Page 1

r

USER'S GUIDE

Vaisala DRYCAP® Dewpoint

Transmitte

DMT142

M210397EN-D

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2006

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

_________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION ............................................................................ 5

About This Manual ................................................................... 5

Contents of This Manual ....................................................... 5

Version Information ............................................................... 6

Related Manuals ................................................................... 6

General Safety Considerations ............................................. 7

Feedback............................................................................... 7

Product Related Safety Precautions ...................................... 7

Recycling .................................................................................. 8

Regulatory Compliances ......................................................... 8

Electromagnetic Compatibility ............................................... 8

Trademarks ............................................................................... 8

Warranty .................................................................................... 9

CHAPTER 2

PRODUCT OVERVIEW .................................................................................. 3

Introduction to Dewpoint Transmitter DMT142 ..................... 3

The Basic Features and Options ............................................ 3

CHAPTER 3

FUNCTIONAL DESCRIPTION ....................................................................... 5

Advanced DRYCAP® Technology ........................................... 5

Auto-Calibration .................................................................... 5

Sensor Purge ........................................................................6

Sensor Warming in High Humidities ..................................... 6

CHAPTER 4

INSTALLATION.............................................................................................. 7

Selecting Location ................................................................... 7

Wiring ........................................................................................9

Optional Connection Cable ................................................. 10

Power Supply Requirements............................................... 11

Mounting .................................................................................13

Direct Measurement in Process Pipeline ............................ 13

Sampling from Pressurized Processes ............................... 14

DMT242SC Sampling Cell ............................................. 14

DMT242SC2 Sampling Cell with Swagelok

Connectors.....................................................................

DSC74 Sampling Cell with Quick Connector and Leak

Screw .............................................................................

DSC74B Two-Pressure Sampling Cell .......................... 17

DSC74C Two-Pressure Sampling Cell with Coil ........... 18

DM240FA Duct Installation Flange ................................ 20

15

15

VAISALA_________________________________________________________________________ 1

Page 4

User's Guide _______________________________________________________________________

CHAPTER 5

SERIAL COMMANDS ..................................................................................21

Connecting Serial Interface ...................................................21

Commands for Basic Settings ..............................................22

Select Nonmetric Unit .......................................................... 22

Select Metric Unit ................................................................22

Scale Dewpoint Analog Output ...........................................22

Select Analog Output Quantity ............................................22

Set Analog Output Mode ..................................................... 23

DMT142 Firmware Version Output......................................23

Pressure Compensation ......................................................24

Test Analog Output Current ................................................ 25

Test Analog Voltage Output ................................................25

Restart Program ..................................................................25

Serial Line Output Commands ..............................................26

Start Measurement Output .................................................. 26

Stop Measurement Output ..................................................26

Set Output Interval............................................................... 26

Polling Mode for DMT142 Transmitter.................................. 27

Set Transmitter Address ...................................................... 27

Set Serial Interface Mode ....................................................27

OPEN Opening the Transmitter in POLL-State................... 28

SEND Outputting a Reading Once...................................... 28

CHAPTER 6

MAINTENANCE............................................................................................29

Calibration and Adjustment...................................................29

Filter Change...........................................................................29

Vaisala Service Centers .........................................................30

CHAPTER 7

TROUBLESHOOTING..................................................................................31

Error States ............................................................................. 31

Technical Support ..................................................................31

CHAPTER 8

TECHNICAL DATA ......................................................................................33

Specifications .........................................................................33

Spare Parts and Accessories ................................................ 36

Dimensions in mm (inches)................................................... 37

Wiring Quick Reference .........................................................37

2 ____________________________________________________________________ M210397EN-D

Page 5

_________________________________________________________________________________

List of Figures

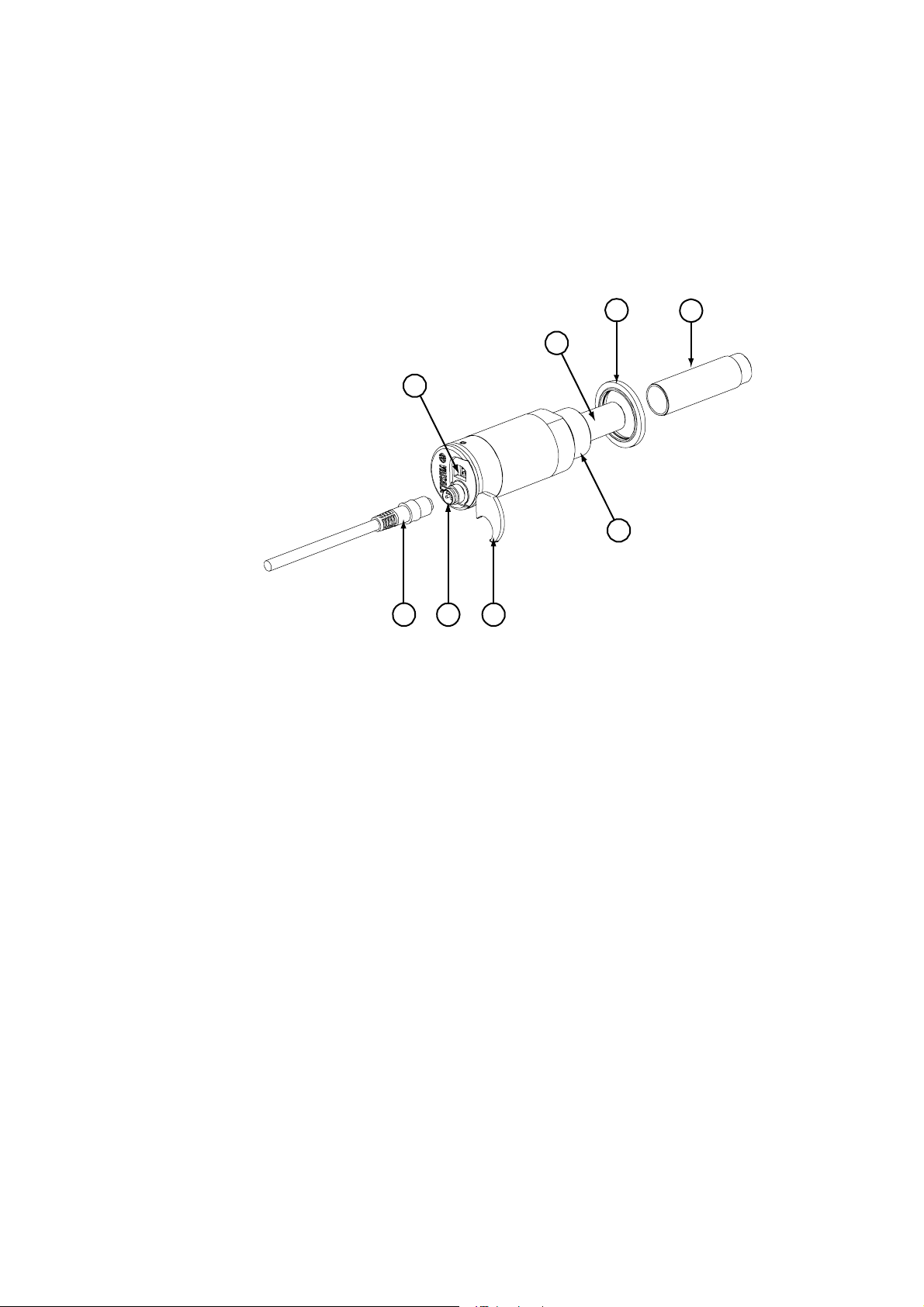

Figure 1 Dewpoint Transmitter DMT142 Components............................. 4

Figure 2 Mounting Dewpoint Transmitter DMT142 .................................. 8

Figure 3 Wiring of Voltage Output Version............................................... 9

Figure 4 Wiring of Current Output Version ............................................... 9

