Page 1

USER'S GUIDE

Vaisala HUMICAP®Humidity and

Temperature Module

HMM211

M210718EN-B

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FI-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2009

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION............................................................................7

About This Manual...................................................................7

Contents of This Manual.......................................................7

Version Information............................................................... 8

Related Manuals...................................................................8

General Safety Considerations.............................................8

Feedback...............................................................................9

Product Related Safety Precautions...................................... 9

ESD Protection.........................................................................9

Recycling ................................................................................10

Regulatory Compliances....................................................... 10

Patent Notice ..........................................................................11

Trademarks............................................................................. 11

Warranty..................................................................................11

CHAPTER 2

PRODUCT OVERVIEW................................................................................ 13

Introduction to HMM211 ........................................................ 13

CHAPTER 3

TO BE NOTED WHEN MEASURING HUMIDITY........................................15

CHAPTER 4

INSTALLATION............................................................................................17

Selecting Location ................................................................. 17

Dimensions............................................................................. 18

Electrical Connections...........................................................18

CHAPTER 5

CALIBRATION.............................................................................................21

One-Point Humidity Calibration............................................22

With the Hand-Held Humidity and Temperature Meter

HM70 or HMI41 Indicator and Calibration Cable................ 22

With Pushbuttons and a Jumper.........................................23

Two-Point Humidity Calibration............................................ 23

Two-Point Humidity Calibration Procedure.........................24

Calibration Table....................................................................25

Temperature Calibration........................................................ 26

Temperature Calibration of an RH and T Module...............26

Temperature Calibration of a Dewpoint Module ................. 27

Temperature Calibration of an RH and T Module with

Two Sensor Heads..............................................................27

VAISALA________________________________________________________________________ 3

Page 4

USER'S GUIDE____________________________________________________________________

CHAPTER 6

CHEMICAL PURGE .....................................................................................29

CHAPTER 7

MAINTENANCE............................................................................................31

Replacing the HUMICAP180R Sensor and the Filter.......31

Replacing Consumables........................................................31

Parts List for Consumables .................................................31

CHAPTER 8

TROUBLESHOOTING..................................................................................33

Troubleshooting Procedure ..................................................33

Technical Support ..................................................................33

Return Instructions ................................................................34

Vaisala Service Centers.........................................................35

CHAPTER 9

TECHNICAL DATA ......................................................................................37

Specifications .........................................................................37

Options....................................................................................39

4 ___________________________________________________________________ M2107

18EN-B

Page 5

________________________________________________________________________________

List of Figures

Figure 1 Measurement Error at 100 %RH when the Temperature

Difference between the Ambient Air and the Sensor is 1 °C...16

Figure 2 Dimensions in mm (inches)......................................................18

Figure 3 Electrical Connections..............................................................19

Figure 4 Calibration Connector for the HM70 or HMI41.........................22

Figure 5 Calibration Pins and Pushbuttons............................................25

Figure 6 Offset and Gain Calibration Examples.....................................27

Figure 7 Decrease of the Sensor Gain Due to an Interfering Chemical

and the Effect of the Chemical Purge Process ........................29

Figure 8 Dewpoint Temperature............................................................. 38

VAISALA________________________________________________________________________ 5

Page 6

USER'S GUIDE____________________________________________________________________

List of Tables

Table 1 Manual Revisions .......................................................................8

Table 2 Related Manuals.........................................................................8

Table 3 Emission Tests .........................................................................10

Table 4 Immunity Tests .........................................................................10

Table 5 Greenspan's Calibration Table with Output Values According

to the Chosen Scale.................................................................25

Table 6 Available Spare Parts...............................................................31

Table 7 Relative Humidity Specifications ..............................................37

Table 8 Temperature Specifications......................................................37

Table 9 Analog Output Specifications ...................................................38

Table 10 General Specifications..............................................................38

Table 11 Operating Voltage Specifications.............................................39

Table 12 Modules, Sensor Heads, and Outputs .....................................39

Table 13 Cable Lengths for Sensor Heads.............................................40

Table 14 Automatic Chemical Purge.......................................................40

6 ___________________________________________________________________ M2107

18EN-B

Page 7

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the product.

About This Manual

This manual provides information for installing, operating, and

maintaining Vaisala HUMICAP® Humidity and Temperature Module

HMM211.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the manual

and the product.

- Chapter 2, Product Overview, introduces the features and advantages

of the Vaisala HUMICAP® Humidity and Temperature Module

HMM211.

- Chapter 3, To Be Noted When Measuring Humidity, describes issues

that need to be noted in the measurement of humidity.

- Chapter 4, Installation, provides you with information that is intended

to help you install this product.

- Chapter 5, Calibration, provides you with information that is intended

to help you calibrate this product.

- Chapter 6, Chemical Purge, provides you with information on

chemical purge.

- Chapter 7, Maintenance, provides information that is needed in basic

maintenance of the product.

- Chapter 8, Troubleshooting, describes common problems, their

probable causes and remedies, and contact information for technical

support.

