Page 1

Translation of the original manual

compiled: 20.04.16

51026_51029_BA_en_Version_05

Pneumatic

Chain Saw

Type 5 1026

5 1027

5 1028

5 1029

Tech. Doc. No. 519

Illustration can differ from the original

Operation and

Maintenance Manual

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Page 2

P n e u m a t i c C h ai n Saw

5 1 0 26 – 5 1029

51026_51029_BA_en_Version_05

Page 1 of 34

Contents

Page

Technical Specification

2

Main Features 2-3

Cutting Sets 4

Labelling 4

Use 4

Signal Word and Symbol definition 5

Employer‘s Obligations 6

Operator’s Obligations 6

Safety Instructions 7-12

Danger Zones 13

Safety Instructions for the Work Place 13-14

Safety Instructions for the Transport 14

Operation Instruction 14-17

Maintenance and Upkeep 17-27

ChainType 28-29

Safety Assembly Parts 30

Spare Parts and Accessories 30

Troubleshooting 31

Disassembly- Re-assembly 31

Environmental Regulations 31

Storage 31

Disposal 31

Miscellaneous 32-33

Declaration of Conformity 34

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the

original manual

compiled: 20.04.16

Page 3

P n e u m a t i c C h ai n Saw

5 1 0 26 – 5 1029

51026_51029_BA_en_Version_05

Page 2 of 34

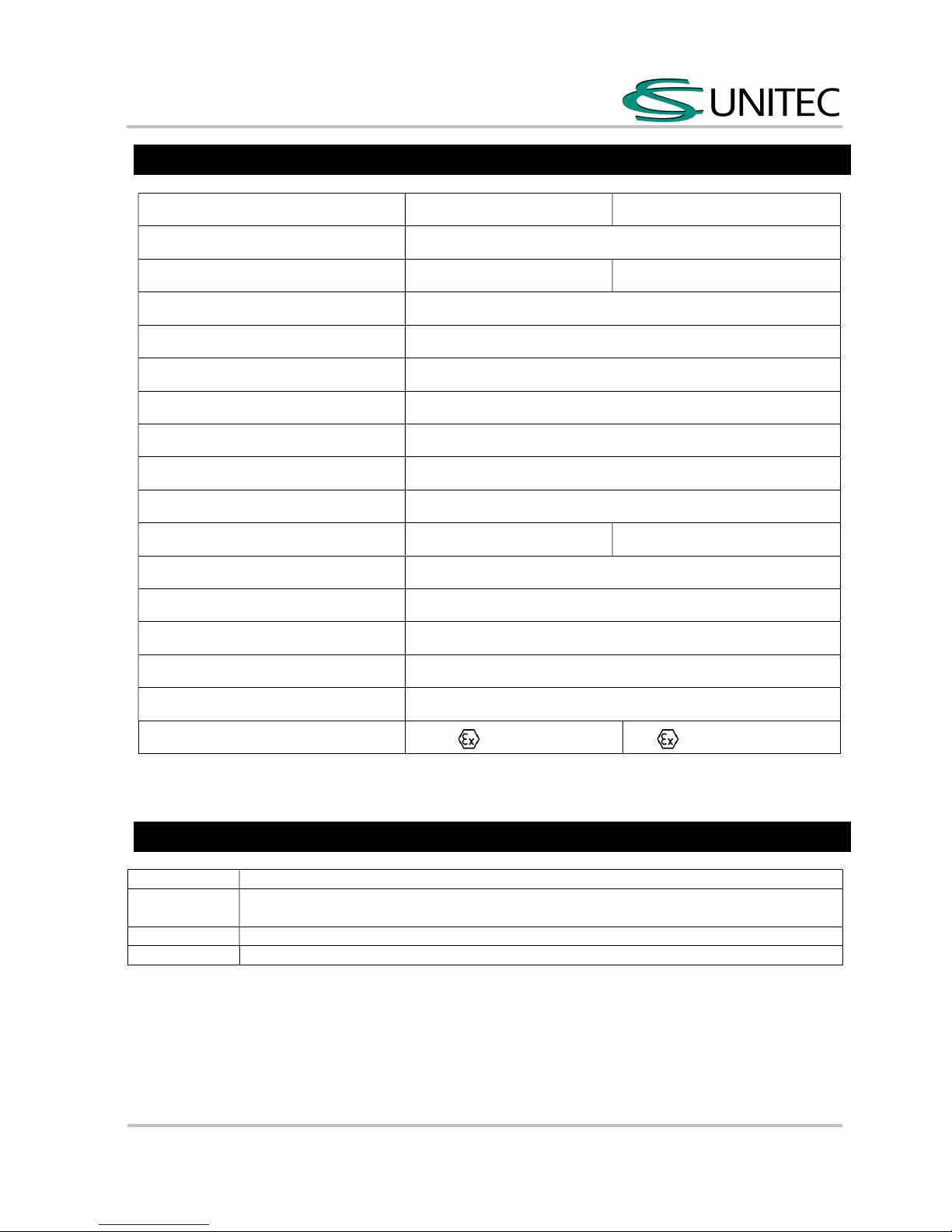

Technical Specification

Type

5 1026 – 5 1028 5 1029 0010

Operating pressure 6 bar

Housing material Aluminium Aluminium coated and Zamak

Chain bar length, usable 40 cm

Air consumption 2.9 m³/ min

Capacity 3 kW

Motor speed 6500 1/min

Max. chain speed 21 m/s

Pneumatic connection R 3/4 “ i

Min. ID of hose 15 mm

Weight without bar and chain 8.5 kg 9.5 kg

Number of teeth of the chain wheel 8

Chain braking time < 0.12 Sec.

Noise pressure level 102.6 db(A)

Noise power level 113.7 db(A)

Vibration (acc. to ISO 22867) < 2.5 m/s²

ATEX classification

- II 2 G c T5 - I M 2 c T5

Main Features

5 1026 xxxx Cutting of wood an wooden objects

5 1027 xxxx Cutting of plastic with water cooling

(4 l/ min water at 3 bar, Ø water hose, inside. min. 7 mm)

5 1028 xxxx Type for under water use

5 1029 xxxx Use in underground coal mining

Attention!

The last four digits of the type description with XXXX refer to the different cutting sets respectively to

