Page 1

CEILOMETER

CT25K

User’s Guide

CT25K-U059en-2.1

26 February 1999

Vaisala 1999

Page 2

© Vaisala 1999

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents be

communicated to a third party without prior written permission of the

copyright holder.

The contents of instruction manuals are subject to change without prior

notice.

Page 3

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Contents

LIST OF FIGURES............................................................................................................ IV

INTRODUCTION TO M ANUAL ........................................................................................ VII

VALIDITY OF T HIS M ANUAL.........................................................................................VIII

SAFETY SUMM ARY.........................................................................................................IX

1. GENERAL INFORMATION....................................................................................... 1

1.1 Product Overview.......................................................................................... 1

1.2 Specifications................................................................................................ 3

1.2.1 Mechanical................................................................................... 3

1.2.2 External Connector J1 - Window conditioner ................................ 3

1.2.3 External Connector J2 - Power inpu t ............................................ 3

1.2.4 Output Interface ........................................................................... 4

1.2.4.1 External Connector J3 - Data line................................................. 4

1.2.4.2 External Connector J4 - Mainte nanc e li ne .................................... 6

1.2.5 Modem Options ............................................................................ 6

1.2.5.1 Modem board DMX5 5................................................................... 6

1.2.5.2 Modem board DMX5 0................................................................... 7

1.2.5.3 ANet Interface DMX611............................................................. 7

1.2.6 Transmitter................................................................................... 8

1.2.7 Receiver....................................................................................... 8

1.2.8 Optical System ............................................................................. 9

1.2.9 Performance ................................................................................. 9

1.2.10 Environmenta l Con ditio ns............................................................. 9

2. INSTALLATION ...................................................................................................... 10

2.1 Unloading and unpacking........................................................................... 10

2.2 Foundation................................................................................................... 11

2.3 Assembling the Unit.................................................................................... 12

2.4 Using the Tilt Feature.................................................................................. 14

2.5 Cable Connections...................................................................................... 15

2.6 Grounding.................................................................................................... 16

2.7 Connection of Maintenance Terminal ........................................................ 17

3. START UP.............................................................................................................. 19

3.1 Start up procedure ...................................................................................... 19

3.1.1 Mobile operation aspects............................................................ 21

3.2 Verification of Proper Op eration ................................................................ 21

3.3 Settings for Normal Operation.................................................................... 22

3.4 Factory settings of user progra mmable p arameter s................................. 22

4. OPERATION........................................................................................................... 25

4.1 Operation Modes ......................................................................................... 25

4.2 Serial Lines. Open and Closed Port ........................................................... 25

4.3 User Commands .......................................................................................... 27

4.4 Data Messages ............................................................................................ 33

i

Page 4

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

4.4.1 Data Message No. 1 ...................................................................33

4.4.2 Data Message No. 2 ...................................................................36

4.4.3 Data Message No. 3 ...................................................................38

4.4.4 Data Message No. 4 ...................................................................39

4.4.5 Data Message No. 5 ...................................................................39

4.4.6 Data Message No. 6 ...................................................................39

4.4.7 Data Message No. 7 ...................................................................40

4.4.8 (Spare) .......................................................................................41

4.4.9 (Spare) .......................................................................................41

4.4.10 DMX611 operation ( optio n) .........................................................41

4.4.11 Status Message "S" .................................................................... 42

4.4.12 Manual Message .........................................................................45

4.5 Polling mode ................................................................................................45

4.6 Prevailing parameter settings .....................................................................46

4.7 Manual angle setting ...................................................................................47

5. FUNCTIONAL DESCRIPT ION ................................................................................49

5.1 Theory of Operation.....................................................................................49

5.2 Technical Description..................................................................................53

5.2.1 General .......................................................................................53

5.2.2 LIDAR Measurement ...................................................................55

5.2.3 Internal Monitorin g and Co ntrol...................................................58

5.3 Module Descriptions....................................................................................58

5.3.1 Optical Subassem bly CTB22.......................................................58

5.3.2 Laser Transmitter CT T 21............................................................59

5.3.3 Receiver CTR21 .........................................................................60

5.3.4 Optics Monitor CTL21 .................................................................61

5.3.5 Board Frame DMF51 ..................................................................62

5.3.6 Processor Board DMC50B ..........................................................63

5.3.7 DC Converter DPS52.................................................................. 67

5.3.8 Ceilometer Interface Board DCT 51 .............................................69

5.3.9 Line and Power Int erface S ubas sem bly CT P241 ........................70

5.3.10 Internal Heaters Subas sem bl y CT25039.....................................72

5.3.11 Tilt Angle Sensor CT3675 ...........................................................73

5.3.12 Window Conditioner CT 2614 / CT2688 .......................................74

5.3.13 Maintenance Term inal PSION 3 (Optio n) .....................................75

5.3.14 Modem DMX55 (Opti on) .............................................................76

5.3.15 Modem DMX50 (Opti on) .............................................................78

5.3.16 DMX611 ANet Interface (Option)..............................................80

5.4 Sky Condition Algorithm .............................................................................83

5.4.1 General.......................................................................................83

5.4.2 Option code ................................................................................83

5.4.3 Activation.................................................................................... 83

5.4.4 Algorithm overvie w......................................................................84

6. PERIODIC M AINTENANCE ....................................................................................87

6.1 Alarms and warnings...................................................................................87

6.2 Window Cleaning .........................................................................................87

6.3 Battery check ...............................................................................................88

6.4 Storage.........................................................................................................88

7. TROUBLESHOOTING ............................................................................................89

7.1 Normal Operation .........................................................................................89

7.1.1 Equipment ..................................................................................89

ii

Page 5

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

7.1.2 Instructions ................................................................................. 89

7.2 Troubleshooting.......................................................................................... 93

7.2.1 Warnings.................................................................................... 93

7.2.2 Alarms........................................................................................ 96

7.2.3 Miscellaneous............................................................................. 97

7.3 Failure Diagnosis ........................................................................................ 98

8. REPAIR.................................................................................................................. 99

8.1 General......................................................................................................... 99

8.2 Writing conventions used........................................................................... 99

8.3 Start-up procedure for replacem ent (all parts).........................................100

8.4 Transmitter CTT21......................................................................................101

8.4.1 Removal....................................................................................101

8.4.2 Replacement .............................................................................102

8.4.3 Compensation a djustm ents .......................................................105

8.5 Receiver CTR21 ..........................................................................................108

8.5.1 Removal....................................................................................108

8.5.2 Replacement .............................................................................109

8.5.3 Coaxial Cable Rep lacem ent ......................................................111

8.5.3.1 Removal....................................................................................111

8.5.3.2 Replacement .............................................................................112

8.6 Compensation Fiber...................................................................................113

8.6.1 Compensation Fi ber re placem ent..............................................113

8.7 Optics Monitor CTL21 ................................................................................114

8.7.1 Removal....................................................................................114

8.7.2 Replacement .............................................................................115

8.8 Boards of Board Fram e DM F51 .................................................................116

8.8.1 Removing boards ......................................................................116

8.8.2 Replacing boards ......................................................................117

8.8.2.1 Parameter settings of Ceilom eter I nterfac e bo ard DCT5 1 .......... 117

8.9 Line & Power Subassembly CTP241 .........................................................117

8.9.1 Removal....................................................................................117

8.9.2 Replacement .............................................................................119

8.9.3 Internal Heater S ubas sem bly CT25 03 9 Rep lacem ent ................ 120

8.9.4 Battery 4592 replac em ent instruc tions.......................................121

INDEX.......................................................................................................................... ... 123

iii

Page 6

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

LIST OF FIGURES

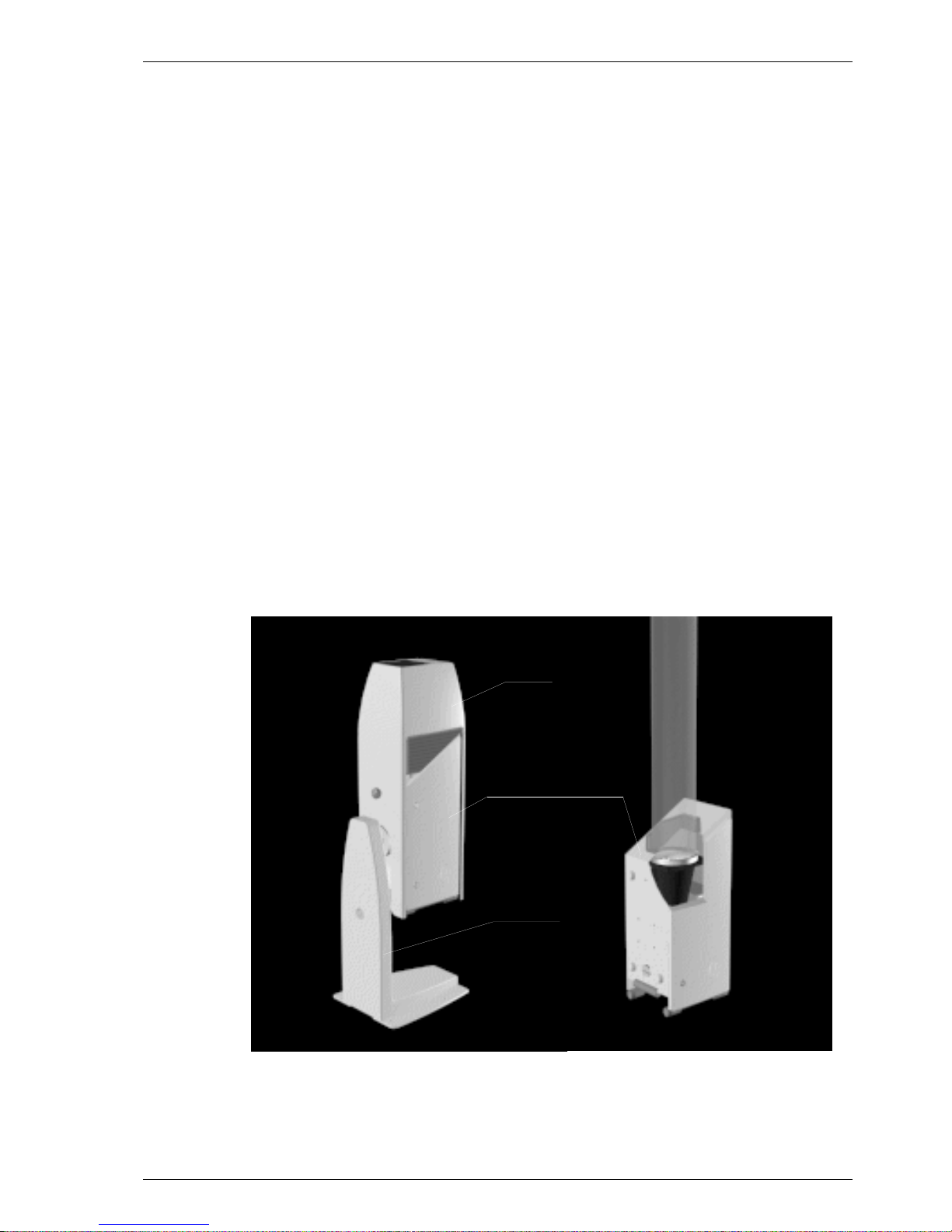

Figure 1-1 Ceilometer CT25K ..........................................................................................1

