Page 1

Pneumatic

Drill

Types 2 1310 0010

2 1310 0020

2 1311 0010

Techn. Doc.-No. 207

Illustration can differ from the original

Operation and

Maintenance Manual

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 1 of 20

Page 2

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

TECHNICAL SPECIFICATION

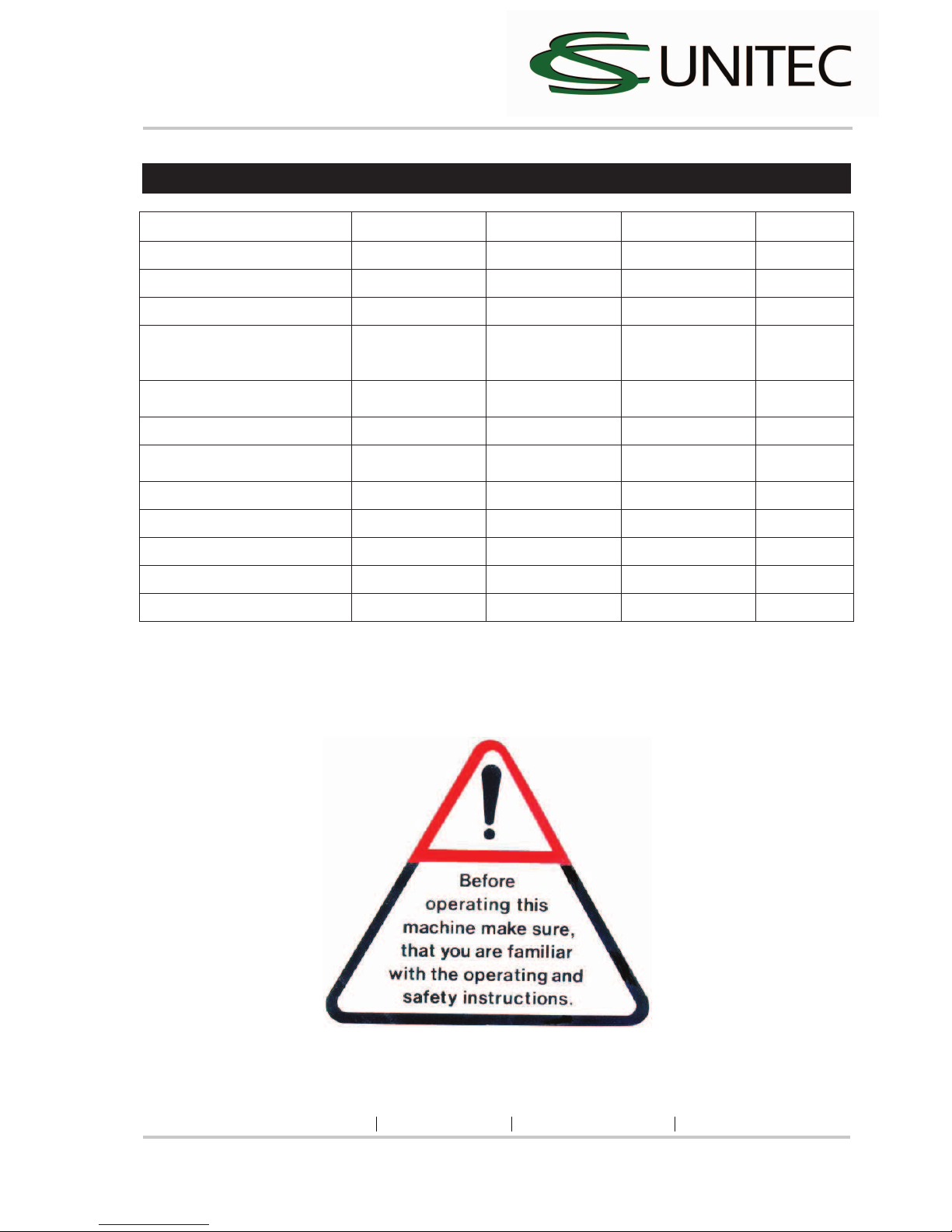

Type No. 2 1310 0010 2 1310 0020 2 1311 0010

Operating/Flow pressure 6 6 6 bar

Motor power 0.65 0.65 0.65 kW

Speed under load 650 650 650 rpm

Drill chuck

Geared chuck

dia. 13

Quick-release

chuck dia. 13

TP 1 mm

Drilling capacity in steel max. 15 max. 13 max. 15 mm

Air connection R 3/8“ R 3/8“ R 3/8“ female

mm 31 31 31 esoh fo DI

Air consumption 0.68 0.68 0.68 m³/min.