the usable bar lengths.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 4

P n e u m a t i c C h ai n Saw

5 1 0 26 – 5 1029

51026_51029_BA_en_Version_05

Page 3 of 34

5 1026 00 Standard

5 1027 00 with water cooling

5 1028 00 with exhaust duct underneath the saw

5 1029 00 like the standard saw, but coated

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 5

P n e u m a t i c C h ai n Saw

5 1 0 26 – 5 1029

51026_51029_BA_en_Version_05

Page 4 of 34

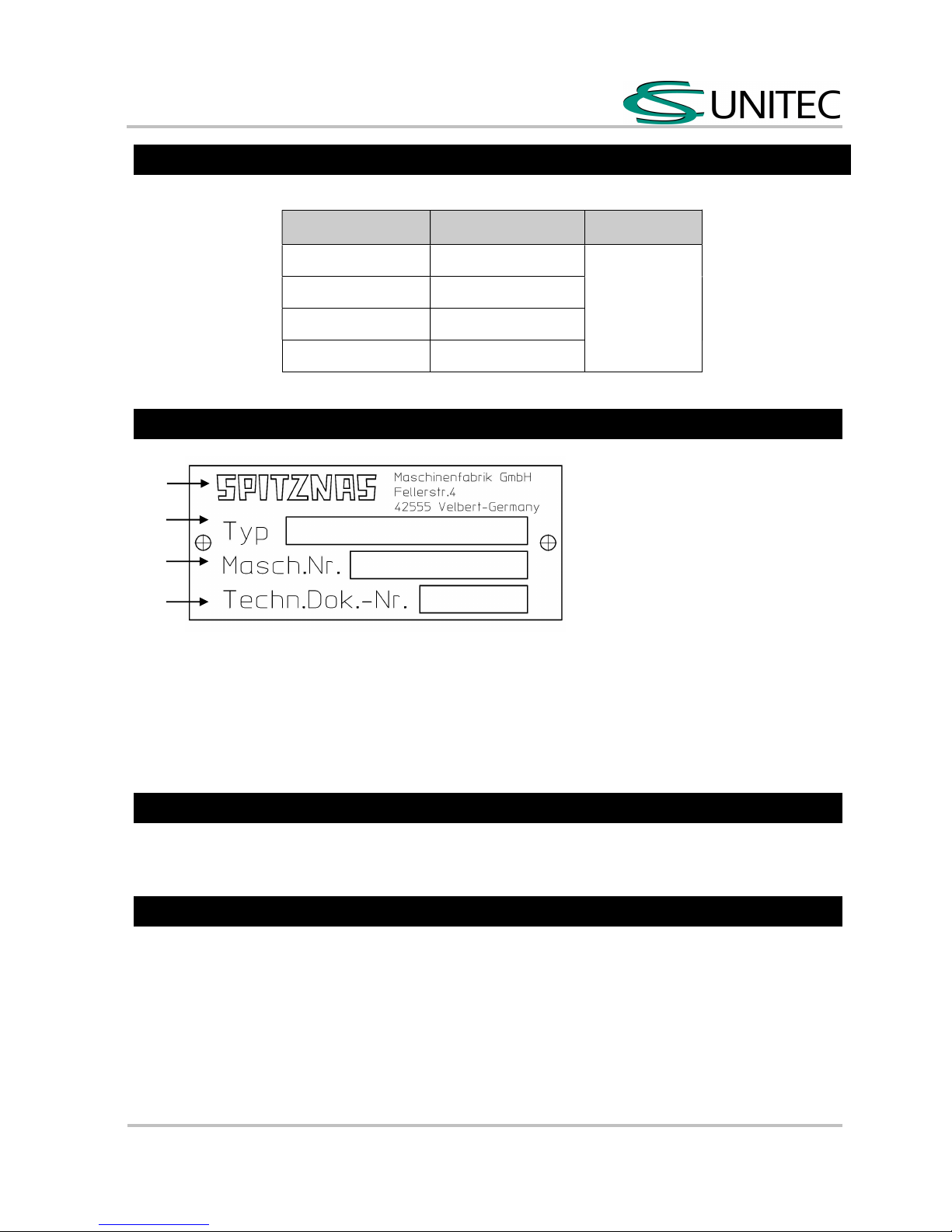

Cutting Sets

Type Bar length Chain pitch

X XXXX 0070 27 cm

0.404”

X XXXX 0010

43 cm

X XXXX 0050 63 cm

X XXXX 0060 73 cm

Labelling

1

2

3

4

1 – Name and adress of the company

2 – Type description

3 – Description of the series (the first two digits refer to the year of manufacturing and the rest

refers to the series)

4 – Indication of the technical ATEX document number

Intended Use

Cutting of wood and plastics in dry, wet and explosive areas (depending on the type and

classification)

Improper Use

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment.

Operating the machine in an explosive area, for which the machine is not approved.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 6

P n e u m a t i c C h ai n Saw

5 1 0 26 – 5 1029

51026_51029_BA_en_Version_05

Page 5 of 34

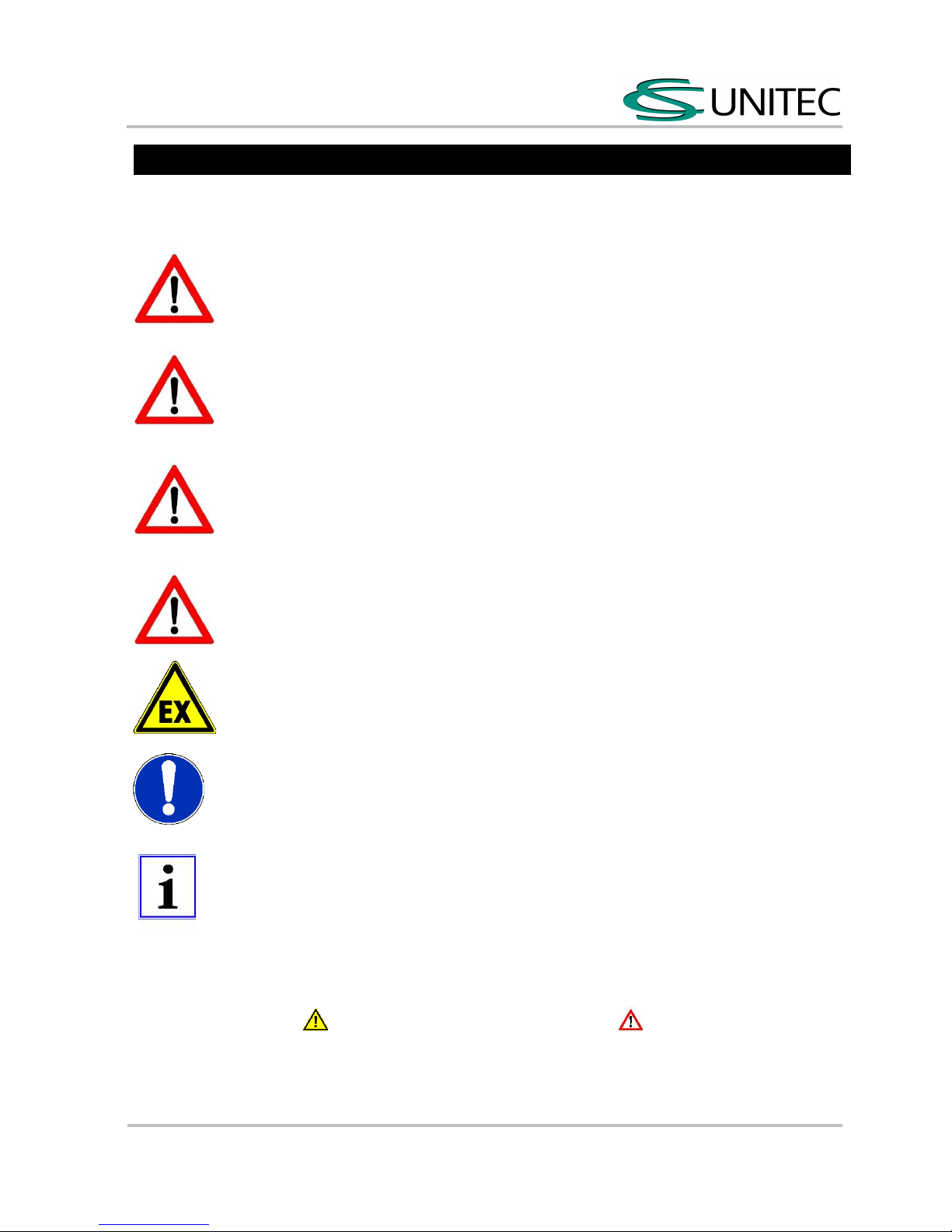

Signal Word and Symbol Definition

The signal words and symbols used in the technical documentation (safety instructions, operating

booklet, etc.) have the following meaning:

DANGER

Indicates an immediate danger, which causes serious injuries or even death,

if not avoided.

