Page 1

r

USER'S GUIDE

Vaisala DRYCAP® Hand-Held

Dewpoint Mete

DM70

M010091EN-F

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2007

No part of this manual may be reproduced in any form or by any means, electronic or

mechanical (including photocopying), nor may its contents be communicated to a third

party without prior written permission of the copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding obligations for

Vaisala towards the customer or end user. All legally binding commitments and

agreements are included exclusively in the applicable supply contract or Conditions of

Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION............................................................................6

Safety......................................................................................... 6

General Safety Considerations.............................................6

Feedback...................................................................................6

Recycling ..................................................................................7

Trademarks............................................................................... 7

Warranty....................................................................................8

CHAPTER 2

PRODUCT OVERVIEW.................................................................................. 9

Introduction to Vaisala DRYCAP® Hand-Held Dewpoint

Meter DM70 ............................................................................... 9

Basic Features and Options................................................10

Parts Description.................................................................11

CHAPTER 3

PREPARATIONS BEFORE USE.................................................................13

Installing and Removing the Battery Pack ..........................13

Charging the Battery Pack .................................................... 14

Buttons and Navigation.........................................................15

Turning on the Device............................................................15

CHAPTER 4

DEWPOINT MEASUREMENT.....................................................................17

Measuring ...............................................................................17

CHAPTER 5

USER INTERFACE ...................................................................................... 19

Basic Display.......................................................................... 19

Menus...................................................................................... 20

Display Menu..........................................................................21

Quantities and Units............................................................21

Rounding.............................................................................22

Hold/Save............................................................................ 23

Graphic History ...................................................................23

Functions Menu......................................................................24

Alarm...................................................................................24

Analog Output .....................................................................26

Selecting and Scaling the Analog Output ...................... 26

VAISALA________________________________________________________________________ 1

Page 4

USER'S GUIDE____________________________________________________________________

Auto-Calibration...................................................................27

Automatic Auto-Calibration.............................................27

Turning off Automatic Auto-Calibration..........................28

Manual Auto-Calibration.................................................28

Sensor Purge.......................................................................29

Turning on/off Automatic Sensor Purge.........................30

Changing Automatic Sensor Purge Interval...................30

Manual Sensor Purge.....................................................31

Calibrate Transmitters (used only with DMP248)................32

Recording/Viewing Menu.......................................................32

Recording Data....................................................................32

Stopping Recording........................................................34

View Recorded Data ...........................................................34

Memory Status ....................................................................34

Clear Data Memory .............................................................35

Transferring Recorded Data to PC......................................35

Environment Menu .................................................................36

Pressure Settings................................................................36

Settings Menu.........................................................................37

User Interface......................................................................37

Language .......................................................................37

Automatic Power Off ......................................................38

Program Shortcut Keys..................................................38

Button Tones and Backlight ...........................................39

Date and Time.....................................................................39

Measurement Settings ........................................................40

Automatic Auto-Calibration.............................................40

Automatic Purge.............................................................40

Molecular Weight............................................................40

Purge Interval.................................................................41

Device Information...............................................................41

Factory Settings...................................................................42

CHAPTER 6

FIELD CALIBRATION CHECK OF FIXED TRANSMITTERS.....................43

Field Calibration Check of DMT340/DMT242/DMT142 ........43

Field Calibration Check of DMP248......................................44

CHAPTER 7

SAMPLING FROM PROCESSES................................................................47

Sampling Cells........................................................................48

DSC74.................................................................................48

DSC74B...............................................................................49

DSC74C ..............................................................................49

DMT242SC..........................................................................52

DMT242SC2........................................................................52

Connection to Pressurized Processes Using the DSC74

Sampling Cell..........................................................................52

DSS70A Sampling System.....................................................54

DSS70A Sampling Procedure.............................................55

DSS70A Maintenance.........................................................56

Recharging the Battery...................................................56

2 ___________________________________________________________________ M010091EN-F

Page 5

________________________________________________________________________________

Changing the Battery .....................................................57

Changing the Filter......................................................... 59

Changing the Fuses.......................................................60

CHAPTER 8

MEASURING MOISTURE IN SF6 GAS-INSULATED EQUIPMENT...........61

Overview .................................................................................61

Operating Environment.......................................................62

Measuring............................................................................62

CHAPTER 9

CALIBRATION, ADJUSTMENT, AND MAINTENANCE............................. 65

Calibration............................................................................... 65

User Calibration and Adjustment........................................65

Adjusting DM70.............................................................. 66

Adjusting DMT340 Series Transmitters Using DM70 as

Reference or Terminal...................................................66

Adjusting Dewpoint................................................................67

Two-Point Relative Humidity Adjustment............................67

Two-Point Relative Humidity Adjustment of DMT340

Series Transmitters Using DM70...................................68

Adjusting Dewpoint T

T

Adjustment of DM70.................................................70

d/f

T

Adjustment of DMT340 Series Transmitters using

d/f

........................................................70

d/f

DM70..............................................................................71

To Same as T

......................................................72

d/f I/II

1-Point Adjustment....................................................73

Adjusting Temperature..........................................................74

Temperature Adjustment of DM70......................................74

One-Point Adjustment....................................................74

Two-Point Adjustment....................................................75

Temperature Adjustment of DMT340 Series Using DM70 .75

To Same as T

..............................................................76

I/II

1-Point Adjustment......................................................... 76

2-Point Adjustment......................................................... 77

Vaisala Service Centers......................................................... 78

CHAPTER 10

DE-COMMISSIONING, DISMANTLING, AND DISPOSAL.........................79

CHAPTER 11

TECHNICAL SPECIFICATIONS..................................................................81

Measured Variables................................................................81

Dewpoint Temperature........................................................81

Temperature...................................................................83

PPM (ppmv or ppmw)......................................................83

Absolute Humidity (DMP74A Probe Recommended)....84

Mixing Ratio (DMP74A Probe Recommended).............84

Relative Humidity (DMP74A).........................................84

Measurement Environment............................................84

Probe General................................................................85

VAISALA________________________________________________________________________ 3

Page 6

USER'S GUIDE____________________________________________________________________

MI70 Indicator......................................................................85

DMP74 Probe + MI70 Indicator = Vaisala DRYCAP® DM70

Hand-Held Dewpoint Meter.................................................86

Accessories.........................................................................89

Dimensions..........................................................................90

List of Figures

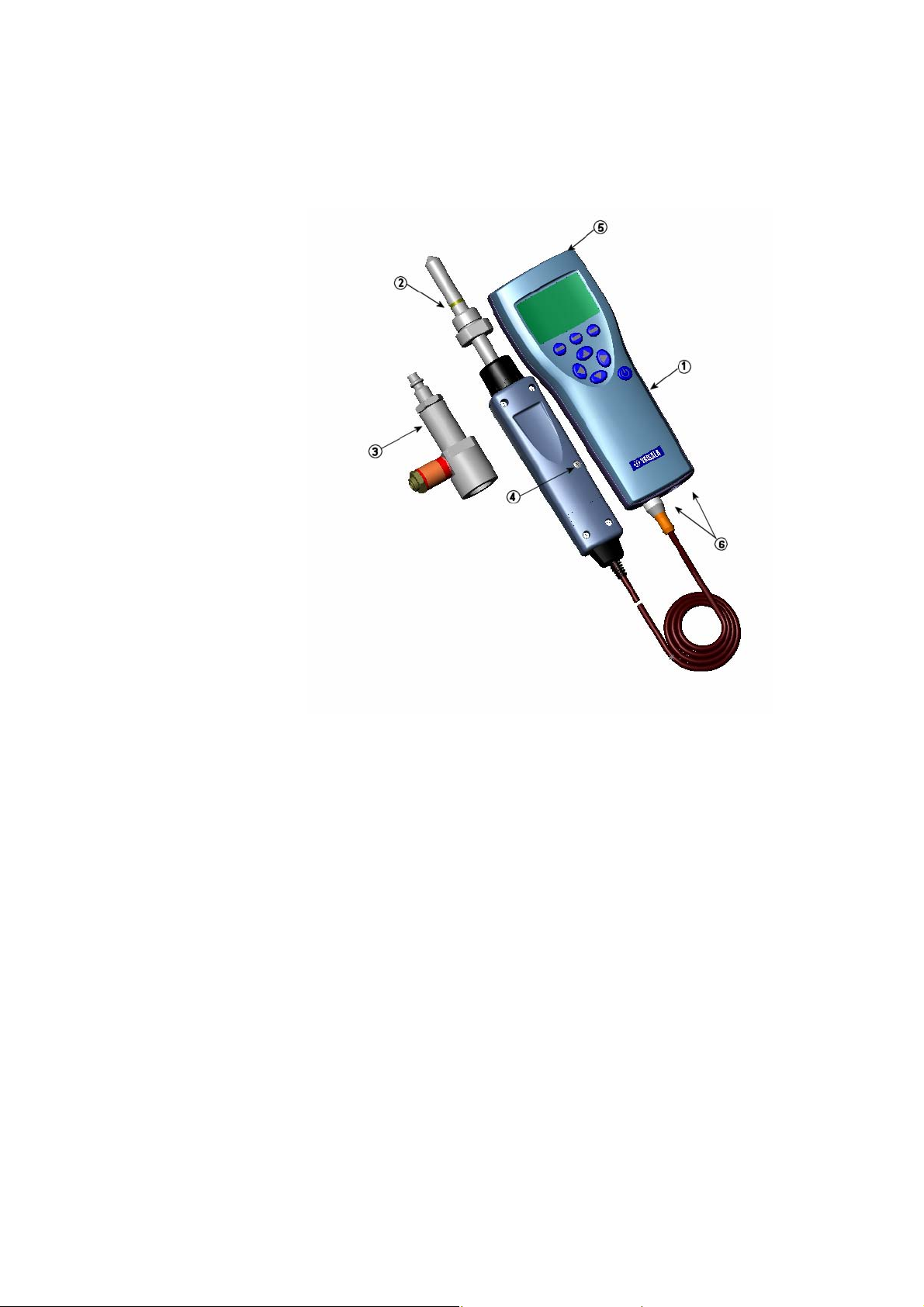

Figure 1 Hand-Held Dewpoint Meter DM70............................................11

