

controllers in the oil lines.

2. Clean the oil valves on the transformer from the outside and the inside. Use the

degreasing cleaning spray.

3. Install the adapters to the inlet and outlet valves on the transformer to match them to

the size of the oil pipe material.

23

Page 26

OPT100 Installation Guide M211857EN-A

4. Measure the distance from the oil valves to the DGA monitor, and plan the length and

shape of the oil pipe sections. Minimize the amount of joints.

5. Cut and bend the oil pipe to appropriate sections for building the oil lines.

6. Remove any sharp edges from the cut surfaces.

7. Clean any metal shavings from inside the pipes using pressurised air.

8. Build the oil lines between the valves and the oil connections on the DGA monitor

marked Oil In and Oil Out.

9. Remove the plugs from the oil connections on the DGA monitor and store them for

possible later use. Check that the oil connections are clean.

10. Connect both oil lines to the oil connections. Use the supplied adapters (delivered in a

separate bag) and read their instructions for use before making the connections.

a. Insert nut of the connector over the oil pipe.

b. Insert the two ferrules over the pipe.

c. Fully insert the pipe into the

fitting and against the shoulder; rotate the nut finger-

tight.

d. Hold the base of the connector with a second wrench to keep it from turning when

tightening.

e. Mark the nut position.

f. Tighten the nut one and one quarter turns with a wrench.

If you are not using the recommended oil pipe size, install adapters into the oil

connections

first. Then connect the oil pipe to the adapter.

11. Install pipe supports where necessary to support the pipe mechanically. The pipe

should be supported at least every two meters (six feet).

To verify that the oil connections are tight, check for leaks during commissioning when the

DGA monitor is pumping oil. Ideally, check the connections again after the DGA monitor

has been running for some time (for example, the next day).

3.5 Attaching the Power Supply Unit

• 6 mm hex key

1. If the Ground Mounting Set is used:

a. Attach the power supply unit to the middle of the mounting stand.

24

Page 27

Chapter 3 – Mechanical Installation

2. If the Wall Mounting Set is used:

a. Attach the power supply unit to the cradle.

b. Support the power supply unit and cradle and attach them to the bottom of the

OPT100 enclosure.

3.6 Attaching the Radiation Shield

• Radiation Shield (Vaisala item OPTSHLD1)

• Radiation shield (delivered in three parts)

• Screws and washers

1. Attach the radiation shield to the OPT100 enclosure:

a. Attach the left side panel. Note that the panels have an assigned side, they are not

identical.

b. Attach the right side panel.

c. Verify that all screws holding the side panels of the radiation shield are tight.

d. Attach the top panel.

25

Page 28

OPT100 Installation Guide M211857EN-A

26

Page 29

1 2 3 4 5 6 7

Chapter 4 – Electrical Installation

4. Electrical Installation

4.1 Cable Glands and Connectors

Figure 8 OPT100 DGA Monitor Cable Glands and Connectors

1 Oil Out: connection for oil return line

2 Oil In: connection for oil intake

3

4 RS-485: cable gland for RS-485 connection

5 Relay control out: cable gland for relay control to power supply unit

6 DC in: 24 VDC connection from power supply unit

7 Ethernet: external RJ-45 connector for permanent Ethernet connection

Ground terminal

27

Page 30

1 2 3 4 5 6 7

OPT100 Installation Guide M211857EN-A

Figure 9 OPTPSU1 Power Supply Unit Cable Glands and Connectors

1

Ground terminal

2 AC in: Mains power input. 100 ... 240 VAC, 50 ... 60 Hz, 10 A

3 Spare

4 Spare

5 Relay out: Relay output. Max 250 VAC, 10 A

6 Relay control in: Relay control from DGA monitor

7 DC out: DC out to DGA monitor. 24 VDC, 20 A

4.2 Grounding the DGA Monitor

• Grounding cable with max 16 mm2 conductor. Enough to reach from the DGA monitor

and the power supply unit to the grounding point(s).