WARNING

Indicates a threatening danger, which can cause serious injuries or even

death, if not avoided.

CAUTION

Indicates a danger or unsafe procedure which can cause injuries to a person

or material damages, if not avoided.

Notice

Indicates a potentially dangerous situation which can cause damage to the

product or its surroundings, if not avoided.

ACHTUNG – Danger of explosion

Complementary regulations and instructions apply in explosive areas.

Observe the safety instructions of the employer as well.

NOTICE

Gives recommendations and important hints for handling the product.

IMPORTANT

Indicates tips and other particularly useful information.

REMARK:

In each case the symbol used cannot replace the safety text. The text must always be fully read. In

some cases other symbols will be used with the signal words.

The normative symbol was replaced by an informative symbol , in order to increase the

attention.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 7

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 6 of 34

Owner Obligations

Generally, the machine operator is responsible for correct conditions/ operation of the machine and

adherence to the safety regulations. The machine is built according to the level of technology and

the recognized technical safety regulations. However there is still a risk of accidents to the operator

or third parties or damage to the machine or other objects.

All current regulations and specifications which apply to the site of operation in regards to accident

prevention, installation of electrical and mechanical systems as well as radio interference must be

observed.

IMPORTANT

The operator must make sure that…

Assessment of the specific risks, which can occur due to any use of the machine,

was done

the function of the safety equipment is regularly checked.

the safety symbols and safety notes on the machine/device and the operating instruction booklet

are observed.

the safety instructions and the operating instruction booklet are available completely and in

legible condition on site with the machine.

The operator is obliged to only allow personnel to work on the machine who…

are familiar with the basic work environment safety rules and accident preventing regulations

and who have have been instructed in the correct use of the machine.

have read and understood the safety and warning notes in the operating instruction booklet as

well as all other documentation pertaining to the machine.

have been tested at regular intervals in regards to their safety-conscious operation of the

machine.

Safety-conscious operation

Additionally to the safety instructions listed in this booklet and to the intended use, the following

safety instructions are valid:

Accident prevention instructions, safety and operation regulations

Explosion protection directives

Safety rules for handling dangerous substances

Standards and laws being effective

Operator Obligations

All persons who are assigned to work with the machine are obligated to:

- always pay attention to the basic safety and accident preventing regulations.

- always read and follow the safety and warning notes in the operating instruction booklet.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 8

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 7 of 34

Safety Instructions

Any power tool can be dangerous.

Please follow these simple procedures.

They are for your protection.

Special safety measures are necessary at working with the chain saw.

Working with it is a lot faster than with an axe or hand saw and because you

are working with a high speed chain.

The clothing has to be appropriate and shall not hinder.

Wear tight clothes with cut protection inlay - insert-combined suit, no working

suit!

There should be no clothing, no scarf, no tie, no jewels – that can possibly get

into wood or undergrowth. Take care of long hair (hair-net)!

Wear tight and non-slip gloves -made of chromium leather, preferably!

Wear safety boots with maximal grip and steel cap!

Use a hard hat if parts could fall down!

Wear ear protection!

Wear safety goggles!

Wear personal noise protection – like e. g. ear flaps!

Consider sufficient cooling and lubrication of chain and bar.

Observe the accident prevention regulations of the employer’s liability insurance association.

Who is working with such a saw for the first time, should be instructed by the seller how to

handle it or should take part at a special course of instruction.

Minors are not allowed to work with such a saw except for juveniles over the age of 16, who get

trained under supervision.

Keep children, animals and viewers away!

The user is reported for accidents or risks, which can be against other people or their property!

Do only give the motor saw to people who know the model and its handling and do always give

the operating instructions to them.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 9

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 8 of 34

Who is working with a motor saw has to be fit

- awake, healthy and in good shape

- has to lodge working breaks in good time

- is not allowed to work with such a saw while you are under the influence of

- medication, alcohol, or other drugs, because that can affect the reaction.

With hear protecting that has been put on, you have to be attentive and careful, because the

recognizing of dangerous sounds (screaming, signal sounds, etc.) is disturbed.

Do not work alone!

You have to keep a position where other people can hear you, if an accident happens and you

start screaming.

Do only use attachments, which have been delivered by SPITZNAS or have been explicitly

released for the attaching!

Other attachments are not allowed to be used, because they could lead to bigger dangers.

SPITZNAS takes out any liability for person- and property damage, in which use of not

approved attachments has occurred.

Before starting the saw

Check if the saw is in safe condition.

Observe the corresponding chapter in the operating manual:

The guide (bar) has to be fixed properly

Chain has to be tensioned properly

Valve lever and valve lever latch have to be fingertip easy.

Valve lever has to rebound into the neutral position by itself.

Do not make changes concerning the operating and safety equipment!

Keep the handles clean and dry from resin – for the safe guiding of the motor saw!

Correct operation pressure (see technical specifications)

Chain-break must be in proper condition

When working in explosive areas, pay attention to proper lubricating and cooling of the

chain and the bar.

The chain saw should only be used in totally safe condition (Danger of accident).

Starting the chain saw

The chain saw is only used by one person. Do not tolerate other people in the working area!

Do always hold the saw tight in both of your hands for the proper guiding.

The right hand is holding the rear handle (even left-hander) - pipe handle and handle should be hold

tight with the thumb.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 10

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 9 of 34

Make sure that you are standing very solidly.

Put the saw under full power into the cut and place the spiked strip fixed- only then start to cut.

Defend dangers in general

When you have put on the ear protection, you need to be very attentive and careful because

you cannot recognize dangers soon enough (sounds like screams, signals etc.)

If there is a danger, immediately switch off the motor.

Do not put parts of the body into the enlarged sawing range of the chain.

Pull the saw out of wood only if the chain is still working.

Never work without a stop. The saw can possibly pull the worker to the front.

Work attentively and quietly,

- only with good light and clear sight

- do not get others in danger,

- attentive working is important.

Use a guide which is as short as possible

Be careful at slickness,

when wet, snow, ice, on slopes or uneven off-road,

on fresh peeled wood (bark).

When you work in higher altitude, a lift working platform should always be used! Never

work on a ladder!

Never work in unsolid places!

Never work above shoulder level!

Never work with only one hand!

Chain saw shall only be used for cutting, not for lifting up or

scooping away cut-off pieces.

Only wood or wooden things shall be cut.

Do not let foreign substances touch the saw. Stones, nails, etc. can sling away and

can damage the chain and the chain saw can possibly bound up!

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 11

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 10 of 34

At the slope do always stand at the top or at the side of the log or of the laying tree.

Take care of the down-rolling logs!

Danger of stumbling!