Figure 2 Installing the Battery Pack........................................................13

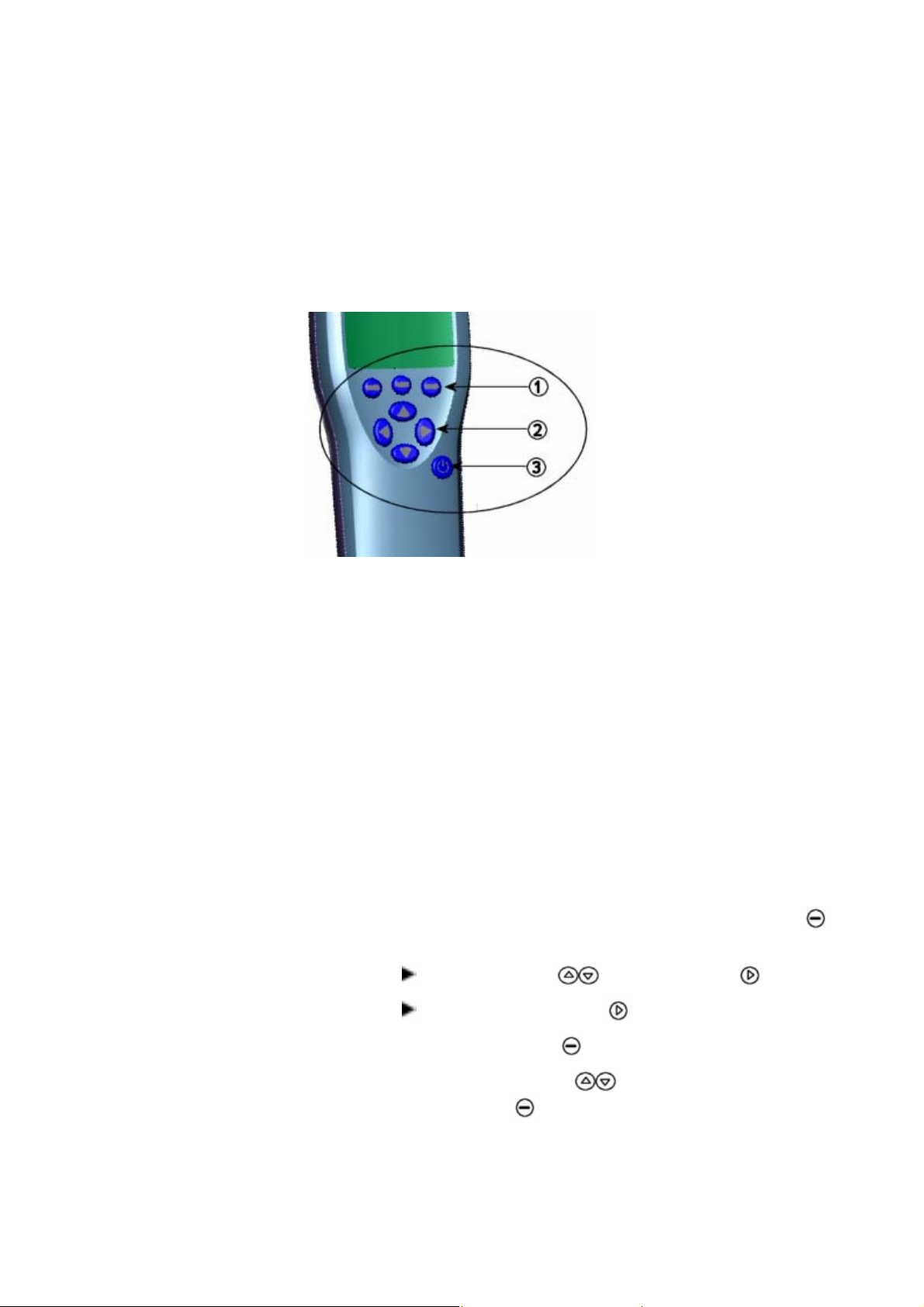

Figure 3 Buttons......................................................................................15

Figure 4 Basic Display............................................................................19

Figure 5 Menus.......................................................................................21

Figure 6 Quantities and Units Menu.......................................................22

Figure 7 Alarm ........................................................................................24

Figure 8 Analog Output...........................................................................26

Figure 9 Auto-Calibration Displays.........................................................29

Figure 10 Sensor Purge Displays.............................................................31

Figure 11 Calibrate Transmitters Display .................................................32

Figure 12 Recording .................................................................................32

Figure 13 Environment Menu ...................................................................36

Figure 14 User Interface...........................................................................37

Figure 15 Hold/Save Replaced by Auto Cal.............................................39

Figure 16 Measurement Settings Menu....................................................40

Figure 17 Device Information....................................................................41

Figure 18 Indicator and Probe Information...............................................42

Figure 19 Calibrate Transmitters Message...............................................45

Figure 20 DSC74 Sampling Cell with the Adapters..................................48

Figure 21 DSC74B....................................................................................49

Figure 22 Default Assembly of DSC74C ..................................................50

Figure 23 Alternative Assembly of DSC74C for Tight Spaces .................51

Figure 24 DMT242SC and DMT242SC2 Sampling Cells.........................52

Figure 25 DM70 with the Case .................................................................55

Figure 26 Lifting the System.....................................................................57

Figure 27 Sampling System Upside Down...............................................58

Figure 28 Changing the Filter ...................................................................59

Figure 29 Gas Collection Option...............................................................62

Figure 30 Removing the Leak Screw........................................................63

Figure 31 DMP74A Accuracy ...................................................................82

Figure 32 DMP74B Accuracy ...................................................................82

Figure 33 DMP74C Accuracy ...................................................................82

Figure 34 Dimensions in Millimeters (Inches)...........................................90

Indicator General............................................................85

Battery Pack...................................................................86

General...........................................................................86

Electromagnetic Compatibility........................................87

Sampling Cells ...............................................................87

DMT242SC Sampling Cell........................................87

DMT242SC2 Sampling Cell with Swagelok

Connectors................................................................87

DSC74 Sampling Cell for Pressurized Gases...........87

DSC74B Two-Pressure Sampling Cell .....................87

DSC74C....................................................................88

DMCOIL ....................................................................88

DSS70A Sampling System.............................................88

4 ___________________________________________________________________ M010091EN-F

Page 7

________________________________________________________________________________

List of Tables

Table 1 Measurement Intervals and Maximum Recording Times.........33

Table 2 List of Accessories ...................................................................89

VAISALA________________________________________________________________________ 5

Page 8

USER'S GUIDE____________________________________________________________________

CHAPTER 1

GENERAL INFORMATION

Safety

General Safety Considerations

WARNING

CAUTION

NOTE

Feedback

Throughout the manual, important safety considerations are

highlighted as follows:

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or

even death.

Caution warns you of a potential hazard. If you do not read and

follow instructions carefully at this point, the product could be

damaged or important data could be lost.

Note highlights important information on using the product.

Vaisala Customer Documentation Team welcomes your comments

and suggestions on the quality and usefulness of this publication. If

you find errors or have other suggestions for improvement, please

indicate the chapter, section, and page number. You can send

comments to us by e-mail: manuals@vaisala.com

6 ___________________________________________________________________ M010091EN-F

Page 9

Chapter 1 ________________________________________________________ General Information

Recycling

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

Trademarks

DRYCAP® is a registered trademark of Vaisala. Microsoft®,

Windows®, and Windows NT® are registered trademarks of Microsoft

Corporation in the United States and/or other countries.

VAISALA________________________________________________________________________ 7

Page 10

USER'S GUIDE____________________________________________________________________

Warranty

Vaisala hereby represents and warrants all Products

manufactured by Vaisala and sold hereunder to be

free from defects in workmanship or material

during a period of twelve (12) months from the date

of delivery save for products for which a special

warranty is given. If any Product proves however to

be defective in workmanship or material within the

period herein provided Vaisala undertakes to the

exclusion of any other remedy to repair or at its

own option replace the defective Product or part

thereof free of charge and otherwise on the same

conditions as for the original Product or part

without extension to original warranty time.

Defective parts replaced in accordance with this

clause shall be placed at the disposal of Vaisala.

Vaisala also warrants the quality of all repair and

servi

ce works performed by its employees to

products sold by it. In case the repair or service

works should appear inadequate or faulty and

should this cause malfunction or nonfunction of the

product to which the service was performed Vaisala

shall at its free option either repair or have repaired

or replace the product in question. The working

hours used by employees of Vaisala for such repair

or replacement shall be free of charge to the client.

This service warranty shall be valid for a period of

six (6) months from the date the service measures

were completed.

This warranty does not however apply when the

has been caused through

defect

a) normal wear and tear or accident;

b) misuse or other unsuitable or unauthorized use

of

the Product or negligence or error in storing,

maintaining or in handling the Product or any

equipment thereof;

c) wrong installation or assembly or failure to

service the

Vaisala's service instructions including any

repairs or installation or assembly or service

made by unauthorized personnel not approved

by Vaisala or replacements with parts not

manufactured or supplied by Vaisala;

d) modifications or changes of the Product as well

as an

y adding to it without Vaisala's prior

authorization;

e) other factors depending on the Customer or a

ird party.

th

Notwithstanding the aforesaid Vaisala's liability

nder this clause shall not apply to any defects

u

arising out of materials, designs or instructions

provided by the Customer.