VAISALA________________________________________________________________________ 7

Page 8

USER'S GUIDE____________________________________________________________________

Version Information

Table 1 Manual Revisions

Manual Code Description

U337EN-1.1 December 1998

M210718EN-A September 2005: EMC test data revised

M210718EN-B This manual, December 2009 - HUMICAP® sensor

type has been changed.

Related Manuals

Table 2 Related Manuals

Manual Code Manual Name

M210316EN-A Vaisala HUMICAP® Indicator HMI41 and Probes

HMP41/45/46 User's Guide

M210777EN-B Calibration of Digital Transmitters with Vaisala

HUMICAP

19164ZZ and 25917ZZ User's Guide

M210185EN-C Vaisala Humidity Calibrator HMK15 User's Guide

M210297EN-E Vaisala HUMICAP® Hand-Held Humidity and

Temperature Meter HM70 User's Guide

®

Humidity Indicator HMI41 Cables

WARNING

CAUTION

NOTE

General Safety Considerations

Throughout the manual, important safety considerations are highlighted

as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

8 ___________________________________________________________________ M2107

18EN-B

Page 9

Chapter 1 ________________________________________________________ General Information

Feedback

Vaisala Customer Documentation Team welcomes your comments and

suggestions on the quality and usefulness of this publication. If you find

errors or have other suggestions for improvement, please indicate the

chapter, section, and page number. You can send comments to us by email: manuals@vaisala.com

Product Related Safety Precautions

The Vaisala HUMICAP® Humidity and Temperature Module HMM211

delivered to you has been tested for safety and approved as shipped from

the factory. Note the following precautions:

WARNING

CAUTION

CAUTION

Ground the product, and verify outdoor installation grounding

periodically to minimize shock hazard.

Do not modify the unit. Improper modification can damage the product

or lead to malfunction.

Do not touch the sensor element.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the product

by delivering electrostatic discharges when touching, removing, or

inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground yourself

to the equipment chassis before touching the boards. Ground yourself

with a wrist strap and a resistive connection cord. When neither of the

above is possible, touch a conductive part of the equipment chassis

with your other hand before touching the boards.

VAISALA________________________________________________________________________ 9

Page 10

USER'S GUIDE____________________________________________________________________

- Always hold the boards by the edges and avoid touching the

component contacts.

Recycling

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations. Do

not dispose of with regular household refuse.

Regulatory Compliances

The Vaisala HUMICAP® Humidity and Temperature Module HMM211

complies with the following performance and environmental test

standards:

The emission and immunity tests have been performed according to

standard EN61326-1.

Table 3 Emission Tests

Test Setup According to

RF field emission CISPR 22 Class B (EN55022)

Conducted emissions CISPR 22 B (EN55022)

Table 4 Immunity Tests

Test Setup According to

Electrostatic discharge IEC 1000-4-2 (EN 61000-4-2)

Fast transient burst IEC 1000-4-4 (EN 61000-4-4)

RF field immunity IEC 1000-4-3 (EN 61000-4-3)

Conducted RF immunity

NOTE: cable length max. 8 meters

Surge IEC 1000-4-5 (EN 61000-4-5)

Voltage dips, short interrupts IEC 1000-4-11 (EN 61000-4-11)

IEC 1000-4-6 (EN 61000-4-6)

10 __________________________________________________________________ M2107

18EN-B

Page 11

Chapter 1 ________________________________________________________ General Information

Patent Notice

The Vaisala HUMICAP® Humidity and Temperature Module HMM211

is protected by the following patents and patent applications and their

corresponding national rights:

Finnish patents 98861 and 99164, French patents 6650303 and 9504397,

German patents 69418174 and 19513274, Japanese patents 3585973 and

2801156, UK patent 0665303, and US patent 5607564.

Trademarks

Vaisala Trademark is a registered trademark of Vaisala Oyj.

Warranty

HUMICAP

Vaisala hereby represents and warrants all Products manufactured by

Vaisala and sold hereunder to be free from defects in workmanship or

material during a period of twelve (12) months from the date of delivery

save for products for which a special warranty is given. If any Product

proves however to be defective in workmanship or material within the

period herein provided Vaisala undertakes to the exclusion of any other

remedy to repair or at its own option replace the defective Product or part

thereof free of charge and otherwise on the same conditions as for the

original Product or part without extension to original warranty time.

Defective parts replaced in accordance with this clause shall be placed at

the disposal of Vaisala.

Vaisala also warrants the quality of all repair and service works

performed by its employees to products sold by it. In case the repair or

service works should appear inadequate or faulty and should this cause

malfunction or nonfunction of the product to which the service was

performed Vaisala shall at its free option either repair or have repaired or

replace the product in question. The working hours used by employees of

Vaisala for such repair or replacement shall be free of charge to the

client. This service warranty shall be valid for a period of six (6) months

from the date the service measures were completed.

®

is a registered trademark of Vaisala Oyj.

