Page 1

http://www.tyco-reproducts.com

Close

Model ACC‑1 Dry Pipe Valve Accelerator

External Resetting Quick Opening Device

For Dry Pipe Valves

General

Description

The Model ACC‑1 Accelerator is a quick

opening device intended for attachment

Tyco Fire & Building Products, 2‑1/2,

to the

3, 4 or 6” Model DPV‑1 Dry Pipe Valve. The

Model ACC‑1 Accelerator reduces the time

for valve operation following the operation

of one or more automatic sprinklers.

The Model ACC‑1 Accelerator automatical‑

ly adjusts to both small and slow changes

in system pressure, but trips when there is

a rapid and steady drop in pressure (as in

the case of a sprinkler operation). Upon

tripping, the Accelerator transmits system

air pressure to the intermediate chamber of

the Model DPV‑1 Dry Pipe Valve. This neu‑

tralizes the dierential pressure holding the

Model DPV‑1 Dry Pipe Valve closed and per‑

mits it to open.

The Model ACC‑1 Accelerator has a unique,

e ac

positiv

and a ball oat which combine to prevent

water and water borne debris from entering

the more sensitive operating areas of the

acceler

latches immediately upon operation of the

Model ACC‑1 Accelerator without waiting

for a pressure build‑up in the intermediate

chamber of the dry pipe valve. The latching

featur

even while the system is being drained. The

ball oat seals the pilot chamber inlet port

if there is an inadvertent trip of the dry pipe

valve, due for example, to an air compressor

failure combined with a slow loss in system

air pressure due to a leak.

The Model ACC‑1 Dry Pipe Valve Accelerator

is a direct replacement for the Central Mod‑

el B, Gem Model F311, and Star Model S430.

Contact the Technical Services Department

for information concerning the use of the

ACC‑1 for use with dry pipe valves other

than the Model DPV‑1.

tion, internal anti‑ood device

ator. The anti‑ood device seals and

e keeps the anti‑ood device sealed,

WARNING

The Model ACC‑1 Dry Pipe Valve Accelerator

described herein must be installed and main‑

tained in compliance with this document, as

well as with the applicable standards of the

National Fire Protection Association, in addi‑

to

the standards of any other authori‑ties

tion

having jurisdiction. Failure to do so may im‑

pair the integrity of this device.

The owner is responsible for maintaining their

re protection system and devices in proper

operating condition. The installing contrac‑

tor or sprinkler manufacturer should be con‑

tacted relative to any questions.

Technical Data

Approvals

UL and ULC Listed. FM and LPCB Approved.

Maximum Working Water Pressure

17,2 bar (250

Maximum Working Air Pressure

4,8 bar (70

Pressure Decay For Trip

0,07 bar/min (1

Physical Characteristics

Body components constructed of alodine

coated aluminum alloy with austenitic se‑

ries stainless steel internal components.

Seals are EPDM and silicone.

psi)

psi)

psi/min)

Design Data

The connection to the system piping,

Figure 4, must be located so that drain

back water will not ow into the Accel‑

erator piping and it must be located at

a point above the maximum expected

level of the drain back/condensate water.

If the connection is made to the riser, it

must be located at least two feet above

the level of the dry pipe valve. Connec‑

tions to a feed or cross main must be

made either to the side or top of the main.

NOTES

Failure to follow the above instructions can

result in accidental tripping due to closure of

the ball oat.

Quick operation of the Accelerator does not

ensure that the re protection system will

meet the water delivery time requirement of

the authority having jurisdiction (following

opening of the Inspector’s Test Connection).

The sprinkler system designer needs to be

aware that water delivery time is primarily

determined by the conguration and volume

of the piping network, system air pressure

at time of Accelerator trip, and water supply

characteristics.

