V 7-025 NW

V 7-035 NW

V 7-050 NW

DE, EN, HR, IT, TR

EN

2

Contents

Split Type Installation Manual

Contents

1 Your Safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

1.1 Symbols used

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

1.2 Correct Use of the Unit

. . . . . . . . . . . . . . . . . . . . . . .

3

. . . . . . . . . . . . . .

3

3 Identification of the Unit

. . . . . . . . . . . . . . . . . .

3

4 Declaration of Conformity

. . . . . . . . . . . . . . . .

4

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller

. . . . . . . . . . . . . . . . . . . . . . . . . .

connections

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Unpacking

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualification of the Installation Personnel

. . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

9

9 Installation of the Indoor Unit

. . . . . . . . . . . . .

9

9.1 Selecting the Indoor Unit Location

. . . . . . . . . . . . .

9

9.2 Fixing the Assembly Plate

. . . . . . . . . . . . . . . . . . . .

9

9.3 Installation of the Pipe Work

. . . . . . . . . . . . . . . . .

9.3.1

Correct Removal of the Condensate Water

. . . . .

1

9.3.2 Handling the Refrigerant Pipes

. . . . . . . . . . . . . . .

1

9.3.3

. .

1

1

9.3.4

Making Holes for the Pipes

. . . . . . . . . . . . . . . . . . .

9.3.5 Correct installation of the refrigerant pipe work

.

9.3.6 Installation of the Indoor Unit Body

. . . . . . . . . . . .

3

10 Installation of the Outdoor Unit

. . . . . . . . . . .

1

3

10.1 Selecting the Assembly Location

. . . . . . . . . . . . . .

1

3

10.2 Planning the Refrigerant Return

. . . . . . . . . . . . . .

10.3 Connection of the Refrigerant Pipe Work

. . . . . .

10.4 Connection of the Pipe for the Removal of

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1

11 Electric Wiring

. . . . . . . . . . . . . . . . . . . . . . . . . .

1

11.1 Safety Precautions

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1

11.2

. . . .

11.3 Electric Connection to the Indoor Unit

. . . . . . . .

11.4 Electric Connection to the Outdoor Unit

. . . . . . . .

11.5 Electrical Characteristics

. . . . . . . . . . . . . . . . . . . .

1

12 Preparation for Use

. . . . . . . . . . . . . . . . . . . . . .

1

9

12.1 Checking for Leaks

. . . . . . . . . . . . . . . . . . . . . . . . .

1

9

12.2 Evacuating the Installation

. . . . . . . . . . . . . . . . . . .

1

9

12.3 Start Up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

Error Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Split Type Installation Manual

3

EN

1.1 Symbols used

Danger!

Danger!

Warning

Note!

1.2 Correct Use of the Unit

sole purpose of comfort cooling and heating occupied

the unit's installation manual.

Note!

the unit.

Note!

The information relating to this unit is divided between

two manuals: installation manual and user manual.

Your Safety 1

Extreme operating conditions 2

Identification of the Unit 3

Note!

The relevant personnel performing any service of

maintenance operations involving the handling of

the refrigerant fluid must have the necessary

certification to comply with all local and

international regulations.

2 Extreme Operating Conditions

these ranges are not exceeded.

CALEFACCIÓN

3 Identification of the Unit

to know the specific model of your unit please refer to

the unit nameplates.

Note!

This equipment contains R-410A refrigerant. Do

not vent R-410A into atmosphere: R-410A, is a

fluorinated greenhouse gas, covered by Kyoto

Protocol, with a Global Warming Potential (GWP)

= 1975.

Note!

The refrigerant fluid contained in this

equipment must be properly recovered for

recycling, reclamation or destruction before

the final disposal of the equipment.

Outdoor

43ºC D.B.

-10ºC D.B.

18ºC D.B.

18ºC D.B.

27ºC D.B.

24ºC D.B.

-15ºC D.B.

OOLING

HEATING

27ºC D.B.