Product or otherwise follow

This warranty is however subject to following

nditions:

co

a) A substantiated written claim as to any alleged

s shall have been received by Vaisala

defect

within thirty (30) days after the defect or fault

became known or occurred, and

b) The allegedly defective Product or part shall,

shoul

d Vaisala so require, be sent to the works

of Vaisala or to such other place as Vaisala may

indicate in writing, freight and insurance

prepaid and properly packed and labelled,

unless Vaisala agrees to inspect and repair the

Product or replace it on site.

This warranty is expressly in lieu of and excludes

all o

ther conditions, warranties and liabilities,

express or implied, whether under law, statute or

otherwise, including without limitation any implied

warranties of merchantability or fitness for a

particular purpose and all other obligations and

liabilities of Vaisala or its representatives with

respect to any defect or deficiency applicable to or

resulting directly or indirectly from the Products

supplied hereunder, which obligations and

liabilities are hereby expressly cancelled and

waived. Vaisala's liability shall under no

circumstances exceed the invoice price of any

Product for which a warranty claim is made, nor

shall Vaisala in any circumstances be liable for lost

profits or other consequential loss whether direct or

indirect or for special damages.

8 ___________________________________________________________________ M010091EN-F

Page 11

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

Introduction to Vaisala DRYCAP® Hand-Held Dewpoint Meter DM70

DM70 measures dewpoint temperature accurately in a measurement

range from -60 °C up to +60 °C depending on the probe version.

DM70 incorporates the advanced DRYCAP® technology, which

enables reliable and high-performance dewpoint measurement. DM70

measures the following quantities:

- dewpoint/frost point1) temperature T

- dewpoint temperature

- temperature T (°C/°F)

- dewpoint/frost point in the atmospheric pressure T

(°C atm/°F atm)

- dewpoint in the atmospheric pressure Td (°C atm/°F atm)

- relative humidity RH (%)

- humid air /dry air H2O ppmv/ppm

- absolute humidity a (g/m3)

- mixing ratio x (g/kg)

1)

T

shows the dewpoint temperature above the freezing point (0

d/f

°C/32 °F) and frost point temperature Tf (dewpoint over ice) below the

freezing point. This is considered as the industry standard.

2)

Td (°C/°F)

w

(°C/°F)

d/f

d/f

2)

Td shows the dewpoint over water throughout the entire

measurement range.

VAISALA________________________________________________________________________ 9

Page 12

USER'S GUIDE____________________________________________________________________

DM70 consists of two main units: the MI70 indicator and DMP74

probe, versions A, B, or C. DM70 can be used with the optional

sampling cell to measure process dewpoint. With DSS70A, DM70

forms a part of a complete portable sampling system for measuring

process dewpoint.

Basic Features and Options

DM70 has the following basic features and options:

- Numerical and graphical multilingual displays.

- Data recording possibility.

- A tool for checking the reading of the fixed transmitters DMT340,

DMP248, DMT242 and DMT142

- A possibility for an analog output (voltage signal

0 ... 1 V)

- An optional, ready-to-use Microsoft Windows® software, which

allows an easy way to handle measurement data using a serial line

or a USB instrument cable

- The optional sampling system DSS70A (see section DSS70A

Sampling System on page 54)

10 __________________________________________________________________ M010091EN-F

Page 13

Chapter 2 __________________________________________________________ Product Overview

Parts Description

0403-031

Figure 1 Hand-Held Dewpoint Meter DM70

The following numbers refer to Figure 1 above.

1 = MI70 indicator

2 = DMP74 probe

3 = Sampling cell DSC74 (optional)

4 = Calibration button

5 = Recharger connector

6 = Connector ports for probes and cables

VAISALA_______________________________________________________________________ 11

Page 14

USER'S GUIDE____________________________________________________________________

This page intentionally left blank.

12 __________________________________________________________________ M010091EN-F

Page 15

Chapter 3 ____________________________________________________ Preparations Before Use

CHAPTER 3

PREPARATIONS BEFORE USE

Installing and Removing the Battery Pack

NOTE

If you have previously used a battery pack, put the metal contact at

the lower end of the batteries before installing the alkaline batteries.

If DM70 is ordered with a battery pack, it is already installed at the

factory.

1. Unscrew the back plate of the indicator.

2. Remove the old batteries. Detach the black connector by pulling

it up carefully from the wires.

0403-032

Figure 2 Installing the Battery Pack

3. Connect the black connector of the new battery pack. Make sure

the red and black wires are on the upper edge of the connector.

VAISALA_______________________________________________________________________ 13

Page 16

USER'S GUIDE____________________________________________________________________

Do not push the connector with any conducting material. See

Figure 2 on page 13.

NOTE

NOTE

If you have previously used alkaline batteries, remove the metal

contact before installing the battery pack.

4. Replace the battery pack, close the back plate, and tighten the

screw.

5. Charge the battery before use.

Old batteries must be disposed of according to the local laws and

regulations.

Charging the Battery Pack

NOTE

Do not use DM70 during the first charging.

1. Plug the recharger connector to the base of the indicator.

2. Connect the recharger to a wall socket. A battery sym bol in the

corner of the display will start rolling.

3. When the battery symbol stops rolling, the battery pack is fully

charged.

4. Disconnect the recharger.

The duration of recharging is typically 4 hours. However, the

recommended first charging time is 6 hours.

14 __________________________________________________________________ M010091EN-F

Page 17

Chapter 3 ____________________________________________________ Preparations Before Use

Buttons and Navigation

To turn on the device, press the Power On/Off button. To open

menus, press an arrow button and then press the shortcut buttons. To

activate a function shown above the shortcut button, press the shortcut

button. To navigate in the menus, press arrow buttons.

0403-033

Figure 3 Buttons

The following numbers refer to Figure 3 above.

1 = Shortcut buttons

2 = Arrow buttons

3 = Power on/off button

Turning on the Device

1. Connect the probe to either one of the base connectors in the

indicator.

2. Press the Power On/Off button.

3. Press any of the arrow buttons and open a menu by pressing

Open.

4. Select Settings using the buttons and press .

5. Select User interface and press .

6. Select Language and press Set.

7. Select the language using the buttons. Confirm the

selection by pressing Select.

VAISALA_______________________________________________________________________ 15

Page 18

USER'S GUIDE____________________________________________________________________

8. If you want to set the date at this point, return to the Settings

menu by pressing .

NOTE

The language can be selected also later. See section Language on

page 37.

9. To change the date, select Date and press Set. Then change

the date using the buttons. To confirm the selection, press

Select. As a default, the date format is year-month-day You

can select from two other alternative formats.

10. To change the time, select Time and press Set. Then change

the time by using the arrow buttons. Confirm the selection by

pressing OK. As a default, the time format is based on the

24-hour clock. If you want to use the 12-hour clock, select 12-

hour clock and then press On.

11. To return to the basic display, press Exit.

16 __________________________________________________________________ M010091EN-F

Page 19

Chapter 4 _____________________________________________________ Dewpoint Measurement

CHAPTER 4

DEWPOINT MEASUREMENT

The following recommendations should be taken into account when

measuring in very dry environments.

- A clean environment is always best for humidity measurements.

Measuring

- The number of connections should be minimized to avoid leaks.

- The flow rate must be adequate.

- Dead ends must be avoided as they cannot be flushed easily.

- The tube temperature must never lie under the dewpoint of the

sample gas. This may lead to condensation and false results.

- The sample tubing should be of as short length as possible. The

surface area should be minimized using the narrowest tubing that

the flow conditions allow.

- The surface finish of the pipework is important. Polished or

electro-polished steel is recommended for best results.

- Hygroscopic materials should be avoided in the sampling lines. Use

stainless steel membranes instead of rubber membranes.

- Impermeable materials should be selected to avoid inward diffusion

of moisture through the sampling tubes and enclosures. Such

impermeable materials are, for example, high-quality stainless steel

and metals. Avoid PVC or nylon tubes.

If you start DM70 for the first time, see section Preparations Before

Use on page 13. Otherwise, follow the instructions below.

1. Connect the probe to the MI70 indicator.

2. Press the Power On/Off button.

VAISALA_______________________________________________________________________ 17

Page 20

USER'S GUIDE____________________________________________________________________

3. Install the probe to the measuring position. If you are measuring

in pressurized processes, see section Connection to Pressurized

Processes Using the DSC74 Sampling Cell on page 52. When

using other sampling cells than DSC74, make sure that the

threads are compatible with the probe threads (G ½" ISO228/1).

Be careful not to damage the sintered filter when installing the

probe.

4. Before measuring, make sure that the air pressure settings of

DM70 are correct and that auto-calibration has taken place (see

section Automatic Auto-Calibration on page 27)

5. The basic display opens. Let the reading stabilize.

CAUTION

NOTE

If you need to disconnect the probe from the indicator, first press the

Power On/Off button to turn the indicator off. This ensures that all

the settings and data are saved properly.

When measuring low dewpoints, the stabilization times can be long,

for example, one to two hours. Therefore, turn off the automatic

power-off function (see section Automatic Power Off on page 38),

turn on the automatic auto-calibration (see section Automatic AutoCalibration on page 27), and turn on the automatic sensor purge (see

section Turning on/off Automatic Sensor Purge on page 30).

Thus, the stabilization can be monitored, the auto-calibration ensures

an accurate measurement, and the purge ensures the shortest possible

response times.

18 __________________________________________________________________ M010091EN-F

Page 21

Chapter 5 _____________________________________________________________User Interface

CHAPTER 5

USER INTERFACE

This chapter contains information that is needed to operate this

product.

Basic Display

When DM70 is turned on, the display shown in Figure 4 below

appears.

0403-034

Figure 4 Basic Display

The following numbers refer to Figure 4 above.

1 = The state of the battery.