Figure 5 Pin Order of DMT142 Connector (Transmitter Side) ............... 10

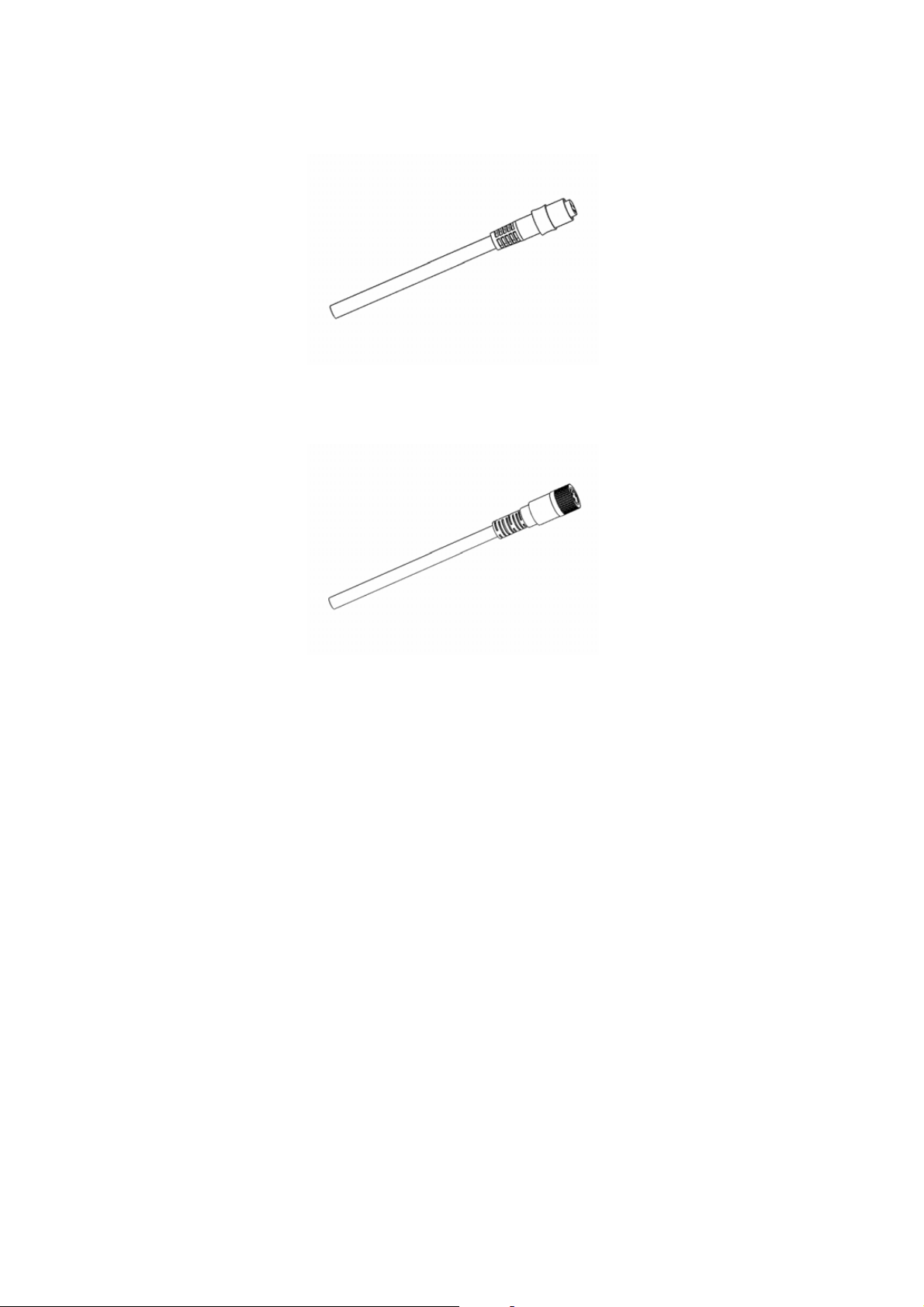

Figure 6 Snap-On Type Cable................................................................ 11

Figure 7 Screw Fitting Type Cable ......................................................... 11

Figure 8 Example Of Sensor Purge Current (at Room Temperature with

24 VDC)....................................................................................

Figure 9 Example of Auto-Calibration Current (at Room Temperature

with 24 VDC) ............................................................................

Figure 10 DMT142 Installed Directly to Pipeline ...................................... 13

Figure 11 DMT242SC Sampling Cell ....................................................... 14

Figure 12 DMT242SC2 Sampling Cell with Swagelok Connectors.......... 15

Figure 13 DSC74 Sampling Cell with Accessories................................... 16

Figure 14 DSC74B.................................................................................... 17

Figure 15 Removing the Leak Screw ....................................................... 17

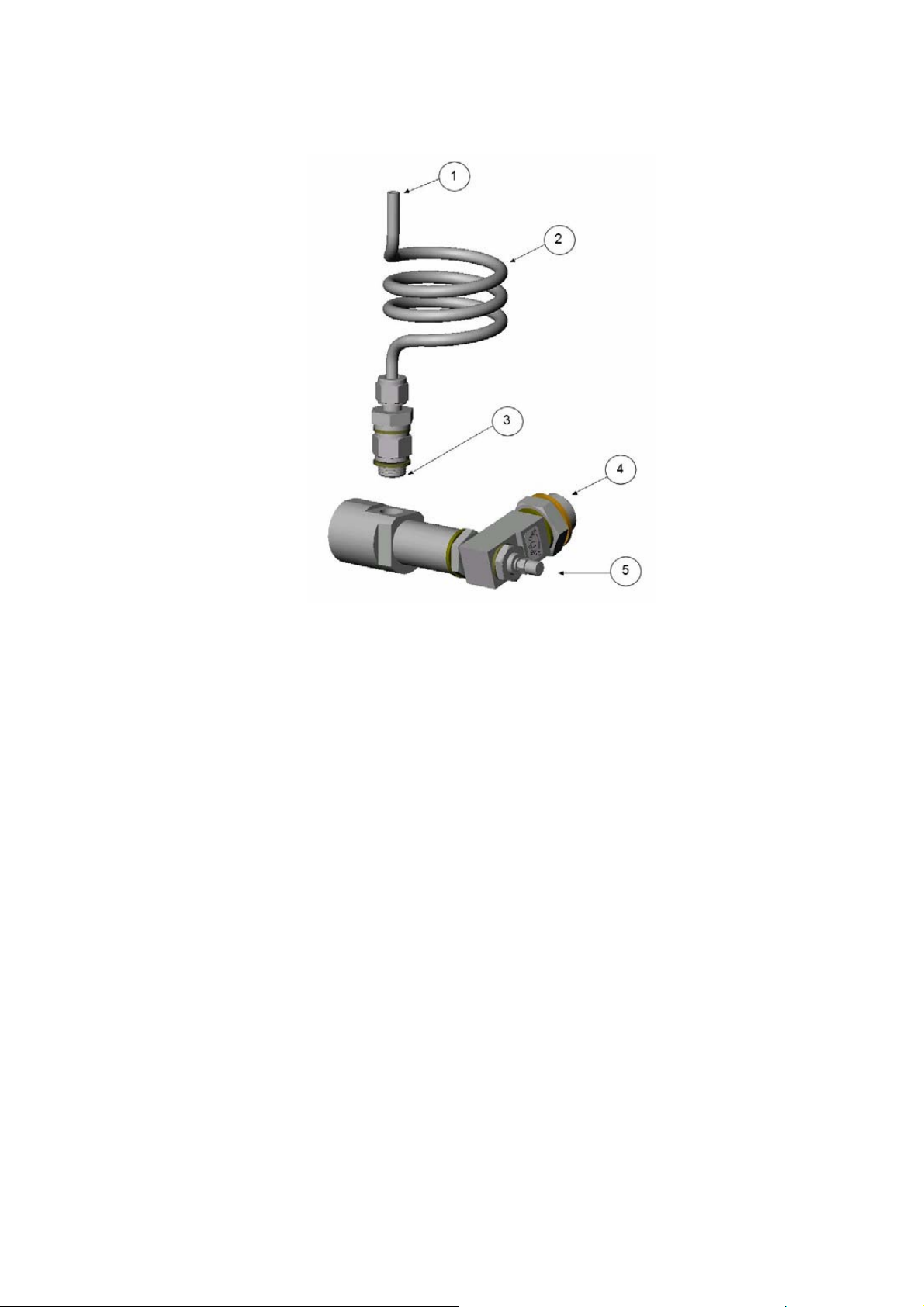

Figure 16 Default Assembly of DSC74C .................................................. 18

