Page 1

M-855

Industrial

Motherboard

User’s Manual

Recycled Paper

60070024IHA00

Page 2

Page 3

© Copyright 2004 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 1.00: August 16, 2004

The information in this document is subject to change without prior notice in order

to improve reliability, design, and function and does not represent a commitment

on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use or inability to use the product or

documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All rights

are reserved. No part of this manual may be reproduced by any mechanical,

electronic, or other means in any form without prior written permission of the

manufacturer.

Trademarks

NuDAQ

®

, NuIPC®, NuDAM®, NuPRO® are registered trademarks of ADLINK

Technology Inc. Other product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered trademarks of their

respective companies.

Page 4

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc. If you need any

help or service, please contact us.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan

Please email or FAX your detailed information for prompt, satisfactory, and

consistent service.

Detailed Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Questions

Product Model

OS:

Computer Brand:

M/B: CPU:

Environment

Detail Description

Chipset: BIOS:

Video Card:

NIC:

Other:

Suggestions for ADLINK

Page 5

Table of Contents

Chapter 1 Introduction.................................................................................1

1.1 Unpacking Checklist.................................................................2

1.2 Features .....................................................................................3

1.3 System Block Diagram.............................................................5

1.4 Specifications.............................................................................6

Chapter 2 Installation ..................................................................................9

2.1 System Installation....................................................................9

2.2 Board Layout ...........................................................................13

2.3 Jumper Settings ......................................................................14

2.4 Connector Descriptions..........................................................16

Chapter 3 Award BIOS Setup.................................................................33

3.1 BIOS Instructions...................................................................33

3.2 Main Menu ...............................................................................33

3.3 Standard CMOS Features.....................................................35

3.4 IDE Adapters ...........................................................................37

3.5 Advanced BIOS Features......................................................39

3.6 Advanced Chipset Features..................................................42

3.7 Integrated Peripherals............................................................45

3.8 Power Management Setup....................................................49

3.9 PnP/PCI Configurations.........................................................52

3.10 PC Health Status.....................................................................53

3.11 Frequency/Voltage Control....................................................54

3.12 Load Fail-Safe Defaults..........................................................54

3.13 Load Optimized Defaults........................................................55

3.14 Supervisor/User Password Setting.......................................55

3.15 Exiting BIOS Setup.................................................................56

Warranty Policy .............................................................................................57

Table of Contents • i

Page 6

Page 7

1

Introduction

The M-855 series combines the high performance and exceptional value of the Intel®

855GME chipset with a full-featured, next generation, industrial board. The Intel

855GME advanced chipset supports socket 478-pins Intel

ranging from 1.30GHz to 1.80GHz, and up to 2GB DDR SDRAM memory on its

400/533MHz FSB. It includes an integrated LVDS and VGA, an onboard Intel

Gigabit Ethernet controller (supporting 10/100/1000 Base-TX Ethernet), audio

line-out, four COM ports, two internal USB2.0 ports, 2 SATA ports, and a

CompactFlash™ type II connector. M-855 uses include ATM, CTI, KIOSK, POS, and

other high-end applications.

The 82801DB I/O Controller Hub (ICH4) employs the Intel

Architecture to make a direct connection from the graphics chip and memory to the

integrated Ethernet controller, IDE controllers (ATA/33, ATA/66, or ATA/100), and six

USB ports.

The M-855 industrial board supports Windows

system.

®

98/NT/2000/XP and Linux® operation

®

Pentium® M processors

®

Accelerated Hub

®

®

82541

Introduction • 1

Page 8

1.1 Unpacking Checklist

1. Take out the M-855 series unit from the carton box, check if the unit is properly

secure in its plastic bag.

2. Check the contents of the carton box:

¡ Industrial Board ¡ Installation Guide

¡ ATA-66/100 HDD ribbon cable ¡ Floppy ribbon cable

¡ S-ATA & Power cable (1 Set) ¡ Driver CD

¡ COM3 ribbon cable (1 Set) ¡ External K/B & M/S cable

(for RS-232/422/485) (6-pin to 6-pin)

2 • Introduction

Page 9

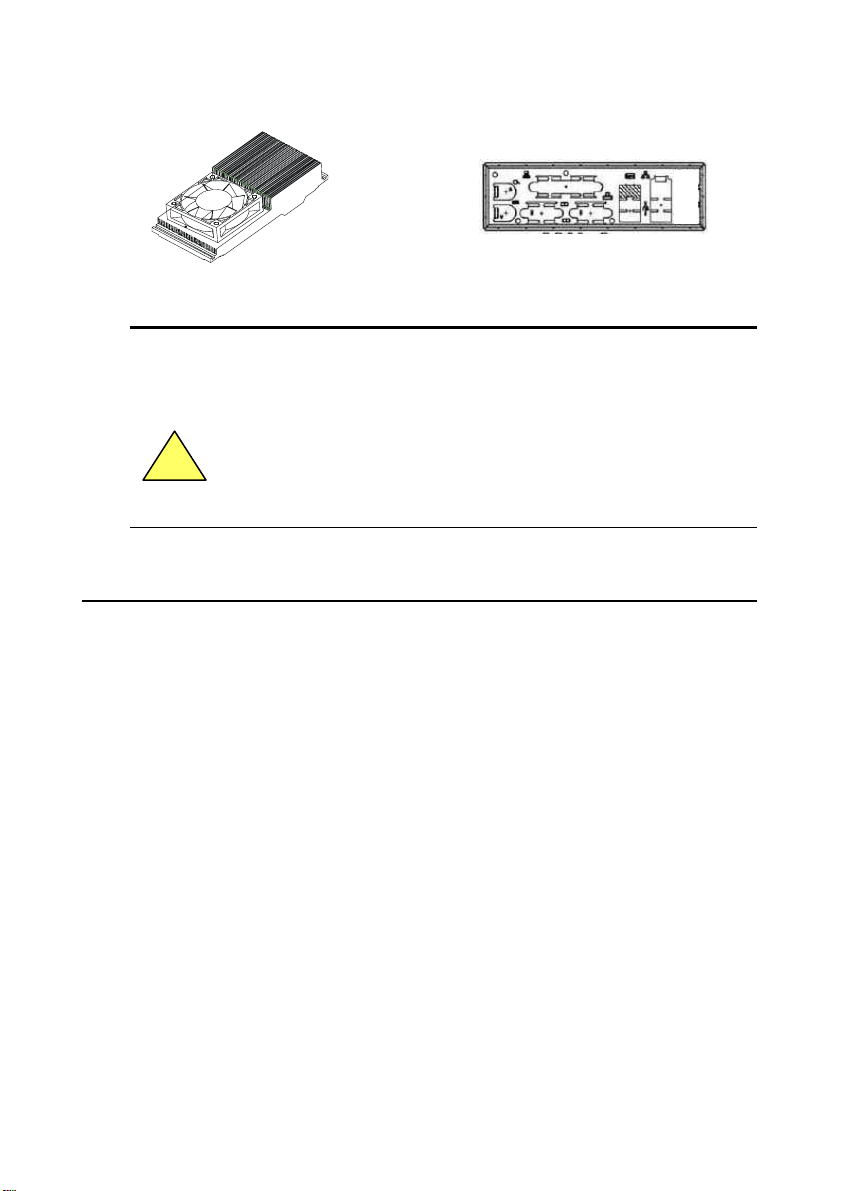

¡ Low profile heat sink with fan ¡ I/O Shield

Note: M-855 OEM versions with non-standard co nfig ur ati ons may var y

in fu n ct i o n or c o nt e n t s according to request.

CAUTION: This board must be protected from static discharge and physica l

shock. Never remove any of the socketed parts except at a

static-free workstation. Use the anti-static bag shipped with the

!

product to handle the board. Wear a wrist strap grounded through

one of the system's ESD Ground jacks while servicing system

components.

1.2 Features

• Intel® Pentium® M / Celeron® M processor

• Intel

• Support 2GB DDR266/333 SDRAM (max.) memory

• Front Side Bus Frequency: 400/533MHz

• Chipset integrated graphic & LVDS function

• Single 10/100/1000 Mbps Gigabit Ethernet using Intel

• Software programmable watchdog timer

• Hardware Monitoring

• AC97 Audio Lin-out pin-header

Hardware Monitoring

Hardware monitoring allows the user to monitor various aspects of system operations

and status (including the CPU temperature, voltage, and fan RPM).

I/O Shield Connector

The SBC is equipped with an I/O bracket. Please use the appropriate I/O shield.