2 = Pressure settings.

VAISALA_______________________________________________________________________ 19

Page 22

USER'S GUIDE____________________________________________________________________

3 = Selected quantities. Up to three of the following quantities

can be selected at a time: dewpoint (T

d/f, Td

), relative

humidity (RH), absolute humidity (a), mixing ratio (x), parts

per million (H2O), temperature (T).

4 = The Graphic1) shortcut button changes the display into a

curve mode.

5 = The Hold/Sa1) shortcut button holds the display and allows

you to save the reading into the memory.

6 =

The Record shortcut button takes you to the

Recording/Viewing menu. This is the default shortcut

button. In the figure it has been changed to Start/S.

1)

The Graphic, Hold/Sa, and Record functions above the shortcut

buttons are set at the factory. You can change them to refer to other

functions as shown in Figure 4 on page 19 where Start/S has replaced

Record. See also section Program Shortcut Keys on page 38.

Menus

The settings can be changed and functions can be selected in the

menus. Follow the instructions below:

1. Open the main menu by pressing one of the buttons.

2. Press Open within 5 seconds. Otherwise, the basic display

returns. If this happens, start from step 1 again.

3. Move in the menus using the

4. Select an item with the

button.

buttons.

5. To return to the previous level, press .

6. To return to norm al operation, press Exit.

20 __________________________________________________________________ M010091EN-F

Page 23

Chapter 5 _____________________________________________________________User Interface

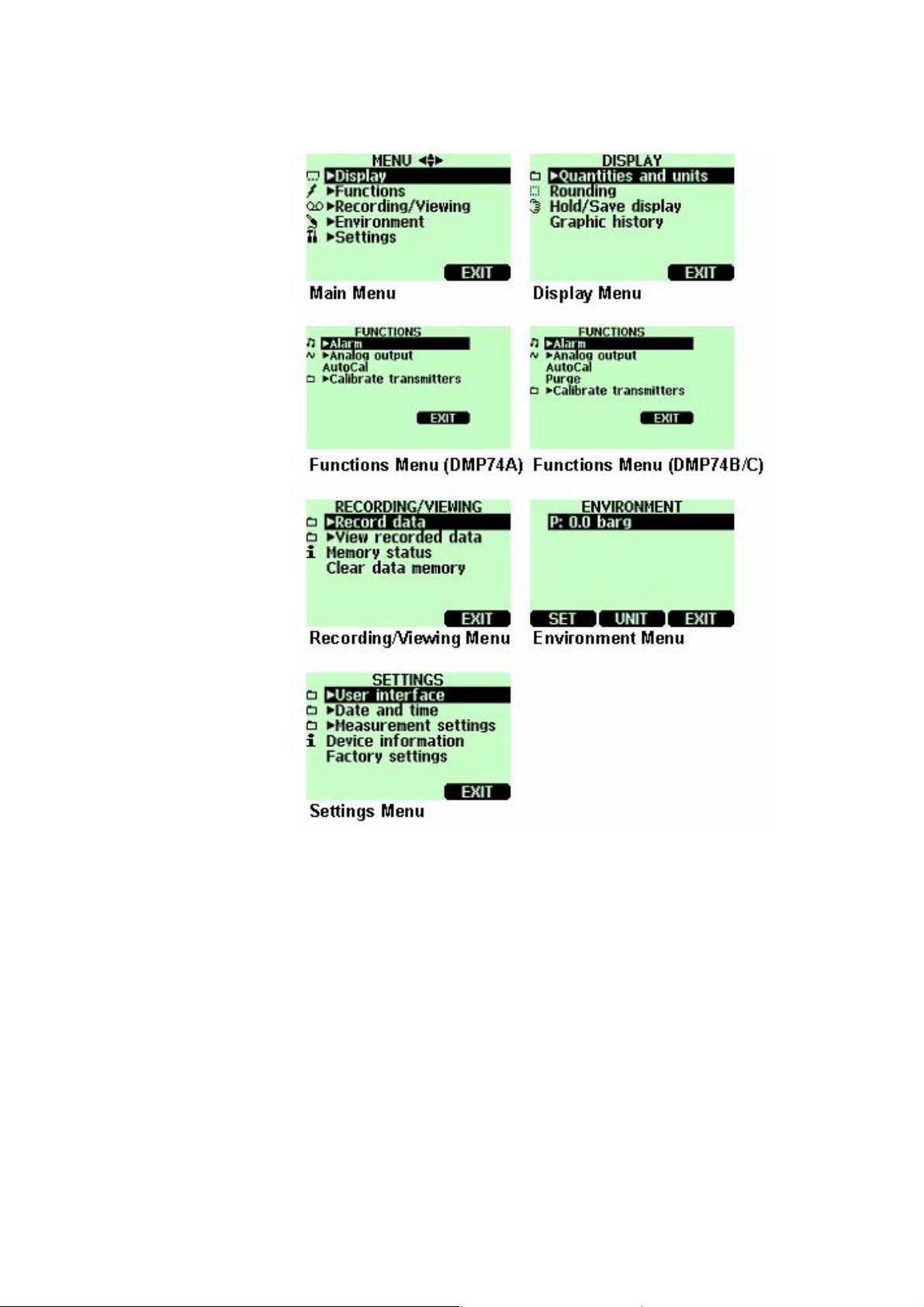

0403-035

Figure 5 Menus

Display Menu

Quantities and Units

You can select 1 ... 3 display quantities at a time. The unit of

quantities (T

default is °C.

To select a quantity, do the following:

VAISALA_______________________________________________________________________ 21

, Td, or T) can be selected between °C or °F. The

d/f

Page 24

USER'S GUIDE____________________________________________________________________

1. Open the menu by pressing Open.

2. Select Display and press .

3. Select Quantities and units and then press .

4. To select a quantity, move on the desired quantity using the

arrow buttons and then press Select.

5. To change the unit, move on the desired quantity using the

arrow buttons and then press Unit (°C or °F).

6. To hide a quantity, move on the desired quantity using the arrow

buttons and then press Hide.

7. To return to the basic display, press Exit.

8. If you want to check the environment settings, press

Yes. Otherwise press No.

NOTE

Units °C atm and °F atm indicate that the dewpoint or frost point is

converted from process pressure to atmospheric pressure.

Below you will find an example of the Quantities and Units menu.

0404-021

Figure 6 Quantities and Units Menu

Rounding

You can select a one- or two-decimal display using Rounding. As a

default, rounding is turned off

(=a two-decimal display is in use).

1. Open the menu by pressing Open.

2. Select Display and then press .

3. Select Rounding.

22 __________________________________________________________________ M010091EN-F

Page 25

Chapter 5 _____________________________________________________________User Interface

4. To turn rounding on (=a one-decimal display), press

On. To turn rounding off (=a two-decimal display), press

Off.

5. To return to the basic display, press Exit.

NOTE

Rounding does not affect the measurement accuracy. Accuracy is

defined in Chapter 11 on page 81.

Hold/Save

With the Hold/Save function you can hold a selected display reading

and save it into the memory. Several readings can be saved. The

reading saved first is called data point 1, the second saved reading is

called data point 2 , and so on. All the individual readings (data

points) are stored in the same file marked with

in the indicator memory even when the indicator is switched off.

1. Open the menu by pressing Open.

2. Select Display and then press .

3. Select Hold/Save display.

4. To hold the display, press Hold. The measurement data is

displayed.

. The file will remain

5. To save the reading, press Save. To return to the basic

display, press Exit.

6. To view the saved readings, press

display. Then select View recorded data and press .

7. Select the file marked with

the saved data readings. To view the recording time stamps,

press

8. To return to the basic display, press

Times.

and press . Now you can view

Record in the basic

Exit.

Graphic History

The graphical display shows the measurements as a curve. From the

curve, you can examine the data trend and history of the last minutes.

VAISALA_______________________________________________________________________ 23

Page 26

USER'S GUIDE____________________________________________________________________

The graphical display shows the curve of the uppermost quantity

shown in the basic display.

1. Open the menu by pressing Open.

2. Select Display and press .

3. To go to the Graphical history display, select Graphic history

and press Show.

4. To get the statistical info on the graph area (minimum,

maximum, and average values), press

Info.

5. To get the curve of the other selected quantities, press

To get the curves of all the quantities, press Next until the

text ALL appears on the display. Then press All.

6. To zoom in a curve, press . To zoom out, press . To move

the curve horizontally, press .