Page 1 of 10 TFP1112_EN

Page 2

Page 2 of 10 TFP1112_EN

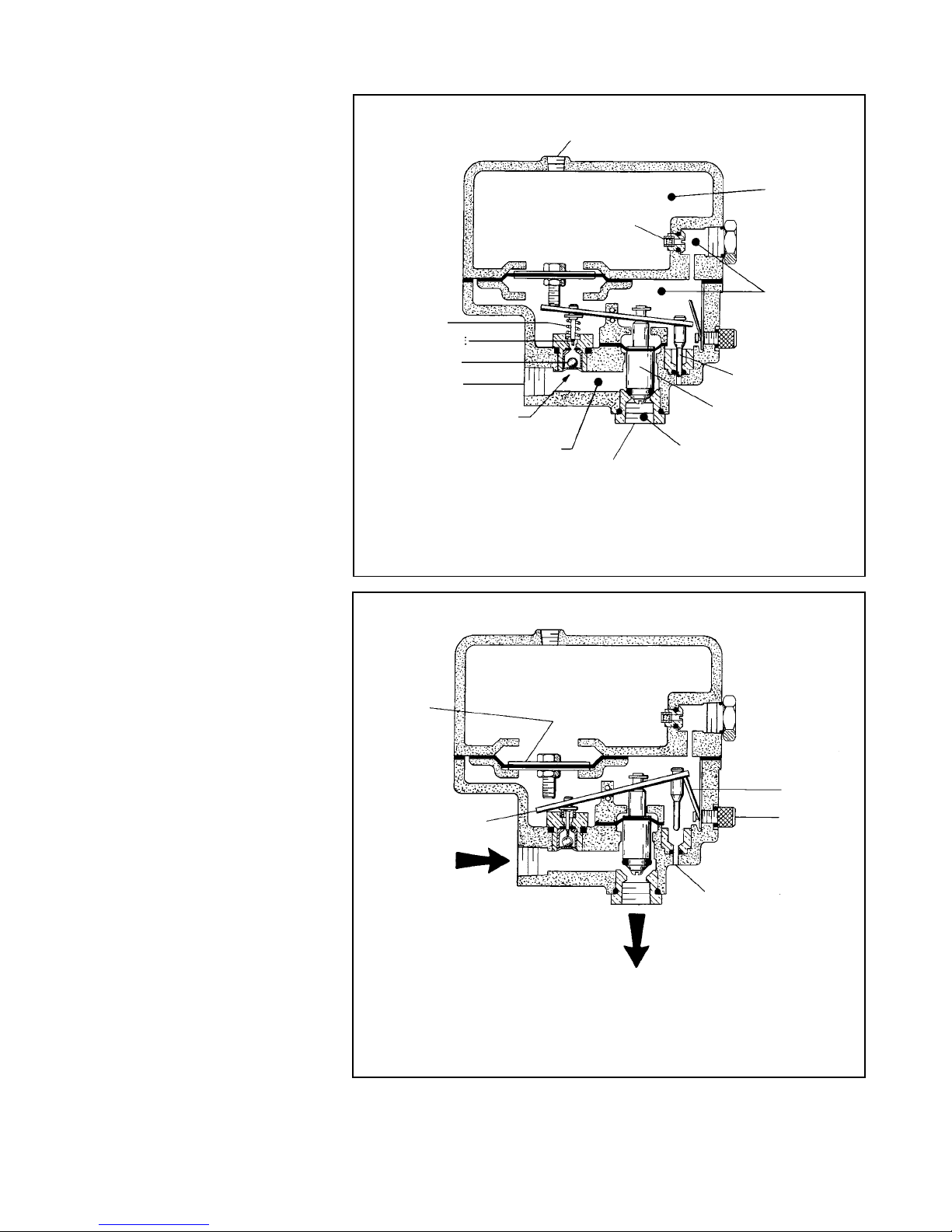

FIGURE 1

MODEL ACC-1 ACCELERATOR IN SET POSITION

FIGURE 2

MODEL ACC-1 ACCELERATOR IN TRIPPED POSITION

TFP1112

Operation

The Inlet Chamber of the Accelerator, Fig‑

ure 1, is pressurized via its connection to

the system (at a point above the maximum

expected level of drain back water). The Pi‑

lot Chamber is, in turn, pressurized through

its inlet port which is formed by the annular

opening around the lower tip of the Anti‑

Flood Valve. As the Pilot Chamber increases

in pressure, the Dierential Chamber is

pressurized through the Restriction.

