Page 1

®

USE AND CARE GUIDE

COMBO® MODELS

REFRIGERATOR / FREEZER MODELS

CO2175FF

CO29

2175RF

C2275DWR

The Built-In Undercounter Leader Since 1962

U-LINE.COM

Page 2

FOR PRODUCT ASSISTANCE, CALL 1-800-779-2547

MILWAUKEE, WI U.S.A.

Serial/Serie:Model/Modele:

HIGH SIDE DESIGN PRESSURE 300 PSI

LOW SIDE DESIGN PRESSURE 140 PSI

REFRIGERATOR AND/

BTL

LISTED 674R

OR FREEZER

HOUSEHOLD

U

C

L

R

US

www.u-line.com

1

2

Introduction

IMPORTANTIMPORTANT

Congratulations on your purchase of a U-Line refrigeration

product.

Building on 45 years, U-Line has captivated those with an

appreciation for the finer things with exceptional design, inspired

innovations and attention to even the smallest details.

U-Line is synonymous with premium built-in under counter ice

making, refrigeration and wine storage appliances, the U-Line

Corporation is committed to luxury under the counter. U-Line is

known and respected for unwavering dedication to product

innovation, quality and selection. A bold and broad line of models

is the product of visionaries in the pursuit of distinctive living

environments in the kitchen and spaces beyond.

In 1962, Henry Uihlein founded U-Line Corporation as an

outgrowth of Ben-Hur Freezer Company and was the first to

develop and patent an automatic stand-alone under counter

residential ice maker. His foresight and determination to develop

new ideas and to succeed when there were no clear guidelines or

solutions are evident today. The Milwaukee, Wisconsin based

family operated business provides continuity and vision from which

innovations continue to be born.

Going forward, U-Line will continue offering best-in-class products

that build on the company's numerous patents and world firsts to

guide the under counter industry in realizing its unlimited

potential.

Read and save this Use and Care Guide.

Please Record Your Model Information

You will need your product model and serial number when you

request additional information or services. You can find this

information on the serial plate located on the upper right or back

wall in the interior of your product. This information also appears

on the warranty registration card.

Please record the model number (1), serial number (2), date of

purchase, and dealer contact information for your U-Line product

below:

Model Number:

________________________________________________

Serial Number:

________________________________________________

Purchase Date:

READ all instructions in this guide completely before

using the appliance for the first time.

For future reference, keep this guide in a safe, accessible location.

If you need additional information or assistance, please contact ULine Corporation direct. Contact information appears on the back

cover of this guide.

Before Calling Service. If you think your U-Line product is

malfunctioning, read the OPERATION section of this guide to

understand clearly the function of the control. If the problem

persists, read the TROUBLESHOOTING GUIDE section of this

guide to help you quickly identify common problems, and provide

information on possible causes and remedies.

________________________________________________

Dealer Name:

________________________________________________

Dealer Address:

________________________________________________

Dealer Telephone:

________________________________________________

Introduction to U-Line

Page 3

1 Table of Contents

U-Line Combo® Models and Ice Makers

i - Introduction .................................................................................................................................................................i

Read and save this Use and Care Guide. .........................................................................................................i

Please Record Your Model Information ...........................................................................................................i

1 - Table of Contents .....................................................................................................................................................1

2 - Safety Precautions .....................................................................................................................................................3

Safety Alert Definitions ........................................................................................................................................3

General Precautions .............................................................................................................................................3

3 - Product Features .......................................................................................................................................................4

Combo® Model Features: ..................................................................................................................................4

Ice Makers Feature: ..............................................................................................................................................4

4 - Product Operation Touch Control ......................................................................................................................5

Air Flow ...................................................................................................................................................................5

Electronic Control Panel .....................................................................................................................................5

Adjusting Air Temperature .................................................................................................................................5

Initial Startup ..........................................................................................................................................................5

Checking Product Temperature ........................................................................................................................6

Interior Lighting .....................................................................................................................................................6

Electronic Control Quick Guide .......................................................................................................................7

5 - Product Operation Manual Control .....................................................................................................................8

Air Flow ...................................................................................................................................................................8

Initial Startup ..........................................................................................................................................................8

Control Dial ...........................................................................................................................................................8

Adjusting Air Temperature .................................................................................................................................9

Checking Product Temperature ........................................................................................................................9

6 - Food Storage ........................................................................................................................................................... 10

Drawers ............................................................................................................................................................... 10

Other Models ..................................................................................................................................................... 10

7 - Ice Maker ................................................................................................................................................................. 11

Ice Maker Adjustment ....................................................................................................................................... 11

Ice Maker Operation ......................................................................................................................................... 11

8 - Maintenance ............................................................................................................................................................ 12

Leveling ................................................................................................................................................................. 12

Removing and Installing Interior Shelves ...................................................................................................... 12

Removing and Installing Door Shelves .......................................................................................................... 13

Removing and Installing Grille ......................................................................................................................... 13

9 - Self-Closing Doors ................................................................................................................................................ 15

Door Alignment and Adjustment ................................................................................................................... 15

Door Reversability ............................................................................................................................................. 15

Reversing the door ............................................................................................................................................ 15

10 - Standard Doors .................................................................................................................................................... 17

Door Alignment and Adjustment ................................................................................................................... 17

Door Reversability ............................................................................................................................................. 17

Reversing the door ............................................................................................................................................ 17

11 - Standard Drawers ............................................................................................................................................... 19

Checking Drawer Alignment ........................................................................................................................... 19

Adjusting Drawer Alignment ........................................................................................................................... 19

Re-installation of Drawer ................................................................................................................................. 20

12 - Cleaning ................................................................................................................................................................. 21

Exterior Cleaning ............................................................................................................................................... 21

Interior Cleaning ................................................................................................................................................ 21

Defrosting ....................................................................................................................

Condensor Cleaning .......................................................................................................................................... 22

Storage, Vacation and Moving ......................................................................................................................... 22

Product Disposal ................................................................................................................................................ 22

13 - Service .................................................................................................................................................................... 23

Normal Operating Sounds ............................................................................................................................... 23

Troubleshooting Guide ..................................................................................................................................... 23

Before Calling for Service ................................................................................................................................ 23

If Service is Required ......................................................................................................................................... 23

Replacement Parts ............................................................................................................................................. 23

14 - U-Line Corporation Limited Warranty .......................................................................................................... 25

........................................ 21

U-Line Use and Care Table of Contents 1

Page 4

2 U-Line Use and Care Guide

Page 5

IMPORTANTIMPORTANT

DANGER

WARNING

CAUTION

2 Safety Precautions

DANGER

WARNING

WARNING

CAUTION

IMPORTANTIMPORTANT

• PLEASE READ all instructions before installing,

operating, or servicing the appliance.

General Precautions

Use this appliance for its intended purpose only and follow these

general precautions with those listed throughout this guide:

• Proper installation procedures must be followed when

completing an installation or relocation of a unit.

Consult the installation guide before any installation

begins. U-Line contact information appears on the rear

cover of this guide.

• This unit requires connection to a dedicated 15 Amp

grounded (three-prong), polarized receptacle, installed

by a qualified electrician, compliant with applicable

electrical codes.

Safety Alert Definitions

Throughout this guide are safety items labeled with a Danger,

Warning or Caution based on the risk type:

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take off the doors and leave shelves

in place so children may not easily climb inside.

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance on

the unit until the electricity has been disconnected.

• Never remove the round grounding prong from the

plug and never use a two-prong grounding adaptor.

• Altering, cutting of power cord, removal of power

cord, removal of power plug, or direct wiring can

cause serious injury, fire and or loss of property and

or life, and will void the warranty.

• Never use an extension cord to connect power to the

unit.

• Always keep your working area dry.

Install provided Anti-Tip kit on all Wine Captain

Models and Beverage Centers. Serious personal injury

could occur.

Warning means that failure to follow this safety

statement could result in serious personal injury,

property or equipment damage.

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property

or equipment damage.

• Use care when moving and handling the unit. Use gloves

to prevent personal injury from sharp edges.

• If your model requires defrosting, DO NOT use an ice

pick or other sharp instrument to help speed up

defrosting. These instruments can puncture the inner

lining or damage the cooling unit. DO NOT use any type

of heater to defrost. Using a heater to speed up

defrosting can cause personal injury and damage to the

inner lining.

• Do not lift unit by door handle.

• Never install or operate the unit behind closed doors.

Be sure front grille is free of obstruction. Obstructing

free airflow can cause the unit to malfunction and will

void the warranty.

• Failure to clean the condenser every six months can

cause the unit to malfunction. This could void the

warranty.

• Allow unit temperature to stabilize for 24 hours before

use.