7. To return to the basic display, press Back and Exit.

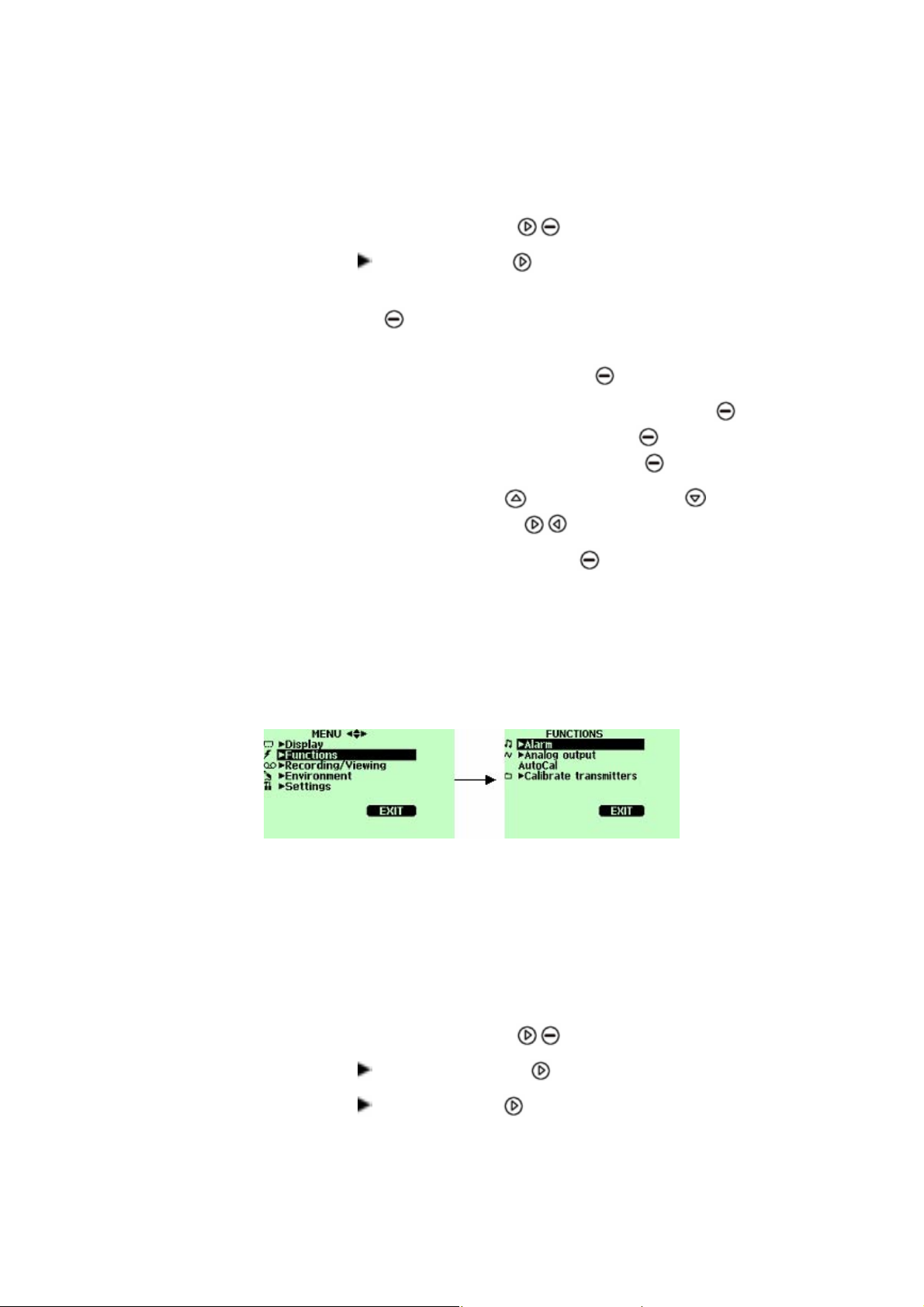

Functions Menu

Alarm

0403-042

Next.

Figure 7 Alarm

When the alarm goes off, DM70 beeps and the backlight blinks. The

alarm is turned on when the measured value is not between the alarm

limits, that is, the permitted area. The alarm level(s) can be set for

only one quantity at a time. To set the alarm levels, follow the

instructions below:

1. Open the menu by pressing

2. Select Functions and press .

3. Select Alarm and press .

24 __________________________________________________________________ M010091EN-F

Open.

Page 27

Chapter 5 _____________________________________________________________User Interface

4. Select Quantity and press Set to select the quantity.

5. Select the quantity and press Select. Only one active quantity

can be selected at a time. To change which quantities are active,

go to Menu - Display - Quantities and units.

6. Select the first limit and press Set (if the alarm function is

on, turn it off). Use the arrow buttons to set the alarm level. To

select the sign for the alarm level, press the +/- button. To

save the settings, press

OK.

7. Select the second limit and follow the instructions in step 6. The

alarm will go off when either the upper or lower limit is

exceeded.

If you will use only one limit, for example, if you want to detect

if the dewpoint will rise above -40 °C, do the following:

Set the upper limit to -40 °C and the value of the lower limit so

low that it will never be reached, for example, to -80 °C. Thus,

DM70 will alert when Td rises above

-40 °C.

NOTE

8. To activate the alarm and to return to the basic display, select

Alarm On/Off and press On. The note symbol ♫ will appear

in the upper left corner of the display.

9. When the alarm level is reached, you can stop the alarm by

pressing OK. To reactivate the alarm, press Yes. To

completely stop the alarm, press

No.

The alarm does not work when the device is turned off.

VAISALA_______________________________________________________________________ 25

Page 28

USER'S GUIDE____________________________________________________________________

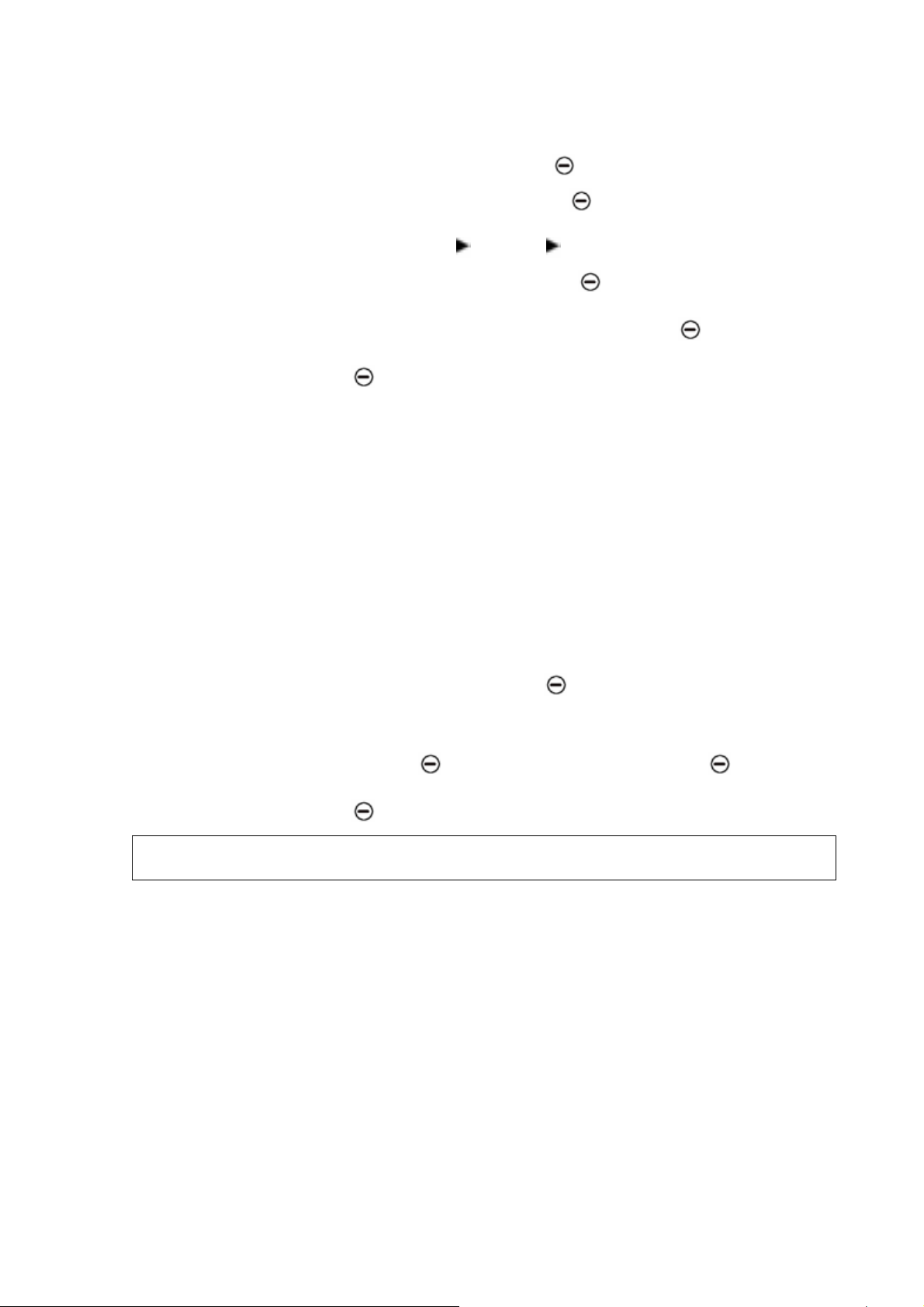

Analog Output

Selecting and Scaling the Analog Output

0403-052

Figure 8 Analog Output

To get analog measurement data, an analog signal cable is needed (see

section Accessories on page 89).

1. Connect the signal cable connector of the analog output to the

base connector of the indicator. Connect the screw terminal

block as follows:

Brown wire: common wire (-)

Yellow-green wire: signal (+)

2. Open the menu by pressing Open.

3. Select Functions and press .

4. Select Analog output and press .

5. Select Quantity and press Set.

6. Select Quantity and press

can be selected at a time. To change the quantities, go to Menu -

Display - Quantities and units.

Select. Only one active quantity

7. To set the value for the 0.0 V output signal, select

0.0 V and press

Set the low value using the arrow buttons. To select the sign for

the value, press

8. To set the value for the 1.0 V output signal, select

1.0 V and press Set. Set the high value using the arrow

buttons. To select the sign for the value, press

+-. To confirm the setting, press OK.

9. To activate the analog output and to return to the basic display,

select Analog output on/off and press On. The following

symbol ~ appears in the upper left corner of the basic display.

26 __________________________________________________________________ M010091EN-F

Set. If the analog output is on, turn it off.

+-.

Page 29

Chapter 5 _____________________________________________________________User Interface

10. To deactivate analog output, go to Menu - Functions -

Analog output - Analog output on/off and press Off.

Auto-Calibration

To obtain the best possible accuracy in measurements taken in dry

environments, DM70 has a built-in, automatic calibration. During the

auto-calibration, DM70 adjusts the dry-end reading to correspond to

the calibrated values. This is a unique and patented method to avoid

errors in accuracy when monitoring low dewpoints.

