Page 1

1. ANALYSER LAYOUT AND FEATURES

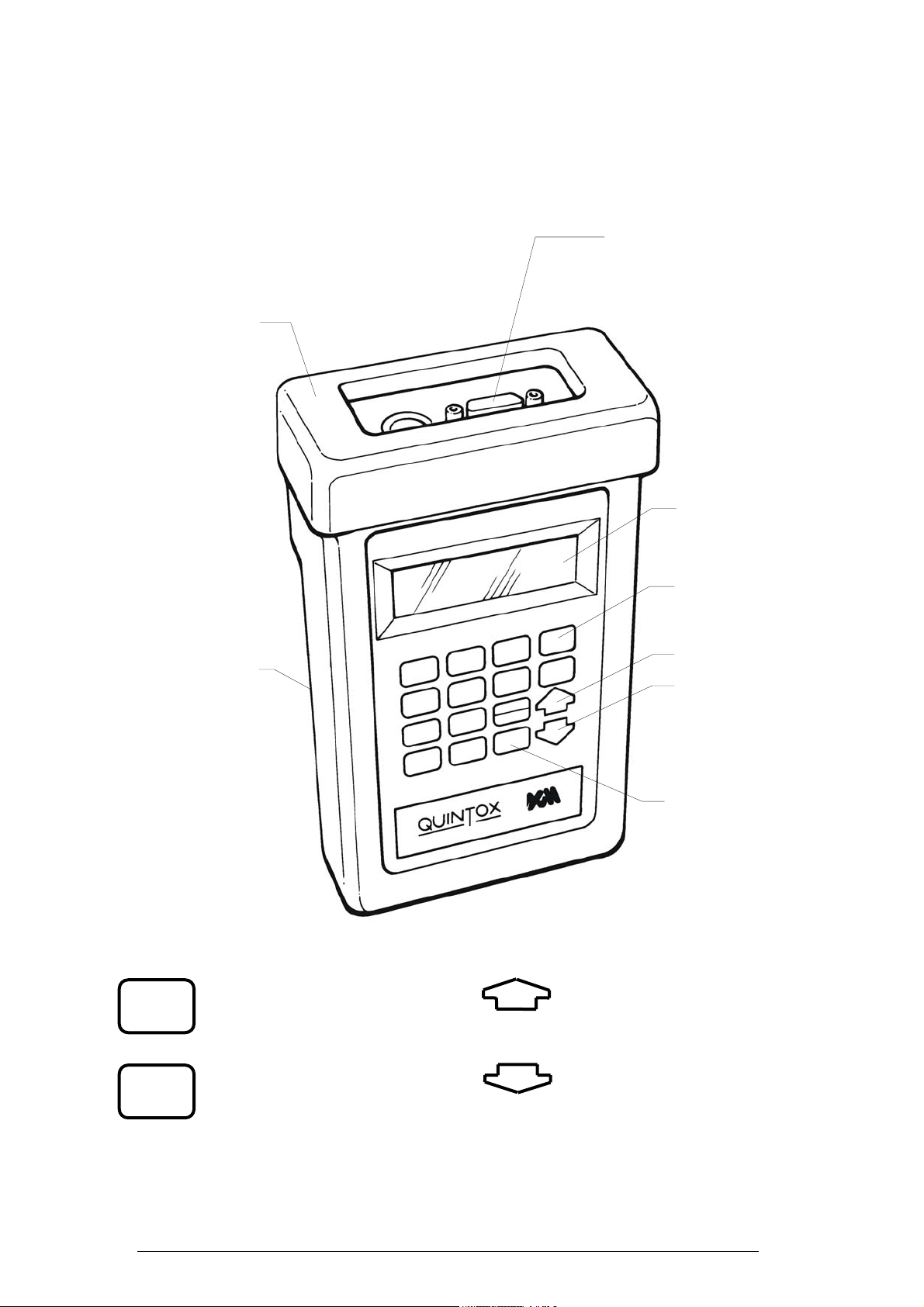

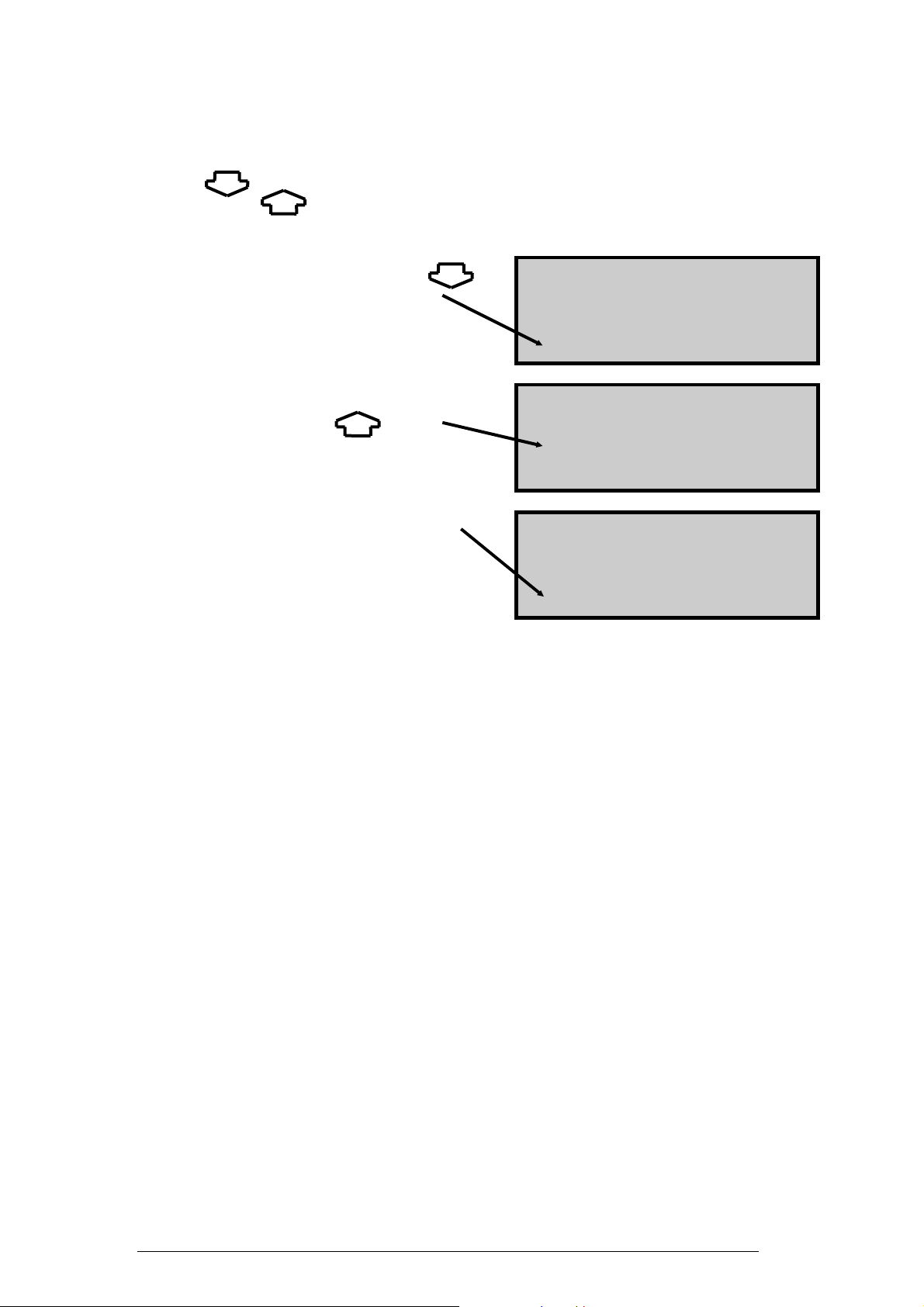

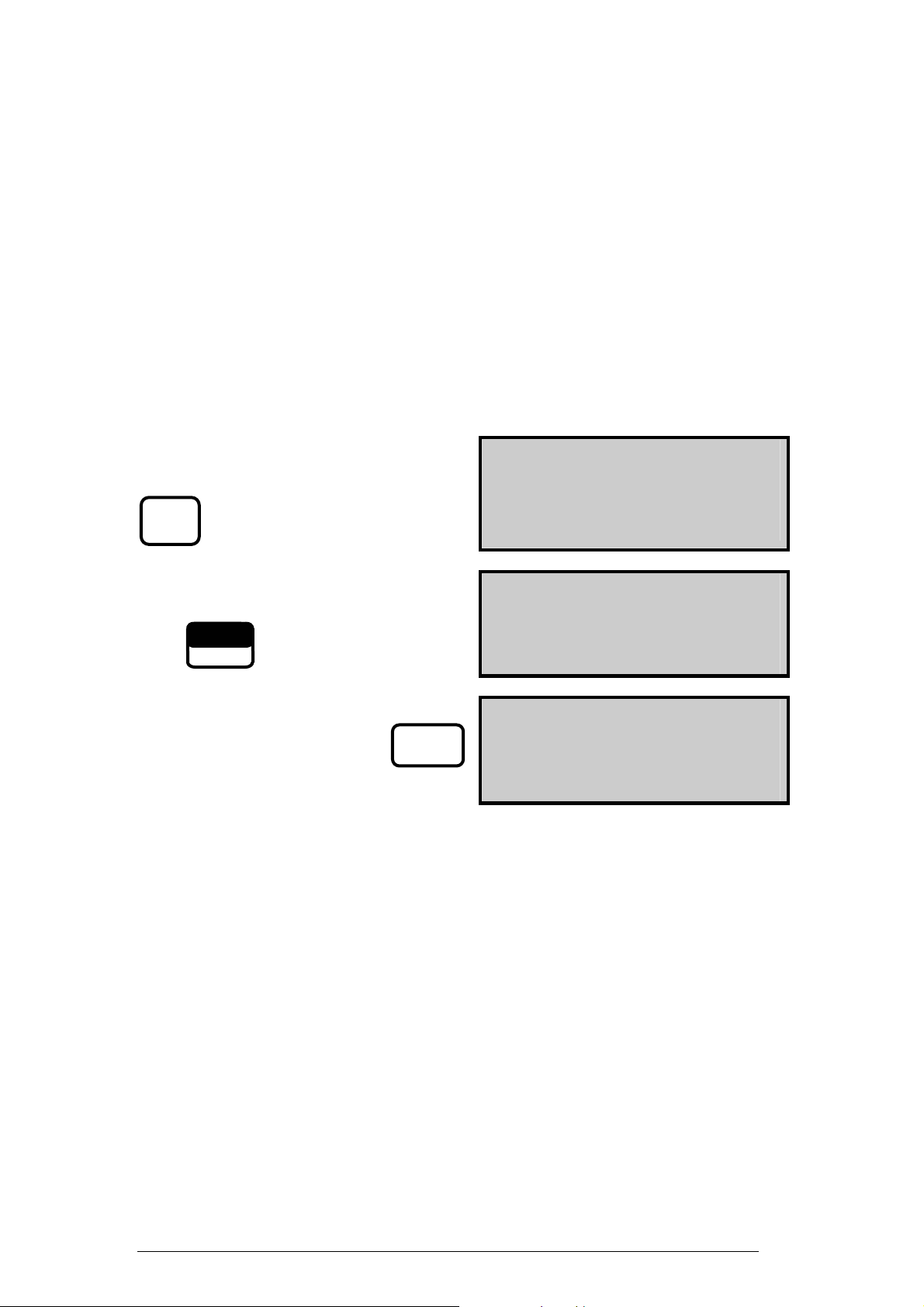

1.1 Handset Features

Remote lead socket

(15 pin D type)

Also used for

downloading data

Rubber boot

to PC

4 line display

Battery

Compartment

(back)

Commonly used keys

ON/OFF UP

ON

OFF

ENTER & SET/CAL

SET/CAL

ENTER

Accepts parameters

Enters values

ON/OFF Key

UP key

DOWN key

ENTER/SETCAL

keys

Pages up through screens

Scrolls up through options, ie Fuel

DOWN

Pages down through screens

Scrolls down through options

KM9106 Operators Manual

1

Page 2

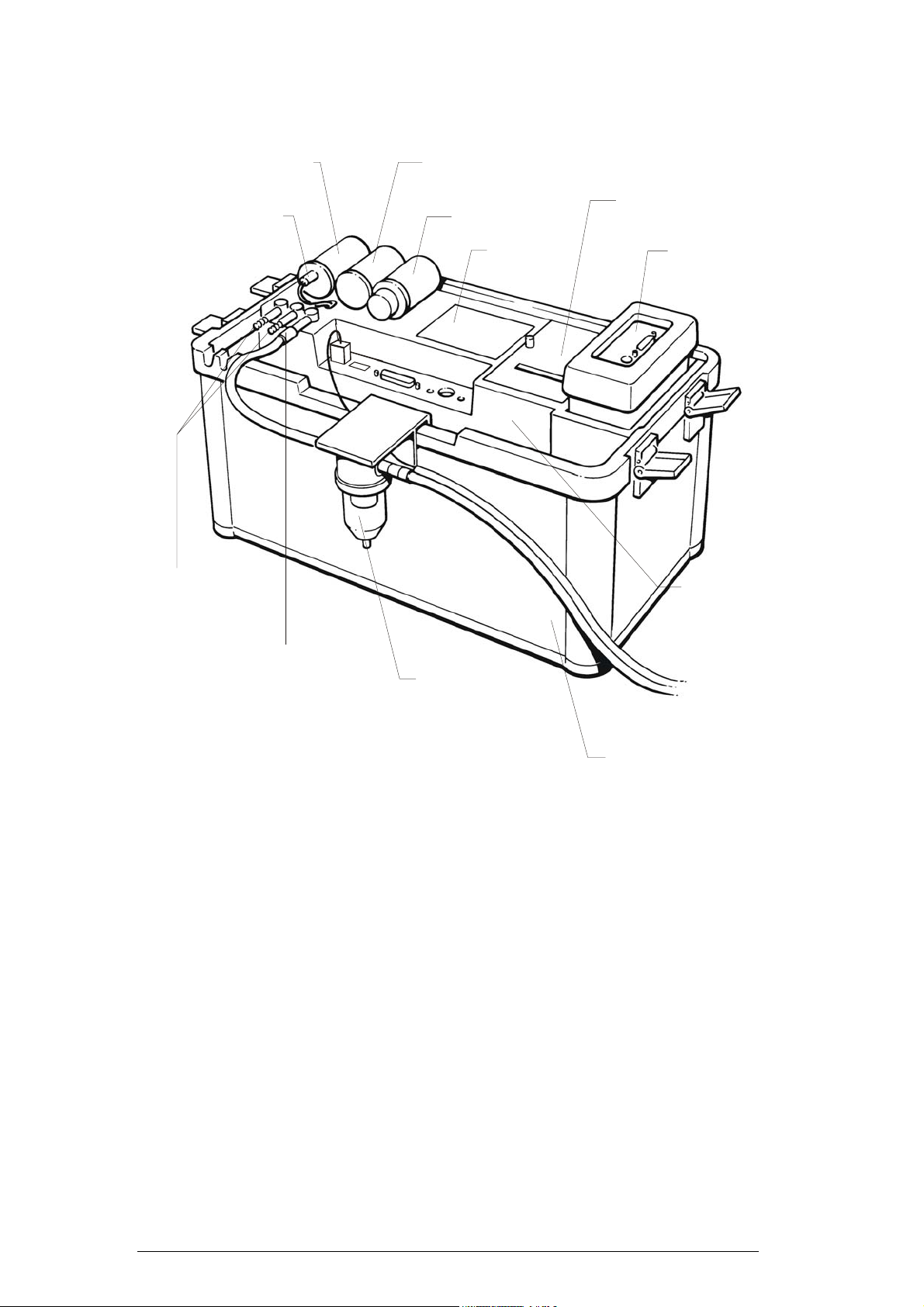

1.2 Analyser Layout

Oxygen Sensor Filter Bridge

Connection lead

for Oxygen

sensor

or Sulphur Filter

Particle Filter

Battery

enclosure

Printer unit

Handset

(stored in

pocket)

Dual

pressure ports

Water trap

connection

Water trap

located on

side of instrument

Accessory

storage

space

(leads/water

trap etc.)

