Vaisala Instruments Catalog 2009

Ref. B210768EN rev. A

P.O. Box 26, FI-00421 Helsinki, FINLAND

Email: industrialsales@vaisala.com

www.vaisala.com/OMT355

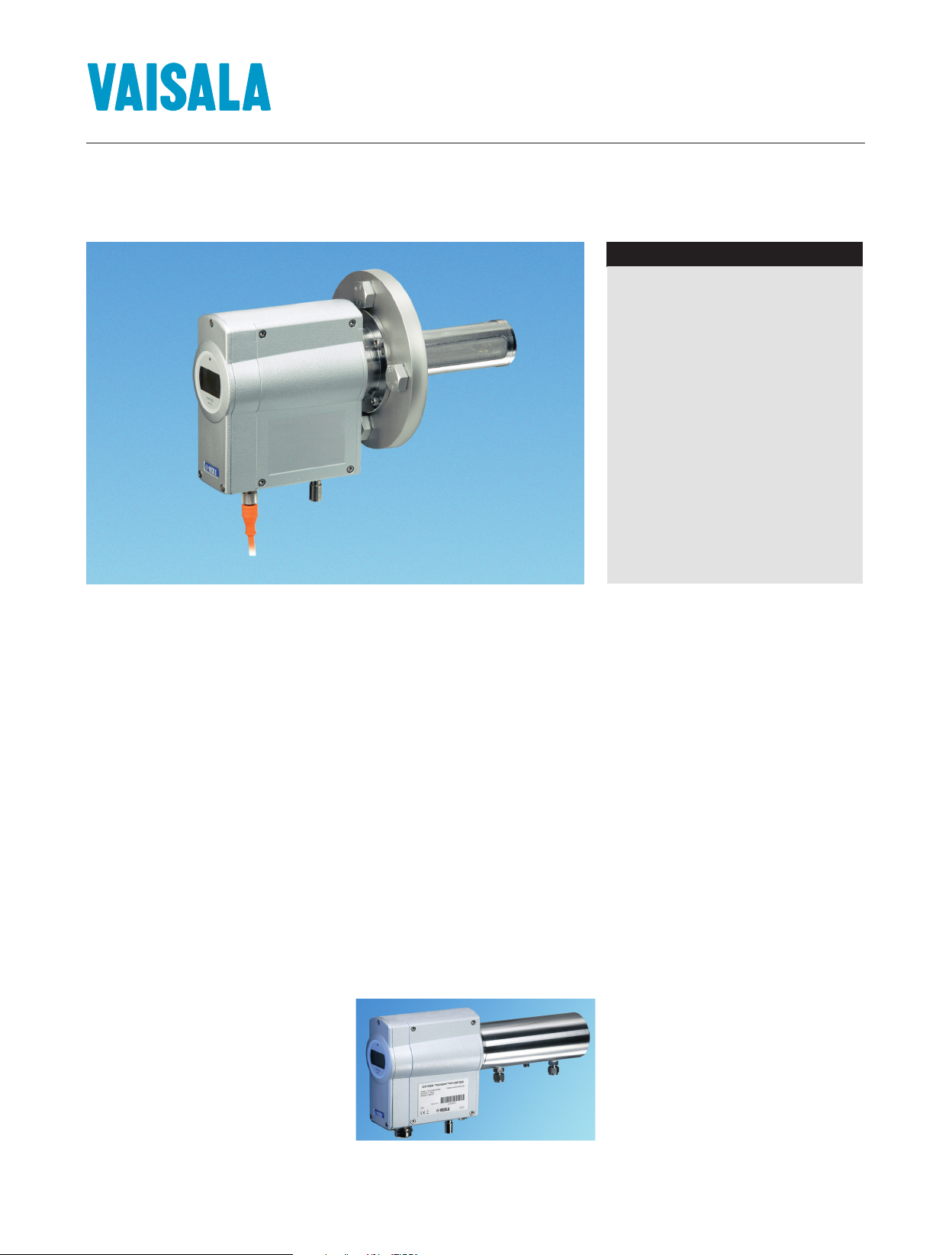

OMT355 Oxygen Transmitter for Industrial

Process Measurements

Features/Benefits

• Minimizes need for sample

conditioning equipment

• In-situ probe or sampling cell

options

• Tolerates aggressive chemicals

• Tolerates excessive amounts of

moisture even in liquid form

• Low maintenance

• Diagnostic output for preventive

maintenance

• Heated optical surfaces to prevent

condensation

Tel: +358 9 894 91

Fax: +358 9 8949 2485

e Vaisala SPECTRACAP® Oxygen Transmitter.

e Vaisala SPECTRACAP® Oxygen

Transmitter OMT355 is ideal for

oxygen monitoring in moist and

aggressive process gases. Typical

applications include gas generation,

inert gas blanketing, fermentation and

composting process monitoring.

