Page 1

TECHNICAL REFERENCE

I2C Protocol Implementation

HMM105 Humidity Module

M211638EN-A

Page 2

PUBLISHED BY

Vaisala Oyj

Street address: Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

Mailing address: P.O. Box 26, FI-00421 Helsinki, Finland

Phone: +358 9 8949 1

Fax: +358 9 8949 2227

Visit our Internet pages at www.vaisala.com.

© Vaisala 2014

No part of this manual may be reproduced, published or publicly displayed in any form

or by any means, electronic or mechanical (including photocopying), nor may its

contents be modified, translated, adapted, sold or disclosed to a third party without prior

written permission of the copyright holder. Translated manuals and translated portions

of multilingual documents are based on the original English versions. In ambiguous

cases, the English versions are applicable, not the translations.

The contents of this manual are subject to change without prior notice.

This manual does not create any legally binding obligations for Vaisala towards

customers or end users. All legally binding obligations and agreements are included

exclusively in the applicable supply contract or the General Conditions of Sale and

General Conditions of Service of Vaisala.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 2

About This Manual ................................................................... 2

Version Information ................................................................. 2

Related Manuals ....................................................................... 2

CHAPTER 2

I2C INTERFACE ............................................................................................. 3

Overview ................................................................................... 3

Physical Interface .................................................................. 3

Communication Parameters .................................................. 4

Addressing ............................................................................ 4

Communication Flow ............................................................... 5

HMM105 State Machine ........................................................ 6

Examples of Communication Flow ........................................ 7

Timing .................................................................................... 9

Status Byte ............................................................................ 9

Checksum ............................................................................. 9

Status Word......................................................................... 10

Commands .............................................................................. 11

Get_Interface_Version ........................................................ 11

Get_Parameter .................................................................... 12

Example: Read RH Measurement Result ...................... 13

Set_Parameter .................................................................... 14

Example: Set Compensation Pressure .......................... 15

Get_Parameter_Info ............................................................ 16

Adjust .................................................................................. 17

Adjusting Measurement......................................................... 18

One Point Adjustment ......................................................... 18

Two Point Adjustment ......................................................... 18

