Tyco BFV-300, BFV-300C Specification

Model BFV-300/BFV-300C

Butterfly Valve

Grooved End

Page 1 of 8 JUNE 2016 TFP1511

Worldwide

Contacts

www.tyco-fire.com

Technical

Data

Approvals

UL Listed

FM Approved

CE Certified

VdS Approved

Russian Fire Certificate

CNPP R1 Li sted – APSAD

Listed by California State Fire Marshall

Refer to Tables A, B and C for applicability.

All laboratory listings and approvals are for

indoor and outdoor use.

Sizes

2 – 12 Inch ( DN50 – DN30 0)

UL/FM Maximum Working Pressure

2 – 8 Inch (D N50 – DN200 ) . . . . 300 psi ( 20,7 bar)

10 – 12 I nch (D N250 – DN30 0) . . 175 psi (12,1 bar)

VdS Maximum Working Pressure

2 – 8 Inch (D N50 – DN200 ) . . . . 300 psi ( 20,7 bar)

10 Inch (DN250) . . . . . . . . . . . 232 psi (16,0 bar)

12 Inch (DN300 ) . . . . . . . . . . . . 175 psi (12,1 bar)

Maximum Working Temperature

212°F (100°C) in accordance with UL 1091

Materials of Construction

Body . . . . . . . . . . . . . . . . . . . . . . . . . Ductile Iron

Body Coating . . . . . . . . . . . RILSAN PA11 Black

Disc . . . . . . . . . . . . . . . . . . . . . . . . . . Ductile Iron

Disc Seal ...............EPDM Encapsulated

Upper & Lower Stem . . . . . . . . . . Stainless Steel

Handwheel . . . . . . . . . . . . . . . . . . . . Ductile Iron

(BFV-300 red painted; BFV-300C black painted)

Actuato r, 2 – 6 Inch (D N50 – DN150) :

• IP 65, bronze traveling nut gea rbox, ductile

iron housing

Actuato r, 8 – 12 In ch (DN 200 – DN30 0):

• IP 65, brass segmented gearbox, ductile iron

housing

Tapping Bosses

Two factory-plugged NPT threaded tapping

bosses in the valve body are located on the

up- and downstream sides of the disc for

connection to valve trim. Tapping boss

sizes:

2 – 3 inch (D N50 – DN80 ) .............3/8 NPT

4 – 12 inch ( DN100 – DN30 0) ..........1/2 NPT

100% Silicone Free

Model BFV-300/BFV-300C Butterfly Valves

are produced and assembled using no

silicone lubricants in any form (like grease

or aerosol spray) and are suitable for paint

or oxygen applications.

General

Description

The TYCO Models BFV-300 and BFV-

300C Grooved End Butterfly Valves

are indicating type valves designed for

use in fire protection systems where

a visual indication of open or closed

valve condition is required. They are

used, for example, as system, sec-

tional and pump water control valves.

They have grooved inlet and outlet con-

nections that are suitable for use with

grooved end pipe couplings listed or

approved for fire protection systems.

For applications requiring supervi-

sion of the open or closed state of the

valve, the Gear Operators for the Model

BFV-300/BFV-300C Butterfly Valves

feature two sets of factory installed

internal switches each having SPDT

contacts ( Ref. Figure 3). The super-

visory switches transfer their electri-

cal contacts when there is movement

from the open or closed disc position

during the first two revolutions of the

handwheel.

NOTICE

The Model BFV-300/BFV-300C

Grooved End Butterfly Valves described

herein must be installed and maintained

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Asso-

ciation, in addition to the standards of

any other authorities having jurisdiction.

Failure to do so may impair the perfor-

mance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Control Valve Seat Leakage

Class IEC 60534-4

CLASS VI (Type C) Control Valve Seat

Leakage according to ANSI/FCI

70-2-2006 (ASME B16.104)