You can fall over roots, stumps of trees or ditches:

Be careful when you cut spilling wood. There is a danger of injuring with spilling pieces of

wood.

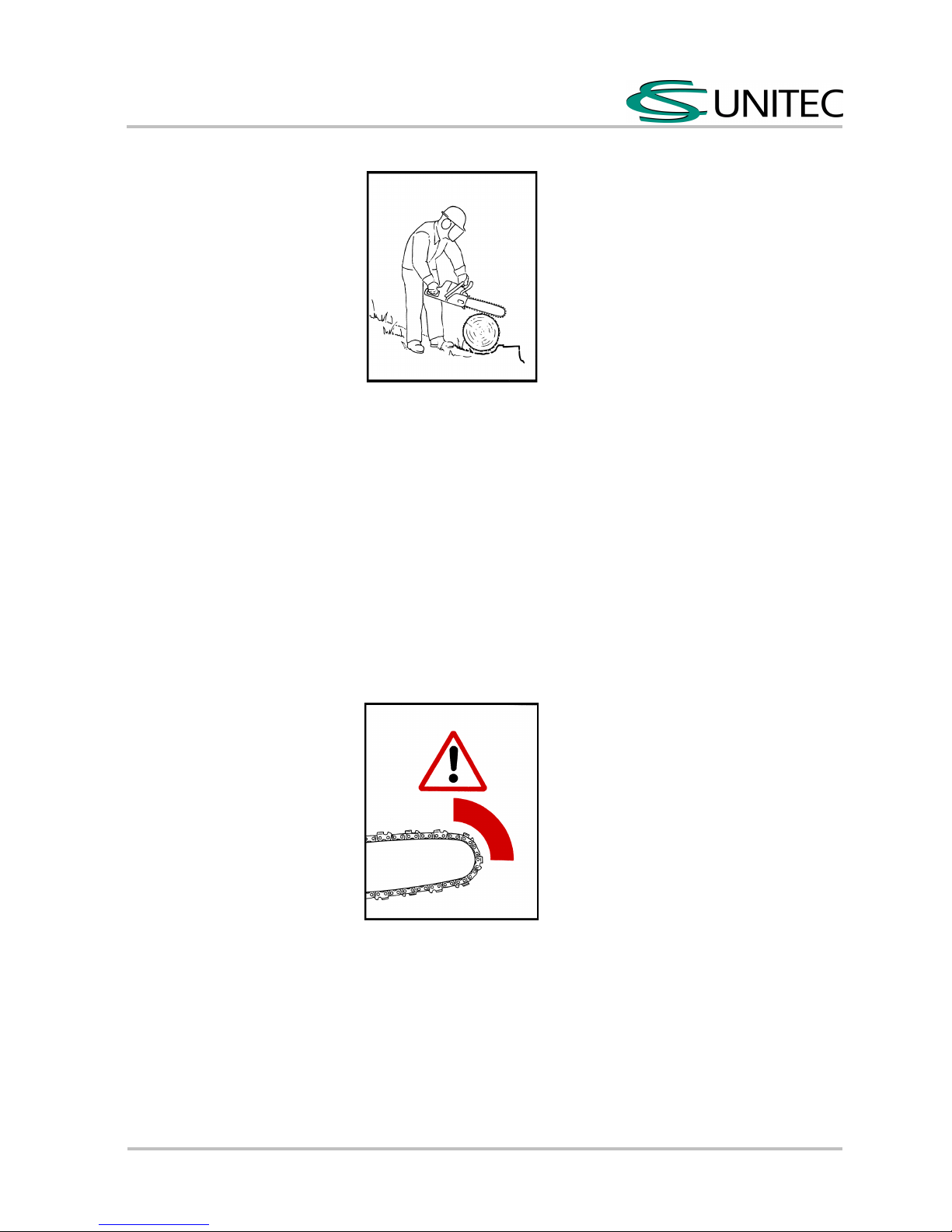

Danger because of kickback! Kickback can lead to deadly cutting injury!

If a kickback happens, the saw suddenly can sling towards the user, e.g.

if the chain hits unintentionally wood or a hard object in the area around the upper

quarter of the bar nose.

If the chain on the bar nose gets stuck in the cut.

Reducing danger of kickback

Hold the saw tightly with both hands and safe grip

Do only cut with full power

Do always watch the bar nose

Do not cut with the bar nose

Do not bend forward so far

Do not cut above shoulder level

Do only put the bar very carefully in the cut

Do only "plunge", if you are familiar with that working

procedure

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com

• www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 12

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 11 of 34

Pay attention to the position of the trunk and to the forces which close the cutting slot and

can jam the chain

Do only work with an appropriately sharpened and tensioned chain. The clearance of the depth

limiter should not be too large.

Decreasing the danger of accidents

Quick-stop chain-brake:

With this the danger of injuring can be reduced in certain situations, but the kickback itself

cannot be avoided. When releasing the chain-brake the chain comes to standstill in a split

second as described in paragraph „Chain-break“.

Cutting set:

Kickback arms, properly sharpened chains as well as a bar with a little bar head

decrease danger of kickback.

It is a lot safer to avoid kickback with clever and proper work.

Avoid drawing in and rebound!

A = To draw in

If at the cutting with the subside of the bar (forehand-cut), the chain jams or touches a tough

object in the wood, the chain saw can be abruptly pulled towards to the trunk.

The spiked strip shall always be fixed safely!

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 13

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 12 of 34

B = Rebound

The chain saw can be pushed back towards the operator, if during cutting with the upper side of

the bar (backhand-cut) the chain touches a tough object in the wood.

Danger Zones

Operational

condition

---------------Life phase

Normal function Malfunction Improper use Expected use

Transport Transport of the

machine in an

inoperable

condition

Dropping the

machine

Transport of the

machine in an

operable condition

unknown

Start-up

Operation

Operating the

machine with

designated device

unknown unknown Working without

device

Operation Machine only

works with

actuated valve

Machine runs

without actuated

valve

Valve is blocked in

actuated condition

unknown

Machine moves the

tool

Tool blocks unknown unknown

Maintenance Operation at a

maintenance unit

Breakdown of the

machine

unknown unknown

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 14

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 13 of 34

Safety Instructions for Prevention of Workplace Hazards

WARNING

The following applies unless otherwise stated in the machine’s

operating instructions booklet:

The machine is not insulated to protect against an electrical power surge.

CAUTION– Risk of injury!

Hands can be squeezed, entangled or otherwise hurt. Keep hands away

from areas being labeled with this warning symbol.

Caution – risk of injury!

Remove all sources of danger which could lead to slipping, tripping or falling

(e.g. slippery surface, hoses, cables).

Keep the work area clean and dry

PROHIBITION

Eating, drinking and smoking are forbidden during operation.

ATTENTION – Danger of explosion!

Only use the machine according to the intended use.

The machine is designed for the use in areas exposed to explosion hazards as

well. Please observe:

The generation of heat and possibly the generation of sparks is

characteristic for cutting work.

Work places nearby should always be protected from flying sparks, e. g.

by movable walls or curtains.

Flammable and explosive substances have to be removed from the work

area before starting the work.

Among others, this applies for dust deposits, cardboard, packing, textile,

wood and splints, but for flammable fluids and gas as well.

Make sure there is adequate lighting.