®

855GME + ICH4 AGPset

®

82541 chip

Introduction • 3

Page 10

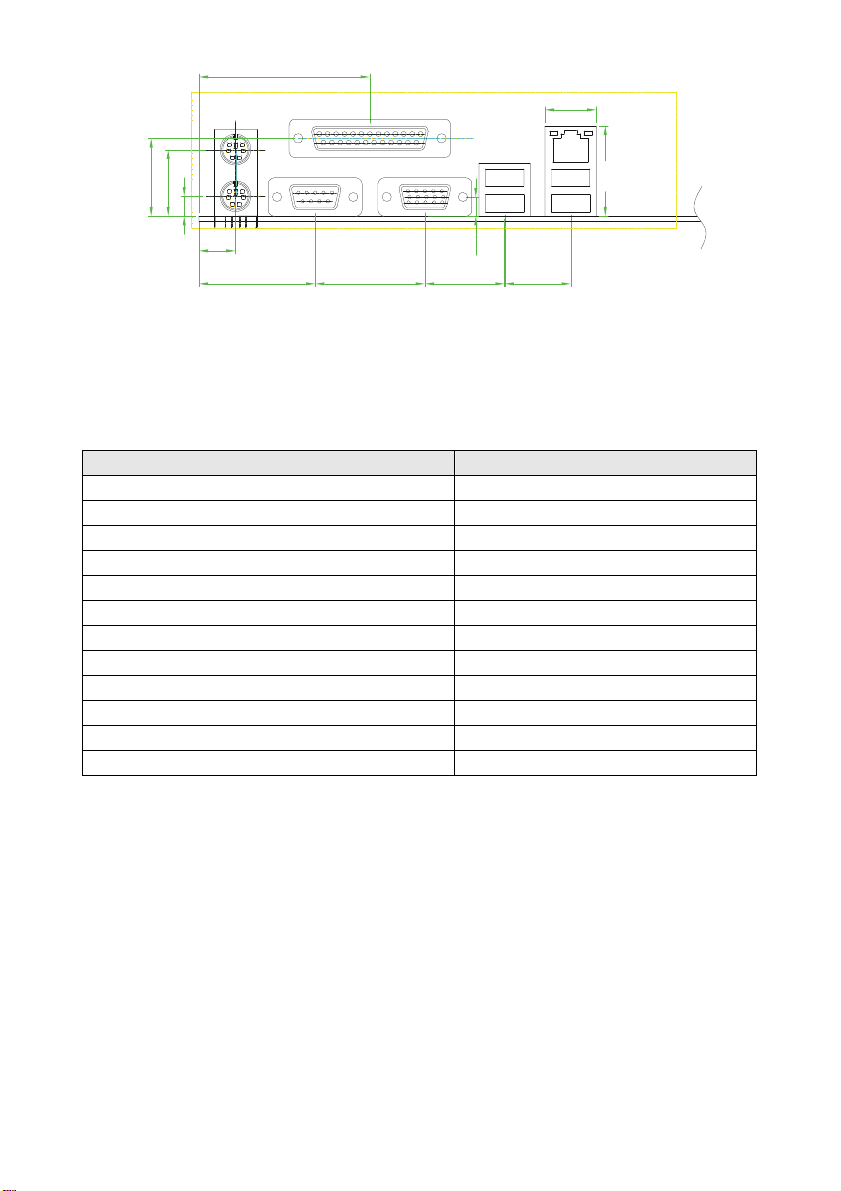

56.05

16.80

25.42

21.75

6.50

26.13

6.22

21.6435.97

11.96

38.10

29.50

Figure 1: I/O back panel layout

M-855 Series Overview

Function M-855

¡ Chipset Intel® 855GME

¡ LVDS

¡ VGA

¡ Gigabit Ethernet

¡ 40-pins EIDE interface 2

¡ Type II CF socket 1

¡ Parallel ports 1

¡ Serial ports 4

¡ PCI slots 3

¡ USB 2.0 ports (two for USB cable) 6

¡ Audio Line-out pin-header 1

¡ Fan connector 2

4 • Introduction

Page 11

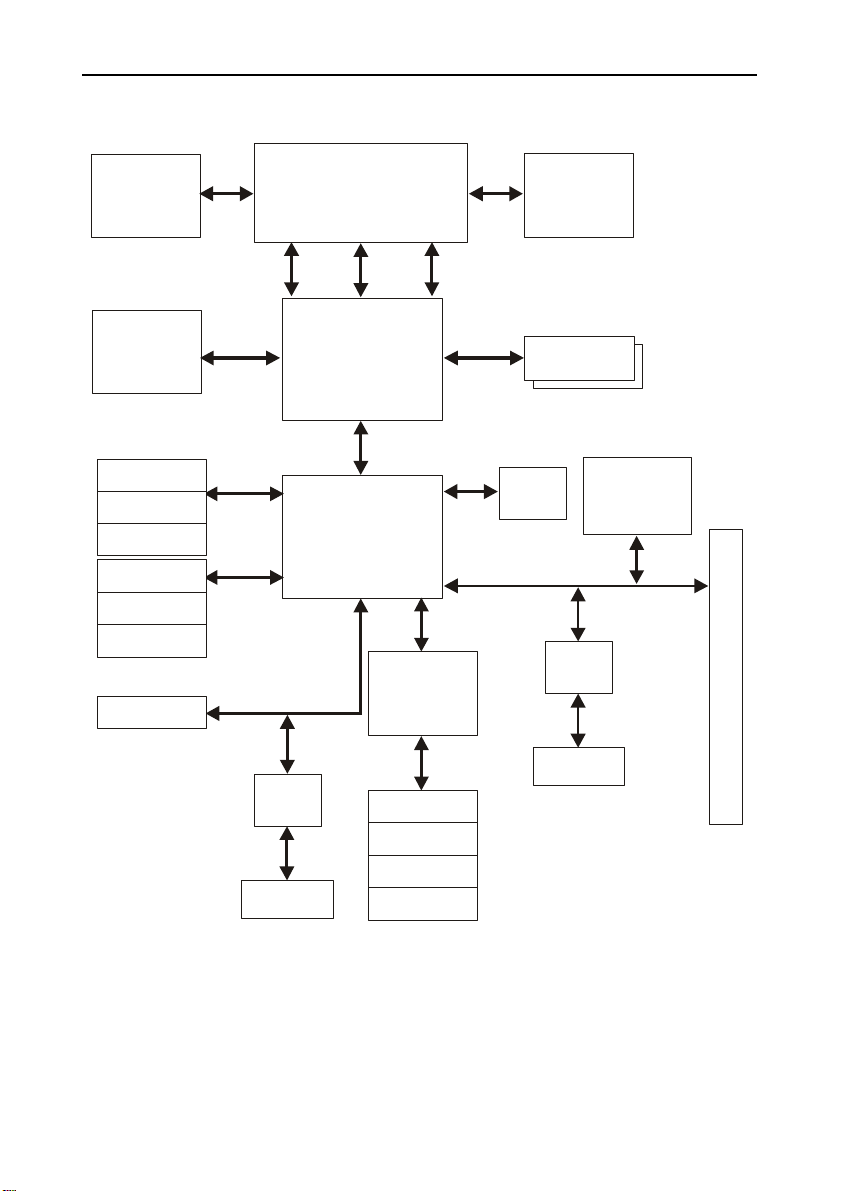

1.3 System Block Diagram

Socket 478-pins

for

Intel Pentium M

LVDS

or

LCD / CRT

Device

VGA

GMCH (855GME)

732 Micro FCBGA

ClockVRM

DATACTRLADD R

400/533 MHz FSB

DDR266/333 X2

IDE Primary

IDE Secondary

CF Socket

USB Port 0/1

USB Port 2/3

USB Port 4/5

FWH

ATA100

USB2.0

ICH4

421 BGA

Super I/O

W83627 H F

FINTEK

F81216D

COM1/2

COM3/4

Keyboard

Mouse

Floppy

LPT Port

Figure 2: System Block Diagram

AC97

Audio

Codec

PCI BUS

10/100/1000

S-ATA

S3112

SATA Port 1/2

Intel

82541

Base-TX

PCI SLOTS

Introduction • 5

Page 12

1.4 Specifications

¡ Processor:

- System bus frequency at 400 / 533 MHz FSB

Make sure you use the correct CPU (Pentium® M processor). Using a standard

Pentium® 4 CPU may crash the system.

¡ Chipset:

- Intel® 855GME + ICH4 AGPset

¡ DRAM Module:

- Support DDR SDRAM up to 2GB (max.)

¡ LVDS & VGA:

¡ Gigabit Ethernet:

- 10/100/1000 Base-TX Ethernet

- Onboard RJ-45 Ethernet connector

¡ External Connector:

(using a CF card will occupy the IDE2 master)

¡ Expansion Slot:

¡ Onboard I/O:

- On-Chip I/O integrated with Keyboard, Mouse, Parallel and Serial,

and Power-ON controller

¡ Onboard PCI / IDE:

- Intel

- PCI rev2.2 Compliant

- ACPI Compliant Power Management

- PCI Bus IDE Port with PIO / Ultra DMA-100 x 2 (up to 4 devices)

6 • Introduction

®

- Intel

Pentium® M processor with socket 478-pins package

- Processor operating at 1.3GHz and up to 1.8GHz

- 2 x 184-pin DIMM socket

- DDR 266/333 memory

- Intel® 855GME Chipset integrated LVDS & Graphic controller

- Onboard 15-pin VGA connector

- Intel® 82541 Ethernet controller

- 1 x type II CompactFlash™ connector

- 1 x 6-pin KB/MS extender

- Three PCI slots

®

ICH4 south bridge controller

Page 13

¡ Rear I/O Connectors:

- PS/2 Mouse and PS/2 style Keyboard

- D-Sub 25-pins Printer port connector

D-Sub 9-pins COM1 Serial port connector for RS-232

D-Sub 15-pins VGA connector

- 2 x USB2.0 connectors

- RJ-45 Ethernet and 2 x USB2.0 connectors

- Audio for Line-In, Line-Out, MIC phone jack (Optional)

¡ Internal I/O Connectors (pin-header):

- 3 x Serial ports, COM2 for RS-232 and COM3 / 4 for RS-232/422/485

(Serial cable with bracket)

- 2 x USB2.0 connectors (USB cable with bracket)

- 2 x S-ATA connectors

- Audio Line-Out pin-header

¡ BIOS:

- Award Plug & Play BIOS

¡ Form Factor:

- 9.6” x 9.6” (244 x 244mm) Micro ATX Size

¡ Weight:

- 1.44lb (650g) --- M-855 series

Introduction • 7

Page 14

Page 15

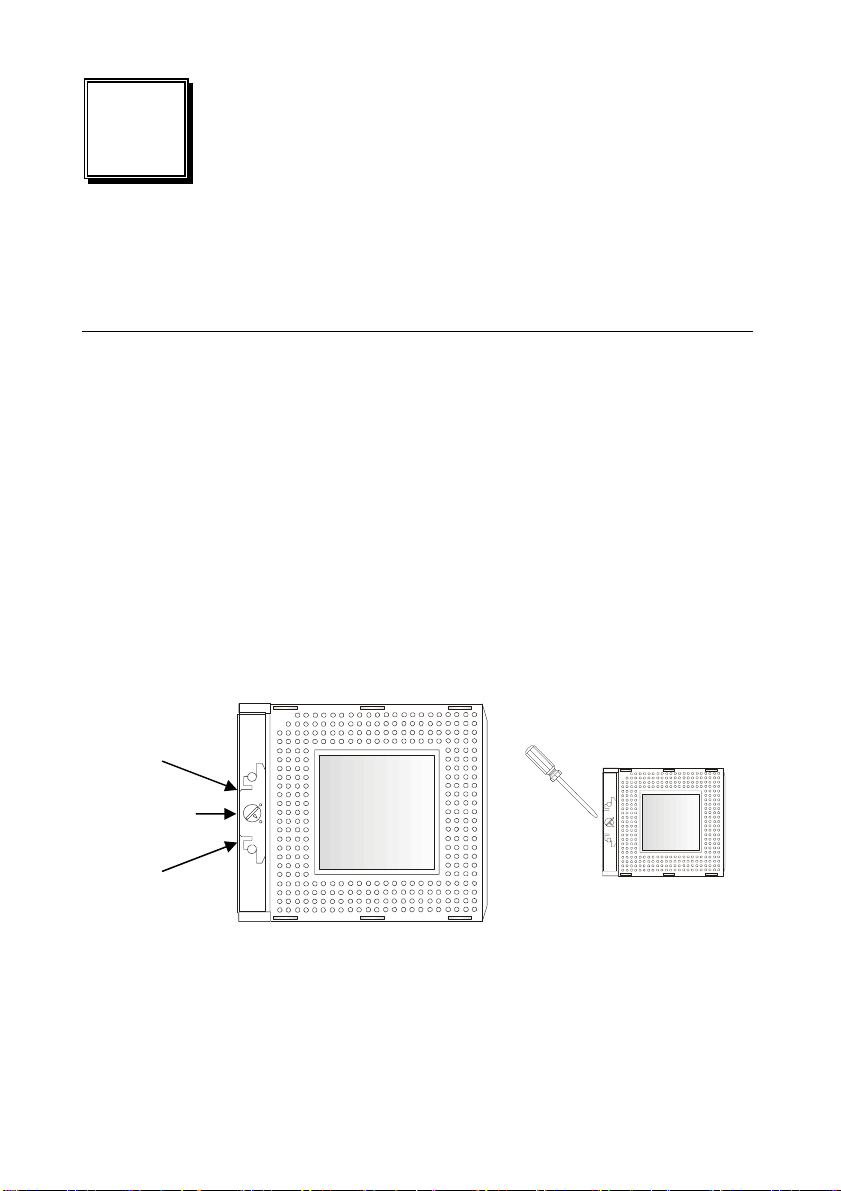

2

Installation

2.1 System Installation

CPU Installation

Carefully follow the steps below to install the CPU:

1. Check and confirm that the jumpers are correctly set for the CPU you are going

to install (figure 3).