The Accelerator is in its set position while it

is being pressurized as well as after the In‑

let, Pilot Chamber and Dierential Chamber

pressures have equalized. When in the Set

position, the Outlet Chamber is sealed o

by the Exhaust Valve which is held against

its seat by a combination of the Spring

pushing up against the Lever and the net

downward force exerted by the pressure in

the Pilot Chamber.

Both small and slow changes in system pres‑

sure are accommodated by ow through

the Restriction. When, however, there is a

rapid and steady drop in system (i.e., Inlet

and Pilot Chamber) pressure, the pressure

in the Dierential Chamber reduces at a

substantially lower rate. This condition cre‑

ates a net downward force on the Plunger

which rotates the Lever. As the Lever is ro‑

tated, Figure 2, the Relief Valve is raised out

of the Relief Port and the Anti‑Flood Valve is

depressed downward into the Pilot Cham‑

ber Inlet Port, venting the Pilot Chamber.

The system pressure in the Inlet Chamber

then forces (raises) the Exhaust Valve o its

seat. This continues the rotation of the Le‑

ver into the tripped (latched) position, Fig‑

ure 2. As the Exhaust Valve is raised o its

seat, system pressure is transmitted to the

intermediate chamber of the dry pipe valve

which neutralizes the dierential pressure

holding the valve closed.

Following the dry pipe valve trip, major wa‑

ter borne debris is prevented from entering

the Accelerator (via the connection to the

system piping) by the Strainer located at its

Inlet. Water and any ne water borne debris

such as silt is prevented from entering the

Pilot Chamber by virtue of the Anti‑Flood

Valve having sealed o its inlet port. The

Check Valve located downstream of the Ac‑

celerator Outlet prevents any water borne

debris from entering the Accelerator via the

connection to the intermediate chamber of

the dry pipe valve.