Figure 17 Alternative Assembly of DSC74C (for Tight Spaces)............... 19

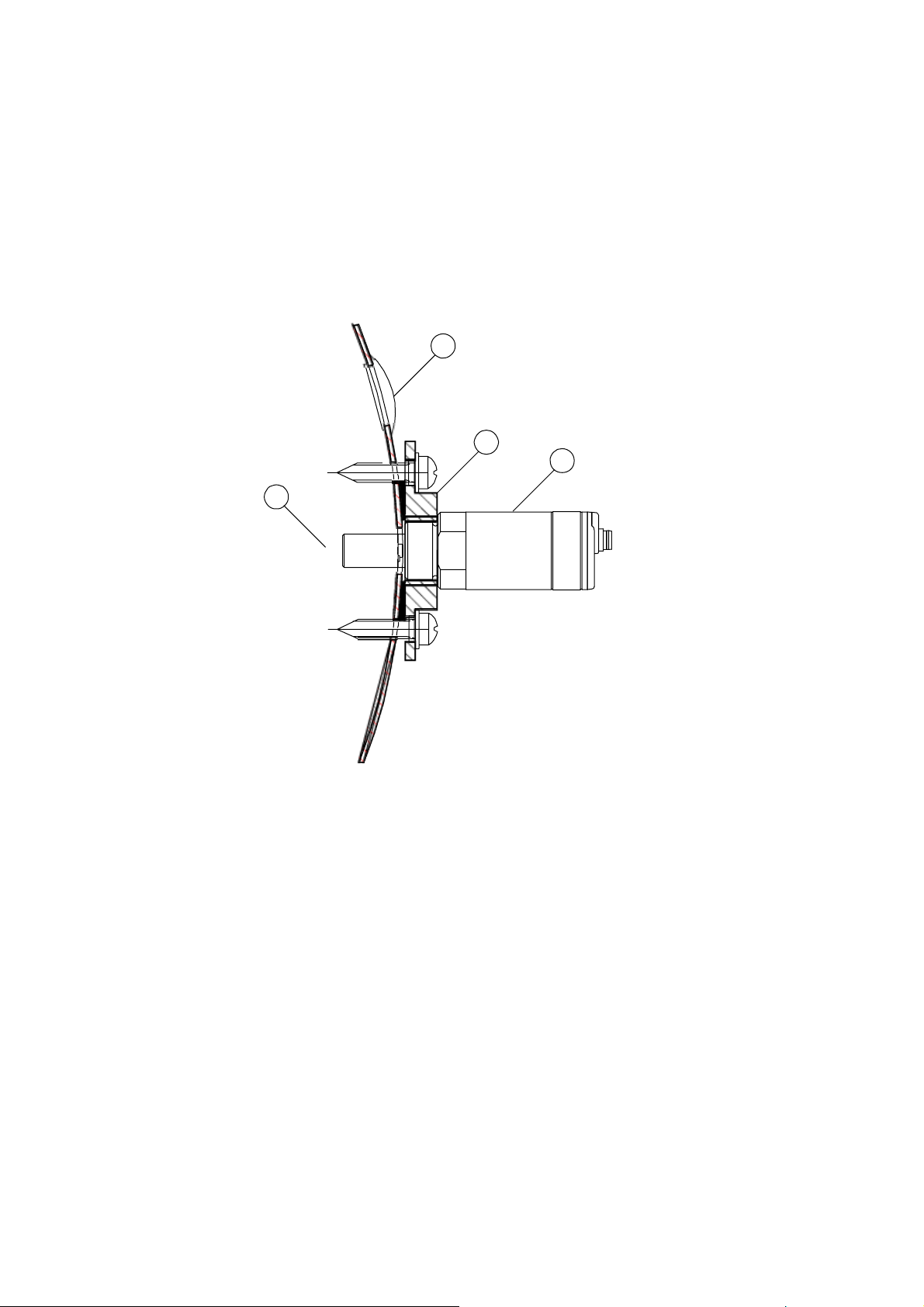

Figure 18 DM240FA with DMT142 ........................................................... 20

Figure 19 DMT142 Dewpoint Measurement Accuracy Graph ................. 34

Figure 20 DMT142 Dimensions ................................................................ 37

12

12

List of Tables

Table 1 Manual Revisions ....................................................................... 6

Table 2 Related Manuals ........................................................................ 6

Table 3 Wiring Table ............................................................................... 9

Table 4 Description of DMT142 Connection Cable............................... 10

Table 5 DMT142 Serial Interface Setting .............................................. 21

Table 6 Pressure Conversion Coefficients............................................ 24

Table 7 Measured Variable ...................................................................33

Table 8 Operating Environment Specifications ..................................... 34

Table 9 Output Specifications ............................................................... 34

Table 10 General Specifications ............................................................. 35

VAISALA_________________________________________________________________________ 3

Page 6

User's Guide _______________________________________________________________________

This page intentionally left blank.

4 ____________________________________________________________________ M210397EN-D

Page 7

Chapter 1 _________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the manual and the product.

About This Manual

This manual provides information for installing, operating, and

maintaining Dewpoint Transmitter DMT142.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information, provides general notes for the

manual and the product.

- Chapter 2, Product Overview, introduces the features and

advantages of Dewpoint Transmitter DMT142.

- Chapter 3, Functional Description, describes the advanced

functionality of Dewpoint Transmitter DMT142, including the

auto-calibration, sensor purge and sensor warming functions.

- Chapter 4, Installation, provides you with information that is

intended to help you install Dewpoint Transmitter DMT142.

VAISALA_________________________________________________________________________ 5

Page 8

User's Guide _______________________________________________________________________

- Chapter 5, Serial Commands, contains the operating instructions

for the serial interface of Dewpoint Transmitter DMT142.

- Chapter 6, Maintenance, provides information that is needed in

basic maintenance of Dewpoint Transmitter DMT142, and contact

information for Vaisala Service Centers.

- Chapter 7, Troubleshooting, describes the error states and provides

contact information for technical support.

- Chapter 8, Technical Data, provides the technical data of Dewpoint

Transmitter DMT142.

Version Information

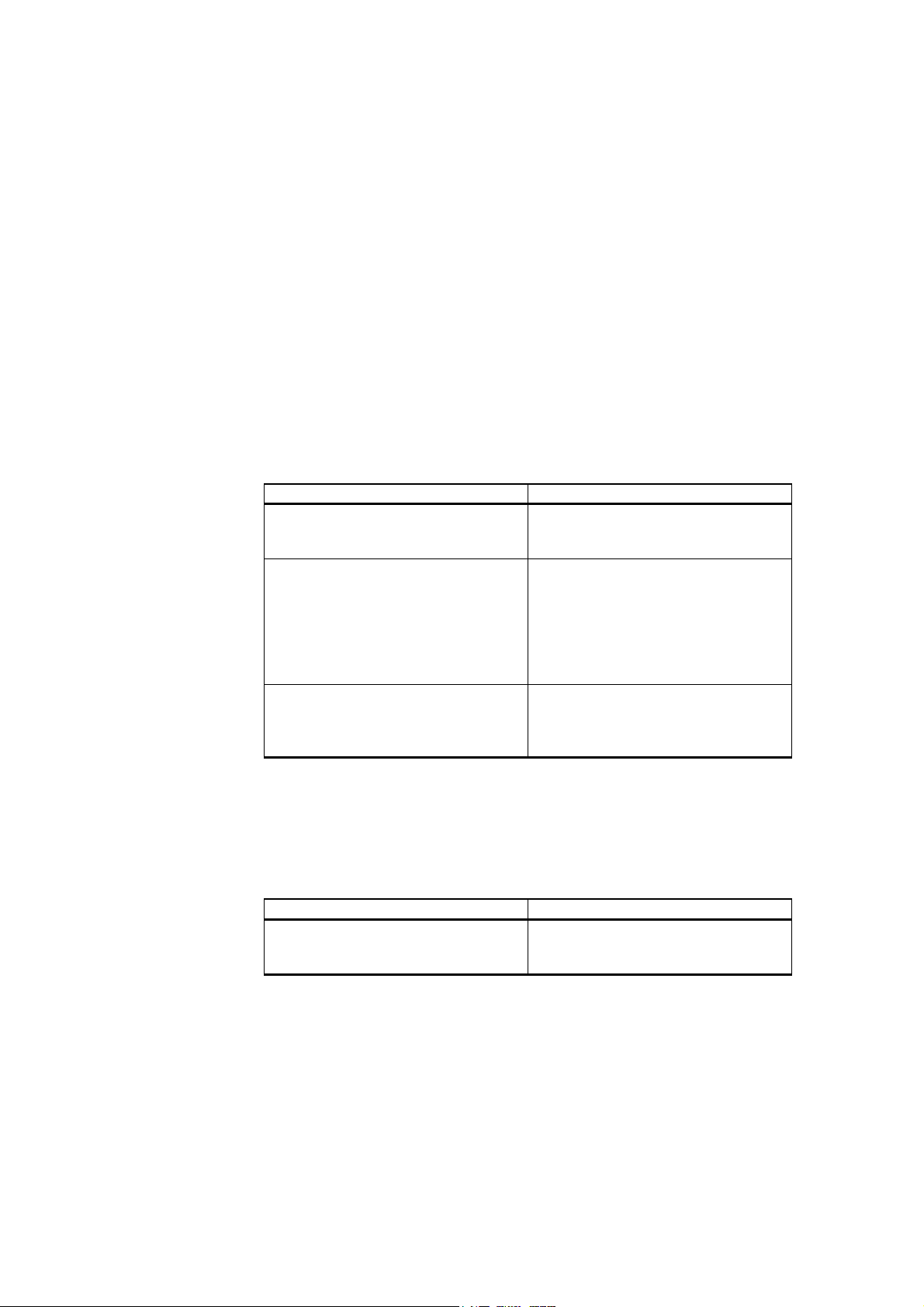

Table 1 Manual Revisions

Manual Code Description

M210397EN-A Vaisala DRYCAP® Dewpoint

Transmitter DMT142 Advanced User

Manual, April 2003

M210397EN-B Vaisala DRYCAP® Dewpoint

Transmitter DMT142 User's Guide,

October 2005

Td measurement and operating

pressure range specification revised

New sampling cell, installation flange

and connection cable options added

M210397EN-C Vaisala DRYCAP® Dewpoint

Transmitter DMT142 User's Guide,

March 2006; this manual

Corrected wiring diagrams

Related Manuals

Table 2 Related Manuals

Manual Code Manual Name

M210396EN-A Vaisala DRYCAP® Dewpoint

Transmitter DMT142 Quick

Reference Guide

6 ____________________________________________________________________ M210397EN-D

Page 9

Chapter 1 _________________________________________________________ General Information