The auto-calibration is carried out if the following criteria for the

measurement environment are fulfilled:

- Relative humidity must be <5 % (DMP74A).

<2 % (DMP74B/C).

- Temperature must be 0<T<60 ºC.

NOTE

- Humidity environment must be stable. The maximum change in the

dewpoint can be 1 ºC within 30 seconds.

Auto-calibration cannot operate if the above conditions are not

fulfilled.

If the adjustment in the auto-calibration reaches a preset, maximum

value or if the auto-calibration correction fails, for example, because

of unstable conditions, a new auto-calibration may take place later (if

the automatic auto-calibration is turned on). Auto-calibration can be

either automatic or manual.

Automatic Auto-Calibration

As a default, the automatic auto-calibration in DM70 is turned on. In

this mode, the calibration takes place automatically if the dewpoint or

temperature changes significantly, typically more than 10 ºC.

However, if there are no changes in the conditions, the calibration will

take place at an interval of one hour or at least, after one hour from the

last auto-calibration.

VAISALA_______________________________________________________________________ 27

Page 30

USER'S GUIDE____________________________________________________________________

Turning off Automatic Auto-Calibration

NOTE

If the automatic auto-calibration is turned off, the auto-calibration

should be started when starting measuring after the probe has not

been used for a while and always at least once every hour.

The automatic auto-calibration can be turned off as follows:

1. Open the menu by pressing

2. Select

3. Select Measurement settings and press .

4. To turn off the automatic auto-calibration, press

On.

5. To return to the basic display, press Exit.

Settings and press .

Off. To reactivate the automatic auto-calibration, press

Open.

Manual Auto-Calibration

To check that auto-calibration has taken place for obtaining the most

accurate measurement in a very dry environment, you can autocalibrate manually before measuring as follows:

NOTE

1. Open the menu by pressing Open.

2. Select

3. Select AutoCal and press Start.

4. If you want to start auto-calibration, press Yes. If the autocalibration conditions are not fulfilled, a note appears on the

display informing that the calibration cannot be made or that a

new attempt will be made later.

5. When the auto-calibration is completed, the display returns to

the basic display automatically.

Auto-calibration takes about 2 minutes. When the auto-calibration is

in progress, an estimate of the measurement readings may appear on

the display. Messages concerning the remaining auto-calibration time

are shown periodically. See Figure 9 on page 29.

If it is too humid, auto-calibration will not start.

Functions and press .

28 __________________________________________________________________ M010091EN-F

Page 31

Chapter 5 _____________________________________________________________User Interface

0403-045

Figure 9 Auto-Calibration Displays

Sensor Purge

Sensor purge feature is only available in the DMP74B/C probe. The

purge should be carried out to achieve the shortest response times and

the best long-term stability.

Sensor purge is an automatic procedure, in which the sensor is dried.

Thus, the sensor will response very fast when installing the probe

from an ambient to a dry gas. This will also ensure together with autocalibration the best measurement accuracy and long-term stability.

VAISALA_______________________________________________________________________ 29

Page 32

USER'S GUIDE____________________________________________________________________

The purge is performed automatically if humidity changes

significantly or quickly and if the dewpoint is low enough.

As a default, the automatic sensor purge is turned on automatically in

DM70. It is recommended not to turn it off. The automatic sensor

purge can also be started manually, which is necessary if the purge has

not been performed during the last 24 hours. If the power is

continuously turned on in DM70, or if DM70 has been left in logging

mode (display on or off), the automatic sensor purge will be

performed at set interval (default = 24 hours).

Turning on/off Automatic Sensor Purge

NOTE

When the sensor purge is performed on a regular basis, the

measurement will have the best accuracy and fastest response time.

Perform the sensor purge when starting measuring after the probe has

been stored and always at least once every 24 hours.

The automatic sensor purge can be turned on or off as follows:

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select Measurement settings and press .

4. Select Autom.Purge and press .

5. To turn the automatic sensor purge off, press Off. To

reactivate the automatic sensor purge, press

6. To return to the basic display, press

Exit.

On.

Changing Automatic Sensor Purge Interval

If there are high chemical concentrations present in the measurement

environment, it may cause some sensor drift. If you experience this

kind of drift, it may be necessary to perform the sensor purge more

often. The purge interval can be varied between 1 ... 48 hours. Note

however, that more frequent sensor purge will reduce battery

operation time.

1. Open the menu by pressing

2. Select Settings and press .

30 __________________________________________________________________ M010091EN-F

Open.

Page 33

Chapter 5 _____________________________________________________________User Interface

3. Select Measurement settings and press .

4. Select Purge interval and press Set.

5. Set the desired purge interval with the arrow buttons. Press

OK to confirm.

6. To return to the basic display, press Exit.

Manual Sensor Purge

To check that the sensor purge has been performed to ensure the best

possible response times or before calibration, start the purge manually

as follows:

NOTE

NOTE

Although the sensor purge is in the automatic mode, it can also be

performed manually.

1. Open the menu by pressing Open.

2. Select Functions and press .

3. Select Purge and press Start. Confirm the selection by

pressing Yes.

4. When the sensor purge is completed, the display returns to the

basic display automatically. The stabilization of the temperature

reading can take a few minutes.

If the dewpoint is low, automatic auto-calibration will take place

immediately after the sensor purge.

The purge will take up to 5 minutes to complete. During the purge,

there are no readings on the display. A message appears on the display

every 15 seconds to inform of the time required to complete the purge.

The purge symbol also appears in the upper left corner of the display.

See Figure 10 on page 31.

0403-044

Figure 10 Sensor Purge Displays

VAISALA_______________________________________________________________________ 31

Page 34

USER'S GUIDE____________________________________________________________________

You can also change one of the shortcut keys to refer to the sensor

purge. See section Program Shortcut Keys on page 38.

Calibrate Transmitters (used only with DMP248)

In this menu, you can set the baud rate, serial format, and start

calibration. For details, refer to Chapter 6, Field Calibration Check of

Fixed Transmitters, on page 43.

Figure 11 Calibrate Transmitters Display

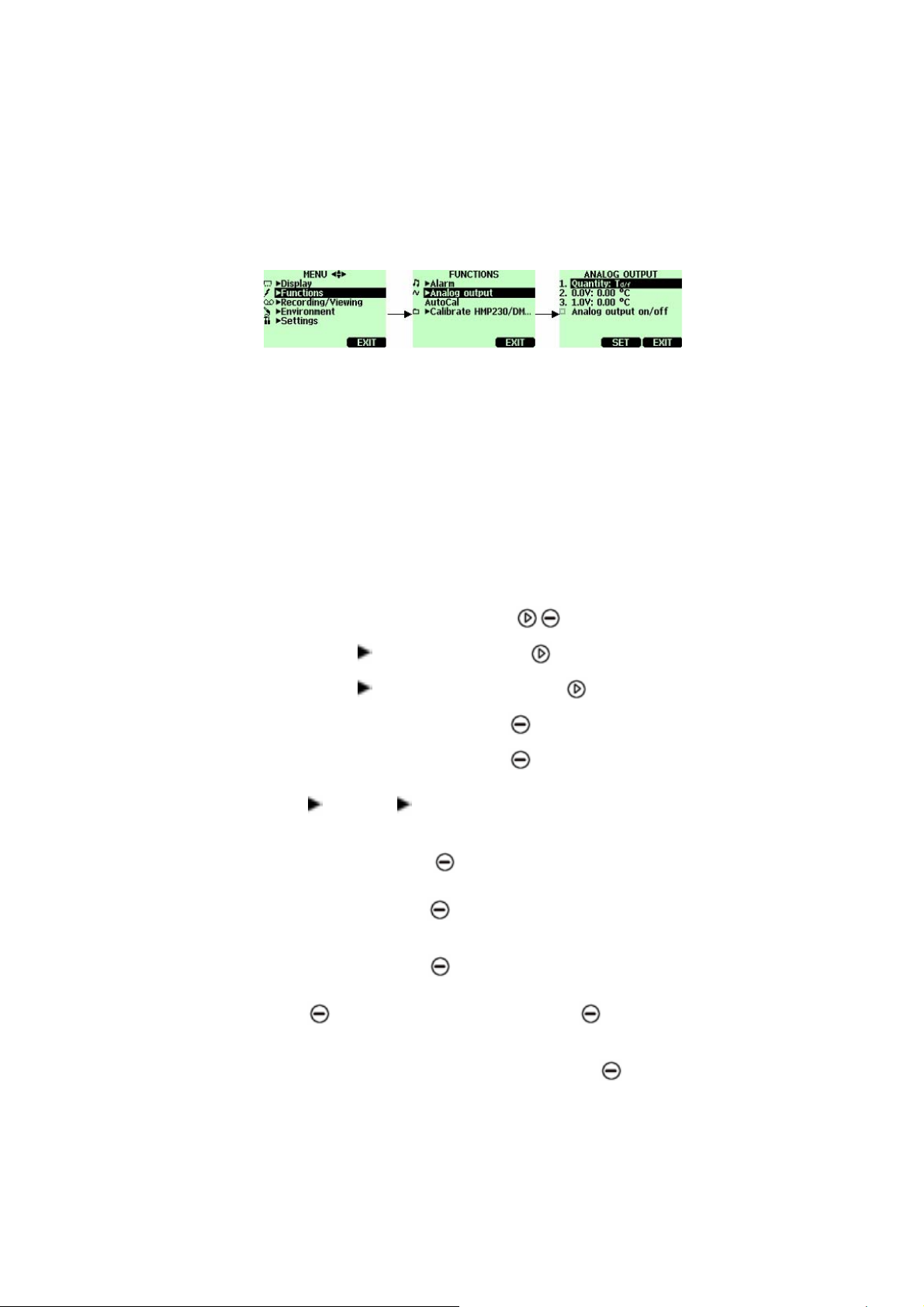

Recording/Viewing Menu

Recording Data

Figure 12 Recording

You can record measurement data and view it on the display. Do the

following:

0403-043

1. Press

Recording/Viewing.