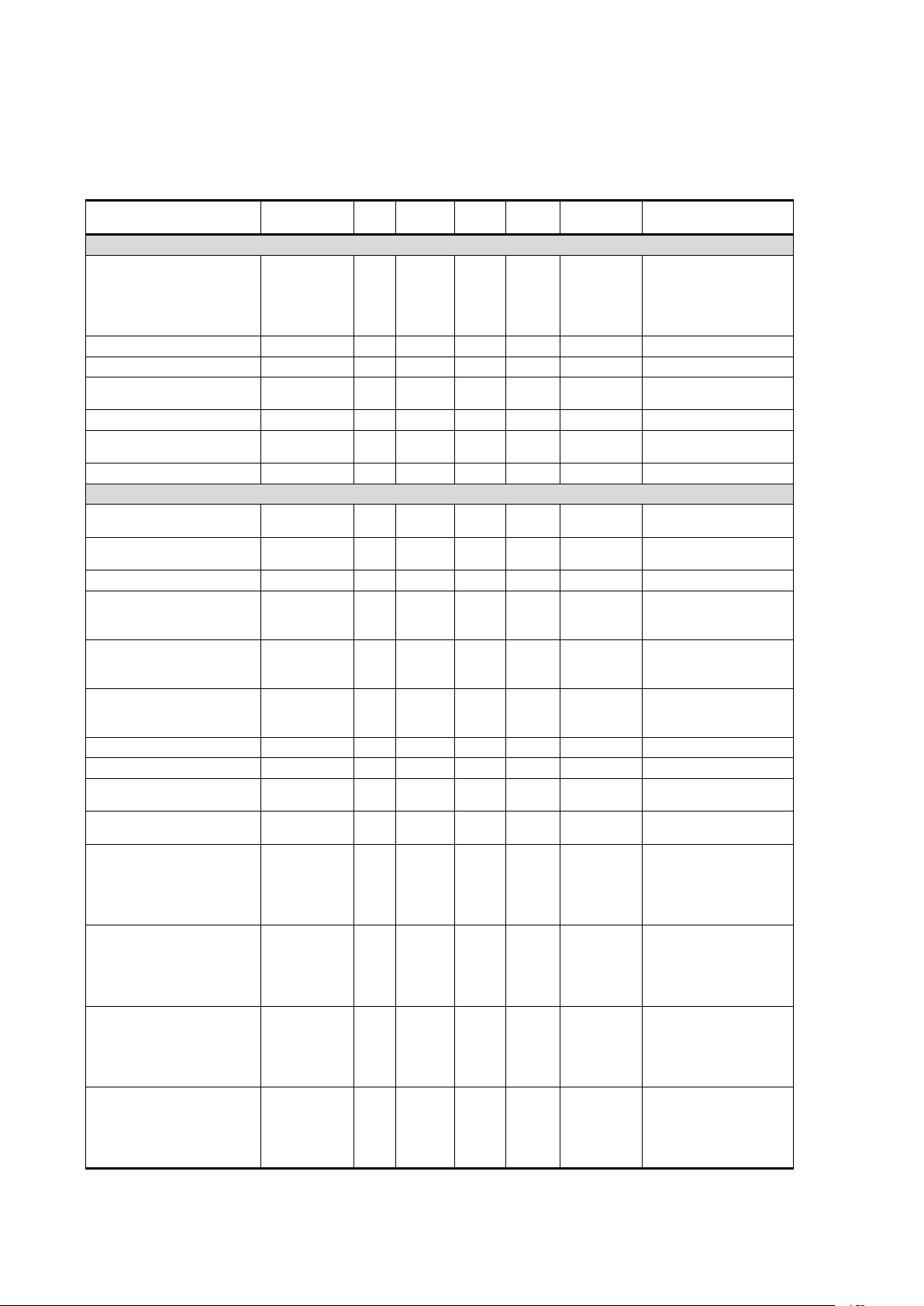

Data Registers ........................................................................ 19

Data Formats .......................................................................... 19

Register Table ..................................................................... 20

VAISALA _____________________________________________________________________ 1

Page 4

Technical Reference _________________________________________________________________

Manual Code

Description

M211638EN-A

May 2014. First version.

Manual Code

Manual Name

M211637EN

HMM105 Quick Guide

CHAPTER 1

GENERAL INFORMATION

About This Manual

This manual describes the I2C interface implementation of the

Vaisala HUMICAP® Humidity Module HMM105.

Version Information

Table 1 Manual Revisions

Related Manuals

Table 2 Related Manuals

2 _________________________________________________________________ M211638EN-A

Page 5

Chapter 2 _______________________________________________________________ I2C Interface

3.3 V

5.0 V

SD

A

SCL

GND

2 x 10 kΩ

2 x 10 kΩ

uP

Bu

ffer and

level shi

ft

CHAPTER 2

I2C INTERFACE

Overview

HMM105 has an inter-integrated circuit (I2C) interface for interfacing

with the incubator’s control computer. HMM105 implements I2C slave

functionality, with the incubator’s computer acting as the master. The

interface can be used to read measurement values and status information,

set operation parameters, and make adjustments.

Physical Interface

The physical interface is a non-isolated 3-wire interface. Wires are SDA,

SCL and ground. SDA and SCL lines are buffered. Ground is shared

with power supply. There are small pull-up resistors for SCL and SDA.

Maximum cable length should not exceed 5 m and maximum capacitance

between communication lines and ground should not exceed 500 pF.

1405-072

Figure 1 Hardware Schematic

The physical connector is a Molex 87832-1007, 2 mm pitch shrouded

pin header with a locking window. It is marked X6 on the component

board. See Table 3 on page 4.

VAISALA _____________________________________________________________________ 3

Page 6

Technical Reference _________________________________________________________________

Connector Pinout

Pin #

Function

6, 8

Supply voltage input

10 ... 35 VDC or 24 VAC

5, 7

Ground

1, 3

5 V I2C bus SDA

2, 4

5 V I2C bus SCL

0 1 0 1 1 1 1

R/W

Device type

Sub-address

Read/write bit

(LSB)

0 0 1 0 1 1 1 1 MSB

Device type

Sub-address

24

6810

1

3579

Table 3 HMM105 Signal and Power Connector X6

9, 10 Not connected

Communication Parameters

HMM105 supports a maximum clock speed of 50 kHz. Protocol bits are

sent most significant bit (MSB) first. Parameter bytes are sent using little

endian order.

