VACUUBRAND DVR 4S User Manual

page 1 of 20

Technology for Vacuum Systems

Instructions for use

DVR 3 II 2 G EEx ia IIC T4

DVR 4 II 1/2 G EEx ia IIC T5

DVR 4S II 1/2 G EEx ia IIC T5

Digital/Analogue Rough Vacuum Gauges

PTB 98 ATEX 2207

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

page 2 of 20

Dear customer,

Your VACUUBRAND vacuum gauge shall support you at your work for a long time without any trouble and

with full load output. Thanks to our large practical experience we attained much information how you could

add to an efficient application and to personal safety. Please read these instructions for use prior to the

initial start-up of your controller.

VACUUBRAND vacuum gauges are the result of many years of experience in construction and practical

operation of these vacuum gauges combined with the latest results in material and manufacturing technology.

Our quality maxim is the ”zero fault principle”:

Every delivered vacuum gauge is tested extensively including an endurance run. Due to this endurance

run, also faults, which occur rarely, are reported an can be corrected. Every single vacuum gauge is tested

on achievement of the specification after the endurance run.

Every VACUUBRAND controller leaving our factory achieves the specification. We feel obliged to

this high quality standard.

We are aware that the controller should not draw a part of the real work and we hope to contribute with our

products to an effective and troublefree realisation of your work.

Yours

VACUUBRAND GMBH + CO KG

After sales service: Contact your local dealer or call (++49) 9342/808-193.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

page 3 of 20

Contents

Safety information! ....................................................................................................4

Technical data ............................................................................................................5

Accessories ............................................................................................................... 7

Spare parts ................................................................................................................7

Use and operation ..................................................................................................... 8

Description of the current loop (DVR 4S) ..............................................................10

Troubleshooting ......................................................................................................12

Readjustment of the vacuum gauge ......................................................................13

Calibration in the factory......................................................................................... 14

Readjustment of the current loop (DVR 4S) ..........................................................15

Replacement of power supply unit ........................................................................16

Notes on return to the factory ................................................................................ 17

Health and safety clearance form ..........................................................................18

Attention! Important notes!

Not permitted! Misuse may cause damage.

Caution! Hot surface!

Isolate equipment from mains.

Note.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

page 4 of 20

Safety information!

Remove all packing material, remove the product from its packing-box, remove the protective covers and

keep them, inspect the equipment.

If the equipment is damaged, notify the supplier and the carrier in writing within three days; state the item

number of the product together with the order number and the supplier’s invoice number. Retain all packing

material for inspection.

Do not use the equipment if it is damaged.

If the equipment is not used immediately, replace the protective covers. Store the equipment under suitable

conditions.

☞ Read and obey this manual before installing or operating the equipment.

The devices DVR 3, DVR 4 and DVR 4S are electronic rough vacuum gauges of the facility performance

group II for the intended use in hazardous areas. They have a special approval and are subject to the

guideline 94/9/EG (see ”Declaration of Conformity)”.

Obey the instructions for use.

☞☞

☞ Respect the permitted connection parameters.

☞☞

☞☞

☞ Obey all applicable regulations and realize all required measures.

☞☞

☞☞

☞ Electrical and vacuum components might require a separate approval (see also ”Accessories”).

☞☞

The vacuum gauges DVR 4 and DVR 4S are devices to be operated with the vacuum connection mounted

at hazardous areas of category 1 (or higher) whereas the housing is within hazardous areas of category 2

(or higher).

☞ Check the devices together with the regularly pressure test of the recipient regarding tightness.

☞☞

☞ Obey the requirements according to EN 50284.

☞☞

Attention:

DVR 3 has only an approval for zone 1.

DVR 4 / DVR 4S has only an approval for zone 1, only the measuring connection

has an approval for zone 0.

Prevent any condensate to reach the pressure transducer inside the vacuum gauge (risk of false

measurement).

Max. permitted pressure at the vacuum gauge:

☞ DVR 3: 1.1 bar absolute; with small flange connection 2.5 bar absolute.

☞ DVR 4 / DVR 4S: 2.5 bar absolute; when using clamping rings made of stainless steel, the max.

permitted pressure at the measuring connection is 6.0 bar absolute.

☞ The display flashes at a pressure above 1060 mbar.