Be extra careful in unfamiliar surroundings. There is a risk of hidden hazards such as electric lines

or other supply lines.

Make sure when operating the machine that no electrical cables, gas pipes or similar equipment

could be damaged.

Use suitable and personal protective equipment.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 15

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 14 of 34

Safety Instructions for Prevention of Transport Hazards

DANGER

Improper transport

Danger to life by parts falling down! Damage of the machine!

Never attach the machine to the connection line.

Do not work or stay under suspended loads.

NOTICE

Separate the machine from any external energy source before transportation.

Check that the machine is undamaged and in proper condition.

Always install chain protection – also for transports at short distances and for storage.

Only carry the chain saw at the handle pipe – guide bar pointing backwards!

When transporting in vehicles:

Prevent saw from tilting and from damages. When the chain saw is not used, it has to be stored in a

way that it does not endanger others.

Operation Instruction

Maintain the saw regularly. Make only maintenance and repairs that have been described in the

Operating Manual.

Let other work be done by SPITZNAS service. Only original SPITZNAS spare parts should be used.

Do not change anything at the chain saw. The safety could be endangered.

Disconnect from air supply

for checking tension of chain

for tensioning the chain

for changing the chain

for clearing a fault

Check the chain catcher,

Replace it, if damaged.

Pay attention to sharpening instructions for proper handling of chain and bar.

Keep chain in a perfect shape, properly sharpened and tensioned and lubricated.

Replace chain, guide and sprocket in due time.

Keep motor and chain lubricating oil only in correctly labelled and approved containers.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 16

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

Translation of the original manual

compiled: 20.04.16

51026_51029_BA_en_Version_05

Page 15 of 34

ATTENTION!

In case of malfunction of the chain brake, stop chain saw immediately – Risk of injury!

Contact CS Unitec service!

Do not use the chain saw until this problem is not solved (see chapter „Chain brake“).

Assembling of bar and chain

Pitch of the chain has to be adjusted to spacing of the sprocket and the bar and the thickness of

drive link has to be adjusted to the width of the groove of the bar.

Turn-off nuts and remove cover.

Turn adjusting wheel to the left, until clamp nut (2) lies close to the left of housing recess.

Loosening the chain-brake:

Press hand protection (3) against the pipe handle.

Pull on protecting gloves. Put on the chain (starting at the bar nose).

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Page 17

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 16 of 34

Put the guide bar over the screws (4). (The cutting edges have to face to the right) and put the fixing

bore (5) over the pin of the clamp nut. At the same time put the chain over the sprocket (6). Turn

adjusting screw (7) to the right, until the chain still hangs out a little bit and the noses of drive links are

put into bar groove.

Attach the cover back and tighten the nuts lightly by hand.

After this, adjust tension of chain. (Paragraph „Adjust tension of chain“)

Assembly of spiked strip

2 x screw M 6

at motor housing

Tensioning the saw chain

Adjust tension during operation:

Stop motor and disconnect it from air supply. Only then loosen the nuts (1)!

Lift bar nose and screw clamp nut (1) with a screwdriver to the right until the chain lies at

the underside of the bar. Go on lifting up the bar and tighten the nuts (1) very strongly.

Check chain tension

Stop the motor.

Put on protecting gloves!

The chain has to lie at the underside of the bar and it has to be pulled over the guide bar by hand

when the chain brake is released.

If necessary, adjust tension.

A new chain has to be adjusted more often than a chain which is already used for a longer period.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 18

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 17 of 34

Check chain tension more often – paragraph „During the operation“!

Maintenance and Upkeep

Basic Safety Instructions:

Caution

Skin exposure to hazardous dusts may cause severe dermatitis. Dust present

at the work place could be disturbed during the maintenance procedure and

inhaled.

Clean machine and work place before maintenance work.

NOTICE

Only use original SPITZNAS service tools, in order to avoid damage.

Make sure that the technical data according to the instruction manual has

been adhered to after all maintenance work.

PROHIBITION

Eating, drinking and smoking are forbidden during maintenance and repair

work.

WARNING

Maintenance and repair work on pneumatic equipment:

Air under pressure can cause severe injury.

Unpressurize the pneumatic equipment of the machine prior to maintenance

and repair work.

Replace hose lines regularly as a preventative measure, even when there is

no visible damage. (Pay attention to the manufacturer’s information)

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 19

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 18 of 34

NOTICE

After completing maintenance and repair work and before restarting

production make sure that…

all materials, tools and other equipment which were required for maintenance

or repairs have been removed from the work area of the machine.

any fluid leaks have been removed.

all safety devices on the machine are functioning properly.

the oil level was checked.

fixtures of screw connections are checked.

any removed container covers, screens or filters have been re-assembled.

Inspection and maintenance can be done by the operator, disassembly and re-assembly of the

machine have to be executed by qualified staff only. Incorrect assembly can lead to danger of

accident for the operator and to defects on the machine.

ATTENTION

Parts can be damaged when falling down!

ATTENION

– Danger of explosion!

Generation of sparks during maintenance work !

Observe local safety instructions.

NOTICE

Avoid applying any force when disassembling and re-assembling the machine.

WARNING

Unintentional start of the machine. Risk of injury by moving assembly parts!

Prevent machine from unintentional starting .

Only work on the machine, when all lines are disconnected.

WARNING

Operating supplies being dangerous to health !

Risk of injury!

Observe legal regulations.

Take preventive measures for persons and environment.

WARNING

Hot surface

Risk of injury!

Let the machine cool down to ambient temperature.

WARNING

Improper lifting/ moving of heavy assembly groups or assembly parts.

Injury to persons and damage to material!

Use appropriate means of transport, hoisting devices and clamp devices for

moving heavy assembly groups or assembly parts.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 20

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 19 of 34

WARNING

Lacking stability

Squeezing of hands and feet!

Prevent machine/ parts from tilting, falling over or falling down during

re-assembly/ disassembly

NOTICE

Spitznas service is at your disposal for all maintenance, upkeep and assembly

work.

Service life and performance of the chain saw are determined by

a) Degree of air purity

b) Lubrication and maintenance

To a) Blow the air hose clear before connecting it to the saw. Install dirt and water separators

upstream of the saw, if it is not possible to prevent the formation of rust and water

condensation in the air distribution lines.

To b) The motor is lubricated by the lubricator installed in the handle. Fill the lubricator with resin-

and acid-free SAE 5W – SAE 10W lubricating oil. Thick flowing oil will clog the vanes and

affect the start-up and performance of the motor. Only proper maintenance can ensure

constant performance, reduction in wear and thus, a decrease in operating costs and an

increase in service life.

We therefore highly recommend installing service units upstream of the machine.

Observe the comments in the information sheet “Maintenance of Pneumatic Tools”!

Closed greased ball bearings must not be flushed.

After use, clean the saw and rinse it with light oil or provide alternate corrosion protection.

Regularly check and clean the air inlet screen.

In winter, or when using very moist air, an antifreeze lubricant, such as BP Energol AX 10,

Kilfrost or Kompranol should be used.

Replace wear parts – in particular the vanes – when necessary.

Vanes are considered worn, if their width is less than 16 mm.

Lubricating the saw chain is done automatically by the second lubricating system.