MODEL BFV-300

WITH OPEN SUPERVISORY

SWITCHES

MODEL BFV-300C

WITH CLOSED SUPERVISORY

SWITCHES

TF P1511

Page 2 of 8

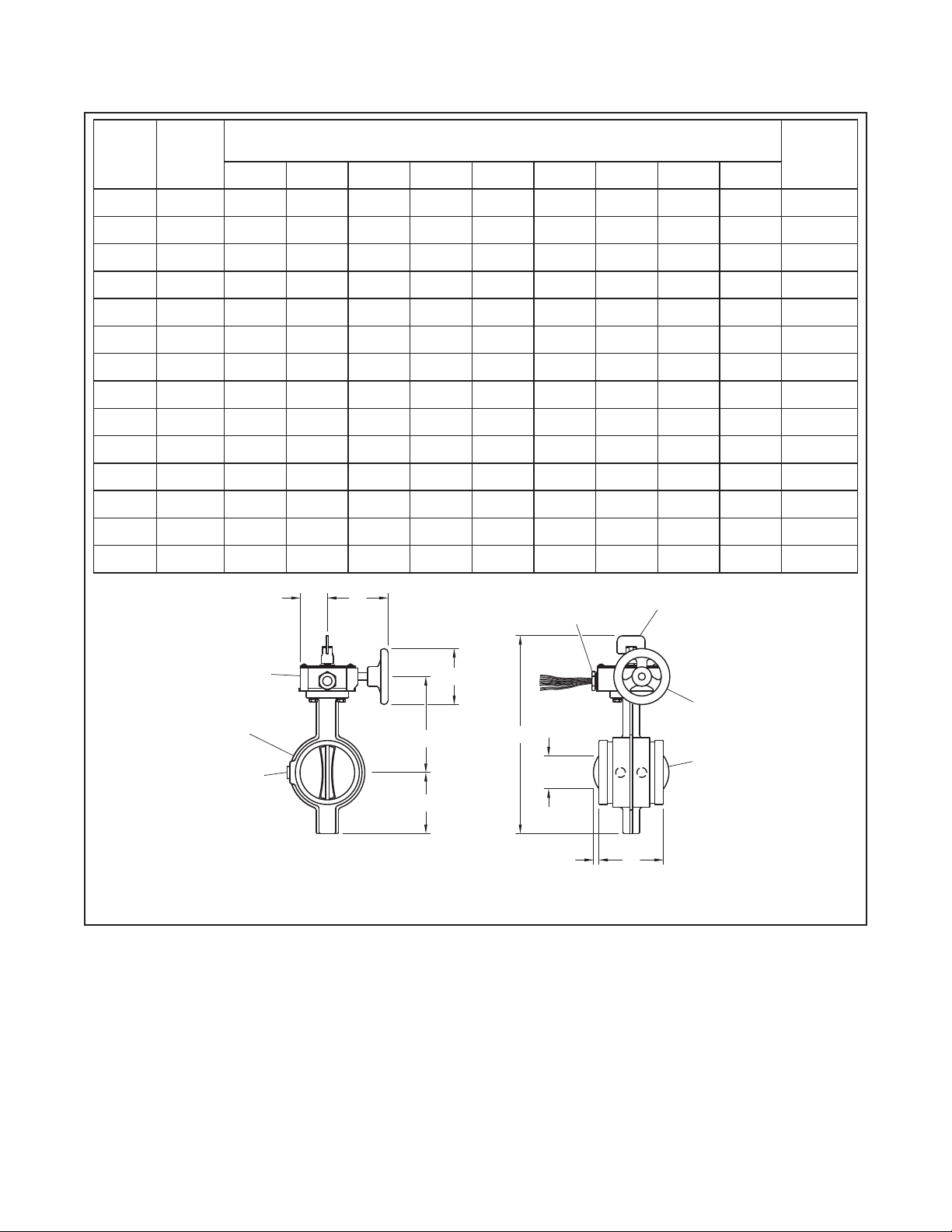

Nominal

Valve Size

Inches

(DN)

Pipe

OD

Inches

(mm)

Nominal Dimensions

Inches

(mm)

Weight

Lbs.

(kg)

A B C D E F G H J

2

(DN50)

2.37

(60,3)

3.8

(96,4)

10.6 3

(270)

2.85

(72,5)

4.90

(124, 5)

4.92

(125)

4.28

(108 ,6)

1.9 9

(50,5)

0 0

10.8

(4,9)

2-1/ 2

(DN65)

2.88

(73,0)

3.8

(96,4)

11.72

(297, 8 )

3.35

(85)

5.5

(139,8 )

4.92

(125)

4.28

(108 ,6)

1.9 9

(50,5)

0 0

13.0

(5,9)

—

(DN65)

3

76 ,1

3.8

(96,4)

11.72

(297, 8 )

3.35

(85)

5.5

(139,8 )

4.92

(125)

4.28

(108 ,6

1.9 9

(50,5)

0 0

13.0

(5,9)

3

(DN80)

3.5

(88,9)

3.8

(96,4)

12.22

(310,3)

3.58

(91)

5.76

(146, 3 )

4.92

(125)

4.28

(108 ,6)

1.9 9

(50,5)

0 0

13.9

(6,3)

4

(DN100)

4.5

(114,3)

4.54

(115,4)

13.92

(353,5)

4.29

(109 )

6.75

(171,5)

4.92

(125)

4.28

(108 ,6)

1.9 9

(50,5)

0 0

17. 6 4

(8,0)

—

(D N125)

5.5

(139,7)

5.83

(148)

16

(406,6)

5.16

(131)

7.9 3

(201,5)