Laser based measurement

e OMT355 incorporates a compact

tunable diode laser (TDL) gas

spectrometer built in the measurement

probe. This optical measurement

technology is well known for

unmatched stability and robustness.

For the first time, the SPECTRACAP®

sensor offers TDL technology in a

compact probe suitable for field use.

Direct installation

In many applications, the OMT355

can be ange-mounted directly into

a process. No sampling or sample

conditioning equipment is needed.

is feature provides real time

measurement data without sampling

or sample switching delays.

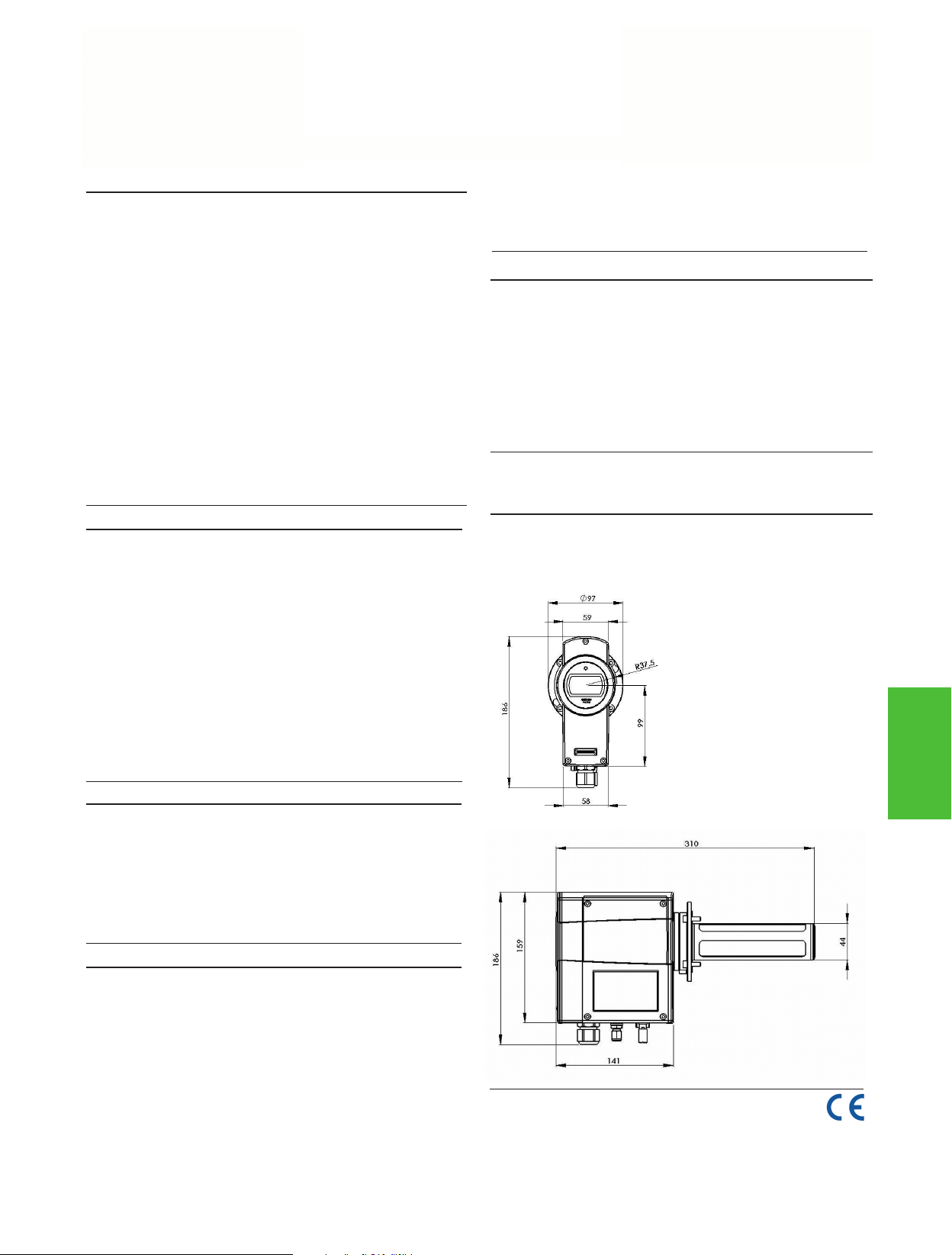

Sampling cell installation

An optional sampling cell is available

for processes with high temperatures,

elevated pressures or extremely

dicult mechanical conditions. Due to

the robustness of the SPECTRACAP®

sensor and its low sensitivity to gas

flow and pressure variations, the

sampling system can be very simple

and it can be installed near the

sampling point.