Addressing

HMM105 uses 7-bit addressing. The address consists of:

- 4-bit device type identifier part (default “0101” for HMM105)

- 3-bit sub address (default “111”)

The full 7-bit default address is “0101111” (2Fh). In I2C communication,

the address should be provided by the master in the standard way after

the I2C start condition, with the read/write bit as the least significant bit

(LSB).

Table 4 HMM105 I2C Address

The I2C implementation of the HMM105 also includes the address inside

the message frame. The purpose of this is to make the I2C

implementation easier, since the I2C address can be lost by the I2C

hardware. This address is provided without the read/write bit, with zero

as the most significant bit (MSB).

Table 5 HMM105 Device Address

NOTE

4 _________________________________________________________________ M211638EN-A

Make sure there are no addressing conflicts if other I2C devices are put

on the same bus. The HMM105 address can be changed, see Table 32 on

page 20.

Page 7

Chapter 2 _______________________________________________________________ I2C Interface

This ACK/NACK refers to message level acknowlegde. I

includes separate byte level acknowledge.

Message Segment

Length

Content

Start

I2C start condition.

I2C address

1 byte

See Table 4 on page 4.

Command

1 byte

Identifier of command.

Device address

1 byte

See Table 5 on page 4.

Frame length

1 byte

Length of invoke message in bytes

Minimum invoke frame length is 5 bytes.

Data

Variable length

Content and length depending on the

contains no data in the invoke message.

Checksum

2 bytes

See section Checksum on page 9.

Stop

I2C stop condition

Message Segment

Length

Content

Start

I2C start condition.

I2C address

1 byte

See Table 4 on page 4.

Status

1 byte

See section Status Byte on page 9.

Command

1 byte

Identifier of the command that was used

valid invoke), command code is FFh.

Device address

1 byte

See Table 5 on page 4.

Frame length

1 byte

Length of the response message in

length is 6 bytes.

Data

Variable length

Content and length depending on the

command.

Checksum

2 bytes

See section Checksum on page 9.

Stop

I2C stop condition

Communication Flow

Basic communication flow always includes I2C write and read

commands. First the master writes a command to the slave device, and

then the master reads the results of that command from the slave.

When the master reads data from the slave, there is an ACK/NACK-bit in

the status byte that informs the master whether or not communication

was success. ACK is defined as zero and NACK is defined as one in the

logical level.

2

NOTE

Command messages sent by the master are called invokes. Replies sent

by the slave are called responses. Note that also responses include the

device address.

Table 6 Invoke Message in HMM105 I2C Interface

C protocol

(excluding I2C address, including CRC).

command. May be left out if command

Table 7 Response Message in HMM105 I2C Interface

in the invoke that the slave is

responding to. If slave is in idle state (no

bytes (excluding I2C address, including

CRC). The minimum response frame

VAISALA _____________________________________________________________________ 5

Page 8

Technical Reference _________________________________________________________________

Wait

Response

Idle

Valid Invoke

Valid Invoke

Response

NACK

Response

ACK + data

Bad Invoke

Bad Invoke

Response

NACK

HMM105 State Machine

The main and initial state of the HMM105 is Idle, and it will change to

WaitResponse state only when a valid invoke is received. In

WaitResponse state HMM105 expects to see an I2C read operation. After

seeing a read operation the HMM105 outputs its response with

ACK/NACK and status signals.

If HMM105 is in WaitResponse state and the master sends a new invoke,

the old response belonging to the old invoke will be lost. When the

master sends the next I2C read command, the HMM105 sends it the

response to the latest invoke.

If HMM105 is in Idle state and I2C read is sent, HMM105 responds with

a NACK-signal. This tells the master that the data which the master may

have received in same I2C read is not valid.

If the HMM105 receives an invalid invoke, it goes to the Idle state. An

invoke message can be invalid because of an unknown command,

erroneous CRC, or invalid message length.

.

Figure 2 HMM105 State Machine

1405-073

6 _________________________________________________________________ M211638EN-A

Page 9

Chapter 2 _______________________________________________________________ I2C Interface

Master

Slave

Get_Parameter,RH_ID

I2C write

Get_Parameter,RH_ID,54.32, ACK

I2C read

Master

Slave

Set_Parameter,Pressure_ID,1013.25

I2C Write

Set_Parameter,Pressure_ID,ACK

I2C Read

Examples of Communication Flow

The basic data transfer communication flows are presented in the

following figures. Each arrow represents an I2C read or write operation

The examples are simplified presentations. For actual message content,

see section Commandson page 11.