After the accelerator/dry pipe valve has

tripped and the sprinkler system has been

drained, the piping from the system to the

Accelerator must also be drained and the

SPRING

ANTI‑FLOOD VALVE

BALL FLOAT

1/2” NPT INLET

PLUNGER

FROM SYSTEM

PIPING

PILOT CHAMBER

INLET PORT

INLET CHAMBER

1/4” NPT GAUGE

CONNECTION

RESTRICTION

1/2” NPT OUTLET

RELIEF VALVE

EXHAUST VALVE

OUTLET CHAMBER

FIGURE 1

MODEL ACC‑1 ACCELERATOR IN SET POSITION

LEVER

RELIEF PORT

TO DRY PIPE VALVE

INTERMEDIATE

CHAMBER

FIGURE 2

MODEL ACC‑1 ACCELERATOR IN TRIPPED POSITION

DIFFERENTIAL

CHAMBER

PILOT CHAMBER

LATCH

RESET KNOB

Page 3

TFP1112_EN Page 3 of 10

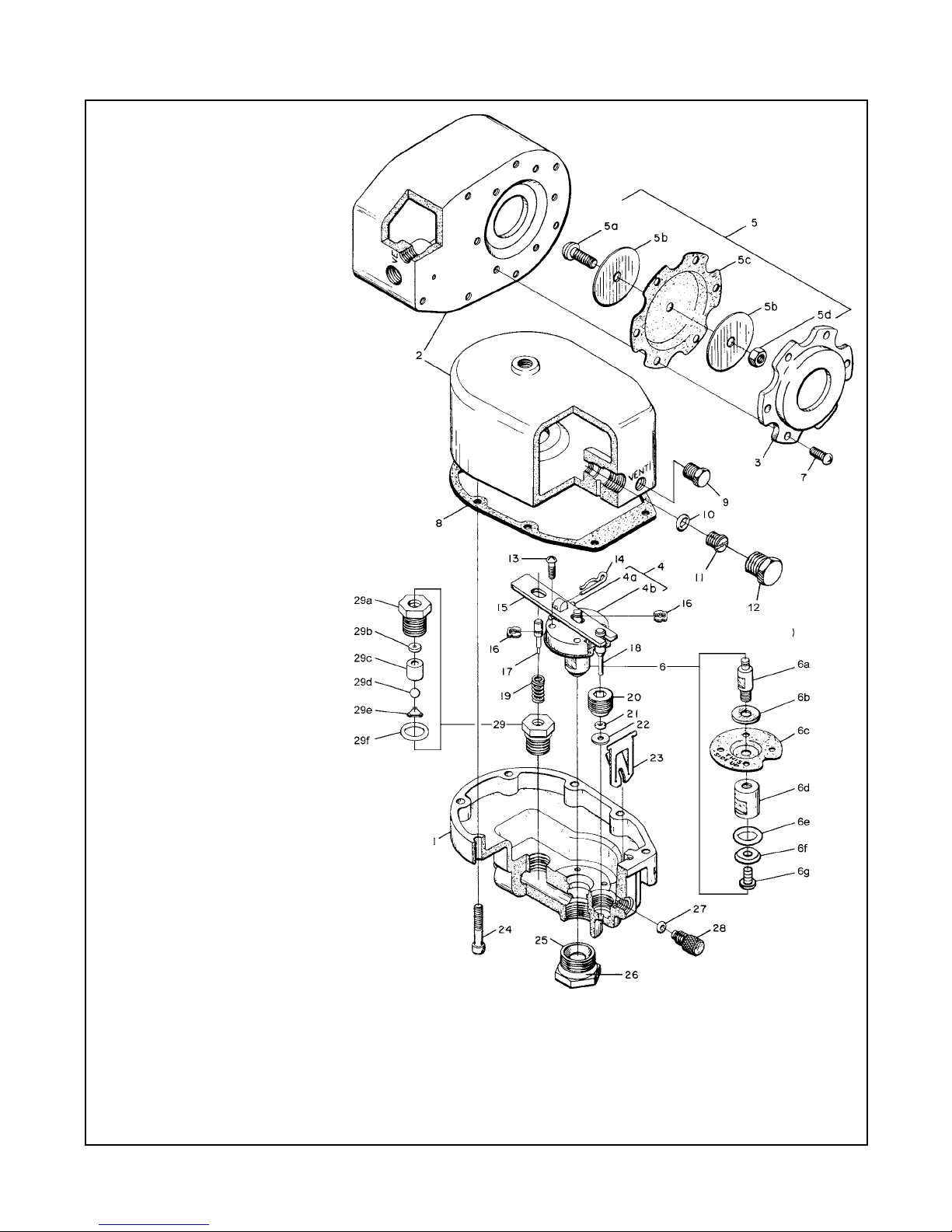

FIGURE 3

MODEL ACC-1 ACCELERATOR ASSEMBLY

NO. DESCRIPTION QTY. P/N

1 Base 1 NR

2 Cover 1 NR

3 Upper Diaphragm

Plate 1 See (c)

4 Pivot Plate

Assembly 1 See (b)

a Spirol Pin 1

b Pivot Plate 1

5 Plunger 1 See (a)

a Pan Hd. Machine

Screw 1

b Upper Diaphragm

Retaining Ring 2

c Upper Diaphragm 1

d Jam Nut 1

6 Exhaust Valve 1 See (a)

a Upper Plug 1

b Washer 1

c Lower Diaphragm 1

d Lower Plug 1

e O-Ring* 1

f O-Ring Retainer 1

g Exhaust Valve Screw 1

7 Rd. Head Machine

Screw,

1/4"-20 UNC x 5/8" 6 See (c)

8 Cover Gasket 1 See (a)

9 Vent Plu g 1 See (c)

10 O-Ring* 1 See (a)

11 Restriction 1 See (a)

12 Restriction Access

Plug 1 See (c)

13 Pan Hd. Machine

Screw,

No. 10-32 UNF x 5/8" 4 See (b)