Instrument case

2

KM9106 Operators Manual

Page 3

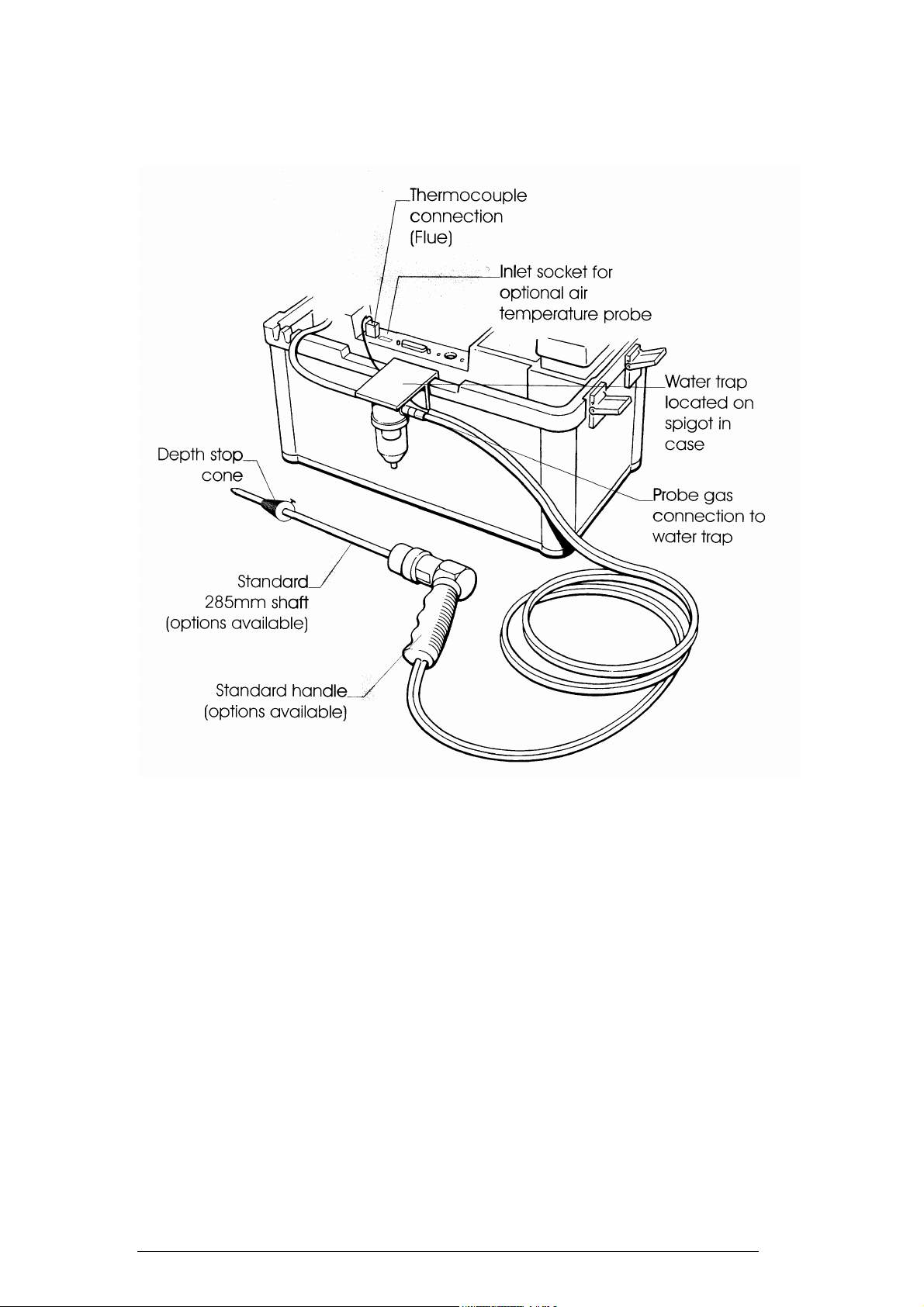

1.3 Standard Probe Configuration

KM9106 Operators Manual

3

Page 4

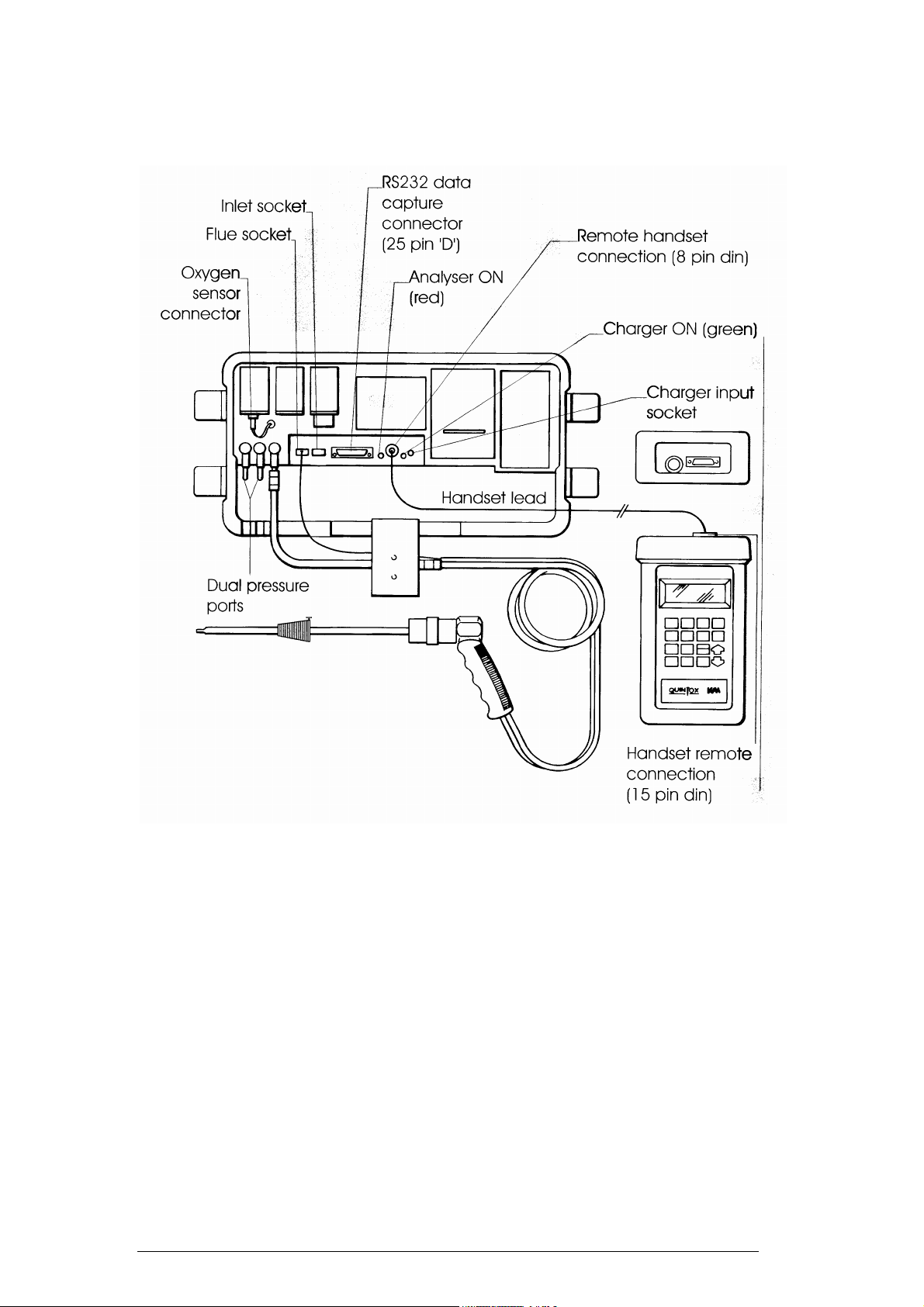

1.4 Analyser Connections

4

KM9106 Operators Manual

Page 5

2. SAFETY WARNING

This analyser extracts combustion gases that may be toxic in relatively low

concentrations. These gases are exhausted from the bottom of the instrument. This

instrument must only be used in well ventilated locations. It must only be used by

trained and competent persons after due consideration of all the potential hazards.

3. FIRST TIME USE

Charge the battery for 12 hours, following this an overnight charge should be

sufficient for an average 8 hour day.

Whilst charging the green LED will be illuminated, the LED will flash when the

battery is fully charged.

Check that you have all the items you have ordered.

We offer a wide choice of probes which are not supplied as standard and must be

ordered as a separate item.

Take time to read this manual fully.

TIP: Take a look at the Spare Parts list and order some replacement filters

and paper rolls now.

When using the analyser for the first time you have the following under your control

:-

PARAMETER SECTION

Display Contrast 5.4

Backlight 5.4

Language 6.4

Line Rejection for mains frequency 6.4

Gas Measurement Scale 6.4

Temperature scale 6.4

Pressure scale 6.4

Reference oxygen 6.4

Time and date 6.1

KM9106 Operators Manual

5

Page 6

Printed header name and telephone number 7.1

6

KM9106 Operators Manual

Page 7

4. NORMAL START UP SEQUENCE

4.1 Every Time You Use The Analyser

BEFORE SWITCH-ON CHECK THAT:

the Oxygen sensor is connected

the particle filter is not dirty

the sulphur filter is fitted for heavy oil or coal

the water trap and probe line are empty of water

all hose connections, etc, are properly made

the paper roll is fitted

the probe is sampling ambient FRESH air

the water trap is vertical

the flue temperature is connected

the instrument is placed on a clean, flat, level surface

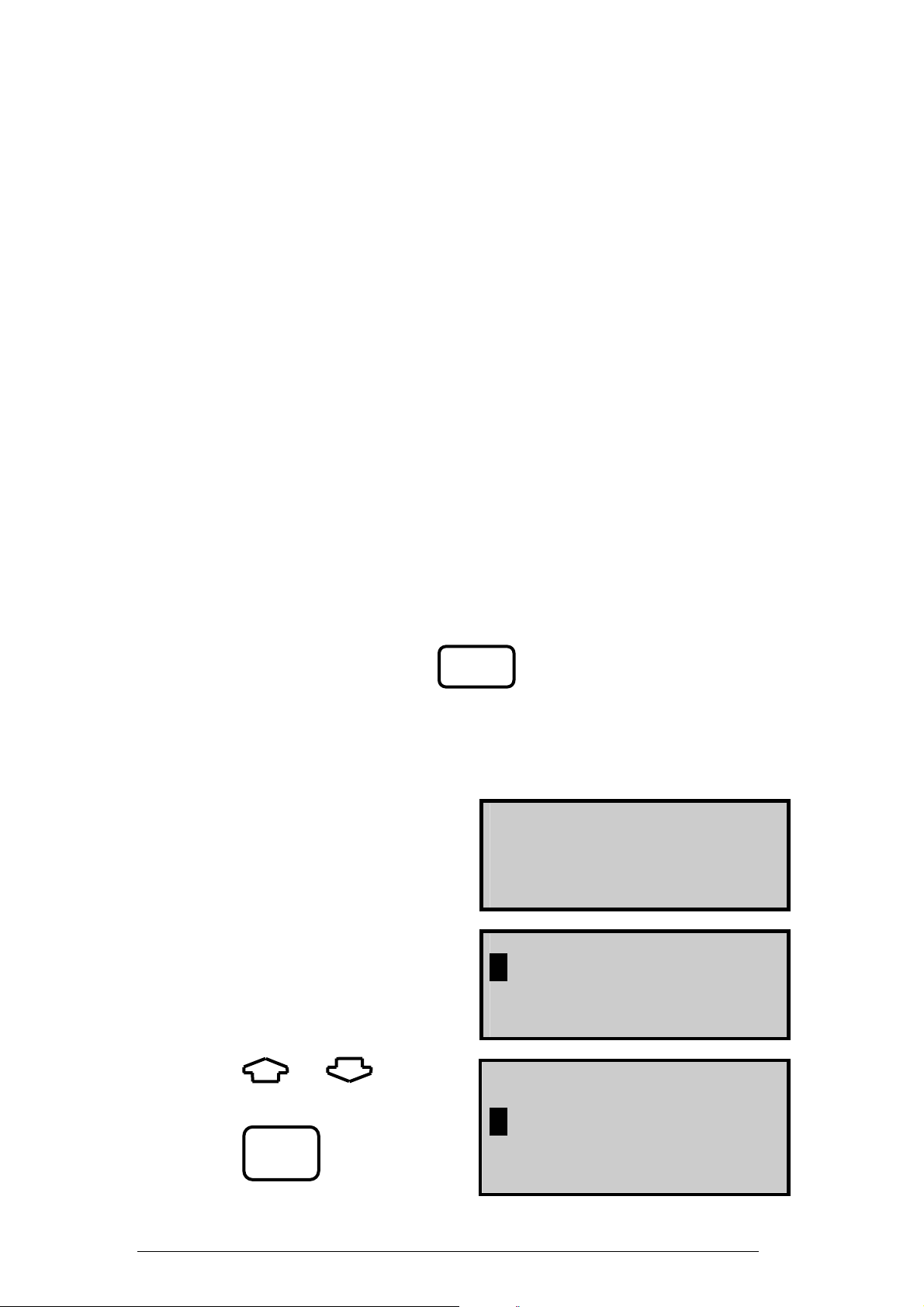

Switch ON the instrument by pressing

4.2 Automatic Calibration

ON

During this sequence the analyser pumps fresh air into the sensors to allow toxic

sensors to be set to zero and the Oxygen sensor to be set to 20.9 %.