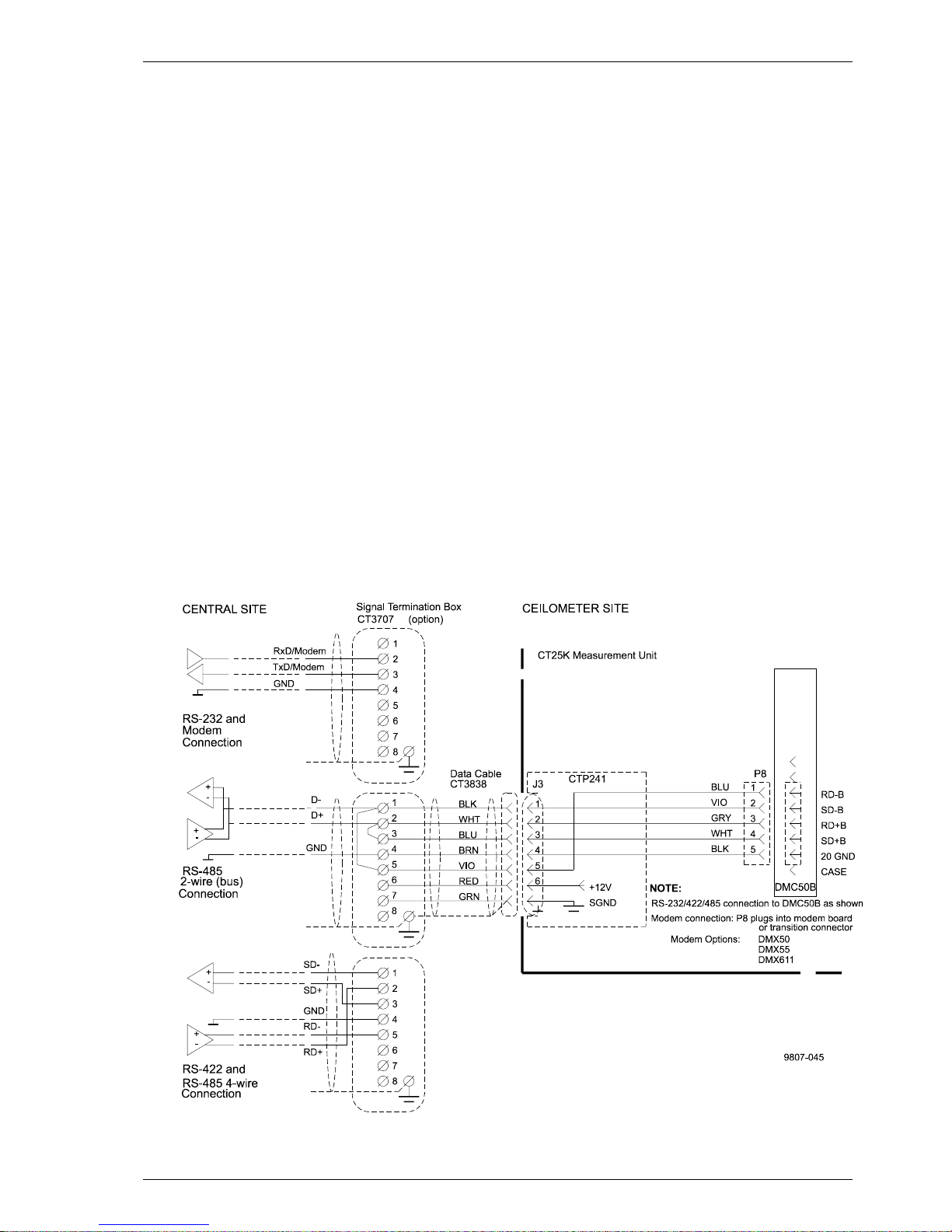

Figure 1-2 Data Line Connection Options......................................................................... 5

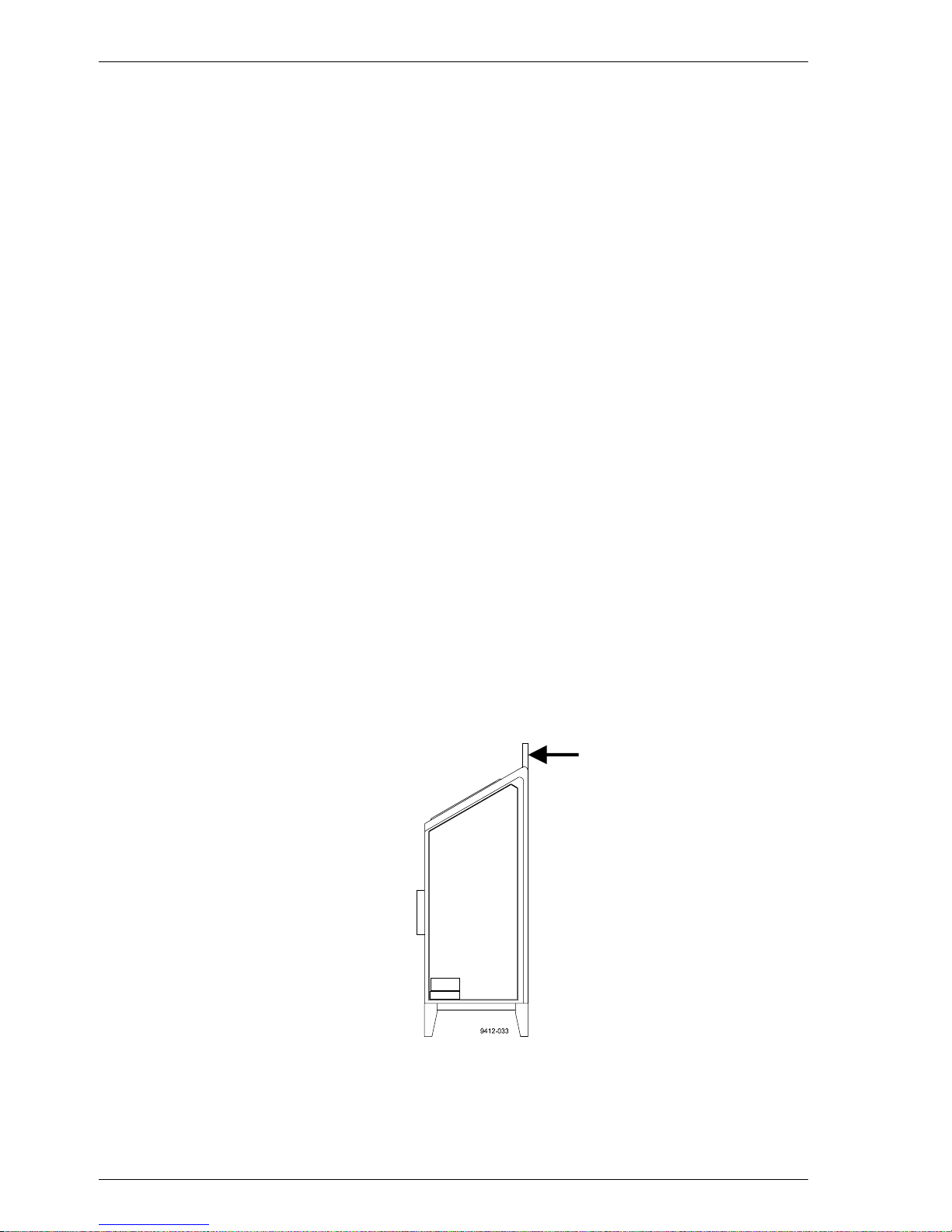

Figure 2-1 Measurement Unit Handle.............................................................................10

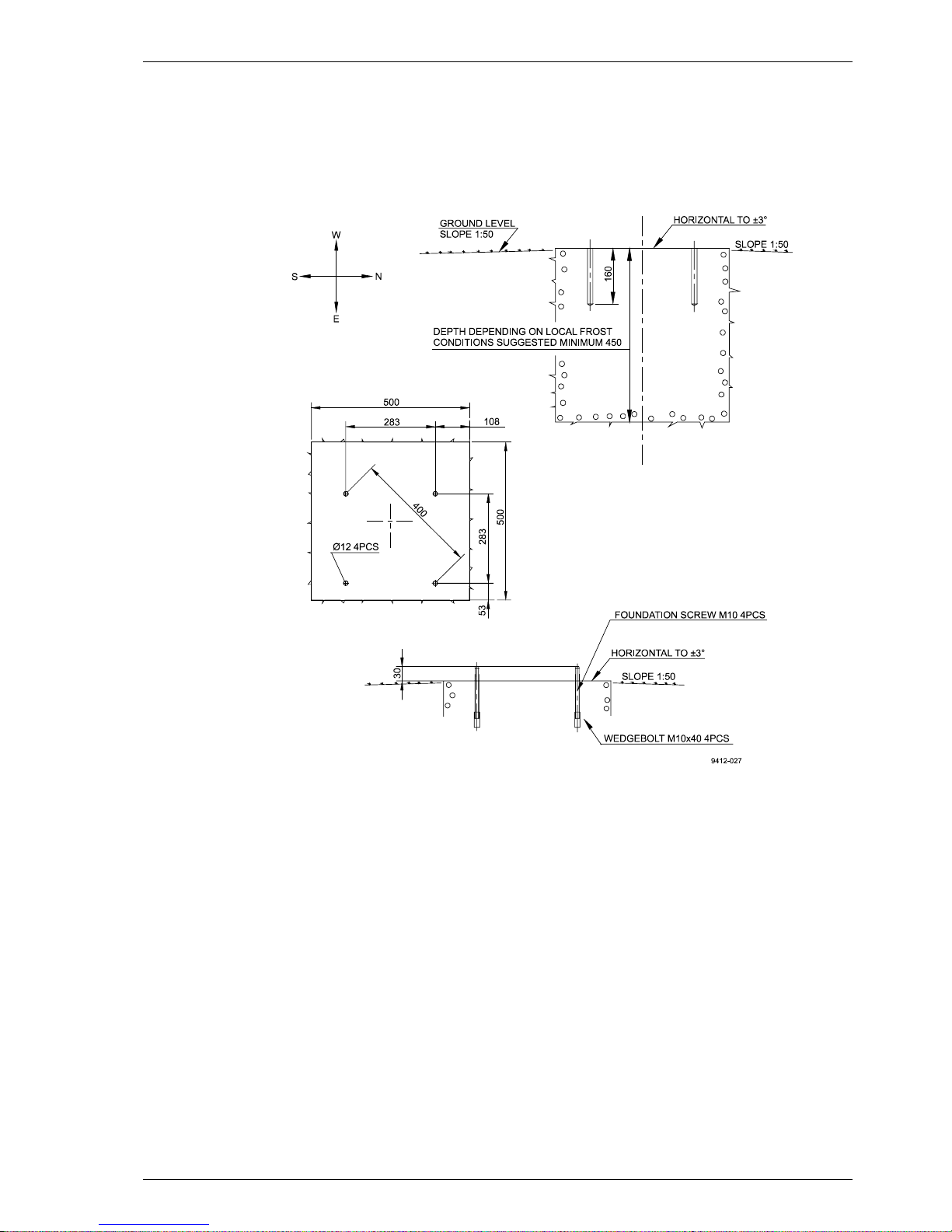

Figure 2-2 Foundation Construction ...............................................................................11

