QUICK REFERENCE GUIDE

Vaisala SPECTRACAP®

Oxygen Transmitter OMT364

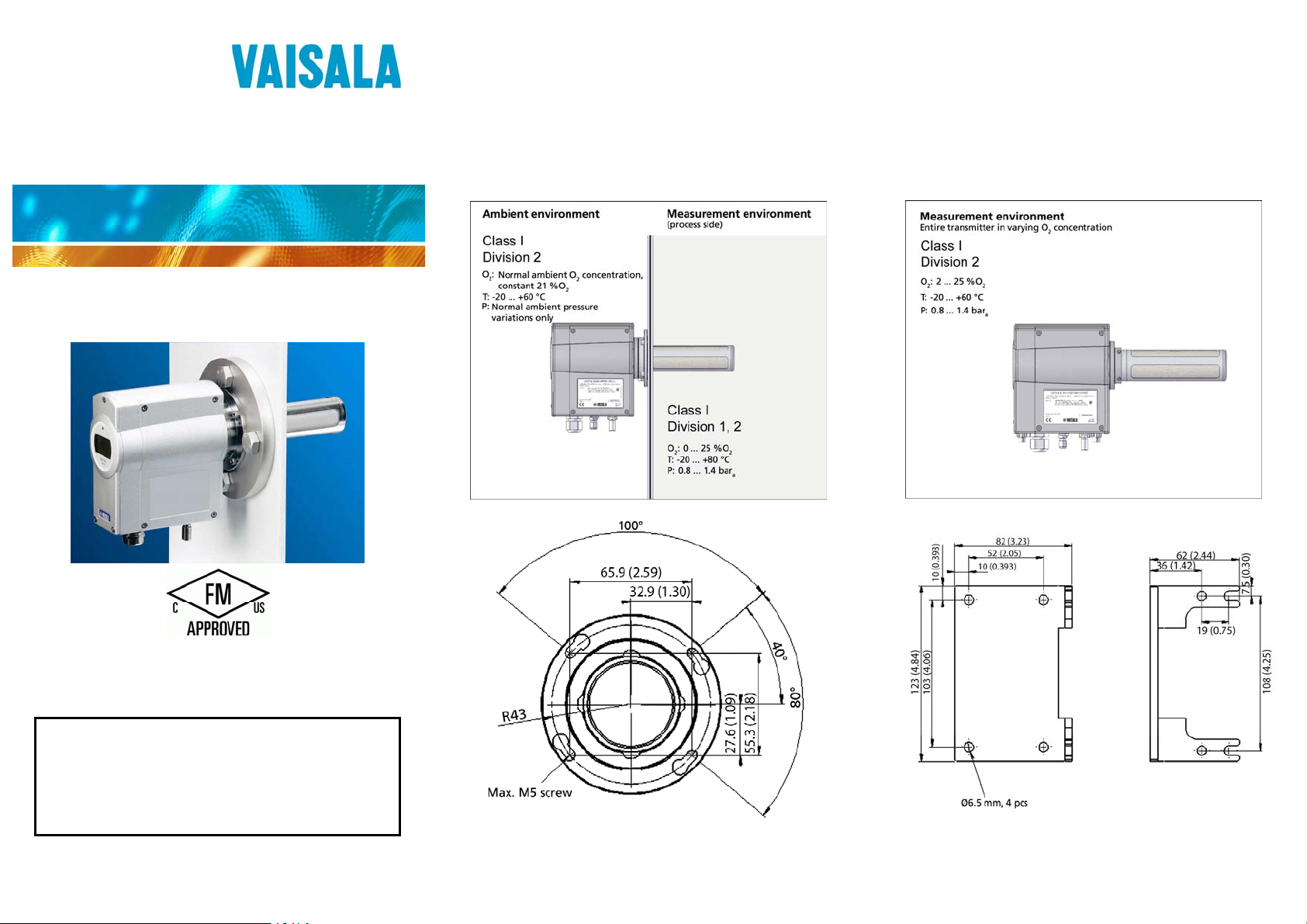

IN-LINE INSTALLATION

The maximum diameter of the OMT364 flange adapter is ø 97

mm. It has been chosen to suit to the center of a DIN 2572/B

flange (mounted with M16 hex bolts). The smallest possible

ANSI flange is ANSI 150 2.5" (mounted with 3/4" hex bolts).