After switch-on the analyser will

briefly display the Kane logo and

telephone numbers:-

777 KANE-MAY 777

TEL +44 (0) 1707 375550

FAX +44 (0) 1707 393277

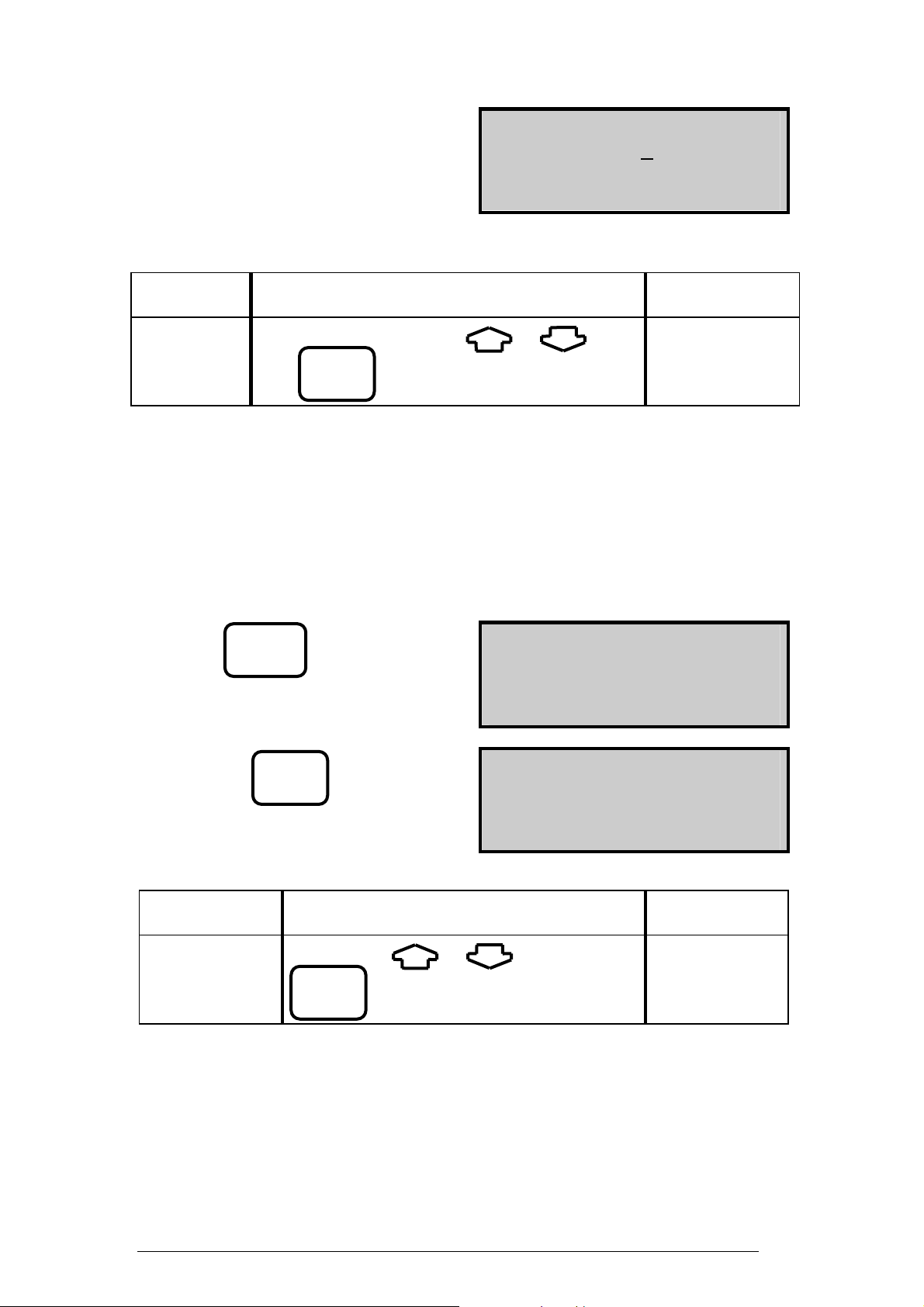

Followed by the logger menu screen :-

9 9 SELECT FUNCTION 9 9

1

. . LOGGER CONTROL

2 . . QUINTOX CONTROL

Use the and keys to

position the cursor over 2 . .Quintox

Control.

Press to access Quintox

Control

ENTER

9 9 SELECT FUNCTION 9 9

1 . . LOGGER CONTROL

2

. . QUINTOX CONTROL

KM9106 Operators Manual

7

Page 8

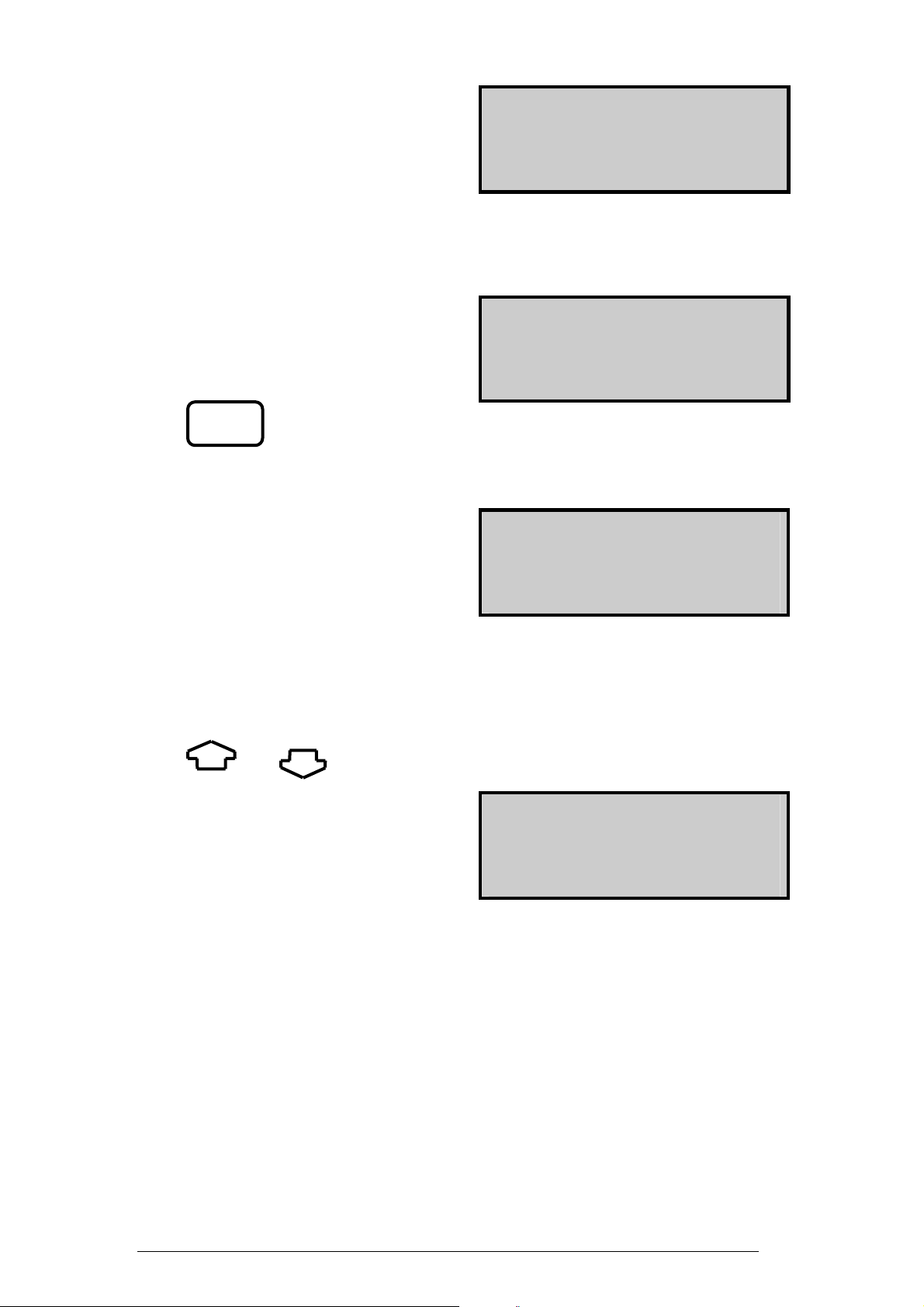

And show the countdown screen :-

-- -- -- -- -- -- -- -- -- -- -- -- --

9 CALIBRATING 9 9

300

-- -- -- -- -- -- -- -- -- -- -- -- --

The display will countdown from 300 to zero in one second steps. If the analyser has

been used recently it may complete automatic calibration in less than 300 seconds

otherwise it will count to zero.

Once the calibration sequence is

complete an audible beep will be heard

and will show the selected fuel on the

following display:-

Press

This zeros the toxic sensor and sets Oxygen to 20.9%. The next screen is the MAIN

DISPLAY of the analyser:-

ENTER

-- -- -- -- -- -- -- -- -- -- -- -- -NATURAL GAS

PRESS ENTER KEY

-- -- -- -- -- -- -- -- -- -- -- -- --

DATE . . . 07-08-96

TIME . . . 12:31:35

INSTABILITY 0

BATTERY % . . 54

MAIN DISPLAY

NOTE : It is advisable to repeat Oxygen Calibration every 2 hours for maximum

accuracy.

Use and to change the display.

NETT C . . . . 0.0

O2 % . . . 20.9

CO ppm . . . 0000

EFF (G) % . . . 0.0

All parameters are detailed in Appendix A - MAIN DISPLAY PARAMETERS.

8

KM9106 Operators Manual

Page 9

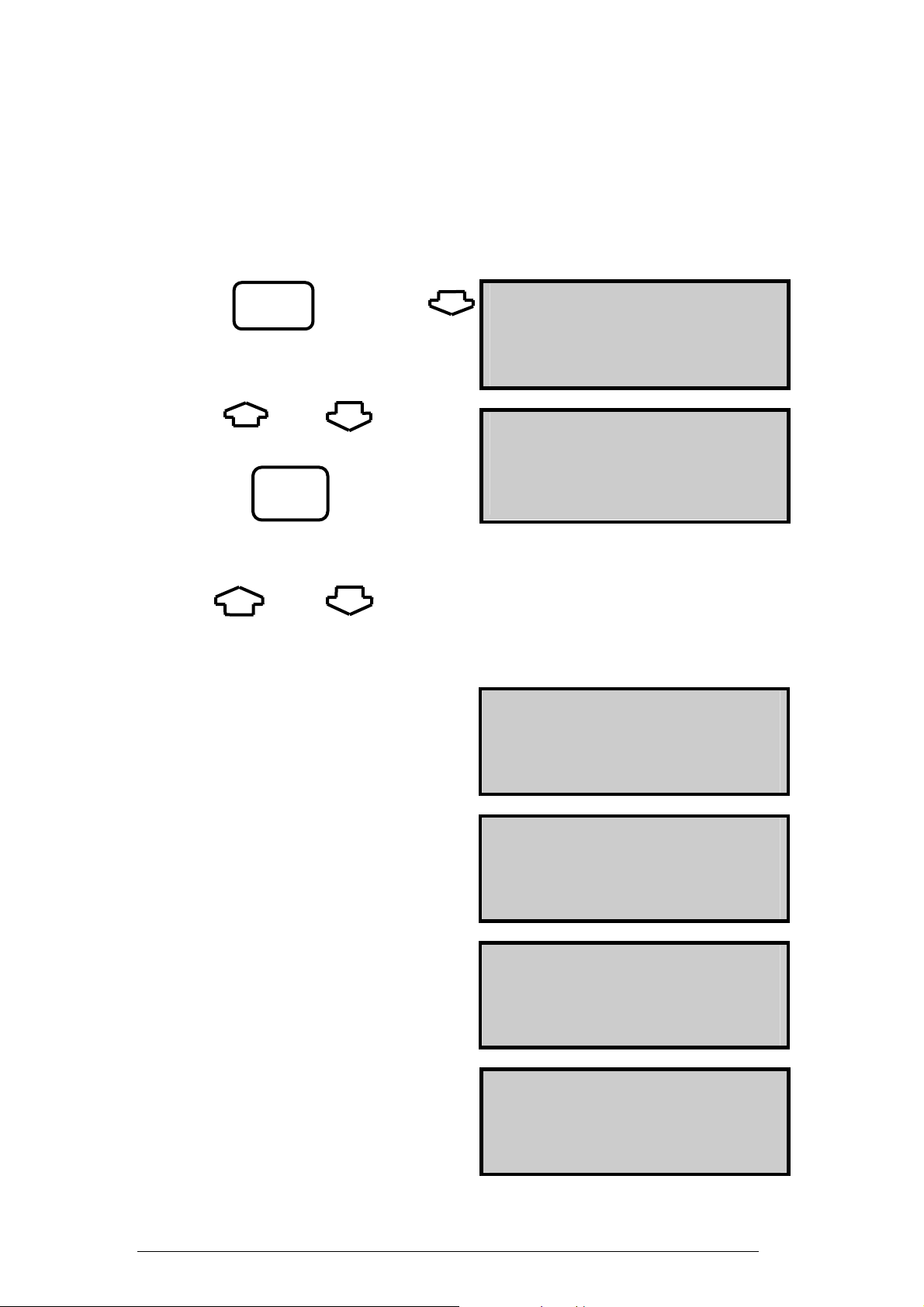

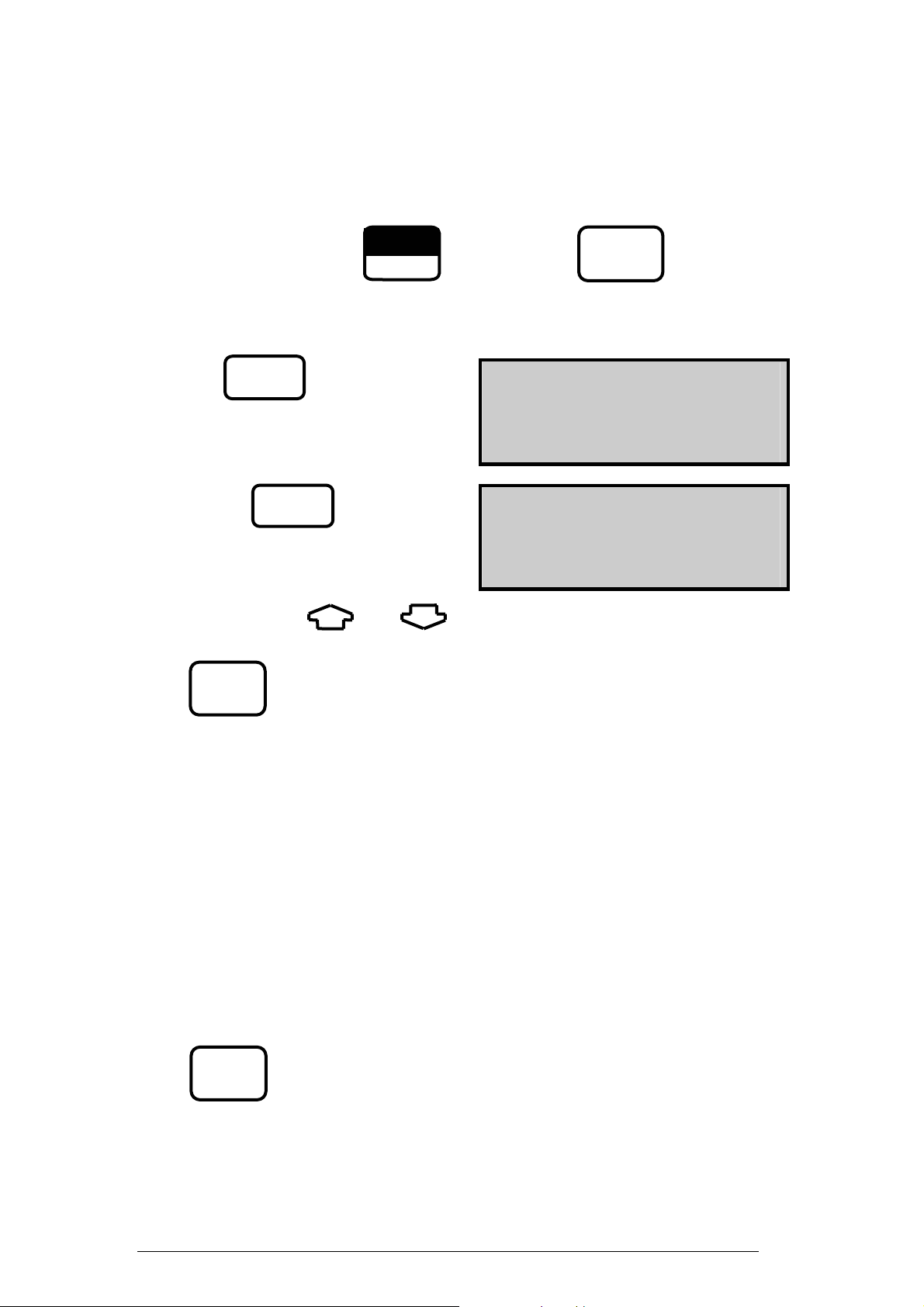

4.3 Main Displays

The main display can be changed to show the following :-

• Page Mode displays 4 lines of data in set format, each page is predefined.

• Line scroll mode allows you to customise the display with the data you require.