Figure 2-3 Mounting the Pedestal ................................................................................... 12

Figure 2-4 Attaching the Measurement Unit and the Shield............................................13

Figure 2-5 External Connectors (bottom view) ...............................................................15

Figure 2-6 Termination Box Wire Connections .............................................................. 16

Figure 3-1 CT25K Switches and LEDs...........................................................................20

Figure 4-1 Operation Modes........................................................................................... 25

Figure 4-2 Open and closed port.....................................................................................26

Figure 5-1 Typical Measurement Signal .........................................................................49

Figure 5-2 Measurement Unit Components .....................................................................53

Figure 5-3 Subassembly Interconnections.......................................................................54

Figure 5-4 Block Diagram of Operational Units ............................................................. 56

Figure 5-5 Optical Subassembly CTB22 with Optics Monitor, Transmitter and Receiver

Subassemblies ............................................................................................... 58

Figure 5-6 CTT21 Block Diagram ..................................................................................59

Figure 5-7 CTR21 Block Diagram..................................................................................60

Figure 5-8 CTL21 Block Diagram ..................................................................................61

Figure 5-9 DMF51 Frame...............................................................................................62

Figure 5-10 DMC50B Block Diagram ............................................................................63

Figure 5-11 DIP Switch Settings of the DMC50............................................................. 66

Figure 5-12 DPS52 Block Diagram................................................................................. 67

Figure 5-13 DCT51 Block Diagram................................................................................69

Figure 5-14 CTP241 Wiring ...........................................................................................71

iv

Page 7

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Figure 5-15 CT25039 Wiring Diagram .......................................................................... 72

Figure 5-16 CT3675 Tilt Angle Sensor.......................................................................... 73

Figure 5-17 Window Conditioner CT2614/CT2688 ....................................................... 74

Figure 5-18 RS Cable..................................................................................................... 75

Figure 5-19 DMX55 Block Diagram.............................................................................. 76

Figure 5-20 DMX50 Block Diagram.............................................................................. 78

Figure 5-21 DMX611 Block Diagram............................................................................ 80

Figure 8-1 Board Connectors of the DMF51 Board Frame............................................101

Figure 8-2 Removing the Laser Transmitter..................................................................102

Figure 8-3 Adjusting the compensation.........................................................................106

Figure 8-4 Adjusting the compensation.........................................................................107

Figure 8-5 Removing the Receiver ................................................................................ 109

Figure 8-6 Removing the Optics Monitor ......................................................................115

Figure 8-7 Boards of the DMF51 Board Frame.............................................................116

Figure 8-8 Removing Line and Power Interface Subassembl y CTP241 .........................119

Figure 8-9 Internal heater replacement..........................................................................121

Figure 8-10 Battery replacement...................................................................................122

v

Page 8

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

This page intentionally left blank.

vi

Page 9

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

INTRODUCTION TO MANUAL

The purpose of this User’s Guide is to be a general information source as well

as a detailed operational guide for the user of Ceilometer CT25K.

This document is divided into 8 chapters. Chapter 1 offers an overview and

technical specifications of the CT25K Ceilometer. The following chapters 2

and 3 contain installation and start up instructions. Operational instructions

with user commands and data messa ges are included in chapter 4. Chapter 5

includes functional description of the Ceilometer and chapters 6, 7 and 8

instructions for maintenance, troubleshooting and repair.

vii

Page 10

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

VALIDITY OF THIS M ANUAL

This manual covers ceilometer CT25K in all its configurations as defined by

the parts and options listed in section 1.1, running under software re vision

CT25K- 2.01 or 2.01a

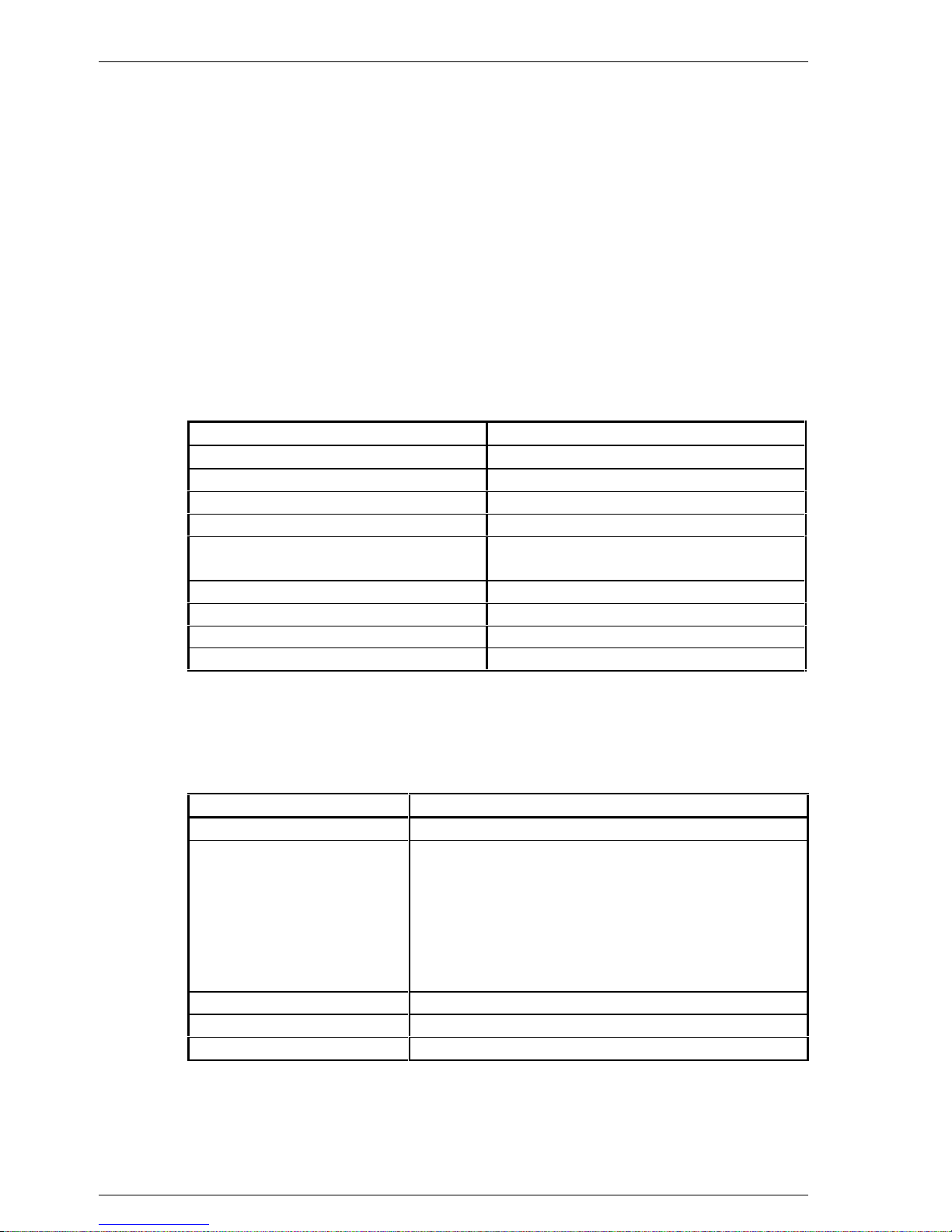

Table 1-1 lists the revision history that may apply in comparison to other units

in use:

Software revision s Description

CT25K-1.01 First Release

CT25K-1.02 Intermediate release (not in us e)

CT25K-1.03 Intermediate release (not in us e)

CT25K-1.04 Production rev. 95-05-15...97-02-03

CT25K-1.04h Special rev. with Qualimetrics and

DR21 messages

CT25K-1.05 Production rev. 97-02-03...

CT25K-2.00 Production rev. 97-11-01...

CT25K-2.01 Production rev. 98-03-17...

CT25K-2.01a Production r ev. 99-02-09…

Table 1-1 Software Revisions

Table 1-2 lists the hardware history that may apply in comparison to other

units in use:

Hardware history Description

CT25K model A First Release

CT25K model B Enclosur e CT1669 replaced with CT15035.

Model A pedestal CT2665 (Fiberglass) is option

New Metal Pedestal CT25106 is standard.

Line and Power Interface Subassembly CTP21

changed to CTP241.

Internal Heaters Subassembl y CT2690 replaced

with CT25039.

CTB22 Replaces CTB21 since 97-05-26

DMC50B Replaces DMC50A since 97-11-05

DPS52 Replaces DPS51

Table 1-2 Hardware Hi sto ry

viii

Page 11

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

SAFETY SUMMARY

The following safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to compl y with these

precautions or with specific wa rnings elsewhere in this manual violat es safety

standards of design, manufacture, and intended use of the instrument.

VAISALA assumes no liability for the customer’s failure to comply with these

requirements.

LASER SAFETY

The CT25K is officially certified as a Class 1 laser device in accordance with

European standard EN 60 825-1:1994. It is also classified in accordance w ith

U.S. regulation 21 CFR 1040 as a Class 1 laser device. This means that a

CT25K Ceilometer installed in a field environment with instrument covers on

and pointed vertically or near-vertically poses no established biological

hazard to humans.

The device is equipped with the following label:

The instrument is intended for operation in an area restricted from public

access, and to be pointed vertically or near-vertically up. The following

precautions are to be noted and followed during service and maintenance of

the instrument:

• Never look directly into the Laser Transmitter with magnifying optics

(glasses, binoculars, telescopes, etc.)

• When operating, avoid looking at the ceilometer unit from the beam

direction. When tilting the unit, make sure that it is not being viewed from

the beam direction with magnifying optics.

• Only trained personnel should perform maintenance fun ctions. Work area

access by unauthorized persons during service operations must be

prevented.

ix

Page 12

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be

connected to an electrical ground. The instrument is equipped with a

three-conductor AC power connector. The power cable must either be

plugged into an approved three-contact electrical outlet or the instrument must

be carefully earthed to a low-resistance sa fet y ground.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless anothe r person, capable

of rendering first aid and resuscitation, is pres ent.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification to the instrument.

Return the instrument to a VAISALA office or authorized Depot for service

and repair to ensure that safety features are maintained.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified maintenance

personnel. Do not replace components with power cable connected. Under

certain conditions, dangerous voltages may exist even with the power cable

removed. To avoid injuries, always disconnect powe r and discharge circuits

before touching them.

High voltage will be readily accessible when the transmitter (CTT21) or

receiver (CTR21) covers are removed and they are connected to a powered

unit. High voltage is present in the Line and Power Interface Subassembly

(CTP241), the Internal Heaters subassembly, the Frame (DMF51) Mother

Board, and the Window Conditioners at the top of the Shield.

Transmitter (CTT21), Receiver (CTR21), and Line and Power Input

Subassembly (CTP241) have the following warning label:

WARNING! +,*+9 2/7$*(, 16,' (7+,6( 1&/26 85(

x

Page 13

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Internal Heaters Subassembly can be hot and has the following warning

labels:

DANGEROUS PROCEDURE WARNINGS

Warnings, such as the example below, precede potentially dangerous

procedures throughout this manual. Instructions contained in the warnings

must be followed:

WARNING

Dangerous voltages, capable of causin g death, are present

in this instrument. Use extreme caution when handling,

testing, and adjusting.