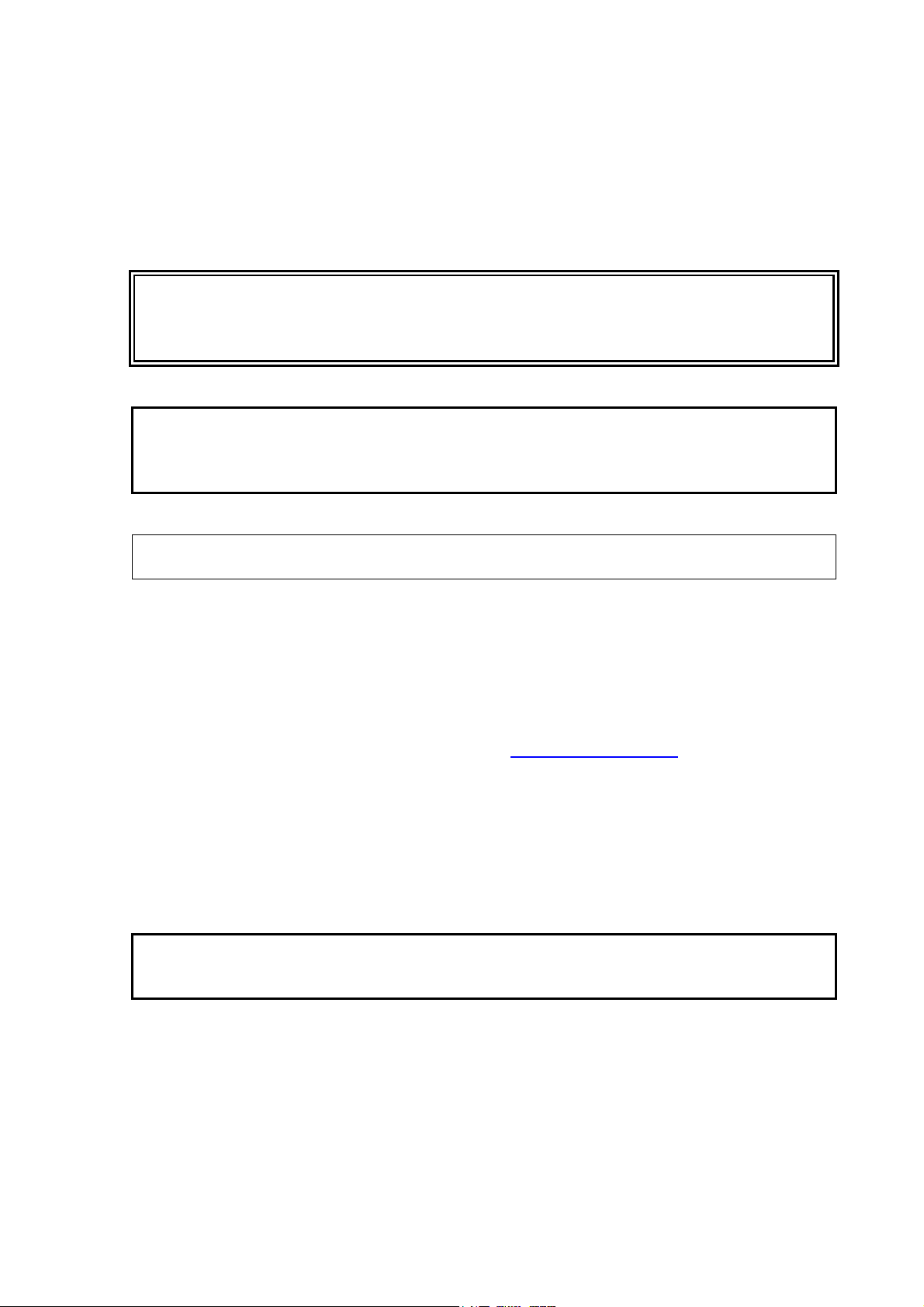

General Safety Considerations

Throughout the manual, important safety considerations are

highlighted as follows:

WARNING

CAUTION

NOTE

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or

even death.

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

Note highlights important information on using the product.

Feedback

Vaisala Customer Documentation Team welcomes your comments

and suggestions on the quality and usefulness of this publication. If

you find errors or have other suggestions for improvement, please

indicate the chapter, section, and page number. You can send

comments to us by e-mail: manuals@vaisala.com

Product Related Safety Precautions

The Dewpoint Transmitter DMT142 delivered to you has been tested

for safety and approved as shipped from the factory. Note the

following precautions:

CAUTION

VAISALA_________________________________________________________________________ 7

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

Page 10

User's Guide _______________________________________________________________________

Recycling

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

Regulatory Compliances

Vaisala DRYCAP® Dewpoint Transmitter DMT142 complies with

the following performance and environmental test standards:

Trademarks

Electromagnetic Compatibility

EN 61326-1:1997 + Am1:1998, Electrical equipment for

measurement, control and laboratory use - EMC requirements Industrial environment.

[CISPR16/22 Class B, EN/IEC 61000-4-2, EN/IEC 61000-4-3,

EN/IEC 61000-4-4, EN/IEC 61000-4-5, EN/IEC 61000-4-6]

DRYCAP® is a registered trademark of Vaisala.

8 ____________________________________________________________________ M210397EN-D

Page 11

Chapter 1 _________________________________________________________ General Information

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be

free from defects in workmanship or material

during a period of twelve (12) months from the date

of delivery save for products for which a special

warranty is given. If any Product proves however to

be defective in workmanship or material within the

period herein provided Vaisala undertakes to the

exclusion of any other remedy to repair or at its

own option replace the defective Product or part

thereof free of charge and otherwise on the same

conditions as for the original Product or part

without extension to original warranty time.

Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

service works performed by its employees to

products sold by it. In case the repair or service

works should appear inadequate or faulty and

should this cause malfunction or nonfunction of the

product to which the service was performed Vaisala

shall at its free option either repair or have repaired

or replace the product in question. The working

hours used by employees of Vaisala for such repair

or replacement shall be free of charge to the client.

This service warranty shall be valid for a period of

six (6) months from the date the service measures

were completed.

This warranty does not however apply when the

defect has been caused through

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use

of the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to

service the Product or otherwise follow

Vaisala's service instructions including any

repairs or installation or assembly or service

made by unauthorized personnel not approved

by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well

as any adding to it without Vaisala's prior

authorization;

e) other factors depending on the Customer or a

third party.

Notwithstanding the aforesaid Vaisala's liability

under this clause shall not apply to any defects

arising out of materials, designs or instructions

provided by the Customer.

This warranty is however subject to following

conditions:

a) A substantiated written claim as to any alleged

defects shall have been received by Vaisala

within thirty (30) days after the defect or fault

became known or occurred, and

b) The allegedly defective Product or part shall,

should Vaisala so require, be sent to the works

of Vaisala or to such other place as Vaisala may

indicate in writing, freight and insurance

prepaid and properly packed and labelled,

unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes

all other conditions, warranties and liabilities,

express or implied, whether under law, statute or

otherwise, including without limitation any implied

warranties of merchantability or fitness for a

particular purpose and all other obligations and

liabilities of Vaisala or its representatives with

respect to any defect or deficiency applicable to or

resulting directly or indirectly from the Products

supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and

waived. Vaisala's liability shall under no

circumstances exceed the invoice price of any

Product for which a warranty claim is made, nor

shall Vaisala in any circumstances be liable for lost

profits or other consequential loss whether direct or

indirect or for special damages.

VAISALA_________________________________________________________________________ 9

Page 12

User's Guide _______________________________________________________________________

This page intentionally left blank.

2 ____________________________________________________________________ M210397EN-D

Page 13

Chapter 2 ___________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the features and advantages of Dewpoint

Transmitter DMT142.

Introduction to Dewpoint Transmitter DMT142

Vaisala DRYCAP® dewpoint transmitter DMT142 is designed for a

wide range of OEM applications. The excellent stability and reliability

of its performance is based on advanced DRYCAP® polymer sensor

technology. The DRYCAP® technology has low maintenance needs

due to its excellent long term stability and durability against

condensation. The DMT142 transmitter is easy to install and the

mechanics have been designed for harsh environments requiring

protection against dust, dirt and splashed water.

The Basic Features and Options

- Small size to fit in tight installations.

- Analog outputs: 4 ... 20 mA or 0 - 1 V/0 - 5 V versions.

- Low maintenance requirements due to excellent long term stability.

- DRYCAP® polymer sensor with automatic auto-calibration and

sensor purge ensures long term stability.

- Sensor warming keeps the sensor dry in abnormally high humidity

situations.

- Field check suitability with DM70 hand-held meter.

VAISALA_________________________________________________________________________ 3

Page 14

User's Guide _______________________________________________________________________

- RS232 serial line connection for service use with DMT142RS

cable.

- Optional sampling cells with different installation options available

as DMT142 installation accessories.

3

4

2

1

5

678

0507-093

Figure 1 Dewpoint Transmitter DMT142 Components

The following numbers refer to Figure 1 above:

1 = Serial line connector (for service use)

2 = DRYCAP® sensor protected with sintered filter

3 = Sealing washer

4 = Protective cap for probe

5 = G1/2" ISO 228/1

6 = Protection plug for serial line connector

7 = Cable connector

8 = Connection cable (optional)

4 ____________________________________________________________________ M210397EN-D

Page 15

Chapter 3 _______________________________________________________ Functional Description

CHAPTER 3

FUNCTIONAL DESCRIPTION

This chapter describes the advanced functionality of Dewpoint

Transmitter DMT142, including the auto-calibration, sensor purge and

sensor warming functions.