To change between the different modes :-

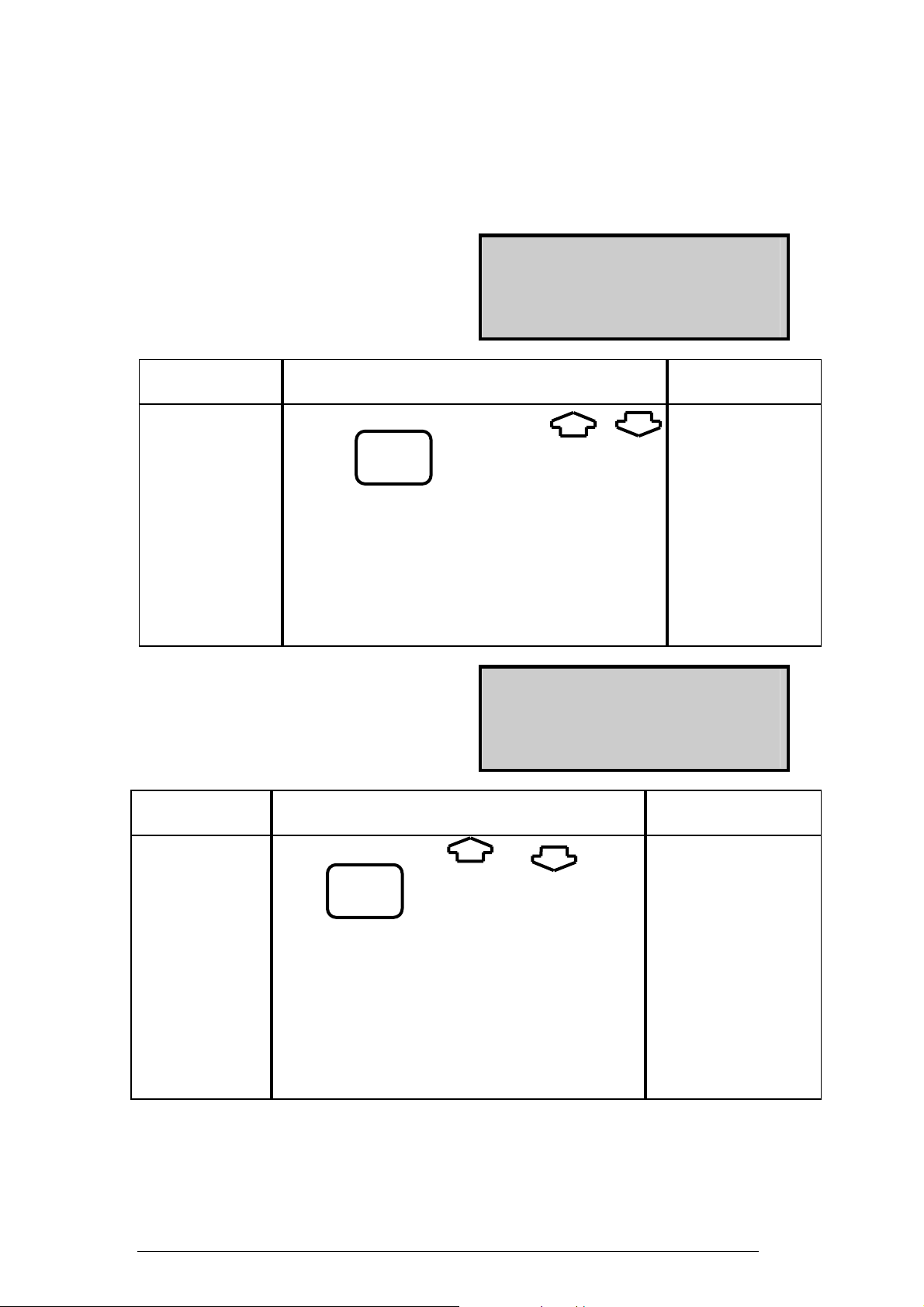

Press followed by

SET/CAL

PAGE MODE

SET

The and keys change

between Page and Line Scroll Modes

Press to select

ENTER

4.3.1 Page Mode

LINE SCROLL MODE

SET

Use the and keys to change the information displayed on the

screen. The following are a number of the pages available. Other parameters on other

screens are detailed in Appendix A.

NETT C . . . 0.0

O2 % . . . 20.9

CO ppm . . 0000

EFF (G) % . . . 0.0

CO2 % . . . 0.0

FLUE C . . . 0.0

INLT NOT FITTED

AMBIENT C . . . 21

CO/CO2 R . . 0.0001

P INDEX % . . . 0.01

XAIR % . . . 0.0

Prs mbar 0.00

This screen only shows readings if optional

sensors are fitted. In this instance the SO2

sensor is NOT FITTED.

NO ppm . . 0000

NO2 ppm . . 0000

NOx ppm . . 0000

SO2 NOT FITTED

KM9106 Operators Manual

9

Page 10

4.3.2 Line Scroll Mode

Line scroll mode allows you to customise the display.

Use the key to change the bottom line of the display. Once the correct line is

displayed press to confirm and move the line up. Select the next parameter and

repeat until all lines display the desired parameters.

Change bottom line using

NETT C . . . 0.0

O2 % . . . 20.9

CO ppm . . 0000

CO2 % . . . 0.0

to select and move

parameter up

O2 % . . . 20.9

CO ppm . . 0000

CO2 % . . . 0.0

CO2 % . . . 0.0

Select next parameter.

Repeat above until

display reads desired data

O2 % . . . 20.9

CO ppm . . 0000

CO2 % . . . 0.0

CO/CO2 R . . 0.0001

10

KM9106 Operators Manual

Page 11

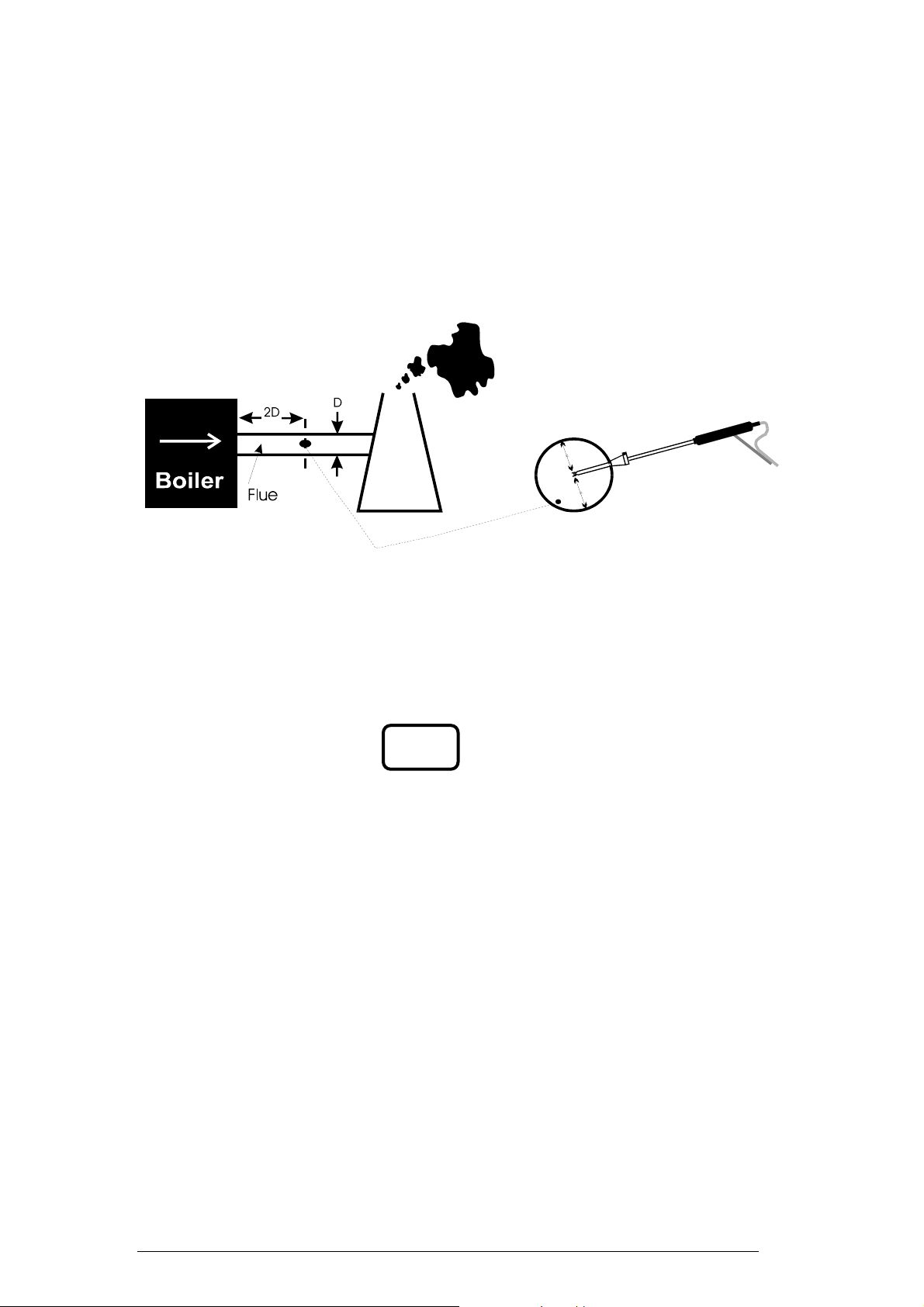

4.4 Sampling the Flue Gas

Once the automatic calibration procedure has been completed and the specific fuel has

been selected the probe can be inserted into the desired sampling point.

It is recommended that the sampling point be located at least two flue diameters

downstream of any bend and that the probe tip is in the centre of the flue (this is

normally the point of the hottest temperature). With balanced flues and other domestic

units the probe should be positioned far enough into the flue so that no air can ‘back

flush’ into the probe.

The probe depth stop cone provided with the instrument allows the probe to be used

in holes whose diameters range from 8 mm to 21 mm (5/16 to 4/5 inch).

The standard probe is rated at 650°C/1202°F. Temperatures of up to 1100°C/2012°F

can be accommodated using an optional high temperature probe.

TIP: To conserve battery power, switch off the pump when you are not taking a

measurement. Use the key to turn the pump ON and OFF.

PUMP

KM9106 Operators Manual

11

Page 12

4.5 Taking a Pressure Reading

With the optional pressure module fitted a flue draught measurement can be made at

any time.

Connect the standard probe to the appropriate pressure sensor inlet and place the

probe in the flue.

The pressure reading will be displayed :-

CO/CO2 R . . 0.0001

P INDEX % . . . 0.01

XAIR % . . . 0.0

Prs mbar 0.00

NOTE: Care must be taken to connect the probe to the correct port as the pressure

will be displayed in reverse i.e. a positive pressure rather than negative

draught.

To perform a combustion test and display draught pressure at the same time a special

probe is required. Contact Kane International or Authorised Distributor for details.

Two pressure ports are provided on the instrument for use with a Pitot tube. Contact

Kane International Ltd. for details of this probe and its availability.

4.6 Regular Checks During Sampling

Care must be taken at all times not to exceed the analyser’s operating specification. In

particular ensure the following :-

• Do not exceed the maximum temperature of the flue probe.

• The analyser’s internal temperature does not exceed normal operating range,

typically 0-40°C.

• DO NOT PLACE THE ANALYSER ON A HOT SURFACE.

• The water trap is vertical at all times. Water condenses in the probe line and can

quickly fill the water trap when the probe is moved. Take care and watch the water

trap closely.

• The in-line particle filter is clean and does not become blocked.

12

KM9106 Operators Manual

Page 13

4.7 Normal Shutdown Sequence

DO THIS EVERY TIME YOU USE THE ANALYSER.

Remove the probe from the flue - TAKE CARE ! THE PROBE WILL BE HOT -

and allow it to cool naturally. Do not immerse the probe in water as this will be drawn

into the analyser and damage the pump and sensors.

Once the probe is removed from the flue, the oxygen reading 20.9% and the CO

reading is zero press and the analyser will switch off.

OFF

Check the water trap and probe tubes for water before packing away.

4.8 Electromagnetic Compatibility

The European Council Directive 89/336/EEC requires that electronic equipment does

not generate electromagnetic disturbances that exceed defined levels and has an

adequate level of immunity to enable it to be operated as intended. The specific

standards applicable to this product are detailed in the appendices.

Since there are many electrical products in use that pre-date this Directive and may

emit electromagnetic radiation in excess of the standards defined in the Directive

there may be occasions where it would be appropriate to check the analyser prior to

use. The following procedure should be adopted:

Go through the normal start up sequence in the location where the equipment is to be

used.

Switch on all localised electrical equipment that might be capable of causing

interference.

Check that all readings are as expected. (A level of disturbance in the readings is

acceptable). If not adjust the position of the instrument to minimise interference or

switch off, if possible, the offending equipment for the duration of the test.

N.B. Maximum cable lengths must be less than 3 metres.

At the time of writing this manual (January 1997) Kane International Ltd is not aware

of any field based situation where such interference has ever occurred and this advice

is only given to satisfy the requirements of the Directive.

4.9 HC104 Module

With this module fitted and working the CO2 value is always the measured value not

the calculated value. The handset display and print out indicate that the CO2 value is

a measured value by showing CO2m. If the module is not fitted, the KM9106

automatically defaults to calculated CO2. If during start up calibration a fault is

detected in the CO2 module, the instrument will default to calculated. If the

instrument displays CO2m FAULT during operation, by switching OFF and then ON,

the instrument will default to calculated CO2.

KM9106 Operators Manual

13

Page 14

5. USING THE KEYPAD

5.1 Basic Operation

Basic operation of the keypad to change the display in PAGE and LINE SCROLL

mode is detailed section 4.3. These modes give you the facility to perform the

following :-

• Page Mode displays 4 lines of data in set format, each page is predefined.

• Line scroll mode allows you to customise the display with the data you require.