• Do not Block any internal Fans

Use only genuine U-Line replacement parts. Imitation

parts can damage the unit, affect its operation or

performance and may void the warranty.

U-Line Safety Precautions 3

Page 6

3 Product Features

®

Combo® Model Features:

Built in. Provides custom look. No additional clearance around

sides, top or rear of unit needed for ventilation.

Built-in or freestanding. Provides custom look when built-in

with no additional venting clearance needed on sides, top or rear.

Do not obstruct the grille.

Ice making and refrigeration in one unit. Provides both ice

production and refrigeration in one compact unit

CO2175FF & C2275DWR

Touch Sensitive Digital Controls. Provides ability to set and

see the temperature. Manages key model functions and provides

user alerts

Sabbath or “Black Out” mode. Easily turn off all lights and

control display

Contemporary grille design. Integrates seemlessly into

surrounding cabinetry.

Stainless Steel Models. Offers a bold full wrap stainless steel

door

Overlay Model. The C2275DWR includes full overlay drawer

capability. Provides a fully integrated appearance with surrounding

décor.

Ice Makers Feature:

High ice production and storage. Combo® Models provide

both ice production and refrigeration in one compact unit.

CO2175FF and CO29FF models produce up to 8 pounds of ice

per day and store 13 pounds. C2275DWR models produce up to 6

pounds of ice per day and store 10 pounds. C2275DWR has 3

cubic feet while the CO2175FF has 4.2 cubic feet and the CO29FF

has 2.1 cubic feet of refrigeration storage.

No drain required. Easy and inexpensive to install. Only requires

a 1/4" outside diameter water line.

Conserves on water. Uses under 3 gallons of water to produce

22 pounds of ice or 2-1/4 gallons for 18 pounds.

Vinyl clad cabinets. Black vinyl cabinet on all models provides a

rich textured look

Leveling Legs. More precise under counter fit, durable, factory

installed.

Recessed interior lights. Automatically illuminate when the

door is opened.

CO29FF

Two Tempered glass shelves. Generous amount of shelf space,

Easy to clean.

In door storage. 3 shelves provide easy access

Flat recessed grille. Blends with and integrates with surrounding

cabinetry.

4 U-Line Combo Model and Ice Maker Product Features

Page 7

123 54

4 Product Operation Touch Control

IMPORTANTIMPORTANT

IMPORTANTIMPORTANT

IMPORTANTIMPORTANT

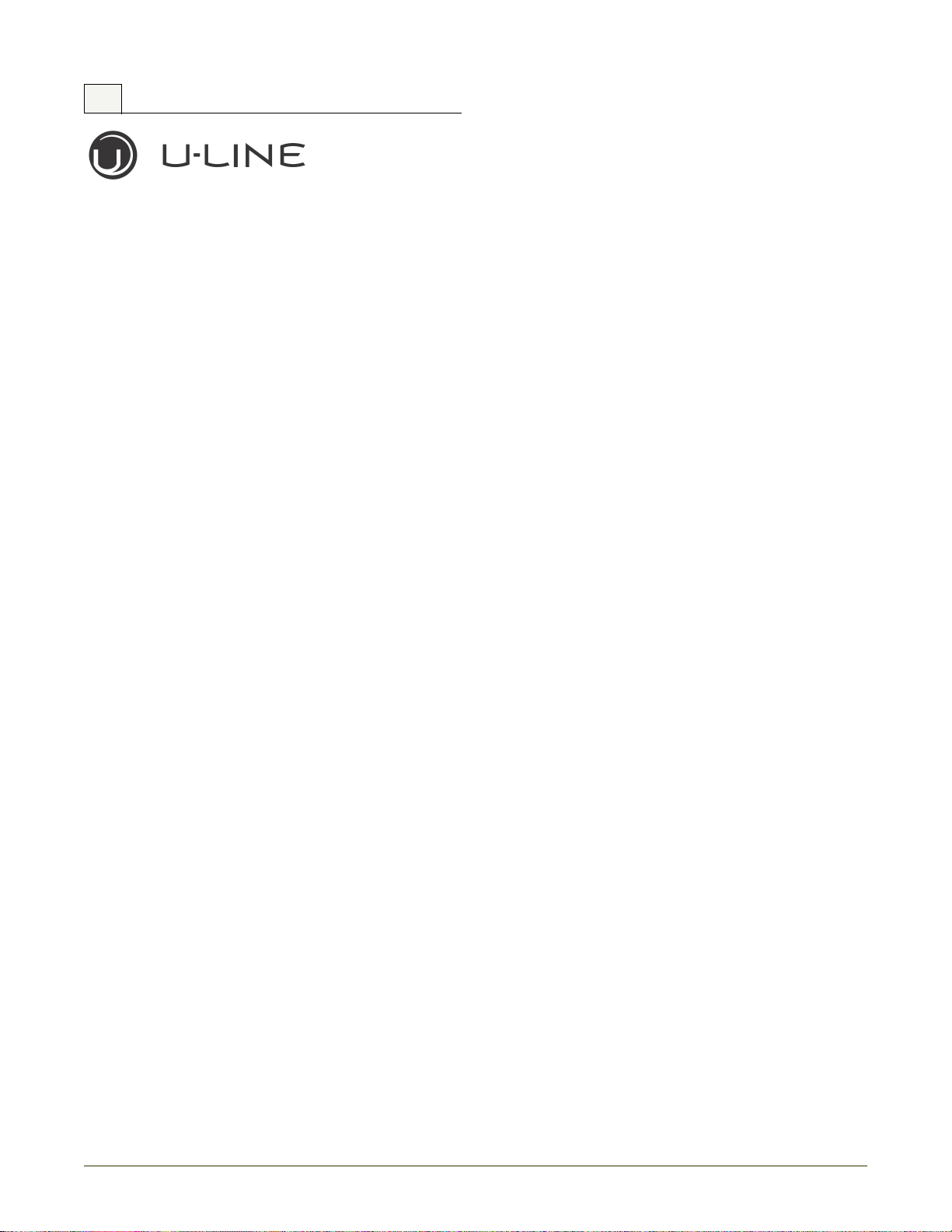

Air Flow

The unit requires proper air flow to perform at its highest

efficiency. Do not block the front grille or internal fans at

any time, or the unit will not perform as expected. Do not

install the unit behind a door.

Initial Startup

All U-Line controls are preset at the factory. Initial startup requires

no adjustments.

U-Line recommends allowing the unit to run overnight

before loading refrigerator or freezer with product.

To turn the unit on or off, press and hold the POWER icon (1) for

about ten seconds and release. The display will show the unit setpoint temperature when turned on and display OFF when the unit

is off.

