1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • email: info@ueitest.com

ATLFSG

INSTRUCTION MANUAL

Introduction

The ATLFSG test lead adapter kit lets you use your standard multimeter

(with micro-amps measurement function) to test common

flame-safeguard circuits that use standard 3.5 mm stereo jack.

Safety Notes

Observe all safety precautions when measuring higher voltages. Turn

off the power to the circuit under test. Connect the test leads to the

meter and then to the circuit under test. Reapply power.

WARNING!

When taking current measurements, the multimeter must be connected in SERIES with the circuit element under test. Never connect the test

leads across a voltage source. To do so may blow the fuse and damage the circuit under test.

Operating Instructions

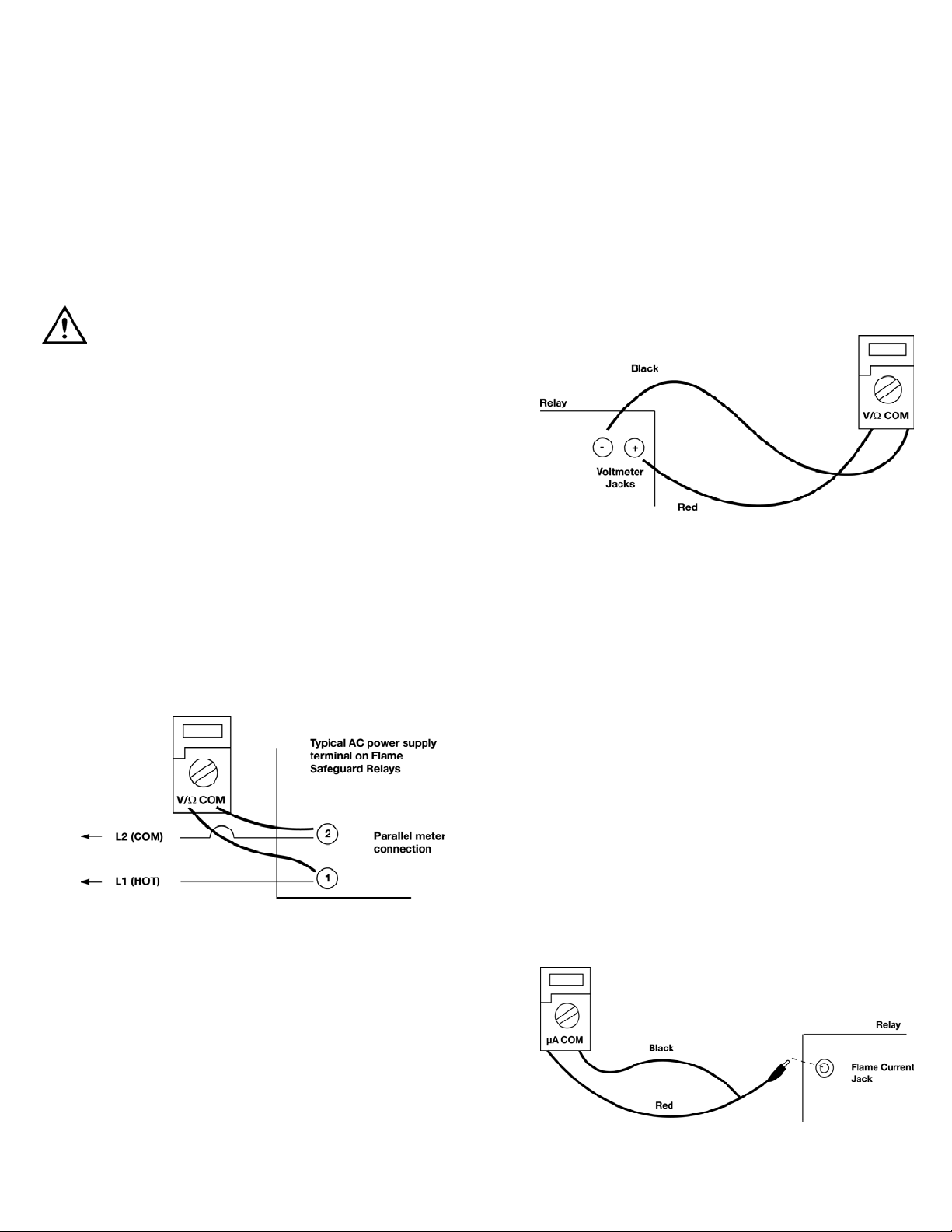

AC Voltage

To determine the voltage of any energized AC circuit up to 300 volts.

proceed as follows:

1. Set range selector switch to AC volts (700 or higher).

2. Connect the red test lead to the V/Ω input and the

black test lead to the common input.