sgk 4.5 7.5 7.5 thgieW

Length with drill chuck 314 314 281 mm

Noise (1m distance) 88.8 88.8 88.8 dB(A)

Vibration at free speed 2.23 2.23 2.23 m/s²

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 2 of 20

Page 3

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Operating Instruction

Handling and proceeding are described here

Spare Parts Documentation

Consisting of parts lists and sectional drawings.

Supplement

Maintenance of pneumatic tools

Notes for oiler setting

OPERATING INSTRUCTIONS

General

The performance / output power of this machine are designed for drilling of different work pieces

and materials. Hold the machine tight against rotation.

Before Operation

% Check the oil level. If necessary, add oil to fill up the oiler (line oiler or service unit).

% Clamp the drill into three-jaw chuck or into morse taper.

% Connect air hose. (In order to remove contaminents, blow out the air hose before connecting).

% Open the valve and begin the

drilling. (Speed can be regulated by opening the valve more or

less).

After finishing the operation

% Shut the valve

% Turn off compressed air and disconnect the air hose.

% Loosen the drill and pull it out.

% Check oiler.

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 3 of 20

Page 4

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

SAFETY INSTRUCTIONS

Any tool can be dangerous. Please follow these simple safety

procedures - they are for your personal protection.

% Do not use this machine in any way other than as directed by these operating instructions.

% Hold the machine tight during operation. When operating with the hammer drill also use the

second handle.

% Regular maintenance is essential - check all screws, fittings etc. for tightness.

% Check the air hose for damage.

% Use only lubricated air during work.

% Never use dull tools or bits.

% Avoid sparks in hazardous environment - created by the drill. In this case flush material and

drill always with sufficient water for cooling during use.

% Wear safety-glasses, non-slip gloves, protective clothing and ear protectors.

% Ensure that you maintain a safe working position.

% Never work under the influence of alcohol, drugs or strong medication.

% Always disconnect machine from the air line for changing drills or working on the machine.

% Remove rings, watches, ties etc. that could be torn by the machine.

% Follow the general current and appropriate Accident Prevention and Safety Procedures.

WARNING! Never use the flexible hose as a lifting handle.

Your safety is in your hand!

Observe these instructions!

Noise and vibration levels

Typically A-weighted noise level of the machine is:

% Sound pressure level: 88.8 dB(A)

Wear ear protection.

The typical weighted acceleration is 2.23 m/s2.

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 4 of 20

Page 5

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

ESU

Intended use

The machine is designed for drilling of different work pieces and materials.

Any use, deviating from the above is not intended use.

Improper use

Drive for lifting goods or people.