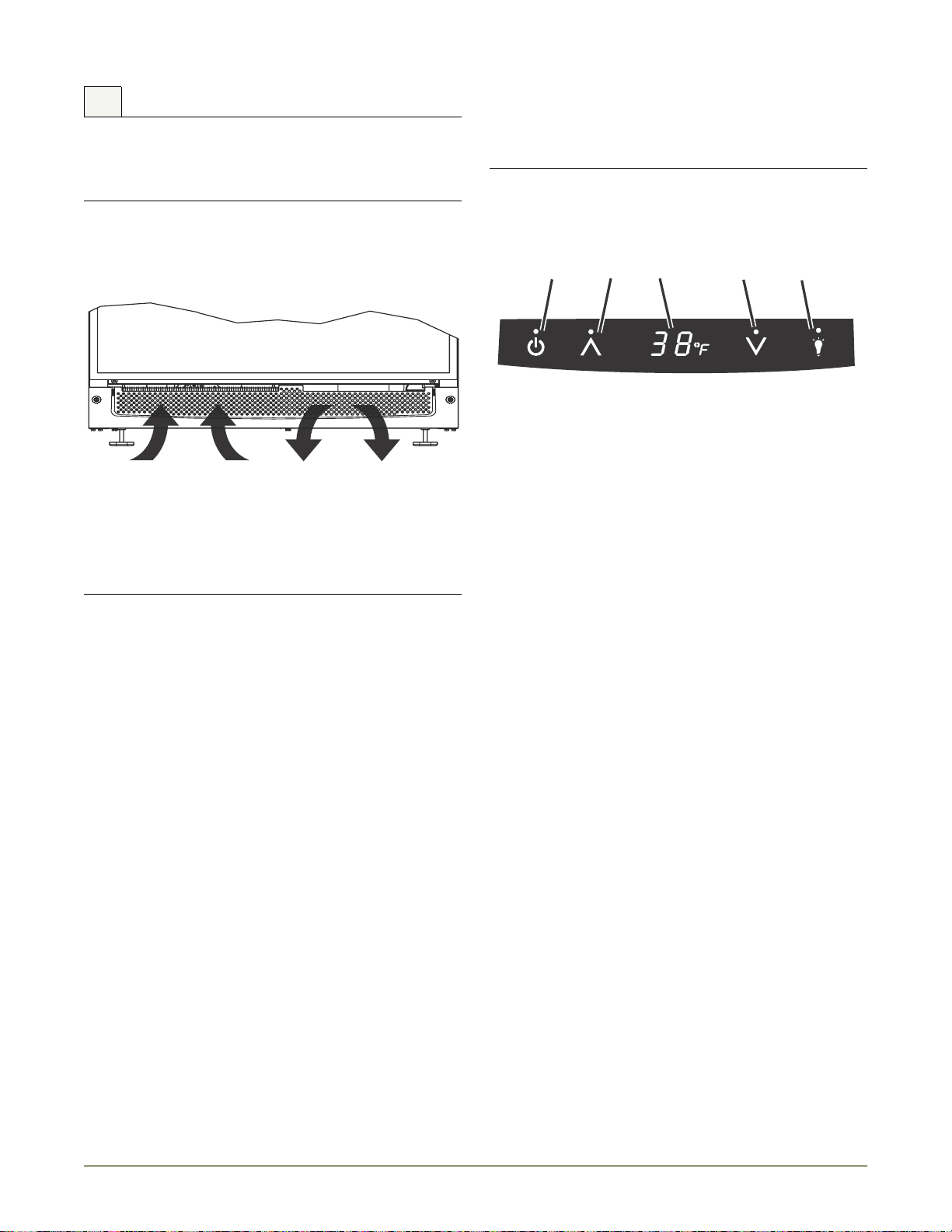

Electronic Control Panel

Digital Display.

The electronic control with digital display shows a single

continuous set-point temperature. This set point is for the middle

zone, it is a base number used by the controller to maintain the

multiple temperature zones in the unit. The factory default setpoint for Beverage Center and Refrigerator models is 38°F. The

factory default set-point Wine Captain models is 50°F. The setpoint temperature is a gauge for further temperature adjustments.

Adjusting Air Temperature

Adjust the set point temperature in single increments,

and wait 24 hours for the temperature to stabilize before

rechecking.

To adjust the set point temperature:

1. Press and release either the WARMER (2) or COOLER (4)

icon to put the controller in the SET TEMPERATURE mode.

The display (3) will begin to flash the °F (or °C) symbol.

NOTE: This mode will self-cancel in five seconds, and the

display (3) will show the original set-point temperature.

2. Within five seconds (while the °F (or °C) symbol is flashing),

press the WARMER or COOLER icon as required to adjust the

set point temperature.

3. The change sets five seconds after adjusting the temperature,

and the display (3) will show the new set-point temperature.

Temperature °F °C Selection. U-Line products supplied for

110 VAC have temperatures displayed (3) default in Fahrenheit

(°F). Models supplied for 220 VAC have temperatures displayed (3)

default in Celsius (°C).

Easily adjust the display for either type of temperature display.

Press and hold the LIGHT icon (1) and simultaneously within

five seconds press the COOLER icon (5) three times to change

the display (3) as needed.

Temperature Display. The digital display shows set-point. air

temperature. Under normal operating conditions the

temperatures will fluctuate based on a number of factors including

door openings, product load, room temperature, and humidity. On

passive cooled units the temperature will always be cool toward

the top and coolest toward the bottom.

To display actual temperature:

1. Press the WARMER icon (2) for five seconds. The display (3)

will indicate the actual temperature.

2. After about 10 seconds, the set point temperature will return to

the display.

U-Line Product Operation 5

Page 8

123 54

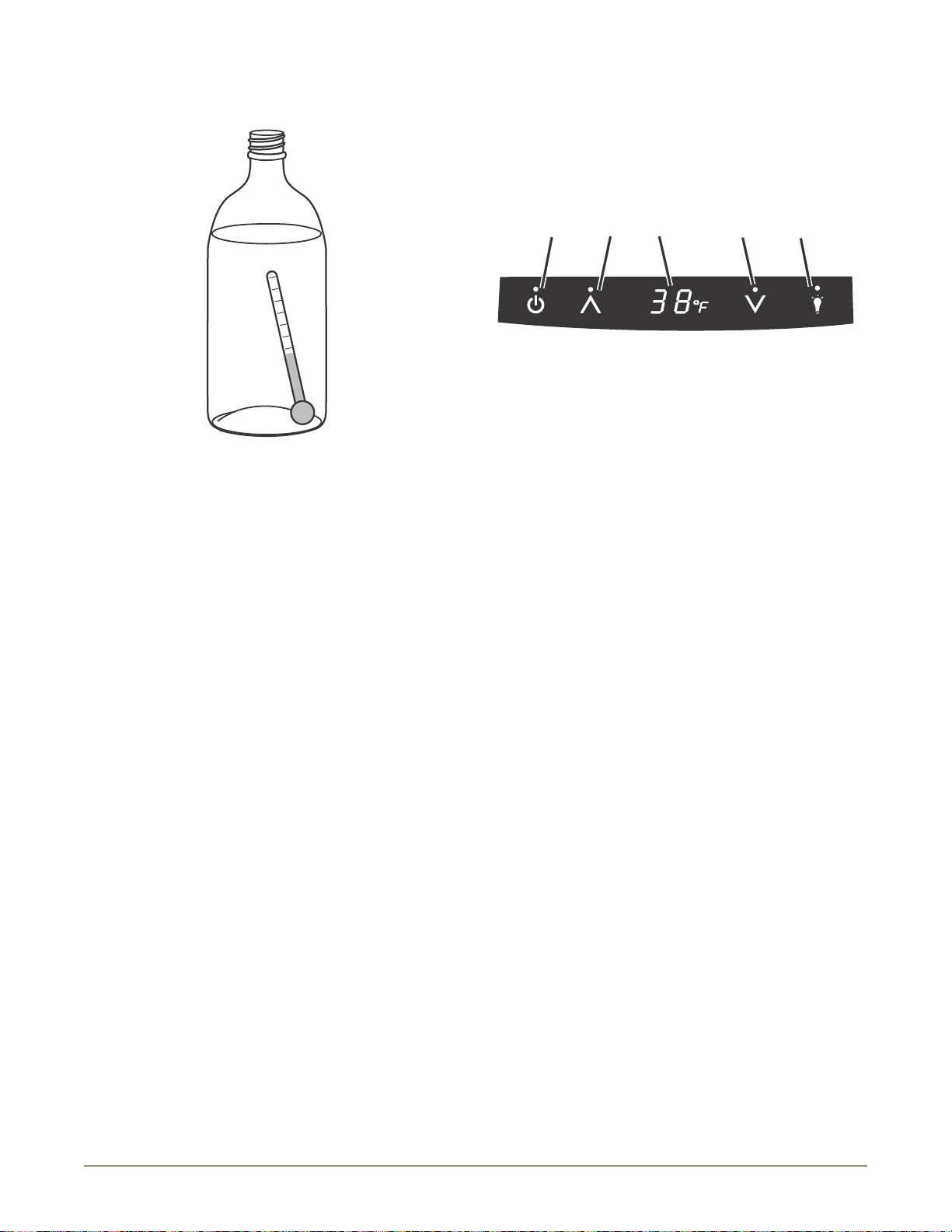

Checking Product Temperature

To check the actual product temperature in the unit.

1. Partially fill a plastic (nonbreakable) bottle with water.

2. Insert an accurate thermometer.

3. Tighten the bottle cap securely.

4. Place the bottle in the desired area for 24 hours.

5. Avoid opening the unit during the testing period.

6. After 24 hours, check the temperature of the water. If required,

adjust the temperature control in a small increment (See

ADJUSTING TEMPERATURE).

Causes which affect the internal temperatures of the

cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Installation in direct sunlight or near a heat source.

• The number of door openings and the time the door is open.

• The time the internal light is illuminated. (This mainly affects

product on the top rack or shelf.)

• The front grille or condenser are obstructed.

Interior Lighting

Normal Operation. Opening the door will cause the interior of

the cabinet to illuminate.

Use the LIGHT icon (5) on the control panel to change the lighting

functions.

Timed Lighting. For Wine Captain Models and Beverage

Centers the interior of the cabinet is illuminated for a timed fourhour period.

1. Press and release the LIGHT icon (5) (the °F symbol will flash

briefly) to switch from door-operated lighting control to the

timed four hour lighting period.

2. At the end of the four-hour period, the light will turn OFF and

door-operated lighting control will resume.

3. To exit the timed lighting control before the end of the fourhour period, repeat Step 1.

Blackout (Sabbath) Mode. The interior of the cabinet and

control display remains darkened for a 36-hour period (Blackout

(Sabbath) Mode is not Star K certified).

To turn the lights and display OFF for a preset 36-hour interval.