14 Cotter Pin 1 See (b)

15 Lever 1 See (b)

16 Retaining Ring 1 See (b)

17 Anti-Flood Valve 1 See (b)

18 Relief Valve 1 See (b)

19 Spring 1 See (b)

20 Relief Valve Seat 1 See (b)

21 O-Ring* 1 See (b)

22 Seal Washer 1 See (b)

23 Latch 1 See (a)

24 Fillerster Hd.

Machine Screw,

1/4"-20 UNC x 1-1/2" 8 See (c)

25 Plug Seat 1 See (c)

26 O-Ring* 1 See (c)

27 O-Ring* 1 See (a)

28 Reset Knob 1 See (c)

29 Anti-Flood Seat

Assembly

w/Ball Float 1 See (b)

a Insert 1

b Seal 1

c Guide 1

d Ball 1

e Clip 1

f O-Ring* 1

* Requires thin film of

FS3452 Fluorosilicone Grease

(a) Repair Parts Kit (a)

Includes Items 5, 6, 8,

10, 11, 23, 27 &

1.5 grams of FS3452 92-311-1-116

(b) Replacement Parts

Kit (b) Includ es Items

4, 13-22, 29 &

1.5 grams of FS3452 92-311-1-117

(c) Replacement Parts

Kit (c) Includes Item s

3, 7, 9, 12, 24-26, 28,

& 1.5 grams of FS3452 92-311-1-118

NR: Not Replaceable

Page 3 of 8

TFP1112

NO. DESCRIPTION QTY P/N

1 Base 1 NR

2 Cover 1 NR

3 Upper Diaphragm Plate 1 See (c)

4 Pivot Plate Assembly 1 See (b)

a Spirol Pin 1

b Pivot Plate 1

5 Plunger 1 See (a)

a Pan Hd. Machine Screw 1

Upper Diaphragm Retaining

b

Ring

2

c Upper Diaphragm 1

d Jam Nut 1

6 Exhaust Valve 1 See (a)

a Upper Plug 1

b Washer 1

c Lower Diaphragm 1

d Lower Plug 1

e O‑Ring* 1

f O‑Ring Retainer 1

g Exhaust Valve Screw 1

7 Rd. Head Machine Screw,

1/4”’‑20 UNC x 5/8”

6 See (c)

8 Cover Gasket 1 See (a)

9 Vent Plug 1 See (c)

10 O‑Ring* 1 See (a)

11 Restriction 1 See (a)

12 Restriction Access Plug 1 See (c)

13 Pan Hd. Machine Screw, No.

10‑32 UNF X 5/8”

4 See (b)

14 Cotter Pin 1 See (b)

15 Lever 1 See (b)

16 Retaining Ring 1 See (b)

17 Anti‑Flood Valve 1 See (b)

18 Relief Valve 1 See (b)

19 Spring 1 See (b)

20 Relief Valve Seat 1 See (b)

21 O‑Ring* 1 See (b)

22 Seal Washer 1 See (b)

23 Latch 1 See (a)

24 Fillerster Hd. Machine Screw,

1/4”‑20 UNC x 1‑1/2”

8 See (c)

25 Plug Seat 1 See (c)

26 O‑Ring* 1 See (c)

27 O‑Ring* 1 See (a)

28 Reset Knob 1 See (c)

29 Anti‑Flood Seat Assembly

w/Ball Float 1 See (b)

a Insert 1

b Seal 1

c Guide 1

d Ball 1

e Clip 1

f O‑Ring* 1

* Requires thin lm of FS3452 Fluorosilicone

Grease

(a) Repair Parts Kit (a) Includes

Items 5, 6, 8, 10, 11, 23, 27 &

1,5 g of FS3452 92‑311‑1‑116

(b) Replacement Parts Kit (b)

Includes Items 4, 13‑22, 29 &

1,5 g of FS3452 92‑311‑1‑117

(c) Replacement Parts Kit (c)

Includes Items 3, 7, 9, 12, 24‑

26, 28 & 1,5 g of FS3452 92‑311‑1‑118

NR: Not Replaceable

FIGURE 3

MODEL ACC‑1 ACCELERATOR ASSEMBLY

(VENT PLUG)