Working without individual safety equipment

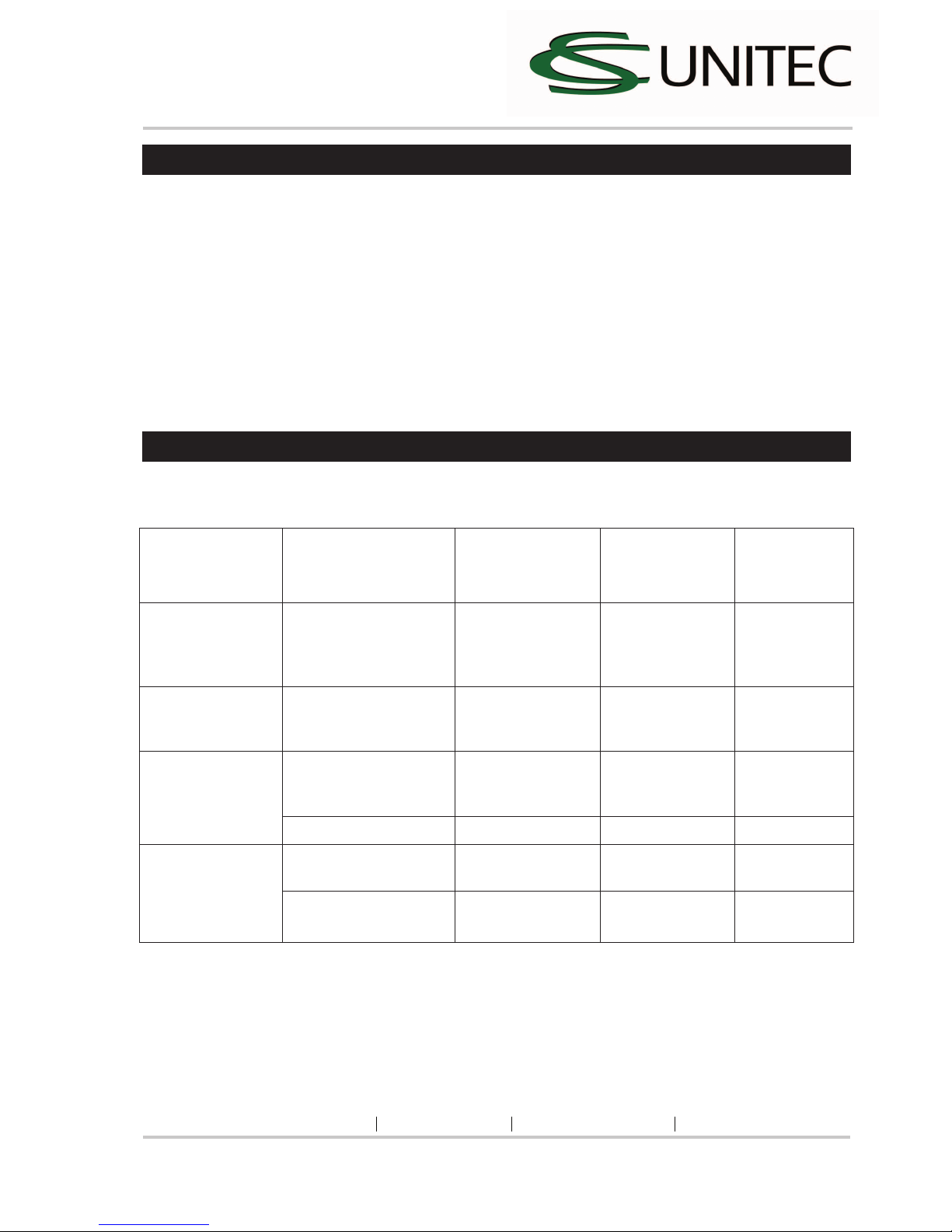

DANGER ZONES

Operational

condition

Normal function Malfunctioning improper use

Expected use

Life phase

Transport

Transport of the

machine in an

inoperable condition

Drop of the

machine

Transport of the

machine in an

operable

condition

unknown

Start-up

Operating with the

machine with

desginated tools

unknown Operating with

approved tools

unknown

Operation

Machine is only

working when valve is

actuated

Machine runs

without intended

actuating

Valve is blocked

while open

unknown

Machine moves tool Tool blocks unknown unknown

Maintenance

Regular change of

vanes

Operation on a

Service Unit

Failure of the

machine

unknown unknown

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 5 of 20

Page 6

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

MAINTENANCE AND ASSEMBLY INSTRUCTIONS

The service life and the performance of the motor are decisively determined by:

a) The air purity

b) The lubrication conditions and maintenance

at a):

Blow out the air hose before connecting it to the machine. Install dirt and water separator

upstream of the motor, if it is not possible to prevent the formation of rust and water

condensation in the air distribution lines.

at b):

Use only resin- and acid-free lubricating oils SAE 5 W - SAE 10 W. Oils of higher viscosity

cause vane sticking (difficult start-up and lower performance). Optimal lubrication will increase

the service life. We thus particularly recommend installing a service unit and line oiler upstream

of the motor. Observe the comments in the supplement

„Maintenance of Pneumatic Tools “

Do not wash out sealed and greased ball bearings and do not rinse the machine in general with

petroleum or similar cleaning fluids.