1. Press and hold the LIGHT icon (5) for ten seconds and release

(the °F symbol will flash briefly at the end of the ten second

period).

2. The interior light and control display (3) will go dark for the next

36 hours.

3. NOTE: Although the display will not be visible, the temperature

controls in the unit remain active, and preserve the interior

temperature.

To exit the Blackout (Sabbath) Mode before the 36-hour period,

repeat Step 1.

6 U-Line Product Operation

Page 9

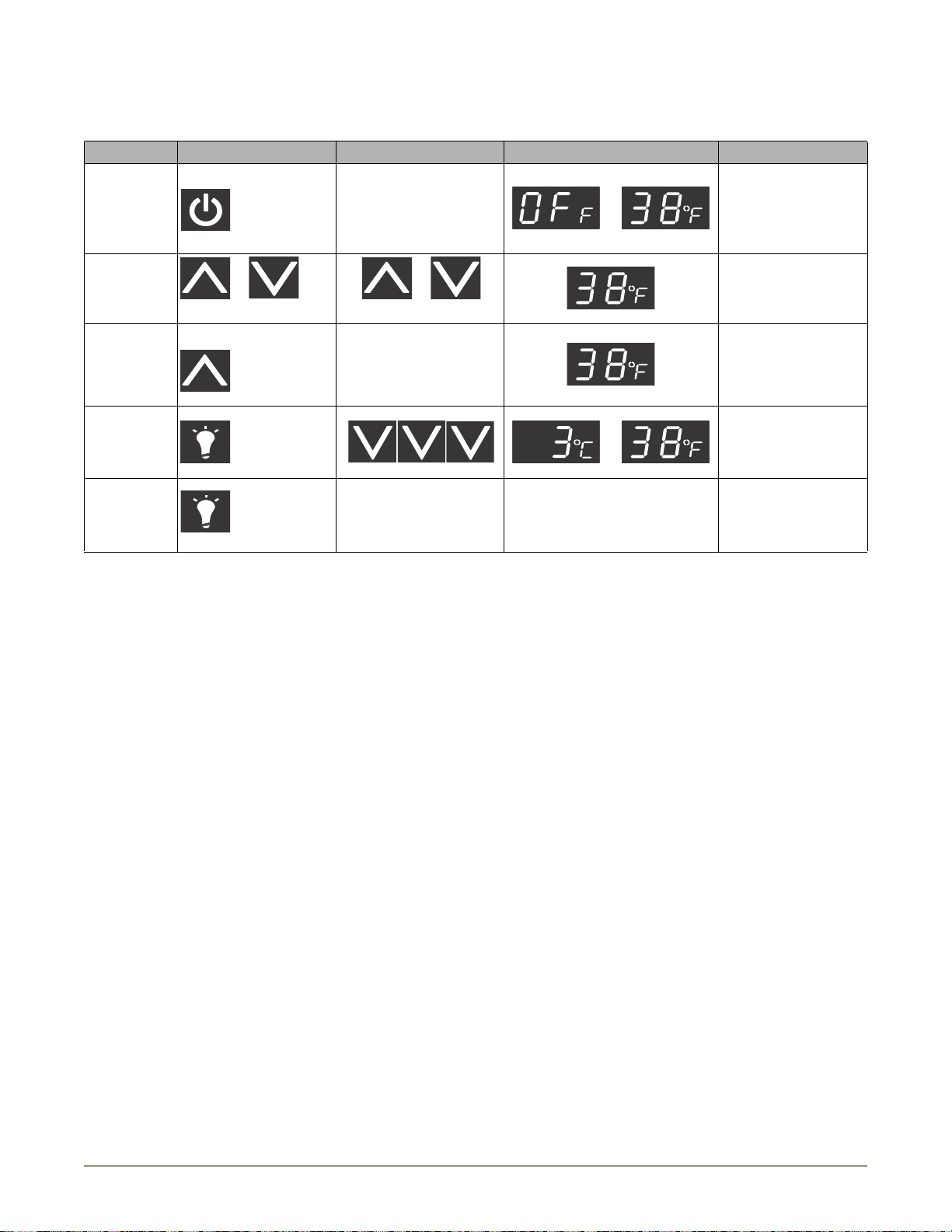

Electronic Control Quick Guide

Ta s k To u c h To u c h Display Comment

Turn ON/OFF Hold 10 seconds Release when °F flashes. or

Adjust

Te m p e r a t u r e

Touch and release

View Actual

Te m p

Change F/C Hold or

Blackout Mode Hold 10 seconds

or

Hold 5 seconds Release when °F flashes.

or

Touch to change temperature

Display (and cabinet light) will not

operate in Blackout Mode.

NOTE: 38°F is an example; the display will vary with actual setpoint.

°F flashes after first touch,

set-point saved after 5

seconds of inactivity and °F

stops flashing.

WC models will scroll top/

mid/bottom temps.

Blackout will end in 36

hours, or hold again to

terminate early.

U-Line Product Operation 7

Page 10

OFF

ON

5 Product Operation Manual Control

IMPORTANTIMPORTANT

IMPORTANTIMPORTANT

IMPORTANTIMPORTANT

Air Flow

The unit requires proper air flow to perform at its highest

efficiency. Do not block the front grille or internal fans at

any time, or the unit will not perform as expected. Do not

install the unit behind a door.

CO29FF

Initial Startup

All U-Line controls are preset at the factory. Initial startup requires

no adjustments.

U-Line recommends allowing the unit to run overnight

before loading refrigerator or freezer with product.

On ice maker equipped units, it is possible that dirt or

scale will dislodge in the water line. Always throw away all

ice cubes made during the first two to three hours of

operation.

To turn the unit on or off:

Press the rocker switch located below the temperature control

dial in the center of the grille(2), inside the door on the front

panel, or behind the grille.

Control Dial

Combo Models provide two temperature zones within the cabinet

to satisfy the specific storage requirements.

The control dial sets a single continuous temperature. This setpoint temperature is a base setting used by the controller to

maintain the temperature zone in the unit. The factory default MID

setting, number 3 or 4 set-point for Beverage Center and

Refrigerator models is 38°F. The factory default set-point Wine

Captain models is 50°F. The set-point temperature is a gauge for

further temperature adjustments.

8 U-Line Product Operation

Page 11

1

2

Adjusting Air Temperature

IMPORTANTIMPORTANT

Combo Models

• Adjust the set point temperature in single increments,

and wait 24 hours for the temperature to stabilize

before rechecking.

• Factory recommended set-point is MID setting on dial

control.

To adjust the set point temperature:

Adjust the temperature by turning the numbered dial (1) in

small increments.

Checking Product Temperature

To check the actual product temperature in the unit.

1. Partially fill a plastic (nonbreakable) bottle with water.

2. Insert an accurate thermometer.

3. Tighten the bottle cap securely.

4. Place the bottle in the desired area for 24 hours.

5. Avoid opening the unit during the testing period.

6. After 24 hours, check the temperature of the water. If required,

adjust the temperature control in a small increment (See

ADJUSTING TEMPERATURE).

Causes which affect the internal temperatures of the

cabinet include:

• Temperature setting.

• Ambient temperature where installed.

• Installation in direct sunlight or near a heat source.

• The number of door openings and the time the door is open.

• The time the internal light is illuminated. (This mainly affects

product on the top rack or shelf.)

• The front grille or condenser are obstructed.

U-Line Product Operation 9

Page 12

6Food Storage

IMPORTANTIMPORTANT

1

Drawers

The drawers should only be removed for servicing by a trained and

certified repair personal.

To p S t or a g e Bi n

Grasp the bin handle and slide backward to access the contents

below. The bin may be completely removed for cleaning once it is

slid forward, making sure it clears the guides on each side of the

drawer. Then lift straight up. If heavy items are stored in bin, push

front of bin down slightly while sliding. Slide bin forward, especially

with heavy items, to ensure that drawer closes completely.

When opening or closing the crisper, pull or push slowly

and carefully. If the crisper is pulled out too far or pushed

in too hard, it could come out all the way and possibly

cause product damage or personal injury.

Other Models

Crisper

Your models may have a lower

crisper drawer for storage.

To open, grasp the crisper

handle and slowly pull out to

access the drawer contents. The

crisper may be completely

removed for cleaning.

If the drawer is pulled out too

far, it will come out of the

cabinet, and may be damaged by

falling.

Crisper

Some models are equipped with a cripser in the lower drawer. To

access the crisper, open the bottom drawer fully. Grasp the handle

to either side of the crisper and slide just enough to access the

contents. To remove crisper, support both ends and slide out

completely. To remove the glass crisper cover (1), remove the

crisper and push up on cover from bottom.

