Urschel E TranSlicer, E TranSlicer Cutter Manual

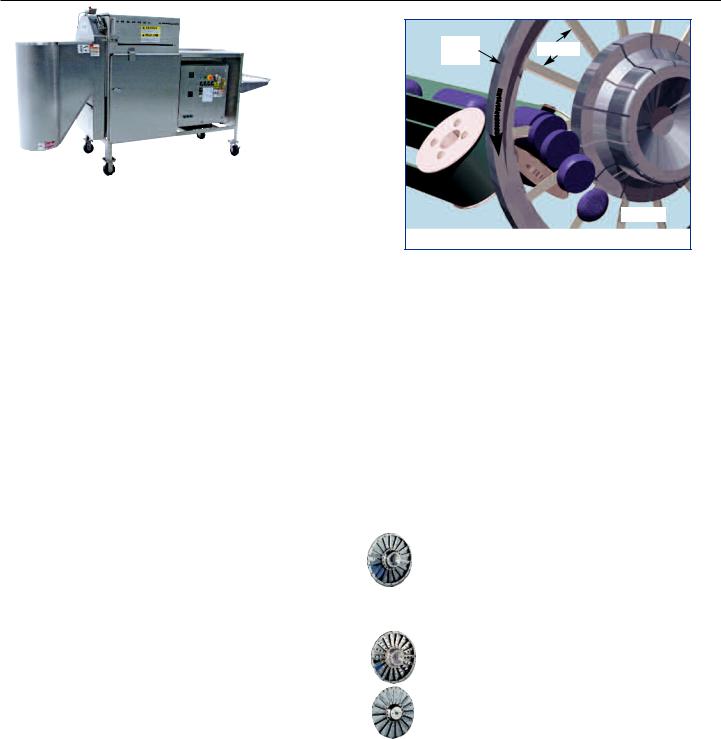

E TranSlicer® Cutter

Efficient, Engineered Excellence

!

SPEciFicaTiOnS

Length: . . . . . . . . . . . . . . . . . . . 100.78" (2560 mm)

. . . . . . . . . . . . . 117.26" (2978 mm) with prep table Width: . . . . . . . . . . . . . . . . . . . . . . 35.31" (897 mm) Height: . . . . . . . . . . . . . . . . . . . . . 61.79" (1569 mm)

. . . . . . . . . . . . . 66.36" (1686 mm) with remote stop

Net Weight: . . . . . . . . . . . . . . . . . . 1300 lb (560 kg) Motor: . . . . . . . . . . . . . . . . . . . . . . . . 3 HP (2.2 kW)

Feed Belt Motor: . . . . . . . . . . . . . . . . 1 HP (.75 kW)

aPPlicaTiOnS

After celebrating the company’s 100 year anniversary (1910 – 2010), Urschel emphasizes its focus on excellence in engineering by introducing the new E TranSlicer® Cutter. Engineered to produce continuous precision slices with extensive detail given to key elements throughout the machine, it joins the production-proven TranSlicer series in the Urschel line-up. The E TranSlicer is ideally suited for elongated vegetables, fruits, and cooked meats.

The E TranSlicer accepts firm products up to 4" (101.6 mm) in diameter and leafy-type, more compressible products up to 6" (152.4 mm) in diameter.

A variety of interchangeable stainless steel cutting wheels offers maximum versatility: slicing wheel, ¥patented MicroSlice® wheel, and julienne wheel. The machine features continuous operation for uninterrupted production.

Elements found throughout the design include:

•Stainless steel materials; machine size designed to fit easily into existing processing lines.

•Newly designed cutting wheel mount/holder assembly allows simple wheel changeovers.

•Hinged/sliding panels offer full access to all key areas of the machine and simplify maintenance and washdowns.

•Sloped surfaces throughout the machine including a selfdraining frame ease cleaning

•Sanitary design with all mechanical components completely separate from the food zone.

•Simple to use integrated electrical enclosure features circuit breakers instead of fuses and a brake motor button that releases the brake to facilitate maintenance.

•Electrical cables raised off of frame to allow simple washdowns and alleviate trapped food particulates.

•Indicator lights on the electrical panel and guardlocks illuminate when guardlocks are properly engaged.

•Available across-the-line start or variable frequency drive.

•Durable stainless steel guardlocks and sensors.

•Optional prep table to assist operators

•Optional remote operator stop button

•Hinged discharge chute features a polished internal slope, so cuts exit smoothly. Chute can be set-up to collect all product or

to separate fines.

Slicing |

Knives |

|

Wheel |

||

|

Product

Product

E TranSlicEr® cuTTEr

OPEraTinG PrinciPlE

Product is delivered onto two high speed feed belts sloping together to form a “V” shaped feed trough. The belts are synchronized with the rotating slicing wheel to ensure proper advance of product per revolution of the wheel. Knives under tension serve as spokes and support the rim of the slicing wheel. The knives are slightly twisted to create a uniform pitch from the hub to the rim. Knife pitch serves to pull product through the slicing wheel and produce a precise slice thickness. Available hold-down assembly enables increased positive feeding if needed. One slice is made at a time which prevents any crushing of the product. The cut slices are then released into a sloped discharge chute to reduce their speed before exiting the machine.

TYPES OF cuTS

SlicinG WHEElS

Flat & crinkle Slices: 1/32 to 3" (.8 to 76.2 mm) Crinkle slices have 4-2/3 waves per inch and with a

crinkle depth of 1/16" (1.6 mm). Slicing wheels can be converted to crinkle slicing by replacing the straight knives with

crinkle knives and using a different shear edge. JuliEnnE WHEElS: Julienne cuts ranging from 1/2 x

1/2" (12.7 x 12.7 mm) to 2 x 2" (50.8 x 50.8 mm) are produced by using julienne knives on the slicing wheel.

MicrOSlicE® WHEElS

Flat Slices: .020 to .240" (.5 to 6 mm)

crinkle Slice: .069" (1.8 mm) thickness with 3-1/3 waves per inch and with a crinkle depth of .080" (2.0 mm)

Oval Shred: This shred has an oval-shaped cross section measuring approximately .125" (3.2 mm) thick by .250" (6.4 mm) wide.

Julienne Strips: A wide range of julienne strips can be made from firm products. Contact your local representative for more information.

If your product application is not mentioned on this page, contact your local Urschel representative to determine the most effective solution to your size reduction needs.

(over)

Loading...

Loading...