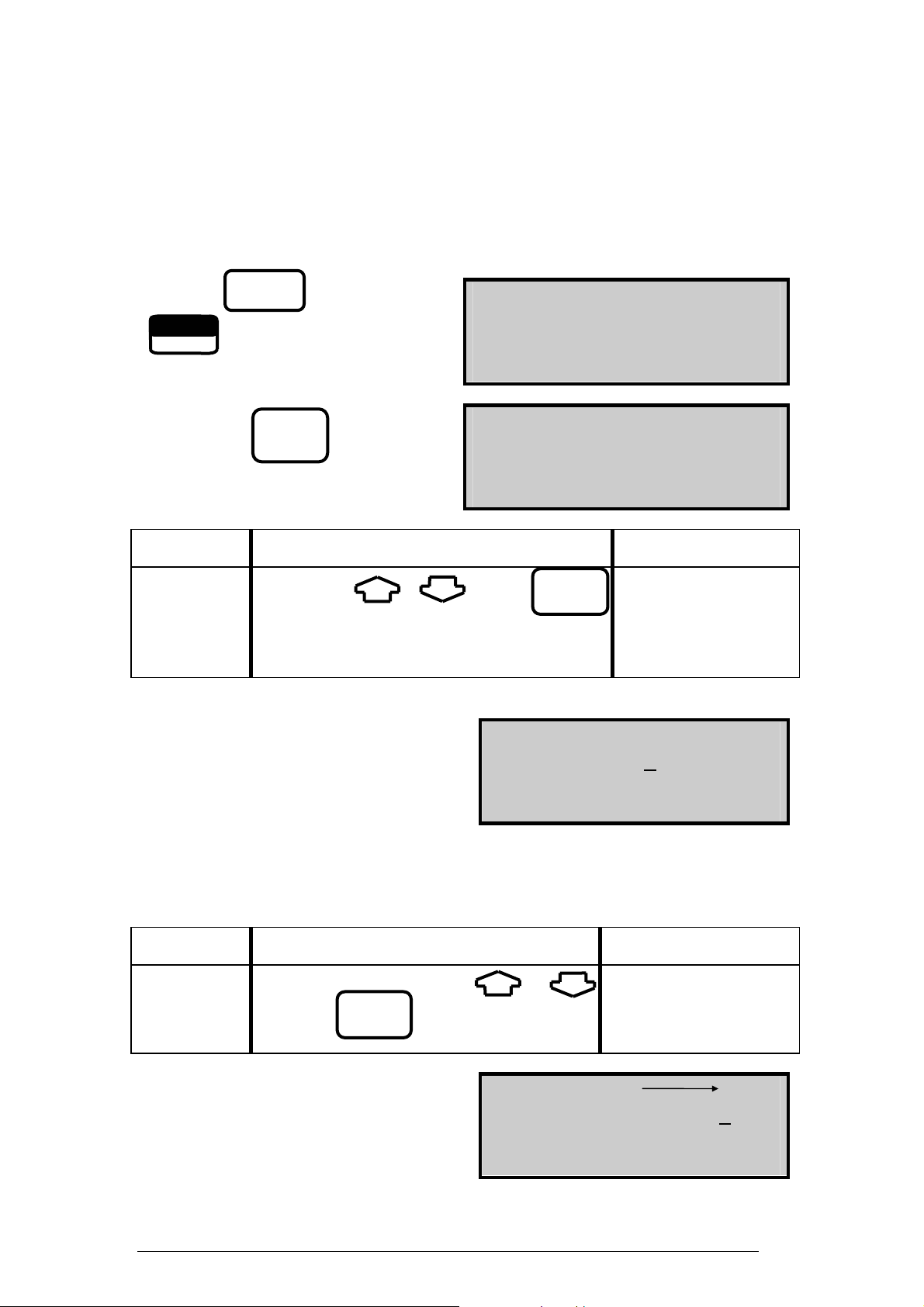

5.2 QUICK key operation

To allow parameters to be viewed quickly Quintox has a number of QUICK keys.

Many of these keys have two functions.

To select an LOWER PARAMETER

parameter simply press the key i.e.

to display CO2 and three other

CO

2

values

To select a UPPER PARAMETER

parameter press the UPPER FUNCTION

key

Followed by the UPPER PARAMETER

you require parameter key i.e.

NO2

to display NO2 and three

other values

CO2 % . . . 20.9

CO ppm . . . 0000

NETT C . . . . 0.0

XAIR O2 > 20%

-- -- -- -- -- -- -- -- -- -- -- -- -UPPER FUNCTION

-- -- -- -- -- -- -- -- -- -- -- -- --

NO2 ppm . . . . . 0

NO ppm . . . . . 0

NETT C . . . . 0.0

CO ppm . . . . . 0

Other QUICK keys are detailed below :-

LOWER PARAMETER KEYS

NETT to display Nett temperature plus O

FLUE to display Flue temperature plus Ambient, O2 and Prs.

INLET to display Inlet temperature plus Ambient, O2 and Flue

O

2

to display Oxygen reading plus CO, CO2 and Nett

CO2 to display Carbon Dioxide calculation or reading CO, Nett and XAIR

CO to display Carbon Monoxide plus Nett, O2 and CO2

AUX to display AUX1 and CxHy readings plus Nett and CO

FUEL to display chosen fuel and its parameters

EFF to display Gross efficiency plus O2 and CO

14

KM9106 Operators Manual

, CO and Eff.

2

Page 15

UPPER PARAMETER KEYS

ALWAYS Press UPPER FUNCTION first then

SCALE to display Scaling setup parameters

AMBIENT to display ambient temperature plus sensor, Flue and Inlet

SO2 to display Sulphur Dioxide reading plus Nett, O2 and CO

NO2 to display Nitrogen Dioxide reading plus NO, Nett and CO

NO to display Nitric Oxide reading plus NOx, Nett and CO

NO

X

PRESSURE to display the pressure reading plus Flue, Nett and O2

LOSSES to display all four losses

λ to display Excess Air plus CO, Eff and CO2.

All measured and calculated values are detailed in Appendix A - Main Display

Parameters.

to display the Oxides of Nitrogen reading plus NO, CO and Nett

5.3 DISPLAY HOLD

The display hold function allows you to freeze values on the instrument allowing

them to be viewed or printed. No measurements are taken once this function has been

activated. This feature gives the following benefits :-

• Data can be viewed at a particular point in the boiler tuning process.

• Multiple printouts may be obtained of the same data.

• Scales can be changed between printouts giving different units. i.e. ppm and mg/m3

TO TOGGLE DISPLAY HOLD

Press UPPER FUNCTION followed by

# Indicates the display is held.

# NETT C . . . 0.0 #

# O2 % . . . 20.9 #

# CO ppm . . 0000 #

# EFF (G) % . . . 0.0 #

In this function only the battery level will be updated and all other parameters are

frozen. This does not apply when AUTOPRINT is ON, the time and date are also

updated in this mode.

KM9106 Operators Manual

15

Page 16

5.4 DISPLAY BACKLIGHT AND CONTRAST

The display contrast can be adjusted to suit different lighting conditions and the

backlight can be switched on or off.

TO TOGGLE THE BACKLIGHT ON /OFF

Press UPPER FUNCTION followed by

CONTRAST

TO SET THE CONTRAST

Press the followed by

UPPER FUNCTION key

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- -UPPER FUNCTION

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

CONTRAST

SET

CONTRAST

Hold down either the or key and release once the desired level is

set.

Press to confirm setting.

ENTER

NOTE: The screen may flip from all dark to blank very quickly. Do not panic this

is normal - keep pressing the same key until the desired level is displayed.

TIP: If for any reason the display is not visible at switch on, simply

disconnect the handset for a few seconds and re-connect. Then reset

the display contrast as detailed above.

5.5 PUMP

The Pump can be toggled on or off from the handset.

TO TOGGLE THE PUMP ON /OFF

Press

PUMP

TIP: When the pump is switched off the O

reading will go down as the

2

oxygen sensor consumes the oxygen in its housing!

16

KM9106 Operators Manual

Page 17

6. USER SELECTABLE SETTING

The following features are under your control at any time and can be changed as

detailed later in this section.

Time and date

Fuel type

Efficiency

Language

Line Rejection

Gas Scale

ppm(n) or mg/m

Compensation

Temperature scale

Pressure scale

Reference oxygen

NOx Calculation

temperature

Inlet

Oxygen calibration

Toxic sensor zero

Day/ Month order is selectable and the real time clock and

calendar are fully adjustable

.

Standard pre-programmed fuels can be selected or users can

define their own fuel characteristics

Efficiency readings can be selected to be based on Gross or Nett

values.

The analyser is programmed with ten languages.

For optimum mains electricity noise rejection a software

.

filter set for either 50 Hz or 60 Hz. Select 50 Hz in Europe

and 60 Hz in the USA. Check your country's power

frequency.

3

(n)

Normalised or un-normalised ppm or mg/m3 scalings can be

selected. Normalised is also known as referenced readings to

Oxygen. See Reference Oxygen below.

Some sensors are cross sensitive to other gases. Where

appropriate sensors are fitted so this cross sensitivity can be

compensated for, improving accuracy. During re-calibration

this compensation must be disabled

The analyser is programmed for both Celsius and Fahrenheit

The analyser is programmed for inWG, mBar, cmWG and

.

kPa.

Toxic gas measurements can be referenced to defined oxygen

levels.

Determines the level for calculating NOx. Depends on the

sensors fitted and local authority preferences.

The flue temperature probe can be used to measure and

programme the air inlet temperature to the boiler

If the analyser is being used for multiple checks over the

working day it is advisable to re-set the oxygen sensor at

regular intervals. This function allows re-set without the need

to repeat the start-up routine

The CO and other optional toxic sensors can be reset to zero if

KM9106 Operators Manual

17

Page 18

they drift. This may happen if the sensor is taken to very high

R

R

concentrations for long periods of time or over-ranged.

6.1 Time and Date (Setting numbers)

This section gives details on setting the time and date and also the general principle of

setting a number from 0-9 used in other functions.

TO SET THE TIME AND DATE

Press the followed by

UPPER FUNCTION key

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- -UPPER FUNCTION

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

TIME

DAY - MONTH - YEAR

SELECT ORDER

Parameter

DATE

FORMAT:

Controls Options

Select using or key and

ENTE

DAY-MONTH-

YEAR

MONTH-DAY-

YEAR

To Set The Date:

DATE 26-01-97

SET

Each number in the date is to be set. The cursor _ under the two in the DAY above

indicates this number can be changed. Set each number in the date until correct using

the method below, this is also the method for SETTING NUMBERS.

Parameter

DATE: Select each number using or

Controls Options

0 - 9

key and

ENTE

The cursor _ moves to each number in turn

until the last number is set.

DATE 26-01-97

SET

18

KM9106 Operators Manual

Page 19

To Set The Time:

TIME 16-01-12

SET

As with the date each number in the time is to be set.

Parameter Controls Options

TIME: Select each number using or key

and

ENTER

0 - 9

Once the last number has been set the screen will show the main display last shown

before entering the set time routine.

6.2 Changing a fuel

This section gives details on changing a standard fuel and entering a user fuel.

TO SET THE FUEL

Press the

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

FUEL

STANDARD OR USER?

STANDARD FUEL

Parameter

FUEL

STANDARD

Controls Options

Select using or key and

ENTER

STANDARD

FUEL

USER FUEL

KM9106 Operators Manual

19

Page 20

To Set A Standard Fuel:

There are over 70 standard fuels programmed into Quintox. The fuels are arranged

into tables for each country and the table should be selected for the origin of the fuel

used in your boiler. Each table contains different fuel types, choose the fuel that is

closest to the fuel used in your boiler.

SELECT FUEL TABLE

ENGLISH

Parameter

Controls Options

FUEL TABLE:

Select table for your country using or

key and

ENTER

ENGLISH

FRANCAIS

DEUTSCH

NEDERLANDS

ITALIANO

CASTELLANO

SVENSKA

SUOMI

OESTERREICH

ZEALAND

SELECT FUEL TYPE

NATURAL GAS

Parameter

FUEL TYPE:

The table shown above is for the UK. Fuel lists vary depending on the country.

Controls Options for

English Fuel Table

Select fuel type using or key

and

ENTER

NATURAL GAS

NATURAL GAS 2

TOWN GAS

LIGHT OIL

HEAVY OIL

COAL

ANTHRACITE

COKE

PROPANE

BUTANE

GASCOR

NEW

LPG

20

KM9106 Operators Manual

Page 21

To Set A User Fuel:

If one of the standard fuels does not approximate to the one you are using in your

boiler then it is possible to set the Quintox up for a USER FUEL. The information

required to be able to set this are the Chemical Breakdown of the fuel and the Gross

and Nett calorific value. Details of the calculation are shown in the Appendix.

Parameter

K1g 0.350

K2 11.89

K4 32

Controls Options

SET

K1n 0.393

K3 9.83

O2r 3.0

USER FUEL:

Set each number as date using or

key and

ENTER

0 - 9

TIP: If you enter this routine in error, ENTER past all of the numbers to

exit.

Check fuel set by pressing

FUEL

NATURAL GAS

K1g 0.350

K2 11.89

K4 32

K1n 0.393

K3 9.83

O2r 3.0

6.3 Gross or Net Efficiency

The Quintox can calculate efficiency in of one of two ways.

Efficiency = 100% - Losses. See the Appendix for the Efficiency calculation.

• Gross efficiency uses the gross calorific value of the fuel and deems that the

latent heat of vapourisation is lost up the flue of the boiler and is taken as a loss.

Gross is used in the UK and USA.

• Net Efficiency uses the net calorific value and assumes the latent heat is not lost

up the flue. For Natural gas this efficiency can be 11% higher than the Gross

figure. Net is used in France and Germany.

NOTE: Latent heat is the heat required to turn water at 100°C into steam at

100°C, i.e. a change of state from liquid to vapour without rise in

temperature has taken place.

KM9106 Operators Manual

21

Page 22

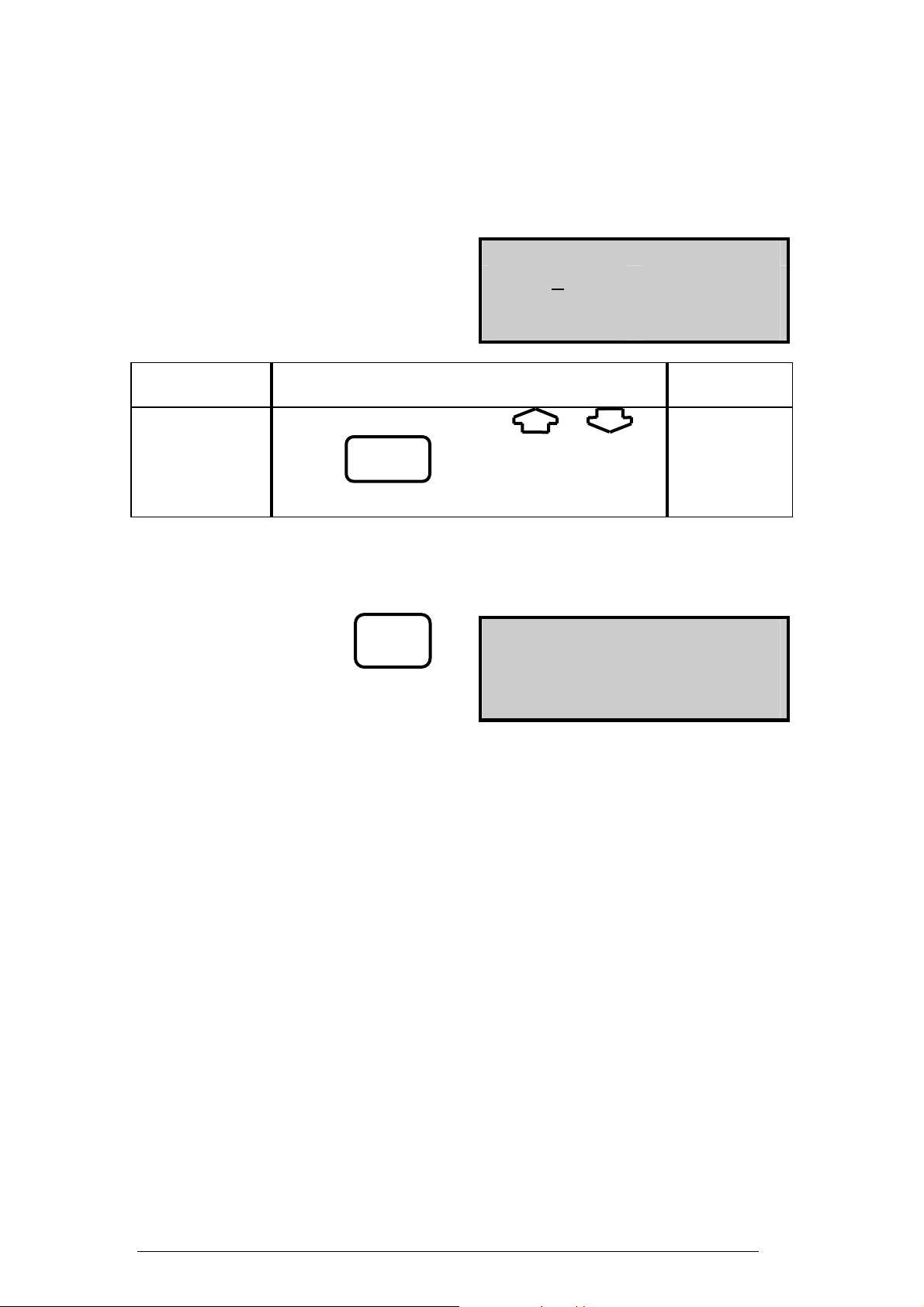

TO SET GROSS OR NETT EFFICIENCY

Press the

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

EFF

SET EFFICIENCY

GROSS

Parameter Controls Options

EFF

Select using or key and

ENTER

6.4 Scale Options

The scale option routine gives you control over :-

• Language

• Line Rejection

• Gas Scale

• Compensation

• Temperature Scale

• Pressure Scale

• Reference Oxygen

• NOx calculation

TO SELECT SCALE OPTIONS

Press the followed by

UPPER FUNCTION key

Pressing the key displays

SET/CAL

SCALE

GROSS

NET

-- -- -- -- -- -- -- -- -- -- -- -- --

UPPER FUNCTION

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

SELECT LANGUAGE

ENGLISH

22

KM9106 Operators Manual

Page 23

Parameter

SELECT

LANGUAGE

Controls Options

Select using or key and

ENTER

NETHERLANDS

ENGLISH

SPANISH

FRENCH

ITALIAN

GERMAN

SWEDISH

FINNISH

SET LINE REJECTION

50 Hz

Parameter

Controls Options

LINE

REJECTION

Select using or key and

ppm(n) or mg/m3(n)

ENTER

Parameter

GAS UNITS

ppm(n) or

mg/m3(n)

NOTE: ppm = parts per million

mg/m3 = milligrams per cubic meter

n denotes the reading is normalised or referenced to Oxygen

See Reference Oxygen in the Appendix

On power up the unit will default to ppm.