CAUTION

The equipment contains parts and assemblies sensitive to

damage by Electrostatic Discharge (ESD). Use ESD

precautionary procedures when touching, removing or

inserting.

xi

Page 14

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

This page intentionally left blank.

xii

Page 15

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

1. GENERAL INFORMATION

1.1 Product Overview

Ceilometer CT25K measures cloud heights and vertical visibilities. The small

and lightweight measurement unit suits well for mobile operation.

The CT25K Ceilometer employs pulsed diode laser LIDAR technology

(LIDAR = Light detection and ranging), where short, powerful laser pulses

are sent out in a vertical or near-vertical direction. The reflection of light backscatter - caused by haze, fog, mist, virga, precipitation and clouds is

measured as the laser pulses traverse the sky. The resulting backscatter

profile, i.e. signal strength versus height, is stored and processed and the

cloud bases are detected. Knowing the speed of light, the time dela y between

the launch of the laser pulse and the detection of the backscatter signal

indicates the cloud base height.

The CT25K is able to detect three cloud layers simultaneously. Besides cloud

layers it detects whether there is precipitation or other obstructions to vision.

No adjustments in the field are needed. The embedded software includes

several service and maintenance functions and gives continuous status

information from internal monitoring. The software is designed to give the

full backscatter profil e.

SHIELD

MEASUREMENT UNIT

PEDESTAL

9412-026

Figure 1-1 Ceilometer CT25K

1

Page 16

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

Ceilometer CT25K consists of three main parts (Figure 1-1):

1. Measurement Unit including

- Optical Subassembly CTB22

- Laser transmitter CTT21

- Receiver CTR21

- Optics Monitor CTL21

- Frame DMF51 including

- Processor Board DMC50B

- DC Converter DPS52

- Ceilometer Interface Board DCT51

- Modem (optional)

- Line and Power Interface Subassembl y CTP241

- No-Break Battery

- Internal Heaters Subassembly CT25039

- Tilt Angle Sensor CT3675

- Internal Cables etc.

2. Shield including

- Built-in Window Conditioner CT2614/CT2688 (warm air blower)

options - 220...240 VAC (CT2614)

- 100...115 VAC (CT2688)

3. Pedestal

- Metal pedestal CT25106 is standard. For off-shore applications it is

recommended to use fiberglass pedestal CT26 65.

The complete delivery also includes mating cables with connectors for power

and communication, installation hardware, an Allen key, a triangle ke y for the

Measurement Unit door and this CT25K User’s Guide.

In addition, the following options may be included in the delivery:

- Maintenance Terminal (Palmtop compute r) PS ION3

- connected to Measurement Unit at the external conn ector J4 via RS232 interface

- Termination Boxes (2) for Line Power CT3709 (external connector J2)

and Communication Cable CT3707 (external connecto r J 3) connections

- Tropics Window CT35043 on Measurement Unit instead of Standard

Window to protect the laser from direct sun radiation.

- Optical Termination Hood CT25184 for indoor service us e

2

Page 17

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

- Shock Absorber CT35022 for ship installations

- PC Terminal cable CT35198 to connect the connector of the RS-232 p ort

of the PC to the maintenance port

1.2 Specifications

1.2.1 Mechanical

Dimensions:

Measurement unit 760 x 280 x 245 mm

(30 x 11 x 10 in.)

Height with shield and pedestal 1320 mm (52 in.)

Weight:

Measurement unit 17 kg (37 lb.)

Shield 10 kg (22 lb.)

Metal pedestal 8 kg (17 lb.)

Fiberglass pedestal (option) 13 kg (28 lb.)

Cardboard transport container size 1170 x 740 x 430 mm (46 x 29 x 17 in.)

Cardboard transport container weight 51 kg (111 lb.)

Plywood transport container size 1240 x 760 x 450 mm (49 x 30 x 18 in.)

Plywood transport container weight 70 kg (152 lb.)

1.2.2 External Connector J1 - Window conditioner

Connector J1: Type Binder series 693, 09-4228-00-07

(female)

Mating connector type: Type Binder series 693, 99-4225-70-07

7-pin (male) elbow

1.2.3 External Connector J2 - Power input

At nominal line voltage 115 V or 230 V

Power consumption (typical)

Total 365 W

Measurement unit 15 W

Internal heater 120 W

Window conditioner heater 200 W

Window blower 30 W

Frequency 45-65 Hz

3

Page 18

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

Power connector (J2): Type Binder series 693, 09-4223-00-04

4-pin (male)

Mating connector type: Type Binder series 693, 99-4222-70-04

(female) elbow

No-break power supply 12V Sealed Lead Acid Battery, 2 Ah

Overvoltage Protection Low-press filter , VDR

1.2.4 Output Interface

The data port can operate according to the following serial line standards :

RS-232

RS-422

RS-485, multidrop, 2-wire / 4-wire

The data port can also be operated through DMX55 and DMX50 modems or

ANet Bus interface DMX611.

The maintenance port is an RS-232 serial line, ex cept when the data line is set

to RS-422 or RS-485; then the maintenance line voltage levels become 0 and

+5 V.

1.2.4.1 External Connector J3 - Data line

The data line is intended to be used for measurement data communi cation, but

it can also be used with Ceilometer Maintenance Terminal, PC or other

terminals.

Connector (J3): Type Binder series 693, 09-4227-00-07

7-pin (male)

Mating connector type: Type Binder series 693, 99-4226-70-07

(female) elbow

Baud Rate: 2400 baud standard with RS-232

300, 4800 and 9600 baud available

300 bit/s with modem DMX55

2400 bit/s standard with modem DMX50

300, 1200, 2400 bit/s available

Data compression allows up to 9600 bit/s

throughput

Max. Distance to Operate: 300m (1000 ft) with RS-232,

4

1.2 km (4000 ft) with RS-422 and RS-485,

all at 2400 baud with typical communication

cables

16 km (10 mi) with Modem

Page 19

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Standard Character F rame: 1 Start Bit

7 Data Bits

Even Parity

1 Stop Bit

Standard Character Code: USASC II

Pin Connections 1 RD- / AN2Lo

2 Modem Lead A / RxD / RD+ / AN1Hi

3 Modem Lead B / TxD / SD+ / AN1Lo

4 Signal Ground

5 SD- / AN2Hi

6 +12 V DC supply (200 mA max for 1

hour, 100 mA continuous, for external

equipment)

Modem circuits are non-polar and symmetrical. All modem circuits are

electrically floating to overvoltage protection ratin g (300V-500 V).

Overvoltage Protection in each circuit:

Primary Noble Gas Surge Arrester

Secondary VDRs, Transient Zener Diodes

or normal Diodes

Figure 1-2 Data Line Connection Options

5

Page 20

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

1.2.4.2 External Connector J4 - Maintenance line

Maintenance line is intended for on-site maintenance and can be used with

Ceilometer Maintenance Terminal, PC or other terminal.

Connector (J3): Type Binder series 693, 09-4224-06-04

4-pin (male)

Mating connector type: Type Binder series 693, 99-4221-70-04

(female) elbow

Baud Rate: 2400 baud standard and default

300, 4800, 9600 baud available

Distance to Operate: 300 m (1000 ft) at 2400 baud with typical

communication cables

Standard Character F rame: 1 Start Bit

7 Data Bits

Even Parity

1 Stop Bit

Standard Character Code: USASC II

Pin Connections 1 RxD / RD+ (0...5 V)

2 TxD / SD+ (0...5 V)

3 +12 V DC supply from internal battery

(100 mA continuous, 200 mA max.)

4 Signal Ground / Equipment Ground

Overvoltage Protection in each circuit:

Primary Noble Gas Surge Arrester

Secondary VDRs, Transient Zener Diodes or

normal Diodes

1.2.5 Modem Options

1.2.5.1 Modem board DMX55

ITU-T V.21 / Bell 103 full duplex modem interface for serial asynchronous

data interchange

Data Rate: 300 bit/s

Modulation method: FSK

6

Page 21

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Answer Mode Standard Frequencies:

V.21 Bell 103

Mark (1) 1650 Hz 2225 Hz

Space (0) 1850 Hz 2025 Hz

Originate Mode Optional

Signal Level: -10 dBm (0.3 V) into 600 Ohm standard

(Jumper selectable)

Max. Distance to Operate 0...16 km (0...10 miles)

with 22 AWG (0.35 mm2) unshielded

twisted pair

The signal circuit is electrically floating to overvoltage protection rating

(300V-500V).

1.2.5.2 Modem board DMX50

Processor: Intel 80C32 custom version

Modem: Signal Processor Chip Silicon Systems SSI

73K224L

Modem standards supported: V.21/ V.22/ V.22bis and Bell 103, Bell 212

Modulation method: 300 FSK/ 1200 DPSK/ 2400 QAM

Compression & error correction: V. 42, V.42bis and MNP 2-5

Adaptive equalization for optimum performance over all lines.

1.2.5.3 ANet Interface DMX611

The DMX611 serves as an interface between the CT25K and Vaisala

proprietary ANet and INet busses.

Baud Rate 2400

Signal Level 0 dBm

Max. Distance to Operate 0…5 km multi-drop network

Standard Character Frame 8 Bit synchronous

Character Code Binary

iNet protocol Packet format.

Twisted pair 22 AWG

7

Page 22

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

1.2.6 Transmitter

Laser Source: Indium Gallium Arsenide (InGaAs) Diode

Laser

Center Wavelength: 905 ± 5 nm at 25 °C (77 °F)

Operating Mode: Pulsed

Nominal Pulse Properties at Full R ange Measu rem ent:

Energy: 1.6 µWs ± 20% (factory adjustment)

Peak Power: 16 W typical

Width, 50%: 100 ns typical

Repetition Rate: 5.57 kHz

Average Power: 8.9 mW (full range measurement)

Max Irradiance: 170 µW/cm ² measured wit h 7 mm aperture

Laser Classification: Officially certified as Class 1 laser device in

accordance with EN 60 825-1:1994

Class 1 in compliance with FDA CFR

1040.10 (Subsection e,3)

Laser Source Geometry: Five-stack, 0.4 mm (16 mil) square

Beam Divergence: ± 0.53 mrad edge, ± 0.75 mrad diagonal

1.2.7 Receiver

Detector: Silicon Avalanche Photodiode (APD)

Responsivity at 905 nm: 65 A/W

(factory adjustment)

Surface Diameter: 0.5 mm (0.02 in.)

Interference Filter: Center wavelength 908 nm typical

50% Pass Band: 35 nm at 890-925 nm typical

Transmissivity at 905 nm: 80 % typical, 70 % minimum

Field-of-View Divergence: ± 0.66 mrad

8

Page 23

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

1.2.8 Optical System

Optics System Focal Length: 377 mm (14.8 in.)

Effective Lens Diameter: 145 mm (5.7 in.)

Lens Transmittance: 96 % typical

Window Transmittance: 98 % typical, clean

1.2.9 Performance

Measurement Range: 0...25,000 ft. (0...7.5 km)

Resolution: 50 ft

25,000 ft. Acquisition Time: min. 15 s

max. 120 s

Receiver Bandwidth: 3 MHz (-3db)

1.2.10 Environmental Conditions

Ambient Temperature: -50...+60 °C (-60 ...+140 °F)

Humidity: to 100 %RH

Wind: to 100 kt (50 m/s)

Vibration: 0.5 g 5 - 500 Hz

9

Page 24

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

2. INSTALLATION

NOTE

Before the installation, make sure that the CT25K

configuration, especially line voltage setting, is in

compliance with local circumstances. Information about

the CT25K configuration in question is included in the

delivery.