The power supply unit BVE 9V is an intrinsically safe electrical operating device of the facility performance

category 2 (PTB 98 ATEX 2206). The user can replace the sealed power supply unit of vacuum gauges

DVR 3 / DVR 4 / DVR 4S within the hazardous area of category 2 (according to the approvals of power

supply unit and vacuum gauge). Further interventions and repair must only be done by the

manufacturer.

☞ Warning: For replacing the power supply unit of the DVR 4S in explosive atmosphere the current loop

must be disconnected.

☞☞

☞ Using non-genuine power supply units or doing further interventions void the approval for use

☞☞

in explosive areas.

In order to comply with law (occupational, health and safety regulations, safety at work law and regulations

for environmental protection) components returned to the manufacturer can be repaired only when certain

procedures (see section “Notes on return to the factory“) are followed.

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

page 5 of 20

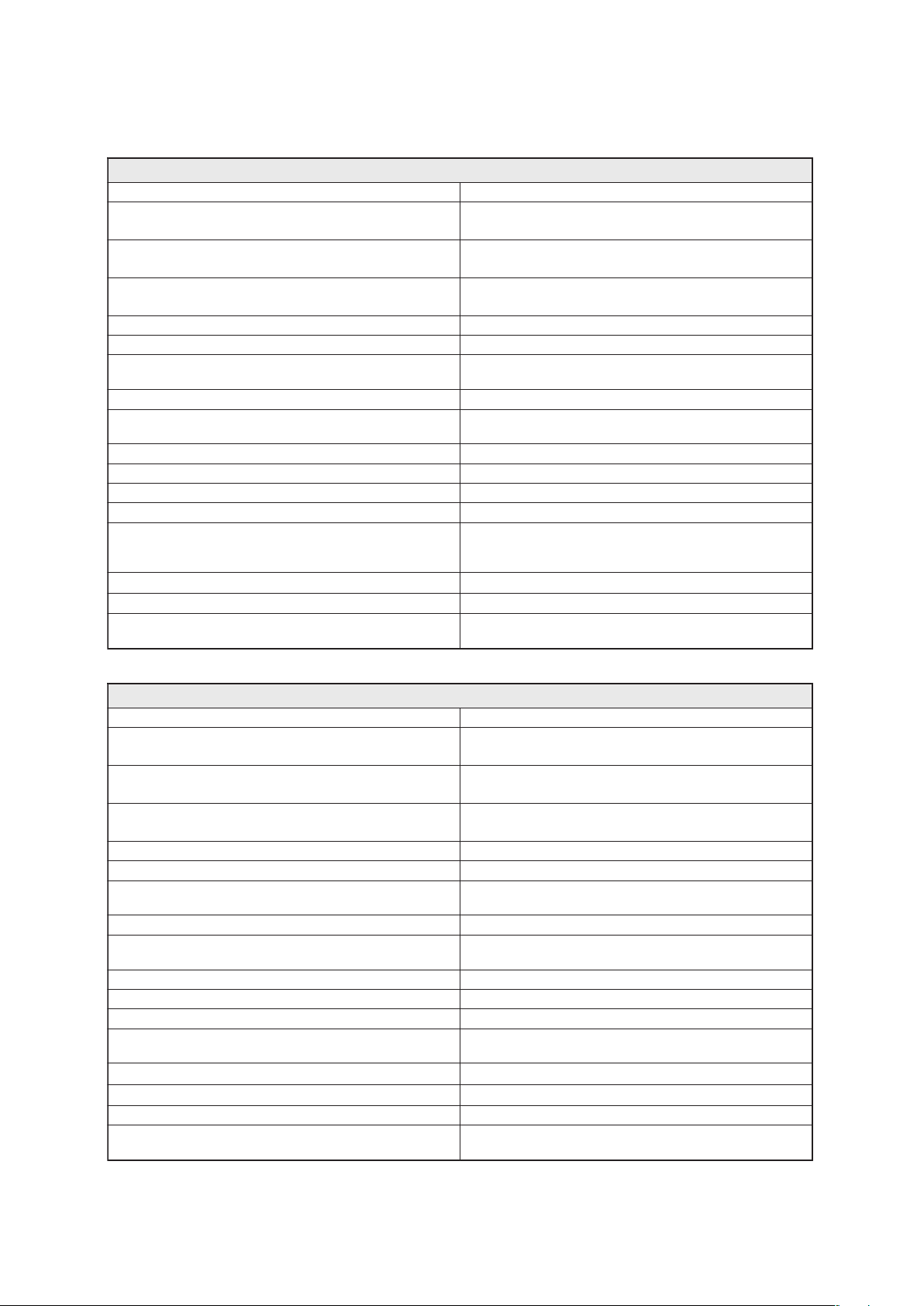

Technical data

3RVDatadlacinhceT

recudsnarterusserPcimarec/eviticapac

doirep"nO" "nO"ro.nim999-1emitnoitarepoelbatcelesresu

gnidaererusserP yalpsidDCLeugolanadnalatigid

emite

lcycgnirusaeM ,s1nihtiwx1,s3nihtiwx1,citamotua:elbatceles

eM )rroT1-rroT018(rabm1-rabm0801

cfoorpxE 1enozniesurof,4TCIIaixEEG2II

thgieWg034

egnargnirusa

udsnarthtiw(ytniatrecnU

)erutarepmettnatsnoctadna

tneiciffeocerutarepmeT )K/

)!ylnosag(recudsnarterusserp

(egnarerutarepmeTC°04+otC°01+

noitacifissalcerusolcnE04

noitacifissal

noitcennocmuucaV esohdeppetsni-wercsdna61WNegnalfllams