For example, Figure 3 below shows the following message sequence:

1. The master invokes the Get_Parameter command to read the RH

parameter using an I2C write operation. This command prepares the

slave to wait for a read operation from the master.

2. The master begins an I2C read operation to read the results of the

Get_Parameter RH command. The slave sends the requested RH

result and an ACK signal to the master.

1401-020

Figure 3 Get_Parameter with ACK

1401-032

Figure 4 Set_Parameter with ACK

VAISALA _____________________________________________________________________ 7

Page 10

Technical Reference _________________________________________________________________

Master

Slave

Get_Parameter,RH_ID

I2C Write

Get_Parameter,RH_ID,nan,NACK

I2C Read

Master

Slave

Get_Parameter,RH_

ID

I2C Write

Get_

Parameter

, RH_ID,66

.55,

Alarm bit = 1, ACK

I2C Read

Get_Parameter,Status_ID

I2C Write

Get

_Parameter,Status_ID,statusword,ACK

I2C Read

1401-022

Figure 5 Get_Parameter with NACK

1401-021

Figure 6 Get_Parameter with Alarm

NOTE

8 _________________________________________________________________ M211638EN-A

Alarm can be any of the state bits in status byte.

Page 11

Chapter 2 _______________________________________________________________ I2C Interface

Operation

Minimum delay

Normal delay between invoke and response

10 ms

Delay when write to non-volatile memory

300 ms

Bit#

Description

0

ACK/NACK

1

Critical error

2

Error

3

Warning

4

Status

5 6 7

Timing

The minimum time delay that the master must wait between the invoke

and response messages depends on the operation. If the operation

includes a write to the non-volatile memory, it takes more time than other

operations.

Table 8 Timing

Status Byte

The status byte gives the master device information about the slave

device’s state, and information about the communication status with the

ACK/NACK bit.

The status byte has bits for signaling Status, Warning, Error and Critical

error statuses. These bits are cleared when the status word is read. Bits

are set when the corresponding status or error state changes in the slave

device.

Table 9 Status Byte

Checksum

HMM105 uses a CRC16-CCITT checksum in its protocol frame. CCITT

(x.25) polynomial is X16+X12+X5+1 = 11021h. Initial value is 0000h and

the final value is XORed with FFFFh. The checksum uses a bit reversed

algorithm.

When the invoke message is received, the checksum is calculated using

bytes from the command byte to the last byte of the data field. The

checksum needs to be valid before data can be accepted. If the checksum

is not valid, the message is rejected and the internal state of the GMP231

is set to Idle.

When the response message is transmitted, the checksum is calculated

using bytes from the status byte to the last byte of the data field.

VAISALA _____________________________________________________________________ 9

Page 12

Technical Reference _________________________________________________________________

Bit#

Type

Purpose

0

Critical Error

1 Critical Error

Parameter memory corrupted

2

Critical Error

Parameter read failed

3

Critical Error

Parameter write failed

4

Error

5 Error

RH measurement error

6

Error

T measurement error

7

Error

8 Error

9 Error

10

Error

11

Error

12

Error

13

Error

14

Warning

15

Warning

16

Warning

17

Warning

18

Warning

19

Status

20

Status

21

Status

22

Status

23

Status

24

Status

25

Status

26

Status

27

Status

28

Status

29

Status

30

Status

31

Status

Status Word

Status word is used to monitor the status of the HMM105 device. It can

be read in the same way as any other slave parameter. Status word is used

as 32-bit long bit field. Each bit represents a state of some error or other

essential status.

Changes in status word bits can be monitored by reading the status byte.

See section Status Byte on page 9.

Table 10 Status Word Content

10 ________________________________________________________________ M211638EN-A

Page 13

Chapter 2 _______________________________________________________________ I2C Interface

Message Segment

Length

Content

I2C address

1 byte

I2C address (write)

Command ID

1 byte

Always 80h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 05h

Checksum

2 bytes

See section Checksum on page 9

Message Segment

Length

Content

I2C address

1 byte

I2C address (read)

Status

1 byte

See section Status Byte on page 9

Command ID

1 byte

Always 80h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 0Ah

Data

1 byte

Device version

1 byte

Protocol frame version

1 byte

Command set version

1 byte

Parameter set version

Checksum

2 bytes

See section Checksum on page 9

Commands

Get_Interface_Version

The Get_Interface_Version command (ID 80h) reads the interface

version information. Recommended for verifying version compatibility

before reading or writing parameters.