2.1 Unloading and unpacking

The CT25K is shipped in one container containing the Measurement Unit,

Shield and Pedestal, and all equipment, accessories an d docum entation ne eded

for carrying out the installation. Store the original packagin g for possible later

transport need.

For opening, the package is t o be placed on a flat surface with t he indicated

top side up. The container is opened from the top side and the ceilometer

including all other parts are carefull y removed.

• Use proper gloves for protection against sharp edges, et c.

• Avoid touching the window or lens surfaces unless cleaning according to

instructions.

• Maintain the integral protective caps on the unus ed external connectors (J3

Data line or J4 Maintenance line).

• Use the measurement unit handle fo r lifting and carr ying (Figure 2-1).

If mishandling occurs during transit or installation, the instrument should be

returned to a VAISALA office or authorized Depot for insp ection.

10

Figure 2-1 Measurement Unit Handle

Page 25

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

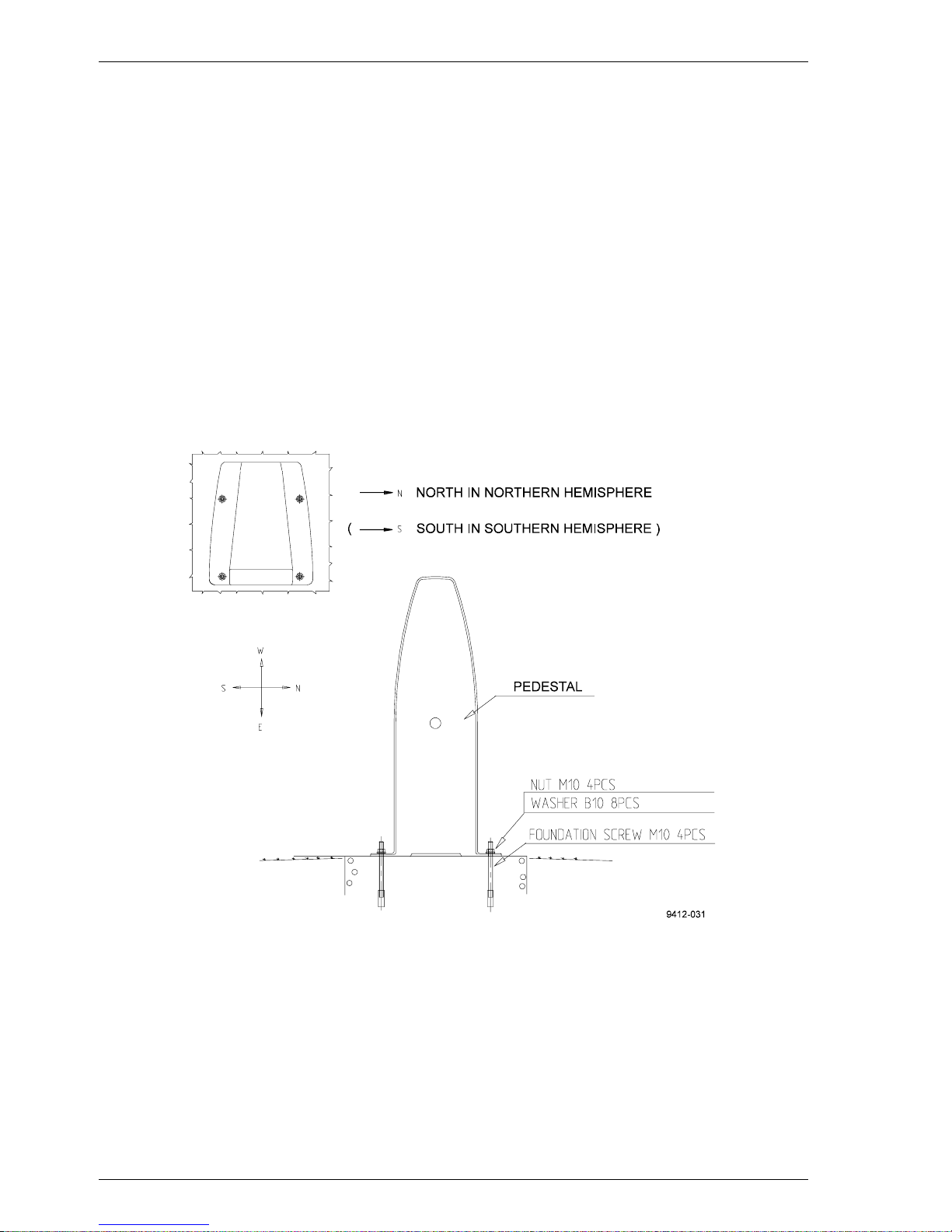

2.2 Foundation

The standard foundation for the CT25K ground installation is a concrete

foundation. The minimum dimensions suggested are present ed in Figure 2-2.

Mounting hardware is included with the delivery.

There are two alternative ways to make a foundation: to cast a new or to use

an existing foundation.

- If a new foundation is laid, the M10x40 Wedge Bolts and Foundation

Screws (4 each), are suggested to be cast into the concrete so that

approx. 30 mm (1.25 in.) of the foundation screw threads stand above

the surface.

- If an existing foundation is used, four holes of diameter 12 mm and

depth 165 mm (0.5 x 6.5 in.) are drilled into the concrete. The Wedge

Bolt and Foundation Screw combinations are placed in the holes, with

Wedge Bolts down; the protruding threads are alternately hammered

and tightened a few times so that the Wedge Bolts attach to the hole

walls.

In case the CT25K replaces a CT12K Ceilometer, the ex isting foundation and

screws can be used.

Figure 2-2 Foundation Construction

11

Page 26

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

If the tilt feature will be used (see section 2.4), observe this in the la yout of

the foundation screws and pedestal placement.

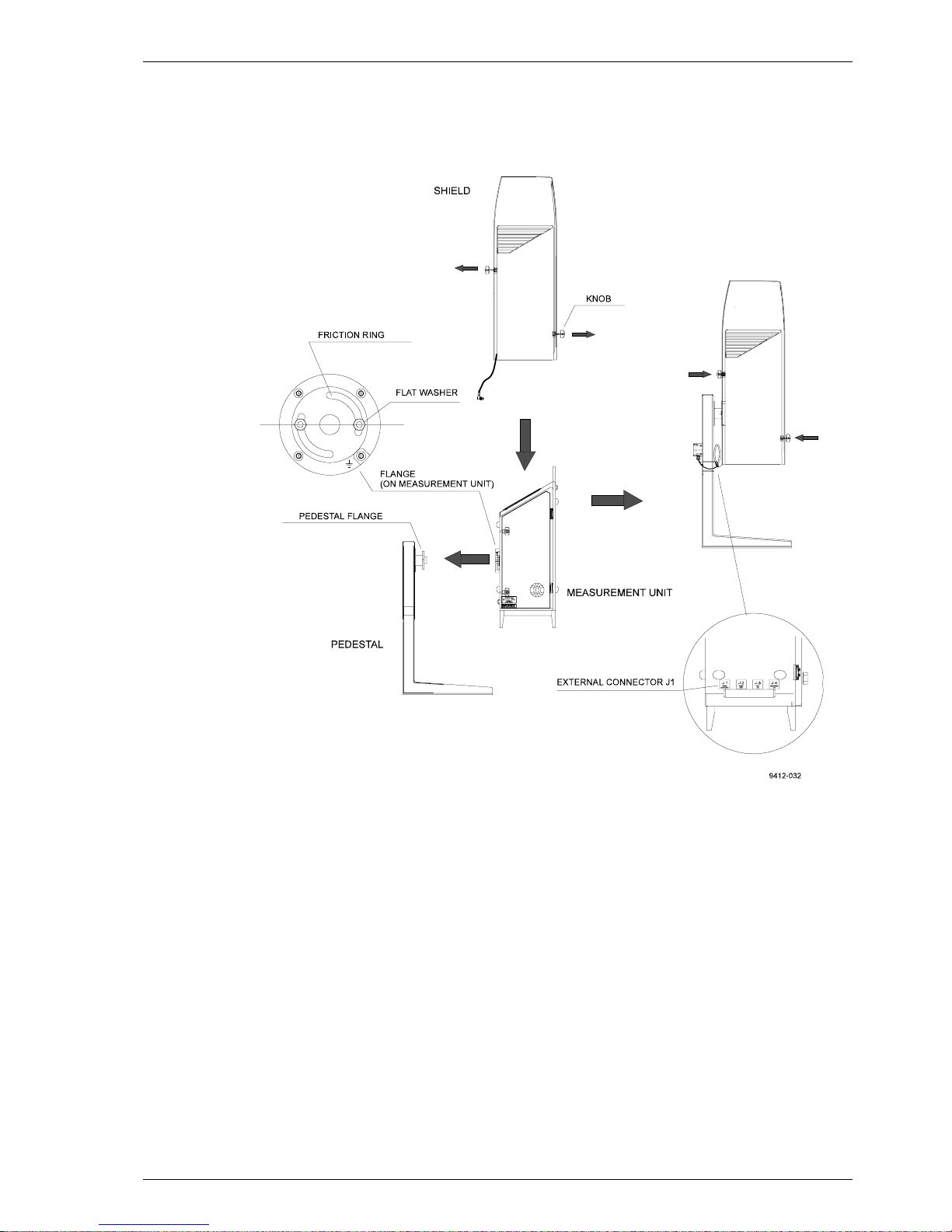

2.3 Assembling the Unit

The CT25K Ceilometer is assembled in four stages:

1. Mount the pedestal on the foundation.

2. Attach the measurement unit to the pedestal.

3. Mount the shield on the measurement unit.

4. Connect the external cabl es.

1. Place the Pedestal on the foundation (or equivalent installation place) so

that the vertical leg of the pedestal faces East in the Northern hemisphere,

and West in the Southern hemisphere.

If the tilt feature will be used (see section 2.4.), observe this in the layout of

the foundation screws and pedestal placement. Place the flat washers on the

foundation screws and fix the nuts (Figure 2-3).

2. Start mounting the measurement unit by rotating the friction ring of the

flange to the position shown in Figure 2-4 (the screw h oles horizontally).

Remove the Allen head screws (2 pcs) and flat w ashers.

12

Figure 2-3 Mounting the Pedestal

Page 27

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Place the measurement unit on the pedestal flange. Attac h the pedestal flange

to the measurement unit by the two Allen head screws with flat washers. An

Allen key is included in the delivery.

Figure 2-4 Attaching the Measurement Unit and the Shield

3. Before placing the shield pull the knobs (pidgeon blue) on the shield

outwards. Place the shield carefully on the Measurement Unit; be careful

with the Window Conditioner cable. Tighten the two attachment knobs

(Figure 2-4).

Before connecting the Window Conditioner cable check that the voltage

rating of the Window Conditioner (written at its connector) is correct.

Connect the Window Conditioner cable plug of the shield to the

measurement unit external connector J1 .

Connect external cables according to section 2. 5.