tinuylppusrewoP 5TCIIaixEEG2II,6022XETA89BTP,V9EVB

uohfosnoisnemiD gnirusaemtuohtiw(mm53xmm611xmm611

)gnitarepo

)egarots(egnarerutarepmeTC°06+otC°01-

)HxWxL(gnis

ehttaaidemsuoesagfoerutarepmet.xaM

eguagmuucavehttaerusserpdettimrep.xaMetulosbarab5.2

detsujdaylluferacrec

otcaf()noitareposuounitnoc(

)elbatceles(rroTroaPh,rabm

)citamotua:tes-yrotcaf(s1nihtiwx3

tigid1-/+)rroT57.0(rabm1-/+<

rroT50.0<(K/rabm70.0-/+<

C°08+

htiwsesohmuucavrofelzzon

retemaid

)noitcennoc

).nim51:tes-yr

edisnimm01/6

S4RVD/4RVDatadlacinhceT

recudsnarterusserPcimarec/eviticapac

doirep"nO" "nO"ro.nim999-1emitnoitarepoelbatcelesresu

gnidaererusserP yalpsidDCLeugolanadnalatigid

emite

lcycgnirusaeM ,s1nihtiwx1,s3nihtiwx1,citamotua:elbatceles

eM )rroT1-rroT018(rabm1-rabm0801

gieWg037

th

egnargnirusa

eguagmuucavehttaerusserpdettimrep.xaMetulosbarab5.2

udsnarthtiw(ytniatrecnU

)erutarepmettnatsnoctadna

tneiciffeocerutarepmeT )K/

)!ylnosag(recudsnarterusserp

(egnarerutarepmeTC°04+otC°01+

noitacifissalcerusolcnE 45:S4RVD/04:4R

noitacifissalcfoorpxE ylno(0enozxEtaesurof,4TCIIaixEEG2/1II

ocmuucaV sretpadatnereffid,61WNegnalfllamsotralimis

noitcenn

tinuylppusrewoP 5TCIIaixEEG2II,6022XETA89BTP,V9EVB

)gnitarepo

)egarots(egnarerutarepmeTC°06+otC°01-

)HxWxL(gnisuohfosnoisnemiD gnirusaemtuohtiw(mm53xmm611xmm611

detsujdaylluferacrec

ehttaaidemsuoesagfoerutarepmet.xaM

otcaf()noitareposuounitnoc(

)elbatceles(rroTroaPh,rabm

)citamotua:tes-yrotcaf(s1nihtiwx3

tigid1-/+)rroT57.0(rabm1-/+<

rroT50.0<(K/rabm70.0-/+<

C°08+

VD

)noitcennoc

).nim51:tes-yr

1enozxEesiwrehto,)emulovgnirusaem

We reserve the right for technical modification without prior notice!