Table 11 Get_Interface_Version Invoke Message

Table 12 Get_Interface_Version Response Message

VAISALA ____________________________________________________________________ 11

Page 14

Technical Reference _________________________________________________________________

Message Segment

Length

Content

I2C address

1 byte

I2C address (write)

Command ID

1 byte

Always 81h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 06h

Data

1 byte

ID of parameter to be read

Checksum

2 bytes

See section Checksum on page 9

Message Segment

Length

Content

I2C address

1 byte

I2C address (read)

Status

1 byte

See section Status Byte on page 9. If

NACK bit is set in the status byte.

Command ID

1 byte

Always 81h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Varies according to data length,

07h ... 39h.

Data

1 byte

ID of parameter

1 ... 50 bytes

Value of parameter. If requested

bytes are left out of the response.

Checksum

2 bytes

See section Checksum on page 9

Get_Parameter

The Get_Parameter command (ID 81h) reads parameter values. You can

use it to read both measurement results and operational parameters. If the

number of bytes the master tries to read exceeds the message size, the

slave sends FFh bytes.

Table 13 Get_Parameter Invoke Message

Table 14 Get_Parameter Response Message

requested parameter ID was unknown,

parameter ID is unknown, these data

12 ________________________________________________________________ M211638EN-A

Page 15

Chapter 2 _______________________________________________________________ I2C Interface

Message Bytes (hex)

Content

2F

I2C address

81

Get_Parameter command

2F

Device address

06

Frame length

4F

RH Parameter ID

6A

CRC high

D4

CRC lo

Message Bytes (hex)

Content

2F

I2C address

00

Status byte (no errors, ACK)

81

Get_Parameter command

09

Device address

0B

Frame length

4F

RH Parameter ID

D4

RH value 14.43086624 %RH

E4

66

41

85

CRC high

6A

CRC lo

Example: Read RH Measurement Result

Table 15 Get_Parameter Invoke Message Example

Table 16 Get_Parameter Response Message Example

VAISALA ____________________________________________________________________ 13

Page 16

Technical Reference _________________________________________________________________

Message Segment

Length

Content

I2C address

1 byte

I2C address (write)

Command ID

1 byte

Always 82h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Varies according to data length,

07h ... 38h.

Data

1 byte

Parameter ID

1 ... 50 bytes

Parameter value

Checksum

2 bytes

See section Checksum on page 9

Message Segment

Length

Content

I2C address

1 byte

I2C address (read)

Status

1 byte

See section Status Byte on page 9.

Command ID

1 byte

Always 82h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 08h.

Data

1 byte

Parameter ID

1 byte

Return code. See Table 19 below.

Checksum

2 bytes

See section Checksum on page 9

Code

Meaning

0

Ok 1 Unknown parameter ID

2

Not writeable parameter

3

Value field too long

4

Value field too short

5

Data value not accepted

Set_Parameter

The Set_Parameter command (ID 82h) writes parameter values to nonvolatile memory. You can use it to set the operational parameters of the

HMM105. Depending on the change, the functionality of the HMM105

may not change immediately.

The length of the invoke message varies depending on the data length.

The master must write as many bytes as indicated in the frame length of

the invoke message. If the master tries to write a longer or shorter

message, HMM105 rejects the message.

Table 17 Set_Parameter Invoke Message

Table 18 Set_Parameter Response Message

Table 19 Set_Parameter Return Codes

14 ________________________________________________________________ M211638EN-A

Page 17

Chapter 2 _______________________________________________________________ I2C Interface

Message Bytes (hex)

Content

2F

I2C address

82

Set_Parameter command

2F

Device address

0A

Frame length

40

Parameter ID of compensation pressure

00

Pressure 1000 hpa

00

7A

44

D8

CRC high

31

CRC lo

Message Bytes (hex)

Content

2F

I2C address

04

Status byte (error active, ACK)

82

Set_parameter command

2F

Device address

08

Frame length

40

Parameter ID of compensation pressure

00

Return code: Ok

D6

CRC high

5C

CRC lo

Example: Set Compensation Pressure

Table 20 Example Set_Parameter Invoke Message

Table 21 Example Set_Parameter Response Message

VAISALA ____________________________________________________________________ 15

Page 18

Technical Reference _________________________________________________________________

Message Segment

Length

Content

I2C address

1 byte

I2C address (write)

Command ID

1 byte

Always 83h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 06h.