Low maintenance

A stainless steel mesh lter and an

optional porous PTFE lter protect

the OMT355 probe optics from dust

and dirt. An intelligent measurement

algorithm further minimizes

contamination eects and provides

a maintenance alert well before the

measurement performance is aected.

OMT355 with the sampling cell.

Long calibration interval

Calibration or eld checking of

the instrument can be done either

with ambient air or with zero/span

gases injected through an optional

calibration gas connector. e

calibration interval of the OMT355 is

12 months.

User friendly interfaces

For calibration and conguration, the

OMT355 features both software and

keypad user interfaces and an LCD

di sp lay.

TDL Technology

e Tunable Diode Laser (TDL)

technology used in the SPECTRACAP®

sensor is one of the most powerful

technologies in gas measurement on

the market today.

e technology is based on measuring

the attenuation of a beam of laser light

in the sample gas. For oxygen sensing

the laser is tuned to a wavelength

which is characteristic and unique for

the oxygen molecule. erefore, the

measured attenuation is an extremely

selective measure for the amount of

oxygen on the path of the laser beam.

106

106

Vaisala Instruments Catalog 2009

Ref. B210768EN rev. A

OMT355 OXYGEN

Technical Data

Performance

Measurement range 0 ... 100 % O2

Accuracy

(including noise, linearity, and repeatability)

Temperature dependence over T range ±2 % of reading

Stability ±1 % of reading/yr

Zero drift ±0.1 % O

Response time of measurement 3 s

Diusion limited response in still air T

without lters 10 s / 20 s

with stainless steel mesh lter 10 s / 25 s

with stainless steel mesh and PTFE lters 30 s / 70 s

Pressure dependence without pressure compensation

0.8 ... 1.2 bar -2 % of reading

1.2 ... 1.4 bar -5 % of reading

Accuracy of pressure compensation ±0.25 % of reading

Background gas eects for CO

Accuracy of background gas compensation

0 ... 50 vol-% CO

0 ... 300 g/m

Operating Environment

Operating temperature range

for probe (in-line installation) -20 ... +80 °C

for electronics (housing) -40 ... +60 °C

for transmitter (ambient gas

measurement -20 ... +60 °C

Storage temperature range -55 ... +80 °C

Operating pressure range 0.8 ... 1.4 bar

Maximum pressure range for probe up to 10 bar

Compliance

IEC(EN)-61326 Electrical equipment for measurement, control

and laboratory use. EMC requirements

EN50104 Electrical apparatus for the detection and

measurement of oxygen. Performance requirements and test

methods.

EN50271 Electrical Apparatus for the Detection and

Measurement of Combustible Gases, Toxic Gases or Oxygen

Laser safety Class 3R laser product

2

3

H2O (Td = 80 °C) ±1 % of reading

and H2O, uncompensated

2

<1 % of reading for <6 vol-% CO

<1 % of reading for gas dewpoint < 30 °C

±0.2 % O

2

63/T90

±0.5 % of reading

Inputs and Outputs

Power supply

input range 11 ... 36 VDC

Power consumption

maximum 6 W

typical 3 W

Analog output 0/4 ... 20 mA, sourcing

maximum load 500 Ω

Serial output (2-wire, non-isolated) RS-485

Alarm/control relay 30 VAC/60 VDC

Mechanics

Housing material G-AlSi10 Mg (DIN 1725)

Probe material AISI 316

Housing classication IP66

Weight 2.2 kg

Mounting ange diameter 97 mm

Can be tted to standard anges. Minimum sizes:

DIN (2527B) DN50 and ANSI (150) 2.5”

/yr

Cable bushing Cable gland M20 x 1.5

Stainless steel mesh lter openings ø 310 µm

2

Wetted materials

AISI 316, EPDM or Kalrez® (optional), PTFE (optional), SiN, MgF

Options and accessories

Hydrophobic PTFE lter, pore size 8 µm

with EPDM O-rings 217055

with Kalrez

1/2” NPT conduit tting 217197

M12 male 8-pin connector for

user cable

Serial interface cable for PC 19446ZZ

USB-RJ45 Serial interface cable 219685

Sample cell with wall mounting bracket

2

with EPDM O-rings 217052

with Kalrez

For complete specications, refer to the User’s Guide.

® O-rings

® O-rings

Dimensions

Dimensions in mm 306 mm x 184 mm x 74 mm

SPECTRACAP® is a registered trademark of Vaisala.

Specications are subject to change without prior notice.

© Vaisala Oyj

2

217056

214806SP

216619

107

107

Loading...

Loading...