Controls Options

Select using or key and

ENTER

60 Hz - USA

50 Hz - UK

ppm

ppmn

mg/m3

mg/m3n

COMPENSATION < >

< OFF >

KM9106 Operators Manual

23

Page 24

Parameter

COMPENSATION

Controls Options

Select using or key and

ENTER

ON

OFF

Parameter

Controls Options

TEMPERATURE

Select using or key and

Parameter

PRESSURE

NOTE: mbar = millibar

inWG = inches of water gauge

Controls Options

Select using or key and

SET TEMPERATURE

CELSIUS

ENTER

CELSIUS

FAHRENHEIT

SET PRESSURE

ppm

ENTER

mbar

inWG

Parameter

REFERENCE

O2

24

SET REFERENCE O2

NO

Controls Options

Select using or key and

KM9106 Operators Manual

ENTER

NO

YES

Page 25

Selecting YES allows you to set an oxygen reference value different to that shown in

the fuel constants. For example 3% is set in the Natural Gas constants, to reference

the toxic gas values to a different value select using the screen below (Use the number

setting sequence as detailed in Setting Time) :-

SET REFERENCE O2

REF. %O2 . . 03.0

This may need setting if a local authority require gas readings to be referenced to a

certain oxygen value. As a general rule gaseous fuels are normally referenced to 3%

oxygen.

NOTE: The readings can change dramatically if the wrong Oxygen reference is

set and either ppmn or mg/m3n as the gas units. If you are unsure of the

reference value set ppm or mg/m3 as detailed above.

SET NOx CALC’N

NO

Allows the calculation for NOx to be altered. Select YES to enter the following

routine.

SET NOx REF.

REF %NOx. = 05

With only the NO sensor fitted there is no way of measuring NO2 and an allowance is

made in the calculation of the NOx value. This NOx value is calculated from the

formula shown below :-

• NOx = NO + (P% x NO)

where P% = REF. %NOx and is set to 5% as default.

With both NO and NO2 sensors fitted the formula is as follows :-

• NOx = NO + NO2

SET NOx REF

NOx = SUM

KM9106 Operators Manual

25

Page 26

Parameter Controls Options

REF NOx

Select using or key and

ENTER

NOx = SUM

NOx = NO

NOx = NO2

There are three ways of displaying the value of NOx when the values are converted to

mg/m3. Local authorities may require a certain calculation. The options are as

follows:

• NOx = SUM calculates the mg/m3 figure individually from the NO and NO2

values and then adds them together.

• NOx = NO adds the ppm values together and then converts to NO equivalent.

• NOx = NO2 adds the ppm values together and then converts to NO2

equivalent.

On power up the unit will default to NOx = SUM

26

KM9106 Operators Manual

Page 27

6.5 Inlet Temperature

The Quintox uses as default the internal ambient sensor when calculating the Net

temperature. If an optional inlet probe is fitted then INLET is used in the calculation.

As an alternative to both of the above, the inlet air entering the boiler can be measured

using the flue probe.

NOTE: The probe must not be inserted into the flue until the INLET temperature

has been set. If resetting the inlet temperature after performing a

combustion test ensure the tip of the probe is at the air temperature

TO SET INLET TEMPERATURE

With the flue probe connected to the FLUE temperature connector.

Press the

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

Change to YES

Position the tip of the flue probe near the

Air inlet of the boiler and when the reading

is stable press

The temperature measured by the flue probe will be set in the Quintox.

Press to check the reading.

INLET

INLET

ENTER

SET INLET TEMP

PLACE PROBE BY

AIR INLET

-- -- -- -- -- -- -- -- -- -- -- -- --

FLUE . . . 30.0

NO

KM9106 Operators Manual

27

Page 28

6.6 Oxygen Calibration

If used over long periods the Oxygen sensor may drift slightly and for maximum

accuracy may require resetting.

TO RESET OXYGEN SENSOR

With the flue probe sampling fresh air and the flue temperature reading less than

50°C/122°F, or the temperature plug disconnected from the instrument.

Press the

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

Change to YES

O2

SET O2 = 20.9%

NO

Press to set 20.9% Oxygen.

ENTER

NATURAL GAS

PRESS ENTER KEY

6.7 Toxic sensor zero

The CO and other optional toxic sensors can be reset to zero if they drift. This may

happen if the sensor is taken to very high concentrations for long periods of time or

over-ranged.

Press twice

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

ENTER SERVICE CODE

-- -- -- -- > 0 0 0 0 < -- -- -- --

Press four times

ENTER

CALIBRATE SENSOR

NO

Parameter Controls Options

28

KM9106 Operators Manual

Page 29

CALIBRATE

SENSOR

Select using or key and

ENTER

YES

NO

Select YES

SET ZERO ?

NO

Parameter

Controls Options

SET ZERO

Select using or key and

ENTER

YES

NO

Select YES

SELECT SENSOR

CO -------- . . -17

Parameter

Controls Options

SELECT

SENSOR

Select using or key and

ENTER

LIST OF

FITTED

SENSORS

DISPLAYED

In this example we have selected the CO sensor. The pump will now run if it has been

turned off, this is to draw fresh air through the instrument to allow the sensors to be

zeroed.

Ignore the reading next to the sensor

SET ZERO LEVEL

CO -------- . . -17

INSTABILITY 5

Ensure the instability reads zero

7 CALIBRATING 77

Once the instability has reached zero press to accept the zero calibration

and return to the main display.

If the instability does not reach zero then the instrument will show FAULT. Contact

Kane International or Authorised Distributor for advice.

ENTER

KM9106 Operators Manual

29

Page 30

6.8 CO Alarm

It is possible to set a point in the range of the sensor so that it alarms and warns the

user of a dangerous level of Carbon Monoxide. The default level is set at 400 ppm.

This should be used when there is a local limit on the level of CO that should not be

emitted from a boiler.

TO SET THE CO ALARM LEVEL

Press the

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

Set each number as detailed in Setting Time

When the CO level rises above the set value the following screen will be displayed

every ten seconds. This will continue until the CO level falls below the alarm setting.

CO

SET CO ALARM

-- -- -- -- -- -- -- -- -- -- -- -- -CO ALARM

0400

410 ppm

-- -- -- -- -- -- -- -- -- -- -- -- --

30

KM9106 Operators Manual

Page 31

7. PRINTING INFORMATION

While in any of the main displays a manual print can be obtained by pressing

The display will show the printout as it

is printing :-

7 7 7 PRINTING 7 7 7

-- -- -- -- -- -- -- -- -- -- -- -- - 7 7 KANE-MAY 7 7

-- -- -- -- -- -- -- -- -- -- -- -- --

Standard Printout

The standard printout is shown below :-

-- -- -- -- -- -- -- -- -- -- --

777 KANE-MAY 777

77 KM QUINTOX 77

DATE 02-01-97

TIME 18:14:35

NATURAL GAS

O2 % . . . . 20.9

CO ppm . . . . . 0

Prs mbar 0.05

EFF % FAULT

XAIR O2 > 20%

CO2 % . . . . . . . 0.0

CO/CO2 R . . . 0.0000

PI % . . . . . . 0.00

NO ppm . . . . . 0

NO2 ppm . . . . . 0

NOx ppm . . . . . 0

SO2 ppm . . . . . 0

CxHy % . . . . . . 0.0

NETT C . . . . . 0

FLUE C . . . . . 21

INLT NOT FITTED

AMBIENT C 16.9

-- -- -- -- -- -- -- -- -- -- --

PRINT

KM9106 Operators Manual

31

Page 32

The remainder of this section explains the following :-

Setting auto-timed printing or logging

Allows information to be printed or logged automatically at set time intervals (from

10 seconds to 90 minutes). Care must be taken in setting the interval time; a standard

Quintox printout will take 30 seconds to print, it is advisable to set the interval at 2

minutes or greater if a print is requested. Turn off the printer if less than 2 minutes is

set. If greater than 5 minutes is set the Quintox will switch OFF the pump

immediately after printing and switch it ON again 3 minutes before the next print.

Disabling quintox printer

If only logged information is required without a printout then the Quintox integral

printer can be turned OFF.

Edit the printout header

You can personalise the header on the printout to your own Company name and

Telephone number. Two lines of 16 characters are available.

Changing the format of the printout

The standard printout is detailed on the previous page. You can customise a printout

to your own requirements by selecting lines from the list detailed later in this section.

7.1 Changing printout parameters

Press followed by will display the following screens :

SET/CAL

PRINT

This displays the Auto print status and

the interval time; for this example 2

minutes.

AUTO PRINT 2:00

OFF

Use or keys. To select ON or OFF and press

With Auto print ON the display will

show :-

SET

ENTER

AUTO PRINT 2:00

Use or keys to select from 0:10 to 90:00 and press

ENTER

32

KM9106 Operators Manual

Page 33

The next screen enables or disables the

integral printer. Default is ON.

PRINTER ?

ON

Use or key to select ON or OFF and press

To edit the printout header select YES.

ENTER

SET HEADER ?

NO

Use or keys to select YES or NO and press

The cursor _ will be positioned under

the first 7.

EDIT HEADER

777 KANE-MAY 777

77 KM QUINTOX 77

ENTER & EFF=BACK

Use or to select the alpha/numeric character required. Press

when the character is correct. If you make a mistake the key will take the

cursor back.

When the last character has been set the screen will display the next screen.

Entering NO will select the standard

printout as detailed earlier in this

section. The general principle for

selecting a user printout is detailed

below.

USER PRINTOUT ?

ENTER

EFF

NO

ENTER

KM9106 Operators Manual

33

Page 34

7.2 User Defined Printouts

General Principle: A user defined printout can have a maximum of 40 lines. The

contents of each line can be defined by the user from the master list of parameters

detailed later in this section. The standard printout with line numbers and parameter

numbers is given later in this section as an example. To define a printout you must

allocate a parameter number to each line. The printout must be terminated with a line

of hashes.

Select YES to configure your own

printout.

USER PRINTOUT ?

YES

SET LINE . . . . . . ?

NO

If you have previously configured a printout select NO, selecting YES will allow the

first line of the printout to be changed.

SET LINE . . . . . . 1

7 7 KANE MAY 7 7

Use or keys to select the required line and press

In this example the Time has been

selected for the first line.

Repeat the process for the second line

and so on.

End the printout with a line of hashes.

SET LINE . . . . . . 1

TIME 10:32:36

SET LINE . . . . . . 2

O2 % . . . . . . . 11.2

SET LINE . . . . . . 3

# # # # # # # # # # # # #

ENTER

34

KM9106 Operators Manual

Page 35

The above example will send the Time and Oxygen reading to the printout every two

minutes.

To stop the Quintox Auto printing or logging, select Auto print OFF above and return

to the main displays.

7.2.1 Standard Printout - Parameter Options Used:

LINE

NUMBER

PARAMETER

USED:

(MAX LINES: 40) & STATUS:

1 - - - - - - - - - - - - PRINTOUT START

2

BLANK LINE

3 ***KANE-MAY*** MANUFACTURER ID

4 **KM QUINTOX** ANALYSER ID

5

BLANK LINE

6 DATE 02-01-97 DATE

7 TIME 18 :14:35 TIME

8

BLANK LINE

9 NATURAL GAS FUEL SELECTED

10

BLANK LINE

11 02 % ......20.9 FLUE GAS 02 CONTENT

12 CO ppm .....0.0 FLUE GAS CO CONTENT

13 Prs mbar ....0.05 PRESSURE MEASUREMENT

14 EFF %.....FAULT COMBUSTION EFF CALC

15 BLANK LINE

16 XAIR O2>20% FLUE GAS EXCESS AIR

17 C02 %.......0.0 FLUE GAS CO2 CALC (CO2m% FLUE GAS

CO2 MEASURE)

18 CO/CO2 R....0.00 CO/CO2 RATIO

19 PI % .....0.00 POISON INDEX

20 NO ppm.....0 FLUE GAS NO CONTENT

21 NO2 .....0 FLUE GAS NO2 CONTENT

22 NOx ppm.....0 NOX CALCULATION

23 SO2 ppm.....0.0 FLUE GAS S02 CONTENT

24 CxHy % ...... 0.0 HYDROCARBON READING

25

BLANK LINE

26 NETT C 0.0 NET FLUE GAS TEMP

27 FLUE C 21.0 ACTUAL FLUE GAS TEMP

28 INLT NOT

BOILER INLET TEMP

FITTED

29 AMBIENT C 16.9 AMBIENT AIR TEMP

30 - - - - - - - - - - - - DOTTED LINE

Not all parameters are used. See the master list on the next page if more are required.

KM9106 Operators Manual

35

Page 36

7.2.2 Master List of Printed Parameters

The following list is a master list of printed parameters. Details of the measured and

calculated variables are given in the Appendix.