2. Select Record data and press .

32 __________________________________________________________________ M010091EN-F

Record or open the menu and select

Page 35

Chapter 5 _____________________________________________________________User Interface

3. To change the recording interval, select Interval and press

Set.

4. Select the measurement interval with the arrow buttons. The

measurement intervals and the maximum recording times are

shown in Table 1 on page 33.

Table 1 Measurement Intervals and Maximum

Recording Times

Maximum Recording Time (Memory Full) Measure-ment

Interval

1 s 45 min 22 min 15 min

5 s 3 h 113 min 75 min

15 s 11 h 5 h 3 h

30 s 22 h 11 h 7 h

1 min 45 h 22 h 15 h

5 min 9 days 4 days 3 days

15 min 28 days 14 days 9 days

30 min 56 days 28 days 18 days

1 h 113 days 56 days 37 days

3 h 339 days 169 days 112 days

12 h 1359 days 678 days 451 days

1 quantity 2 quantity 3 quantity

CAUTION

5. Press Select.

6. To set the duration of the recording, select Duration and then

press Set. Select the duration with the arrow buttons and

press Set.

7. To start recording, select Start/Stop recording , press Start.

If you choose Memory full, you will see the maximum recording

time on the display. You can also delete files to empty the

memory. To accept the maximum recording time, press

Start again.

8. You can switch off DM70 during recording to save the battery.

A message will appear on the display to inform that recording

will continue undisturbed even when the power is turned off. If

the indicator is switched off during recording, the progress bar is

shown on the display every 10 seconds (continuously if the

charger is connected). The bar indicates the amount of recorded

data.

Do not disconnect the probe when the data recording is on, even if

the indicator is turned off. This may cause loss of recorded data.

VAISALA_______________________________________________________________________ 33

Page 36

USER'S GUIDE____________________________________________________________________

Stopping Recording

1. To stop recording, press Record.

2. Select Record data and press .

3. Then select Start/Stop recording and press Stop.

4. To view the recorded file, select Show.

View Recorded Data

1. Open the menu by pressing Open.

2. Select Recording/Viewing and press .

3. Select

4. Select the file you want to view and press

identified according to the starting date and time of recording.

5. To go to the graphical view, press Graph. To view the

recording time stamps, press Times. To return to the

recording values, press Values.

6. To return to the basic display, press Exit.

View recorded data and press .

. The files are

Memory Status

You can check the memory status as follows:

1. Open the menu by pressing Open.

2. Select

3. To view the amount of memory that is in use and the estimated

free space left, select Memory status and press

Recording/Viewing and press .

Show.

4. To return to the basic display, press OK and

Exit.

NOTE

34 __________________________________________________________________ M010091EN-F

The estimate of available free space is calculated for the current

number of active quantities. If you change the displayed quantities,

the estimate will change accordingly.

Page 37

Chapter 5 _____________________________________________________________User Interface

Clear Data Memory

The data memory can be cleared as follows:

1. Open the menu by pressing Open.

2. Select Recording/Viewing and press .

3. Select Clear data memory and press Clear. To confirm the

deletion, press Yes.

4. To return to the basic display, press

Exit.

Transferring Recorded Data to PC

The recorded data can be transferred to a PC using the MI70 Link

program. The MI70 Link program can be ordered from Vaisala, see

section Accessories on page 107. You can examine the recorded data

easily in the Microsoft Windows® environment and transfer it further

on a spreadsheet program, such as, Microsoft Excel® for

modifications. Together with the USB instrument cable (optional

accessory 219687) or the serial connection cable it is easy to transfer

logged and real time measurement data from the DM70 to a PC.

When using the USB cable consider the following: the MI70 Link

program contains the driver needed for the USB connection. For the

system requirements and installation, see the back of the installation

CD. Follow the installation instructions on the CD. Check that the

USB cable is not connected. The MI70 Link Setup Wizard will install

Vaisala MI70 Link on your computer. Installing the USB instrument

driver can take a few minutes. After the installation is finished,

connect the USB cable to the USB port on your PC. Windows will

detect the new device, and use the driver automatically.

You can now start monitoring the DM70 readings in real time with a

PC using the MI70 Link program. In case the MI70 Link cannot find

the instrument, check the following:

- the DM70 is switched on

- the USB instrument cable/serial connection cable is properly

connected to the USB/serial port of your PC

- another application has not reserved the connection

VAISALA_______________________________________________________________________ 35

Page 38

USER'S GUIDE____________________________________________________________________

Environment Menu

Pressure Settings

In pressurized environments, the actual process pressure value must be

set for DM70. The pressure can be given in the following units:

P

Gauge pressure is given in the unit of bar. It

barg:

indicates the pressure difference between the normal

atmospheric pressure and the actual process pressure.

P

P

Absolute process pressure is given in the unit of bar.

bara:

Gauge pressure is given in the unit of psi. It indicates

psig:

the pressure difference between the normal

atmospheric pressure and the actual process pressure.

P

To set the values, follow the instructions below:

1. Open the menu by pressing Open.

2. Select Environment with and then press . See Figure

Absolute pressure is given in the unit of psi.

psia:

13 below.

0403-036

Figure 13 Environment Menu

3. To change the pressure unit, press Unit. The default unit is

barg.

4. To set the ambient pressure value, press Set.

5. Set the value using the buttons. To change the sign of

the pressure value, press

OK.

6. To return to the basic display, press

36 __________________________________________________________________ M010091EN-F

+/-. To save the value, press

Exit.

Page 39

Chapter 5 _____________________________________________________________User Interface

Settings Menu

User Interface

0403-038

Figure 14 User Interface

Language

You can select any of the following languages for the user interface:

English, Finnish, Chinese, Russian, Japanese, Swedish, French,

German, or Spanish.

To select the language, follow the instructions below:

1. Open the menu by pressing Open.

2. Select Settings and then press .

3. Select User interface and then press .

4. Select Language and press Set.

5. Then select the desired language and press Select.

6. To return to the basic display, press

Exit.

If you accidentally selected a language you do not want, follow the

instructions below:

1. Return to the basic display by pressing the rightmost

the basic display appears.

2. Go to the Language selection menu by pressing first and

then the button in the middle.

3. Then press , then , then again and finally press again

the button in the middle.

4. Reselect the language.

VAISALA_______________________________________________________________________ 37

until

Page 40

USER'S GUIDE____________________________________________________________________

Automatic Power Off

As a default, the power in DM70 is automatically turned off after 15

minutes of inactivity. This also saves the battery. The inactivity

settings can be changed to 60 minutes or completely turned off. See

the instructions below:

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select User interface and press .

4. Select Auto power off and press Set.

5. Select the inactivity time and press

6. To return to the basic display, press

Select.

Exit.

Program Shortcut Keys

As a default, the three shortcut keys refer to Graphic, Hold/Save, and

Start/S functions. You can change any of the shortcut keys to refer

to functions that better suit your needs. See the instructions below:

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select User interface and press .

4. Select Program shortcut keys and then press

Start.

5. Press the shortcut key you want to change, for example,

Hold/Save.

6. If you want to replace the Hold/Save with the auto-calibration

function, select AutoCal with the arrow buttons and then press

Select. To confirm you selection, press Yes. Otherwise press

No and continue from step 4.

7. To return to the basic display, press Exit

38 __________________________________________________________________ M010091EN-F

Page 41

Chapter 5 _____________________________________________________________User Interface

0403-039

Figure 15 Hold/Save Replaced by Auto Cal

Button Tones and Backlight

You can turn on or off the sound effects for the buttons and the back

light. Follow the instructions below:

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select User interface and press .

4. To turn on or off the sound effect, select Key Click and then

press On/Off.

5. To turn on or off the backlight, select Backlight on key and

press On/Off.

6. To return to the basic display, press

Exit.

Date and Time

As a default, the time format is based on the 24-hour clock. Also a 12hour clock can be used.

The default date format is day.month.year, for example, 25.4.2004.

The date format can be changed to month.day.year. or

year.month.day.

For correct time and date in the recorded data files, follow the

instructions below:

1. Open the menu by pressing

2. Select

VAISALA_______________________________________________________________________ 39

Settings and press .

Open.

Page 42

USER'S GUIDE____________________________________________________________________

3. Select Date and time and press .

4. For the desired date, select Date and then press Set. Use the

arrow buttons to change the date. Confirm the selection by

pressing Select. To change the date format, select from the

alternatives and press Select.

5. For the desired time, select Time and press Set. Use the

arrow buttons to change the time. To confirm the selection,

press OK. To change the time format, select 12-hour clock

and press On/Off .

6. To return to the basic display, press Exit.

Measurement Settings

0602-006

Figure 16 Measurement Settings Menu

Automatic Auto-Calibration

To turn the feature on, press On. To turn the feature off, press

Off.

Automatic Purge

To turn the feature on, press On. To turn the feature off, press

Off.

Molecular Weight

The ppmw M setting is used to give the molecular weight of the

measured gas. This value is required in ppmw (weight) calculation.

40 __________________________________________________________________ M010091EN-F

Page 43

Chapter 5 _____________________________________________________________User Interface

The default values are 28.96 for DMP74A/B (air) and 146.06 for

DMP74C (SF6).

Purge Interval

The time interval at which the automatic sensor purge is performed

can be changed between 1 ... 48 hours. For instructions, refer to

section Changing Automatic Sensor Purge Interval on page 30.

Device Information

0403-040

Figure 17 Device Information

Basic information about the indicator and the probe is found as

follows:

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select Device information and press Show.

4. The first display gives the information on the MI70 indicator.

For details on the probe, press

See Figure 18 below.

