Page 1

Use and Care Guide

Ice Maker Model:

BI2115

BI2115

Page 2

1 Introduction

Congratulations on your purchase of a U-Line refrigeration product. A pioneer in the field for more than 40 years, U-Line

Corporation is the world’s number one manufacturer of built-in, under-counter, specialty refrigeration and ice making

products. U-Line dedicates 100% of its research and development to these products. The result: U-Line technology

consistently leads the market with innovation, design, depth of product line and performance.

U-Line products are making life more convenient in homes, businesses, and hotels around the world. U-Line supports its

products with a strong dealer network, and its commitment to quality even extends to environmentally safe packaging.

IMPORTANT

READ all of the instructions in this guide completely before operating the unit for the first time.

For future reference, keep this guide in a safe, accessible location. If you need additional information or assistance,

please contact U-Line Corporation directly. Contact information appears on the rear cover of this guide.

If you have a problem with the operation of this product, the SERVICE section of this guide will assist you in quickly

identifying common problems and provide information on possible causes and remedies. If your product needs service,

contact U-Line directly.

Warranty Registration

Your U-Line Corporation Limited Warranty is located on the inside rear cover of this guide. To validate your warranty, the

product and its original purchase date must be registered. A Warranty Registration Card has been included for this

purpose in the package containing this manual. Complete and mail the Warranty Registration Card, or register your

product online at www.U-LineService.com as soon as possible after purchase.

If your product registration is not on file and a request for warranty coverage is received, the date of sale to the U-Line

Selling Dealer or Distributor will be established as the first date of warranty coverage for your product.

Please Record Your Model Information

When you request additional information or service, you will be asked for your products model and serial numbers. You

can find this information on the serial plate located on the upper right or rear wall in the interior of your unit. This

information also appears on the warranty registration card.

1

ULIN_0023_A

Figure 1

Please record the model number (Figure 1, 1), serial number (Figure 1, 2), date of purchase, and dealer contact

information for your U-Line product below:

Model Number:

_____________________________________________________

Serial Number:

_____________________________________________________

Purchase Date:

_____________________________________________________

Dealer Name:

_____________________________________________________

Dealer Address:

_____________________________________________________

Dealer Telephone:

_____________________________________________________

2

2 BI2115

Page 3

2 Table of Contents

Introduction ...............................................................................................................................2

Warranty Registration .......................................................................................................2

Please Record Your Model Information ...........................................................................2

Table of Contents .......................................................................................................................3

Safety Precautions ......................................................................................................................5

Safety Alert Definitions .....................................................................................................5

General Precautions ...........................................................................................................5

Product Features ........................................................................................................................6

Échelon Model BI2115 Ice Maker ......................................................................................6

Operation ...................................................................................................................................6

Initial Startup .....................................................................................................................6

Temperature Control .........................................................................................................6

Ice Maker ............................................................................................................................7

Normal Operating Sounds .................................................................................................7

Outdoor, Marine and RV Usage ........................................................................................8

Storage, Vacation, Moving ................................................................................................8

Product Disposal .................................................................................................................8

Cleaning and Maintenance .......................................................................................................9

General Cleaning ...............................................................................................................9

Maintenance ......................................................................................................................9

Service .......................................................................................................................................14

Before Calling for Service ................................................................................................14

If Service is Required ........................................................................................................14

Replacement Parts ...........................................................................................................14

Troubleshooting Guide ....................................................................................................15

U-Line Corporation Limited Warranty ....................................................................................19

BI2115 3

Page 4

This page intentionally left blank

4 BI2115

Page 5

3 Safety Precautions

IMPORTANTIMPORTANT

PLEASE READ all instructions completely before

attempting to install, operate, or service your unit.

• Proper installation procedures must be followed

if this unit is being initially installed, or is moved

to a new location after being in service. An

INSTALLATION GUIDE for your unit, providing

complete installation information is available

from U-Line Corporation directly, and must be

consulted before any installation is begun. U-Line

contact information appears on the rear cover of

this guide.

• This unit requires connection to a grounded

(three-prong), polarized receptacle that has been

placed by a qualified electrician in accordance

with applicable electrical codes.

WARNING

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform

maintenance on the unit until the electricity

has been disconnected.

• Never remove the round grounding prong from

the plug and never use a two-prong grounding

adapter.

• Altering, cutting of power cord, removal of

power cord, removal of power plug, or direct

wiring can cause serious injury, fire and/or loss

of property and/or life, and will void the

warranty.

• Never use an extension cord to connect power

to the unit.

• Always keep your working area dry.

CAUTION

Safety Alert Definitions

Safety items throughout this guide are labeled with a

Danger, Warning or Caution based on the risk type:

DANGER

Danger means that failure to follow this safety

statement will result in severe personal injury or

death.

WARNING

Warning means that failure to follow this safety

statement could result in serious personal injury

or death.

CAUTION

Caution means that failure to follow this safety

statement may result in minor or moderate

personal injury, property or equipment damage.