This warranty is however subject to following conditions:

a) A substantiated written claim as to any alleged defects shall have

been received by Vaisala within thirty (30) days after the defect or

fault became known or occurred, and

VAISALA_______________________________________________________________________ 11

Page 12

USER'S GUIDE____________________________________________________________________

b) the allegedly defective Product or part shall, should Vaisala so

require, be sent to the works of Vaisala or to such other place as

Vaisala may indicate in writing, freight and insurance prepaid and

properly packed and labelled, unless Vaisala agrees to inspect and

repair the Product or replace it on site.

This warranty does not however apply when the defect has been caused

through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use of the Product or

negligence or error in storing, maintaining or in handling the

Product or any equipment thereof;

c) wrong installation or assembly or failure to service the Product or

otherwise follow Vaisala's service instructions including any

repairs or installation or assembly or service made by unauthorized

personnel not approved by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well as any adding to it

without Vaisala's prior authorization;

e) other factors depending on the Customer or a third party.

Notwithstanding the aforesaid Vaisala's liability under this clause shall

not apply to any defects arising out of materials, designs or instructions

provided by the Customer.

This warranty is expressly in lieu of and excludes all other conditions,

warranties and liabilities, express or implied, whether under law, statute

or otherwise, including without limitation ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A

PARTICULAR PURPOSE and all other obligations and liabilities of

Vaisala or its representatives with respect to any defect or deficiency

applicable to or resulting directly or indirectly from the Products supplied

hereunder, which obligations and liabilities are hereby expressly

cancelled and waived. Vaisala's liability shall under no cir-cumstances

exceed the invoice price of any Product for which a warranty claim is

made, nor shall Vaisala in any circumstances be liable for lost profits or

other consequential loss whether direct or indirect or for special damages.

12 __________________________________________________________________ M2107

18EN-B

Page 13

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features and advantages of the Vaisala

HUMICAP® Humidity and Temperature Module HMM211.

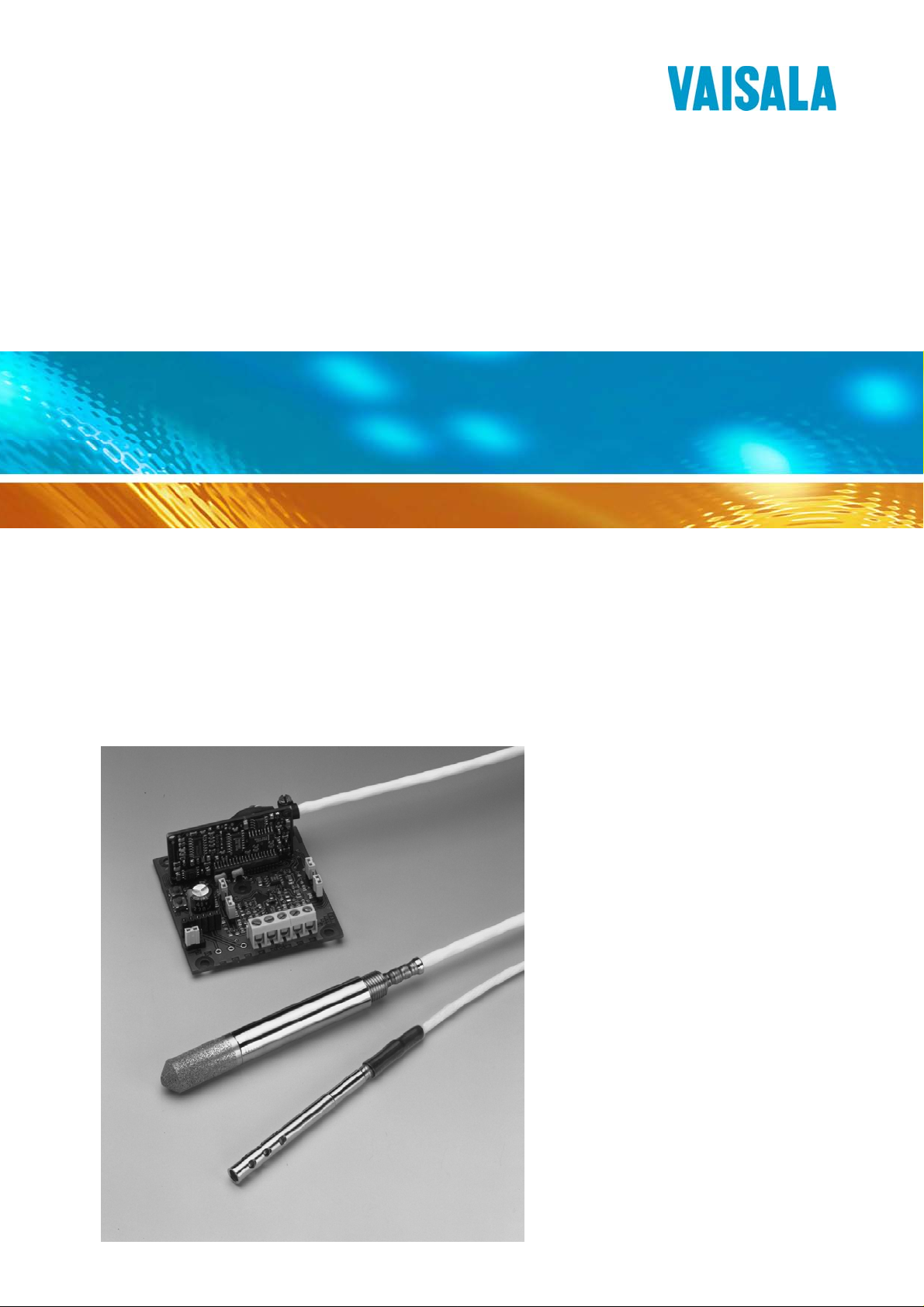

Introduction to HMM211

The HMM211 modules are designed especially for relative humidity

measurements in environmental chamber applications with high

temperature and humidity levels. They also measure temperature and

calculate the dewpoint temperature.