13

Page 28

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

2.4 Using the Tilt Feature

The Measurement Unit and Pedestal of Ceilometer CT25K are designed so

that the unit can operate in a tilted direction. The built-in tilt angle sensor

CT3675 detects the tilt angle, i.e. deviation from the vertical. The tilt angle

ranges from -15 to +90 degrees from vertical; the angle is positive when the

measurement unit door turns towards the ground. The cosine of the tilt angle

is used for automatic correction of the detected cloud base height, which

enables accurate cloud base measurements also in a tilted direction.

Several advantages can be realized with the aid of this feature:

• Heavy weather conditions

Using a slight tilt angle for instance 15 degrees, the measurement unit

window is kept better protected from precipitation, thus enhancing the

availability of correct measurements in heavy weather conditions.

• Aircraft approaches

The beam can be directed towards a direction, which better r epresents the

approach of an aircraft than th e straight vertical. Useful e.g. for helicopter

approaches, and sites where the ceilometer cannot be located exactl y at the

desired spot.

• Hard target and testing purposes

Tilting the unit down by 90 degrees permits verification of operation

against a hard target at a known distance. Useful in connection with

installation and maintenance. Enables real backscatter signal detection

when there are no clouds in the sky.

WARNING

Make sure that nobody is viewing the unit from th e beam

direction with magnifying optics!

• Maintenance

By tilting the unit back -15 degrees, better access is gained to the interior

during maintenance.

• In the tropics

Between the latitudes of ± 25 degrees, where the sun can be straight above

the unit, a slight tilting prevents the laser from direct sun radiation, which

would otherwise destroy the laser. The other alternative is to use a tropics

window on the measurement unit instead of a stand ard window.

14

Page 29

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

As these advantages are partly contradictory and cannot or need not all be

realized, the user must decide the final installation direction. In doing so, the

following must be observed:

NOTE

Unless a tropics window is used, the unit must never be

directed so that the sun shines directly into the optics,

because the lens will focus all radiation into a very hot

spot.

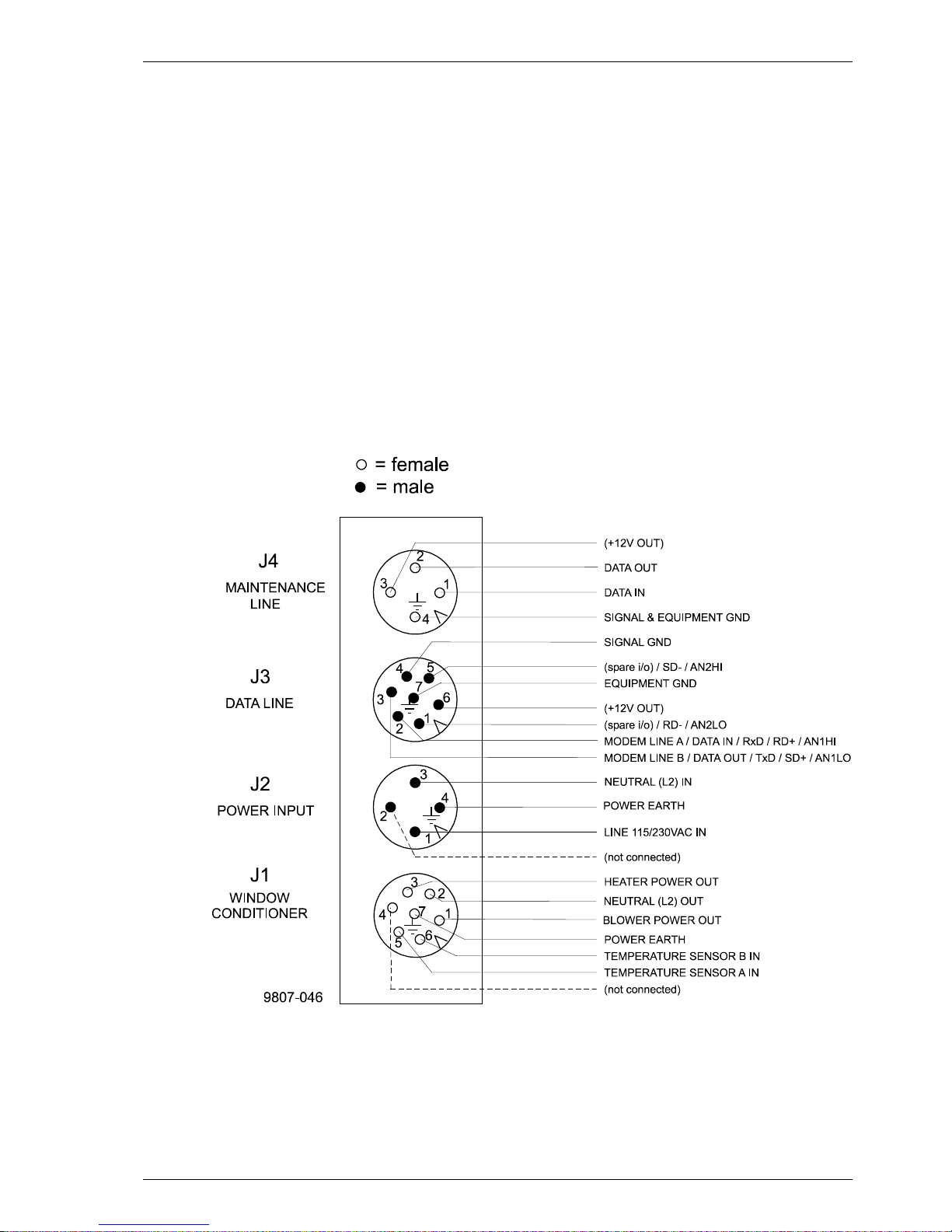

2.5 Cable Connections

All external connectors to the Measurement Unit are located at th e bottom left

edge as seen from the door direction. Figure 2-5 shows the external

connectors J1, J2, J3 and J4.

• The Window Conditioner (warm air blower) mounted in the Shield is

permanently connected to J 1.

• Line Power input is connected to J2.

Figure 2-5 External Connectors (bottom view)

15

Page 30

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

• Remote communication is normally connected to J3.

• A local maintenance terminal, for example PSION3, is intended to be

connected to J4. A protective cap is included for covering J4 when not in

use.

External mating connectors with 2 m (7 ft.) cable are included for J2 and for

J3. The power plug of the J2 cable can be cut when the unit is permanentl y

installed at the final site.

The cables for J2 and J3 are intended to be drawn through the hole of the

pedestal to the connectors. Provide sufficient slack for permitting the unit to

be tilted later.

Figure 2-6 shows the connecting signal leads with optional Powe r and Signal

Termination Boxes.

Figure 2-6 Termination Box Wire Connections

Suggested wire dimensions for the external cablin g are:

Line Power Supply: 3 x 1.5 mm2 (AWG 16)

Remote Communication: 0.35 mm2 (AWG 22) twisted pair with shield

When permanent line power installation is made, the

maximum size of the fuse protecting the power line is 10 A

2.6 Grounding

The power supply connector J2 provides a standard protective ground for the

instrument chassis.

16

NOTE

Page 31

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

The CT25K is equipped with a separate grounding screw o n the measurement

unit flange for external earthing (see Fi gure 2-4).

CONNECTION TO A SOLID EARTH GROUND AT THE

INSTALLATION SITE IS MANDATORY FOR ADEQUATE

LIGHTNING AND TRANSIENT PROTECTION.

2.7 Connection of Maintenance Terminal

Any terminal or PC with serial interface and terminal emulation program can

be used for operation and maintenance of the CT25K Ceilometer. A standa rd

Maintenance Terminal option is offered including the following components:

• Palmtop Computer PSION3

• RS cable (RS-232 Interface)

• Terminal Cable CT3840

• Technical Manuals for the Palmtop Computer

Setting up PSION3

To set up PSION3 for communication for the first time the following steps are

needed. These settings must be done with the RS cable attached to PSION3.

The PSION3 has two normal Mignon AA batteries, which enable operation

for twenty hours.

1. Connect the RS cable to th e PS ION3 comput er.

2. Press the System icon to start the computer.

3. Press the "Menu" key to get the menu on the screen.

4. Select the "Install" from the "Apps" menu.

5. Use cursor keys to move to the "Disk" line and to the "C" disk.

6. See that the "File: Name" line has "Comms.app" . If the line does not

have it add it by typing and press ENTER.

A new icon "Comms" is now installed and can be seen on the System screen.

The terminal emulation i s read y.

7. Choose "Comms" from System screen and press ENTER to start it.

8. Press the "Menu" ke y and set "Port " from "Sp ecial " menu as follo ws:

Baud rate 2400

Data bits 7

Stop bits 1

Parity Even

Ignore parity Yes

17

Page 32

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

9. Exit from "Comms" and select "Save the Setting" from "File" menu

by name "CT25K".

Now there should be the text "CT25K" under the "Comms" applic ation. From

now on PSION3 is ready to communicate with CT25K whenever "CT25K"

from the "Comms" application is chosen.

Connecting PSION3 to CT25K

Connect the cables as follo ws:

1. Connect the Terminal Cable CT3840 to the external connector J4 of

the Ceilometer.

2. Connect the RS cable to the Maintenance Cable

3. Connect the RS cable to the P SION3 com puter.

Operation

Turn on both equipments, the CT25K and the PSION3 computer.

4. PSION3 is turned on for normal operation b y pressing the key "Esc"

or by pressing the special "Psion" key (∪) together with "ON".

5. PSION3 is turned off by pressing the "Psion" key (∪) and "OFF"

Choose the configuration CT25K from the System screen and pr ess ENTER.

The terminal is now ready for dialogue communication with the ceilometer.

Start the program by pressing ENTER. The prompt "CT:"should appear on

the screen. If not, check the cables and port settings (see Setting up PSION3

above).

The port has to be opened by command "OPEN" for giving commands. The

prompt CEILO> should appear. See Chapter 4 Ope ration.

For more information about communication see PSION3 manual included in

the delivery.

18

Page 33

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

3. START UP

3.1 Start up procedure

Open the unit door; the key is included in the delivery. Mak e a visual check o f

the internal connectors, subassemblies, etc. Figure 3-1 describes the switches

and LEDs needed to complete the start up procedure.

1. Turn the main circuit breaker F1 to "OFF" position.

2. Plug in the line supply cable to connector J2 after checking the voltage of

the power supply cable connector.

3. Turn the Main Circuit Breaker F1 and the Battery Switch to the "ON"

position. After initialization routines the following shall happen (LED =

Light Emitting Diode):

DC Converter DPS52 LED D2 stable green

LED D1 blinking yellow

In case the built-in battery is deeply discharged it m ay take hours before

LED D2 goes on.

4. Processor Board DMC50B LED STATUS blinking at regular intervals

(1 sec.)

5. Ceilometer Interface Board DCT51 green LED D4 goes on during the

laser pulse train for about 12 seconds and is repeated according to the

configuration in question. After power-up, it may tak e a couple o f minutes

before the unit starts normal operation.

If LEDs operate in a different way than described above, the unit may need

service or maintenance. Refer to Chapter 7 Troubleshootin g.

19

Page 34

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

20

Figure 3-1 CT25K Switches and LEDs

Page 35

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

3.1.1 Mobile operation aspects

The small and lightweight CT25K Ceilometer is suitable also for mobile

operation. It has a built-in 12V battery, which enables operation without

external power supply for about an hour in normal room temper ature.