General Precautions

Use this appliance for its intended purpose only and

follow these general precautions along with those listed

throughout this guide:

• Use care when moving and handling the unit. Use

gloves to prevent personal injury from sharp

edges.

• If your model requires defrosting, DO NOT use any

type of heater to defrost. Using a heater to speed

up defrosting can cause personal injury and

damage to the inner lining.

IMPORTANTIMPORTANT

• Do not lift unit by door handle.

• Never install or operate the unit behind closed

doors. Be sure front grille is free of obstruction.

Obstructing free air flow can cause the unit to

malfunction and may void the warranty.

• Failure to clean the condenser every three months

can cause the unit to malfunction. This could void

the warranty.

• Allow unit temperature to stabilize for 24 hours

before use.

• If your model requires defrosting, never use an

ice pick or other sharp instrument to help speed

up defrosting. These instruments can puncture

the inner lining or damage the cooling unit.

• Use only genuine U-Line replacement parts.

Imitation parts can damage the unit, affect its

operation or performance and may void the

warranty.

DANGER

RISK OF CHILD ENTRAPMENT. Before you throw away

your old refrigerator or freezer, take off the doors

and leave shelves in place so that children may not

easily climb inside.

BI2115 5

Page 6

4 Product Features 5 Operation

Échelon Model BI2115 Ice Maker

The BI2115 Ice Maker will produce and store up to 25 lbs

(11.3 kg) of ice per day. It conserves on water, using only

2-3/4 gallons (10.4 L) to produce approximately 22 lbs (10

kg) of ice, and features a clear removable ice bucket.

Manual defrosting will be occasionally required.

Exclusive Features of Échelon

• Self-closing door hinges engage when the door is open

approximately 8-10 in. (20-25 cm), ensuring a positive

door seal and preventing door bounce back.

• Black and white models have vinyl clad steel cabinets

that provide a rich textured look, and resist scratching,

peeling, or flaking. They feature a slightly contoured,

across the top, integrated door handle design that

permits the door to be easily reversed. The door comes

standard with a factory-installed flush panel, and will

accommodate a 1/4 in. (0.66 cm) thick custom panel to

achieve a custom, built-in look by matching

surrounding cabinets.

• All stainless steel models have a stainless steel full wrap

cabinet, door, sculpted handle and hinges.

• Stainless steel doors are not field reversible.

• Stainless steel models are deemed suitable for outdoor

use by UL.

• An optional full overlay door panel kit for black and

white units, using a customer provided 3/4 in. (1.9 cm)

thick panel, is available that provides a fully integrated

appearance with surrounding cabinets. Overlay panel

is easily attached to the door.

Features and specifications are subject to change without

notice.