Split Type Installation Manual

4

standard in force with regard to obtaining the CE

1 Indoor Unit

2 Outdoor Unit

3 Remote controller

4 Interconnecting pipework (not supplied)

shown on Figure 5.2 and Table 5.1, depending on the

V 7-025 NHI

285

160

10

V 7-035 NHI

285

160

10

V 7-050 NHI

285

160

10

Table 5.1 Dimensions and weights of the indoor unit.

4 Declaration of Conformity

5 Description of the Unit

Split Type Installation Manual

EN

transferred and released to the outside from the room

shown on Figure 5.3 and Table 5.2, depending on the

A Length of valves

J Distance between fixing supports

C

J

V 7-025 NHO

780

24545265

30

V 7-035 NHO

780

24545265

30

V 7-050 NHO

783

2554870

255

40

Table 5.2 Dimensions and weights of the outdoor unit.

Description of the Unit 5

Split Type Installation Manual

there is a line of sight to the indoor unit.

Accessory

Quantity

Remote control

2

Remote control bracket

1

3

Batteries

2

4

Mounting plate

1

Drain Pipe

Outdoor Unit

1

Rubber mounting feet

4

2

Drain elbow

1

3

Rubber Cap

2

Table 5.3 Accessories supplied with the unit.

5 Description of the Unit

Split Type Installation Manual

7

EN

V 7-025 NW

V 7-035 NW

V 7-050 NW

Power supply

V/Ph/Hz

230/1/50

3,43

4,61

1,07

1,53

A

4,50

4,80

7,06

3,03

3,98

5,32

1,10

1,65

4,50

4,70

7,70

Air Flow volume

3

/h

280/320/350

360/410/450

420/460/500

dB(A)

24/30/36

26/34/38

36/41/45

285x850x160

285x850x160

285x850x160

101010

Outdoor Unit

Air Flow volume

3

/h

1800

2100

1800

dB(A)

gr

700

1000

1350

Scroll

303040

1/4" - 3/8"

1/4" - 3/8"

1/4" - 1/2"

35

35

41,5

151515

101010

101010

Additional charge per metre

gr

202020

Table 5.4 Technical specifications.

Note!

these specifications without prior notice.

Description of the Unit 5

Split Type Installation Manual

Danger of injury and physical damage!

fall and injure anyone within the immediate

vicinity. To avoid this:

correctly (consult the respective user

fixings in the mounting points provided.

equipment (helmet, gloves, safety boots and

Danger of injury and physical damage!

this:

for the unit weight.

correctly (consult the respective user

equipment (helmet, gloves, safety boots and

supplier immediately.

Warning

standards in force. Do not dispose of packaging

Danger of injury and physical damage!

this:

capacity for the unit weight.

equipment (helmet, gloves, safety boots and

Danger of injury and physical damage!

The unit should be installed in accordance with

the Regulations and Standards for refrigeration,

electrical and mechanical installation pertaining

to the country in which the installation is being

Danger!

earthed.

Danger!

Warning

6 Transport

7 Unpacking

8 Installation

Split Type Installation Manual

9

EN

Warning

assembly distances.

1 Indoor Unit

2 Outdoor Unit

3 Condensate connection for outdoor unit

A Clearance to the front of the internal unit (minimum 10 cm)

9.1 Selecting the Indoor Unit Location

Warning

Note!

suit these conditions.

9.2 Fixing the Mounting Plate

Warning

Warning

Installation 8

Installation of the indoor unit 9

Split Type Installation Manual

10

9.3 Installation of the Pipe Work

9.3.1 Correct Removal of Condensate Water

Warning

take the recommendations described in this

section into account.

to cover the flexible pipework.

the condensed water, carrying the condensed water to

Note!

Warning

9.3.2 Handling the Refrigerant Pipes

Danger!

.