• Cable stripping tool

• Metal

• Multimeter

1. Locate the ground terminals on the underside of the DGA monitor and the power

supply unit, and find a good grounding point on the transformer or the surrounding

structures.

file

2. Clean the grounding point of rust for a good connection.

3. Ground the DGA monitor:

a. Run a grounding cable from the ground terminal to the grounding point, and secure

it so it does not hang loose.

b. Connect the cable to the grounding point on the DGA monitor.

c. Connect the other end of the cable to the grounding point.

d. Measuring the resistance from the ground terminal to the grounding point to verify

the grounding.

4. Repeat step 3 to ground the power supply unit as well.

28

Page 31

24 VDC +

Ground

24 VDC -

+

-

BLK/RE D

BLK

GRN/YE L

Chapter 4 – Electrical Installation

4.3 Connecting DC Power to DGA Monitor

• DC power cable (Vaisala cable CBL210544)

• 3 mm slotted screwdriver

• Adjustable wrench

1. Open the cable gland marked DC in on the DGA monitor. Remove the plug and store it

for later use.

2. Insert the DC power cable through the outer nut and the seal insert, and start inserting

the cable through the cable gland. Stop when you reach the section of the cable where

the metal braid is exposed.

3. Bend the cable braid over the seal insert so that it will make contact with metal when

the cable gland is tightened.

4. Push the outer nut and the seal insert against the contact socket of the gland and

tighten the outer nut.