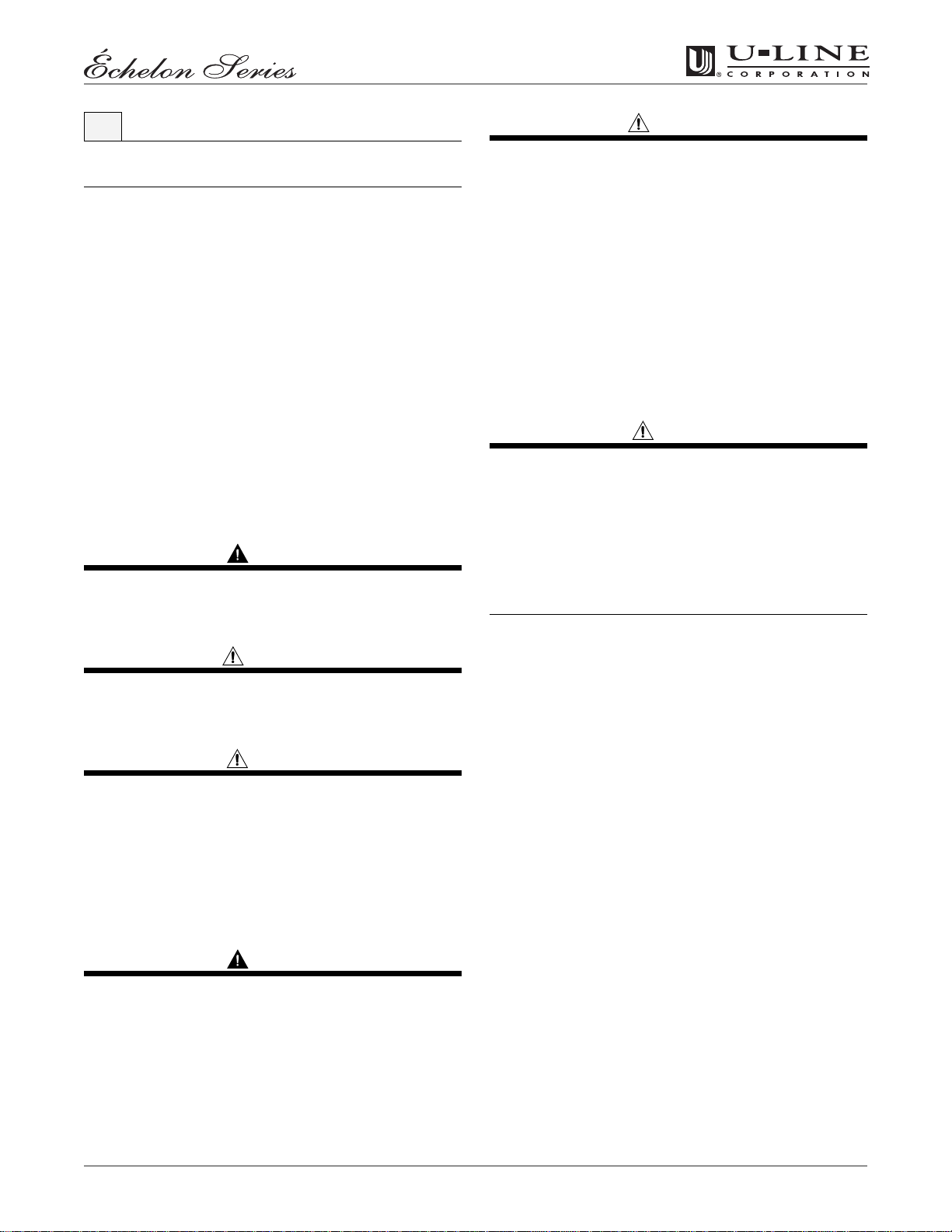

2

Figure 2

1

ULIN_0132_A

IMPORTANTIMPORTANT

Proper air flow (Figure 2) is required for your unit to

operate at its highest efficiently. A grille, located in

the base of the unit, must not be blocked at any

time, or your unit will not perform.

Initial Startup

All U-Line units are shipped with controls that are preset.

No initial adjustments are required.

IMPORTANTIMPORTANT

It is possible that dirt or scale will dislodge in the

water line. Always throw away all ice cubes made

during the first two to three hours of operation.

Open the door to access the power switch. It is located on

the lower front panel (Figure 2, 1).

Depress the ON/OFF switch as required to turn the unit on

or off.

6 BI2115

Temperature Control

Adjusting Temperature

Many factors can affect the internal temperatures of the

cabinet. They include:

• Temperature setting.

• Ambient temperature where installed.

• The number of times and length of time the door is

opened and closed.

• Installation in direct sunlight or near a heat source.

To adjust the temperature setting:

1. Remove the front grille (two screws) (Figure 2, 2).

Page 7

C

O

Figure 3

2. Turn the adjusting screw

screwdriver in a small increment clockwise for a COLDER

setting (slower ice production) or counterclockwise for

a WARMER setting (faster ice production).

3. Replace the front grille (two screws).

R

L

E

D

(Figure 3)

ULIN_0131_A

using a flat tip

Ice Maker

When the ice bucket is full, the ice making mechanism will

shut off. However, the refrigeration system will continue

to cool and maintain the cube supply. Frost-free icemaker

units have lower ice production than manual defrost

units.

IMPORTANTIMPORTANT

Do not place cans or bottles in the ice compartment

because they will freeze.

WARNING

NEVER use an ice pick, knife or other sharp

instrument to separate cubes. Shake the ice

bucket instead.

During periods of limited usage or high ambient

temperatures, it is common for cubes to fuse together.

Shake the bucket to break apart cubes. If the ice maker is

not used regularly, the ice bucket should be emptied

periodically to ensure fresh cubes.

It is normal for cubes to appear cloudy. This is caused by

air being trapped in the water due to fast freezing. It has

nothing to do with the health, taste or chemical make-up

of the water. It is the same air that is in every glass of

water you drink.

The ice bucket can be removed for emptying and

cleaning. To remove the ice bucket, raise the bin arm and

remove the bucket from the ice compartment. Use the ice

bucket for ice storage only.

Normal Operating Sounds

All models incorporate rigid foam insulated cabinets to

provide high thermal efficiency and maximum sound

reduction for its internal working components. In spite of

this technology, your model may make sounds that are

unfamiliar.

Normal operating sounds may be more noticeable

because of the unit’s environment. Hard surfaces such as

cabinets, wood/vinyl/tiled floors and paneled walls have a

tendency to reflect normal appliance operating noises.

Common refrigeration components, and a brief

description of the normal operating sounds they make,

are listed below. NOTE: Your product may not contain all

of the components listed.