2. Take the screwdriver and releasing screw-nut of the Socket 478.

3. Rotate mark of screw-nut to face the “OPEN”.

4. Align the pins of the CPU against the pinholes of the Socket 478. Be sure to pay

attention to the orientation of the CPU.

OPEN

Screw Nut

CLOSED

5. Push down the CPU into the Socket 478.

6. Rotate mark of screw-nut to face the “CLOSED”.

7. Place the CPU cooling fan atop the CPU surface.

OPEN CLOSED

OPEN CLOSED

Figure 3: CPU Socket

Installation • 9

Page 16

8. Push down the opposite side of the ZIF clip and hook it.

9. Connect the cooling fan cable to the socket as shown below. Be careful not to

place the cable on the CPU cooling fan.

Removing a CPU:

1. Before removing the CPU, turn off the power and wait for about 20 minutes until

the heat radiation plate of the cooling fan and the CPU cools down.

2. Rotate mark of screw-nut to face the “OPEN”.

3. To remove the CPU.

WARNING: The CPU and the heat radiation plate are hot and can cause

burns.

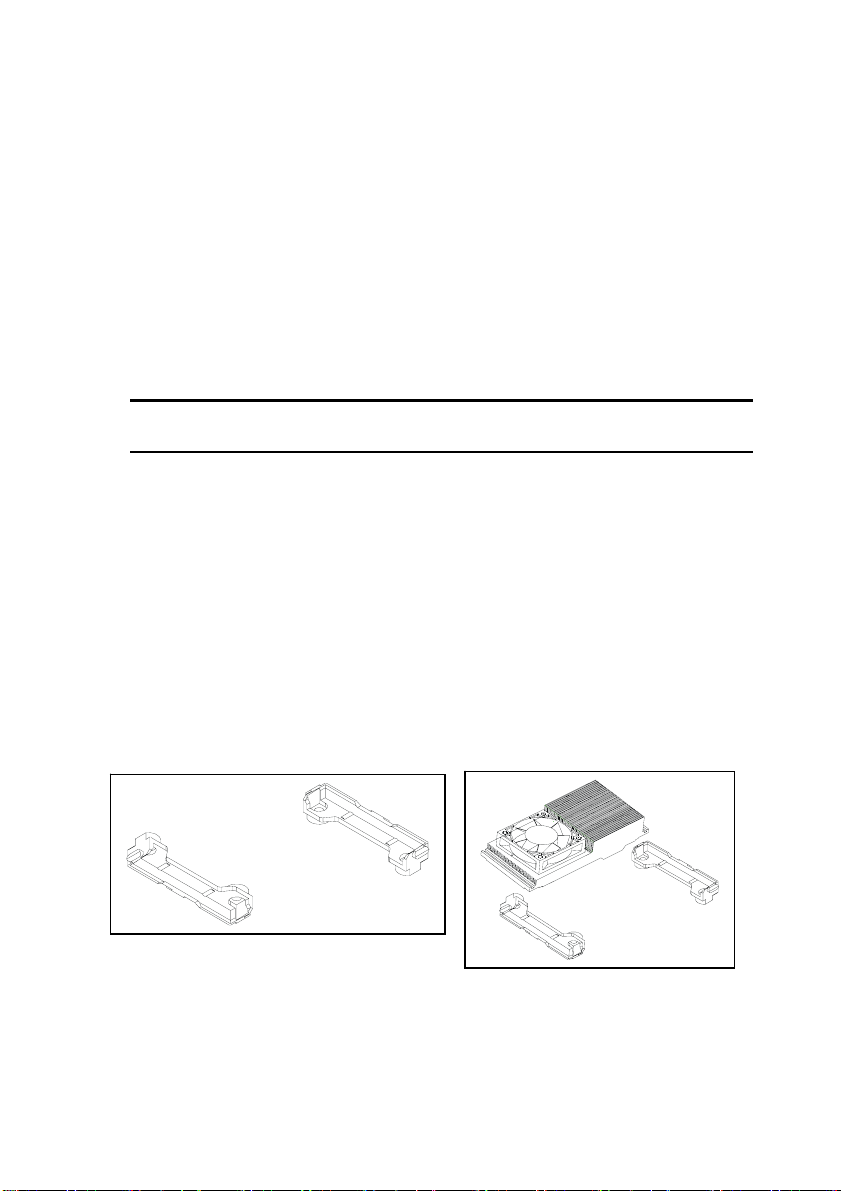

Heat Sink & Retention Module Installation

It is highly recommended that only the M-855 Heat sink and fan (Figure 4), designed

for use in the chassis be used. The use of other heat sinks, including those boxed

with CPUs, may damage the M-855.

Make sure that good contact is made between the process ors and the heat sinks.

Insufficient contact, incorrect types of heat sinks, fans, or thermal compound used or

improper amount of thermal compound applied on the CPU die can cause the

processors to overheat, which may crash the system.

The Retention Module is used to hold up the weight of the Heat sink and fan.

Figure 4: Heat Sink & Retention Module Installation

Memory Module Installation

10 • Installation

Page 17

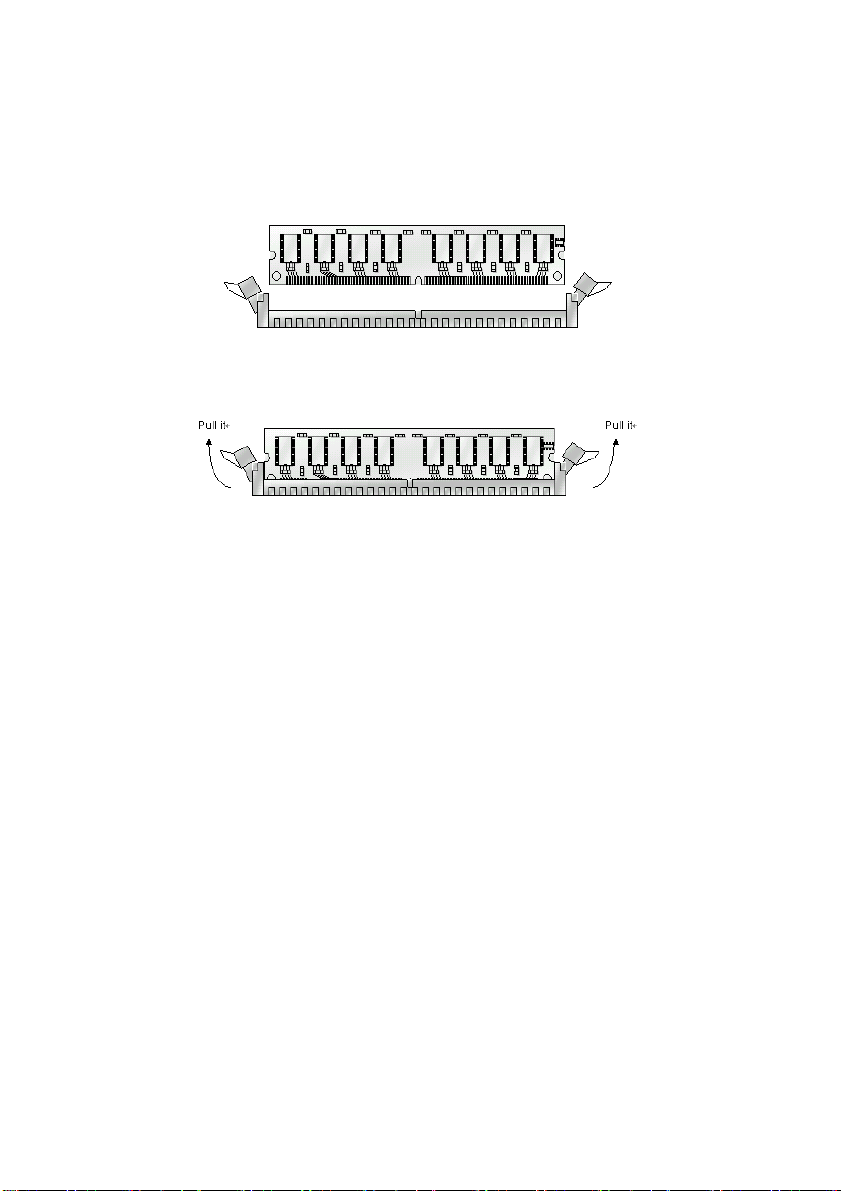

Figure 5 display the notch marks and what they should look like on your DIMM

memory module.

DIMMs have184 pins and two notches that will match with the onboard DIMM socket.

DIMM modules are installed by placing the chip firmly into the socket at a 90-degree

angle and pressing straight down (figure 6) until it fits tightly into the DIMM socket.

Figure 5: DIMM Memory and 184-pins Socket

Figure 6: Memory Installation

Carefully follow the steps below in order to install the DIMMs:

1. To avoid generating static electricity and damaging the DIMM, ground yo urself

by touching a grounded metal surface or using a ground scrap before you touch

the DIMM.

2. Do not touch the connector of the DIMM. Dirt residue may cause a malfunction.

3. Hold the DIMM with its notch to the front side of the M-855 and insert it

completely into the socket. A DIMM should be inserted into the inner socket first.

Guiding the hole at each end of the DIMM over the retaining post at each end of

the DIMM socket.

4. If you install two DIMMs, install the second DI MM using the same procedure as

above.

5. If DIMM does not go in smoothly, do not force it. Pull it all the way out and try

again.

6. Make sure the DIMM is properly installed and locked by the tabs on both sides of

the socket.

Removing a DIMM:

Installation • 11

Page 18

To remove the DIMM, use your fingers or a small screwdriver to carefully push away

the plastic tabs that secure the DIMM at each end. Lift it out of the socket.

Make sure you store the DIMM in an anti-static bag.

Only use the same size and manufacturer of memory modules.