5. Inside the DGA monitor, connect the wires to terminal block Y3:

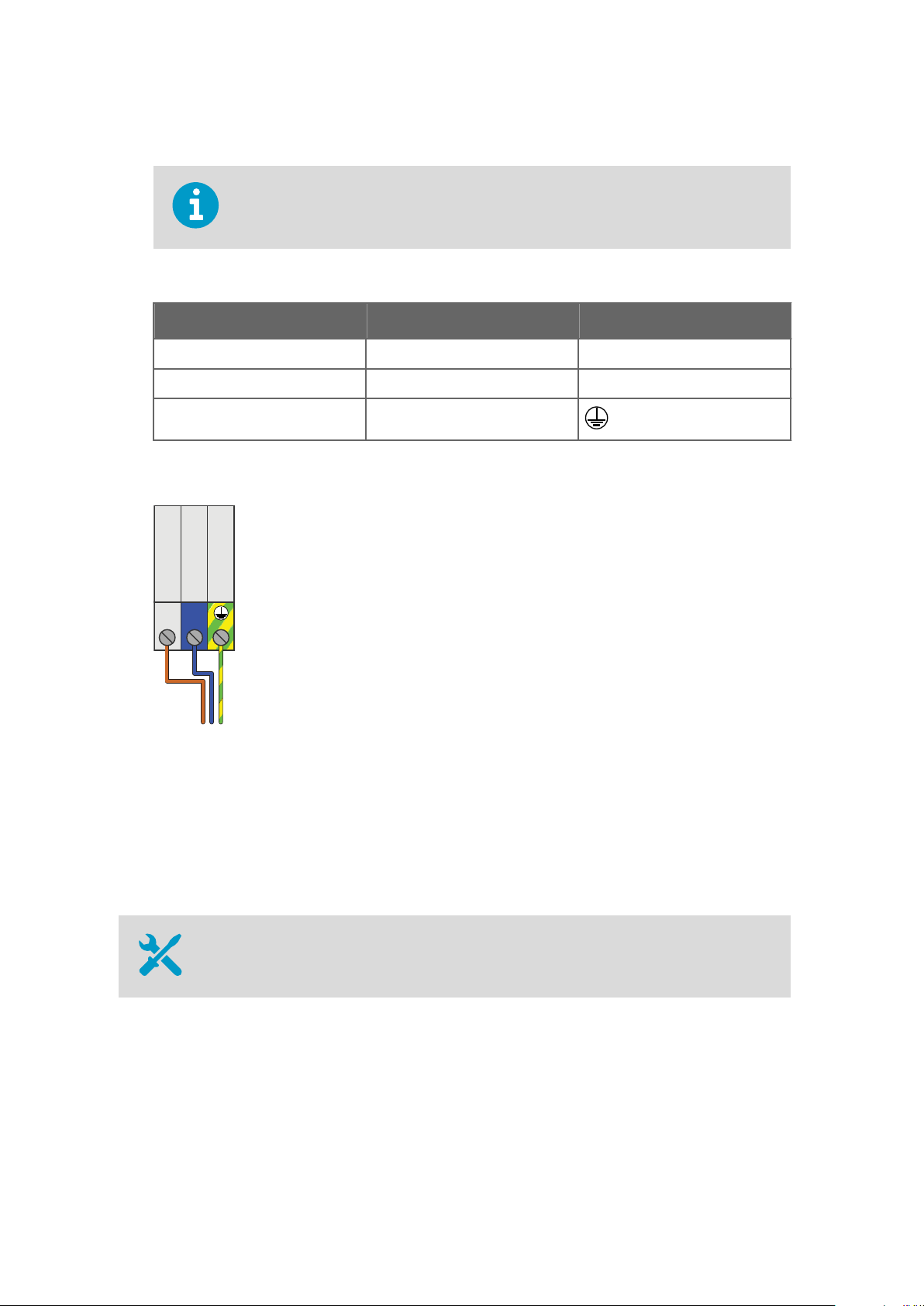

Table 2 Terminal Block Y3 Wiring

Signal Wire Color

Vaisala Cable CBL210544

24 VDC + Black with red marking +

24 VDC - Black -

Ground Green/yellow

Terminal

Figure 10 Terminal Block Y3 Wiring

29

Page 32

24 VDC +

Ground

24 VDC -

BLK/RE D

BLK

GRN/YE L

+ -

OPT100 Installation Guide M211857EN-A

6. Open the cable gland marked DC out on the power supply unit. Remove the plug and

store it for later use.

7. Insert the DC power cable through the outer nut and the seal insert, and start inserting

the cable through the cable gland. Stop when you reach the section of the cable where

the metal braid is exposed.

8. Bend the cable braid over the seal insert so that it will make contact with metal when

the cable gland is tightened.

9. Push the outer nut and the seal insert against the contact socket of the gland and

tighten the outer nut.

10. Inside the power supply unit, connect the wires to terminal X5:

Table 3 Terminal Block X5 Wiring

Signal Wire Color

Vaisala Cable CBL210544

24 VDC + Black with red marking +

24 VDC - Black -

Ground Green/yellow

Terminal

Figure 11 Terminal Block X5 Wiring

30

Page 33

Chapter 4 – Electrical Installation

4.4 Connecting Relay Control to Power

Supply Unit

• Relay control cable (marked RELAY, Vaisala cable CBL210539)

• 3 mm slotted screwdriver

• Adjustable wrench

1. Open the cable gland marked Relay control out on the DGA monitor. Remove the plug

and store it for later use.

2. Insert the relay control cable through the outer nut and the seal insert, and start

inserting the cable through the cable gland. Stop when you reach the section of the

cable where the metal braid is exposed.

3. Bend the cable braid over the seal insert so that it will make contact with metal when

the cable gland is tightened.

4. Push the outer nut and the seal insert against the contact socket of the gland and

tighten the outer nut.

31

Page 34

Relay 1

Relay 2

Relay 3

1 3 5

2 4 6

BRN

WHT

YEL

GRN

PNK

GRY

OPT100 Installation Guide M211857EN-A

5. Inside the DGA monitor, connect the wires to terminal block Y2:

Table 4 Terminal Block Y2 Wiring

Signal Wire Color

Vaisala cable CBL210539

Relay 1 control + White 1

Relay 1 control - Brown 2

Relay 2 control + Green 3

Relay 2 control - Yellow 4

Relay 3 control + Grey 5

Relay 3 control - Pink 6

Terminal

Figure 12 Terminal Block Y2 Wiring

6. Open the cable gland marked Relay control in on the power supply unit. Remove the

plug and store it for later use.

7. Insert the relay control cable through the outer nut and the seal insert, and start

inserting the cable through the cable gland. Stop when you reach the section of the

cable where the metal braid is exposed.