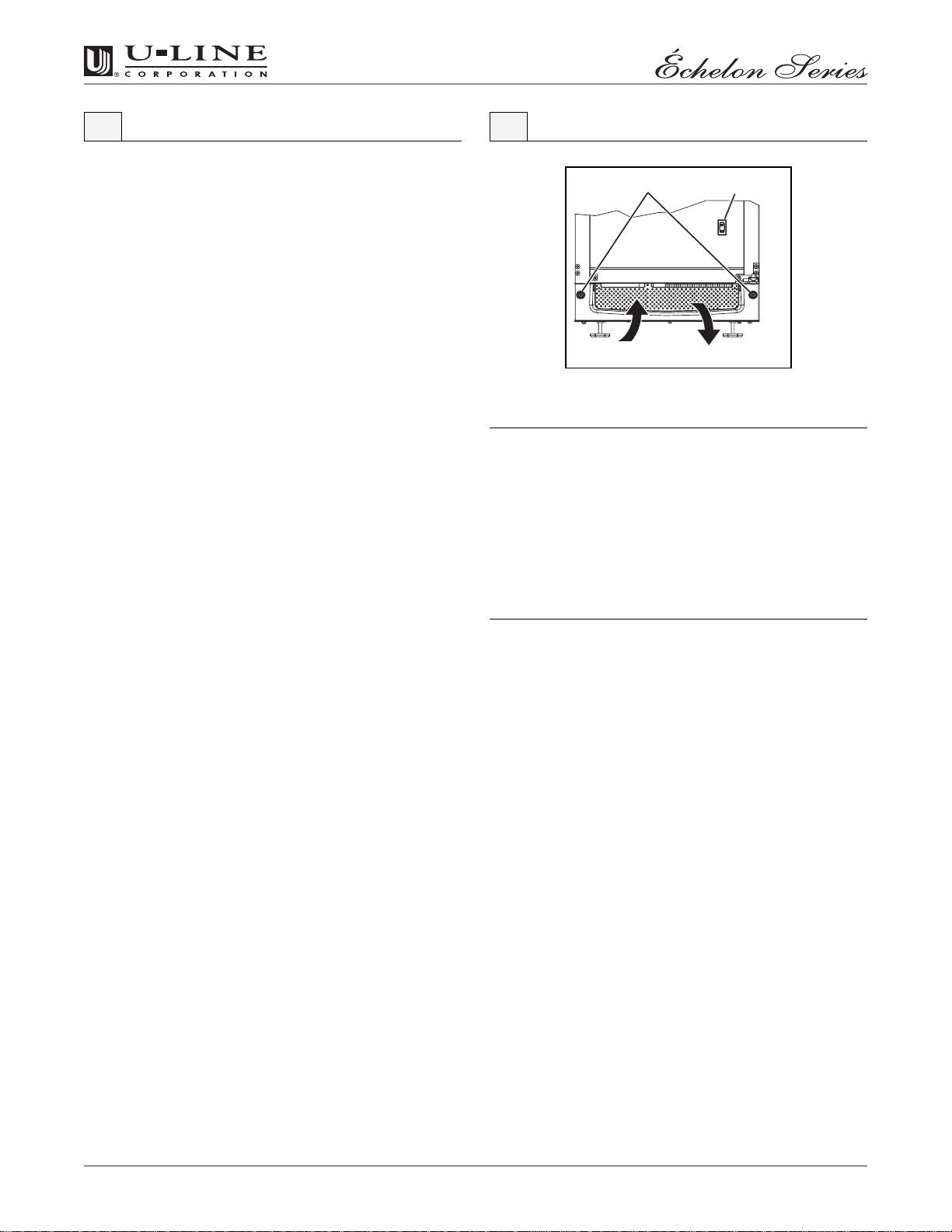

ULIN_0087_A

Figure 4

Ice production may be interrupted by raising the bin arm

into an upright and locked position (Figure 4). The unit

will maintain temperature for ice storage.

IMPORTANTIMPORTANT

If you are not intending to use the ice maker and

turn the supply valve off, it is imperative to raise

the bin arm of the ice maker (Figure 4). Failure to

raise the bin arm may result in damage to the water

valve.

Certain sounds are normal during the unit’s operation.

You may hear the compressor or fan motor, the water

valve, or ice dropping into the ice bucket.

• Compressor: The compressor makes a hum or pulsing

sound that may be heard when it operates.

• Evaporator: Refrigerant flowing through an evaporator

may sound like boiling liquid.

• Condenser Fan: Air moving through a condenser may be

heard.

• Automatic Defrost/Drain Pan: Water may be heard

dripping or running into the drain pan when the unit is in

the defrost cycle.

BI2115 7

Page 8

Outdoor, Marine and RV Usage

Some U-Line models are designed to operate in outdoor,

marine and RV environments. For best performance, keep

the unit out of direct sunlight.

• If the unit will be shut off for five days or more, prop

door open to allow for air circulation and prevent mold

and mildew.

IMPORTANTIMPORTANT

If the ambient temperature is expected to drop

below 45°F, turn off and unplug unit, and drain all

water from the unit to prevent freezing damage not

covered by the warranty.

• High ambient temperatures (110°F or higher) may

reduce the unit's ability to reach low temperatures.

Storage, Vacation, Moving

If the unit will not be used for an extended period, or

otherwise stored, follow these steps completely:

WARNING

Electrical Shock Hazard. Disconnect power before

servicing. Before operating, replace all panels.

Failure to do so may result in death or electrical

shock.