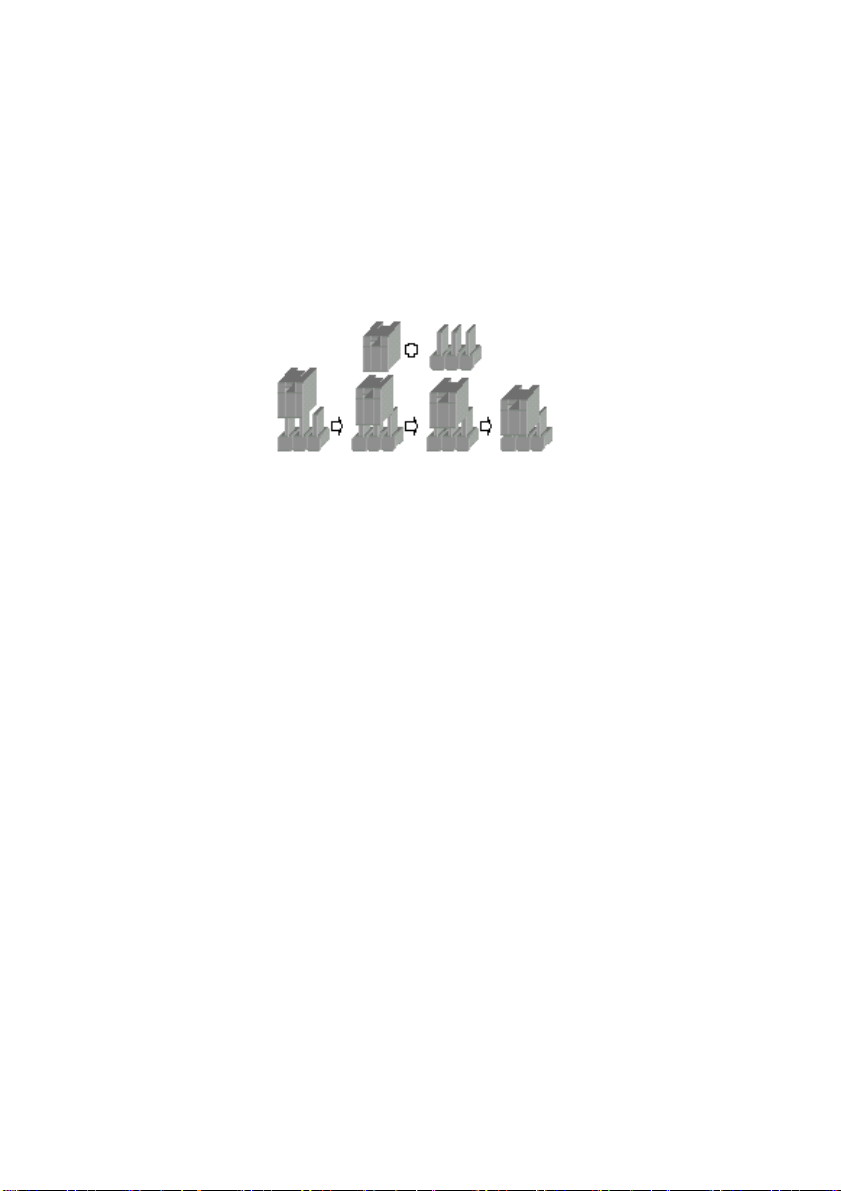

Setting Jumpers and DIP Switches

There are jumpers and DIP-switches on the M/B of the M-855 Series. The jumpers

can be set for various operations.

Figure 7: Jumper Connector

For any three-pins jumpers (Figure 7), the jumper setting is 1-2 when the jumper

connects pins 1 and 2. The setting is 2-3 when pins 2 and 3 are connected. The

numbers “1“ and a “3“ are printed on the circuit board to identify these pins. And also,

there is a second way of indication – one of the lines surrounding jumpers is thick,

which indicates pin number 1.

To move a jumper from one position to another, use needle-nose pli ers or tweezers

to pull the pin cap off the pins and move it to the desired position.

12 • Installation

Page 19

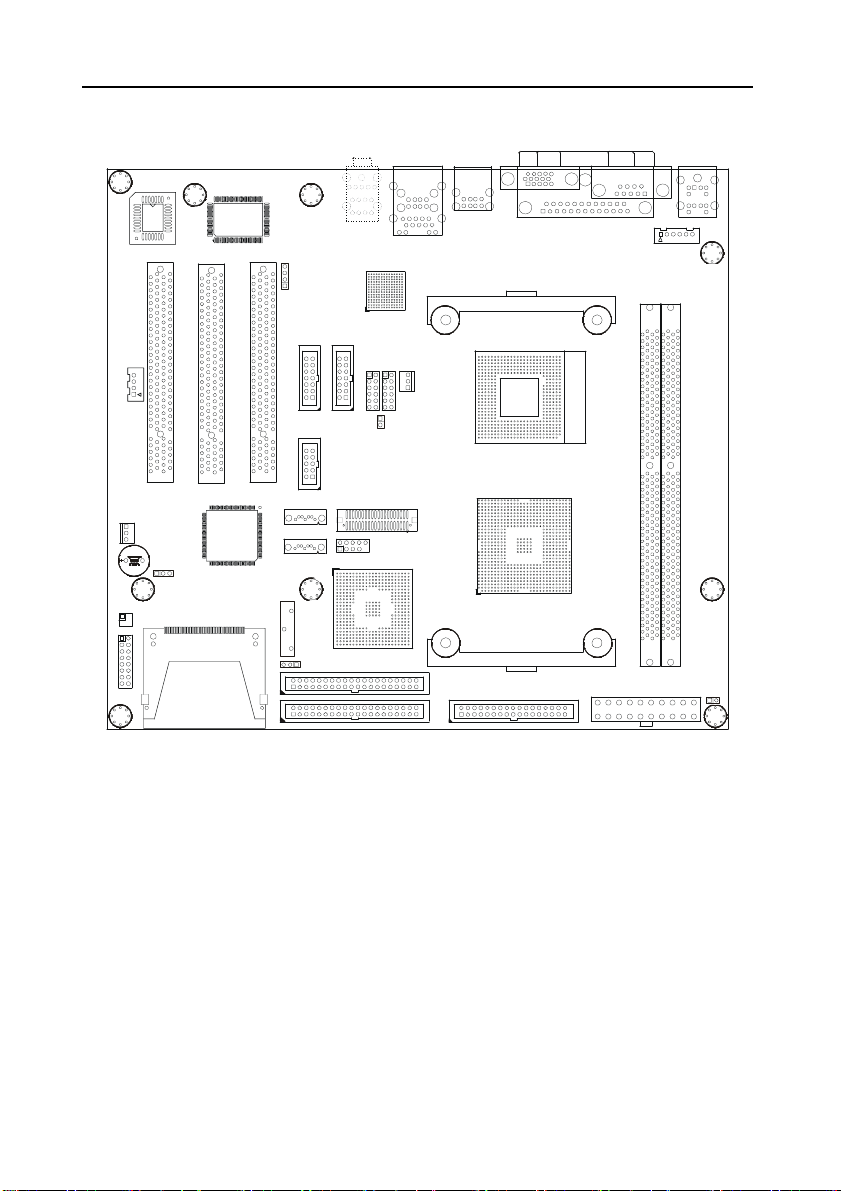

2.2 Board Layout

CN18

JP7

CN20

CN25

CN10

CN1

CN5

(Optional)

CN9

CN14

CN13

JP2JP1

JP3

CN12

CN11

JP4

CF II

CN16

SATA1

SATA2

CN17

CN19

JP5

CN4

CN7

CN15

CN21

CN23

CN3

CN24

CN2

CN6

CN8

DIMM2DIMM1

JP6

CN22

Figure 8: Jumper and Connector Locations

Installation • 13

Page 20

2.3 Jumper Settings

Jumper Location Description:

Use the information in the following table to change the jumpers and the DIP

switches.

Jumpers Functions

JP1 COM3 Port Setting Select

JP2 COM4 Port Setting Select

JP3 CPU Type Setting Select

JP4 Watchdog Timer Setting Select

JP5 Clear CMOS Setting Select

JP6 Power Management Setting Select

A description on setting the jumpers to enable/disable or change functions is

illustrated below. Please refer to the diagrams below for jumper locations.

COM3/COM4 Port Setting Select: JP1/JP2

Function

RS-232 (Default) Off Off Off Off Off On

RS-422 On (Term.) On (Term.) Off On On Off

RS-485 On (Term.) On (Term.) On Off On Off

1-2 3-4 5-6 7-8 9-10 11-12

y Location:

JP1/JP2

14 • Installation

Page 21

CPU Type Setting Select: JP3

Function JP3

CPU FSB 400 MHz (Default) 1-2 On

CPU FSB 533 MHz 1-2 Off

y Location:

Watchdog Timer Setting Select: JP4

Function JP4

NMI 1-2

Reset System (Default) 2-3

y Location:

Clear CMOS Setting Select: JP5

Function JP5

Normal (Default) 1-2

Clear CMOS 2-3

y Location:

Installation • 15

Page 22

Power Management Setting Select: JP6

Function JP6

ACPI Mode On

APM Mode (Default) Off

y Location:

2.4 Connector Descriptions

CN18

JP7

CN20

CN25

CN10

CN1

CN5

(Optional)

CN9

CN14

CN13

JP2JP1

JP3

CN12

CN11

JP4

CF II

CN16

SATA1

SATA2

CN17

CN19

JP5

CN4

CN7

CN15

CN21

CN23

CN3

CN24

CN2

CN6

CN8

DIMM2DIMM1

JP6

CN22

Figure 9: Connector Locations

16 • Installation

Page 23

Table for Connector’s Location Description:

Use the information in the following table to change the connector.

Connectors Functions

CN1 CRT VGA Port Connector

CN2 COM1 RS-232 Serial Port Connector

CN3 Parallel Port Connector

CN4 USB 0/1 Connectors

CN5 Audio Port Connector (Optional)

CN6 PS/2 Keyboard & Mouse Connectors

CN7 Gigabit Ethernet RJ-45 & USB 2/3 Connectors

CN8 External Keyboard & Mouse Connector

CN9 CD-IN Connector

CN13 COM3 RS-232/422/485 Serial Port Connectors

CN14 COM4 RS-232/422/485 Serial Port Connectors

CN15 CPU F an Power Connector

CN16 COM2 RS-23 2 Serial Port Connector

CN17 18/24 Bits LVDS Panel Interface

CN18 System Fan Power Connector

CN19 USB 4/5 (Pin-Header) Connector

CN20 System Panel Indicate Connector

CN21 Secondary IDE Connector

CN22 ATX Power Connector

CN23 Primary IDE Connector

CN24 F loppy Disk Connector

CN25 LINE OUT Connector

JP7 LAN LED Connector

SATA1 S-ATA1 Connector

SATA2 S-ATA2 Connector

CF II Type II CompactFlash™ Connector

Installation • 17

Page 24

CRT VGA Port Connector (D-SUB 15-pins Female): CN1

Pin # Assignment Pin # Assignment

1 Red 2 Green

3 Blue 4 NC

5 Ground 6 Ground

7 Ground 8 Ground

9 VCC 10 Ground

11 NC 12 DData

13 HSync 14 VSync

15 DCK

y Figure:

1

5

11

15

COM1 RS-232 Serial Port Connector (D-Sub 9-pins Male): CN2

Pin # Assignment Pin # Assignment

1 DCD (Data Carrier Detect) 6 DSR (Data Set Ready)

2 RXD (Receive Data) 7 RTS (Request to Send)

3 TXD (Transmit Data) 8 CTS (Clear to Send)

4 DTR (Data Terminal Ready) 9 RI (Ring Indicator)

5 Ground

y Figure:

5

1

9

6

18 • Installation

Page 25

Parallel Port Connector (D-Sub 25-pins Male): CN3

Pin # Assignment Pin # Assignment

1 Line Printer Strobe 14 Auto Feed

2 PD 0, Parallel Data 0 15 Error

3 PD 1, Parallel Data 1 16 Initialize

4 PD 2, Parallel Data 2 17 Select

5 PD 3, Parallel Data 3 18 Ground

6 PD 4, Parallel Data 4 19 Ground

7 PD 5, Parallel Data 5 20 Ground

8 PD 6, Parallel Data 6 21 Ground

9 PD 7, Parallel Data 7 22 Ground

10 ACK, Acknowledge 23 Ground

11 Busy 24 Ground

12 Paper Empty 25 Ground

13 Select 26 N/A

y Figure:

13

1

25

14

USB 0/1 Connectors (4-pins Female): CN4

Pin # Assignment Pin # Assignment

1a VCC 1b VCC

2a USB0 - 2b USB1 3a USB0 + 3b USB1 +

4a Ground 4b Ground

y Figure:

14

14

Installation • 19

Page 26

Audio Port Connector (Audio Phone–Jack): CN5 (Optional)

Pin # Assignment

BLUE Line-In

GREEN Line-Out

Red Mic-In

y Figure:

Blue

Green

Red

PS/2 Keyboard Connector (6-pins Green Mini Din): CN6

Pin # Assignment Pin # Assignment

1 Keyboard Data 2 NC

3 Ground 4 +5V

5 Keyboard Clock 6 NC

y Figure:

6

5

34

2

1

PS/2 Mouse Connector (6-pins Purple Mini Din): CN6

Pin # Assignment Pin # Assignment

1 Mouse Data 2 NC

3 Ground 4 +5V

5 Mouse Clock 6 NC

y Figure:

6

5

34

2

1

20 • Installation

Page 27

Gigabit Ethernet RJ-45 Connector (RJ-45 Phone–Jack): CN7

Pin # Assignment Pin # Assignment

1 Transmit output (+) 5 NC

2 Transmit output (-) 6 Receive input (-)

3 Receive input (+) 7 NC

4 NC 8 NC

y Figure:

USB 2/3 Connector (4-pins Female): CN7

Pin # Assignment Pin # Assignment

1a VCC 1b VCC

2a USB2 - 2b USB3 3a USB2 + 3b USB3 +

4a Ground 4b Ground

y Figure:

14

14

External Keyboard & Mouse Connector (6-pins Pin-Header): CN8

Pin # Assignment Pin # Assignment

1 MS Clock 2 MS Data

3 KB Clock 4 KB Data

5 Ground 6 VCC

y Figure:

16

Installation • 21

Page 28

CD_IN Connector: CN9

1

Pin # Assignment

1 CD_IN_Left

2 CD_GND

3 CD_GND

4 CD_IN_Right

y Figure:

4

COM3 RS-232/422/485 Serial Port Connectors (14-pins Pin-Header): CN13

Pin # Assignment Pin # Assignment

1 DCD 2 RXD

3 TXD 4 DTR

5 Ground 6 DSR

7 RTS 8 CTS

9 RI 10 Ground

11 TXD+ 12 TXD13 RXD+ 14 RXD-

y COM3 Figure:

14

13

2

1

22 • Installation

Page 29

COM4 RS-232/422/485 Serial Port Connectors (14-pins Pin-Header): CN14

Pin # Assignment Pin # Assignment

1 DCD 2 RXD

3 TXD 4 DTR

5 Ground 6 DSR

7 RTS 8 CTS

9 RI 10 Ground

11 TXD+ 12 TXD13 RXD+ 14 RXD-

y COM4 Figure:

14

13

2

1

Note: How to connect a RS485 device with the COM port ribbon cable?

Our Industrial Board encloses a COM port ribbon cable for internal connection.

RS422/485 device must connect to downside D-Sub with 5-pin cable and signal

indication as below.

For RS-232 Connector

5

1

9

6

For RS-422/485 Connector

RS-422/485:

1: TXD2: TXD+

3: RXD4: RXD+

5: GND

Installation • 23

Page 30

CPU Fan Power Connector: CN15

Pin # Assignment

1 Ground

2 VCC

3 Fan Status Signal

y Figure:

3

1

COM2 RS-232 Serial Port Connector (10-pins Pin-Header): CN16

Pin # Assignment Pin # Assignment

1 DCD 2 DSR

2 RXD 4 RTS

3 TXD 6 CTS

4 DTR 8 RI

5 Ground 10 Ground

y Figure:

10

9

2

1

18/24 Bits LVDS Panel Interface (40-pins Male): CN17

Pin # Assignment Pin # Assignment

1 NC 2 NC

3 Ground 4 Ground

5 YAM0 6 YAM1

7 YAP0 8 YAP1

9 Ground 10 Ground

11 YAM2 12 CLKAM

13 YAP2 14 CLKAP

15 Ground 16 Ground

17 YAM3 18 YBM0

19 YAP3 20 YBP0

24 • Installation

Page 31

21 Ground 22 Ground

23 YBM1 24 YBM2

25 YBP1 26 YBP2

27 Ground 28 Ground

29 CLKBM 30 YBM3

31 CLKBP 32 YBP3

33 NC 34 +12V

35 NC 36 +12V

37 NC 38 PVCC

39 BKL 40 PVCC

y Figure:

40

2

39

1

System Fan Power Connector: CN18

Pin # Assignment

1 Ground

2 VCC

3 Fan Status Signal

y Figure:

1

3

Installation • 25

Page 32

USB 4/5 Connector (9-pins Pin-Header): CN19

1

9

Pin # Assignment Pin # Assignment

1 VCC 2 VCC

3 USB4 - 4 USB5 -

5 USB4 + 6 USB5 +

7 Ground 8 Ground

9 --- 10 NC

y Figure:

10

2

System Panel Indicate Connector: CN20

Pin # Assignment Pin # Assignment

SPEAKER PWR LED

1 +5V 2 PWLED+

3 NC 4 NC

5 BUZZER 6 PWLED-

7 SPEAKER

HDD LED

9 HDLED+ 10 Ground

11 HDLED- 12 NC

8 KBLOCK

KEYLOCK

RESET PWR ON

13 RESET+ 14 PWRBT+

15 RESET- 16 PWRBT-

y Figure:

1

2

15

16

26 • Installation

Page 33

Secondary IDE Connector (40-pins 2.54mm Pitch Pin-Header with Housing):

CN21

Pin # Assignment Pin # Assignment

1 Reset IDE 2 Ground

3 Host Data 7 4 Host Data 8

5 Host Data 6 6 Host Data 9

7 Host Data 5 8 Host Data 10

9 Host Data 4 10 Host Data 11

11 Host Data 3 12 Host Data 12

13 Host Data 2 14 Host Data 13

15 Host Data 1 16 Host Data 14

17 Host Data 0 18 Host Data 15

19 Ground 20 NC

21 DRQ 0 22 Ground

23 Host IOW 24 Ground

25 Host IOR 26 Ground

27 IOCHRDY 28 Host ALE

29 DACK 0 30 Ground

31 IRQ 14 32 No Connect

33 Address 1 34 Ground

35 Address 0 36 Address 2

37 Chip Select 0 38 Chip Select 1

39 Activity 40 Ground

y Figure:

2

40

1

39

Installation • 27

Page 34

ATX Power Connector: CN22

Pin # Assignment Pin # Assignment

1 +3.3V 11 +3.3V

2 +3.3V 12 -12V

3 Ground 13 Ground

4 +5V 14 PS-ON

5 Ground 15 Ground

6 +5V 16 Ground

7 Ground 17 Ground

8 NC 18 -5V

9 5VSB 19 +5V

10 +12v 20 +5V

y Figure:

1

10

11

20

Primary IDE Connector (40-pins 2.54mm Pitch Pin-Header with Housing):

CN23

Pin # Assignment Pin # Assignment

1 Reset IDE 2 Ground

3 Host Data 7 4 Host Data 8

5 Host Data 6 6 Host Data 9

7 Host Data 5 8 Host Data 10

9 Host Data 4 10 Host Data 11

11 Host Data 3 12 Host Data 12

13 Host Data 2 14 Host Data 13

15 Host Data 1 16 Host Data 14

17 Host Data 0 18 Host Data 15

19 Ground 20 NC

21 DRQ 0 22 Ground

23 Host IOW 24 Ground

25 Host IOR 26 Ground

27 IOCHRDY 28 Host ALE

29 DACK 0 30 Ground

31 IRQ 14 32 No Connect

33 Address 1 34 Ground

28 • Installation

Page 35

35 Address 0 36 Address 2

37 Chip Select 0 38 Chip Select 1

39 Activity 40 Ground

y Figure:

2

40

1

39

Floppy Disk Connector (34-pins 2.54mm Pitch Pin-Header with Housing):

CN24

Pin # Assignment Pin # Assignment

1 Ground 2 Drive Density Selection

3 Ground 4 NC

5 Ground 6 Drive Density Selection

7 Ground 8 Index

9 Ground 10 Motor Enable 0

11 Ground 12 Drive Select 1

13 Ground 14 Drive Select 0

15 Ground 16 Motor Enable 1

17 Ground 18 Direction

19 Ground 20 Step

21 Ground 22 Write Data

23 Ground 24 Write Gate

25 Ground 26 Track 00

27 Ground 28 Write Protect

29 NC 30 Read Data

31 Ground 32 Head Select

33 NC 34 Diskette Change

y Figure:

2

34

1

33

Installation • 29

Page 36

LINE OUT Connector: CN25

Pin # Assignment

1 LOUT_L

2 AU_GND

3 VCC_5V

4 LOUT_R

y Figure:

4

1

LAN LED Connector: JP7

Pin # Assignment Pin # Assignment

1 LINK_LED 2 VCC_3V

3 ACT_LED 4 VCC_3V

y Figure:

21

34

30 • Installation

Page 37

S-ATA1 Connector (9-pins): SATA1

Pin # Assignment

1 Ground

2 SATA1_TXP

3 SATA1_TXN

4 Ground

5 SATA1_RXN

6 SATA1_RXP

7 Ground

8 Ground

9 Ground

y Figure:

S-ATA2 Connector (9-pins): SATA2

Pin # Assignment

1 Ground

2 SATA2_TXP

3 SATA2_TXN

4 Ground

5 SATA2_RXN

6 SATA2_RXP

7 Ground

8 Ground

9 Ground

y Figure:

9 1

9 1

7 8

7 8

Installation • 31

Page 38

Type II CompactFlash™ Connector: CF II

Pin # Assignment Pin # Assignment

1 Ground 2 D3

3 D4 4 D5

5 D6 6 D7

7 CS#1 8 Ground

9 Ground 10 Ground

11 Ground 12 Ground

13 VCC 14 Ground

15 Ground 16 Ground

17 Ground 18 A2

19 A1 20 A0

21 D0 22 D1

23 D2 24 NC

25 NC 26 NC

27 D11 28 D12

29 D13 30 D14

31 D15 32 CS#3

33 NC 34 IOR#

35 IOW# 36 VCC

37 INTS 38 VCC

39 CSEL# 40 NC

41 IDERST# 42 IORDY

43 NC 44 VCC

45 IDEACTS# 46 DET

47 D8 48 D9

49 D10 50 Ground

51 Ground 52 Ground

53 NC 54 NC

55 NC 56 NC

57 NC 58 NC

y Figure:

CF

32 • Installation

Page 39

3

Award BIOS Setup

3.1 BIOS Instructions

Award’s ROM BIOS provides a built-in Setup program, which allows the user to

modify the basic system configuration and hardware parameters. The modified data

will be stored in a battery-backed CMOS, so that data will be retained even when the

power is turned off. In general, the information saved in the CMOS RAM will stay

unchanged unless there is a configuration change in the system, such as hard drive

replacement or a device is added.

It is possible for the CMOS battery to fail, which would cause data loss in the CMOS

only. If that happens the BIOS settings would need to be reconfigured.

3.2 Main Menu

Once you enter the AwardBIOS™ CMOS Setup Utility, the Main Menu will appear on

the screen. The Main Menu allows you to select from several setup functions and two

exit choices. Use the arrow keys to select among the items and press <Enter> to

accept and enter the sub-menu.