10 U-Line Food Storage

Page 13

OFF

ON

2

1

7Ice Maker

IMPORTANTIMPORTANT

WARNING

CAUTION

IMPORTANTIMPORTANT

Ice Maker Operation

When the ice bucket is full, the ice making mechanism will shut off.

However, the refrigeration system will continue to cool and

maintain the cube supply. Frost-free ice maker units have lower ice

production than manual defrost units.

Do not place cans or bottles in the ice compartment

because they will freeze.

To turn off ice production: Raise the bin arm into an upright

and locked position. The unit will preserve temperature for ice

storage.

Ice Maker Adjustment

Ice Cube Thickness Adjustment.

Interval - As Required

On ice maker equipped models, adjust the cube size by changing

water amount injected into the ice maker assembly as follows:

If not intending to use the ice maker turn the water

supply valve off, it is important to raise the bin arm of the

ice maker (Figure 1). Failure to raise the bin arm may

result in damage to the water valve.

Certain sounds are normal during the unit’s operation. You may

hear the compressor or fan motor, the water valve, or ice

dropping into the ice bucket.

NEVER use an ice pick, knife or other sharp instrument

to separate cubes. Shake the ice bucket instead.

During periods of limited use or high ambient temperatures, it is

common for cubes to fuse together. Gently shake the bucket to

break apart cubes. If not using the ice maker regularly, empty the

ice bucket periodically to ensure fresh cubes.

It is normal for cubes to appear cloudy. The cause is air trapped in

the water because of fast freezing. It is not caused by the health,

taste or chemical make up of the water. It is the same air that is in

every glass of water you drink.

Remove the ice bucket for emptying and cleaning. To remove the

ice bucket, raise the bin arm and remove the bucket from the ice

compartment. Use the ice bucket for ice storage only.

1. Remove the ice maker assembly cover (1).

2. Find the adjusting screw on the ice maker assembly control box

(2). The adjusting screw is just below the minus (-) and plus (+)

signs on the control box.

NOTE: Adjust in small increments. Too large of an adjustment could cause the unit to malfunction.

Too large of an adjustment to the screw can cause the

water to overflow the ice maker and can cause property

damage.

3. Turn the adjusting screw toward the minus (-) sign (clockwise)

for smaller cubes or toward the plus (+) sign (counterclockwise)

for larger cubes.

4. Install the ice maker assembly cover.

U-Line Ice Makers 11

Page 14

8 Maintenance

IMPORTANTIMPORTANT

IMPORTANTIMPORTANT

Leveling

Unit must be level, for proper door and ice maker (if

equipped) operation.

1

For Models with adjustable leveling feet:

1. Use a level to check the levelness of the unit from front to back

and from side to side. Place the level along top edge and side

edge as shown (1).

2. If the unit is not level, rotate the adjustable leveling legs to raise

or lower each corner of the unit (5) as necessary.

3. Check levelness after each adjustment and repeat the previous

steps until the unit is level.

Removing and Installing Interior Shelves

For models equipped with glass shelves having shelf supports,

remove the shelves as follows:

1. Open door completely.

2. Grasp the shelf edge in the center and slide the shelf from the

unit.

Insert the shelves as follows:

Reposition the shelf as required, ensure the raised white edge

strip is toward the rear of the unit and graphics, if applied, are

on the underside of the shelves.

For Models without adjustable leveling feet:

The unit must be located on a level surface, for proper

door and ice maker (if equipped) operation.

Use a level to check the levelness of the unit from front to back

and from side to side. Place the level along top edge and side

edge as shown (1).

12 U-Line Combo® Models and Ice Makers Maintenance

Page 15

1

2

4

4

1

2

5

1

2

Removing and Installing Grille

WARNING

WARNING

5

6

1

2

2

3

1

6

Disconnect electric power to the unit before removing

the grille.

DO NOT touch the condenser fins(4). The condenser

fins are SHARP and can be easily damaged.

Removing the grille.

1. Disconnect power to the unit.

2. Remove control knob (6) if equipped.

3. Loosen the two screws (1). Some models may have only one

screw in the center.

4. Remove grille (2) and grille cap (if equipped)(3) from unit.

Installing the grille:

1. For 15 and 29 models make sure grille cap (3) is behind grille in

slots (2) provided in grille before attaching grille to unit.

2. For 75 models place the hook-hinge located on the rear bottom

side of the grille (2) onto the front lip of the unit base. Swing the

grille up into position.

Ice Maker Models

Removing and Installing Door Shelves

3. Align cabinet and grill holes and secure, but do not overtighten

grille screws (1).

4. Install control knob (6) if equipped.

5. Reconnect power to the unit.

29 Models

75 Models

For models equpped with door shelves:

To re m ov e t he d o o r s h e l f :

1. Grasp shelf in center, and lift until the shelf notches (1) clear

the pins (2).

2. Carefully pull the shelf away from the door.

To install the door shelf:

1. Holding the shelf in the center, center the shelf in the door at

the desired location, slightly above the pins (2).

2. Lower the shelf onto the pins (2).

U-Line Combo® Models and Ice Makers Maintenance 13

Page 16

14 U-Line Use and Care Guide

Page 17

1/8"

(3.175 mm)

1

23

4

9 Self-Closing Doors

IMPORTANTIMPORTANT

Door Alignment and Adjustment

Align and adjust the door if it is not level, or is not sealing properly.

If the door is not sealed the unit may not cool properly, or

excessive frost may form in the interior.

• Properly aligned, the door’s gasket should be firmly in

contact with the cabinet all the way around the door

(no gaps). Carefully examine the door’s gasket to

ensure that it is firmly in contact with the cabinet. Also

make sure the door gasket is not pinched on the hinge

side of the door.

• The door will not be flush with the top of the cabinet.

The top edge of the door will be 1/8 in. (3.175 mm)

below the cabinet top.

5. After adjustment is complete, remove the door closers from the

bottom hinge, clean thoroughly and apply petroleum jelly to the

mating surfaces of the closers. Be sure that pins on closers align

with holes in the door and bottom cabinet hinge plates. Mount

door and install top hinge pivot pin.

Door Reversability

Location of the unit may make it desirable to mount the door on

the opposite side of the cabinet.

Models with black and white doors are field-reversible.

Stainless steel models must be ordered right- or left-hand hinged.

To align and adjust the door:

1. Compare the top edge of the door (opposite the hinges) to the

top edge of the cabinet and note the type (up or down) of

adjustment needed.

2. Remove the top hinge pivot pin with a Phillips screwdriver and

lift door off bottom hinge pin. Be careful not to lose the door

closer insert sets.

3. Turn the door upside down and inspect the hinge plate mounting

holes. The plate has slotted mounting holes. Loosen but do not

remove the two hinge plate screws(1).

4. If door edge opposite the hinges needs to move up, move plate

toward outside of door(2). If door edge needs to move down,

move plate toward inside of door(3). Repeat until top edge of

door is parallel with top of cabinet and tighten screws (1)

securely.

Reversing the door

The Hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

The top hinge hardware will be reinstalled on the bottom of the

opposite side of the cabinet.

The bottom hinge hardware will be reinstalled on the top of the

opposite side of the cabinet.

U-Line Self-Closing Door Alignment and Reversal 15

Page 18

3

4

5

NOTCH

1

To reverse the door:

1

2

Remove door:

1. Hold door to keep it from falling.

2. Remove hinge screw pin (1) from top hinge using a Phillips

screwdriver.

3. Remove door by tilting forward and lifting door off bottom hinge

closer inserts.

4. Reinstall hinge screw pin (1) into top hinge using a Phillips

screwdriver.

Remove hole plugs.

Remove plastic screw plugs (three each, top and bottom)

from new hinge location. Save for reinstallation later.

Remove existing top hinge.

Remove existing top hinge (three screws) (2).

(3)

Remove existing bottom hinge.

Remove the existing bottom hinge (three screws) (2).

Reinstall hinge to top opposite.

Install the hinge just removed from the bottom to the TOP

opposite side of the cabinet (three screws) (2).

Reinstall Hole Plugs.

Install plastic screw plugs (three each, top and bottom)

holes where hinge hardware was removed.

(3)

into

Prepare door for reinstallation.

1. Remove plastic hole plug from top of door handle and reinstall

on opposite side.

2. With bottom of door facing up, remove pivot plate (5) (two

screws).

3. Flip over and install pivot plate on opposite side of door. Ensure

notch in plate faces center.

Install Door.

1. Hold door upright and tilted forward.

4

Reinstall hinge to bottom opposite.

1. Install the hinge just removed from the top to the BOTTOM

opposite side of the cabinet (three screws) (2).

2. Remove the two door closer inserts (4) from the existing

bottom hinge.

3. Install door closer inserts as shown on the new bottom hinge

(4).