Warning

Note!

specific class ‘O’ closed cell insulation.

subsequent refrigerant leaks.

there is no strain on the pipe joints.

thread and may allow water ingress into the

9 Installation of the indoor unit

Split Type Installation Manual

11

EN

9.3.3 Correct Installation of the Condensate Pipe

Warning

water leaks and blockages from unit and

Minimum distance from the floor.

Installation of the indoor unit 9

Split Type Installation Manual

12

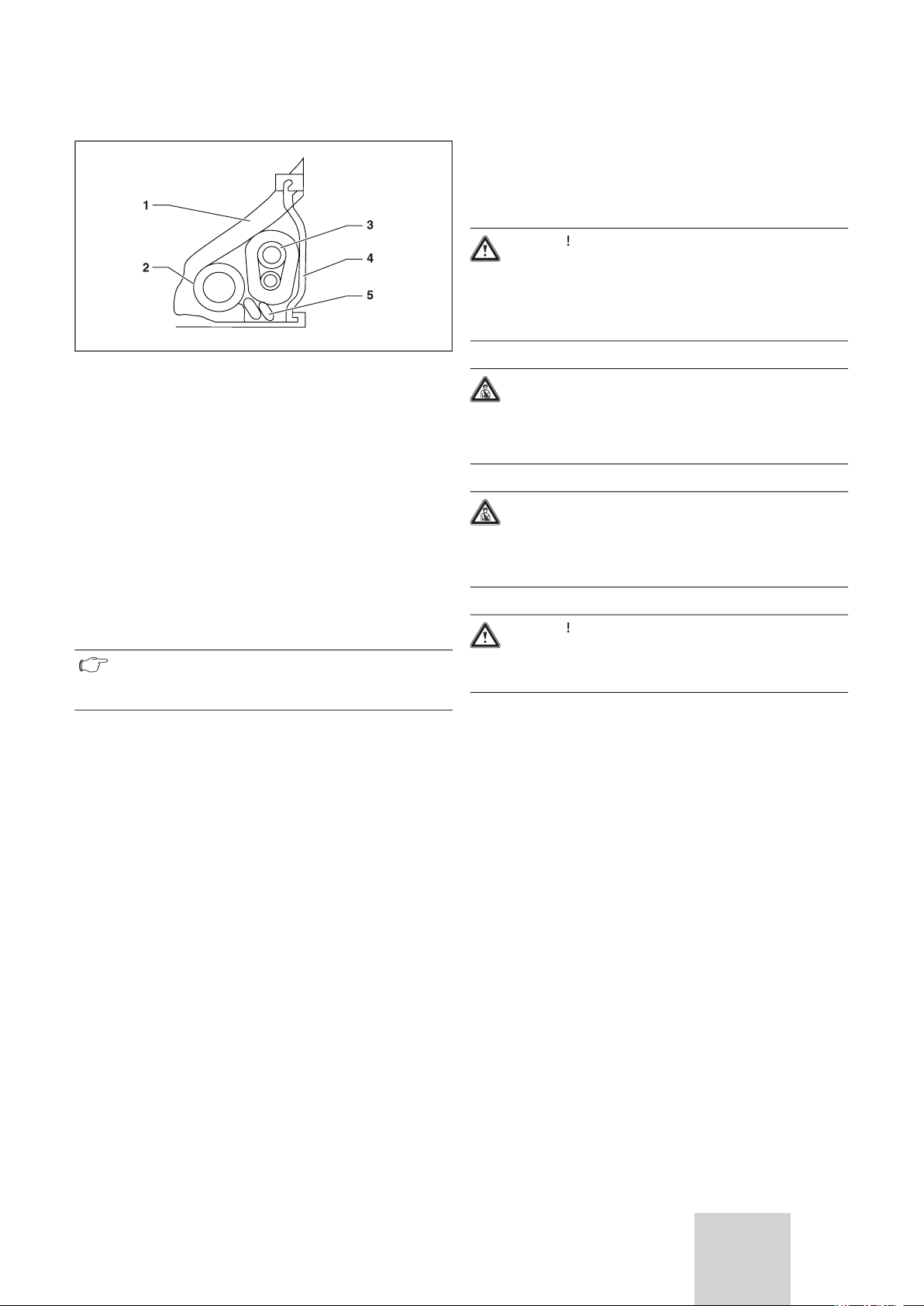

9.3.4 Making Holes for the Pipes

since the indoor unit body has knock outs which can

the most convenient one for the desired outlet

9.7

1 Exit for right piping

2 Exit for indoor piping

3 Securing with adhesive tape

4 Exit for left piping

9.3.5 Correct Installation of Indoor Unit Refrigerant

Warning

to go through the wall width. If this is not the case

the condensed water hose to the installation drain.

separately. To do so, cover any possible cuts with

the corresponding insulation material suitable for air

9 Installation of the indoor unit

Split Type Installation Manual

13

EN

1 Heat-resistant material

2 Drain pipe

3 Insulated refrigeration pipes

4 Piping support plate

9.3.6).

the connections at the rear of the unit first before

Note!

9.3.6 Installation of the Indoor Unit Body

supports properly, repeat this process.

10.1 Selecting the Assembly Location

Warning

for subsequent maintenance and repair

Danger of personal injury and material damage

from explosion!

or liquids or easily combustible substances and

free from thick dust formation.

Danger of personal injury and material damage

from collapse!

and can withstand the weight of the outdoor

Warning

vibrations.

Installation of the indoor unit 9

Installation of the outdoor unit 10

Split Type Installation Manual

14

10.2 Planning the Refrigerant Return

the outdoor unit compressor. To assist the return of the

10.3 Connection of the Refrigerant Pipes

Note!

supplied).

Warning

separately. To do so, cover any joints in the insulation