1. Remove all consumable contents from the unit.

2. Disconnect power to the unit.

3. Shut off water supply to the unit at the main water

source.

7. Disconnect the power cord from its outlet, and leave it

disconnected until the unit is returned to service.

8. Clean and dry the interior of the cabinet (See CLEANING

AND MAINTENANCE: GENERAL CLEANING).

9. During periods of non-use, the cabinet must remain

open to prevent the formation of mold and mildew.

Open door a minimum of 2" (5 cm) to provide the

necessary ventilation.

Product Disposal

If the unit is being removed from service for disposal,

check and obey all Federal, State and/or Local regulations

regarding the disposal and recycling of refrigeration

appliances, and follow these steps completely:

1. Remove all consumable contents from the unit.

2. Disconnect power to the unit and unplug the power

cord from its outlet.

3. Shut off water supply to the unit at the main water

source and disconnect the supply line to the unit’s water

valve.

DANGER

RISK OF CHILD ENTRAPEMENT. Before you throw

away your old refrigerator or freezer, take off the

doors and leave shelves in place so that children

may not easily climb inside.

4. Remove the cabinet door if equipped and secure all

interior shelves to the interior of the cabinet using a

heavy duty cloth or package sealing tape.

IMPORTANTIMPORTANT

• If the ambient temperature is expected to drop

below 45°F, turn off and unplug unit, and drain all

water from the unit to prevent freezing damage

not covered by the warranty.

• The use of anti-freeze or other products of this

nature is not necessary and is not recommended.

4. Disconnect the water valve inlet and outlet lines, and

allow them to drain completely.

5. Reconnect power to the unit, and allow it to run for

one hour (minimum) until any remaining ice has been

ejected from the ice maker assembly.

6. Disconnect power to the unit, dry any remaining water

from the ice maker assembly, and reconnect any lines

removed from the water supply valve.

8 BI2115

Page 9

6 Cleaning and Maintenance

General Cleaning

Exterior Cleaning (As Required)

Black and White Models:

• Surfaces may be cleaned with a mild detergent and

warm water solution. Do not use solvent-based or

abrasive cleaners. Use a soft sponge and rinse with

clean water. Wipe with a soft, clean towel to prevent

water spotting.

Stainless Steel Models:

• Stainless steel surfaces and components can discolor

when exposed to chlorine gas, pool chemicals, salt

water or cleaners with bleach.

• Keep your stainless steel unit looking new by cleaning

with a good quality all-in-one stainless steel cleaner/

polish on a monthly basis. For best results use Claire

Stainless Steel Polish and Cleaner, which can be

purchased from U-Line Corporation (P/N 173348).

Comparable products are acceptable. Frequent

cleaning will remove surface contamination that could

lead to rust. Some installations may require cleaning

on a weekly basis.

• Do not clean with steel wool pads.

• Do not use cleaners that are not specifically

intended for stainless steel on stainless steel

surfaces (this includes glass, tile and counter

cleaners).

• If any surface discoloring or rusting appears, clean it

quickly with Bon-Ami

and a non-abrasive cloth. Always clean in the direction

of the grain. Always finish this process with Claire

Stainless Steel Polish and Cleaner or comparable

product to prevent further problems.

• Using abrasive pads such as Scotchbrite™ will

cause the graining in the stainless steel to

become blurred.

• Rust that is not cleaned up promptly can penetrate into

the surface of the stainless steel and complete removal

of the rust may not be possible.

®

or Barkeepers Friend Cleanser®

®

Maintenance

Proper maintenance of your U-Line product will ensure

efficiency, top performance and long life. The

maintenance intervals listed are based on normal

conditions. You may want to shorten the intervals if you

have pets or other special considerations.

Defrosting

Manual Defrost Models - Every Two Months

(Minimum)

WARNING

DO NOT use any type of electrical heating device,

ice pick, knife or other sharp instrument to

defrost; this could damage the inner lining or

refrigeration system and void the warranty.

IMPORTANTIMPORTANT

The drain pan was not designed to capture the

water created when manually defrosting. To

prevent water from overflowing the drain pan,

place towels or other absorbent materials on the

bottom of the unit (Figure 5, 1), before defrosting.

1

Interior Cleaning (As Required)

• Disconnect power to the unit. Clean the interior and all

removed components using a mild non-abrasive

detergent and warm water solution applied with a soft

sponge or non-abrasive cloth. Rinse the interior using a

soft sponge and clean water.

• Do not use any solvent-based or abrasive

cleaners. These types of cleaners may transmit

taste to the interior products and damage or

discolor the interior.

ULIN_0188_A

Figure 5

BI2115 9

Page 10

To defrost:

2. Loosen two screws

(Figure 6, 1)

completely.

1. Turn unit off.

2. Remove ice bucket and discard ice.

3. Place a towel or other absorbent material on bottom of

unit

(Figure 5, 1)

4. If you would like, place warm water inside ice bucket.

Then place ice bucket back into unit and close door.

5. After approximately one hour, remove ice bucket and

discard water.

