Page 1

XEVL-2021-DPRS

Project

__________________________________________

Item

__________________________________________

Quantity

__________________________________________

Date

__________________________________________

Model

CHEFTOP MIND.Maps Big Plus

Combi steamer

Electric

20 Trays GN 2/1

Hinged left (Right Hand Door)

9.5" Touch control panel

STANDARD COOKING FEATURES

Settings

steps with one simple touch.

Programs

1000+ programs.

CHEFUNOX:

Automatic cooking programs.

MULTI.TIME: Up to 10 timers for multiple products

cooking in the same time.

MISE.EN.PLACE: Sincronize the food loading in the

cooking chamber to have every pan

ready at the same time.

READYCOOK: Ready to use settings for a quick start.

MIND.Maps™: Save up to 48 MIND.Maps™ programs.

Unox intensive cooking

STEAM.Maxi™: Humidity and steam production.

DRY.Maxi™: Forced extraction of humidity.

AIR.Maxi™:

manage fans auto-reverse and pulse

function.

APP & WEB SERVICES

Data Driven Cooking App & webApp.

Top Training App.

Combi guru App.

DESCRIPTION

Technologically advanced combi oven for gastronomy cooking

processes (dehydrating, steaming, low temperature cooking, sous vide

cooking, roasting, grilling, pan frying, regeneration and plate

regeneration) and for fresh or frozen baking process thanks to

CLIMALUX ™, STEAM.Maxi ™, DRY.Maxi™ and AIR.Maxi™

technologies. Automatic management of cooking processes

(CHEFUNOX) assisted by UNOX Intelligent Performance artificial

intelligence which guarantees perfect results and repeatability for any

load size.

KEY FEATURES

Unox intelligent performance

CLIMALUX™: Precise humidity control.

SMART.Preheating:

Automatic and intelligent cooking

chamber preheating.

ADAPTIVE.Cooking™:

Automatic adjustment of cooking

parameter for a perfect result for any

quantity of food load.

AUTO.Soft:

Smooth temperature rising management

for delicate product.

SENSE.Klean™:

Automatic and intelligent washing

system based on actual oven usage.

Data driven cooking

Ethernet: connection board to keep the oven

connected to UNOX cloud and UNOX App.

DDC Stats: Oven usage and consumption reports.

On-line recipe book and possibility to

send programs to ovens.

Unox intensive cooking

STEAM.Maxi™: Humidity and steam production.

DRY.Maxi™: Forced extraction of humidity.

AIR.Maxi™:

Multiple fans and auto-reversing fan

speed.

STANDARD TECHNICAL FEATURES

ROTOR.Klean™ : automatic washing system.

Automatic special washing behind the fan guard

Multipoint core probe: 4 sensors.

Triple glass

WI-Fi-/USB data: download/upload HACCP data.

WI-Fi-/USB data: download/upload programs

Integrated Det&Rinse tank.

LED: chamber illumination integrated in the door.

Tray supports with anti-tipping system

Stainless steel AISI 304 cooking chamber

We reserve the right to make technical improvements - October: 2019

UNOX S.p.A. | Via Majorana 22 - 35010 Cadoneghe PD - Italy - Tel. +39 049 8657511 - Fax. +39 049 8657555 - info@unox.com

Pag. 1 / 3

TEMPERATURE: 30 °C – 300 °C.

CLIMA.Control: Humidity or dry air set by 10%.

FANS: 4 fan speeds with auto-reverse and

pulse function.

MULTI.Point core probe.

Delta T cooking with core probe.