10.4 Connection of the Condensate Drain Pipe to

90º to fix it (see Figure 10.1).

1 Outdoor Unit

2 Drainage elbow

3 Drainage hose (not supplied)

10 Installation of the outdoor unit

Split Type Installation Manual

15

EN

11.1 Safety Precautions

Danger!

Danger!

All electrical works should be completed by an

electrician or a similarly qualified person.

Danger!

two or three pole isolating switch

according to

the model, (single phase or three-phase) with a

distance of at least 3 mm between contacts

Danger!

Danger!

electrical sockets only use with a suitable

adaptor or replace the plug with a UK style one

or remove and connect directly into a suitable

electrical isolator.

Danger!

electrics.

Danger!

cable.

Warning

Warning

Warning

Warning

Installation of the outdoor unit 10

Electric Wiring 11

Split Type Installation Manual

16

11.2 Remark with regard to Directive 2004/108/CE

the start up of the compressor (technical process), the

supply connected directly to the distribution board.

Ensure the completed electrical installation has low

Note!

supply board.

Note!

11.3 Electric Connection to the Indoor Unit

Warning

with type T. 3,15A/250V.

the interior unit.

11 Electric Wiring

Split Type Installation Manual

17

EN

V 7-025 NW, V 7-035 NW and

V 7-050 NW.

1 Terminal connections for the indoor unit

2 Terminal connections for the outdoor unit

11.4 Electric Connection to the Outdoor Unit

Warning

with type T. 25A/250V.

terminal leaving no exposed conductor before

tightening the screws to clamp the cable.

Warning

from water penetration.

Warning

from short-circuits.

the unused cable wires using electrical tape and

Electric Wiring 11

3

(C

)

1

(N

)

2

(L

)

3

(C

)

1

(N

)

2

(L

)

230/1/50

1

Split Type Installation Manual

18

11.5 Electrical Characteristics

V 7-025 NW

V 7-035 NW

V 7-050 NW

230/1/50

230/1/50

230/1/50

Supply

2

)

1,5

1,5

1,5

Thermal-magnetic circuit breaker, type D (A)

101010

2

)

1,5

1,5

1,5

Table 11.1 Electrical Characteristics.