Use anti-freeze lubricants, such as „BP-Energol AX 10", „Kilfrost" or „Kompranol N 74“ in

wintertime or if the compressed air is very moist.

Air connection:

Line, fitting and hose must have the required cross-section to obtain sufficient air (680 litres/min.)

Regularly check and clean the air inlet screen (at item 26).

Operating pressure may

not exceed 6 bar, otherwise the machine will be damaged.

Cleaning the motor:

Rinse the motor with cleansing oil after approx. 10 working hours. Cleansing and oil-ampule (Part

No. 9 9902 0100). Fill the oil into the air connection. Connect air and start the motor (approx. 20

seconds at free speed).

Wear of vanes:

Vanes are main wear parts and are recommended to be replaced in due time. The wear can be

noticed, when the performance decreases clearly (>100 hours operating time by regular

lubrication). They ar

e considered to be worn when the height "H" is less than 11 mm.

new 14

replace < 11

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 6 of 20

Page 7

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Greases (free of resins and acids) Multi-purpose greases for antifriction

bearings and gears

k 2 LK 205215 NID ot gnidrocca noitanigseD

Consistency class DIN 51818 2

Saponification type lithium

Dripping point 185° C

Worked penetration 265 - 295

Temperature range -25°C to +125°C

DEMONTAGE UND MONTAGE

Disassembly

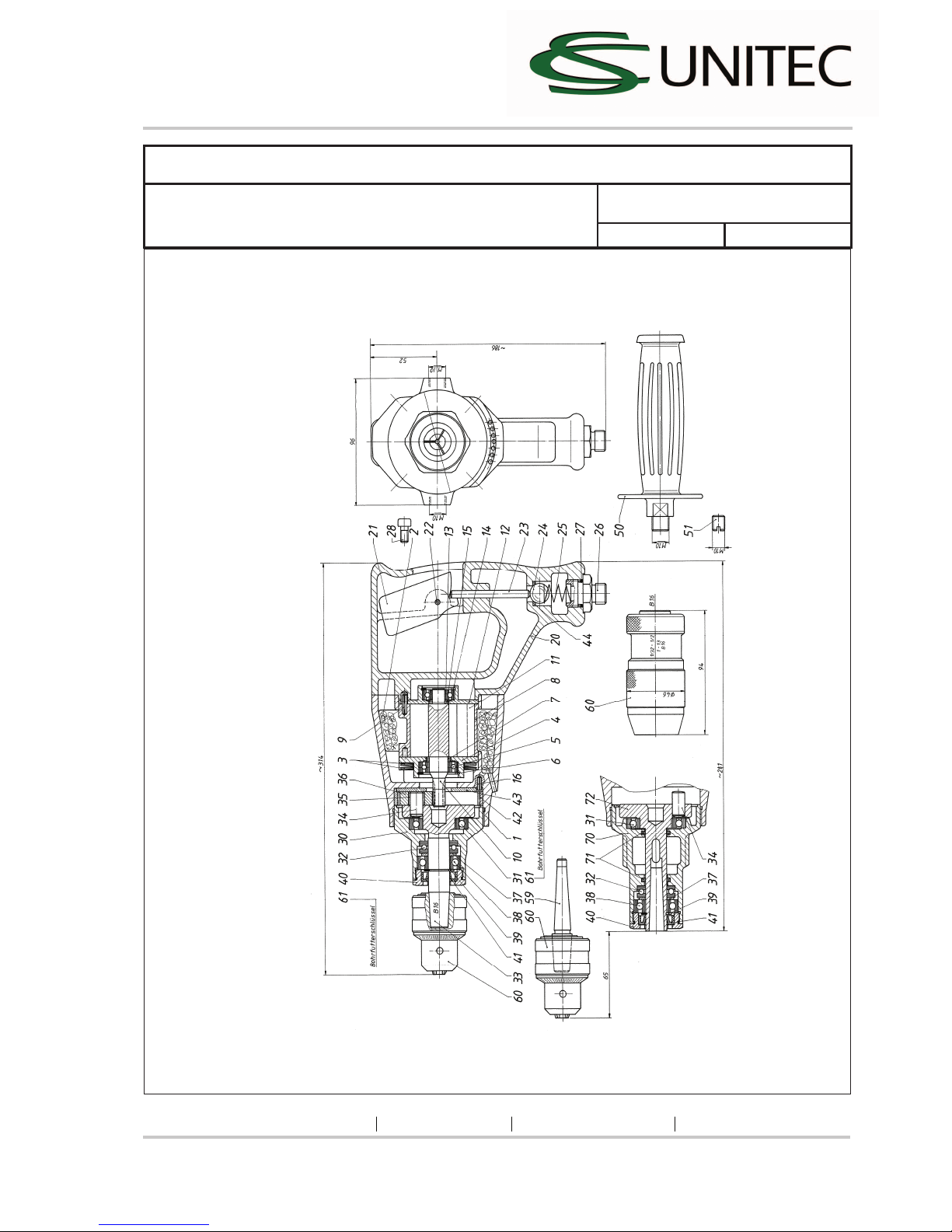

Disassembly and reassembly should only be performed with the assistance of the sectional

drawing.

All parts can be dismantled by light pushing or knocking (wooden base / rubber hammer).

Motor

Loosen screws (item 28), remove handle (item 20), pull out inner motor parts and dismantle. Check

wear parts - especially the vanes (item 11).

Valve

Screw out nipple (item 26) and take out valve parts. Replace worn parts if necessary.

Gearbox

Screw neck (item30 or item 70) out of motor housing. (Attention! Left-hand thread). Remove rim of

the gear (item 42) and washer (item 43). Draw off drill chuck (item 60). Loosen cover lid (item 40),

remove snap ring (item 39) and press out complete planet carrier (item 33 or item 72). Check

wear parts as radial shaft seals (item 41) and ball bearings and replace if necessary.