BIOS Setup • 33

Page 40

Phoenix - AwardBIOS CMOS Setup Utility

¾Standard CMOS Feature

¾Advanced BIOS Feature

¾Advanced Chipset Feature

¾Integrated Peripherals

¾Power Management Setup

¾PnP/PCI Configurations

¾PC Health Status

Esc: Quit ↑ ↓ ← →: Select Item

F10: Save & Exit Setup

Time, Date, Hard Disk Type….

Note: that a brief description of each highlighted selection appears at the bottom of the screen.

¾Frequency/Voltage Control

Load Fail-Safe Defaults

Load Optimized Defaults

Set Supervisor Password

Set User Password

Save & Exit Setup

Exit Without Saving

Setup Items:

The main menu includes the following main setup categories. Recall that some

systems may not include all entries.

Standard CMOS Features:

Use this menu for basic system configuration. See 3.3 for the details.

Advanced BIOS Features:

Use this menu to set the Advanced Features available on your system. See 3.5 for

the details.

Advanced Chipset Features:

Use this menu to change the values in the chipset registers and optimize your

system's performance. See 3.6 for the details.

Integrated Peripherals:

Use this menu to specify your settings for integrated peripherals. See section 3.7 for

the details.

Power Management Setup:

Use this menu to specify your settings for power management. See 3.8 for the

details.

PnP / PCI Configuration:

This entry appears if your system supports PnP/PCI. See 3.9 for the details.

PC Health Status:

34 • BIOS Setup

Page 41

Use this menu to show your system temperature, speed and voltage status. See 3.10

for the details.

Frequency / Voltage Control:

Use this menu to specify your settings for frequency/voltage control. See 3.11 for the

details.

Load Fail-Safe Defaults:

Use this menu to load the BIOS default values for the minimal/stable performance for

your system to operate. See 3.12 for the details.

Load Optimized Defaults:

Use this menu to load the BIOS default values that are factory settings for optimal

performance system operations. While Award has designed the custom BIOS to

maximize performance, the factory has the right to change these defaults to meet

their needs. See 3.13 for the details.

Supervisor / User Password:

Use this menu to set User and Supervisor Passwords. See 3.14 for the details.

Save & Exit Setup:

Save CMOS value changes to CMOS and exit setup. See 3.15 for the details.

Exit Without Save:

Abandon all CMOS value changes and exit setup. See 3.15 for the details.

3.3 Standard CMOS Features

The items in Standard CMOS Setup Menu are divided into 10 categories. Each

category includes none, one, or more than one setup items. Use the arro w keys to

highlight the item and then use the <PgUp> or <P gDn> keys to select the value you

want in each item.

BIOS Setup • 35

Page 42

Date (mm:dd:yy):

Time (hh:mm:ss):

¾ IDE Primary Master

¾ IDE Primary Slave

¾ IDE Secondary Master

¾ IDE Secondary Slave

Drive A

Drive B

Video

Halt On

Based Memory

Extended Memory

Total Memory

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Standard CMOS Features

Mon, JUN 7 2004

16:19:20

13579 MB

None

None

None

1.44M, 3.5 in.

None

EGA/VGA

No Errors

640K

515072K

516096K

____________________________

Menu Level ¾

Change the day, month, year and

century

Item Help

Date: Options MM/DD/YYYY

Set the system date. Note that the ‘Day’ automatically changes when you set the

date.

Time: Options HH : MM : SS

Set the system time.

IDE Primary Master: Options are in its sub menu (described in 3.4)

Press <Enter> to enter the sub menu of detailed options.

IDE Primary Slave: Options are in its sub menu (described in 3.4)

Press <Enter> to enter the sub menu of detailed options.

IDE Secondary Master: Options are in its sub menu (described in 3.4)

Press <Enter> to enter the sub menu of detailed options.

IDE Secondary Slave: Options are in its sub menu (described in 3.4)

Press <Enter> to enter the sub menu of detailed options.

Drive A/ Drive B: Options are None, 360K, 5.25 in/1.2M, 5.25 in/720K, 3.5 in/

1.44M, 3.5 in/2.88M, 3.5 in.

Select the type of floppy disk drive installed in your system.

36 • BIOS Setup

Page 43

Video: Options EGA/VGA/CGA 40/CGA 80/MONO

Select the default video device.

Halt On: Options All Errors/No Errors/All, All but Keyboard/All, All but Diskette/All, All

but Disk/Key

Select the situation in which you want the BIOS to stop the POST process and notify

you.

Base Memory: Option N/A

Displays the amount of conventional memory detected during boot up.

Extended Memory: Option N/A

Displays the amount of extended memory detected during boot up.

Total Memory: Option N/A

Displays the total memory available in the system.

3.4 IDE Adapters

The IDE adapters control the hard disk drive. Use a separate sub menu to configure

each hard disk drive.

Phoenix - AwardBIOS CMOS Setup Utility

IDE HDD Auto-Detection

IDE Primary Master

Access Mode

Capacity

Cylinder

Head

Precomp

Landing Zone

Sector

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

IDE Primary Master

Press Enter

Auto

Auto

13579 MB

26310

16

0

26309

63

IDE HDD Auto-Detection: Options Press Enter

Press Enter to auto-detect the HDD on this channel. If detection is successful, it fills

the remaining fields on this menu.

Item Help

____________________________

Menu Level ¾¾

To auto-detect the HDD’s size,

head... on this channel

BIOS Setup • 37

Page 44

IDE Primary Master: Options None, Auto and Manual

Selecting “Manual” lets you set the remaining fields on this screen. Selects the type

of fixed disk. "User Type" will let you select the number of c ylinders, heads, etc.

Note: PRECOMP=65535 means NONE!

Access Mode: Options CHS, LBA, Large and Auto

Choose the access mode for this hard disk

Capacity: Options Auto Display your disk drive size

Disk drive capacity (Approximated). Note that this size is usually slightly greater than

the size of a formatted disk given by a disk-checking program.

The following options are selectable only if the ‘IDE Prima ry Master’ item is set to

“Manual”

Cylinder: Options Min = 0, Max = 65535

Set the number of cylinders for this hard disk.

Head: Options Min = 0, Max = 255

Set the number of read/write heads

Precomp: Options Min = 0, Max = 65535

**** Warning: Setting a value of 65535 means no hard disk

Landing zone: Options Min = 0, Max = 65535

Sector: Options Min = 0, Max = 255

Number of sectors per track

38 • BIOS Setup

Page 45

3.5 Advanced BIOS Features

This section allows you to configure your system for basic operation. You have the

opportunity to select the system’s default speed, boot-up sequence, keyboard

operation, shadowing and security.

Phoenix - AwardBIOS CMOS Setup Utility

¾ CPU Feature

¾ Hard Disk Boot Priority

Virus Warning

CPU L1 Cache

CPU L2 Cache

Quick Power On Self Test

First Boot Device

Second Boot Device

Third Boot Device

Boot Other Device

Swap Floppy Drive

Boot Up Floppy Seek

Boot Up NumLock Status

Gate A20 Option

Typematic Rate Setting

X Typematic Rate (Chars/Sec)

X Typematic Delay (Msec)

Security Option

OS Select For DRAM > 64MB

Report No FDD For WIN95

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

CPU Feature:

Thermal Management

Advanced BIOS Features

Press Enter

Press Enter

Enabled

Enabled

Enabled

Enabled

Floppy

Hard Disk

LS-120

Enabled

Disabled

Enabled

On

Fast

Disabled

6

250

Setup

Non-OS2

No

Phoenix - AwardBIOS CMOS Setup Utility

CPU Feature

Thermal Monitor 1

____________________________

Menu Level ¾

____________________________

Menu Level ¾¾

Item Help

Item Help

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Thermal Management:

It allows you to select the thermal Monitor.

The Choice: Thermal monitor1.

BIOS Setup • 39

Page 46

Hard Disk Boot Priority:

Press Enter and It shows Bootable add-in Card.

Virus Warning:

Allow you to choose the VIRUS Warning feature for IDE Hard Disk boot sector

protection. If this function is enabled and someone attempts to write data into this

area, BIOS will show a warning message on screen and alarm beep.

Enabled---Activates automatically when the system boots up causing a

warning message to appear when anything attempts to

access the boot sector or hard disk partition table.

Disabled---No warning message will appear when anything attempts to

access the boot sector or hard disk partition table.

CPU L1& L2 Cache:

These two categories speed up memory access. However, it depends on

CPU/chipset design.

Enabled---Enable cache

Disabled---Disable cache

Quick Power On Self Test:

This category speeds up Power On Self Test (POST) after you power up the

computer. If it is set to Enable, BIOS will shorten or skip some check items during

POST.

Enabled---Enable quick POST

Disabled--- Normal POST

First/Second/Third Boot Device:

The BIOS attempts to load the operating system from the devices in the sequence

selected in these items.

The choices: Floppy, LS/ZIP, Hard Disk, CDROM, LAN and Disabled.

Boot Other Device:

When enabled, the system searches all other possible loc ations for an operating

system if it fails to find one in the devices specified under the first, second, and third

boot devices.

The choices: Enabled, Disabled

Swap Floppy Drive:

If the system has two floppy drives, you can swap the logical drive name

assignments.

The choices: Enabled, Disabled.

40 • BIOS Setup

Page 47

Boot Up Floppy Seek:

Seeks disk drives during boot up. Disabling speeds boot up.

The choices: Enabled, Disabled.

Boot Up NumLock Status:

Select power on state for NumLock.

The choices: On, Off

Gate A20 Option:

Select if chipset or keyboard controller should control GateA20.

Normal---A pin in the keyboard controller controls GateA20

Fast---Lets chipset control GateA20

Typematic Rate Setting:

Keystrokes repeat at a rate determined by the keyboard controller. When enabled,

the typematic rate and typematic delay can be selected.

The choice: Enabled, Disabled.

Typematic Rate (Chars/Sec):

Sets the number of times a second to repeat a keystroke when you hold the key

down.

The choice: 6, 8, 10, 12, 15, 20, 24 and 30.

Typematic Delay (Msec):

Sets the delay time after the key is held down before it begins to repeat the

keystroke.

The choice: 250, 500, 750 and 1000.

Security Option:

Select whether the password is required every time the system boots or only when

you enter setup.

System---The system will not boot and access to Setup will be denied if the

correct password is not entered at the prompt.

Setup---The system will boot, but access to Setup will be denied if the

correct password is not entered at the prompt.

Note: To disable security, select PASSWORD SETTING at Main Menu and then you

will be asked to enter password. Do not type anything and just press <Enter>,

it will disable security. Once the security is disabled, the system will boot and

you can enter Setup freely.

OS Select For DRAM > 64MB:

BIOS Setup • 41

Page 48

Select the operating system that is running with greater than 64MB of RAM on the

system.

The choices: Non-OS2, OS2.

Report No FDD For Win 95:

Whether report no FDD for Windows 95 or not.

The choices: Yes, No.

3.6 Advanced Chipset Features

This section allows you to configure the system based on the specific features of the

installed chipset. This chipset manages bus speeds and access to system memor y

resources, such as DRAM and the external cache. It also coordinates

communications between the conventional ISA bus and the PCI bus. It must be

stated that these items should never need to be altered. The default settings have

been chosen because they provide the best operating conditions for your system.