The HMM211 has actually three different module options to choose

from:

- Humidity and temperature module: with a standard humidity and

temperature sensor head

- Dewpoint module: with a warmed sensor head incorporating a

composite RH and T sensor

- Humidity and temperature module with two sensor heads: with a

warmed humidity sensor head incorporating a composite sensor, and

an additional temperature sensor head for ambient temperature

measurement

The HMM211 is a three wire module with four analog output options: 0

... 1 V, 0 ... 5 V, 0 ... 10 V, and 0 ... 20 mA. The module can be ordered

with the output option already selected. Other options include the length

of the humidity probe, the sensor protection and an additional

temperature probe. Furthermore, you can also order the module with a

suitable cable length (0.65 m, 1.50 m, or 3.0 m) and a temperature

measurement range best suited for that particular application (0 ... 100

°C, -20 ... +120 °C, -20 ... +180 °C, -40 ... +180 °C or

-70 ... +180 °C).

Output parameters can also be selected from various options according to

the module type. The output parameters for the RH and T module are

relative humidity and temperature. For the RH and T module with two

sensor heads, the parameters also include relative humidity and

VAISALA_______________________________________________________________________ 13

Page 14

USER'S GUIDE____________________________________________________________________

temperature, and for the dewpoint module, the parameter is dewpoint

temperature. The dewpoint temperature range can be either 0 ... +100 °C

or -40 ... +100 °C.

The probes also have a selectable chemical purge option. Note that with a

warmed sensor head, the probe length is always 90 mm and the sensor is

protected with a sintered filter.

The HMM211 modules are connected to process control systems with

screw terminals. These versatile modules incorporate the

HUMICAP®180R humidity sensor which uses an operating principle

based on changes in the capacitance of a thin polymer film as it absorbs

water molecules. The HMM211 modules measure temperature with the

reliable Pt 100 sensor. If the module is ordered with chemical purge

option, it incorporates a composite sensor.

14 __________________________________________________________________ M2107

18EN-B

Page 15

Chapter 3 ________________________________________ To Be Noted When Measuring Humidity

CHAPTER 3

TO BE NOTED WHEN MEASURING HUMIDITY

This chapter describes issues that need to be noted in the measurement of

humidity.

In the measurement of relative humidity and especially in calibration, it

is essential that the temperature equilibrium is reached. Even a slight

difference in the temperature between the measured object and the sensor

causes an error. For example, at +20 °C (+ 68 °F) and 50 %RH, a

temperature difference of ±1 °C between the measured object and the

sensor causes an error of ±3 %RH. If relative humidity is 90 %RH, the

error is about ±5.4 %RH. A graph of the measurement error at 100 %RH

when the temperature difference between ambient air and the sensor is

1 °C is presented in Figure 1 on page 16.

The error is at its greatest when the temperature of the sensor differs from

that of the surroundings and the humidity is high. A difference of a few

degrees in temperature may cause water to condense on the sensor

surface. Efficient ventilation accelerates the evaporation of the condensed

water whereas in an unventilated space, it may take hours. The

HUMICAP

water has evaporated. Contaminated water condensing on the sensor may

shorten its life span and alter the calibration.

®

180R sensor returns to its normal functioning as soon as

VAISALA_______________________________________________________________________ 15

Page 16

USER'S GUIDE____________________________________________________________________

10

9

8

7

6

5

4

dRH (%RH)

3

2

1

0

-40-200 20406080100

Temperature (°C )

Figure 1 Measurement Error at 100 %RH when the

Temperature Difference between the Ambient Air and

the Sensor is 1 °C

NOTE

With a dewpoint module, the temperature equilibrium is not a problem as

the temperature of the sensor head changes continuously and the sensor

head has a fast humidity response.

16 __________________________________________________________________ M2107

18EN-B

Page 17

Chapter 4 _______________________________________________________________ Installation

CHAPTER 4

INSTALLATION

This chapter provides you with information that is intended to help you

install this product.

Selecting Location

Finding a suitable site for HMM211 is important for getting

representative ambient measurements.

Select a place that gives a true picture of the environment or process and

is as clean as possible. Air should flow freely around the sensor.

Install the sensor head to a sufficient distance from the duct or chamber

walls. Make sure to insert enough cable to the same space with the probe

in order to prevent heat conduction. If an additional temperature probe is

used, install it so that the warmed sensor head does not interfere with the

measurement.