The oil tank situated in the motor housing, size approx. 250 ccm, has to be filled with chain saw oil

before starting. It contains oil for approx. 2 working hours. You can check, if oil is conveyed to the

chain, by holding running saw with the bar pointing downwards and, if adjustment is correct, an oil

trace will be clearly observed on a light coloured floor or paper.

Use machine oil with adhesive additive of a viscosity of 49-55 c ST (6.5 – 7.5 E) at 50°C (122 F).

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 21

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 20 of 34

Filling in chain lubricating oil

- Clean the tank screw-cap and the area around, so that the tank cannot get dirty.

- Use a hopper for re-filling of motor oil and chain oil

- Avoid smoking and naked flame

Adjustment of chain lubrication

When having removed the locking screw item 25, you can see the adjusting screw item 23.

The oil delivery is reduced by tightening, when releasing the screw the oil delivery is increased.

In most of the cases, it will be sufficient to tighten or release the screw by 1/4 to 1/2 turn of a thread.

Attention!

Due to risk of injury, the oil adjustment is only done at standstill of the saw.

The oil reservoir has to be tight (pressure admission).

If the flow in the oil tank does not change, lubricating oil delivery can be interrupted.

Check chain lubrication. Clean the oil passages, possibly look for the SPITZNAS service.

Checking the chain lubrication

The chain always has to sling off little oil.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 22

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 21 of 34

Never work without chain lubrication! If the chain is working dryly, the cutting set can be destroyed

in short time.

Before starting the work always check chain lubrication and the oil level in the tank.

Every new chain needs a run-in period time of 2 to 3 minutes.

After running in, check chain tension and adjust it, if necessary.

Paragraph „Checking chain tension“!

Chain brake

Blocking the chain with the chain brake

When emergency

Hand guard to the bar nose- with the left hand- or automatically- by the kickback:

The chain gets blocked and stops

Releasing the chain brake:

Pull the hand guard to the pipe handle.

Tip: Before opening the handle valve (except for the function control) and before cutting,

the chain brake has to be released.

The chain brake works only, if no change will be made on the hand guard.

Controlling of function of chain brake

Every time before starting work: block the chain (hand guard against nose of the bar and open the

valve of the handle for a short time (max. 3 sec.) The chain should not run either. The hand guard has

to be clean and easy to move.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 23

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 22 of 34

Maintenance of chain brake

The chain brake is subjected to normal wear. For serving a good performance, it has to be maintained

by well trained personnel (e.g. service) at regular intervals:

Professional fulltime work every three months

Half-professional (Agriculture & Construction) twice a year

Hobby and free-time user once a year

Keeping the bar proper

Turn over the bar after every sharpening of the chain or replacing the chain to avoid wear

out on one side only especially at the return steering at the underside.

Clean regularly

1 = Oil inlet hole

2 = Oil outlet port

3 = Bar groove

During the first period of operation

Always pay attention to:

Opening of valve only with released chain brake. Opening of valve at blocked chain brake (chain is

stalled) causes in a short time damages on the chain drive (chain brake).

During operation

Check tension of chain more often!

A new chain has to be adjusted more often than one that is in use for longer time!

In cold state:

The chain must lean against the bottom side of the bar but it has to be still pulled around the bar by

hand. If necessary, adjust tension of the chain again. Paragraph “Tensioning the chain“!

With operating temperature:

The chain stretches and slacks. The drive links at the bottom side of the bar shall not come out of the

groove. Otherwise the chain can spring out.

Adjust tension of the chain, paragraph „Tensioning the chain“!

After work it is important to relieve tension! During cooling the chain shrinks. A chain which is not

relieved from tension can possibly damage the rotor shaft and the bearing.

After operation:

Relieve tension of chain, if it was tensioned during work at operation temperature.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 24

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 23 of 34

Chain shrinks during cooling. A chain which is not relieved from tension can possibly damage the

bearings.

A longer shut down of the machine:

Look at chapter „Storing the saw“

Sharpening the chain

Lowering the depth limiter

1. When sharpening your chain with a file holder, the clearance of the depth limiter must be checked

and adjusted, if necessary after sharpening.

2. Check the clearance of the depth limit at least after every third sharpening, and after every

sharpening when cutting frozen wood.

3. Place depth limiter gauge on cutting tooth. If depth limiter is too high, file off protruding part with a

flat file (Fig. 1)

4. Round off front edge of depth limiter. Its original shape must be preserved (Fig. 2).

General Filing Instructions

1. Place file holder on top of tooth and depth limiter.

2. First file all cutting teeth 3. Keep marks on file

on one side using an outward, holder parallel to chain.

cutting stroke. Then file the cutting

teeth on the other side.

Fig 2 Fig 1

angular

mark

Fi

le holder

file

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 25

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 24 of 34

4. All cutting teeth must be of equal length 5. Always completely file away any damage

Areas on side plate and top of tooth.

The chain supplied with the saw is to be sharpened at the following angles:

Hold file holder at a 10° upward tilt

Chain Repair

Shortening and lengthening the chain

(Chain added between two left-hand cutting teeth)

(Two coupling links and one drive link between cutting teeth)

Most chain saws are assembled with one coupling link between a right-hand and a left-hand cutting

tooth, however there are also chains which are assembled differently due to their length (number of

drive links). If a chain must be shortened or lengthened, it is best to do so at this point. However do

not insert more than two coupling links between two cutting teeth.

Important: When shortening the chain, always remove the standard drive link and not the

safety link.

side plate

top of tooth

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 26

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 25 of 34

Replacing broken drive links

(Grind off rivet heads if necessary)

Lay chain in the corresponding recess of the anvil with the cutting tooth always pointing

upward. Press out rivets

Installation of new parts

1. File the running surface of new 2. Place coupling link with

chain links so that they are the rivets on a flat surface.

the same as those of the worn links.

File back new cutting teeth so that

they correspond to the worn ones.

3. Join ends of chain. 4. Place side plate of coupling

link with mark facing up.

Flatten rivet heads with ball end of

hammer.

Rivet Removal

9 2550 0040

correct wrong

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 27

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 26 of 34

Chain Bar

Important

:

Bars are designed only for the purpose of guiding the chain, and should

never be used as crowbars. Turning, twisting, and using the bar as a lever

will shorten its service life and void the warranty.

The bar of your chain saw needs as much care as the chain. The running surfaces must be flat

and smooth, and the groove must not be expanded. Inspect the groove as shown below:

Place straightedge against bar and If the chain tilts so that there

cutting tooth. If there is clearance is no clearance between the

between the straightedge and the bar, bar and the straightedge, the

the bar is OK. groove is worn.

Replace chain bar!

Bar Condition Cause

Worn groove

Wear due to long service.

Shallow groove, narrow running surface.

Chain tilted. Cutting teeth damaged on one

side. Drive link tongues worn.

Blueish areas on running surface

Groove compressed in the areas.

Friction of drive links has caused heating

and blue coloration.

clearance

clearance

no

Chain tilted

S

T

R

A

I

G

H

T

E

D

G

E

S

T

R

A

I

G

H

T

E

D

G

E

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 28

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 27 of 34

Reinforcement chipped

Bar used improperly. Saw jammed in the cut.

Log slid over bar.

Running surface scored

Improper use caused extreme lateral

pressure on the running surface at the bar

nose. A common problem most often caused

by log slippage.