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

page 6 of 20

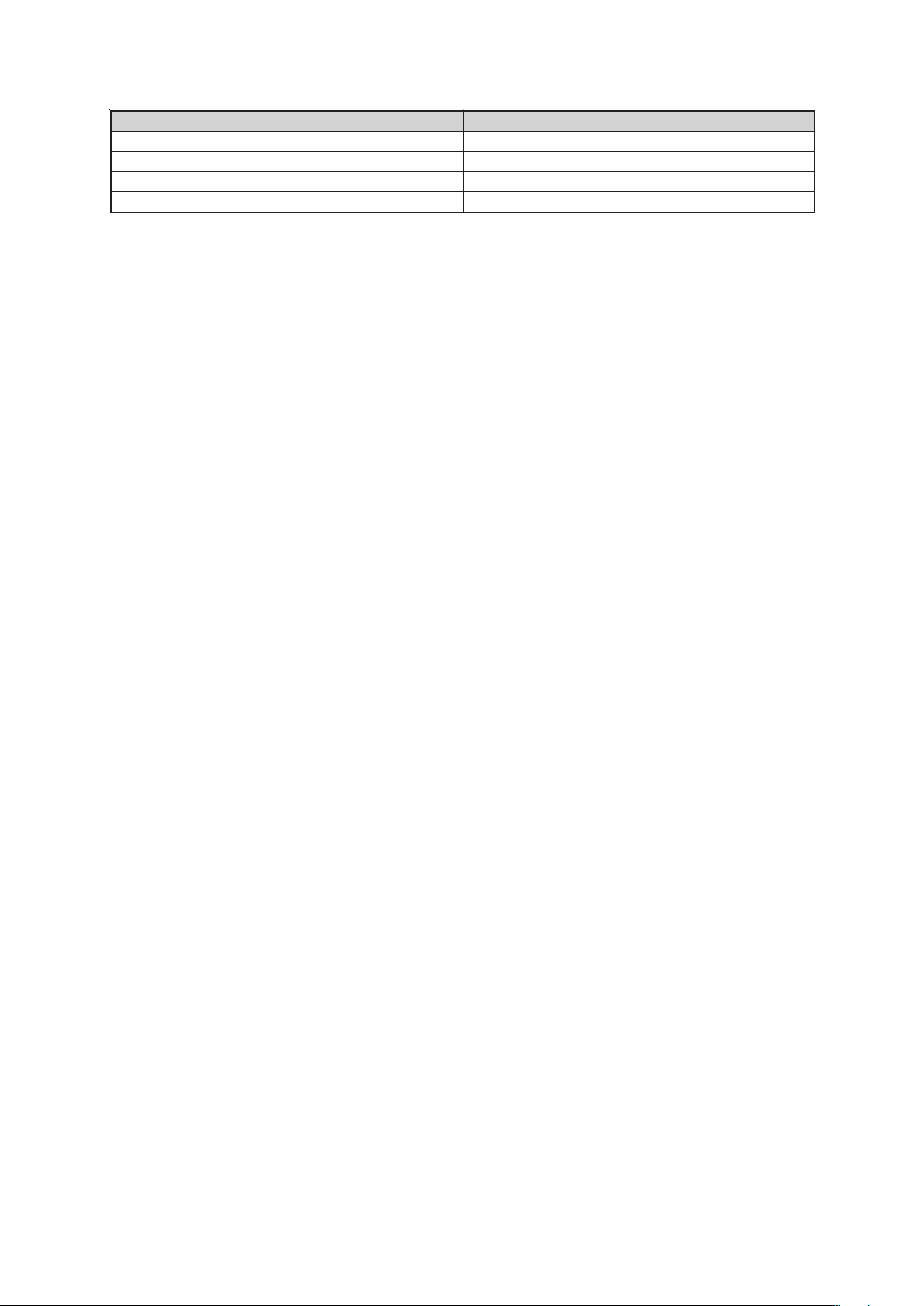

stnenopmoC strapdetteW

noitcennocmuucaVleetssselniats

slaeS remotsaleoroulftnatsiseryllacimehc

erPleetssselniats

gnisuohrecudsnarteruss

recudsnarterusserP cimarec-edixomuinimula

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 99 90 72 / 13/08/2005

Loading...

Loading...