Assembly hints

Repairs should be executed by authorized professionals only and with assistance of the sectional

drawing.

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 7 of 20

Page 8

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Reassembly

Perform reassembly after checking and replacing worn parts. It will be done basically in the reverse

order than the disassembly. Lightly grease all parts to avoid falling apart during reassembly.

Remove any oil and resin residue from the rotor slots. The vanes should fit easily into the rotor

slots.

Motor running

If the motor cannot be turned after reassembly, light axial or lateral tapping with a rubber hammer

on motor housing is helpful. The rotor places and comes into free-wheel position between the end

plates. If not, check length of the rotor, cylinder bushing and vanes.

a. The vanes must not jut out laterally of the rotor slots and not project on the rotor.

b. Cylinder bushing has to be 0.08 mm to 0.10 mm longer than the rotor.

Check all functions after finishing the reassembly, especially free speed and air consumption

according to "Technical Specifications".

Use only original Spitznas Spare Parts for repairs!

Cylinder bushin

g

clearance

clearanc

Vane shorter than rotor

Shorter than cylinder Rotor

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 8 of 20

Page 9

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 9 of 20

Trouble/ Probable Cause/ Remedy

Remedy

Connect and open air line Disassemble and clean motor, check and test

service unit for function

Disassemble motor, clean and replace worn

parts

Disassemble and clean gearbox and replace

worn parts

clean s

eat

Increase operating pressure to 6 bar (on the

machine)

Disassemble and clean motor, replace worn

parts

Disassemble and clean gearbox, replace worn

parts

Dissassemble and clean motor, replace worn

parts

Disassemble and clean motor, replace worn

parts

Disassemble and clean motor, replace worn

parts

Disassemble and clean gearbox, replace worn

parts

Change drill chuck use bigger tool

Clean machine Disassemble gearbox and replace defective

parts

Probable cause

Air not connected Rotor rusted by humid

Vanes jam (worn)