Advanced DRYCAP® Technology

Dewpoint Transmitter DMT142 utilizes an advanced, patented

measurement technology to ensure accurate measurement with

excellent long term stability. This results in very low maintenance

requirements for the transmitter. The lasting performance is achieved

with microprocessor technology and software that automatically

performs self-diagnostic functions in addition to the normal dewpoint

measurement. The self-diagnostic procedures that are conducted are

called auto-calibration, sensor purge and sensor warming.

Auto-Calibration

The auto-calibration feature of the DMT142 transmitter is an

automatic procedure which greatly reduces the possible drift in the dry

end of the dewpoint measurement. It is performed at one hour

intervals, and when the power is switched on. During auto-calibration

the sensor is warmed for a short period (< 1 min) and the sensor

capacitance values are evaluated at the elevated temperature. The

possible dry end drift is then corrected to correspond to the calibrated

values. During the auto-calibration the transmitter outputs the Td value

prior to the procedure.

VAISALA_________________________________________________________________________ 5

Page 16

User's Guide _______________________________________________________________________

Auto-calibration is carried out only if several criteria for the

measurement environment are fulfilled. This ensures the reliability of

the adjustments, and maintains the excellent long term stability that

the patented technology offers. These criteria include for example a

stable enough moisture level in the measured atmosphere. If the

conditions are not fulfilled, the auto-calibration function is postponed

until satisfactory conditions are reached.

Sensor Purge

Sensor purge is also an automatic procedure that minimizes the drift at

the wet end readings of the dewpoint measurement. Sensor purge is

performed once a day or when the power is switched on. The sensor is

heated for several minutes which will then evaporate all excess

molecules out of the sensor polymer. This, together with the autocalibration results in a very small drift of the sensor due to the very

linear behaviour of the polymer technology.

Sensor Warming in High Humidities

Additionally the DMT142 transmitter has a warming feature which

prevents the sensor and filter from becoming wet in high humidities.

High humidity may be present when the dewpoint temperature rises

close to the gas temperature.

Sensor warming is switched on automatically when the humidity in

the measured gas increases to a level where dew can start to form. The

advantage of sensor warming is the rapid response of dewpoint

measurement. A wet sensor and filter would otherwise result in a

dewpoint equal to ambient temperature (that is RH = 100 %).

If in spite of sensor warming the sensor gets soaked, it will recover

fully back to normal operation after it dries out.

6 ____________________________________________________________________ M210397EN-D

Page 17

Chapter 4 ________________________________________________________________ Installation

CHAPTER 4

INSTALLATION

This chapter provides you with information that is intended to help

you install Dewpoint Transmitter DMT142.

Selecting Location

In the mounting of Dewpoint Transmitter DMT142 it is important that

the point of installation represents well the gas to be measured.

Temperature changes do not affect the dewpoint measurement, but

pressure changes will have an effect on the measurement. All leaks in

the system must be eliminated to avoid ambient humidity affecting the

measurement.

VAISALA_________________________________________________________________________ 7

Page 18

User's Guide _______________________________________________________________________

0507-094

Figure 2 Mounting Dewpoint Transmitter DMT142

The numbers in the following list refer to Figure 2 above:

1. Select a proper location to mount the DMT142 and remove the

yellow sensor protective cap.

2. Fit the sealing washer onto the probe.

3. Mount the transmitter to the measurement point. The transmitter

has parallel thread G1/2" ISO 228/1.

4. Connect the wires of the connection cable. When using the cable

provided with DMT142 refer to the following wiring section.

See the power supply requirements on page 11.

5. Plug in the cable to the transmitter and turn on the power supply.

6. Self diagnostics performed at start-up freeze the output during

the first minutes of operation. Typical warm-up time is about 5

minutes before normal operation.

8 ____________________________________________________________________ M210397EN-D

Page 19

Chapter 4 ________________________________________________________________ Installation

Wiring

Table 3 Wiring Table

Pin Number Wire Colour

(in supplied cables

EN50044)

1 Brown + VDC supply voltage

2 White - analog output signal

3 Blue - VDC supply voltage

4 Black + analog output signal

1

Name

sense

(voltage output versions

only)

4

+

2

3

0507-095

-

+

12-28VV

-

Figure 3 Wiring of Voltage Output Version

The numbers below refer to Figure 3 above:

1 = Brown

2 = White

3 = Blue

4 = Black

1

4

+

2

3

mA

-

+

18-28V

-

0507-096

Figure 4 Wiring of Current Output Version

Note the three wire connection. The numbers below refer to Figure 4

above:

1 = Brown

2 = White

3 = Blue

4 = Black

VAISALA_________________________________________________________________________ 9

Page 20

User's Guide _______________________________________________________________________

3

1

24

0507-097

Figure 5 Pin Order of DMT142 Connector (Transmitter

Side)

Optional Connection Cable

DMT142 is delivered optionally with two types of connection cables,

snap-on type or with screw fitting/locking.

Table 4 Description of DMT142 Connection Cable

Property Description / Value

M8 Female, straight connector, molded sensor cable, IEC 60947-5-2

Color Black

Number of contacts 4

Conductors 0.25 mm² (× 4) /

0.00039 inch² (× 4)

Insulation PVC

Cable diameter 5.0 mm / 0.2 inch

Protection class IP67 / NEMA 4

Wire color code EN50044

Snap-on type

Cable length 2 m / 6.6 ft

Screw fitting type

Shielded cable

0.3 m / 1 ft

3 m / 9.8 ft

5 m / 16.4 ft

10 m / 32.8 ft

10 ___________________________________________________________________ M210397EN-D

Page 21

Chapter 4 ________________________________________________________________ Installation

0510-036

Figure 6 Snap-On Type Cable

0510-037

Figure 7 Screw Fitting Type Cable

Power Supply Requirements

The DMT142 transmitters are designed to operate with a supply

voltage of 12 ... 28 VDC (voltage output version) or 18 ... 28 VDC

(current output version).

When measuring in pressures 20 ... 50 bar

temperatures -40 ... 0 °C (-40 ... 32 °F), a supply voltage of

24 ... 28 VDC is required.

The power supply should maintain the voltage for all load conditions.

Current consumption during normal operation is 10 mA. The

consumption increases during the sensor self-diagnostics (autocalibration and sensor purge). The maximum current consumption is

220 mA pulsed current (see the pictures

(290 ... 725 psia) or

a

on page 4).

VAISALA________________________________________________________________________ 11

Page 22

User's Guide _______________________________________________________________________

150 mA

500 ms/div

0507-098. 0507-099

Figure 8 Example Of Sensor Purge Current (at Room

Duration 60 seconds

Temperature with 24 VDC)

↓

Typical duty cycle. Sensor purge current varies with supply voltage

and operating temperature. The peak value is the highest in the lowest

temperature.

150 mA

100 ms/div

0507-100, 0507-101

Figure 9 Example of Auto-Calibration Current (at Room

Duration ~30 seconds

Temperature with 24 VDC)

↓

Typical duty cycle. Auto-calibration current varies with supply

voltage and operating temperature.

12 ___________________________________________________________________ M210397EN-D

Page 23

Chapter 4 ________________________________________________________________ Installation

Mounting

The recommended installation is directly to the measured gas pipeline,

chamber etc. If the gas temperature is higher than the specified

maximum operating temperature of the transmitter, gas sampling and

cooling it to ambient temperature is recommended. Note that the

dewpoint temperature must be clearly lower than the ambient

temperature to avoid condensation in the sampling line. Sampling

from the process is easy by using Vaisala sampling cell options.

Direct Measurement in Process Pipeline

Direct installation to the measured gas is the recommended

installation method if the temperature of the gas is suitable for

DMT142 and no additional filtering is needed due to very dusty or

oily gas. Oil as such is not harmful for the DRYCAP

response time may be slowed down if the sintered filter becomes

clogged up with oil. The maximum measurement pressure is

50 bara / 725 psia (absolute pressure) for direct measurement.

®

sensor, but

Max 50 bar

0507-102

Figure 10 DMT142 Installed Directly to Pipeline

In addition, due to the small size of DMT142 you can use a standard

G1/2" T-shaped pipe fitting (not available from Vaisala) when

installing DMT142 into a pipeline.

VAISALA________________________________________________________________________ 13

Page 24

User's Guide _______________________________________________________________________

Sampling from Pressurized Processes

The maximum measurement pressure is 50 bara / 725 psia (absolute

pressure) for sampling cell use. Pressure change between the process

and sampling point will change the dewpoint temperature resulting in

incorrect dewpoint reading. When sampling pressurized processes

above 50 bar, the pressure must be regulated to 50 bar or below and

the effect of the pressure difference between the process and the

measurement cell must be taken into account in calculating the

dewpoint.

The dewpoint measurement with the DRYCAP® sensor is not flow

sensitive but the flow rate affects the response time. The optimal flow

rate depends of the application but a minimum flow rate of 0.2 l/min is

recommended.

The DMT142 is very light in weight which means that it can be

installed in a sample pipeline in the sampling cells without the need of

any additional mechanical support.

Five different sampling cell options and an installation flange are

available.

DMT242SC Sampling Cell

0507-103

Figure 11 DMT242SC Sampling Cell

The following numebrs refer to Figure 11 above:

1 = G1/4"

2 = G3/8"

DMT242SC is the basic sample cell with G3/8" ISO gas inlet thread

and G1/4" ISO gas outlet thread.