Cavities in bar

Impact of the chain behind the reinforced

area of the bar as a result of the insufficient

chain tension. Dull cutting teeth. Extreme

pressure applied to front area of the bar.

Sprocket

A damaged sprocket will ruin your chain. Replace a damaged sprocket immediately; the

cost is only ¼ that of a new chain. It is therefore uneconomical to run new chains on old sprockets.

Avoid the problems caused by damaged sprocket:

1. Check it each time you mount a new chain, and replace it if it shows signs of wear.

2. Always make sure that the chain tension is sufficient.

Maintaining the chain clean and sharpen.

Cutting without problems with the right sharpened chain.

A saw which was well sharpened pulls itself without problems and light pushing in the wood.

Do not work with a blunt or damaged chain. This leads to a high human exertion, not satisfying

result, and a high wear.

Cleaning and checking the chain - for cracks in the chain links or rivets.

Renew damaged and used chain parts and adjust them to the others and correct them.

Important!

Keep the following angles and dimensions. A chain with a wrong sharpening especially too low

depth limiter can lead to high kickback slope of the saw – danger of injury!

Choose sharpening tools which fit to the pitch of the chain – allowed pitches of the chain, see

„Technical Specification“.

The size for the pitch of the chain (e.g. 3/8“) is stamped in the area of the depth limiter of every

cutting tooth.

Do only use special chain files!

Other files do not fit in shape and cut

The assignment of the filing diameter does only work after the pitch of the chain.

Look at the table at the bottom of this chapter.

A = sharpening angle

B = front angle

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 29

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 28 of 34

Chain Type

Type of chain Angle

A H

Rapid-Micro (RM) 30 85

Rapid-Super (RS) 30 60

Picco-Micro (OM/PMN) 30 85

Mould of teeth:

Micro = Half-chisel tooth

Super = Chisel tooth

Sprocket: 5 1026 7070

Pitch: 0,404“

Thickness of the drive wheels: 0,063“

Type Oregon 59 LG-61 E

The stipulated values for the angles A and B achieve automatically, if you use the stipulated files

and filing machines and if there is a right adjusting.

The angles have to be the same to all teeth of the chain. If the angles differ from each other: the

running of the chain is rough, uneven, and the wear gets tougher – this can go on to the break of the

chain.

As these requirements can be fulfilled only after enough and intense practicing:

Use a file holder!

Controlling the angle

Filing gauge * (look list) a versatile tool for the check of sharpening angle and front angle, the height

of the depth limiter, length of tooth, depth of the groove and for the cleaning of the groove and oil

inlet bores.

Proper sharpening

- if using the file holder and FG 1:

- the chain still stays on the guide bar

- if necessary fix the guide bar

- block the chain - hand guard to the front

- for going on pulling back the chain pull the hand guard to the hand pipe

- sharpen often (do not take away much) - for simple re-sharpening two to three file lines are

enough

- file only from the inner side to the outer

- the file only graps in the forward line - if you move at back lift it up.

- Guide the file:

Horizontal (in a 90°- angle to the side surface of the guide bar) corresponding to the

mentioned angles - of the markings on the file supports

- Do not file the connecting links and drive links

- Turn the files in regular spaces, to avoid wear on one side only

- Remove file burr with a piece of hard wood

- Check the angle with the file gauge.

All cutting theeth must have the same length.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 30

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 29 of 34

When the length of the teeth is unequal also the height of the teeth is different and that causes a

rough running of the chain and cracks in the chain.

File all cutting teeth to the length of the shortest. This can last very long so you better do this in a

work shop with an electric sharpening machine.

The following workings relate to normal operating conditions.

If the conditions get tougher (much dust coming up, very strongly resining wood, tropical wood, etc.)

and longer work time every day you have to shorten the mentioned intervals.

before starting work

after work or daily

weekly

monthly

at breakdown

at damage

if necessary

Complete saw

Visual Checking

(condition, tightness)

X

cleaning X

Valve lever,

Valve lever latch

Functional gauging X

Chain brake

Functional gauging X X

checking by SPITZNAS Service X

Lubricating oil tank

checking X X

Chain lubrication

checking X

Chain

checking, taking care for

sharpness

X X

checking chain tension X X

sharpening X

Guide bar

checking (wear, damage) X

cleaning and turning X X

deburring X

replacing X X

Sprocket

checking X

Accessible screws and nuts

(excepted adjusting screws)

tightening X

Chain catcher

checking X

replacing X

Storing the saw

(At operating breaks from about 3 months on)

- Take off chain and guide bar, clean them and spray them with protective oil.

- Clean the saw properly

- Fill the lubricating oil tank.

- Store the saw at a dry and safe place.

- Protect it from unauthorized use (e.g. from children).

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 31

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 30 of 34

Safety Assembly Parts

Components Material number

Sprocket 5 1026 7070

Brake band 5 1026 1320

Brake spring 9 1804 0200

Front handle 5 1026 2110

Rear handle 5 1026 1910

5 1029 1910

Front handle protection 5 1026 6800

Spare Parts and Accessories

When ordering, please enter the type description. So you can make it easier buying a new cutting

set. Guide bar, chain and sprocket are wear parts. So if you buy these parts, it is enough to indicate

the description of the chain saw, part number and the description of the spare parts.

Only genuine Spitznas spare parts may be used. There is no warranty for damages and liability is

disclaimed, if non-original spare parts and accessories are used.

The repairing of the machine is allowed authorized expert companies only.

The accessories applicable with our machine are listed in our brochure.

ACCESSORIES

Length Application Order number

Chisel chain 27 cm wood 5 1007 9960

43 cm wood 5 1007 9930

63 cm wood 5 1007 9940

73 cm wood 5 1007 9970

Carbide-tipped saw chain 27 cm plastic 5 1021 9960

43 cm plastic 5 1005 9950

63 cm plastic 5 1021 9940

73 cm plastic 5 1005 9970

Chain bar 27 cm 5 1005 7160

43 cm 5 1005 7120

63 cm 5 1005 7140

73 cm 5 1005 7170

Sprocket 5 1026 7070

Maintenance unit (portable) with pressure regulator ¾” 9 2406 0260

Combination wrench 9 1316 0080

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 32

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 31 of 34

Troubleshooting

Problem Cause Remedy

a Machine does not

start

Air not connected Connect and open air line

b Machine rotates too

slowly

Operating pressure too low Increase operating pressure (on

the machine ) to 6 bar

d Other problems Contact authorized expert

company

Disassembly – Re-assambly

Disassembly and re-assembly: see repair instruction.

Environmental Regulations

When working on or with the equipment, it is imperative to observe all

requirements in regards to waste- disposal and proper recycling.

In particular during installation, repair and maintenance work, water damaging

agents, such as

- lubricating grease and oil,

- hydraulic fluid,

- coolant,

- solvent containing cleaning agents

must not leak into the ground or reach the sewage system.

These materials must be stored, transported, contained and disposed of in

suitable containers!

Storage

Unused machines and machine tools should be kept in a dry, closed room. Keep them free from

damaging influences such as damp, frost or large temperature fluctuations as well as mechanical

damage

Disposal

Worn/ defect machine tools must be disposed of according to regional/ national specifications.

Fully disassemble machine for the necessary disposal.

Separate materials according to local environmental specifications.