The only time you might consider making any changes would be if you discovered

that data was being lost while using your system.

Phoenix - AwardBIOS CMOS Setup Utility

DRAM Timing Selectable

X CAS Latency Time

X Active To Precharge Delay

X DRAM RAS# To CAS# Delay

X DRAM RAS# Precharge

DRAM Data Integrity Mode

MGM Core Frequency

System BIOS Cacheable

Video BIOS Cacheable

Memory Hole At 15M-16M

Delayed Transaction

Delay Prior To Thermal

AGP Aperture Size (MB)

** On-Chip VGA Setting **

On-Chip VGA

On-Chip Frame Buffer Size

Boot Display

Pannel Number

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

DRAM Timing Selectable:

Advanced Chipset Features

By SPD

2.5

6

3

3

Non-ECC

Auto Max 266MHz

Enabled

Disabled

Disabled

Enabled

16 Min

64

Enabled

32MB

VBIOS Default

1

____________________________

Menu Level ¾

Item Help

42 • BIOS Setup

Page 49

Select the operating system that is selecting DRAM timing, so select SPD for setting

SDRAM timing by SPD.

The choices: Manual, By SPD.

CAS Latency Time:

When synchronous DRAM is installed, the number of clock c ycles of CAS latency

depends on the DRAM timing.

The choices: 2, 2.5.

Active To Precharge Delay:

Select the operating system that is active to precharge delay.

The choices: 5, 6, 7.

DRAM RAS# To CAS# Delay:

This field lets you insert a timing delay between the CAS and RAS strobe signals,

used when DRAM is written to, read from, or refreshed. Fast gives faster

performance; and Slow gives more stable performance . This fiel d applie s only when

synchronous DRAM is installed in the system.

The choices: 2, 3.

DRAM RAS# Precharge:

If an insufficient number of cycles are allowed for the RAS to accumulate its charge

before DRAM refresh, the refresh may be incomplete and the DRAM may fail to

retain data. Fast gives faster performance; and Slow gives more stable performance.

This field applies only when synchronous DRAM is installed in the system.

The choices: 2, 3.

DRAM Data Integrity Mode:

This item shows you if the DRAM has ECC or not.

The choices: Non-ECC, ECC.

MGM Core Frequency:

This item allows you to determine the MGM core frequency.

The choices: Auto Max 266MHz, 400/266/133/200MHz,

400/200/100/200MHz, 400/200/100/133MHz,

400/266/133/267MHz, 400/333/166/250MHz,

Auto Max 400/333.

System BIOS Cacheable:

Selecting “Enabled” allows caching of the system BIOS ROM at F0000h-FFFFFh,

resulting in better system performance. However, if any program writes to this

memory area, a system error may result.

BIOS Setup • 43

Page 50

The choices: Enabled, Disabled.

Video BIOS Cacheable:

Select “Enabled” allows caching of the video BIOS, resulting in better system

performance. However, if any program writes to this memory area, a system error

may result.

The choices: Enabled, Disabled.

Memory Hole At 15M-16M:

You can reserve this area of system memory for ISA adapter ROM. When this area is

reserved, it cannot be cached. The user information of peripherals that need to use

this area of system memory usually discusses their memory requirements.

The choices: Enabled, Disabled.

Delayed Transaction:

The chipset has an embedded 32-bit posted write buffer to support delay

transactions cycles. Select “Enabled” to support compliance with PCI specification

version 2.2.

The choices: Enabled, Disabled.

Delay Prior To Thermal:

Select this item allows the delay prior to thermal time.

The choices: 4Min, 8Min, 16Min and 32Min.

AGP Aperture Size (MB):

This field determines the effective size of the Graphic Aperture used for a particular

GMCH configuration. It can be updated by the GMCH-specific BIOS configuration

sequence before the PCI standard bus enumeration sequence takes place. If it is not

updated then a default value will select an aperture of maximum size.

The choices: 4, 8, 16, 32, 64, 128 and 256.

**On-Chip VGA Setting**

On-Chip VGA:

This item allows you to control the on-chip VGA.

The choices: Enabled, Disabled.

On-Chip Frame Buffer Size:

This item allows you to control the on-chip frame buffer size.

The choices: 1M, 4M, 8M, 16M and 32M.

Boot Display:

This item allows you to select the boot display device.

44 • BIOS Setup

Page 51

The choices: VBIOS Default, CRT, LFP and CRT+LEP.

Panel Number:

This item allows you to select the panel resolution.

The choices: 1-8.

3.7 Integrated Peripherals

Phoenix - AwardBIOS CMOS Setup Utility

¾ Onboard IDE Device

¾ Onboard Device

¾ SuperIO Device

Onboard Lan Boot ROM

Onboard Serial Port 1

Serial Port 3 Use IRQ

Onboard Serial Port 2

Serial Port 4 Use IRQ

Onboard Serial Port 3

Serial Port 3 Use IRQ

Onboard Serial Port 4

Serial Port 4 Use IRQ

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Onboard IDE Device:

On-Chip Primary PCI IDE

IDE Primary Master PIO

IDE Primary Slave PIO

IDE Primary Master UDMA

IDE Primary Slave UDMA

On-Chip Secondary PCI IDE

IDE Secondary Master PIO

IDE Secondary Slave PIO

IDE Secondary Master UDMA

IDE Secondary Slave UDMA

IDE HDD Block Mode

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Integrated Peripherals

Press Enter

Press Enter

Press Enter

Disabled

3F8

IRQ4

2F8

IRQ3

3E8

IRQ10

2E8

IRQ11

Onboard IDE Device

Enabled

Auto

Auto

Auto

Auto

Enabled

Auto

Auto

Auto

Auto

Enabled

Item Help

____________________________

Menu Level ¾

If your IDE hard drive supports block

mode select Enabled for automatic

detection of the optimal number of

block read/write per sector the drive

can support

Item Help

____________________________

Menu Level ¾

If your IDE hard drive supports block

mode select Enabled for automatic

detection of the optimal number of

block read/write per sector the drive

can support

BIOS Setup • 45

Page 52

OnChip Primary/Secondary PCI IDE:

The integrated peripheral controller contains an IDE interface with support for two

IDE channels. Select “Enabled” to activate each channel separately.

The choices: Enabled, Disabled.

IDE Primary/Secondary Master/Slave PIO:

The four IDE PIO (Programmed Input/Output) fields let you set a PIO mode (0-4) for

each of the four IDE devices that the onboard IDE interface supports. Modes 0

through 4 provide successively increased pe rformance. In Auto mode, the system

automatically determines the best mode for each device.

The choices: Auto, Mode 0, Mode 1, Mode 2, Mode 3 and Mode 4.

IDE Primary/Secondary Master/Slave UDMA:

Ultra DMA/33 implementation is possible only if your IDE hard drive supports it and

the operating environment includes a DMA driver (Windows 95 OSR2 or a third-party

IDE bus master driver). If your hard drive and your system software both support

Ultra DMA/33, select “Auto” to enable BIOS support.

The choices: Auto, Disabled.

IDE HDD Block Mode:

Block mode is also called block transfer, multiple commands, or multiple sector

read/write. If your IDE hard drive supports block mode (most new drives do), select

Enabled for automatic detection of the optimal number of block read/writes per sector

the drive can support.

The choices: Enabled, Disabled

Onboard Device:

USB Controller

USB 2.0 Controller

USB Keyboard Support

USB Mouse Support

AC97 Audio

Init Display First

Onboard Device

Enabled

Enabled

Disabled

Disabled

Auto

Onboard/AGP

Item Help

____________________________

Menu Level ¾

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

USB / USB 2.0 Controller:

Select “Enabled” if your system contains a Universal Serial Bus (USB) / USB 2.0

controller and you have USB peripherals.

The choices: Enabled, Disabled.

46 • BIOS Setup

Page 53

USB Keyboard Support:

Select “Enabled” if your system contains a Universal Serial Bus (USB) controller and

you have a USB keyboard.

The choices: Enabled, Disabled.

USB Mouse Support:

Select “Enabled” if your system contains a Universal Serial Bus (USB) controller and

you have a USB mouse.

The choices: Enabled, Disabled.

AC97 Audio:

This item allows you to decide to auto or disable the chipset family to support AC97

Audio.

The choices: Auto, Disabled.

Init Display First:

This item allows you to decide to active whether PCI Slot or on-chip VGA first.

The choices: PCI Slot, Onboard/AGP.

SuperIO Device:

Power ON Function

X KB Power ON Password

X Hot Key Power ON

Onboard FDC Controller

Onboard Parallel Port

Parallel Port Mode

X EPP Mode Select

X ECP Mode Use DMA

PWRON After PWR-Fail

SuperIO Device

BUTTON ONLY

Enter

Ctrl-F1

Enabled

378/IRQ7

SPP

EPP1.7

3

Off

Item Help

____________________________

Menu Level ¾

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Power On Function:

You can use this item to select operating Power On the system.

The choices: Password, Hot KEY, Any KEY, BUTTON ONLY,

Keyboard 98

BIOS Setup • 47

Page 54

KB Power ON Password:

You can use this item to limit operating KB Power On system.

The choice: Enter

Hot Key Power ON:

You can use this item to select operating Hot Key to Power On system.

The choices: Ctrl-F1~Ctrl-F12.

Onboard FDC Controller:

Select “Enabled” if your system has a floppy disk controller (FDC) installed on the

system board and you wish to use it. If you install and-in FDC or the system has no

floppy drive, select Disabled in this field.

The choices: Enabled, Disabled.

Onboard Parallel Port:

This item allows you to determine access onboard parallel port controller with which

I/O address.

The choices: 3BC/IRQ7, 378/IRQ7, 278/IRQ5 and Disabled.

Parallel Port Mode:

Select an operating mode for the onboard parallel (printer) port. Select Normal,

Compatible, or SPP unless you are certain your hardware and software both support

one of the other available modes.

The choices: SPP, EPP, ECP and ECP+EPP.

EPP Mode Select:

Select EPP port type 1.7 or 1.9.

The choices: EPP1.7, 1.9.

ECP Mode Use DMA:

Select a DMA channel for the parallel port for use during ECP mode.

The choices: 3, 1.

PWRON After PWR-Fail:

This item allows you to select if you want to power on the system after power failure.

The choices: Off, On and Former-Sts.

Onboard Lan Boot ROM:

Select “Enabled” if your system has a LAN device installed on the system board and

you wish to use it.

The choices: Enabled, Disabled.

48 • BIOS Setup

Page 55

Onboard Serial Port 1/Port 2:

Select an address for the first and second serial ports.

Serial Port 1/Port 2 Use IRQ:

Select an IRQ for the first and second serial ports.

Onboard Serial Port 3/Port 4:

Select an address for the third and forth serial ports.

Serial Port 3/Port 4 Use IRQ:

Select an IRQ for the third and forth serial ports.

3.8 Power Management Setup

The Power Management Setup allows you to configure you system to most

effectively save energy while operating in a manner consistent with your own style of

computer use.