Gearbox blocks

Contaminates in valve

Operating pressure too low Rotor grinds on end plates / cylinder bushing

Gear parts jam Vanes worn or broken, broken parts stick between rotor

and cylinder bushing

No lubrication - ball bearings have run dry, rotor has

rubbed on end plates

Coarse impurities in motor area jam between rotor and

cylinder bushing

Toothing is clattering Ball bearings defective

Drill chuck defective Diameter of tool too small

Dirt in reversing area Steel rollers clamp

Trouble

Machine does not start

Trigger clamps Machine rotates too slowly

Motor sticks / jams

Gearbox makes loud noises

Tool not able to be clamped

Reversing „drilling / hammering “ clamps

Page 10

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

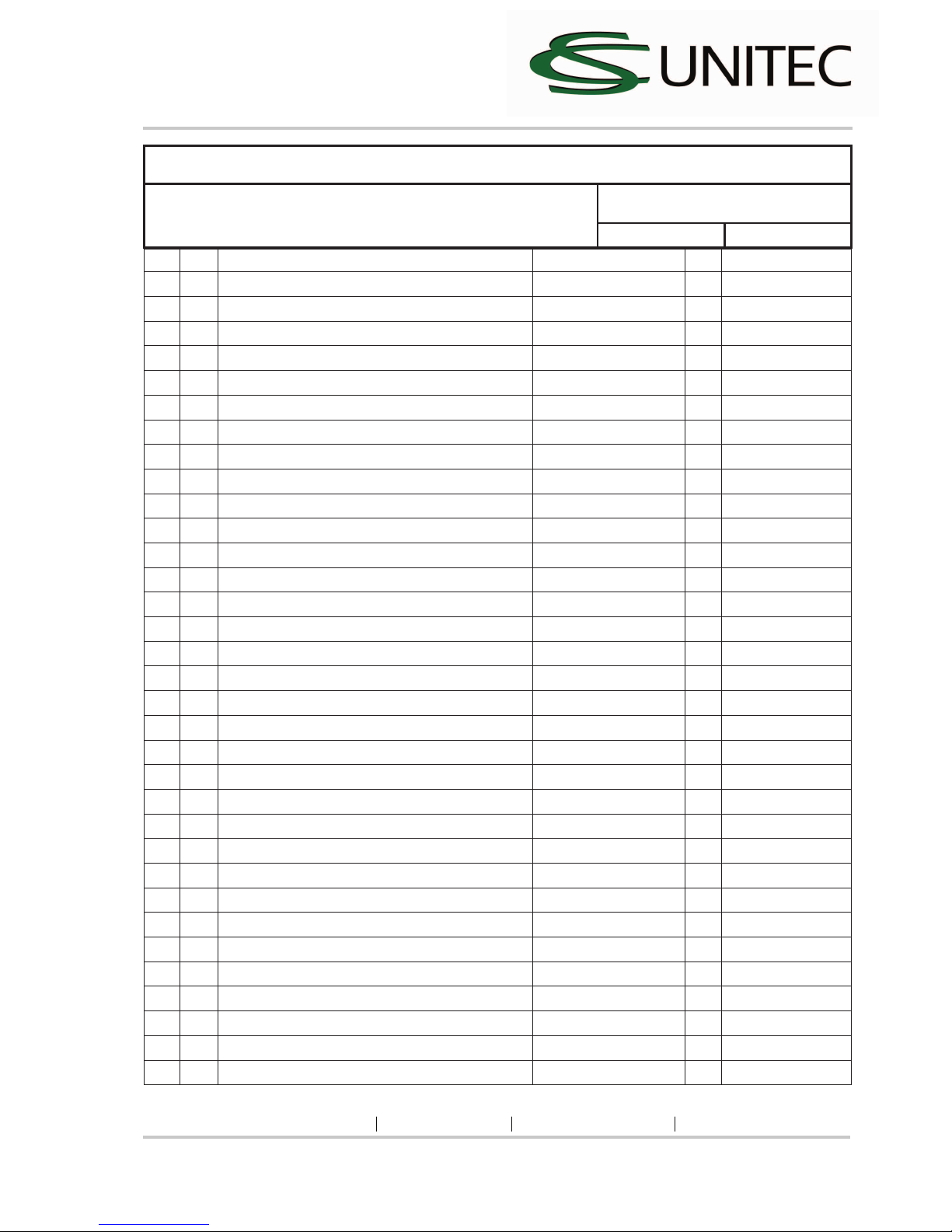

Spare Parts List

Description: Part and drawing number

Pneumatic

Drill

2 1310 0010

Page no.: 1/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

1 1

Motor housing

2 1311 1010

2 2

Damping material

1 2034 6100

3 2

Belleville spring

9 1802 0260

4 1

End plate

7 1401 1100

5 1

Grooved ball bearing

9 1003 0030

6 1

Snap ring

9 1703 0100

7 1

Spacer

1 1501 1090

8 1

Cylinder bushing

1 1379 1020

9 1

Adapter sleeve

9 1630 0510

10 1

Rotor

2 1311 1030

11 6

Vane

2 1310 1050

12 1

End plate

2 1310 1110

13 1

Grooved ball bearing

9 1003 0010

14 1

Snap ring

9 1703 0050

15 1

Spacer

2 1301 1090

16 2

Adapter sleeve

9 1630 0140

20 1

Handle

2 1310 6010

21 1

Valve pusher

2 1311 3040

22 1

Double notched pin

9 1641 0020

23 1

Cylindrical pin

9 1619 1360

24 1

Ball

9 1017 0080

25 1

Compression spring

9 1803 0250

26 1

Nipple

9 2205 1190

27 1

O-Ring

9 1901 3230

28 4

Fillister-head screw

9 1110 4010

30 1

Neck

2 1301 7010

31 1

Grooved ball bearing

9 1002 0040

32 1

Journal bearing

9 1021 0040

33 1

Planet carrier

2 1310 4910 With item 34

34 3

Cylindrical pin

9 1631 0170

35 3

Needle cage

9 1015 0110

36 3

Planetary wheel

2 1301 4040

37 2

Fitting washer

9 3331 0230

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 10 of 20

Page 11

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1310 0010

Page no.: 2/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

38 1

Grooved ball bearing

9 1003 0040

39 1

Snap ring

9 1702 0100

40 1

Cover lid

2 1311 4100

41 1

Radial shaft seal

9 1905 0020

42 1