14 ___________________________________________________________________ M210397EN-D

Page 25

Chapter 4 ________________________________________________________________ Installation

DMT242SC2 Sampling Cell with Swagelok Connectors

DMT242SC2 is mechanically similar to DMT242SC but has welded

Swagelok connectors for 1/4" tubing/pipeline. Welded connectors

eliminate the possibility of leakage in the connectors.

0507-104

Figure 12 DMT242SC2 Sampling Cell with Swagelok

Connectors

The following number refers to Figure 12 above:

1 = Swagelok 1/4" connectors

DSC74 Sampling Cell with Quick Connector and Leak Screw

Vaisala DSC74 sampling cell allows quick and easy connection of the

transmitter into pressurized processes. The quick connector allows the

transmitter to be plugged in to the pipeline in seconds. The leak screw

maintains the process pressure in the sampling cell but allows a small

flow through the sampling cell. The DSC74 includes the following

parts:

- DMT242SC sampling cell

- adjustable leak screw, thread 3/8"G

- quick connector (type D, NIP08, Quick 08)

- thread adapter, type male- male 3/8"G-1/2"G

- thread adapter, type male-female 3/8"G-1/4"G

VAISALA________________________________________________________________________ 15

Page 26

User's Guide _______________________________________________________________________

0507-105

Figure 13 DSC74 Sampling Cell with Accessories

The following numbers refer to Figure 13 above:

1 = Thread adapter type 3/8"G-1/2"G

2 = Thread adapter type 3/8"G-1/4"G

3 = Quick connector

4 = Leak screw

5 = Sampling cell DMT242SC

When using the DSC74, seal the threads of the quick connector or

thread adapter carefully with PTFE thread seal tape. Tighten with a

fork spanner. Ensure that the leaking screw of the sampling cell is

open but not too much as to cause a pressure drop inside the sampling

cell. Close the screw fully first, then turn 1/2 turn to open it.

16 ___________________________________________________________________ M210397EN-D

Page 27

Chapter 4 ________________________________________________________________ Installation

DSC74B Two-Pressure Sampling Cell

The DSC74B can be used as the DSC74 for measurements in process

pressure. DSC74B limits the flow rate with a leak screw. The

maximum flow can also be increased by removing the leak screw and

adjusting the flow manually with the valve. To remove the leak screw,

see Figure 15 below.

0510-032

Figure 14 DSC74B

The following numbers refer to Figure 14 above:

1 = Gas goes in

2 = Gas comes out

0510-033

Figure 15 Removing the Leak Screw

VAISALA________________________________________________________________________ 17

Page 28

User's Guide _______________________________________________________________________

DSC74C Two-Pressure Sampling Cell with Coil

The DSC74C is mechanically like the DSC74B, but it is supplied with

a coil for measurements in atmospheric pressure. The coil can also be

used as a cooling coil for sampling from high temperature processes.

0510-034

Figure 16 Default Assembly of DSC74C

The following numbers refer to Figure 16 above:

1 = Gas goes in. Also the coil can be used here.

2 = Gas comes out

3 = Coil

4 = Valve

18 ___________________________________________________________________ M210397EN-D

Page 29

Chapter 4 ________________________________________________________________ Installation

0403-113

Figure 17 Alternative Assembly of DSC74C (for Tight Spaces)

The following numbers refer to Figure 17 above:

1 = Gas comes out

2 = Coil

3 = Thread, max. size 7 mm

4 = Gas goes in

5 = Valve

The thread size cannot exceed 7 mm. Use the provided adapter to

avoid damage to the probe.

VAISALA________________________________________________________________________ 19

Page 30

User's Guide _______________________________________________________________________

DM240FA Duct Installation Flange

The transmitter can be installed directly in the process wall through

DM240FA duct installation flange. When the probe is installed

directly on the process wall or pipe, note that a closing valve may be

needed on both sides of the installed probe so that the sensor head can

be removed from the process for calibration or maintenance.

4

3

2

1

0510-035

Figure 18 DM240FA with DMT142

Numbers refer to Figure 18 above:

1 = Measured gas

2 = DMT142 transmitter

3 = DM240FA flange (thread G1/2" ISO)

4 = Recommended additional hole (plugged) for Td field check

reference measurement probe (for example, Vaisala DM70)

20 ___________________________________________________________________ M210397EN-D

Page 31

Chapter 5 ___________________________________________________________Serial Commands

CHAPTER 5

SERIAL COMMANDS

This chapter contains the operating instructions for the serial interface

of Dewpoint Transmitter DMT142.

Connecting Serial Interface

The use of the DMT142 via the serial bus requires a DMT142 serial

interface cable (Vaisala order code: DMT142RS).

1. Connect the serial cable between your PC and DMT142 serial

port.

2. Open the terminal program.

3. Set the serial settings, see the following table.

Table 5 DMT142 Serial Interface Setting

Property Description / Value

Baud rate 2400

Parity none

Data bits 8

Stop bits 1

Flow control Xon/X

The commands function as described when the serial interface is in

full duplex mode. All commands can be issued either in upper or

lower case letters.

(none)

off

The notation <cr> refers to pressing the carriage return (Enter) key on

your computer keyboard.

VAISALA________________________________________________________________________ 21

Page 32

User's Guide _______________________________________________________________________

Commands for Basic Settings

Select Nonmetric Unit

The DMT142 Transmitter outputs dewpoint temperature Td in either

Celsius or Fahrenheit degrees depending on the unit selection.

Syntax: UNIT n<cr>

Select Metric Unit

Syntax: UNIT m<cr>

Scale Dewpoint Analog Output

Syntax: ASCL x yy zz<cr>

where

x = 0 (zero)

yy = the lower limit of the scaling (given in °C or °F)

zz = the upepr limit of the scaling (given in °C or °F)

Select Analog Output Quantity

Syntax: ASEL c zzz<cr>

where

c = channel number

zzz = channel output quantity = RH, ppm or TD

Example:

>asel 0 rh

RH lo : -30.00 %RH

RH hi : 60.00 %RH

>

22 ___________________________________________________________________ M210397EN-D

Page 33

Chapter 5 ___________________________________________________________Serial Commands

Set Analog Output Mode

The AMODE command can be used to change the analog output

mode of the voltage output version of the transmitter between 0 ... 1 V

and 0 ... 5 V modes. The analog output mode of a current output

version of the transmitter is always 4 ... 20 mA.

Syntax: AMODE n0 n1<cr>

where

n0 = channel 0 analog output mode = 0 or 1

0 = 0 ... 1 V

1 = 0 ... 5 V

n1 = 0 (channel 1 analog output mode = always zero)

Example:

NOTE

>amode 0 0

AMODE CH0: 0

AMODE CH1: 0

>

Even though the software of the transmitter supports two channels,

the transmitter only has one analog output channel (channel 0). The

output mode of channel 1 is always set to 0 in the AMODE command

syntax.

DMT142 Firmware Version Output

Syntax: VERS<cr>

Example:

>vers

DMTS142C / 1.01

>

VAISALA________________________________________________________________________ 23

Page 34

User's Guide _______________________________________________________________________

Pressure Compensation

In pressurized environments, in order to optimize the accuracy of the

DMT142, the actual process pressure can be set to the DMT142 if the

pressure setting is not configured when ordering the product. In a

worst case scenario, an incorrect pressure setting may result in an

additional uncertainty of 1.5 °C in the dewpoint measurement. The

worst case is considered to be the dewpoint temperature Td at its

lowest limit with the widest possible pressure setting difference.

Syntax: PRES pppp.pp<cr>

where

pppp.pp = absolute pressure (bara) in the measuring point

Example:

>pres 1.01325

Pressure : 1.013

in use : 1.013

>

The pressure conversion coefficients from other pressure units to bars

is given in the table below.

NOTE

Table 6 Pressure Conversion Coefficients

From To bara

PaN/m² 0.00001

mmHg torr 0.001333224

inHg 0.03386388

mmH2O 0.00009806650

inH2O 0.002490889

atm 1.01325

at 0.980665

psia 0.06894757

Example:

29.9213 inHg = 29.9213 × 0.03386388 = 1.01325 bara

Conversions from mmHg and inHg are defined at 0 °C and from

mmH2O and inH2O at 4 °C.

24 ___________________________________________________________________ M210397EN-D

Page 35

Chapter 5 ___________________________________________________________Serial Commands

Test Analog Output Current

The operation of the analog current output can be tested by forcing the

output to a given value which can then be measured with a current

meter from the analog output.

Syntax: ITEST aa.aaa x<cr>

where

aa.aaa = current (mA)

x = 0 (zero)

Example:

>itest 4.56 0

4.56000 D78 0.00000 0

Test Analog Voltage Output

The operation of the analog voltage output can be tested by forcing the

output to a given value which can then be measured with a voltage

meter from the analog output.

Syntax: UTEST aa.aaa x<cr>

where

aa.aaa = voltage (V)

x = 0 (zero)

Example:

>utest 1.23 0

1.23000 310 0.00000 0

Restart Program

Restarts the program. All changed settings stay in the memory after

reset or power shutdown.