11 Electric Wiring

Split Type Installation Manual

19

EN

12.1 Checking for leaks

1 Suction valve (gas)

2 Return valve (liquid)

3 Service manifold (suitable for R410a refrigerant)

4 Non-return valve

Warning

testing should only be undertaken by competent

the gas line stop valve of the outdoor unit.

the refrigerant gauges.

the service valve on the outdoor unit as this will release

the pre-charged refrigerant from the outdoor unit.

valves on the service manifold and remove the

test has been successfully completed.

tests are performed and the results correctly logged into

the maintenance record of the machine. The leakage

test must be done with the following frequency:

12.2 Evacuating the Installation

12.2 Evacuating the installation

1 Suction valve (gas)

2 Return valve (liquid)

3 Service manifold (suitable for R410a refrigerant)

4 Non-return joint

the gas line of the outdoor unit.

the service manifold.

vacuum pump

15 minutes (depending on the size of the installation)

to carry out the vacuum.

Preparation for Use 12

Split Type Installation Manual

20

should indicate -0.1 MPa (-76 cmHg - >3 Torr). If the

service manifold gauge is not capable of measuring to

these pressures a separate Torr vacuum gauge should

open and vacuum pump operational.

15 minutes have elapsed: the pressure should not rise.

them (Check all joints and connections to the service

Warning

satisfactory evacuation of the installation has

closed and the vacuum pump switched off: checking

for leaks.

Warning

12.3 Start Up

1 Two-way valve

2 Allen key to open valves

the allen key anticlockwise as far as it will go.

1 Two-way shut off valve

2 Three-way service valve

3 Allen key (not supplied) to open valves

12 Preparation for Use

Split Type Installation Manual

21

EN

1 Valve cap

2 Two and three-way valve covers

12.4 Troubleshooting

Warning

Warning

Preparation for Use 12

Split Type Installation Manual

22

13 Error Codes

OUTDOOR

E1

/

1) Room-temperature sensor may be faulty

2) Indoor PCB may be faulty

E2

/

1) Heat-exchange sensor may be faulty

2) Indoor PCB may be faulty

1) Defrosting temperature sensor may be faulty

2) Outdoor PCB may be faulty

1) Exhaust temperature sensor may be faulty

2) Outdoor PCB may be faulty

so.

1) Ambient temperature sensor may be faulty

2) Outdoor PCB may be faulty

so.

1) Suction temperature sensor may be faulty

2) Outdoor PCB may be faulty

1) The outdoor mainboard may be damp and needs drying

2) The indoor mainboard may be damp and needs drying

3) The linking cable between the indoor and outdoor units

4) The indoor PCB may be faulty

1)

The wiring of compressor is incorrect or the connection is

faulty

2) The SPDU may be faulty

3) Compressor may be damaged.

1) The refrigerant may have been leaked during installation,

2) Exhaust temperature sensor may be faulty

3) The outdoor mainboard is damaged and needs be

Split Type Installation Manual

23

EN

Error Codes 13

OUTDOOR

1) The SPDU may be faulty

2) The power supply is incorrect

3) The system may have been over or under charged with

1) IPM Module may be overheating

2) IPM Module may be damaged

3) Compressor may be damaged

1) Check whether the indoor unit has poor airflow due to

2) The system is over charged with refrigerant.

3) Indoor pipe sensor may be faulty.

1) The indoor PCB might be damaged

2) The outdoor PCB might be damaged

/

1) Check whether Terminal CN2 on the indoor mainboard is

2) The indoor mainboard may be faulty

3) The motor of the indoor unit may be faulty

1) Check whether terminal CN2 on the outdoor mainboard

2) The mainboard of the indoor unit may be faulty

3) The motor of the Outdoor unit may be faulty

1) The connection between IPM and the outdoor PCB may

2)The mainboard of the outdoor unit may be damaged

3)The IPM module may be damaged

1) The IPM module may be damaged

2) Check power supply is correct

3) The transformer of outdoor mainboard is damage

4) The rectifying bridge or IPM module may be faulty

Loading...

Loading...