Rim of the gear

2 1301 4020

43 1

Washer

2 1311 4080

50 1

Handle

2 1312 6010

60 1

Drill chuck

9 2901 0120

61 1

Spanner for drill chuck

9 1419 0030

44 1

Seal

9 1903 0160

51 1

Hexagon screw

9 1107 6140

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 11 of 20

Page 12

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1310 0010

Page no.: 3/3 Date: 03/08

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 12 of 20

Page 13

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number

Pneumatic

Drill

2 1310 0020

Page no.: 1/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

1 1

Motor housing

2 1311 1010

2 2

Damping material

1 2034 6100

3 2

Belleville spring

9 1802 0260

4 1

End plate

7 1401 1100

5 1

Grooved ball bearing

9 1003 0030

6 1

Snap ring

9 1703 0100

7 1

Spacer

1 1501 1090

8 1

Cylinder bushing

1 1379 1020

9 1

Adapter sleeve

9 1630 0510

10 1

Rotor

2 1311 1030

11 6

Vane

2 1310 1050

12 1

End plate

2 1310 1110

13 1

Grooved ball bearing

9 1003 0010

14 1

Snap ring

9 1703 0050

15 1

Spacer

2 1301 1090

16 2

Adapter sleeve

9 1630 0140

20 1

Handle

2 1310 6010

21 1

Valve pusher

2 1311 3040

22 1

Double notched pin

9 1641 0020

23 1

Cylindrical pin

9 1619 1360

24 1

Ball

9 1017 0080

25 1

Compression spring

9 1803 0250

26 1

Nipple

9 2205 1190

27 1

O-Ring

9 1901 3230

28 4

Fillister-head screw

9 1110 4010

30 1

Neck

2 1301 7010

31 1

Grooved ball bearing

9 1002 0040

32 1

Journal bearing

9 1021 0040

33 1

Planet carrier

2 1310 4910 With item 34

34 3

Cylindrical pin

9 1631 0170

35 3

Needle cage

9 1015 0110

36 3

Planetary wheel

2 1301 4040

37 2

Fitting washer

9 3331 0230

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 13 of 20

Page 14

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1310 0020

Page no.: 2/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

38 1

Grooved ball bearing

9 1003 0040

39 1

Snap ring

9 1702 0100

40 1

Cover lid

2 1311 4100

41 1

Radial shaft seal

9 1905 0020

42 1

Rim of the gear

2 1301 4020

43 1

Washer

2 1311 4080

50 1

Handle

2 1312 6010

60 1

Quick release drill chuck

9 2902 0040

44 1

Seal

9 1903 0160

51 1

Hexagon screw

9 1107 6140

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 14 of 20

Page 15

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1310 0020

Page no.: 3/3 Date: 03/08