6. Allow the frost to completely melt naturally. Clean the

interior and ice bucket using a mild non-abrasive

detergent and warm water solution applied with a soft

sponge or non-abrasive cloth.

solvent-based or abrasive cleaners. They will discolor or

damage the interior.

7. Dampen a soft sponge or non-abrasive cloth in clean

water and wipe down the cabinet interior and ice

bucket to remove any detergent residue. Rinse the

sponge or cloth in clean water and repeat as necessary

until the cabinet and ice bucket are clean.

.

NOTE: DO NOT

use any

IMPORTANTIMPORTANT

DO NOT place ice bucket in dishwasher. Dishwasher

will warp/discolor ice bucket and render it useless.

8. When the interior is dry, turn unit back on.

NOTE: To safeguard against contaminants in ice,

discard first three batches of ice made after defrosting

unit.

Condenser Cleaning

Interval - Every Three Months

To maintain operational efficiency, keep the front grille

free of dust and lint and clean the condenser every three

months. Depending on environmental conditions, more

or less frequent cleaning may be necessary.

NOTE: Screws are held in the grille by o-ring retainers,

and will not come free of the grille.

3. Remove the grille.

WARNING

DO NOT touch the condenser fins. The condenser

fins are SHARP and can be easily damaged.

CAUTION

DO NOT use any type of cleaner on the condenser

unit.

4. Clean the condenser coil

brush with a “combing” action or vacuum cleaner. Do

not touch the condenser coil.

5. Position the grille to align the mounting screws with

the holes in the cabinet.

6. Secure, but do not over-tighten both grille screws.

7. Reconnect power to the unit.

(Figure 6, 2)

using a soft

Ice Maker Maintenance

Inlet Screen

Interval - Every Twelve Months

The solenoid valve inlet screen must be cleaned at least

once each year as follows:

1. Shut off the water at the main supply valve.

2. Pull the unit out to access the back panel.

3. Disconnect electrical power to the unit.

2

WARNING

Disconnect electric power to the unit before

cleaning the condenser.

To remove and replace the grille for access to the

condenser fins, follow this procedure:

1

2

Figure 6

1. Disconnect electrical power to the unit.

10 BI2115

ULIN_0203_A

1

ULIN_0054_A

Figure 7

4. Disconnect the hose connector

water solenoid valve

5. DO NOT remove the inlet screen from the water

solenoid valve. Use a tooth brush to gently clean any

sediment from the inlet screen.

6. Re-connect the water supply hose connector

7, 1)

to the water solenoid valve

the connector securely.

(Figure 7, 2)

(Figure 7, 1)

.

(Figure 7, 2)

from the

(Figure

. Tighten

Page 11

7. Open the water main supply valve and check for

leakage at the water hose connection. Ensure that the

water supply line is not kinked.

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+) sign

(counterclockwise) for larger cubes.

8. Reconnect power to the unit before re-installing.

Ice Cube Thickness Adjustment

Interval - As Required

On ice maker equipped models, the cube size may be

adjusted by changing the amount of water injected into

the ice maker assembly as follows:

ULIN_0275_A

Figure 8

1. Remove the ice maker assembly cover (Figure 8).

4. Install the ice maker assembly cover.

IMPORTANTIMPORTANT

Use only genuine U-Line replacement parts. U-Line

ice maker parts are not the same as standard FSP

Whirlpool parts. Using non U-Line parts can reduce

ice rate, cause water to overflow from ice maker

mold, damage the unit, and may void the warranty.

Leveling

1

ULIN_0043_A

Figure 10

ULIN_0056_A

Figure 9

2. Locate the adjusting screw on the ice maker assembly

control box. The adjusting screw is just below the minus

(-) and plus (+) signs on the control box

(Figure 9)

.

NOTE: Make adjustments in small increments. Too

large of an adjustment could cause the unit to

malfunction.

CAUTION

Too large of an adjustment to the screw can cause

the water to overflow the ice maker and can cause

property damage.

1.

Use a level to check the levelness of the unit from front

to back and from side to side. Level should be placed

along top edge and side edge as shown

1

ULIN_0044_A

(Figure 10)

.

Figure 11

2. If the unit is not level, adjust the feet on the corners of

the unit as necessary

(Figure 11)

.

3. Check the levelness after each adjustment and repeat

the previous steps until the unit is level.

BI2115 11

Page 12

Door Alignment Check and Adjustment

IMPORTANTIMPORTANT

When properly aligned:

• The door will not be flush with the top of the

cabinet. The top edge of the door will be 1/8 in.

(3.175 mm) below the cabinet top.

• The door gasket will be firmly in contact with the

perimeter of the cabinet and not pinched on the

hinge side of the door.

The following procedure will correct for up to 1/4 in.

misalignment:

1

23

Figure 14

3. Turn the door upside down and inspect the hinge plate

mounting holes.

ULIN_0201_A

1/8"

(3.175 mm)

ULIN_0016_A

Figure 12

1. Compare the top edge of the door (opposite the

hinges) to the top edge of the cabinet (Figure 12) and

note the type (up or down) of adjustment needed.