VAISALA_______________________________________________________________________ 17

Page 18

USER'S GUIDE____________________________________________________________________

Dimensions

)

4

1

.

0

(

2

)

2

0

.

1

(

6

~

6

5

(2

.

5

6

)

Figure 2 Dimensions in mm (inches)

Electrical Connections

Connect wires according to Figure 3 on page 19 (A = voltage output, B =

with current module).

18 __________________________________________________________________ M2107

18EN-B

Page 19

Chapter 4 _______________________________________________________________ Installation

2

1

3

Figure 3 Electrical Connections

The following numbers refer to Figure 3 above:

1 = During normal use, leave the jumper as indicated here (factory

setting).

2 = Calibration connector for the HM70 or HMI41

3 = Calibration jumper when not in use

VAISALA_______________________________________________________________________ 19

Page 20

USER'S GUIDE____________________________________________________________________

This page intentionally left blank.

20 __________________________________________________________________ M2107

18EN-B

Page 21

Chapter 5 _______________________________________________________________ Calibration

CHAPTER 5

CALIBRATION

This chapter provides you with information that is intended to help you

calibrate this product.

Vaisala recommends a recalibration of the HMM211 module after six

months of use. After the first recalibration, the recommended calibration

interval is approximately 12 months. However, please note that these

intervals depend on the operating conditions and the required accuracy.

When calibrating humidity instruments, it is important that the probe, the

reference instrument, and the calibrator are in thermal equilib rium.

Therefore, always allow enough time for stabilization before starting the

actual calibration.

- Calibration in the chamber: leave the calibrator (for example, the

HMK15) in the chamber overnight with the chamber door open.

- Calibration of a humidity and temperature module: allow at least one

hour for the stabilization of the calibrator (for example, HM70 handheld humidity and temperature meter with a reference probe).

- Calibration of a dewpoint module or of a humidity and temperature

module with two sensor heads: allow at least three hours for

stabilization if the sensor head is in such an environment that the

warming function has been active. The warming function can be

deactivated by connecting the jumper to any calibration connector (see

Figure 5 on page 25). Note also that when humidity calibrating a Td

transmitter, the Td signal on Channel 2 is replaced by the RH signal 0

... 100 %RH with the chosen output range. For example, if the Td

output range is 0 ... 5 V, the output during RH calibration is 0 ... 100

%RH < > 0 ... 5 V.

- Calibration of a module with chemical purge option option: chemical

purge is activated when the power is connected. When calibrating a

probe, turn the power on with the sintered stainless steel filter on the

probe, wait for 3 minutes, and remove the filter. Allow to stabilize and

perform the calibration.

NOTE

VAISALA_______________________________________________________________________ 21

Do not turn the power off during calibration.

Page 22

USER'S GUIDE____________________________________________________________________

One-Point Humidity Calibration

With the Hand-Held Humidity and Temperature Meter HM70 or HMI41 Indicator and Calibration Cable

You can calibrate the HMM211 module with the Hand-Held Humidity

and Temperature Meter HM70 or HMI41 indicator and an appropriate

calibration cable (for HM70: 27159ZZ; for HMI41: 19164ZZ).

Connect the cable to the test connector of the HMM211 module and

insert the jumper as indicated in Figure 4 below. For detailed

instructions, see the following documents:

- Vaisala HUMICAP® Indicator HMI41 and Probes HMP41/45/46

User's Guide

- Vaisala HUMICAP® Hand-Held Humidity and Temperature Meter

HM70

- Calibration of Digital Transmitters with Vaisala HUMICAP®

Humidity Indicator HMI41 Cables 19164ZZ and 25917ZZ User's

Guide

2

1

Figure 4 Calibration Connector for the HM70 or HMI41

The following numbers refer to Figure 4 above:

22 __________________________________________________________________ M2107

18EN-B

Page 23

Chapter 5 _______________________________________________________________ Calibration

The following numbers refer to Figure 4 above:

1 = For calibration with the HM70 or HMI41, insert the jumper as

indicated here.

2 = Calibration connector for the HM70 or HMI41

NOTE

NOTE

The serial communication parameters are:

1200 bauds, no parity, 8 data bits, 1 stop bit

When the connection is being established, the message 'CON ERROR'

blinks on the HMI41 display for a couple of times after which

measurement readings appear. This is quite normal and requires no

action; however, if the message is not replaced by measurement readings,

it is an indication of an operation error.

With Pushbuttons and a Jumper

You can also perform the calibration with pushbuttons and a jumper on

the component board (see Figure 5 on page 25). In addition, you need a

digital multimeter (DMM). There are two pushbuttons (UP and DOWN)

and six pairs of pins (RH offset, RH gain, T offset, T gain, Ta offset, and

Ta gain) that are connected with the calibration jumper. Vaisala

recommends using the RH offset pins if the RH is less than 65 %RH and

the gain pins if the RH is greater than 65 %RH.