2. Lift door on to bottom hinge closer inserts.

3. Tilt door forward into position.

4. Hold door to keep it from falling.

5. Reinstall hinge screw pin (1) into top hinge using a Phillips

screwdriver.

Align and adjust the door:

Align and adjust the door, see DOOR ALIGNMENT AND

ADJUSTMENT above.

16 U-Line Self-Closing Door Alignment and Reversal

Page 19

10 Standard Doors

IMPORTANTIMPORTANT

Plastic

Plug Hole

Plastic

Plug Hole

Right Side

Door Swing

Left Side

Door Swing

Door Alignment and Adjustment

Align and adjust the door if it is not level, or is not sealing properly.

If the door is not sealed the unit may not cool properly, or

excessive frost may form in the interior.

Properly aligned, the door’s gasket should be firmly in

contact with the cabinet all the way around the door (no

gaps). Carefully examine the door’s gasket to assure that

it is firmly in contact with the cabinet. Also make sure the

door gasket is not pinched on the hinge side of the door.

To align and adjust the door:

1. Loosen (do not remove) top and bottom hinge screws.

2. Align door squarely with cabinet.

3. Make sure gasket is firmly in contact with cabinet all the way

around the door (no gaps).

4. Tighten bottom hinge screws.

5. Tighten top hinge screws.

Door Reversability

Location of the unit may make it desirable to mount the door on

the opposite side of the cabinet.

To reverse the door:

Remove grille:

Remove the grille see MAINTENANCE section of this guide.

Remove top hinge, and door:

1. Hold door to keep it from falling.

2. Remove top hinge from cabinet by removing three or four

screws, depending on model.

3. Remove door by tilting forward and lifting door off bottom

hinge.

4. Remove three or four plastic screw plugs from hinge holes on

the opposite side. Reinstall into holes where the hinge was

Models with black and white doors are field-reversible.

Stainless steel models with glass doors without locks are fieldreversible.

Stainless steel models without glass doors must be ordered rightor left-hand hinged.

Reversing the door

The Hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

The hinge plate is flipped over when it is reinstalled on the

opposite side of the cabinet.

removed. Ensure not to scratch cabinet.

Remove bottom hinge:

1. Remove bottom hinge from cabinet. Some models will have a

gusset with two screws. Other models will have a plate with

three screws.

2. Remove corresponding screws on opposite side of cabinet. On

U-Line Standrd Door Alignment and Reversal 17

Page 20

Install bottom hinge:

1

1

2

3

4

1. If you have a plate hinge, reorient the pivot screw so it

protrudes the opposite direction form the hinge. Remove the

pivot screw from the hinge. Turn the plate over and reinstall

the screw.

2. Align hinge outer edge with cabinet. For models with a plate

hinge, the flat edge of the hinge alignes with the outer edge of

the cabinet.

Install two or three screws, depending on model. Replace nuts if

used.

Prepare door for reinstallation:

For stainless steel models with glass doors:

3. Stainless glass doors are flipped upside down to be reversed.

4. Lay the door on it’s side. Remove the plastic hole plug (1) and

install in the corner opposite of where it was removed.

5. Remove the plastic hinge bushing (2) and install in the corner

opposite of where it was removed.

6. Remove the U-Line nameplate (3) from door. This will reveal

mounting holes for the door actuator bracket.

Prepare door for reinstallation:

For black or white doors:

1. Remove plastic hole plug from top of door handle and reinstall

on opposite side.

2. Remove plastic hinge bushing on bottom of door and reinstall on

opposite side. Clean out bushing hole in door bottom with a

screwdriver if necessary.

Install top hinge, and door:

1. Reorient the pivot screw so it protrudes the opposite

direction from the hinge. Remove the pivot screw from the

hinge. Turn the plate over and reinstall the screw.

2. Hold door to keep it from falling.

3. Lift the door on to the bottom hinge.

4. Align flat edge of the hinge with the outer edge of the unit.

5. Install

Align and adjust the door:

1. Align and adjust the door, see DOOR ALIGNMENT AND

Install grille:

three or four screws, depending on model.

ADJUSTMENT above.

Install the grille, see MAINTENANCE section of this guide.

7. Remove door actuator (4) from door. Be sure to only remove

the two screws holding the actuator to the door. Reinstall the

actuator (4) on the opposite end of the door where the

nameplate was removed.

8. Install new nameplate where the actuator assembly was

removed.

9. Install screws into holes on opposite side, where the hinge was

removed. Replace nuts if used.

18 U-Line Standard Door Alignment and Reversal

Page 21

WARNING

CAUTION

IMPORTANTIMPORTANT

11 Standard Drawers

Aligned

Side-to-Side

Aligned

Front-to-Back

Aligned

Top-to-Bottom

Mounting

Screw

Top View of Unit

Not Aligned Side-to-Side

Push Slide

Backward

Loosen

Mounting Screws

Mark and Drill New

Mounting Holes

Push Slide

Backward

k

Side View of Unit

Checking Drawer Alignment

The unit’s drawers are aligned at the factory before shipment.

However, their alignment could have been disturbed during

shipment or during overlay panel installation. Check each drawer

to confirm that it is aligned:

Drawer adjustments are made by moving the slide that carries the

drawer’s rail. Minor adjustments may be made by loosening one of

the slide’s mounting screws, adjusting the slide and retightening the

screw. Severe adjustments may be made by removing the slides’

mounting screws, drilling new mounting holes and remounting the

slide.

Side-to-Side Adjustment

The drawer will need a Side-toSide Adjustment if, when viewed

from the top, the drawer front is

not square with the sides of the

cabinet. This is caused by one of

the slides being mounted too far

forward on the unit’s liner.

Minor Adjustment:

Note: The mounting holes on the

slide are slightly larger than the

screws’ diameter.

1. Loosen the slide’s mounting

screws.

• Side-to-Side — When viewed from the top, the drawer front

should be square with the sides of the cabinet.

• Front-to-Back — When viewed from the side, the drawer

front should be straight with the cabinet’s sides, not cocked

forward or back.

• Top-to-Bottom — When viewed from the front, the drawer

should be level horizontally.

Adjusting Drawer Alignment

SHOCK HAZARD — The unit must be unplugged from

the wall outlet during drawer removal, adjustment and

re-installation.

Drawer Removal

1. Confirm that the unit is

unplugged from wall outlet.

2. Unplug the drawer’s connection

wiring (top drawer only).

3. Remove the mounting screws.

4. Pull the drawer completely out

of the unit.

Use care when handling the drawer. Drawer edges, drawer

rail and the unit’s slide may be sharp.

2. Push the slide backward.

3. Retighten the screws.

Severe Adjustment:

Note: The slides have extra

mounting holes that may be used.

1. Remove the slide’s mounting

screws.

2. Reposition the slide so it is the

same distance from the front

of the liner as the other slide.

Measure to confirm.

3. Mark new drilling holes using

different sets of mounting holes on the slide.

Note: Front location holes are shown. Corresponding rear holes

will also need to be marked.

4. Drill all the new holes with a #30 drill bit.

5. Remount the slide.

Not Aligned Front-to-Bac

Front-to-Back Adjustment

The drawer will need a Front-toBack Adjustment if, when viewed

from the side, the drawer front is

cocked forward or back. This is

caused by the front slide

mountings not being level with

the rear slide mountings.

U-Line Drawer Alignment 19

Page 22

Minor Adjustment:

CAUTION

Screws Should

Be Loose

Level the Slide

Mark and Drill New

Mounting Holes

Level the Slide

Not Aligned Left-to-Right

Top View of UnitFront View of Unit

Not Aligned

Top-to-Bottom

Push Slide

Upward or

Downward

Mounting Screws

Mark and Drill New

Mounting Holes

Push Slide

Upward or

Downward

Note: The mounting holes on the

slide are slightly larger than the

screws’ diameter.

1. Loosen one slide’s mounting

screws.

2. Level the slide.

3. Retighten the screws. See

Figure 18.

4. Repeat procedure for the

other slide.

Severe Adjustment:

Note: The slides have extra mounting holes that may be used.

1. Loosen one slide’s rear

mounting screws.

2. Remove the slide’s front

mounting screws.

3. Reposition the slide so it is

level.

4. Mark new front drilling holes

using a different set of

mounting holes on the slide.

5. Drill the new holes with a #30 drill bit.

6. Remount the slide.

7. Repeat procedure for the other slide.

Top-to-Bottom (and Left-to-Right) Adjustment

Minor Adjustment:

Note: The mounting holes on the slide are slightly larger than the

screws’ diameter.

1. Loosen one slide’s mounting

screws.

2. Push the slide upward or

downward to match the

position of the other slide.

3. Retighten the screws.

4. Repeat the procedure with

the other slide if necessary.