• Your plate has slotted mounting holes (Figure

14, 1). Loosen but do not remove the two hinge

plate screws.

4. If door edge opposite the hinges needs to move up,

move plate toward outside of door

(Figure 14, 2)

door edge needs to move down, move plate toward

inside of door

(Figure 14, 3)

. Repeat until top edge of

door is parallel with top of cabinet and tighten screws

securely

(Figure 14, 1)

.

. If

ULIN_0133_A

Figure 13

2. Remove the top hinge pivot pin with a Phillips

screwdriver

(Figure 13)

and lift door off bottom hinge

pin. Be careful not to lose the door closer insert sets.

12 BI2115

1

ULIN_0004_A

Figure 15

5. After adjustment is complete, remove the door closers

from the bottom hinge, clean thoroughly and apply

petroleum jelly to the mating surfaces of the closers. Be

sure that bosses on closers

(Figure 15, 1)

align with

holes in the door and bottom cabinet hinge plates.

Mount door and install top hinge pivot pin.

Page 13

Door Reversal

1

ULIN_0002_A

Figure 18

2. Remove plastic screw plugs (three each, top and

bottom)

not discard.

(Figure 18, 1)

from new hinge location. Do

ULIN_0202_A

Figure 16

All U-Line black or white units may be left- or right-hand

opening. Stainless steel unit doors cannot be reversed.

The doors are easily reversed by moving the hinge

hardware to the opposite side. The top hinge hardware

will be used on the bottom of the other side and the

bottom hinge hardware will be used on the top of the

other side (Figure 16).

To reverse the door:

1

3. Remove top hinge (three screws)

reinstall hinge screw pin

(Figure 17, 1)

(Figure 17, 2)

.

and

1

ULIN_0005_A

Figure 19

4. Install the removed top hinge mount on opposite side

BOTTOM

(Figure 19)

.

2

ULIN_0003_A

Figure 17

1. Remove top hinge screw pin (Figure 17, 1) from door

using a Phillips screwdriver. Remove door by tilting

forward and lifting off bottom hinge pin.

1

ULIN_0004_A

Figure 20

BI2115 13

Page 14

5. Remove the two door closer inserts

the existing bottom hinge and install as shown on the

new bottom hinge

6. Remove existing bottom hinge (three screws) and

remount on opposite side TOP. Remove hinge screw pin.

7. Remove the plastic hole plug from the top of the door

to allow the pivot pin to be inserted in the new

location. Install the plug into the vacated hole on the

opposite side.

8. With bottom of door facing up, remove pivot plate

(two screws), flip over, and remount on opposite side of

door

(Figure 21). Be sure notch in plate faces

center.

9. Holding door upright with top of door tilted forward,

place hole of door pivot plate on bottom hinge screw

pin/closer inserts

10. Tilt top of door into position in top hinge and install top

hinge screw pin.

11. Install plastic screw plugs removed in Step 2 in old hinge

holes (three each, top and bottom).

(Figure 19, 1)

Figure 21

(Figure 19, 1)

(Figure 20, 1)

.

ULIN_0006_A

.

from

7 Service

Before Calling for Service

If your U-Line product appears to be malfunctioning, read

through the OPERATION section of this guide to ensure

that the function of all controls are clearly understood. If

the malfunction persists, the TROUBLESHOOTING GUIDE

in this guide will assist you in quickly identifying common

problems, and provide information on possible causes and

remedies. Most often, this will resolve the problem

without the need to call for service.

If Service is Required

If you do not understand a troubleshooting remedy, or

your product needs service, contact U-Line Corporation

directly. Contact information appears on the rear cover of

this guide.

You will be asked for your product Model and Serial

Numbers. This information should be recorded inside the

front cover of this guide, following the products original

purchase. It also appears on the Model and Serial number

plate located on the upper right or rear wall of the

interior of your product.

Replacement Parts

When you need replacement parts, always request that

genuine U-Line replacements be used. U-Line products

have been designed and engineered using components

that work efficiently, and provide superior service life and

performance. The use of aftermarket parts or components

may affect the safety, operation, performance or

durability of your product, and may also void its warranty.

14 BI2115

Page 15

Troubleshooting Guide

DANGER

ELECTROCUTION HAZARD

Never attempt to repair or perform maintenance on

the unit until the main electrical power has been

disconnected.

Troubleshooting - What to check when problems occur:

PROBLEM POSSIBLE CAUSE REMEDY

The unit frosts up. High ambient temperatures or

Water is leaking out the back of the

unit.

Ice cubes sticking together Infrequent use of cubes Break apart cubes.

Noise during operation Copper water supply tubing

No ice Bin arm locked in upright position Lower bin arm.