For example, to perform a one-point humidity calibration using saturated

NaCl salt solution at 75.5 %RH as a reference, do as follows:

1. Insert the probe into a NaCl salt chamber and let stabilize.

2. Connect a DMM to the RH output and wait until the reading

stabilizes.

3. Connect a jumper to the RH gain pins and adjust the DMM reading

with buttons UP and DOWN until the output corresponds to

75.5 %RH.

4. Disconnect the jumper.

Two-Point Humidity Calibration

You can also perform a two-point calibration with saturated salt

calibrators (for example HMK15), or you can send the instrument to

Vaisala or a Vaisala representative for recalibration. See contact

VAISALA_______________________________________________________________________ 23

Page 24

USER'S GUIDE____________________________________________________________________

information for Vaisala Service Centers on page 35. Figure 6 on page 27

illustrates the difference between offset and gain calibrations.

Two-Point Humidity Calibration Procedure

1. Leave the calibrator and the probe in the same environment for at

least one hour so that their temperatures have time to equalize. For

information on more accurate stabilization times, see Chapter 4,

Installation, on page 17.

2. Insert the probe into the measurem ent hole of the LiCl salt chamber

in the humidity calibrator.

3. Wait for 20 to 40 minutes.

4. Check the temperature and read the closest corresponding RH

value in the calibration table (Table 5 on page 25).

5. Connect the jumper to the RH offset pins (see Figure 5 on page 25)

and adjust the output signal with push buttons to the value given in

the calibration table (Table 5 on page 25).

6. Insert the probe into the m easurement hole of the NaCl chamber.

7. Wait for 20 to 40 minutes.

8. Check that the reading corresponds within the desired accuracy to

the reading given in the calibration table. If not, connect the jumper

to the RH gain pins and adjust the reading with push buttons.

9. Check again the reading at the first point and repeat the procedure

if necessary.

24 __________________________________________________________________ M2107

18EN-B

Page 25

Chapter 5 _______________________________________________________________ Calibration

Figure 5 Calibration Pins and Pushbuttons

With the jumper connected to the RH gain pins, each pressing of the UP

or DOWN button changes the value approximately 0.05 %RH at

75 %RH. With the jumper connected to the RH offset pins, each pressing

changes the value approximately 0.05 %RH.

With the jumper connected to the T offset pins, each pressing of the UP

or DOWN button changes the value 0.05 °C or 0.05 °F in all

temperatures. With the jumper connected to the T gain pins, each

pressing changes the value 0.05 °C or 0.05 °F in the temperature

currently prevailing in the process.

Calibration Table

Table 5 Greenspan's Calibration Table with Output Values

Temperature

LiCl

4 ... 20 mA mA 5.81 5.81 5.81 5.81

0 ... 20 mA mA 2.26 2.26 2.26 2.26

0 ... 1 V V 0.113 0.113 0.113 0.113

0 ... 5 V V 0.565 0.565 0.565 0.565

0 ... 10 V V 1.13 1.13 1.13 1.13

According to the Chosen Scale

°C

°F

%RH

15

59

*)

20

68

11.3

25

77

11.3

30

86

11.3

35

95

11.3

VAISALA_______________________________________________________________________ 25

Page 26

USER'S GUIDE____________________________________________________________________

Temperature

NaCl

4 ... 20 mA mA 16.10 16.08 16.05 16.02 15.98

0 ... 20 mA mA 15.12 15.10 15.06 15.02 14.98

0 ... 1 V V 0.756 0.755 0.753 0.751 0.749

0 ... 5 V V 3.780 3.775 3.765 3.755 3.745

0 ... 10 V V 7.56 7.55 7.53 7.51 7.49

°C

°F

%RH

*) If the LiCl solution is used or stored in temperatures below +18 °C (+64 °F), the equilibrium

humidity of the salt solution may change permanently.

Temperature Calibration

NOTE

The temperature channel of the HMM211 is very stable and the modules

have been calibrated at the factory. Unless there is a strong reason to

believe that the adjustments have changed, do not perform a temperature

calibration. This is a very demanding procedure and requires both

expertise and extremely accurate references. Furthermore, it is important

to allow enough time for the stabilization during calibration. If for some

reason it is necessary to perform the temperature calibration, follow

attentively the instructions given in this section.

15

59

75.6

20

68

75.5

25

77

75.3

30

86

75.1

35

95

74.9

Temperature Calibration of an RH and T Module

1. Allow enough time for the instruments to stabilize to the

temperature in which calibration is performed.

2. Connect a jumper to the T offset or the T gain pins. The

temperature signal is now on Channel 2. Adjust the reading with

UP and DOWN switches (see Figure 5 on page 25). Note that

during gain adjustment, the offset point does not change:

26 __________________________________________________________________ M2107

18EN-B

Page 27

Chapter 5 _______________________________________________________________ Calibration

C

offset correction gain correction

voltage range

(for example, 0 ... 5 V)

before correction

voltage range

(for example, 0 ... 5 V)

before correction

after gain correctionafter offset correction

-20 20 40 60 80 100 120 -20 20 40 60 80 100 120

°C

°

Figure 6 Offset and Gain Calibration Examples

3. After having performed the calibration, disconnect the jumper.

Temperature Calibration of a Dewpoint Module

1. The warming function must be deactivated by connecting a jumper

to the T offset or T gain calibration pins (see Figure 5 on page 25).