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 15 of 20

Page 16

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number

Pneumatic

Drill

2 1311 0010

Page no.: 1/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

1 1 Motor housing 2 1311 1010

2 2 Damping material 1 2034 6100

3 2 Belleville spring 9 1802 0260

4 1 End plate 7 1401 1100

5 1 Grooved ball bearing 9 1003 0030

6 1 Snap ring 9 1703 0100

7 1 Spacer 1 1501 1090

8 1 Cylinder bushing 1 1379 1020

9 1 Adapter sleeve 9 1630 0510

10 1 Rotor 2 1311 1030

11 6 Vane 2 1310 1050

12 1 End plate 2 1310 1110

13 1 Grooved ball bearing 9 1003 0010

14 1 Snap ring 9 1703 0050

15 1 Spacer 2 1301 1090

16 2 Adapter sleeve 9 1630 0140

20 1 Handle 2 1310 6010

21 1 Valve pusher 2 1311 3040

22 1 Double notched pin 9 1641 0020

23 1 Cylindrical pin 9 1619 1360

24 1 Ball 9 1017 0080

25 1 Compression spring 9 1803 0250

26 1 Nipple 9 2205 1190

27 1 O-Ring 9 1901 3230

28 4 Fillister-head screw 9 1110 4010

70 1 Neck, Assy. 2 1302 7910

71 2 Felt ring 9 1902 0090

31 1 Grooved ball bearing 9 1002 0040

32 1 Journal bearing 9 1021 0040 With item 34

72 1 Planet carrier 2 1311 4910

0710 1361 9 denedrah ,nip lacirdnilyC 3 43

35 3 Needle cage 9 1015 0110

36 3 Planetary wheel 2 1301 4040

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 16 of 20

Page 17

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1311 0010

Page no.: 2/3 Date: 03/08

Item skrameR .on gniward dna traP noitpircseD .ytQ

37 2 Fitting washer 9 3331 0230

38 1 Grooved ball bearing 9 1003 0040

39 1 Snap ring 9 1702 0100

40 1 Cover lid 2 1311 4100

41 1 Radial shaft seal 9 1905 0020

42 1 Rim of the gear 2 1301 4020

43 1 Washer 2 1311 4080

50 1 Handle 2 1312 6010

44 1 Seal 9 1903 0160

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 17 of 20

Page 18

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

Spare Parts List

Description: Part and drawing number:

Pneumatic

Drill

2 1311 0010

Page no.: 3/3 Date: 03/08

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 18 of 20

Page 19

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 19 of 20

Page 20

Pneumatic

Drill

2 1310 0010-0020, 2 1311 0010

ne_010011312_02_010001312 80.30.52 :delipmoC

CS Unitec, Inc 22 Harbor Ave USANorwalk, CT 06850

Phone: (203) 853 9522 Fax: (203) 853 9921 info@csunitec.com

Page 20 of 20

Loading...

Loading...