MIND.Maps™: Draw cooking processes made of infinite

Page 2

XEVL-2021-DPRS

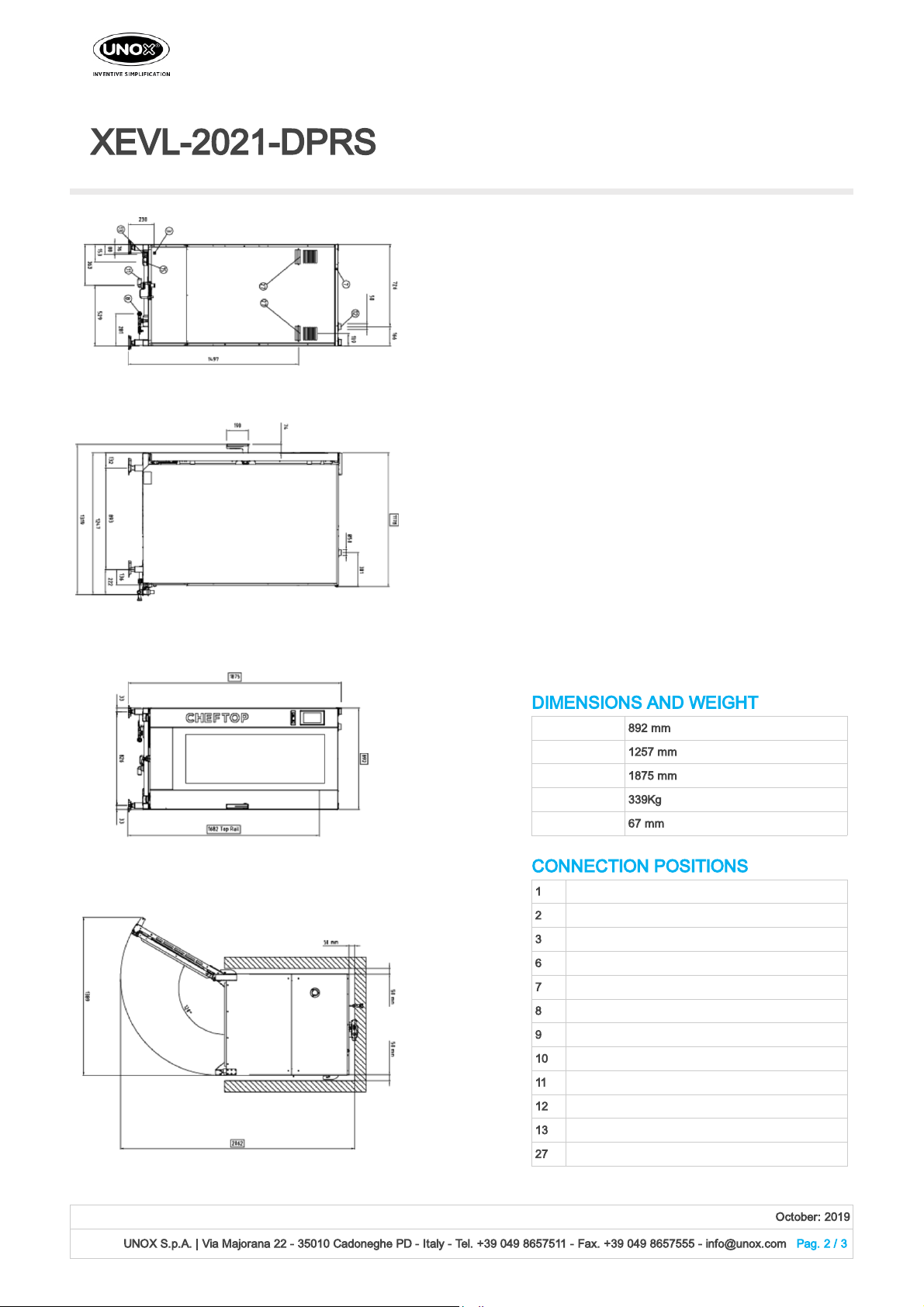

Views

Connection positions

Dimensions and Weights

DIMENSIONS AND WEIGHT

Width: 892 mm

Depth: 1257 mm

Height: 1875 mm

Net Weight: 339Kg

Pan Spacing: 67 mm

CONNECTION POSITIONS

1 Terminal board cover box

2 Terminal board power supply

3 Unipotential terminal

6 Technical data plate

7 Safety thermostat

8 3/4 " Thread water inlet

9 3/4" Gas inlet

10 Rotor.KLEAN connection

11 Cavity drain pipe

12 Hot fumes exhaust chimney

13

Accessories connection

27 Cooling air outlet

We reserve the right to make technical improvements - October: 2019

UNOX S.p.A. | Via Majorana 22 - 35010 Cadoneghe PD - Italy - Tel. +39 049 8657511 - Fax. +39 049 8657555 - info@unox.com

Pag. 2 / 3

Page 3

XEVL-2021-DPRS

Power and gas supply

Water connections

Installation requirements

Accessories

POWER AND GAS SUPPLY

STANDARD

Voltage 220-240 V

Phase 3PH+PE

Cycle 50-60 Hz

Total power 65 kW

Maximum Amp Draw 167 A

Required breaker size * 200 A

Power cable requirement H07RN-F 5G 3x1x70+35 mm²

Cord diameter 20 mm

Plug NOT INCLUDED

INSTALLATION REQUIREMENTS

Installations must comply with all local electrical systems, particularly

as for minimum wire gauge required for field connection, hydraulic

and ventilation supply.

Exhaust and fume analysis must be performed in case of gas ovens.

WATER CONNECTION

Supply

USING A WATER SUPPLY NOT MEETING UNOX’s MINIMUM

WATER QUALITY STANDARDS WILL VOID ANY WARRANTY.

It is the responsibility of the purchaser to ensure that the incoming

water supply is compliant with the specifications listed through

adequate treatment measures.

Line pressure:

Drinking water inlet: 3/4" NPT*, line

pressure: 21 to 87 psi; 1.5 to 6 Bar

Inflow water specifications

Free chlorine ≤ 0.2 ppm

Chloramine 0.1 ppm

pH 7 ÷ 8.5

Steam circuit: inflow water specifications

Total hardness (TH) ≤ 8 °d

Chlorides ≤ 25 ppm

Alkalinity

≤ 150 ppm as CaCO3

Clean circuit: inflow water specifications

Total hardness (TH) ≤20 °d

Chlorides ≤80 ppm

Alkalinity

≤ 250 ppm as CaCO3

ACCESSORIES

Det&Rinse PLUS

Concentrated detergent and rinse aid

Det&Rinse ECO detergent with natural ingredient

VENTLESS HOOD

Steam condensing hood (water required)

Activated Carbon filter for waterless hoods

COOKING ESSENTIALS

Special trays

Quick load and trolley system

UNOX PURE

Osmosis filter

UNOX PURE-RO Reverse osmosis filter

Sous-vide

extra-fine core probe for sous-vide

Wi/Fi Connection board to keep the oven

connected to UNOX cloud mandatory to

extend warranty

HYPER.Smoker

Smoker box for wood chips and sawdust

to smoke inside the cooking chamber

without extra electrical supply

Available in different voltage

Register to access data and product

specifications

infonet.unox.com

We reserve the right to make technical improvements - October: 2019

UNOX S.p.A. | Via Majorana 22 - 35010 Cadoneghe PD - Italy - Tel. +39 049 8657511 - Fax. +39 049 8657555 - info@unox.com

Pag. 3 / 3

Loading...

Loading...