Severe Adjustment:

Note: The slides have extra mounting holes that may be used.

1. Remove one slide’s mounting

screws.

2. Reposition the slide so it is

the same distance from the

bottom of the liner as the

other slide. Measure to

confirm.

3. Mark new drilling holes using

different sets of mounting

holes on the slide. See Figure

22.

Note: Front location holes are shown. Corresponding rear holes

will also need to be marked.

4. Drill all the new holes with a #30 drill bit.

5. Remount the slide.

The drawer will need a Top-to-Bottom Adjustment if, when viewed

from the front, the drawer is not level horizontally. Viewed from

the top, one side will protrude. This is caused by one of the slides

being mounted higher than the other slide on the unit’s liner.

Re-installation of Drawer

Use care when handling the drawer. Drawer edges, drawer

rail and the unit’s slide may be sharp.

1. Set the drawer’s rails onto the slides.

2. Re-install the rails’ mounting screws. See Figure 13 on Page 10.

3. Plug in the drawer’s connection wiring (top drawer only).

20 U-Line Drawer Alignment

Page 23

IMPORTANTIMPORTANT

1

.

CAUTION

1

12 Cleaning

Defrosting

Exterior Cleaning

Vinyl Clad (Black or White) Models:

• Clean surfaces with a mild detergent and warm water solution.

Do not use solvent-based or abrasive cleaners. Use a soft

sponge and rinse with clean water. Wipe with a soft, clean

towel to prevent water spotting.

• Clean any glass surfaces with a non-chlorine glass cleaner.

Stainless Models:

• Stainless door panels, handles and frames can discolor when

exposed to chlorine gas, pool chemicals, saltwater or cleaners

with bleach.

• Keep your stainless unit looking new by cleaning with a good

quality all-in-one stainless steel cleaner polish monthly. For best

results use Claire® Stainless Steel Polish and Cleaner, which can

be purchased from U-Line Corporation (Part Number 173348).

Comparable products are acceptable. Frequent cleaning will

remove surface contamination that could lead to rust. Some

installations may require cleaning weekly.

• Do not clean with steel wool pads.

• Do not use stainless steel cleaners polishes on any glass

surfaces.

• Clean any glass surfaces with a non-chlorine glass cleaner.

• Do not use cleaners not specifically intended for

stainless steel on stainless surfaces (this includes glass,

tile and counter cleaners).

• If any surface discoloring or rusting appears, clean it quickly

with Bon-Ami® or Barkeepers Friend Cleanser® and a

nonabrasive cloth. Always clean towards the grain. Always finish

with Claire Stainless Steel Polish and Cleaner or comparable

product to prevent further problems.

• Using abrasive pads such as Scotchbrite™ will cause

the graining in the stainless to become blurred.

• Rust not cleaned up promptly can penetrate the surface of the

stainless steel and complete removal of the rust may not be

possible.

Interior Cleaning

• Disconnect power to the unit.

• Clean the interior and all removed components using a mild

nonabrasive detergent and warm water solution applied with a

soft sponge or non-abrasive cloth.

• Rinse the interior using a soft sponge and clean water.

• Do not use any solvent-based or abrasive cleaners.

These types of cleaners may transfer taste to the interior

products and damage or discolor the interior.

Automatic Defrost Models

Frost on the rear wall is normal and will melt during each off cycle.

If there is excessive build-up of 1/4” or more, manually defrost the

unit.

• Ensure the door is closing and sealing properly.

• High ambient temperature and excessive humidity can also

produce frost.

DO NOT use an ice pick or other sharp instrument to

help speed up defrosting. These instruments can puncture

the inner lining or damage the cooling unit. DO NOT use

any type of heater to defrost. Using a heater to speed up

defrosting can cause personal injury and damage to the

inner lining.

To d e f ro s t :

1. Disconnect power to the unit.

2. For combo models remove all products from the interior.

3. Remove ice bucket and discard ice.

4. Place towel or other absorbent materialon bottom of ice bin.

For combo models also place in bottom of unit.

5. Fill the ice bucket half full with warm, not hot water. This will

help the unit defrost faster.

6. Place the ice bucket back into the unit on top of the towel or

other absorbent material.

7. Prop the door in an open position (2 in. (5 cm) minimum).

8. After about 1 hour remove the ice bin and discard water.

9. Allow the frost to melt naturally.

10. After the frost melts completely clean the interior and all

removed components. (See INTERIOR CLEANING)

DO NOT clean ice bucket using a dishwasher. The bucket

is not dishwasher safe and will be damaged.

11. When the interior is dry, reconnect power and turn unit on.

NOTE: To safeguard against contaminates in ice, discard first

three batches of ice after defrosting.

U-Line Combo® Models and Ice MakersCleaning 21

Page 24

Condensor Cleaning

WARNING

WARNING

IMPORTANTIMPORTANT

WARNING

IMPORTANTIMPORTANT

DANGER

1

2

2

1

3

5

4

Storage, Vacation and Moving

Interval - Every Six Months

To maintain operational efficiency, keep the front grille free of dust

and lint, and clean the condenser every three months. Depending

on environmental conditions, more or less frequent cleaning may

be necessary.

Disconnect electric power to the unit before cleaning

the condenser.

DO NOT touch the condenser fins. The condenser fins

are SHARP and can be easily damaged.

DO NOT use any type of cleaner on the condenser unit.

1. Remove the grill. (See MAINTENANCE)

2. Clean the condenser coil (4) using a using a soft brush with a

“combing” action or vacuum cleaner. Do not touch the

condenser coil.

3. Install the grill. (See MAINTENANCE)

If not using the unit for an extended period, or otherwise stored,

follow these steps completely:

Electrical Shock Hazard. Disconnect power before

servicing. Before operating, replace all panels. Failure

to do so may result in death or electrical shock.

If the ambient temperature is expected to drop below

50°F, turn off and unplug unit, and drain all water from the

unit to prevent freezing damage not covered by the

warranty.

1. Remove all consumable contents from the unit.

2. Disconnect the power cord from its outlet, and leave it

disconnected until the unit is returned to service.

3. Clean and dry the interior of the cabinet.

4. During periods of nonuse, the cabinet must remain open to

prevent formation of mold and mildew. Open door a minimum

of 2 in. (5 cm) to provide the necessary ventilation.

Product Disposal

4

5

75 Models

Typical Model Shown

29 Models

Typical Model Shown

If the unit is being removed from service for disposal, check and

obey all Federal, State and or Local regulations regarding the

disposal and recycling of refrigeration appliances, and follow these

steps completely:

1. Remove all consumable contents from the unit.

2. Disconnect power to the unit and unplug the power cord from

its outlet.

RISK OF CHILD ENTRAPEMENT. Before you throw away

your old refrigerator or freezer, take off the doors and leave

shelves in place so children may not easily climb inside.

3. Remove the cabinet door.

22 U-Line Combo® Models and Ice Makers Cleaning

Page 25

13 Service

DANGER

Before Calling for Service

If you think your U-Line product is malfunctioning, read the

OPERATION section of this guide to understand clearly the

function of the control.

If the problem persists, read the NORMAL OPERATING

SOUNDS and TROUBLESHOOTING GUIDE section of this guide

to help you quickly identify common problems, and possible causes

and remedies. Most often, this will resolve the problem without

the need to call for service.

If Service is Required

If you do not understand a troubleshooting remedy, or your

product needs service, contact U-Line Corporation directly.

Contact information appears on the rear cover of this guide.

When you call, you will need your product Model and Serial

Numbers. This information can be recorded inside the front cover

of this guide. It also appears on the Model and Serial number plate

located on the upper right or rear wall of the interior of your

product.

Replacement Parts

When you need replacement parts, always request genuine U-Line

replacements. U-Line designs and engineers products using

components that work efficiently, and provide superior service life

and performance. The use of aftermarket parts or components

may affect the safety, operation, performance or durability of your

product, and may also void its warranty.

Normal Operating Sounds

All models incorporate rigid foam insulated cabinets to provide

high thermal efficiency and maximum sound reduction for its

internal working components. Despite this technology, your model

may make sounds that are unfamiliar.

Normal operating sounds may be more noticeable because of the

unit’s environment. Hard surfaces such as cabinets, wood, vinyl or

tiled floors and paneled walls have a tendency to reflect normal

appliance operating noises.

Listed below are common refrigeration components with brief

description of the normal operating sounds they make. NOTE:

Your product may not contain all the components listed.

• Compressor: The compressor makes a hum or pulsing sound

that may be heard when it operates.

• Evaporator: Refrigerant flowing through an evaporator may

sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may be heard.

• Automatic Defrost Drain Pan: Water may be heard dripping or

running into the drain pan when the unit is in the defrost cycle.