Installation with probe pointing upwards prohibited. Installation

allowed only with probe horizontal or at a maximum of 45°

downward angle.

AMBIENT MEASUREMENT

Attach the wall mounting bracket to the desired location.

1.

Pre-fix the two outer M6 screws to the threads at the

2.

bottom of the transmitter

Attach the two inner screws as you place the transmitter

3.

on the wall mounting bracket.

Finish the installation by tightening all four screws.

4.

OMT364 Oxygen Transmitter is approved for Class I, Division

2, Groups A, B, C and D. Sensor for Class I, Division 1 and 2,

Groups A, B, C and D hazardous indoor and outdoor locations

with an enclosure rating IP66. Temperature class T4.

CAUTION OMT364 is a Class 1 laser product. Normal

handling and operation of the device is eyesafe because laser radiation is collimated and

maintained inside the probe. No laser

radiation is emitted outside the probe. Do not

place reflective surfaces directly into the

probe when the transmitter is in operation.

© Vaisala 2009. All rights reserved.

*M210901EN*

Figure 1 Flange Adapter Dimensions

Figure 2 Wall Mounting Bracket Dimensions

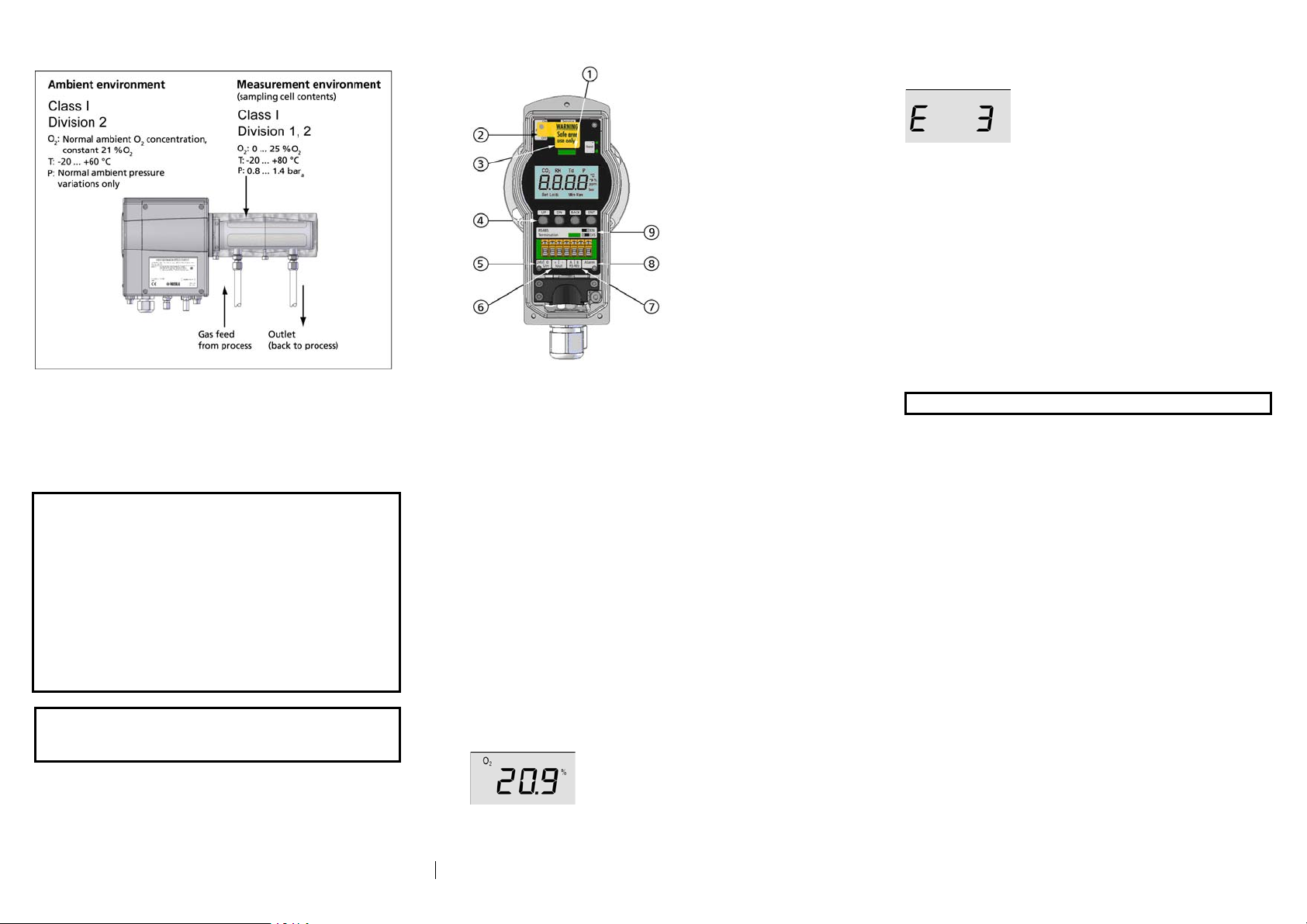

SAMPLE CELL INSTALLATION

WIRING

Open the front cover (never open the side cover) with the 3 mm

Allen key provided in the packing box to access the terminals.

In order to fulfill EMC requirements, the transmitter should be

connected to earth using the external terminal provided.

Installation notes:

Vin = 11 … 36 VDC, Pmax = 6 VA

For screw terminal connections use conductor AWG 20-16.

Always connect unpowered wires to transmitter to avoid

sparks on hazardous area. Make sure that Power ON switch

under yellow protective cover is in ON position before

making any wiring.

Install using Division 2 wiring methods as specified by the

NEC or CEC, as applicable.

WARNING Explosion hazard. Do not connect or

disconnect equipment when a flammable or

combustible atmosphere is present.

LOCAL INTERFACE LAYOUT

Figure 3 OMT364 Local Interface

1 = LED (red for startup or error, green for normal operation)

2 = Power ON/OFF switch (under the yellow tag)

3 = Service Port (RS-232) (under the yellow tag)

4 = Local interface keypad pushbuttons

5 = Supply voltage terminals

6 = Current output terminals

7 = RS-485 terminals

8 = Relay contact terminal