Syntax: RESET<cr>

VAISALA________________________________________________________________________ 25

Page 36

User's Guide _______________________________________________________________________

Serial Line Output Commands

Start Measurement Output

The transmitter outputs continuous measurement values as an ASCII

text string to the PC.

Syntax: R<cr>

Example:

>r

58.289 23.051 14.424

58.276 23.058 14.426

58.278 23.035 14.406

. . .

where

in the first column: relative humidity (%RH)

in the second column: ambient temperature (°C or °F)

in the third column: dewpoint (°C or °F)

Outputting the results continues in intervals issued with the command

INTV. Stop the output with the command S.

Stop Measurement Output

Syntax: S<cr>

Set Output Interval

Syntax: INTV n xxx<cr>

where

n = time interval = 0 ... 255

xxx = time unit = "S", "MIN", or "H"

Example:

>INTV 10 MIN

Output interval: 10 MIN

>

The shortest output interval (with n = 0 [zero]) is approximately one

second due to the internal measurement cycle.

26 ___________________________________________________________________ M210397EN-D

Page 37

Chapter 5 ___________________________________________________________Serial Commands

Polling Mode for DMT142 Transmitter

The polling mode can be used when more than one transmitter is

connected to one serial bus. When set to POLL state, the transmitters

communicate one at a time when the specific transmitter address is

called on the serial line.

Note that using the DMT142 serial output requires the DMT142RS

serial line cable.

Set Transmitter Address

Syntax: ADDR n<cr>

where

n = address (0 ... 99)

Set Serial Interface Mode

Syntax: SMODE xxx<cr>

where

xxx = STOP, RUN, or POLL

In STOP mode: outputting only when command is issued, any

command can be used.

In RUN mode: outputting automatically, only command S can be used

In POLL mode: outputting only with command SEND.

Examples:

>smode stop

Output mode : STOP

>

>smode run

Output mode : RUN

>

>smode poll

Output mode : POLL

>

VAISALA________________________________________________________________________ 27

Page 38

User's Guide _______________________________________________________________________

OPEN Opening the Transmitter in POLL-State

Syntax: OPEN nn<cr>

where

nn = address (0 ... 99)

Resulting (only in POLL-state):

>DMT nn line opened for operator commands<CR>

= ASCII 7 ( CTRL-G )

SEND Outputting a Reading Once

Syntax: SEND<cr>

Syntax in POLL-state: SEND nn<cr>

where

nn = address (0 ... 99)

28 ___________________________________________________________________ M210397EN-D

Page 39

Chapter 6 _______________________________________________________________ Maintenance

CHAPTER 6

MAINTENANCE

This chapter provides information that is needed in basic maintenance

of Dewpoint Transmitter DMT142, and contact information for

Vaisala Service Centers.

Calibration and Adjustment

The DMT142 is fully calibrated as shipped from factory. The

recommended calibration interval is 2 years. However, calibration

should be done if there is a reason to believe that device is not within

the accuracy specifications.

A simple field-checking operation can be performed by comparing the

readings of the DMT142 and the DM70 hand-held dewpoint meter

with a calibrated reference probe. For the comparison you need a

connection cable, Vaisala order code: 211917ZZ.

If there is need for calibration or adjustment contact Vaisala Service

Center or your local Vaisala representative.

Filter Change

The DRYCAP® sensor in the DMT142 transmitter is protected with a

stainless steel sintered filter. The filtering grade is 34 μm.

The filter is recommended to be changed whenever it looks dirty or as

a part of the periodical maintenance procedure. The recommended

replacement interval depends heavily on the application and can vary

from less than a year up to several years.

VAISALA________________________________________________________________________ 29

Page 40

User's Guide _______________________________________________________________________

A dirty or corroded filter may cause increased response times. In case

the DMT142 transmitter is used in a drying system with silica gel (or

other drying agent) the dust from the dryer may collect on the sensor

slowing the response but also generating a micro climate around the

sensor altering the dewpoint at the sensor. This is easily corrected by

changing or cleaning the filter.

CAUTION

Touching the sensor may damage it. Take special care to avoid

touching the sensor when removing and replacing filters.

To replace the filter:

1. Unscrew the existing filter from the sensor head and remove it

very carefully. Avoid touching the sensor.

2. Screw a new filter onto the sensor head.

Vaisala Service Centers

Send the device to Vaisala Instruments Service Centre for calibration

and adjustment, see contact information below.

If the product needs repair, please contact Vaisala Instruments Service

Center in your region. Follow the instructions given to you to speed

up the process and to avoid extra costs.

30 ___________________________________________________________________ M210397EN-D

Page 41

Chapter 7 ____________________________________________________________ Troubleshooting

CHAPTER 7

TROUBLESHOOTING

This chapter describes the error states and provides contact

information for technical support.

Error States

- Analog 4-20 mA current output in error state: error state value for

the analog current output is 0 mA.

- Analog voltage output in error state: error state value for the

analog voltage output is 0V.

- Serial output in error state: serial line outputs asterisk characters

(*** **) to indicate an error sate.

In the case of an error, reset the transmitter by disconnecting the

power or issuing the RESET command on the serial line. If the source

of error is not found and the transmitter does not return to the normal

state with the reset, please contact Vaisala Instruments Service or

local Vaisala representative, see section Vaisala Service Centers on

30.

page

Technical Support

For technical questions, contact the Vaisala technical support:

E-mail helpdesk@vaisala.com

Fax +358 9 8949 2790

VAISALA________________________________________________________________________ 31

Page 42

User's Guide _______________________________________________________________________

This page intentionally left blank.

32 ___________________________________________________________________ M210397EN-D

Page 43

Chapter 8 _____________________________________________________________ Technical Data

CHAPTER 8

TECHNICAL DATA

This chapter provides the technical data of Dewpoint Transmitter

DMT142.

Specifications

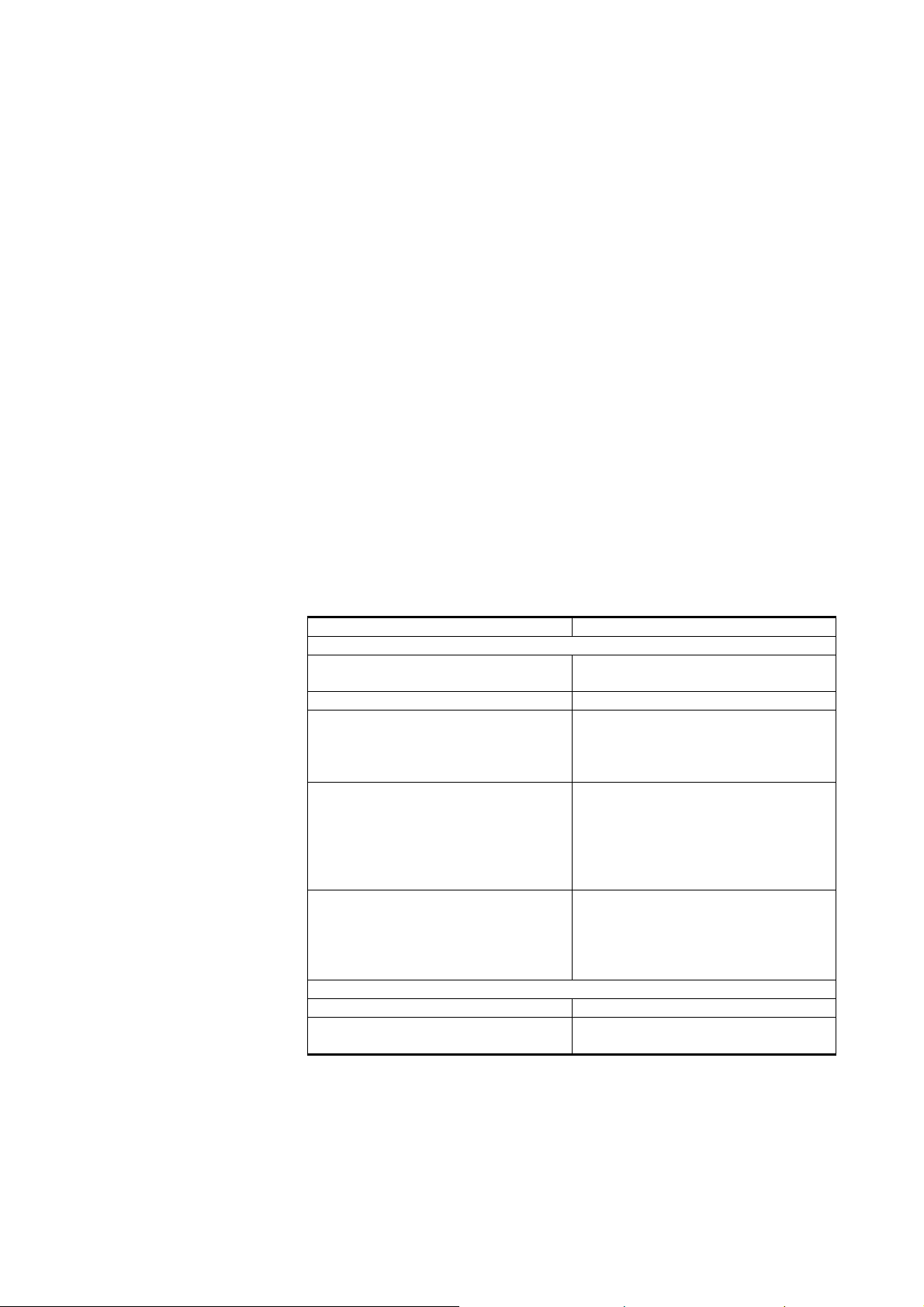

Table 7 Measured Variable

Property Description / Value

Dewpoint temperature

Measurement range -80 ... +60 °C (-112 ... +140 °F) Td

Standard version -60 ... +60 °C (-76 ... +140 °F) Td

Analog output scalings

option 1

option 2

option 3

Accuracy

(-60 … +60 C / -76 ... +140 °F)