Phoenix - AwardBIOS CMOS Setup Utility

ACPI Function

Power Management

Video Off Method

Video Off In Suspend

Suspend Type

Suspend Mode

HDD Power Down

CPU THER-Throttling

Wake-Up by PCI card

Resume by Alarm

X Date (of Month) Alarm

X Time (hh:mm:ss) Alarm

** Reload Global Timer Events **

Primary IDE 0

Primary IDE 1

Secondary IDE 0

Secondary IDE 1

FDD, COM, LPT Port

PCI PIRQ [A-D]#

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

ACPI Function:

Power Management Setup

Enabled

User Define

DPMS

Yes

Stop Grant

Disabled

Disabled

50.0%

Enabled

Disabled

0

0 : 0 : 0

Disabled

Disabled

Disabled

Disabled

Disabled

Disabled

____________________________

Menu Level ¾

Item Help

BIOS Setup • 49

Page 56

This item allows you to enable or disable the Advanced Configuration and Power

Management (ACI).

The choices: Enabled, Disabled.

Power Management:

This category allows you to select the type (or degree) of power saving and is directly

related to the following modes:

1. HDD Power Down

2. Doze Mode

3. Suspend Mode

Min. Power Saving:

Minimum power management. Doze Mode = 1 hr., Standby Mode = 1 hr.,

Suspend Mode = 1 hr., and HDD Power Down = 15 min.

Max. Power Saving:

Maximum power management -- ONLY AVAILABLE FOR SL CPU’s. Doze

Mode = 1 min., Standby Mode = 1 min., Suspend Mode = 1 min., and HDD

Power Down = 1 min.

User Defined:

Allow you to set each mode individually. When not disabled, each of the ranges

is from 1 min. to 1 hr. except for HDD Power Down, which ranges from 1 min. to

15 min. and disable.

Video Off Method:

This determines the manner in which the monitor is blanked.

V/H SYNC+Blank:

This selection will cause the system to turn off the vertical and horizontal

synchronization ports and write blanks to the video buffer.

Blank Screen:

This option only writes blanks to the video buffer.

DPMS:

Initial display power management signaling.

Video Off In Suspend:

This determines the manner in which the monitor is blanked.

The choices: Yes, No.

50 • BIOS Setup

Page 57

Suspend Type:

Select the Suspend Type.

The choices: PWRON Suspend, Stop Grant.

Suspend Mode:

When “Enabled” and after the set time of system inactivity. All devices except the

CPU will be shut off.

The choices: Enabled, Disabled.

HDD Power Down:

When “Enabled” and after the set time of system inactivity, the hard disk drive will be

powered down while all other devices remain active.

The choices: Enabled, Disabled.

CPU THER-Throttling:

Select the CPU THRM-Throttling rate.

The choices: 12.5%, 25.0%, 37.5%, 50.0%, 62.5%, 75.0% and 87.5%.

Wake-Up by PCI Card:

An input signal from PME on the PCI card awakens the system from a soft off state.

The choices: Enabled, Disabled.

Resume by Alarm:

When “Enabled”, your can set the date and time at which the RTC (real-time clock)

alarm awakens the system from Suspend mode.

The choices: Enabled, Disabled.

PM Events:

PM events are I/O events whose occurrence can prevent the system from entering a

power saving mode or can awaken the system from such a mode. In effect, the

system remains alert for anything, which occurs to a devic e, which is configure d as

Enabled, even when the system is in a power down mode.

Primary IDE 0

Primary IDE 1

Secondary IDE 0

Secondary IDE 1

FDD, COM, LPT Port

PCI PIRQ [A-D] #

BIOS Setup • 51

Page 58

3.9 PnP/PCI Configurations

This section describes configuring the PCI bus system. PCI, or Personal Computer

Interconnect, is a system that allows I/O devices to operate at speeds nearing the

speed the CPU itself uses when communicating with its own special components.

This section covers some very technical items and it is strongly recommended that

only experienced users should make any changes to the default settings.

Phoenix - AwardBIOS CMOS Setup Utility

Reset Configuration Data

Resources Controlled By

X IRQ Resources

PCI/VGA Palette Snoop

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Reset Configuration Data:

Normally, you leave this field Disabled. Select “Enabled” to reset E xtended S ystem

Configuration Data (ESCD) when you exit Setup if you have installed a new add-on

and the system reconfiguration has caused such a serious conflict that the operating

system cannot boot.

The choices: Enabled, Disabled.

Resources Controlled By:

It allows you can automatically configure all the boot and Pl ug and Play-compatibl e

devices. If you select Auto, all the interrupt request (IRQ) and DMA assignment fields

disappear, as the BIOS automatically assigns them.

IRQ Resources:

When resources are controlled manually, assign each system interrupt a type,

depending on the type of device using the interrupt.

PCI/VGA Palette Snoop:

Leave this field at “Disabled”.

The choices: Enabled, Disabled.

PnP/PCI Configurations

Disabled

Auto (ESCD)

Press Enter

Disabled

Item Help

_________________________

Menu Level ¾

52 • BIOS Setup

Page 59

3.10 PC Health Status

Phoenix - AwardBIOS CMOS Setup Utility

CPU Warning Temperature

SYS Temperature

CPU Temperature

CPU FAN

SYSFAN

VDIMM

VCORE

+3.3

+ 5 V

+12 V

-12 V

- 5 V

VBAT (V)

5VSB (V)

Shutdown Temperature

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

CPU Warning Temperature:

This item will prevent CPU from overheating.

The choices: 50°C /122°F ~70°C /158°F, Disabled.

SYS Temperature:

Displays the current system temperature.

CPU Temperature:

Displays the current CPU temperature.

CPUFAN:

Displays the current CPU fan operating speed.

SYSFAN:

Displays the current system fan operating speed.

VDIMM:

Displays the voltage level of the DRAM.

VCORE:

Displays the voltage level of CPU (Vcore).

PC Health Status

Disabled

32°C / 89°F

28°C / 82°F

5152RPM

3283RPM

2.48

4.42V

3.34V

4.94V

11.85V

-12.28V

-4.99V

3.02V

5.04V

Disabled

Item Help

____________________________

Menu Level ¾

BIOS Setup • 53

Page 60

+3.3V/+5V/+12V/-12V/-5V/5VSB(V):

Displays the voltage of +5V/+12V/-12V/-5V.

VBAT (V):

Displays the voltage level of the battery.

Shutdown Temperature:

This item allows you to set up the CPU shutdown Temperature. This item is only

effective under Windows

®

98 ACPI mode.

The choices: Disabled, 60°C / 140°F, 65°C / 149°F, 70°C / 159°F and

75°C / 167°F.

3.11 Frequency/Voltage Control

Phoenix - AwardBIOS CMOS Setup Utility

Auto Detect PCI CLK

Spread Spectrum

↑↓→←Move Enter: Select +/-/PU/PD: Value F10: Save ESC: Exit F1: General Help

F5: Previous Values F6: Fail-safe defaults F7: Optimized Defaults

Frequency/Voltage Control

Enabled

Disabled

____________________________

Menu Level ¾

Item Help

Auto Detect PCI CLK:

When “Enabled”, this item will auto detect if the PCI slot have devices and will send

clock signal to PCI devices. When disabled, it will send the clock signal to PCI slot.

The choices: Enabled, Disabled.

Spread Spectrum:

This item allows you to enable or disable the Spread Spectrum.

The choices: Disabled, -0.25%, -0.50% and -0.75%.

3.12 Load Fail-Safe Defaults

When you press <Enter> on this item you get a confirmation dialog box with a

message similar to:

54 • BIOS Setup

Page 61

Load Fail-Safe Defaults (Y/N)? N

Pressing ‘Y’ loads the BIOS default values for the most stable, minimal-performance

system operations.

3.13 Load Optimized Defaults

When you press <Enter> on this item you get a confirmation dialog box with a

message similar to:

Load Optimized Defaults (Y/N)? N

Pressing ‘Y’ loads the default values that are factory settings for optimal performance

system operations.

3.14 Supervisor/User Password Setting

You can set either supervisor or user password, or both of then. The differences

between are:

Set Supervisor Password: can enter and change the options of the setup menus.

Set User Password: just can only enter but do not have the right to change the

options of the setup menus. When you select this function, the following message

will appear at the center of the screen to assist you in creating a password.

ENTER PASSWORD:

Type the password, up to eight characters in length, and press <Enter>. The

password typed now will clear any previously entered password from CMOS

memory. You will be asked to confirm the password. Type the password again and

press <Enter>. You may also press <Esc> to abort the selection and not enter a

password.

To disable a password, just press <Enter> when you are prompted to enter the

password. A message will confirm the password will be disabled. Once the password

is disabled, the system will boot and you can enter Setup freely.

BIOS Setup • 55

Page 62

PASSWORD DISABLED.

When a password has been enabled, you will be prompted to enter it every time you

try to enter Setup. This prevents an unauthorized person from changing any part of

your system configuration.

Additionally, when a password is enabled, you can also require the BIOS to request a

password every time your system is rebooted. This would prevent unauthorized use

of your computer.

You determine when the password is required within the BIOS Features Setup Menu

and its Security option (see Section 3). If the Security option is set to “System”, the

password will be required both at boot and at entry to Setup. If set to “Setup”,

prompting only occurs when trying to enter Setup.

3.15 Exiting BIOS Setup

Save & Exit Setup

Pressing <Enter> on this item asks for confirmation:

Save to CMOS and EXIT (Y/N)? Y

Pressing “Y” stores the selections made in the menus in CMOS – a special section of

memory that stays on after you turn your system off. The next time you boot your

computer, the BIOS configures your system according to the Setup selections stored

in CMOS. After saving the values the system is restarted again.

Exit Without Saving

Pressing <Enter> on this item asks for confirmation:

Quit without saving (Y/N)? Y

This allows you to exit Setup without storing in CMOS any change. The previous

selections remain in effect. This exits the Setup utility and restarts your computer.

56 • BIOS Setup

Page 63

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the after-sales

services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow the instructions

exactly. When sending in damaged products for repair, please attach an RMA application

form which can be downloaded from: http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for products bought

in China.

• The warranty period starts on the day the product is shipped from ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK will be covered by

the original manufacturers' warranty.

• For products containing storage d evices (hard drives, flash cards, etc.), please back

up your data before sending them for repair. ADLINK is not responsible for any loss of

data.

• Please ensure the use of properly licensed software with our systems. ADLINK does

not condone the use of pirated software and will not service systems using such

software. ADLINK will not be held legally responsible for products shipped with

unlicensed software installed by the user.

• For general repairs, please do not include peripheral accessories. If peripherals need

to be included, be certain to specify which items you sent on the RMA Request &

Confirmation Form. ADLINK is not responsible for items not listed on the RMA

Request & Confirmation Form.

3. Our repair service is not covered by ADLINK's guarantee in the following situations:

• Damage caused by not following instructions in the User's Manual.

• Damage caused by carelessness on the user's part during product transportation.

• Damage caused b y fire, earthquakes, floods, lightening, pollution, other acts of God,

and/or incorrect usage of voltage transformers.

• Damage caused by inappropriate storage environments such as with high

temperatures, high humidity, or volatile chemicals.

• Damage caused by leakage of battery fluid during or after change of batteries by

customer/user.

• Damage from improper repair by unauthorized ADLINK technicians.

• Products with altered and/or damaged serial numbers are not entitled to our service.

• This warranty is not transferable or extendible.

• Other categories not protected under our warranty.

4. Customers are responsible for all fees necessary to transport damaged products to

ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

Warranty Policy • 57

Loading...

Loading...