5.91

(150 )

5.79

(147 )

2.32

(58,9)

0 0

26.4

(11,9)

5

(D N125)

5.56

(141,3)

5.83

(148)

16

(406,6)

5.16

(131)

7.9 3

(201,5)

5.91

(150 )

5.79

(147 )

2.32

(58,9)

0 0

26.4

(11,9)

—

DN15 0

6.5

16 5 ,1

5.83

(148)

17. 0 7

(433,6)

5.71

(145)

8.44

(214, 5)

5.91

(150 )

5.79

(147 )

2.32

(58,9)

0 0

30,42

(13, 8)

6

(DN150)

6.63

(168 ,3)

5.83

(148)

17. 0 7

(433,6)

5.71

(145)

8.44

(214, 5)

5.91

(150 )

5.79

(147 )

2.32

(58,9)

0 0

30,42

(13, 8)

8

(DN200)

8.63

(219,1)

5.24

(133 )

19.67

(499,5)

6.69

(170)

9.29

(236)

8.86

(225)

8.19

(208)

2.76

(70)

5.66

(143,7)

1.24

(31, 4)

47.1 8

(21, 4)

10

(DN250)

10.75

(273)

6.26

(159)

22.46

(570,5)

7.6 8

(195 )

11.1

(282)

11.14

(283)

8.19

(208)

2.91

(74)

7. 2 1

(183 ,1)

1.65

(41,8)

73.41

(33,3)

—

(DN250)

10.75

(273)

6.26

(159)

22.46

(570,5)

7.6 8

(195 )

11.1

(282)

11.14

(283)

8.19

(208)

2.91

(74)

7. 2 1

(183 ,1)

1.65

(41,8)

73.41

(33,3)

12

(DN300)

12.75

(323,9)

6.5

(165 )

25.39

(645)

9.5

(241,5 )

12.2

(310)

11.14

(283)

8.19

(208)

2.91

(74)

9.96

(252,9)

2.7

(68,5)

89.29

(40,5)

—

(DN300)

12.75

(323,9)

6.5

(165 )

25.39

(645)

9.5

(241,5 )

12.2

(310)

11.14

(283)

8.19

(208)

2.91

(74)

9.96

(252,9)

2.7

(68,5)

89.29

(40,5)