8. Bend the cable braid over the seal insert so that it will make contact with metal when

the cable gland is tightened.

9. Push the outer nut and the seal insert against the contact socket of the gland and

tighten the outer nut.

32

Page 35

BRN

WHT

YEL

GRN

PNK

GRY

Relay 1

Relay 2

Relay 3

2

1

9

8

7

6

5

4

3

Chapter 4 – Electrical Installation

10. Inside the power supply unit, connect the wires to terminal block X4:

Table 5 Terminal Block X4 Wiring

Signal Wire Color

Vaisala cable CBL210539

Relay 1 control + White 2

Relay 1 control - Brown 3

Relay 2 control + Green 5

Relay 2 control - Yellow 6

Relay 3 control + Grey 8

Relay 3 control - Pink 9

Terminal

Figure 13 Terminal Block X4 Wiring

4.5

Connecting RS-485

• RS-485 cable

• 3 mm slotted screwdriver

• Cable stripping tool

33

Page 36

OPT100 Installation Guide M211857EN-A

The default settings of the RS-485 line are:

• Serial settings 19200, 8, E, 1

• Modbus RTU slave

• MAC address 240

1. Open the cable gland marked RS-485 on the DGA monitor. Remove the plug and store

it for later use.

2. Prepare the cable for connection:

a. Measure how much cable you need to reach from the cable gland to terminal block

Y1.

b. Remove the outer sheath and cable braid from the part of the cable that will be left

inside the DGA monitor.

c. Strip the ends of the individual wires to expose the conductors for 1 cm (0.4 in).

d. Remove some more of the outer sheath to expose more cable braid. This part of the

braid should be connected to the cable gland.

3. Insert the cable through the outer nut and the inner seal, and start inserting the cable

through the cable gland. Stop when you reach the section of the cable where the metal

braid is exposed.

4. Arrange the cable braid so that it makes contact with the cable gland when it is closed.

Push the inner seal in place and tighten the outer nut.

34

Page 37

5. Inside the DGA monitor, connect the wires to terminal block Y1:

RS-485 +

RS-485 -

Common

1 3 5

2 4 6

BLU/WHT

BLU

BRN

Verify the wiring colors of your cable before making any connections.

Table 6 Terminal Block Y1 Wiring

Signal Terminal

RS-485 + 1

RS-485 - 3

Common 5

Chapter 4 – Electrical Installation

Figure 14 Terminal Block Y1 Wiring Example

4.6

Connecting Ethernet

• Shielded outdoor Ethernet cable with a RJ-45 connector for the permanent Ethernet

connection

• Protection shell for Ethernet connector

35

Page 38

OPT100 Installation Guide M211857EN-A

Ethernet connector ETH1 inside the DGA monitor is intended for temporary local use only.

For a permanent network connection, use the Ethernet connector under the DGA monitor.

1. Assemble the protection shell over the RJ-45 connector on your Ethernet cable.

Assemble according to Code A: see instructions on top of the bag that contains the

parts.

CAUTION!

rating of the enclosure.

You must use the protection shell to maintain the ingress protection

2. Open the plug marked Ethernet under the DGA monitor.

3. Plug in the Ethernet cable.

4. Tighten the connector by hand.

4.7 Connecting Relays

• Relay cable

• 3 mm slotted screwdriver

• Adjustable wrench

Maximum switching current of the relays:

• 6A (at 250VAC)

• 2 A (at 24 VDC)

• 0.2 A (at 250 VDC)

1. Open the cable gland marked Relay out on the power supply unit. Remove the plug

and store it for later use.

2. Prepare the cable for connection:

a. Measure how much cable you need to reach from the cable gland to terminal block

X3.

b. Remove the outer sheath and cable braid from the part of the cable that will be left

inside the power supply unit.

c. Strip the ends of the individual wires to expose the conductors for 1 cm (0.4 in).

d. Remove some more of the outer sheath to expose more cable braid. This part of the

braid should be connected to the cable gland.