(RESTRICTION

ACCESS PLUG)

(RESET KNOB)

Page 4

FIGURE 4

MODEL ACC-1 DRY PIPE VALVE ACCELERATOR TRIM

FOR 2-1/2, 3, 4, AND 6 INCH MODEL DPV-1 DRY PIPE VALVES

PRESSURE

ACCELERATOR

GAUGE

ACCELERATOR

CONTROL VALVE

(NORMALLY OPEN)

8

2

7

1

7

5

10

4

7

6

6

7

5

9

7

6

7

RESET

KNOB

PLUG

VENT

ACCESS PLUG

RESTRICTION

PRESSURE

ACCELERATOR

GAUGE

ACCELERATOR

TRIM CONNECTION

TO INTERMEDIATE

CHAMBER

1/2" NPT

2-1/2 or 3 INCH (DN65 or DN80)

6 INCH (DN150)4 INCH (DN100)

PRESSURE

ACCELERATOR

GAUGE

8

7

7

5

7

5

7

9

7

6

4

7

10

6

6

2

1

ACCELERATOR

CONTROL VALVE

(NORMALLY OPEN)

8

2

7

1

7

5

10

4

7

6

6

7

5

9

7

6

7

CONNECTION TO

SYSTEM PIPING

1/2" NPT

PIPE VALVE

DRY

ACCELERATOR

PRESSURE

ACCELERATOR

GAUGE

PIPE VALVE

DRY

ACCELERATOR

PIPE VALVE

DRY

ACCELERATOR

ACCELERATOR

ACCELERATOR

TRIM CONNECTION

TO INTERMEDIATE

CHAMBER

1/2" NPT

ACCELERATOR

TRIM CONNECTION

TO INTERMEDIATE

CHAMBER

1/2" NPT

NOMENCLATURE

NO QTYDESCRIPTION P/N

6 1/2" 90° Elbow 3 CH. . . .

8

9

1/2" x 1-1/2"

1/2" x 3" Nipple

1/2" x 3-1/2"

6

1

1

CH

CH

CH

7

Nipple

Nipple

. . . .

. . . . . . . . . . .

. . . . . . . . . . .

Nipple

10 1/2" x 5-1/2"

1 CH. . . . . . . . . . .

CH: Common Hardware

NO QTYDESCRIPTION P/N

5 1/2" Union 2 CH. . . . . . . .

46-050-1-0043 1/2" Ball Valve 1. . . .

46-049-1-004

4 1/2" Swing

1Check Valve . . . . . .

NO

1 250 psi/ 1750 kPa

1

QTY

92-343-1-012

DESCRIPTION P/N

52-353-1-0052 1/2" Y-Strainer 1

Air Pressure

Gauge . . . . . . . . . . .

. . . .

PIPE VALVE

DRY

ACCELERATOR

3

*

ACCELERATOR

CONTROL VALVE

(NORMALLY OPEN)

CONNECTION TO

SYSTEM PIPING

1/2" NPT

3

*

3

*

CONNECTION TO

SYSTEM PIPING

1/2" NPT

In accordance with the 2007 edition of NFPA 13, 7.2.4.4, the Accelerator Control Valve

*

shall be supervised. Where a signaling service is to utilized, replace the Ball Valve with

a BVS-1/2" electrically supervised control valve.

*

*

*

Page 4 of 10

TFP1112

Page 4 of 10 TFP1112_EN

NO. DESCRIPTION QTY. P/N

1 17,5 bar (250 psi) Air

Pressure Gauge . . . . . . . . 1 92‑343‑1‑012

2 1/2” Y‑Strainer . . . . . . . . . . 1 52‑353‑1‑005

* In accordance with the 2007 edition of NFPA 13, 7.2.4.4, the Accelerator Control

Valve shall be supervised. Where a signaling service is to utilized, replace the Ball

Valve with a BVS‑1/2” electrically supervised control valve.