Properly dispose lubricating, cooling or cleaning agents, which are harmful to the environment, in

order to avoid environmental contamination.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 33

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 32 of 34

Maintenance of Pneumatic Tools

Only proper maintenance can

ensure constant performance,

reduction in wear and thus, a

decrease in operating costs and an

increase in service life.

Our pneumatic tools are equipped

for an operating pressure of 6 bar.

A regulator setting for an operating

pressure of 4 bar is possible as well

as expedient for grinding machines

with a built-in regulator so as to

take full advantage of the speed

prescribed for the corresponding

grinding wheels.

Pneumatic tools should not run

empty, because this results in heat

and higher wear. The compressed

air

should be clean and dry. This is

guaranteed by a proper pneumatic

system. Blow through the

pneumatic hose before connecting

it. For the economical use of

pneumatic tools. The prescribed air

quantities are necessary, i. e. , the

line, armatures and hoses must

have the required cross sections so

that the flow pressure remains

constant. Proper lubrication is a

must; for this reason, our

pneumatic tools usually have builtin oilers. Which are located

between the inlet valve and the

motor, and which function in any

position. In smaller and lighter hand

tools, these oilers must often be left

out, because the machines would

then be too heavy and not

easy to manage. In such cases,

lubrication must be carried out by

service units or by manual hose

oilers. We recommend service units

for permanently installed

workplaces (see accessories list).

However, where longer hose lines

are necessary. line oilers built into

the hose lines are more effective.

The distance between the tool and

oiler should not be more than 5 m.

Most of pneumatic tools have

located at the connection a lined-up

screen, which is to be regularly

checked and cleaned.

After ending a working task, the

machines are to be flushed with a

thin oil, or protected some other

way against corrosion.

Visible grease nipples ar provided

for regular lubrication of the gears

with a grease gun. Note the

following for grease lubrication:

Every 60 hours of operation check

striking mechanism, friction

bearings and antifriction bearings; if

necessary, grease them. Every 300

hours of operation grease the gears

and antifriction bearings anew.

In the case of impact wrenches,

use a grease gun to grease the

anvil guide before beginning daily

work or every 6 to 8 hours.

All inner parts must be lubricated

before storing for longer periods of

time in order to prevent rusting.

It is recommended to check the vanes and

bearings at regular intervals.

Store pneumatic tools in dry rooms only.

Lubricating oils to be used:

Generally SAE 5 W to SAE 10

For gearless impact wrenches and small

grinders, only SAE 5 W.

For damp compressed air, oils are to be

used that take up water

( without losing the lubricating effect) and

that contain anticorrosive additives. At

lower temperatures (especially for work

outside) it may be necessary to use an

antifreeze lubricant (e.g. Kilfrost, BP

Energol AX 10, Kompranol N 74).

For saw-chain lubrication on chain saws:

Machine oil with adhesive additive,

viscosity c ST 49-55’

(6.5-7.5 E)/ 50°C

Greases ( free of resins and acids) Multi-purpose greases for

antifriction and friction bearings

Special greases for high-speed miter gears

Designation in accordance with DIN

51502

Consistency class (DIN 51818)

Saponification type

Dripping point

Worked penetration

Temperature range

K L 2 k

2

Lithium

185 °C

265 to 295

-25°C to + 125°C

G 000 h

00

Sodium

145°C

400 to 410

-25°C to + 100°C

Before starting:

Check correct oiler

setting!

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 34

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 33 of 34

Oiler Types Used

on or with Our Tools

Oiler to mount on the machine or connect in the

hose line

Setting the oiler: The adjustment screw item 2 is visible

after removing the screw plug item 3. Theoil supply is

decreased by tightening the screw, and by loosening

the screw, more oil gets into the machine. In most

cases it is sufficient to tighten or loosen the screw by

¼ or ½ of a turn. When plugged, clean borehole

(dia. 2 mm) with wire.

Correct setting; When under pressure and with the

filler screw (item 4) open, the oil must bubble slightly.

The fillint lasts for approx. 8 operating hours.

Line oiler

For stationary pneumatic machines and motors, the

lubrication is carried out by lined-up oilers for

horizontal or vertical installation.

Setting of oilers: Shut off air supply. Open plug item 3.

Loosen visible lock nut item 5 with a socket wrench.

Using a screw driver turn back the tightened screw

plug item 4 by ¼ to ½ of a turn and then lock again.

No oil is to get into the borehole “a” when filling. Close

plug item 3 and open the air supply.

Correct setting: A piece of paper held for a short time

in front of the outlet must be coated with oil without

drops forming.

Transparent oiler

For installing in permanently equipped workplaces

(especially for type using service units – see

accessories list)

The transparent supply containers allow for good

checking as well as for good setting possibility by

means of a screw driver via a set screw with visible

dripping. (The set screw is above the lateral thread

connection – turning to the right for less oil; turning to

the left for more oil) The setting (2 to 5 drops per

m³/min air consumption) is to be carried out when air is

flowing through, i.e., when the machine is running.

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 35

P n e u m a t i c C h a i n S a w

5 1 0 26 – 5 1 0 2 9

51026_51029_BA_en_Version_05

Page 34 of 34

D e c l a r a t i o n o f C o n f o r m i t y

as defined in the European Union Machine Directive 2006/42/EC and in the

EU-ATEX-Directive 2014/34/EU for usable machines

We, the company

SPITZNAS Maschinenfabrik GmbH, Fellerstraße 4, 42555 Velbert– Langenberg,

declare that the following product

Description: Pneumatic Chain Saw

Model 5 1026

5 1027

5 1028

5 1029 *

in the version supplied by us, complies with the European Union Machine Directive

2006/42/EC and the EU-Directive 2014/34/EU (ATEX – group II, category 2, G c T 5

respectively *group I, category M2, c T 5).

Applied harmonized norms are:

DIN EN ISO 12100

DIN EN ISO 11681-1

DIN EN 1127-1

DIN EN 1127-2

DIN EN 13463-1

DIN EN 13463-5

The EC type approval test was done by:

DPLF

Deutsche Prüf- und Zertifizierungsstelle

für Land- und Forsttechnik GbR

Spremberger Straße 1

D-64823 Groß-Umstadt

EC type approval no.: K-EG 2011/6024

According to section 13 (1) ii) of the Directive 2014/34/EU the technical documentation is

deposited under reference no. 557/ Ex- Ab 1700/11 at the following office:

TÜV Rheinland Industrie Service GmbH

Moltkeplatz 1, 45138 Essen

(Registration No. 0035

for the scope of

the Directive 2014/34/EU)

Name of the authorized person for documentation: Mr. Simon Witt

Address of the authorized person for documentation: see manufacturer’s address

42555 Velbert, 20.04.2016

CS Unitec, Inc. • Toll-free: 800-700-5919 • Ph: 1-203-853-9522 • Email: info@csunitec.com • www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Page 36

51026_51029_BA_en_Version_05

22 Harbor Ave, Norwalk, CT 06850 USA

Toll-free: 1-800-700-5919 (USA & Canada)

Phone: 203-853-9522 (outside USA & Canada)

Fax: 203-853-9921

E-Mail:

info@csunitec.com Internet:

www.csunitec.com

Translation of the original manual

compiled: 20.04.16

Loading...

Loading...