36

Page 39

BRN

WHT

YEL

GRN

PNK

GRY

Relay 1

Relay 2

Relay 3

2

1

9

8

7

6

5

4

3

Chapter 4 – Electrical Installation

3. Insert the relay cable through the outer nut and the inner seal, and start inserting the

cable through the cable gland. Stop when you reach the section of the cable where the

metal braid is exposed.

4. Arrange the cable braid so that it makes contact with the cable gland when it is closed.

Push the inner seal in place and tighten the outer nut.

5. Inside the power supply unit, connect the wires to terminal block X3. Wire the

connection as normally open (NO) or normally closed (NC) according to the table

below.

Verify the wiring colors of your cable before making any connections.

Table 7 Terminal Block X3 Wiring

Signal Terminal

Relay 1 NC 1

Relay 1 common 2

Relay 1 NO 3

Relay 2 NC 4

Relay 2 common 5

Relay 2 NO 6

Relay 3 NC 7

Relay 3 common 8

Relay 3 NO 9

Figure 15 Terminal Block X3 Wiring for Normally Open (NO) Relay Connection

37

Page 40

OPT100 Installation Guide M211857EN-A

4.8 Connecting AC (Mains) Power

• AC power cable with 2.5 mm2 (AWG10) wires and 9 ... 16 mm external diameter. Must

be compliant with local regulations for mains power cables.

• Cable stripping tool

• 3 mm slotted screwdriver

• Adjustable wrench

WARNING!

adhere to local and state legislation and regulations.

WARNING!

regulations at all times.

WARNING!

cable gland marked AC in, you can use either of the two cable glands marked Spare

(diameter 5 ... 10 mm). If you are not wiring any relay outputs, you can also use cable

gland marked Relay out (diameter 7 ... 12 mm). If the AC in cable gland is left unused,

remember to plug it so that the enclosure remains tight.

If the power supply unit has no suitable cable gland free, you can replace the cable

gland marked AC in with a certified cable gland that is suitable for protecting the cable

and providing strain relief.

Only licensed experts may install electrical components. They must

Make sure that you prepare only de-energized wires.WARNING!

Keep away from live circuits. Operating personnel must observe safety

If the diameter of your mains power cable is not compatible with the

1. Install an external disconnection device for the AC power connection (for example, a

circuit breaker). Note the following:

• The disconnection device must be rated 16 A or 20 A at 250 VAC, and must conform

to any additional local regulations.

• The disconnection device must be visible from the DGA monitor, or lockable with a

key to prevent accidental switching on during installation and maintenance.

• The DGA monitor should not block access to the disconnection device after it has

been installed. The disconnection device should remain easy to operate.

2. Clearly mark the disconnection device as the disconnection device for the OPT100 DGA

Monitor.

38

Page 41

Chapter 4 – Electrical Installation

3. Make sure the external disconnection device is turned o. If possible, lock it in the o

position.

4. Run the AC cable between the external disconnection device and the power supply unit

of the DGA monitor.

5. Connect the AC cable to the external disconnection device.

6. Open the cable gland marked AC in on the power supply unit. Remove the plug and

store it for later use.

7. Prepare the cable for connection to the power supply unit:

a. Strip 14 cm (5.51 in) of the AC cable to expose the wires.

b. Cut

o 2 cm (0.79 in) of the line and neutral wires (brown and blue). Leave the green

and yellow grounding wire 14 cm (5.51 in) long.

CAUTION!

neutral wires. Under mechanical stress, the grounding wire must be the last to

disconnect from the protective ground terminal.

Make sure that the grounding wire is longer than the line and

c. Strip the ends of the individual wires to expose the conductors for 1 cm (0.4 in).

8. Insert the cable through the outer nut and the inner seal.

9. Start inserting the cable through the cable gland, and stop when the unstripped cable

is visible through the gland.

39

Page 42

Line

Neutral

Earth

BRN

BLU

GNR/YEL

L N

OPT100 Installation Guide M211857EN-A

10. Inside the power supply unit, connect the wires to terminal block X1:

Wiring colors may be dierent depending on your cable.