5. To return to the basic display, press

More and then press OK.

Exit.

VAISALA_______________________________________________________________________ 41

Page 44

USER'S GUIDE____________________________________________________________________

0403-041

Figure 18 Indicator and Probe Information

The following numbers refer to Figure 18 above.

1 = Software version of the MI70 indicator

2 = Serial number of the MI70 indicator

3 = Probe type

4 = Software version of the probe

5 = Serial number of the probe

Factory Settings

The factory settings can be restored to clear all the changed settings

and data memory of the indicator. Restoring factory settings does not

affect the probe calibration.

1. Open the menu by pressing Open.

2. Select Settings and press .

3. Select Factory settings and press

selection, press

Yes. Power is turned off automatically.

Revert. To confirm the

When turning on DM70 again, the factory settings are restored. You

will have to set the language, date, and time again.

42 __________________________________________________________________ M010091EN-F

Page 45

Chapter 6 ____________________________________ Field Calibration Check of Fixed Transmitters

CHAPTER 6

FIELD CALIBRATION CHECK OF FIXED TRANSMITTERS

To compare measurement readings or to read the output of a fixed

transmitter directly on the DM70 display, connect DM70 to a fixed

Vaisala transmitter using the connection cable accessories.

Vaisala DRYCAP® Dewpoint and Temperature Transmitter Series

DMT340 can be adjusted in laboratory conditions using DM70 as a

reference. Please refer to Chapter 9, Calibration, Adjustment, and

Maintenance on page 65 for more information.

Field Calibration Check of DMT340/DMT242/DMT142

You can use DM70 to display the reading of DMT340, DMT242 or

DMT142 and to compare the readings of DM70 and

DMT340/DMT242/DMT142.

To connect DMT340 you need connection cable 211339. For

DMT242, you will need the 27160ZZ cable and for DMT142, you

will need the 211917ZZ cable (see section Accessories on page 89).

For field calibration check, follow the instructions below.

1. Turn off DM70.

2. Connect the cable between DMT340 (service port) or

DMT242/DMT142 (serial port) and DM70 (connector I or II).

Turn on both the devices.

VAISALA_______________________________________________________________________ 43

Page 46

USER'S GUIDE____________________________________________________________________

3. If you are requested to check the environment settings, press

Yes. Then check the pressure settings. To set the ambient

pressure, see section Pressure Settings on page 36.

4. Check that the pressure units of DM70 and

DMT340/DMT242/DM142 are the same.

If not, and you are checking DMT242/DMT142, change the

DM70 pressure unit to bara by pressing Unit on the

corresponding row. You cannot change the pressure unit for

DMT242/DMT142. Then adjust the values as instructed in

section Pressure Settings on page 36.

When using DM70 to check DMT340, you can change the

pressure unit of DMT340 by pressing Unit on the

corresponding row. It is also possible to change the pressure unit

of DMT340 through the transmitters local display/keypad

interface, for instructions, please refer to the DMT340 User's

Guide. Then adjust the values as instructed in section Pressure

Settings on page 36.

5. When the pressure settings are correct, press Exit. Now the

display shows the dewpoint readings T

DMT340/DMT242/DMT142, and the difference between the

readings ∆T

Roman numerals (I and II) after the quantity

d/f.

abbreviations indicate from which port the readings are coming.

You can follow the measurement trend from the graphical

display.

6. Wait until the readings are stabilized. It can take up to one hour

in very low dewpoints. If the difference between the dewpoint

readings is less than 3 ˚C, there is no immediate need for

adjustment. However, in applications where optimum accuracy

is essential, it is recommended to send the

DMT340/DMT242/DMT142 transmitter to Vaisala (see section

Vaisala Service Centers on page 78) when the difference is

considered significant.

7. Press the Power On/Off button.

8. Disconnect the connection cable.

Field Calibration Check of DMP248

of DM70,

d/f

You can use DM70 to display the readings of DMP248 and to

compare readings of DM70 and DMP248. To make the connection,

you will need the 27159ZZ cable. See section Accessories on page 89.

44 __________________________________________________________________ M010091EN-F

Page 47

Chapter 6 ____________________________________ Field Calibration Check of Fixed Transmitters

1. Connect the cable between DMP248 (connector X5,

6-pin connector on the left of the motherboard) and DM70

(connector I or II). Turn on both the devices.

2. Open the menu by pressing Open.

3. Select Functions and press .

4. Select Calibrate transmitters and press .

5. Select 1. Baud rate and 2.Serial format. To change the serial

settings, press Set. The serial settings of DMP248 and DM70

must be the same. As a default, the DMP248 serial settings are

4800 bps, 7 Even.

6. Select 3. Start calibration and press

Start. If the serial settings of DM70 are not compatible with

the settings of DM248, or the cable connection is not working,

the following message appears:

0405-007

Figure 19 Calibrate Transmitters Message

Check that the serial settings of DMP248 and the settings of

DM70 are the same. Check the cable connection. Then retry

from step 6.

7. After the connection has been established, press

OK.

8. Select the qu antity to check (Td or T) and press

Select.

9. Check the environment settings of the DM70 probe, if needed.

Press Yes or No.

10. The measurement value of DMP248 is shown on the upper row

and the value of DM70 on the second row. The third row shows

the difference between the measurements of DMP248 and

DM70.

VAISALA_______________________________________________________________________ 45

Page 48

USER'S GUIDE____________________________________________________________________

11. Wait until the readings are stabilized (can take one hour in very

low dewpoints). If the difference between the dewpoint readings

is less than 3 ºC, there is no immediate need for adjustment.

However, in applications where best possible accuracy is

essential, it is recommended to send the DMP248 transmitter to

Vaisala (see section Vaisala Service Centers on page 78) if the

difference is considered significant.

12. To return to the basic display, press Exit.

46 __________________________________________________________________ M010091EN-F

Page 49

Chapter 7 ____________________________________________________Sampling from Processes

CHAPTER 7

SAMPLING FROM PROCESSES

When the dewpoint of a process needs to be measured using DM70,

the process can be sampled using one of the following devices:

- DSC74

- DSC74B

- DSC74C

- DSS70A

- DMT242SC

- DMT242SC2

Use the DSC74 sampling cell when the sample is taken from the

pressurized process, where the process pressure forces the sample gas

into the sample cell.

Use the DSC74B sampling cell as DSC74. DSC74B is enhanced

version of DSC74. With version B, harmful gases can be recovered.

DSC74C complements DSC74B with a diffusion coil, which allows

measuring in the atmospheric pressure.

Use the DSS70A sampling system when the process is not

pressurized, that is, the sample must be pumped from the process and

when the process is dirty or too hot for direct measurements.

Use the DMT242SC sampling cell when only the body (thread 3/8"G

and 1/4"G) of the main sampling cell is needed.

Use the DMT242SC2 sampling cell with the welded Swagelok

connectors. This is ideal for sampling in a 1/4" pipeline.

VAISALA_______________________________________________________________________ 47

Page 50

USER'S GUIDE____________________________________________________________________

Sampling Cells

DSC74

- sampling cell with a leakage screw, thread 3/8"G

- quick coupling, type NIP08, type D

- thread adapter, type 3/8" - 1/4"G

- thread adapter, type 3/8" - 1/2"G (for DMP248 and DMT242

fittings)

0403-047

Figure 20 DSC74 Sampling Cell with the Adapters

The following numbers refer to Figure 20 above.

1 = Thread adapter type 3/8" - 1/2"G

2 = Thread adapter type 3/8" - 1/4"G

3 = NIP08, type D

4 = Leakage screw

5 = Sampling cell DSC74

48 __________________________________________________________________ M010091EN-F

Page 51

Chapter 7 ____________________________________________________Sampling from Processes

DSC74B

- sampling cell, thread 3/8"G

- connection part with a needle valve and an integrated leakage

screw

- Reducing Nipple (thread adapter), 3/8"G - 1/2"G

- Reducing Adapter (thread adapter), 3/8"G - 1/4"G

0403-111

Figure 21 DSC74B

The following numbers refer to Figure 21 above.

1 = Gas goes in

2 = Gas comes out

DSC74C

- sampling cell, thread 3/8"G

- connection part with a needle valve and an integrated leakage

screw

- Reducing Nipple (thread adapter), 3/8"G - 1/2"G

- Reducing Adapter (thread adapter), 3/8"G - 1/4"G

- diffusion coil (for measurements in atmospheric pressure)

VAISALA_______________________________________________________________________ 49

Page 52

USER'S GUIDE____________________________________________________________________

0403-112

Figure 22 Default Assembly of DSC74C

The following numbers refer to Figure 22 above.

1 = Gas goes in. Also the coil can be used here.

2 = Gas comes out

3 = Coil

4 = Valve

50 __________________________________________________________________ M010091EN-F

Page 53

Chapter 7 ____________________________________________________Sampling from Processes

0403-113

Figure 23 Alternative Assembly of

DSC74C for Tight Spaces

The following numbers refer to Figure 23 above.

1 = Gas comes out

2 = Coil

3 = Thread, max. size 7 mm

4 = Gas goes in

5 = Valve

The thread size cannot exceed 7 mm. Use the provided adapter to

avoid damage to the probe.

VAISALA_______________________________________________________________________ 51

Page 54

USER'S GUIDE____________________________________________________________________

DMT242SC

DMT242SC is a sampling cell with threads 3/8"G and 1/4"G. See

Figure 24 on page 52.

DMT242SC2

DMT242SC2 is a sampling cell with 1/4" welded Swagelok

connectors. See Figure 24 below.

0405-013

Figure 24 DMT242SC and DMT242SC2 Sampling Cells

Connection to Pressurized Processes Using the DSC74 Sampling Cell

DSC74 is a Vaisala sampling cell for connecting DM70 to the