Data

1 byte

Parameter ID

Checksum

2 bytes

See section Checksum on page 9

Message Segment

Length

Content

I2C address

1 byte

I2C address (read)

Status

1 byte

See section Status Byte on page 9.

Command ID

1 byte

Always 83h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 12h.

Data

1 byte

Parameter ID

1 byte

Parameter datatype. See Table 24

below.

1 byte

Parameter length in bytes.

1 byte

Parameter persistence. Describes if the

Table 25 below.

8 bytes

Parameter name. If the name is shorter

00h.

Checksum

2 bytes

See section Checksum on page 9

Code

Meaning

0

Unknown parameter ID

1

Byte

2

Integer (16-bit)

3

Unsigned Integer (16–bit)

4

Float (32-bit)

5

String

Code

Meaning

0

Void

1

Volatile

2

Non volatile

Get_Parameter_Info

The Get_Parameter_Info command (ID 83h) reads the properties of a

single parameter from the HMM105. The command is useful for adapting

to parameters that have been added in a new software version. If the

requested parameter ID is not valid, data type Unknown Parameter ID

is returned.

Table 22 Get_Parameter_Info Invoke Message

Table 23 Get_Parameter_Info Response Message

parameter value is volatile (lost at reset)

or non-volatile (survives reset). See

than 8 bytes, extra bytes are filled with

Table 24 Parameter Data Types

Table 25 Parameter Persistence

16 ________________________________________________________________ M211638EN-A

Page 19

Chapter 2 _______________________________________________________________ I2C Interface

Message Segment

Length

Content

I2C address

1 byte

I2C address (write)

Command ID

1 byte

Always 84h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Varies according to data length,

07h ... 0Bh.

Data

1 byte

Adjustment subcommand.

See Table 28 below.

1 byte

Parameter to be adjusted.

See Table 29 below.

4 bytes

Value of parameter. Used only with

subcommands 2 and 3.

Checksum

2 bytes

See section Checksum on page 9

Message Segment

Length

Content

I2C address

1 byte

I2C address (read)

Status

1 byte

See section Status Byte on page 9.

Command ID

1 byte

Always 84h

Device address

1 byte

See Table 5 on page 4

Frame length

1 byte

Always 07h.

Data

1 byte

Return code. See Table 30 on page 18.

Checksum

2 bytes

See section Checksum on page 9

Code

Adjustment operation

0

Start 1 point adjustment

1

Start 2 point adjustment

2

Record measured point 1, reference value is given in parameter

3

Record measured point 2, reference value is given in parameter

4

Cancel adjustment (previous adjustment is reverted)

5

End (adjustment is saved and new values are taken in use)

6

Revert to factory calibration (clear user adjustment)

Code

Purpose

0

All parameters (valid with revert to factory calibration)

1

Not used

2 T 3

Not used

4

RH

Adjust

The Adjust command (ID 84h) controls the user adjustment sequence of

the HMM105.

Table 26 Adjust Invoke Message

Table 27 Adjust Response Message

Table 28 Adjustment Subcommands

Table 29 Adjustment Parameters

VAISALA ____________________________________________________________________ 17

Page 20

Technical Reference _________________________________________________________________

Code

Meaning

0

Ok 1 Function not supported

2

Sequence error

3

Recorded-Reference difference too large

4

2-point adjustment: Points too close

Table 30 Adjustment Return Codes

Adjusting Measurement

HMM105 can be adjusted while it remains installed in an incubator.

Create the reference environment inside the chamber, and use the Adjust

command to perform the adjustment sequence.

Adjustment can fail for a number of reasons. Refer to the list of return

codes for the Adjust command in Table 30 above.

One Point Adjustment

To perform a one point adjustment of relative humidity (RH) or

temperature (T), you must perform the following sequence:

1. Using the Adjust command, start 1 point adjustment for the

chosen parameter.

2. Place the sensor in the reference environment and wait until the

measurement has stabilized.

3. Using the Adjust command, record the measured point and give

the reference value.