Table 8 Terminal Block X1 Wiring

Signal Wire Color Terminal

Line Brown L

Neutral Blue N

Ground Green/yellow

Figure 16 Terminal Block X1 Wiring

11. Tighten the AC in cable gland. The cable gland is also the strain relief for the cable, so

make sure the gland holds the cable tight.

4.9

40

Verifying Tightness of Cable Glands

• Adjustable wrench

Page 43

Chapter 4 – Electrical Installation

To maintain enclosure tightness and provide strain relief to the cables, all cable glands on

the DGA monitor and the power supply unit must be tightened. Unused cable glands must

remain plugged.

1. Check every cable gland that is in use:

a. Pull on the cable slightly to verify that the cable is securely held by the cable gland.

b. Tighten the cable gland if the cable moves easily.

2. Check that every unused cable gland is plugged and tightened.

41

Page 44

OPT100 Installation Guide M211857EN-A

42

Page 45

Chapter 5 – Commissioning

5. Commissioning

5.1 Turning On the DGA Monitor

Verify that the DGA monitor is fully wired and grounded before turning it on.CAUTION!

1. Turn on AC power from the external disconnection device.

2. Turn on the circuit breaker F1 Main and switch S1 inside the power supply unit.

3. Check the DC OK LED on the power supply:

• If the LED is lit solid green, DC power to the DGA monitor is successfully turned on.

• If the LED keeps blinking, it is likely that the 24 VDC connection to DGA monitor is

wired incorrectly. Turn

attempting to power on the DGA monitor again.

o switch S1 and AC power, and correct the problem before

4. Turn on the circuit breaker Main inside the DGA monitor.

5. Turn on the circuit breaker Heat inside the DGA monitor.

5.2

Connecting to the User Interface

• Laptop computer with:

• RJ-45 Ethernet connector

• Web browser (Google Chrome, Microsoft Internet Explorer, or Mozilla Firefox)

• Ethernet cable with RJ-45 connectors for temporary use

• Administration password for your OPT100 DGA Monitor

1. Connect your computer to the same network as the DGA monitor. If you are connecting

locally, connect the network cable between your computer and the port marked ETH1

on the processing unit inside the DGA monitor.

2. Open a web browser on the computer, and enter the IP address of the DGA monitor in

the address bar:

• If you are connecting locally through the ETH1 port, the IP address is always

192.168.28.2.

• If you are connecting through the network meant for SCADA integration, use the IP

address that has been assigned to the DGA monitor.

3. Enter Admin as the user name.

43

Page 46

OPT100 Installation Guide M211857EN-A

4. Enter the unique administration password for this OPT100 DGA Monitor. The password

is included in the OPT100 delivery documentation.

5. Select Log in. The user interface opens in your browser.

5.3 Initializing the DGA Monitor

• 5 mm hex key

Before starting the initialization, make sure that:

• DGA monitor is fully installed and wired.

• All oil connections are completed.

• DGA monitor is turned on.

• You are connected to the user interface with a web browser.

You must have physical access to the DGA monitor enclosure and the oil valves on the

transformer. Do not try to perform the initialization remotely.

You can stop the initialization sequence at most phases by selecting Control > Cancel.

1. In the user interface, select Control.

2. Read the instructions on screen and verify that the DGA monitor is waiting to be

initialized.

3. Select Start to start the initialization sequence.

4. Turn the manual override switch 90° counterclockwise on the side of the bleed valve to

unlock it. Select OK when done.

5. Remove the pipe plug from the bleed valve using the 5 mm hex key. Select OK when

done.

6. Open the oil intake and outlet valves on the transformer and select OK .

7. Wait for the DGA monitor to

beginning of the filling, and assisted using the oil pump of the DGA monitor in the later

stage. The duration of this step depends on the oil pressure, viscosity, temperature, and

length of the oil lines.

8. When instructed to do so, replace the pipe plug on the bleed valve. Select Continue

when done.

fill with oil. Oil pressure from the transformer is used in the

9. The user interface informs you when the initialization is complete. The DGA monitor is

now in standby mode.