NOTE

For switching power to the CT25K fully OFF, turn also

the Battery Switch OFF in addition to the line power

switch. Having the unit ON with battery supply only will

drain the battery.

NOTE

Do not attempt to carry a fully assembled unit alone. Lift

the CT25K from Measurement Unit Base or Pedest al only

(not from the shield). The three main parts - Measurement

Unit, Shield and Pedestal - can be lifted and carried

separately by one person.

3.2 Verification of Proper Operation

Proper operation of the Ceilometer can be checked with help of the

maintenance terminal. Turn the power on. After 30-45 seconds ask for the

status message with the command GET STATUS. Information about

commands can be found in chapter 4 Operation. The message should not

contain any warnings or alarms. In the opposite case see Chapter 7

Troubleshooting.

If a solid, stable cloud base is present at a range of 1,000-5,000 ft., and no fog

or precipitation is present, a quick-check of the detection and the unit

sensitivity can be carried out by observing the variable SUM on the third line

of data message No.2. SUM indicates the sum of detected and normalized

backscatter and its value should be in the range 150...200 if parameter SCALE

has the standard value 100 %. See para graph 4.4.2 for details.

If suitable clouds are not present for proper operation verification, the unit

may be tilted towards a hard target at known distance. The minimum distance

to the hard target should be at least 300 meters (1,000 ft.). Unexpected

behavior is not totall y excluded if e. g. a stron g refl ector sat urates th e recei ver.

When tilting the unit, make sure that nobod y is wat ching it

with binoculars or other magnifying optics.

WARNING

21

Page 36

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

3.3 Settings for Normal Operation

Switch settings for normal operation are as follows:

Main circuit breaker F1 ON

Window conditioner circuit breaker ON

Battery switch ON

Data message and interface configuration and the configuration of measuring

interval and transmission speed are standard factory settings. When required,

the settings can be changed by giving commands with the terminal.

During the factory alignment procedur e, the optical adjustments are caref ully

carried out to fulfill the requirements and specifications of the device. Optical

adjustments have been made at factory or depot, thus there is no need to

readjust in the field.

3.4 Factory settings of user programmable parameters

Table 3-1 next page shows the standard factory settings of user programmable

parameters. The prevailing parameter settings can be seen by the command

GET parameter_group

Parameter groups are displayed as bold text in table 3-1. As response to the

command a list of parameters with prevailing parameter values is shown.

The standard factory-set param eter valu es, which ma y be ch anged b y the us er,

are collected in the second column in table 3-1. The values displayed in the

first column are factory settings that the user cannot change. For changing a

value to the desired content and function, depending on the particular

installation, the corresponding command is

SET parameter_group parameter

22

Page 37

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

Table 3-1 Factory paramete r settin gs

Response to User’s Menu

commands...

CEILO>get...

...data_acq

AUTOADJUSTMENTS: ON

DATA-ACQ. INTERVAL: 15 SEC. 15... 120 seconds availa ble

RECEIVER

GAIN: H

BANDWIDTH: N

SAMPLING RATE: 10 MHz Constant

TRANSMITTER

LENGTH OF PULSE: L

POWER OF PULSE: 188 Varies with unit, temperature, and

QUANTITY OF PULSES: 64K Constant

COMPENSATION

COARSE COMPENSATION: 13 Varies with unit and

FINE COMPENSATION: 125 Varies with unit and

...message

MESSAGE

ANGLE CORRECTION: ON Shall be ON if unit is operated

HEIGHT OFFSET: 0 Insert i nstallati on heig ht if sig nifi-

MODE: AUTOSEND Option POLLING. Transmits date

NOISE H2 COMPENSATION: OFF Option: ON. Affects the visual

PROFILE SCALE: 100 % Scales backscatter values of

PORT: DATA Optional selecti on:

TYPE: MSG1 Message No. 1. Options: MSG2,

UNITS: FEET Option: METERS. Note also

WARNING DELAY: OFF Option ON. Sets a 5 minutes delay

Standard fac tor y

settings of User’s

Menu parameters

Notes

age

contamination

contamination

tilted. May be ON even if u nit is

operated vertical. Option OFF will

turn detected values into dista nces

rather than heights.

cantly different from reference

(zero) heig ht, i n re port ing unit s.

message only whe n polled.

appearance of message No. 2

graphical presentation. Selection

OFF gives less noisy appearance.

message No. 2 an d cor res pond in g

SUM value.

MAINTENANCE.

MSG3, MSG6, MSG7 and

Status (S).

HEIGHT OFFSET.

for warning

23

Page 38

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

...oper_mode

OPERATION MODE: CONTINUOUS Option STANDBY requires

command START for carrying out

each cycle.

…options

[MODEM NAME]

SKY CONDITION:

HUMITTER:

BLOWER:

INSTALLED

INACTIVE

INACTIVE

ACTIVE

Modem name is: DMX 55, DMX 50

or DMX611

ACTIVE

ACTIVE

INACTIVE

... port

MAINTENAN CE PO RT BAU DS: 2400, E71 Optional bau d rate s 300, 24 00,

4800, 9600.

DATA PORT BAUDS: 300, E71 Optional baud rate s 300, 12 00,

2400, 4800, 9600. NOTE: Reverts

to 300 if standard mode m DMX55

is plugged in. 2400 is factory

setting if this modem is not

present.

MODEM: CCITT (300)

If modem DMX 55 i nstalle d.

Options: Bell 103 a nd IT U-T

V.21.

DMX50 V42

BIS MODE

(1200-9600)

if modem DMX50 is installed.

Options: Bell 103, Bell 212A,

ITU-T V.21, ITU-T V.22, V42

MODE, V42 BIS MODE

MODEM STATUS: ON OFF

YOU ARE USING: DATA PORT Option: MAINTENANCE PORT

...unit_id

UNIT ID: 0 Insert 1...9, A...Z if polling or

message logg ing fr om se ver al

units requires separating

identifiers

24

Page 39

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

4. OPERATION

4.1 Operation Modes

There are two operation modes, continuous i.e. normal and standby.

Commands OPER_MODE STANDBY and OPER_MODE CONTINUOUS

are used to switch between the modes. In NORMAL mode continuous

measurement and message transmission occurs according to chosen

parameters. In STANDBY mode the wearing parts are tu rned off and it ca n be

used e.g. during periods when measurement is not needed. It allows singlecycle measurement b y command START.

Figure 4-1 Operation Modes

4.2 Serial Lines. Open and Closed Port

Two serial lines are provided, termed "MA INTENANCE" (extern al connector

J4, Line/Port A at Processor Board) and "DATA" (external connector J3,

Line/Port B at Processor Board). Line B is intended to be used for

measurement data communication and can be operated through modem or

baseband. Line A is intended for on-site maintenan ce access, and is us ed only

baseband. However, functionally the operation of the lines is identical; the

same commands, operations and messages operate through any of the lines,

and the following description applies to both of them.

Factory default setting is 7 data bits, Even parity, 1 Stop bit, and for baseband

lines, 2400 baud. Baud rate is selectable in the user menu.

7-bit USASCII character format is used. Letter case UPPER/lowe r c an both b e

used; response will use the upper case.

Standard operation of the serial lines requires no handshake si gnals.

A communication port, i.e. serial line, has two internal states (Fi gure 4-2):

25

Page 40

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

CLOSED Measurement data message transmitting state. In this state messages

are transmitted automatically at predetermined intervals, or as a

response to a polling input string, depending on the corresponding

settings. User commands are not accepted, except command OPEN,

which turns the line into the OPEN state. No input is echoed but

ENTER inputs are responded to by character string CT:

OPEN User dialo g state. In this state the user commands are responded to.

Command input is echoed. A command prompt CEILO> is

displayed as an indication of readiness for command input from the

user. Command line termination and command execution is by key

and character ENTER = RETURN = CARRIAGE RETURN. No

automatic measurement data message transmission is executed in

the OPEN state. The port reverts into the CLOSED state by

command CLOSE. Automatic 2-minute time-out after last character

input is applied. A 2...60-minute time-out may be set by command

SET PORT TIME_OUT.

NOTE

Only one of the ports can be OPEN for commands at a

time. Only one of the ports transmits measurement

messages at a time. Additionally, in RS-485 mode a unit

ID must be given with the command OPEN.

26

Figure 4-2 Open and closed port

Page 41

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

4.3 User Commands

User commands, command hierarchy and description are described in table 41 below. User commands are accessible after opening the line by command

OPEN (no password needed).

The command line interpreter provides interactive help support, so that the

exact format of commands doesn’t have to be remembered. At each level of

the menu, keying ENTER first provides an output of the menu available, the

second ENTER provides an eventual HELP text . Keying in a letter followed

by ENTER outputs all commands with the same first letter; keying in two

letters followed by ENTER outputs all commands with the same first two

letters, etc.; when only the one desired command is left, then it is executed

when ENTERed. This way one needs to know only approximately what one

wants to do, and the system provides the necessar y aid.

In addition to the user’s menu and command set there is a second in-depth

maintenance and service level menu and command set, which is intended for

more profound system changes and diagnostics. Password for this level is

"advanced". Commands on this level should be used only according to

instructions described in this manual.

27

Page 42

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

28

Table 4-1 List of user and advanced level commands. Advanced level commands are marked bold.

1st (TOP)

LEVEL

2nd LEVEL 3rd LEVEL 4th LE VEL 5th LEVEL DESCRIPTION

CLOSE Release port for message transmission, i.e. abort command dialog

BACK Back to normal user command set

RESET NO Do not reset

YES Make full reset

SET

ALGORITHM DEFAULTS Set default algorithm parameter settings

CONTROL BLOWER ON Turn window conditioner blower ON

OFF Turn window conditioner b lower OFF

BLOWER MANUAL Set window conditioner blower to manua l control

AUTO Set window conditioner blowe r to auto matic contro l

INHEATER ON T urn internal heater ON

OFF Turn interna l hea ter OFF

OUTHEATER ON Turn window conditioner hea ter ON

OFF Turn window conditioner hea ter OFF

DATA_ACQ

AUTOADJ ON Data Acquis ition parameters are software controlled

OFF Data Acquisition parameters are manual controlled

COMP COARSE Set internal crosstalk compensation setting coarse code value

FINE Set internal crosstalk compensation setting fine code value

INTERVAL 15...120 Data Acquisition: Set interval for measurement and message sending.

TRANSMIT POWER_OF_P Set pulse energy input code value

FACTORY INLASER Set pulse energy input code value (at start-up)

OUTLASER Set pulse energy target value for software adjustment

RECVALUE Set receiver test reference value

WIN_CLEAN Set clean window reference value

Page 43

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

29

1st (TOP)

LEVEL

2nd LEVEL 3rd LEVEL 4th LE VEL 5th LEVEL DESCRIPTION

SET MESSAGE ANGLE_COR OFF Angle correction: Clo ud and vert ical visib ility hei ghts (dis tances) i n

messages are NOT corrected for the tilt angle

ON Angle correction: Cloud and vertical visibility heights (d ista nces) in

messages ARE corrected for the tilt angle

ANGLE_MEAS AUTO Automatic angle measurement for angle correction

MANUAL 0..89 Manual angle value (degrees) for angle correction

HGTH_OFFSET -1000... 1000 (ft)

or -304... 304 (m)

Height Offset: Cloud and vertical visibility values are corrected by

this offset val ue. P ositi ve v alue s add to, ne gat ive val ues su btr act fro m

measured height. Unit is m or ft. as set by UNITS command.