B

D

A

C

H

DISC

BOSSES

TAPPING

G

BODY

GEAR

OPERATOR

E

HANDWHEEL

CONNECTION

1/2" NPT

CONDUIT

F

INDICATOR

FLAG

J

FIGURE 1

MODEL BF V-300/BF V-30 0C GROOVED END BUTTERFLY VALVE

NOMINAL DIMENSIONS

TF P1511

Page 3 of 8

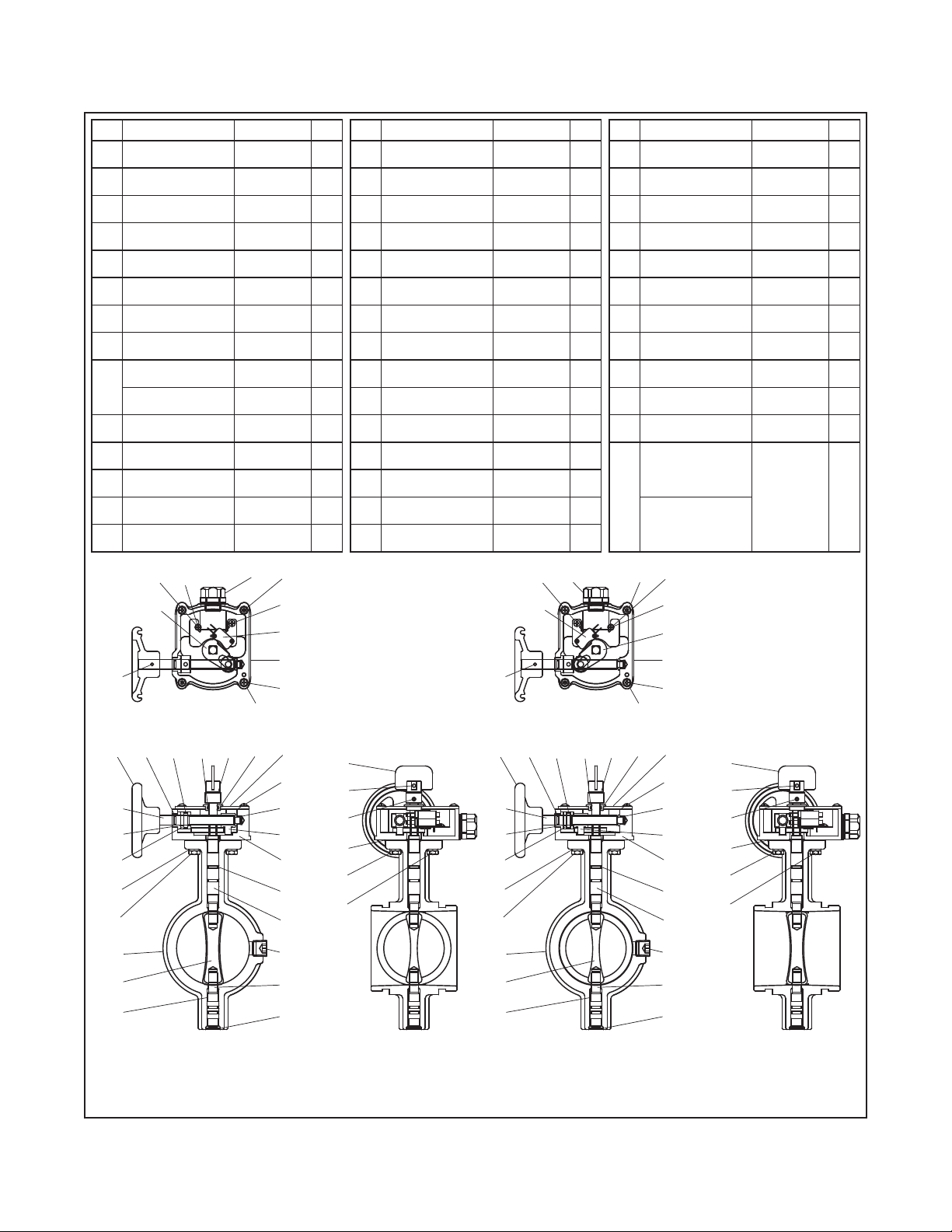

BFV-300 Normally Open Valve

Supervisory Switch Arrangement

BFV-300C Normally Closed Valve

Supervisory Switch Arrangement

No. Part Material Qty.

01 Body

ASTM

A-536

1

02 Upper Stem AI SI 410 1

03 Lower Stem AI SI 410 1

04 Disc EPDM 1

05 O- Rin g (P12) EPDM 4

06

Oiless B/R

(M B1410)

— 4

07

End Cap

2-1/2 – 4 Inch

EPDM 1

08 Gear Box

ASTM

A-536

1

09

Traveling Nut

2 – 6 Inch

Bronze 1

Segment Gear

8 – 12 Inch

C3604BD 1

10 Bushing (2) FD-0205-45 1

11 Cover

ASTM

A- 619

1

12 Bushing Fe 1

13

Headless Wrench

Bolt M5 x 7L

ASTM

A-307

1

14 Stem Housing Fe 1

No. Part Material Qty.

30 Bolt (Round)

ASTM

A-167

3

31 Plate Washer

ASTM

A-167

4

32 Switch Assembly — 1

33 T/R Bolt

ASTM

A-307

2

34

Tapping Screw

ST3.5 x 7.5

S10C 1

35 Tooth Washer 4# S10C 1

36 Lever

ASTM

A- 619

1

37 Connector — 1

38 Sticker — 1

39 Sticker — 1

40

Spring Pin

Ø3 x 0.6T x 25

ASTM

A-228

1

41

Headless Plug

3/8 NPT

2 – 3 Inch

ASTM

A-307

2

Headless Plug

1/2 N PT

4 – 12 Inch

No. Part Material Qty.

15 Spring Pin

ASTM

A-228

1

16 Indicator

ASTM

A- 619

1

17 O-Ring NBR 1

18 Cover Gasket Paper 1

19

Spring Pin

Ø5 x 1T x 25

ASTM

A-228

1

20 O-Ring (P10) EPDM 1

21 Worm Shaf t A ISI 410 1

22 Bushing (1) FD-0205-45 1

23 Collar FD-0205-45 1

24 Spring Washer

ASTM

A-167

4

25

Hex Bolt

M8 x 20L

ASTM

A-167

2

26

Hex Bolt

M8 x 25L

ASTM

A-167

2

27 Gasket Paper 1

28

Spring Pin

Ø4 x 0.8t x 25

ASTM

A-228

1

29 Handwheel

ASTM

A-536

1

26

25

15

27

13

16

30

32

06

23

25

01

04

24

22

21

29 20

28

17 14

40

37

19,

35

36

34

31

38, 39

18

11

10

09

05

03

41

02

08

07

30

33

12

38, 39

28

25

21

22

29

23

24

04

01

06

34

19,

40

17

20

36

35

30

37 33

30

32

31

18

08

05

09

11

10

03

07

41

02

1214

16

13

15

27

26

25

FIGURE 2

MODEL BF V-300/BF V-30 0C GROOVED END BUTTERFLY VALVE

AS S E M B LY

Loading...

Loading...