3. Attach the meter leads in parallel with the voltage to

be measured (Fig 1).

4. Read meter display.

DC Voltage

To determine the voltage of any energized DC circuit up to 150 V,

proceed as follows:

1. Set range selector switch to DC volts (400 or higher).

2. Attach the meter leads in parallel with the voltage to

be measured (Fig 2).

3. Read meter display.

NOTE: Fig 2 illustrates how flame circuit voltages (instead of current)

are measured on flame safeguard controls using lead sulfide

photocell detectors. (Suitable lead sulfide detector voltage readings

are 100 - 140 V DC).

Meter connections for checking performance of lead sulfide photocell

with R478B or R4074B relay.

Flame Current Check

The flame current is the best indicator of proper flame detector

application. The check should be done at the time of installation, at

any time service is done on the system, and at least once a month or

sooner while the system is in operation. This will prevent shutdowns

due to poor flame signal.

The test is done by connecting your multimeter in series with the flame

detector using µA (microamp) range and reading the flame signal when

the burner is operating.

Insert the ATLFSG red test lead to the “mAµA” jack and the black test

lead to the “COM” jack on the meter and the mini-plug into the test

jack on the RA890F. This automatically puts the meter in series with the

flame detector.

1. For a flame safeguard relay having a flame current jack, such as

RA89E, F, & G, R890E, F, & G, R4138, R4150, R4181, R4795A,

C, D (Fig 3).

(Fig 1)

(Fig 2)

(Fig 3)

ATLFSG-MAN P. 1

(Fig. 5)

2. Insert cable connector plug into flame current jack. This puts the

meter in series with the flame lead. The system must be operating

and detector sighting flame for current to flow through the meter.

Minimum safe current is 2µA (Fig 4).

RA890F and 0270A sub-base

Location of test jack on the RA890F

3. For a flame safeguard relay without flame current test jack, such

as R890, R485, RA1 90B, RA890B & C, R 178, R407A, R7023, W1

24, hook-up (Fig 5).

4. For pulsing-type relay without a flame current test jack, such as

R4075B and some models of R4138A, hook-up (Fig 5). Use the

20µA selector setting and read direct. To stop cycling, manually

hold in relay 2K (2R in older models) and pull out the

vacuum tube.

NOTE: System must be operating and detector sighting flame for

current to flow through the meter.

ATLFSG-MAN P. 2

(Fig 4)

(Fig 5)

5. For pulsing-type flame safeguard relays with the flame current

jack and push-button for eliminating pulses, used with a

self-checking C7012E flame detector, such as R4138A and

R4181A (Fig 6).

6. Insert cable connector plug into flame current test jack to put

meter in series with flame lead (Fig 6). To stabilize meter reading,

hold relay 2K in with one hand, press test push-button with other

hand, read µA scale and release button. When normal pulsing is

reestablished, release relay 2K. A stable reading, with the

push-button depressed and 2K held in, of 4 to 4-1/2 minroamps

is the minimum acceptable flame current.

CAUTION!

To eliminate the possibility of injury to operator and damage to the

instrument and equipment, the following procedure is recommended.

Exercise care and caution on all ranges, particularly the voltage

ranges, and follow all standard published safety rules and wear

appropriate personal protective equipment (ppe). Misuse, abuse and

carelessness cannot be prevented by any written word and is fully the

operator’s responsibility.

(Fig 6)

Limited Warranty

The AT L FSG is warranted to be free from defects in materials and workmanship

for a period of one year from the date of purchase. If within the limited lifetime warranty

period your instrument should become inoperative from such defects, the unit will be

repaired or replaced at UEi’s option. This warranty covers normal use and does not cover

damage which occurs in shipment or failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper maintenance. Batteries and consequential damage resulting from failed batteries are not covered by warranty.

Any implied warranties, including but not limited to implied warranties of merchantability

and fitness for a particular purpose, are limited to the express warranty. UEi shall not be

liable for loss of use of the instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such damage, expenses or

economic loss. A purchase receipt or other proof of original purchase date will be required

before warra n ty repairs will be rendered. Instruments out of warra n ty will be repaired

(when repairable) for a service charge. Return the unit postage paid and insured to:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

ATLFSG

Flame Safeguard Relay Test Kit

Copyright © 2007 UEi ATLFSG-MAN 2/07

Loading...

Loading...