PRINT DESCRIPTION

1 *** KANE-MAY *** COMPANY IDENTIFICATION

2 ** KM QUINTOX** ANALYSER IDENTIFICATION

3 BLANK BLANK LINE

4 DATE DATE

5 TIME TIME

6 INSTABILITY FLUE GAS STABILITY STATUS

7 BATTERY BATTERY STATUS

8 OS11 O2 SENSOR STATUS

9 SENSOR SENSOR TEMPERATURE

10 AMBIENT AMBIENT AIR TEMPERATURE

11 Prs PRESSURE MEASUREMENT

12 NATURAL GAS FUEL SELECTED

13 K1g SELECTED FUEL GROSS CALORIFIC VALUE

14 K1n SELECTED FUEL NET CALORIFIC VALUE

15 K2 SELECTED FUEL MAX THEORETICAL CO2

16 K3 SELECTED FUEL MAX WET LOSS

17 K4 SELECTED FUEL ALPHA VALUE

18 REF%O2 O

REFERENCE - mg/m3n MEASUREMENTS

2

19 NETT NET FLUE GAS TEMPERATURE

20 FLUE ACTUAL FLUE GAS TEMPERATURE

21 INLT BOILER AIR INLET TEMPERATURE

22 O2 FLUE GAS OXYGEN CONTENT

23 XAIR EXCESS AIR CALCULATION

24 CO FLUE GAS CO CONTENT

25 CO2 FLUE GAS CO2 CALCULATION (CO2m FLUE GAS CO2

MEASUREMENT)

26 CO/CO2 R CO DIVIDED BY CO2 RATIO

27 PI POISON INDEX CO/CO2 RATIO X 100

28 EFF COMBUSTION EFFICIENCY CALCULATION

29 LOSS TOTAL LOSSES CALCULATION

30 DRY HIGH TEMPERATURE & EXCESS AIR LOSSES

31 WET LATENT HEAT LOSSES

32 CO LOSS % INCOMPLETE COMBUSTION LOSSES

33 NO FLUE GAS NO CONTENT

34 NO2 FLUE GAS NO2 CONTENT

35 NOX FLUE GAS NOX CALCULATION

36 SO2 FLUE GAS CO2 CONTENT

37 CxHy HYDROCARBON MEASURMENT

38 H2xc CO/H2 CROSS SENSITIVITY MEASUREMENT

39 AUX1 AUXILIARY 1 SENSOR MEASUREMENT

40 --------- DOTTED LINE

41 # # # # # # # # STOPS PRINTOUT

36

KM9106 Operators Manual

Page 37

8. QUINTOX LOGGING AND PC DOWNLOAD

8.1 Overview

8.1.1 Description

Data is sent to the handset through the connection lead and can be stored if required.

All information logged can be displayed on the hand-set, down-loaded to a computer

or output directly to a printer.

The hand-set will store up to a maximum of 1926 pages (standard Quintox output).

Information is stored each time the key is manually pressed or an autotimed print is requested.

The location number where the data is to be stored is displayed allowing it to be

recorded on any paperwork e.g. job sheets.

8.1.2 Switching the Logger on

The logger can be operated either connected to the Quintox or as a standalone unit,

(batteries are required if not connected). To turn the logger on use the

switch, the following will be shown on the display followed by the

MENU screen.

PRINT

ON

OFF

9 9 KANE MAY 9 9

TEL +44 (0) 1707 375550

FAX +44 (0) 1707 393277

9 9 SELECT FUNCTION 9 9

1 . . LOGGER CONTROL

1

2 . . QUINTOX CONTROL

LOGGER MENU

A flashing cursor will be positioned over the number 1, control of the cursor is

through and and . Move the cursor to the desired function and press

enter to select.

To return to the MENU at any time press and simultaneously.

KM9106 Operators Manual

37

Page 38

8.1.3 Logging Data

Data logging is done with the handset operating in 2. QUINTOX CONTROL and by

either pressing the key or requesting an auto print, information will be

captured by the logger and stored.

The display will show the following screen to confirm information has been stored

correctly.

PRINT

DATA LOGGED 0123

In the display shown above the data has been stored in location 123. Make a note of

this on any paperwork you are using for that job so that the information can be

retreived later.

8.2 Batteries

The logging handset can either be powered from the Quintox through the lead or from

its own batteries. Batteries are inserted in the back of the logger by removal of the

rear cover.

TIP: It is advised that batteries are used at all times to ensure no data is lost or

corrupted.

Four 'AA' alkaline batteries can be used or a Nicad rechargeable equivalent, if Nicad

batteries are used they can be recharged by plugging the Quintox charger into the side

of the handset. Typical recharge time is 12 hours.

Take care to insert batteries correctly, indication of polarity is in the battery

enclosure.

38

KM9106 Operators Manual

Page 39

8.3 Logger Control

This facility allows access to all of the information stored in the handset; data can be

cleared, viewed on the display or output to a printer or PC. The logger records each

page of Quintox information and gives it a unique log number; as additional logs are

sent to the handset the log number is increased by 1 until a maximum of 1926 pages is

reached. Once the memory is full, data will STOP logging.

To select 1. LOGGER CONTROL position the cursor on the 1 in the MENU using

and and press . The first screen sets the language option,

ENTER

SELECT LANGUAGE

ENGLISH

Parameter Controls Options

SELECT LANGUAGE

Use and to select the

desired language, press when

correct

ENTER

ENGLISH

SPANISH

NETHERLANDS

FRENCH

ITALIAN

GERMAN

SWEDISH

FINNISH

CLEAR MEMORY

NO

Clear Memory allows you to clear all stored information prior to logging during tests,

this resets the log number to 0001 so that the first new log is given this number.

Select YES or NO using and press . A warning display

ENTER

is shown and you are requested to confirm you want to delete all of the data stored !

CONFIRM DELETION

YES

Select YES or NO using and press .

ENTER

KM9106 Operators Manual

39

Page 40

LOG DATA ?

NO

ENTER YES to tell the logger to store data in memory and NO to disable the logging

function.

DOWNLOAD MEMORY

NO

Download Memory allows you to output the stored information to a PC, output is in

our own format and requires a special program to extract the data. Contact Kane

International or Distributor for information on the ‘Fireworks’ range of software.

Selecting YES will set the handset in READY mode, this allows the PC software to

access the data stored.

READY

Once the PC has extracted the data from the handset the logger will revert back to the

LOGGER MENU.

WARNING ! The logger will stay in READY mode until all of the data in extracted

from the handset. Do not enter this mode unless you are going to download data - you

will have to switch OFF the handset if you do.

DISPLAY MEMORY

NO

Display Memory allows you to view stored information on the hand-set display.

Select YES to access the following screen.

40

DISPLAY MEMORY

SELECT 0000 TO 0123

0000

KM9106 Operators Manual

Page 41

ENTER the desired location to display the memory FROM. Entering numbers is

detailed in section 6.

LOG NO.

DATE

TIME

BATTERY %

To scroll through data, use and , note the log starts with the Log

Number followed by Quintox data. Note also that once at the top of a log the

will take you to the top of the previous log i.e.

LOG NO.

DATE

TIME

BATTERY %

Using the will scroll through that particular log moving one line at a time.

DATE

TIME

BATTERY %

INSTABILITY

To exit Display Memory, press and together and return to the

LOGGER DISPLAY.

0100

23/10/96

10:32:36

54

0099

23/10/96

10:31:36

54

23/10/96

10:31:36

54

1

8.4 Downloading Information

Data can either be downloaded from the handset or stored directly in a PC realtime.

To extract the data from the handset contact Kane International for information of the

FIREWORKS range of software. The software allows information to be extracted

from the handset or gather information from the PC.

Other features of the FIREWORKS software are :-

• Graph and print stored and realtime data.

• Display information on bar graphs and large LED type display.

• Compile tuning reports and emissions reports.

• View data stored in tabular format.

• Export files to spreadsheet format.

• Allow the PC to act as a virtual handset and control the Quintox.

Stored data can not be extracted from the handset without the FIREWORKS software.

Information can be captured from the RS232 on the Quintox. A standard RS232 serial

lead is required to connect the Quintox RS232 to the PC serial port. Contact your

computer supplier or Kane International for the required lead. Leads are supplied with

the FIREWORKS software.

KM9106 Operators Manual

41

Page 42

8.4.1 Setting Up Your PC

A standard communications package will be able to collect the data from the Quintox.

Windows Terminal software is a suitable package. The communications protocol

should be set to :-

42

KM9106 Operators Manual

Page 43

8.4.2 Capturing Data From Quintox

To capture data direct from the Quintox into a PC the RS232 port on the Quintox has

to be connected to the serial port on your PC. Using the standard RS232 lead, and

IBM/AT lead if you serial port is a 9 pin D type, connect the Quintox to the PC.

The RS232 can output in two formats, Comma Separated variable (CSV) and Binary (for

the logger).

The standard default setting is binary and will always be set if the instrument is switched

off and on. To change between the outputs press followed by .

SET/CAL

ENTER

AUX

The instrument will beep and change the output, repeat the key sequence to change back.

The format for the CSV output is as follows:-

Time Date Instability Battery Sensor Ambient Pressure Fuel

16:28:30 20-05-96 0 49 23.5 24.5 0.3 12

K1g K1n K2 K3 K4 O2 Reference Nett temp Flue

temp

0.35 0.39 11.8 9.8 32 3 120 144

Inlet temp Oxygen

reading

N 8.3 28 55 3.5 83 17 8

Wet

loss

7 2 20 N 21 N 12 N N

CO

Loss

Excess

air

CO

Reading

Calculation Efficiency Losses Dry

loss

NO NO2 NOx SO2 H2xc Aux1 Aux2

The output will be as the example below:-

16:28:30, 20-05-96, 0, 49, 23.5, 24.5, 0.3, 12, 0.35, 00.39, 11.8, 9.8, 32, 3, 120, 144, N,

8.3, 28, 55, 3.5, 83, 17, 8, 7, 2, 20, N, 21, N, 212, N, N

Where a number is not displayed the following meanings can be taken:-

N = Not fitted

F = Fault

O = Over range (i.e. Oxygen reading 20.9% hence excess air can not be calculated)

8.4.3 Downloading Logged Data

The FIREWORKS software allows data to be downloaded from the handset. This

section is supplied to explain how to set the handset in a state ready to transmit data.

Using the lead RE5PC supplied with FIREWORKS connect the 15 pin D connector to

the handset and the 9 pin D connector to your PC serial port. Most PCs have a 9 pin D

serial port if yours has a 25 pin contact your computer supplier for a convertor.

Set the logger to DOWNLOAD data and ensure it is in READY mode.

NOTE: You will require batteries to run the logger and download the data.

KM9106 Operators Manual

43

Page 44

9. CONTINUOUS MONITORING

The Quintox is designed primarily as a portable emissions monitoring analyser. It can

however be used for longer periods if the gas is treated correctly before being

supplied to the analyser.

The main problem with continuous monitoring is the build-up of water in the water

trap. There are two methods available for extracting the water. Both are optional

extras available :-

• Pump drained water trap with built-in level sensor. This connects via RS232

connections and will automatically drain the water trap if the level rises too high. The

electronics in the water trap will also stop the Quintox from pumping if the water

level does not drop.

Gas Conditioning Unit with heated line and cooled chamber. This should be used

when accurate NO2 and SO2 readings are required. A Main Purge solenoid should

also be fitted to the Quintox when monitoring for longer periods of time. This is to

supply fresh air to the sensors and hence prevent them drying out. See Recommended

Operation in next section.

44

KM9106 Operators Manual

Page 45

10. Main Purge

The main purge facility for Quintox is used where longer sampling of flue gas is

required. It should be used with the KM9008 gas conditioning unit or in conjunction

with any other water removal system.

If dry gas is supplied to the Quintox for a long period of time the operating cells will

dry out and stop working. Supplying fresh ambient air to the sensors on a periodic

basis will prevent or reduce the drying effect and prolong sensor life. Ideally the fresh

air should be at 50% relative humidity but it is understood under certain conditions

this may not be possible.

Main purge introduces a solenoid valve into the gas train after the water trap

connection to the Quintox. With the purge turned OFF the instrument will draw gas

from the probe and flue, with purge ON the solenoid is activated and the instrument

draws fresh air from within its case. The solenoid can be switched either manually or

through a timed operation.

Manual Operation

This function allows the user to switch the solenoid ON or OFF manually through

pressing a sequence of keys. It can be performed at any time during Quintox operation

but has no effect during a timed operation.

ON/OFF Toggle operation

SET/CAL

ENTER

Timed Operation

This requires the user to set the following :-

Purge duration - The amount of time fresh air is draw into the instrument. This can

be set between 5 and 30 minutes and is a function of the gas concentration and the

humidity of the ambient air. For dry ambient conditions and high gas concentrations a

longer purge duration should be set.

Purge interval - This is the time between purge operation, i.e. the time the instrument

is sampling gas. It can be set between 9 and 99 minutes.

Auto zero - Allows all toxic cells to be set to zero and the oxygen cell to 20.9% on

completion of the purge cycle. i.e. if 10 minutes is set in the ‘Purge duration’

following this time the cells would be Auto zeroed. Note sufficient time must be

allowed for the cells to return to zero, if concentrations of gas are high then a long

purge duration should be set.

NOTE: If the analyser is positioned where levels of gases are higher than fresh air

ambient conditions then auto zero should not be used.

NOx

AUX

KM9106 Operators Manual

45

Page 46

To access timed purge enter the following :-

SET/CAL

ENTER

Enter the code 0000 at the following display :-

SET/CAL

ENTER

ENTER SERVICE CODE

-- -- -- -- > 0 0 0 0 < -- -- ---

The following screens will be displayed, enter NO to both :-

CALIBRATE SENSOR

NO

PRINT MEMORY ?

NO

The purge sequence now begins, by using the arrow keys select YES to

‘SET PURGE ?’ and press .

ENTER

SET PURGE ?

YES

Enter the purge duration and similarly the purge interval by changing each character.

Note the line below the zero indicates the number to be changed. Enter when correct.

If a time of less than the minimum or greater than the maximum then these will set as

the default values.

PURGE DURATION 05

<05 . . . . . . . . . . . . 09>

46

PURGE INTERVAL 30

<09 . . . . . . . . . . . . 99>

KM9106 Operators Manual

Page 47

Set YES or NO depending on whether auto zero is required or not.

AUTO ZERO ?

NO

Note: During both Manual and Timed purge operation the following screen will

be displayed for approximately one second every 3 seconds.

-------------------------------------PURGE ON

--------------------------------------

Recommended Operation

Each monitoring situation will be different and a degree of user judgement will apply.

The following basic guidelines should be followed :-

• Maximum duration without purge 4 hours followed by 40 minutes purge.

• For monitoring up to 12 hours per day purge should be for 10 minutes every hour.

• For monitoring up to and over 24 hours per day purge should be for 10 minutes

every 30 minutes. This could be a sequence of 5 minutes purge followed by 10

minutes sample.

Sensor Over-range

The main purge will also operate when any gas concentration goes over the stated

range of that sensor. Fresh air will be drawn into the Quintox until the gas level is

down to 80% of the sensor range.

KM9106 Operators Manual

47

Page 48

11. MAINTENANCE

11.1 Emptying and Cleaning the In-line Water Trap

The water trap should be checked and emptied on a regular basis. Water vapour will

condense and gather in the probe line this may move suddenly to the trap when the

probe is moved. Care should be taken at all time.

Emptying of the water trap is detailed below :-

Carefully remove the end cap from the in-line housing. Dispose of the condensate in a

suitable drain, care must be taken as it could be acidic. If condensate spills onto the

skin or clothing, clean off immediately using fresh water, seek medical advice if

problems occur.

11.2 Changing the Particle Filter

This is a very important part of the analyser and should be changed regularly. It

prevents dust and dirty particles entering the pump and sensors and hence causing

damage. The filter MUST be changed when it appears discoloured.

Remove the end cap from the filter housing. Carefully remove the paper filter element

and dispose of it. Clean the inside of the filter housing with a suitable soft cloth. Insert

a new filter element onto the spigot on the filter end cap and carefully insert it into the

filter body.

48

KM9106 Operators Manual

Page 49

11.3 Charging the Battery

It is important that the battery is charged on a regular basis. The instrument constantly

powers the internal sensors and may flatten the battery if left unattended for some

months. Connect the charger supplied with the instrument to the correct mains

supply.

Note: The correct charger type is required for your local voltage i.e. 110 or 220

volts AC

Insert the plug in the socket marked CHARGER INPUT SOCKET as detailed in

section 1.4.

The CHARGER ON GREEN LED will illuminate showing the instrument is

charging.

11.4 Changing the Paper Roll

To change the paper roll remove the printer cover by loosening the two screws

holding it down. Remove the old paper roll core and insert the new roll so that it sits

as follows :-

Feed the free end of paper into the printer through the metal slot beneath the printer

ribbon. Start the paper feed sequence until the paper has emerged from the top of the

printer, feed the loose end through the cover and refit.