44

Page 47

Chapter 5 – Commissioning

5.4 Starting Measurement Mode

In the measurement mode the DGA monitor repeats the measurement cycle continuously.

Before starting the measurement mode, make sure that:

• DGA monitor has been successfully initialized and is currently in standby mode.

1. Start the measurement mode from Control > Start Measuring.

2. Wait for the

conditions, it may take up to 90 minutes.

3. After the

or inside the DGA monitor.

first measurement cycle to complete. Depending on the starting

first cycle has been completed, verify that there are no oil leaks in the oil pipes

The DGA monitor will warm up furing the

made during the warm-up cycles are not guaranteed to be within the accuracy

specification.

first three measurement cycles. Measurements

5.5 Finalizing the Installation

1. If you have connected the DGA monitor to a host system using the Ethernet or RS-485

connections, verify the availability of the measurement data from the host system.

2. Verify that you have performed all installation steps according to the 6.1 Installation

Checklist (page 47).

3. Before leaving the installation site, perform a safety check and lock up accoding to the

6.2 Safety Checklist (page 48).

45

Page 48

OPT100 Installation Guide M211857EN-A

46

Page 49

Chapter 6 – Installation Verification

6. Installation Verification

6.1 Installation Checklist

Fill in the checklist and save it to record the tasks you have carried out. Make copies of the

list when needed.

Installation Preparations

Recommended tools available

Required materials and installation accessories available

Installation site safety requirements met

DGA monitor installation location selected

Oil intake and outlet connection valves available

Data connection to host system available at the installation site

Mechanical Installation

DGA monitor installed to selected location

Installation is vertical and not tilted more than 5 degrees

Oil intake and outlet pipes built between connection valves and DGA monitor installation location

Oil pipes connected to DGA monitor and transformer's oil valves

Insulation installed over oil pipes (if needed)

Electrical Installation

Grounding cable installed between DGA monitor enclosure and grounding point

Grounding cable installed between power supply unit and grounding point

Mains power connected to power supply unit

DC power cable installed between DGA monitor and power supply unit

Data connection cable installed (RS-485 or Ethernet)

47

Page 50

OPT100 Installation Guide M211857EN-A

Electrical Installation

Relay control cable installed between DGA monitor and power supply unit

Relay connections made to power supply unit (if needed)

All unused cable glands blocked

Cable glands tightened

Commissioning

DGA monitor turned on

Oil intake and outlet connection valves open

Connection to service interface OK

Pipe plug removed from bleed valve

Manual bleed valve override open

DGA monitor initialization cycle completed

Pipe plug installed to bleed valve

Completed first measurement cycle

DGA monitor in measurement mode

Data connection to host system verified

6.2 Safety Checklist

Verify all items in this safety checklist after you have completed all installation steps.

Safety

Mechanical installation stable and secure

Oil pipe connections checked for leaks

No active alarms in user interface

48

Status LED on DGA monitor door is green

Mains power connection and protective grounding verified

Pipe plug in place over the bleed valve

DGA monitor housing closed and locked with all three locks

Page 51

Safety

Power supply unit housing closed and locked

DGA monitor installation location

Transformer

Inspection date

Inspected by

Chapter 6 – Installation Verification

Comments

49

Page 52

OPT100 Installation Guide M211857EN-A

50

Page 53

Technical Support

Contact Vaisala technical support at helpdesk@vaisala.com. Provide at least the following

supporting information:

• Product name, model, and serial number

• Name and location of the installation site

• Name and contact information of a technical person who can provide further

information on the problem

For more information, see www.vaisala.com/support.

Warranty

For standard warranty terms and conditions, see www.vaisala.com/warranty.

Please observe that any such warranty may not be valid in case of damage due to normal

wear and tear, exceptional operating conditions, negligent handling or installation, or

unauthorized

for details of the warranty for each product.

modifications. Please see the applicable supply contract or Conditions of Sale

Recycling

Recycle all applicable material.

Follow the statutory regulations for disposing of the product and packaging.

51

Page 54

OPT100 Installation Guide M211857EN-A

52

Page 55

Page 56

www.vaisala.com

Loading...

Loading...