Troubleshooting Guide

ELECTROCUTION HAZARD. Never attempt to repair or

perform maintenance on the unit until disconnecting the

main electrical power.

Troubleshooting - What to check when problems occur:

Problem Possible Cause and Remedy

Interior Light

Does Not

Illuminate.

Light Remains

on When Door

is Closed.

Unit Develops

Frost on

Internal

Surfaces.

Unit Develops

Condensation

on External

surfaces

Product is

Freezing in

Combo Models.

Product is Not

Cold Enough in

Combo models.

Ice Cubes

Sticking

To g e t h e r

No Ice

Production

Not Enough Ice Ensure the condenser coil is clean and free of any dirt

Water in Bucket Ensure cube size adjustment is not se too high.

The light bulb may be defective.(See MAINTENACE)

Adjust light actuator bracket ob bottom of door.

Unit is a manual defrost model that will require

occasional defrosting. When there is build-up of 1/4”

or more, manually defrost the unit.

Ensure the door is closing and sealing properly.

High ambient temperature and excessive humidity

can also produce frost.

The unit is exposed to excessive humidity, moisture

will dissipate as humidity levels increase.

Adjust the temperature to a warmer set-point. (See

OPERATION)

Air temperature does not indicate product

temperature. See OPERATION - Checking Product

Te m p e r a t u r e .

Adjust the temperate to a cooler set-point. (See

OPERATION)

Ensure unit is not located in excessive ambient

temperatures or in direct sunlight.

Ensure the door is closing and sealing properly.

Ensure the interior light has not remained on too

long.

Ensure nothing is blocking the front grille, found at

the bottom of the unit.

Ensure the condenser coil is clean and free of any dirt

or lint build-up.

During periods of limited use or high ambient

temperatures, it is common for cubes to fuse

together. Gently shake the bucket to break apart

cubes.

Ensure the bin arm is not in the up (off) position.

or lint build-up.

U-Line Combo® Models and Ice Makers Service 23

Page 26

24 U-Line Use and Care Guide

Page 27

U-Line Corporation Limited Warranty

1. U-Line Corporation ("U-Line") warrants each U-Line

product to be free from defects in materials and

workmanship for a period of one year from the date of

purchase. U-Line further warrants the sealed system

(consisting of the compressor, the condenser, the

evaporator, the hot gas bypass valve, the dryer and the

connecting tube) in each U-Line product to be free from

defects in materials and workmanship for a period of five

years from the date of purchase.

2. During the initial one year warranty period for all U-

Line products U-Line shall: (1) repair any product or

replace any part of a product; and (2) for all Marine, RV

and Domestic U-Line products sold and serviced in the

United States (including Alaska and Hawaii) and Canada,

U-Line shall be responsible for the labor costs performed

by a U-Line authorized service company, incurred in

connection with the replacement of any defective part.

During years two through five of the warranty period for

the sealed system, U-Line shall: (1) at U-line’s option repair

or replace any part of the sealed system; and (2) for all

Marine, RV and Domestic U-Line products sold and

serviced in the United States (including Alaska and

Hawaii) and Canada, U-Line shall be responsible for the

labor costs incurred in connection with the replacement

of any defective part of the sealed system. All other

charges, including transportation charges for

replacements under this warranty and labor costs not

specifically covered by this warranty, shall be the

responsibility of the purchaser. This warranty extends

only to the original purchaser of the U-Line product. The

registration Card included with the product should be

promptly completed by you and mailed back to U-Line or

you can register on-line at www.u-lineservice.com.

continue to be covered by the warranty terms set forth in

Paragraphs 1 and 2 above, to the extent such models:

A. Are subjected to temperatures between 50 and 100

degrees Fahrenheit. Although these products will

function in ambient temperatures below 50 degrees and

above 100 degrees Fahrenheit, performance may decline.

Performance degradation due to operating above or

below the designated ambient temperature range is not a

manufacturing defect and any issues resulting from

exposure to higher temperatures, such as spoiled food or

low ice production, are not covered under this warranty

policy; and/or

B. Come into contact with rain by virtue of outdoor use.

Exposure to other sources of water shall also cause this

warranty to be void, including flooding of the area in

proximity of the unit greater than 1/8” deep in water,

hurricanes, splashing of pool water, or directing a spray

from a hose or similar device into and around the unit.

5. If a product defect is discovered during the applicable

warranty period, you must promptly notify either U-Line

at P.O. Box 245040, Milwaukee, Wisconsin 53224 or at

800-779-2547 or the dealer from whom you purchased the

product. In no event shall such notification be received

later than 30 days after the expiration of the applicable

warranty period. U-line may require that defective parts

be returned, at your expense, to U-Line's factory in

Milwaukee, Wisconsin, for inspection. Any action by you

for breach of warranty must be commenced within one

year after the applicable warranty period.

3. The following conditions are excluded from this limited

warranty: damage caused by outdoor use; use of cleaners

other than the recommended stainless steel cleaners and

U-Line Clear Ice Maker cleaner; installation charges;

damages caused by disasters or acts of God, such as fire,

floods, wind and lightning; damages incurred or resulting

from shipping, improper installation, unauthorized

modification, or misuse/abuse of the product; customer

education calls; food loss and spoilage; door and water

level adjustments (except during the first 30 days from the

date of installation); defrosting the product; adjusting the

controls; door reversal; and cleaning the condenser.

4. U-Lines' Outdoor Limited Warranty, set forth in this

Paragraph 4, shall apply to U-Line models deemed

suitable for outdoor use by Underwriters Laboratory

("UL") as noted in the U-Line Product Catalog, U-Line's

website and/or on the serial tag located inside the

product. Exposure to temperatures below freezing may

cause damage to the product. Damage resulting to the

product (and/or the surroundings) caused by this exposure

is not covered under this warranty. Such models shall

U-Line Warranty

6. THIS LIMITED WARRANTY IS IN LIEU OF ANY AND

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE, ALL OF WHICH

ARE DISCLAIMED. U-Line’s sole liability and your

exclusive remedy under this warranty is set forth in

the paragraphs above. U-Line shall have no liability

whatsoever for any incidental, consequential or

special damages arising from the sale, use or

installation of the product or from any other cause

whatsoever, whether based on warranty (express or

implied) or otherwise based on contract, tort or any

other theory of liability.

7. Some states do not allow limitations on how long an

implied warranty lasts or the exclusion or limitation of

incidental or consequential damages, so the above

limitations may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights

which vary from state to state.

Page 28

®

USE AND CARE GUIDE

PRODUCT INFORMATION

Installation Guides with complete installation information, Custom Wood Panel Size Specifications & Installation

Instructions, CAD Drawings, Use and Care Guides, Specifications & Feature Benefits are available for viewing

and download on-line at www.u-line.com/specs/.

SERVICE INFORMATION

If you have a problem with this appliance, your use and care guide has troubleshooting information to help you

quickly identify common problems and provide information on possible cause and remedy. Answers to

Customers Frequently Asked Questions are available at www.u-line.com/customer/faq.cfm. You may contact

U-Line directly:

GENERAL INQUIRIES:

U-Line Corporation

P.O. Box 245040

Milwaukee, Wisconsin 53224-9540 U.S.A.

Phone (414) 354-0300

FAX (414) 354-7905

Email: sales@u-line.com

www.u-line.com

SERVICE ASSISTANCE:

Phone (800) 779-2547

FAX (414) 354-5696

Email: onlineservice@u-line.com

www.u-lineservice.com

PARTS ASSISTANCE:

E-mail: onlineparts@u-line.com

ABOUT U-LINE

Building on 45 years, U-Line has captivated those with an appreciation for the finer things with exceptional

design, inspired innovations and attention to even the smallest details.

U-Line is synonymous with premium built-in undercounter ice making, refrigeration and wine storage appliances, the U-Line Corporation is committed to luxury under the counter. U-Line is known and respected for

unwavering dedication to product innovation, quality and selection. A bold and broad line of models is the product of visionaries in the pursuit of distinctive living environments in the kitchen and spaces beyond.

In 1962, Henry Uihlein founded U-Line Corporation as an outgrowth of Ben-Hur Freezer Company and was

the first to develop and patent an automatic stand-alone undercounter residential ice maker. His foresight and

determination to develop new ideas and to succeed when there were no clear guidelines or solutions are evident today. The Milwaukee, Wisconsin based family operated business provides continuity and vision from

which innovations continue to be born.

Going forward, U-Line will continue offering best-in-class products that build on the company's numerous patents and world firsts to guide the undercounter industry in realizing its unlimited potential.

The Built-In Undercounter Leader Since 1962

U-LINE.COM

©2009 U-Line Corporation

Publication Number 30265 7/2010 Rev.C

Loading...

Loading...