The temperature signal is now on Channel 2 (previously Td signal).

Note that the chosen output range corresponding to -70 ... +180 °C

is now scaled on this channel. For example, if the Td output range

is 0 ... 5 V, the T output during calibration is 0 ... 5 V < > -70 ...

+180 °C (-94 ... +356 °F).

2. Allow enough time for the instruments to stabilize to the same

temperature.

3. Adjust the reading with UP and DOWN switches (see Figure 5 on

page 25). Note that during gain adjustment, the offset point

(-70 °C) does not change (see Figure 6 above).

4. After having performed the calibration, disconnect the jumper.

Temperature Calibration of an RH and T Module with Two Sensor Heads

1. Connect a jumper to the T offset or T gain calibration pins (see

Figure 5 on page 25). The temperature signal of the humidity probe

is now on Channel 1 (previously RH signal). Note that the chosen

output range corresponding to -70 …+180 °C is now scaled on this

channel, for example if the RH output range is 0 ... 5 V, the T

output during calibration is 0 ... 5 V < > -70 ... +180 °C (-94 …

+356 °F).

VAISALA_______________________________________________________________________ 27

Page 28

USER'S GUIDE____________________________________________________________________

2. Allow enough time for the instruments to stabilize to the same

temperature.

3. Adjust the reading with UP and DOWN switches (see Figure 5 on

page 25). Note that during gain adjustment, the offset point

(-70 °C) does not change (see Figure 6 on page 27).

4. Calibrate the additional (Ta) temperature probe the same way; note

that the signal is on Channel 2 and the connectors used are the Ta

offset and Ta gain.

5. After having performed the calibration, disconnect the jumper.

28 __________________________________________________________________ M2107

18EN-B

Page 29

Chapter 6 ___________________________________________________________ Chemical Purge

y

O

i

l

CHAPTER 6

CHEMICAL PURGE

This chapter provides you with information on chemical purge.

In some applications, the sensor gain may decrease gradually due to an

interference caused by some chemical present in the ambient air (see

Figure 7 below). The sensor polymer absorbs the interfering chemical;

this reduces the polymer's ability to a

decreases the sensor gain. In chemical purge, the interfering chemical is

evaporated by heating the humidity sensor to a temperature level of

approximately +160 °C. Automatic chemical purge takes place at startup.

bsorb water molecules and so

Calibration

values

Chemical purge

Measured values

gna

utput s

Humidit

after chemical

exposure

Figure 7 Decrease of the Sensor Gain Due to an Interfering

Chemical and the Effect of the Chemical Purge Process

The sensor with chemical purge option is a composite sensor in which

the HUMICAP® and Pt 100 temperature sensors are attached to each

other. Chemical purge option requires that the sensor is protected with a

stainless steel sintered filter (part no. HM46670).

VAISALA_______________________________________________________________________ 29

Page 30

USER'S GUIDE____________________________________________________________________

This page intentionally left blank.

30 __________________________________________________________________ M2107

18EN-B

Page 31

Chapter 7 ______________________________________________________________Maintenance

CHAPTER 7

MAINTENANCE

This chapter provides information that is needed in basic maintenance of

the product.

Replacing the HUMICAP180R Sensor and the

Filter

Remove the damaged sensor and insert a new one. Handle the sensor by

the plastic socket. Recalibrate the transmitter.

CAUTION

Do not touch the sensor element.

Replace a dirty filter to ensure a maximum lifetime and a fast response

for the sensor.

Replacing Consumables

This section describes how to replace consumables.

Parts List for Consumables

Table 6 Available Spare Parts

Spare Part Order Code

HUMICAP®180R Sensor HUMICAP180R

Stainless steel sintered filter HM46670

VAISALA_______________________________________________________________________ 31

Page 32

USER'S GUIDE____________________________________________________________________

This page intentionally left blank.

32 __________________________________________________________________ M2107

18EN-B

Page 33

Chapter 8 ___________________________________________________________ Troubleshooting

CHAPTER 8

TROUBLESHOOTING

This chapter describes common problems, their probable causes and

remedies, and contact information for technical support.

Troubleshooting Procedure

When troubleshooting the product, write a problem report consisting of

the following issues:

- What failed (what worked / did not work)?

- Where did it fail (location and environment)?

- When did it fail (date, immediately / after a while / periodically /

randomly)?

- How many failed (only one defect / other same or similar defects /

several failures in one unit)?

- What was connected to the product and to which connectors?

- Input power source type, voltage and list of other items (lighting,

heaters, motors etc.) that were connected to the same power output.

- What was done when the failure was noticed?

Technical Support

For technical questions, contact the Vaisala technical support:

E-mail helpdesk@vaisala.com

Fax +358 9 8949 2790

VAISALA_______________________________________________________________________ 33

Page 34

USER'S GUIDE____________________________________________________________________

Return Instructions

If the product needs repair, please follow the instructions below to speed

up the process and to avoid extra costs to you.