Not enough ice Ice cube size too large Set cube size smaller (See MAINTENANCE; ICE MAKER;

Water leaks into ice bucket. Water level set too high Set cube size smaller (See MAINTENANCE; ICE MAKER;

humidity

Unit is a manual defrost unit. Model BI2115 is a manual defrost unit (See

Door gasket not sealing properly Adjust door (See MAINTENANCE; DOOR ALIGNMENT

Water supply connection leaking Tighten fitting as required.

contacting internal components

Certain sounds are normal. Soft sounds from the fan and ice dropping from the ice

No water to unit Turn on water or contact plumber.

Dirty condenser coils Clean condenser (See MAINTENANCE; CONDENSER

Airflow to front grille blocked Airflow must not be obstructed to front grille (See

Temperature not set cold enough Set control to cooler setting (See OPERATION). Allow 24

Defrost unit manually (See MAINTENANCE;

DEFROSTING).

MAINTENANCE; DEFROSTING).

CHECK AND ADJUSTMENT and DOOR REVERSAL).

Carefully bend tubing away from cabinet and

components.

maker will be heard.

ICE CUBE THICKNESS ADJUSTMENT).

CLEANING).

OPERATION).

hours for temperature to stabilize (See OPERATION).

ICE CUBE THICKNESS ADJUSTMENT).

BI2115 15

Page 16

This page intentionally left blank

16 BI2115

Page 17

This page intentionally left blank

BI2115 17

Page 18

This page intentionally left blank

18 BI2115

Page 19

U-Line Corporation Limited Warranty

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship for a period of

one year from the date of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the

evaporator, the hot gas bypass valve, the dryer and the connecting tubing) in each U-Line product to be free from

defects in materials and workmanship for a period of five years from the date of purchase. During the initial one-year

warranty period for all U-Line products U-Line shall: (1) at U-Lines option, repair any product or replace any part of a

product that breaches this warranty; and (2) for all Marine, RV and Domestic U-Line products sold and serviced in the

United States (including Alaska and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with

the replacement of any defective part. During years two through five of the warranty period for the sealed system, ULine shall: (1) repair or replace any part of the sealed system that breaches this warranty; and (2) for all Marine, RV and

Domestic U-Line products sold and serviced in the United States (including Alaska and Hawaii) and Canada, U-Line shall

cover the labor costs incurred in connection with the replacement of any defective part of the sealed system. All other

charges, including transportation charges for replacements under this warranty and labor costs not specifically covered

by this warranty, shall be borne by you. This warranty is extended only to the original purchaser of the U-Line product.

The Registration Card included with the product should be promptly completed by you and mailed back to U-Line or you

can register on-line at www.U-LineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or acts of God,

such as fire, floods, wind and lightening; damages incurred or resulting from shipping, improper installation,

unauthorized modification, or misuse/abuse of the product; customer education calls; food loss/spoilage; door and water

level adjustments (except during the first 90 days from the date of purchase); defrosting the product; adjusting the

controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the dealer from

whom you purchased the product or U-Line at P.O. Box 245040, Milwaukee, Wisconsin 53224 or at 414-354-0300. In no

event shall such notification be received later than 30 days after the expiration of the applicable warranty period. U-Line

may require that defective parts be returned, at your expense, to U-Lines factory in Milwaukee, Wisconsin, for

inspection. Any action by you for breach of warranty must be commenced within one year after the expiration of the

applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not limited to any

implied warranty of merchantability or fitness for a particular purpose; provided however, that to the

extent required by law, implied warranties are included but do not extend beyond the duration of the

express warranty first set forth above. U-Lines sole liability and your exclusive remedy under this warranty

is set forth in the initial paragraph above. U-Line shall have no liability whatsoever for any incidental,

consequential or special damages arising from the sale, use or installation of the product or from any other

cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract, tort or

any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitations may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

BI2115 19

Page 20

For General Inquir ies:

P.O. Box 245040

Milwaukee, Wisconsin

53224-9540 U.S.A.

Phone (800) 779-2547

FAX (414) 354-5696

www.U-Line.com

For Service and Parts

Assistance:

Phone (800) 779-2547

(414) 354-0300

FAX (414) 354-5696

Email:

OnLineService@U-Line.com

www.U-LineService.com

E-mail:

OnlineParts@u-line.com

For more than four decades, U-Line has distinguished itself as the

leader in built-i n under-counter ice making, refrigeration and

wine storage appliances.

An INSTALLATION MANUAL for your unit, providing complete

installation information, is available for download at

www.U-Line.com. Information for custom panel inserts per model,

including panel size, and instructions are available by visiting

www.U-Line.com.

When you need r eplacement parts, always request genuine U-Line

replacements be used. Visit www.U-Line.com to locate a parts

distributor in your area.

U-Line Corporation, located in Milwaukee, WI, is a family operated manufacturer of built-in

undercounter ice makers, Combo

refrigerator s, re fri g er ated d raw e rs and refri ge ra tor/ fre e ze rs.

®

ice maker/refrigerators, Wine Captain® wine storage units,

©2006 U-Line Corporation

Publication No. 30097

01/2006 Rev. A

Loading...

Loading...