4. Use the Adjust command to end the adjustment.

Two Point Adjustment

To perform a two point adjustment of relative humidity (RH) or

temperature (T), you must perform the following sequence:

1. Using the Adjust command, start 2 point adjustment.

2. Place the sensor in the low end reference and wait until the

measurement has stabilized.

3. Using the Adjust command, record the first measured point and

give the first reference value.

4. Place the sensor in the high end reference and wait until the

5. Using the Adjust command, record the second measured point and

6. Use the Adjust command to end the adjustment.

18 ________________________________________________________________ M211638EN-A

measurement has stabilized.

give the second reference value.

Page 21

Chapter 2 _______________________________________________________________ I2C Interface

Data type name

Size (Bytes)

Other

Byte

1

Value range 0...255

Integer

2

Value range -32768...32767

Unsigned integer

2

Value range 0…65535

Long integer

4

Value range

−2,147,483,648…2,147,483,647

Unsigned long integer

4

Value range 0…4,294,967,295

Float

4

According to IEEE-754. NaN

is available

String

Max. 50

All characters accepted

(00h…FFh)

Maximum string size refers to

Actual reserved storage space for each parameter can be seen

on page 20

Integers and floating point numbers are sent LSB first.

Data Registers

The register table describes all available parameters and their properties.

The properties are: parameter meaning, ID, name, data type, length and

persistence. Persistence defines if the parameter is saved in EEPROM

(non-volatile memory) or in RAM. Make sure not to write excessively to

the EEPROM, as it has a maximum lifetime of approximately 30000

cycles.

Data Formats

Table 31 Data Formats

NOTE

NOTE

(7FC00000) is returned if no value

maximum communication buffer size.

in Table 32

VAISALA ____________________________________________________________________ 19

Page 22

Technical Reference _________________________________________________________________

Meaning

Name

ID

Size

(bytes)

Type

Read/

Write

Persistent

Other

Factory information

Device Address

ADDR

0 1 Byte

R

Yes

Normally 0x2F.

1 ... 7.

Device serial number

SNUM

1

12

Str R Yes

Example: A1234567

Sensor number

SSNUM

2

12

Str R Yes

Example: B1234567

Component board

number

CBNUM

3

12

Str R Yes

Example: C1234567

Software version number

VERS

4

12

Str R Yes

Example: 1.2.3.4567

Factory calibration date

DDMMYYYY

CDATE

6 4 Uint R Yes

Example: 19052014

Factory calibration info

CTEXT

7

19

Str R Yes

Example: "CAL INFO"

General parameters and variables

Device status word

STATUS

8 4 Str R No

See section Status

Word on page 10.

Unit representation

selection

UNITS

10 2 Byte

R/W

Yes

0 = Metric units

1 = Nonmetric units

RH result

RH

79 4 Float

R

No

%RH

Temperature result

T

65 4 Float

R

No

degrees of

(see UNITS)

Dew/Frost point Tdf

TDF

88 4 Float

R

No

degrees of

(see UNITS)

Ambient pressure in hPa

P_AMB

64 4 Float

R/W

Yes

Ambient pressure in

result.

RH Gain

RH_G

96 4 Float

R/W

Yes

RH gain

RH Offset

RH_O

97 4 Float

R/W

Yes

RH offset

Temperature Gain

T_G

94 4 Float

R/W

Yes

Temperature gain

adjustment

Temperature Offset

T_O

95 4 Float

R/W

Yes

Temperature offset

adjustment

Temperature reference

T_RP1

90 4 Float

R/W

Yes

Temperature

calibration command.

Temperature reference

T_RP2

91 4 Float

R/W

Yes

Temperature

calibration command.

RH reference point 1

RH_RP1

92 4 Float

R/W

Yes

RH adjustment

command.

RH reference point 2

RH_RP2

93 4 Float

R/W

Yes

RH adjustment

command.

Register Table

Table 32 HMM105 Register Table

Only 3 LSBs are

changeable. Address

range is therefore

point 1

point 2

celsius/fahrenheit

celsius/fahrenheit

hPa. Used for RH

adjustment reference

point 1. Write ref 1

here when using the

adjustment reference

point 2. Write ref 2

here when using the

reference point 1.

Write ref 1 here when

using the calibration

20 ________________________________________________________________ M211638EN-A

reference point 2.

Write ref 2 here when

using the calibration

Page 23

*M211638EN*

www.vaisala.com

Loading...

Loading...