9 = RS-485 line termination jumper

STARTUP AND SELF-TEST SEQUENCE

Make sure that the power switch (located below the yellow

warning tag) is in the ON position, and attach the front cover

securely. Switch on the supply voltage.

After the self-test and warm-up are complete, oxygen

measurement starts. The entire start-up sequence takes

approximately 2.5 minutes.

Note that the transmitter may output some errors to the serial line

immediately after the self-test is over. These errors are expected.

No errors should remain active.

Figure 4 Oxygen Measurement Reading

If the self-test finds any errors, the error code is shown on the

display. Refer to the User’s Guide for the list of error codes.

Figure 5 Error Code on Display

USING THE DISPLAY/KEYPAD

The OMT364 has a local interface that can be accessed by

opening the front cover. The interface allows you to, for

example, view measurement information, enter compensation

parameters, perform calibration, and change the analog output

scaling. Refer to the User’s Guide for a full description.

To enter the menu, press the Up or Dn key. Use the Up and Dn

keys to scroll through the menu, and activate functions by

pressing the Ent key. To interrupt a function, use the Back key.

USING THE SERVICE PORT

WARNING Use the service port in safe area only.

The transmitter has an RS232C serial port for service functions.

Refer to the User’s Guide for connection cable options. If you

need to reconfigure device alarm level(s), Customer Interface or

other settings, the Service Interface provides a wider range of

options than the keypad and display functions.

Default serial communication settings are: Baud rate 19200,

8 data bits, no parity, 1 stop bit.

SERIAL COMMANDS

The list below provides some useful serial commands. Refer to

the User’s Guide for a full command list.

? Shows information about the device

CO2 Shows/sets CO2 for compensation

COXY1 Perform one-point adjustment

COXY2 Perform two-point adjustment

ERRS Shows detected errors

H2O Shows/sets H2O for compensation

HELP Lists commands

PRES Shows/sets pressure for compensation

R Starts continuous output

S Stops continuous output

SEND Sends measurement results

SIL Measures signal level

VERS Shows product name and software version

Visit our Internet pages at www.vaisala.com

Ref. M210901EN-A

Loading...

Loading...