Standard version (-50 … +60 C)

When the dewpoint is below 0 °C

(32 °F) the transmitter outputs

frostpoint

Response time 63% [90%] at

+20 °C gas temperature and 1 bar

pressure

-60 → -20 °C Td (-76 → -4 °F Td) 5 s [10 s]

-20 → -60 °C Td (-4 → -76 °F Td) 45 s [10 min]

ppm volume concentration

Measurement range 70 … 200 000 ppm

Accuracy at +20 °C (+68 °F),

1013 mbar

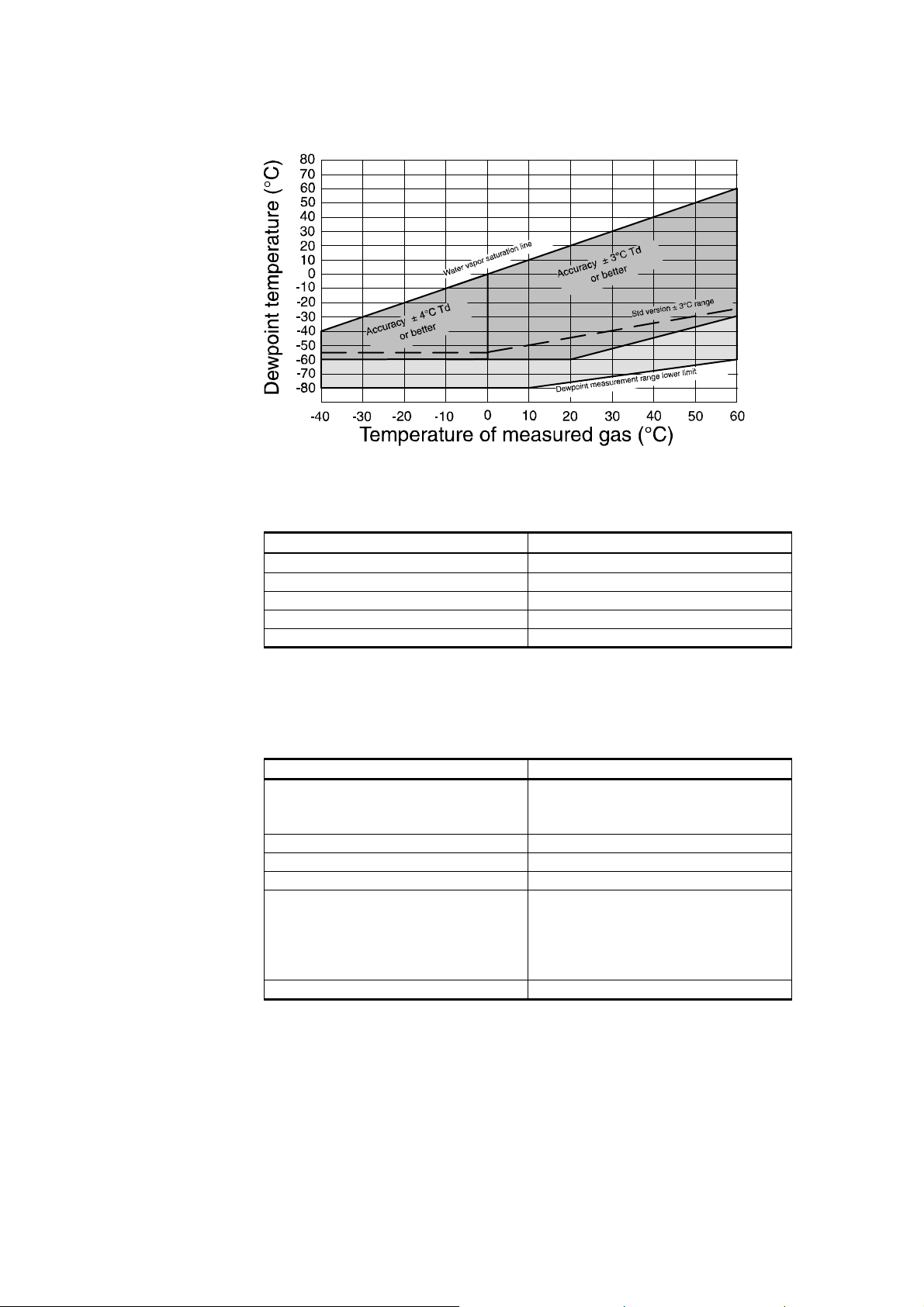

see graph on page

-80 ... +20 °C (-112 ... +68 °F) T

-60 ... +40 °C (-76 ... +104 °F) T

free scaling

± 3 °C (± 5.4 °F) T

7.3 ppm + 9.2 % of reading

34

d

d

d

VAISALA________________________________________________________________________ 33

Page 44

User's Guide _______________________________________________________________________

0610-073

Figure 19 DMT142 Dewpoint Measurement Accuracy Graph

Table 8 Operating Environment Specifications

Property Description / Value

Temperature 1) 0 … +60 °C (+32 ... +140 °F)

Relative humidity 0 ... 100 %RH

Pressure 1) 0 ... 50 bara (0 ... 725 psia)

Sample flow rate no effect on measurement accuracy

Measured gases noncorrosive gases

1) For extended temperature down to -40 °C (-40 °F) or pressure up to 50 bar

supply voltage must be 24 … 28 VDC

(725 psia) the

a

Table 9 Output Specifications

Property Description / Value

Analog output (scalable) 4 ... 20 mA (three-wire)

0 ... 1 V

0 ... 5 V

Resolution for current output 0.002 mA

Resolution for voltage output 0.3 mV

Typical temperature dependance 0.005 % of span/°C

Connector 4-pin M8 (IEC 60947-5-2)

AERO AE65-221-FA35PN (DMT142

PALL OEM model)

2 m connection cable with snap-on

or thread locking available

RS232 serial line for service use with DMT142RS cable

34 ___________________________________________________________________ M210397EN-D

Page 45

Chapter 8 _____________________________________________________________ Technical Data

Table 10 General Specifications

Property Description / Value

Sensor Vaisala DRYCAP®180D

Measured gases noncorrosive gases (SF6 gas with

special model)

Recommended calibration interval to

confirm the specified accuracy

Operating voltage

with current output

with voltage output

Supply current

during measurement

during auto-calibration

during sensor purge

Load for current output max 500 Ω

Load for voltage output min 10 kΩ

Housing material stainless steel (AISI 316L)

Mechanical connection G1/2" ISO 228/1 thread with bonded

Housing classification IP65 (NEMA 4)

Storage temperature range -40 ... +80 °C (-40 ... +176 °F)

Weight 118 g (4.16 oz)

2 years

18 ... 28 VDC

12 ... 28 VDC

10 mA + load current

max 220 mA pulsed

max 220 mA pulsed

plastic cap (ABS/PC)

stainless steel sintered filter

(part no. DRW010335)

seal ring (U-seal)

VAISALA________________________________________________________________________ 35

Page 46

User's Guide _______________________________________________________________________

Spare Parts and Accessories

Order Code Description

211598 M8 output cable 2 m with snap-on

locking (IEC 60947-5-2)

HMP50Z032 Shielded M8 output cable 0.32 m

with thread locking

HMP50Z300 Shielded M8 output cable 3 m with

thread locking

HMP50Z500 Shielded M8 output cable 5 m with

thread locking

HMP50Z1000 Shielded M8 output cable 10 m with

thread locking

DMT142RS RS232 serial line service cable

211917ZZ Connection cable for DM70

DM240FA Installation flange

DRW010335 Stainless steel sintered filter, 32 µm

Sampling cells

DMT242SC Sampling cell

DMT242SC2 Sampling cell with 1/4" Swagelok

connectors

DSC74 Sampling cell with quick connector,

leak screw and thread adapters

DSC74B Two-pressure sampling cell

DSC74C Two-pressure sampling cell with coil

DMCOIL Separate cooling/venting coil for

sampling cells

36 ___________________________________________________________________ M210397EN-D

Page 47

Chapter 8 _____________________________________________________________ Technical Data

Dimensions in mm (inches)

0507-107

Figure 20 DMT142 Dimensions

Wiring Quick Reference

Wiring of the connector

1 = VDC supply + (brown)

2 = signal sense – (voltage output only) (white)

3 = VDC supply – (blue)

4 = signal + (black)

3

0507-097

1

24

VAISALA________________________________________________________________________ 37

Page 48

Page 49

Page 50

www.vaisala.com

Loading...

Loading...