MANUAL_MSG "30 01000 02000

03000 12345678"

Sets test message (example)

"" Cancels manual message

MODE AUTOSEND Measurement messages are transmitted automatically as set b y

command INT ERV AL

POLLING Measurement messages are transmitted according given polling string

PORT DATA Message is directed to the Data port (default), non-volatile

MAINTENANCE Message is directed to the Maintenance port, non-volatile

PROFILE SCALE 0...999 Factor for scaling the range gate data items of Message No. 2.

Normal value: 100 (%)

NOISE_H2 OFF Range gates data is range normalized only if backscatter is contained

ON Range gates data is always range normalized , even noise

TYPE MSG1 Message No. 1 is transmitted

MSG2 Message No. 2 is trans mitted

MSG3 Message No. 3 is trans mitted

MSG6 Message No. 6 is trans mitted

MSG7 Message No. 7 is trans mitted

STATUS Status message is transmitted

UNITS FEET Reported heights unit is feet

METERS Reported heights unit is meters

WARN_DELAY OFF Warning character W is set in message immediately

ON Warning character W is set in message after 5 minutes dela y

VLIM 1...100 Set vertical visibility reporting limit (%) for sky condition

Page 44

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

30

1st (TOP)

LEVEL

2nd LEVEL 3rd LEVEL 4th LE VEL 5th LEVEL DESCRIPTION

SET OPER_MODE

COMP_MONIT Run internal crosstalk compensation monitor until ESC

CONTINUOUS Operation Mode: Continuous measurement mode

STANDBY Standby mode, no measurement unless commanded by START

(initiates one cycle)

OPTION SKY_COND ON CODE Activate sky condition option

OFF Deactivate sky condition option

HUMITTER ON Enable humitter option

OPTION HUMITTER OFF Disable humitter option

BLOWER ON Enable blower related status and warning information, needs reset

OFF Disable blower related status and warning information

PORT TIMEOUT 2...60 Timeout for automatic CLOSE of dialog mode. Value in minutes.

Default: 2 minutes

MAINTENANCE B300 Set maintenance port bit rate to 300 bits/s

B2400 Set maintenance port bit rate to 2400 bits/s

B4800 Set maintenance port bit rate to 4800 bits/s

B9600 Set maintenance port bit rate to 9600 bits/s

DATA MODEM BELL_103 300 bits/s modem mode

V21 300 bits/s modem mode

BELL_212A 1200 bits/s modem mode

V22 1200 bits/s modem mode

V42_NORMAL 1200-2400 bits/s modem mode, with error correction (V.22bis + V.42)

V42_BIS 1200-9600 bits/s modem mode, with error correction and data

compression (V.22bis + V.42bis)

OFF Sw itch mode m off and use s erial line co mmunicatio n

INTERFACE RS232 Use RS232 serial line

RS422 Use RS422 4-wire serial line

RS485_2W Use RS485 2-wire serial line

RS485_4W Use RS485 4-wire serial line

Page 45

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

31

1st (TOP)

LEVEL

2nd LEVEL 3rd LEVEL 4th LE VEL 5th LEVEL DESCRIPTION

SET BAUD B300 Set data port serial line baud rate to 300

B1200 Set data port serial line baud rate to 1200

B2400 Set data port serial line baud rate to 2400

B4800 Set data port serial line baud rate to 4800

B9600 Set data port serial line baud rate to 9600

SW_STATUS OK Set report / algorithm conflict status bit ok

UNIT_ID 0...Z Unit Identifier: Alphanumerical character for message and polling

identification

GET ALGORITHM Print values of Algorithm parameters

DMC_SN Print DMC50 board serial number

DATA_ACQ Print settings of Data Acquisi tion

FACTORY Print values of Factory settings

INFO Print identifying infor mation for t his equip ment con figuratio n

MESSAGE Print Message Setting

OPER_MODE Print Operating Mode

OPTIONS Print installed modem and active options

PORT Print values of Port settings

STATUS Print STATUS message

SW_STATUS Print report / algorithm conflict status bit

UNIT_ID Print Unit Identification string

VALUE OTHERS ANGLE Print value of tilt angle sensor, range -15...+90 degrees from vertical

POWER_OF_P Print measured value of laser pulse po wer, units: mV at A-to -D

converter input

RECVALUE Print measured receiver test values

RADIANCE Print measured value of background radiance, units: mV at A-to-D

Converter input

WINDOW Print measured value of Window Contamination Monitor, units: mV

at A-to-D Converter input

Page 46

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

32

1st (TOP)

LEVEL

2nd LEVEL 3rd LEVEL 4th LE VEL 5th LEVEL DESCRIPTION

GET VALUE TEMPERATURE BLOWER Print value of measured blower temperature, units: °C

CPU Print value of measured CPU board temperature, units: °C

LASER Print value of measured laser temperature, units: °C

LENS Print value of measured temperature adjacent to lens, units: °C

OUTSIDE Print value of measured outside temperature, units: °C

VOLTAGE BCIRCUIT Print status of battery circuit, connected / disconnected = 1/0

BATTERY Print value of battery voltage, approx. +13V

CHARGE P rint value o f battery charge volta ge, approx. +13 V

VCA Pri nt value of i nter nal r aw volta ge, a pp rox. +25 V

PHV Print value of Receiver high voltage, approx. +200V

PFB Print value of Receiver switcher internal feedback voltage, appr +2V

VALUE VOLTAGE P65 Print value of Transmitter high voltage, approx. +65V

P18 Pr int value o f ge nera l interna l sup ply vo ltage +18V

P13 Pr int val ue o f Rece iver supp ly vo ltage +13V

P12 Pr int value o f ge nera l interna l sup ply vo ltage +12. 5V

P5G Print value of g enera l inter nal s uppl y volta ge +5V

P5R P rint val ue o f Rec eive r sup pl y volta ge +5V

M13 Print value o f Rec eive r s uppl y volta ge -13 V

M12 Print value of g enera l inte rnal supp ly vo ltage -12 .5V

M5R Print value o f Rec eive r s uppl y volta ge -5V

M5G Print va lue o f gene ra l inter nal s uppl y volta ge -5V

VERSION Print identifier for Software version

VLIM Print sky condition vertical visibility reporting limit (%)

START Start single-cycle measurement in operatio n mode ST ANDBY. Refer

to command SET OPER_MODE STANDBY.

STOP Stop internal compensation routine

Page 47

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

4.4 Data Messages

The following standard messages are provided:

Data message No. 1, 2, 3, 6 and 7.

ANet / INet communication with DMX611.

Status message S.

Each port can be set to transmit a specified message automatically.

Alternatively the port can be set to transmit the set message only when polled

by a predetermined polling string of characters, or the polling string can

contain the message identification.

NOTE

All characters are 7-bit USASC II.

↵ symbolizes Carriage Return+Line Feed (2 characters)

throughout this document.

Start-of-Header, Start-of-Text, End-of-Text, Carriage

Return and Line Feed are non-printing characters in most

practical terminal use.

4.4.1 Data Message No. 1

This message is intended for cloud height/vertical visibility measurement

when no other measurement information is desi red. The message includes th e

most elementary status information, which enables a host system or operato r

to see that no warnings or alarms are present. An example of data message

no.1 is presented below:

CTA2010J↵ 1st line 11 char.

(

30 01230 12340 23450 FEDCBA98↵ 2nd line 31 char.

↵ 3rd line 3 char.

L

-----------------total 44 characters

Transmission time and size :

0.18 s at 2400 baud (10-bit char.)

10.6 kbytes/h, 253 kbytes/d, 7.6 Mbytes/mo. at 4 msg./min., uncompressed.

33

Page 48

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

Interpretation of the message is as follows :

1ST LINE

Example: (CTA2010 J↵

where

( St art-of-He ading char acter

CT Ceilometers’ identification string; always CT

A Unit number 0...9, A...Z

20 Software level id 00...99

1 Message numbe r; this message is al wa ys = 1

0 Spare character for futur e subclasses o f message

J Start-of-Text C haracte r

2ND LINE

Example: 30 01230 12340 23450 FEDCBA98↵

where

3 First digit of line: detection status as follows:

0 No significant backscatter

1 One cloud base detected

2 Two cloud bases detected

3 Three cloud bases detected

4 Full obscuration determined but no cloud base detected

5 Some obscuration detected but determined to be transparent

/ Raw data input to algorithm missing or suspect

0 Second digit of line: Warnings and Alarm information as follows:

0 Self-check OK

W At least one Warning active, no Alarms

A At least one Alarm active

01230 If detection status is 1, 2 or 3: Lowest cloud base height

If detection status is 4: Vertical Visibility as

calculated

If detection status is 0 or 5: /////

12340 If detection status is 2 or 3: Second lowest cloud base

If detection status is 4: Highest signal detected

If detection status is 0, 1 or 5: /////

23450 If detection status is 3: Highest cloud base height

If detection status is 0, 1, 2, 4, 5: /////

34

height

Page 49

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

FEDCBA98 Alarm (A), Warning (W), and internal status information. Each character

is a hexadecimal representation of four bits, altogether 32 bits (b00-b31),

with the following breakdown. Interpretation as follows:

F: b31 Laser temperature shut-off (A)

b30 Laser failure (A)

b29 Receiver failure (A)

b28 Voltage failure (A)

E: b27 (spare) (A)

b26 (spare) (A)

b25 (spare) (A)

b24 (spare) (A)

D: b23 Window contaminated (W)

b22 Battery low (W)

b21 Laser power low (W)

b20 Laser temperature high or low (W)

C: b19 Internal temperature high or low (W)

b18 Voltage high or low (W)

b17 Relative Humidity is > 85 % (option) (W)

b16 Receiver optical cross-talk

compensation poor (W)

B: b15 Blower suspect (W)

b14 (spare) (W)

b13 (spare) (W)

b12 (spare) (W)

A: b11 Blower is ON

b10 Blower heater is ON

b09 Internal heater is ON

b08 Units are METERS if ON, else FEET

9: b07 Polling mode is ON

b06 Working from battery

b05 Single sequence mode is ON

b04 Manual settings are effective

8: b03 Tilt angle is > 45 degrees

b02 High background radiance

b01 Manual blower control

b00 (spare)

For example, if the battery voltage is too low, the internal heater is on and

units are meters, a warning is given and the s econd line appe ars as

0W ///// ///// ///// 00400300.

3RD LINE

L↵ End-of-Text and CRLF

35

Page 50

Ceilometer CT25K

User’s Guide CT25K-U059en-2.1

4.4.2 Data Message No. 2

Data message no. 2 contains the range and sensitivity normalized backscatter

profile within a range of 0..25000 ft, which makes it suitable for e.g. graphical

plotting of the atmosphere.

Data resolution is 100ft = 30 m with distance, and 16 bits (four hex-ASCII

characters) with si gnal magnitude.

NOTE

Message no. 2 should not be used with slow baud rate and

short data acquisition interval; this may lead to overflow

of the transmit buffer. E.g. 300 baud rate requires 45 sec.

data acquisition interval with message 2. In case the buffer

is filling up, the response time to user command may

extend to minutes.

An example of data message no. 2 is presented be low:

(

CTA2023

30 01230 12340 23450 FEDCBA98↵ 2nd line 31 char.