1. Read the section Warranty on page 11.

2. Contact a Vaisala Service Center or a local Vaisala representative.

The latest contact information and instructions are available from

www.vaisala.com. Addresses of the Service Centers are provided

in section Vaisala Service Centers on page 35.

Please have the following information on hand:

- serial number of the unit

- date and place of purchase or last calibration

- description of the fault

- circumstances in which the fault occurs/occurred

- name and contact information of a technically competent person

who can provide further information on the problem

3. Pack the faulty product in a strong box of adequate size, with

proper cushioning material to avoid damage.

4. Include the information specified in step 2 in the box with the

faulty product. Also include a detailed return address.

5. Ship the box to the address specified by your Vaisala contact.

34 __________________________________________________________________ M2107

18EN-B

Page 35

Chapter 8 ___________________________________________________________ Troubleshooting

Vaisala Service Centers

Vaisala Service Centers perform calibrations and adjustments as well as

repair and spare part services. See contact information below.

Vaisala Service Centers also offer accredited calibrations, maintenance

contracts, and a calibration reminder program. Do not hesitate to contact

them to get further information.

VAISALA_______________________________________________________________________ 35

Page 36

USER'S GUIDE____________________________________________________________________

This page intentionally left blank.

36 __________________________________________________________________ M2107

18EN-B

Page 37

Chapter 9 ____________________________________________________________ Technical Data

CHAPTER 9

TECHNICAL DATA

This chapter provides the technical data of the product.

Specifications

Table 7 Relative Humidity Specifications

Property Value

Measurement range 0 ... 100 %RH

Accuracy (including non-linearity,

hysteresis and repeatability)

±2 %RH (0 … 90 %RH)

±3 %RH (90 …100 %RH)

Response time (90 %) at +20 °C in still air

(with sintered filter)

Typical temperature dependence of

electronics

Humidity sensor HUMICAP®180R

60 s

0.02 %RH/°C

Table 8 Temperature Specifications

Property Value

Measurement range -70 ... +180 °C

Typical accuracy of electronics at +20 °C ±0.1 °C

Typical temperature dependence of

electronics

Temperature sensor Pt 100 RTD 1/ 3 IEC 751 Class B

0.0025 °C/°C

VAISALA_______________________________________________________________________ 37

Page 38

USER'S GUIDE____________________________________________________________________

Figure 8 Dewpoint Temperature

Table 9 Analog Output Specifications

Property Value

Two analog outputs selectable 0 ... 1 V, 0 ... 5 V, 0 ... 10 V

0 ... 20 mA (4 ... 20 mA)

Typical accuracy ±0.1 % full scale

Resolution CH1: 0.025 %RH

CH2: 0.01 % full scale

Typical temperature dependence 0.004 % full scale/°C

Table 10 General Specifications

Property Value

Operating temperature range

Probe

Electronics

Storage temperature range

(electronics)

Sensor protection:

Standard

Connections Screw terminals for 0.5 ... 1.5 mm2 wires

-70 ... +180 °C

-5 … +55 °C

-40 … +70 °C

Stainless steel sintered filter

38 __________________________________________________________________ M2107

18EN-B

Page 39

Chapter 9 ____________________________________________________________ Technical Data

Table 11 Operating Voltage Specifications

Ouput DC AC

0 ... 1 V 10 ... 35 V 9 ... 24 V

0 ... 5 V 14 ... 35 V 12 ... 24 V

0 ... 10 V 19 ... 35 V 16 ... 24 V

0 ... 20 mA (R

0 ... 20 mA (R

)

= 0 )

L

= 500

L

10 ... 35 V 11 ... 24 V

20 ... 35 V 17 ... 24 V

NOTE

Options

AC supply only possible without warming or chemical purge option.

Current consumption without warming or

chemical purge option

Voltage output:

Average power needed during warming

(optional)

12 mA @ 35 VDC

20 mA @ 24 VAC

1 W (100 … 300 mA

modulated current)

Maximum power needed during chemical

purge (optional):

1.4 W (100 … 300 mA

modulated current)

Table 12 Modules, Sensor Heads, and Outputs

Module Sensor Heads Output

RH and T module One sensor head RH and T output

Dewpoint module Warmed humidity sensor

head

RH and T module with

two sensor heads

Warmed humidity sensor

head

Dewpoint output

RH and T output

VAISALA_______________________________________________________________________ 39

Page 40

USER'S GUIDE____________________________________________________________________

Table 13 Cable Lengths for Sensor Heads

Sensor Head Cable Length

Humidity sensor head 65, 150, 300 cm

Optional T sensor head/module with

two sensor heads

150 or 300 cm

Table 14 Automatic Chemical Purge

Module Automatic Chemical Purge at

Startup

RH and T module Yes

Dewpoint module Yes

RH and T module with two sensor

heads

Yes

40 __________________________________________________________________ M2107

18EN-B

Page 41

Page 42

*M210718

EN

*

www.vaisala.com

Loading...

Loading...