TO START PAPER FEED

Press the followed by

UPPER FUNCTION key

SET/CAL

-- -- -- -- -- -- -- -- -- -- -- -- --

UPPER FUNCTION

SET

-- -- -- -- -- -- -- -- -- -- -- -- --

Pressing the key displays

PRINT

Press any key to stop.

PAPER FEED

KM9106 Operators Manual

49

Page 50

11.5 Changing the Printer Ribbon

The printer ribbon cartridge will last for approximately two rolls of paper. Remove

the printer cover as detailed above.

Marked on one end of the cartridge is PUSH. Gently press down on this end and the

ribbon cartridge will pop up at the other end. Remove the cartridge and dispose of.

Fit a new ribbon guiding the paper roll between the exposed ribbon and cartridge

body.

Refit printer cover.

50

KM9106 Operators Manual

Page 51

12. PROBLEM SOLVING

The following is a list of problems that may occur on the instrument through its

operating life. If the cause of the fault is not easy to identify then we advise you to

contact the Kane International Service Department or an International Distributor for

expert advice.

Fault symptom Causes

• Oxygen too high

• CO2 too low

• Oxygen Error (FAULT)

• Toxic sensor Error (FAULT)

• Analyser not holding charge

• Analyser not charging

• Analyser does not respond to flue

gas

• Flue temperature readings erratic • Temperature plug reversed in socket.

• Analyser automatically switches

off in operation.

• Display is blank. • The contrast setting has been lost and

• Air leaking into probe, tubing, water trap,

connectors or internal to instrument.

• Oxygen cell needs replacing.

• Calibration time set too short and

instrument not allowed to stabilise

• Instrument has been stored in a cold

environment and is not at normal working

temperature.

• Oxygen cell or toxic sensors needs

replacing.

• Battery exhausted.

• AC charger not giving correct output.

• Fuse blown in charger plug.

• Particle filter blocked.

• Probe or tubing blocked.

• Pump not working or damaged with

contaminents.

• Probe connected to pressure connector.

• Faulty connection or break in cable or

plug.

• Battery below alarm level.

• Battery quickly discharging and is faulty.

requires resetting. Disconnect handset lead

and reconnect. Set contrast as in Section

5.4

KM9106 Operators Manual

51

Page 52

13. ANNUAL RE-CALIBRATION

Whilst the sensors have an expected life of more than two years in normal use it is

recommended that the analyser is re-calibrated at least annually. This is so that long

term drift on the sensors and electronics can be eliminated. Local regulation may

require more frequent re-calibration and users should check with appropriate

authorities to ensure they comply with relevant guidelines.

52

KM9106 Operators Manual

Page 53

14. HOW TO GET EXPERT HELP

R

R

There will be occasions when despite having read the manual there will be problems

that you cannot resolve and so you need external help.

Before calling Kane International or one of its International Distributors please first

check the following:

Find the serial number of the instrument. It is located on the label close to where the

charger and handset leads plug into the analyser. Also make a note of which sensor

are fitted by observing the tick boxes on the same label.

If the handset and analyser are operating you can also determine the issue of software

loaded in the analyser. To find this complete the start-up calibration routine and the

press twice .

The display will show

Use the key to change the numbers

Then press to step to the next number

Press again and the display will show

ENTER

ENTE

ENTE

You need to enter

ENTER SERVICE CODE

--------> 0 0 0 0 <--------

ENTER SERVICE CODE

---------> 1 1 1 1 <--------

Issue 15.0 . . . . .. ... . . G

- 1 2 3 4 5

Please record the issue number.

Press any key to exit this mode.

When you call the relevant Service Dept please have this information available so that

the technician has the best chance of being able to help you. If you have a modem

you may be asked to connect the RS232 interface of the analyser to your modem so

that the technician can operate the analyser remotely and extract from it information

stored in its memory that might help to resolve your problem.

KM9106 Operators Manual

53

Page 54

15. PRODUCT SPECIFICATION

INSTRUMENT

Parameter Resolution Accuracy Range

Temp Measurement

Flue Temperature

Inlet Temperature

Gas Measurement

Oxygen (02):

Carbon Monoxide

(CO):

Carbon Monoxide

(CO):

Nitric Oxide (NO):

Nitrogen Dioxide

(NO2):

NitrogenOxide (NO)H:

Sulphur Dioxide (SO

2

Pressure:

Carbon Dioxide (CO

)

2

Carbon Dioxide

(CO2)*2:

Efficiency *2:

Hydrocarbons (HC):

*1

Using dry gases at STP

*2

Calculated

LEL = L

ower Explosive Limit

0.1o (C/F)

0.1o (C/F)

0.1%

1ppm

0.01%

1ppm

1ppm

5ppm

1ppm

0.01mbar/k

pa

0.1%

):

0.1%

0.1%

0.01%

1.O o C +/-0.3% of reading

1.O o C +/-0.3% of reading

-0.1% +0.2%

+/-20ppm < 400ppm

5% of reading < 2000ppm

+/- 10% of reading

>2000ppm

+/- 5% of reading from

0.1% to 10%

+/- 5ppm < 100ppm

+/-5% of reading>100ppm

+/-5ppm<100ppm

+/-5ppm<100ppm

+/- 10ppm < 500ppm

+/-5% of reading >

500ppm

+/-5% of reading>100ppm

+/-0.5% Full scale

+/-7% of reading +/-0.4%

+/-0.3%

+/-1%

0-5% Methane (LEL)

0 - 1100°C, 32 - 2140°F

* Use high temperature

probe for gases >

600°C/1112°F

0 - 600°C

0-999°F

0-25%

0 - 10,000ppm

0 - 10%

0 - 5,000ppm

0 - 1,000ppm

0 - 10,000pm

0 - 5,000pm

0 - 150mbar

0 – 20%

0 - Fuel Value

0-100%

+/-5% of reading

54

KM9106 Operators Manual

Page 55

HANDSET

Dimensions 220 mm long

120 mm high

50 mm wide

Keypad 16 tactile keys with sounder

Display 4 line LCD with backlight and contrast control

EXTENSION CABLE

Specification: 8 pin DIN to 15 pin ‘D’ screened cable

Cable lengths: 5m Standard

10-20m-Optional

PROBE

Choose from a range of probe options. See probe leaflet.

BATTERY

Type: Lead acid rechargeable (12V, 2 AH)

Life: 8 hours from full charge

Charge time: 12 hours

BATTERY CHARGER

Input: 110-120V AC/220-240V AC.

Output: 16V AC (RMS)@ 1 amp, 50-60 hz.

PUMP

Flow rate: 2 Litres/Minute nominal

PRINTER

16 character dot matrix.

RS232

25 way plug connector,

9600 Baud,

No parity,

8 Data bits,

2 Stop bits.

QUINTOX

PC

Pin 2: TXD Pin 2: TXD

Pin 3: RXD Pin 3: RXD

Pin 4: RTS Pin 4: RTS

Pin 5: CTS Pin 5: CTS

Pin 7: Ground Pin 7: Ground

KM9106 Operators Manual

55

Page 56

AMBIENT OPERATING RANGE

0 - 40°C (+32°F to 104°F)

20 - 80% RH non condensing

Storage: 0-50°C

Maximum gas temperature at sensors: Continuous +40°C

Intermittent +55°C

56

KM9106 Operators Manual

Page 57

APPENDICES

A - Parameter Meanings

The parameters and their meanings are detailed as follows : -

DATE : Analyser date. See Section 6.1 to change.

TIME : Analyser time. Use Section 6.1 to change.

INSTABILITY : This is an indication of how stable the signals are from all the

sensors. 0 = high stability, 10 = high instability. When measuring

flue gases, pressure and temperature this number will rise as the

sensed inputs varies. At start up when sampling fresh air this

number is invariably 0.

BATTERY : Displays the battery level from 0-100%. The analyser will flash

RECHARGE BATTERY at less than 10 % of charge. The

analyser may show levels greater than 100% when the charger

connected.

FUEL : The fuel used in calculation of efficiency and Carbon Dioxide.

K1g: Gross calorific fuel constant. See Appendix B for calculation.

K1n : Gross calorific fuel constant. See Appendix B for calculation.

K2 : Percentage Maximum theoretical CO2 (dry basis).

K3: Percentage wet loss.

K4 : Percentage unburnt carbon loss.

O2r : Toxic gas measurements can be referenced to defined oxygen

levels.

Oxygen referencing is required by some regulations such as TA-LUFT. If a reference

value is selected the toxic gas measurements will be displayed with the symbol n

attached to the units. i.e.ppmn

What does Oxygen reference mean ?

If 3 % O2 reference is selected and 5 % O2 is measured in the flue then toxic gas

values will be recalculated as if 3 % were measured. The equation for referencing is

detailed in the Appendix.

Oxygen referencing prevents false readings being submitted, e.g. allowing more air

into the boiler will increase the oxygen level in the flue and hence dilute any toxic gas

reading. Oxygen referencing gives readings as if they were undiluted.

KM9106 Operators Manual

57

Page 58

NETT : Nett temperature calculated by deducting the internal AMBIENT

temperature

from the measured FLUE temperature. Displays in either

Centigrade C or Fahrenheit F and will display NOT FITTED if

flue probe not connected.

If an external INLET probe is used then INLET is deducted from

FLUE.

O2 : Oxygen reading in percentage %.

CO : Carbon Monoxide reading indicated in ppm or mg/m3. If the

figures are referenced to oxygen then the display will show

ppmn or mg/m3n. See Section 6.4 for oxygen reference. Note

with a high CO sensor fitted the reading will be displayed in

percentage %.

EFF (G) : Combustion Efficiency calculation displayed in percentage.

Gross G or Net N can be set see Section 6.3. The calculation is

determined by fuel type see Appendix B for calculation. The

efficiency is displayed during a combustion test, 00.0 is

displayed while in fresh air.

CO2m: Carbon Dioxide reading in percentage %

CO2 : Carbon Dioxide calculation determined by the type of fuel. This

only shows a reading when a combustion test is being carried out.

Zero (0.0) is displayed while in fresh air.

FLUE : Temperature measured by flue gas probe in Centigrade or

Fahrenheit. Will show ambient temperature after fresh air

calibration and NOT FITTED or FAULT if probe

disconnected.

INLET : Temperature measured by the optional inlet air probe or stored

using the Flue probe See Section 6.5. The air probe is plugged

into the instrument through the INLET socket. This figure is used

to calculate the NET temperature instead of AMBIENT when

fitted.

AMBIENT : Temperatrue measured by the internal sensor, used in the NET

temperature

58

KM9106 Operators Manual

Page 59

CO/CO2 R : The CO/CO2 ratio, is the ratio of measured CO divided by CO2.

It gives an indication of the following :-

• How good a gas sample the instrument is reading.

• How clean the boiler is running.

For example : A new or clean domestic boiler will display a ratio

of less than 0.004, a unit in need of cleaning 0.004-0.008 and a

unit in need of major overhaul will show greater than 0.008.

This only shows a reading when a combustion test is being

carried out. 0.0000 is displayed while in fresh air.

P INDEX : The CO/CO2 ratio expressed as a percentage %, called the

‘Poison Index”

i.e. P INDEX % = 100 x CO/CO2. 0.00 is displayed while in

fresh air.

XAIR % : Excess air calculated from the measured oxygen and type of fuel

used.

Displays reading during a combustion test. O2 > 20% is

displayed while in fresh air.

Prs : Flue draught pressure reading. Displayed when pressure sensor

fitted. See section 4.5 for taking a reading and Section 6.4 for

changing for scale.

NO: Nitric Oxide reading in ppm or mg/m3. Displayed when Nitric

Oxide sensor fitted. Reading can also be referenced to oxygen

ppmn or mg/m3n.

NO2: Nitrogen Dioxide reading in ppm or mg/m3. Displayed when

Nitrogen Dioxide sensor fitted. Reading can also be referenced to

oxygen ppmn or mg/m3n.

NOx : Calculated total Nitric oxides displayed in ppm or mg/m3.

For more details on NOx calculation see Section 6.4 Scales.

Reading can also be referenced to oxygen ppmn or mg/m3n.

SO2 : Sulphur Dioxide reading in ppm or mg/m3. Displayed when

Sulphur Dioxide sensor fitted. Reading can also be referenced to

oxygen ppmn or mg/m3n.

KM9106 Operators Manual

59

Page 60

CxHy : Unburnt HydroCarbon reading in % of LEL of Methane, the

sensor is calibrated with Methane. Displayed when a

HydroCarbon sensor fitted.

LEL is the Lower Explosive Limit of a gas when mixed with air,

for Methane this has the ratio of 19:1 Air:Methane. Below the

LEL the mixture can not ignite and burn. In the Flue an unburnt

HydroCarbons should be well below this level or there is the

potential for an explosion.

LOSS : Total losses calculated from Combustion Theory. This is the

summation of the next three parameters.

DRY : Calculated heat lost in turning the Carbon in the fuel to Carbon

Dioxide (CO2).

WET : Calculated heat lost in turning the Hydrogen in the fuel into

water (H2O).

CO LOSS % : Calculated loss due to partially burnt Carbon. Any Carbon

Monoxide (CO) in the flue has the potential to be turned into

Carbon Dioxide and release more heat, hence this heat is lost up

the flue.

OS11 % : Oxygen sensor life indicator. This is an approximation calculated

from the output voltage of the sensor in fresh air. Note ! This is

not valid when a combustion test is being performed.

H2xc : The Carbon Monoxide sensor is Hydrogen compensated. This

parameter is the reading from the Hydrogen sensor built into CO

sensor. It is an indication of the level if Hydrogen in the flue and

can NOT be used as an exact level, it is only used to cross

compensate the CO sensor.

AUX1 : Auxilliary sensor position, to be used for future sensors.

60

KM9106 Operators Manual

Page 61

B. NOx CALCULATIONS

ONLY an NO Sensor fitted.

working in ppm: NOx referenced to NO

The user can select the assumed NO2 percentage and the O2 normalised level

then: NOx in ppm = NO in ppm multiplied by (1 + assumed NO2 percentage)

in this setup NOx can only be displayed as NOx = NO

then normalising:

NO in ppmn = NO in ppm multiplied by (21 minus the O

and then divided by (21 minus the actual O2 reading)

For a worked example assume:

NO is 1000ppm

NO2 is 5% of NO

O

is set to 3%

2norm

actual O2 is zero

NOx in ppm = 1000 x (1 +5/100) =1000 x1.05 = 1050 ppm

NO ppm n = 1000 x (21 - 3)/(21-0) = 1000 x 18 / 21 = 857 ppm n

NOx ppm n = 1050 x 18 / 21 = 900 ppm n

or

NOx ppm n = 857 x 1.05 = 900 ppm n

3

working in mg/m

: NOx referenced to NO or NO2

2norm

setting)

The user can select the assumed NO2 percentage, the O2 reference level and whether

the NOx reading is referenced to NO or NO

2

referenced to NO

NO in mg/m3 = NO in ppm multiplied by 1.34

NOx in mg/m3 = NO in mg/m3 multiplied by (1 + assumed NO2 percentage)

KM9106 Operators Manual

61

Page 62

NOx referenced to NO

2

NOx in mg/m3 = NO in ppm multiplied by 2.05 multiplied by (1 + assumed

NO2 percentage)

or

NOx in mg/m3 = NO in mg/m3 divided by 1.34, multiplied by 2.05 and

multiplied by (1 + assumed NO2 percentage)

normalising readings

normalised reading = initial reading multiplied by (21 minus the O

2norm

setting) and then divided by (21 minus the actual O2 reading)

BOTH NO and NO2 sensors Fitted

Working in ppm NOx = NO + NO2

normalising readings