ACCELERATOR

PRESSURE GAUGE

DRY PIPE VALVE

ACCELERATOR

ACCELERATOR

PRESSURE GAUGE

DRY PIPE VALVE

ACCELERATOR

CONTROL VALVE*

(NORMALLY OPEN)

ACCELERATOR

CONTROL VALVE*

(NORMALLY OPEN)

ACCELERATOR

2-1/2 or 3” (D65 or DN80)

1/2” NPT CONNECTION

TO SYSTEM PIPING

1/2” NPT CONNECTION

TO SYSTEM PIPING

NO. DESCRIPTION QTY. P/N

3 1/2” Globe Valve . . . . . . . 1 46‑047‑1‑004

4

1/2” Swing Check Valve .

5 1/2” Union . . . . . . . . . . . . . 2 CH

1/2” NPT ACCELERATOR

TRIM CONNECTION

TO DRY PIPE VALVE

INTERMEDIATE CHAMBER

1/2” NPT

ACCELERATOR TRIM

CONNECTION TO

DRY PIPE VALVE

INTERMEDIATE

CHAMBER

1 46‑049‑1‑004

PRESSURE GAUGE

4” (DN100)

NO. DESCRIPTION QTY. P/N

6 1/2” 90° Elbow . . . . . . . . . 3 CH

7 1/2” x 12,5 mm Nipple . 6 CH

8 1/2” x 80 mm Nipple . . . 1 CH

9 1/2” x 90 mm Nipple . . . 1 CH

10 1/2” x 140 mm Nipple . . 1 CH

CH: Common Hardware

ACCELERATOR

DRY PIPE VALVE

ACCELERATOR

ACCELERATOR

NOMENCLATURE

ACCELERATOR

CONTROL VALVE*

(NORMALLY OPEN)

1/2” NPT

CONNECTION TO

SYSTEM PIPING

DRY PIPE VALVE

ACCELERATOR

6” (DN150)

ACCESS PLUG

RESTRICTION

VENT PLUG

RESET KNOB

ACCELERATOR

PRESSURE GAUGE

ACCELERATOR TRIM

CONNECTION TO

DRY PIPE VALVE

1/2” NPT

INTERMEDIATE

CHAMBER

MODEL ACC‑1 DRY PIPE VALVE ACCELERATOR TRIM

FOR 2‑1/2, 3, 4 AND 6” MODEL DPV‑1 DRY PIPE VALVES

FIGURE 4

Page 5

TFP1112_EN Page 5 of 10

Page 5 of 10

TFP1112

FIGURE 5

MODEL ACC-1 DRY PIPE VALVE ACCELERATOR TRIM

— INSTALLATION DIMENSIONS —

8"

(200 mm)

2-1/2 & 3 INCH

(DN65 & DN80)

VALVE

12"

(300 mm)

15"

(380 mm)

4 INCH

(DN100)

VALVE

11-1/2"

(290 mm)

6 INCH

(DN150)

VALVE

23-3/4"

(600 mm)

11-1/8"

(283 mm)

24-1/2"

(625 mm)

21-1/8"

(540 mm)

15"

(380 mm)

2‑1/2 & 3”

(DN65 & DN80)

VALVE

4”

(DN100)

VALVE

6”

(DN150)

VALVE

MODEL ACC‑1 DRY PIPE VALVE ACCELERATOR TRIM

FIGURE 5

‑INSTALLATION DIMENSIONS‑

Page 6

Page 6 of 10 TFP1112_EN

Accelerator reset/inspected according to

the instructions given in the Setting Proce‑

dure Section.

The rate‑of‑ow through the Restriction

has been set such that the Model ACC‑1

Accelerator provides the maximum practi‑

cal sensitivity to a loss in system pressure

due to a sprinkler operation while still be‑

ing capable of automatically compensating

for normal variations in system pressure

such as are caused by environmental tem‑

perature changes. A test for verifying that

the rate‑of‑ow through the Restriction is

within the range for optimum Accelerator

performance is given in the Setting Proce‑

dure Section.

Installation

The Model ACC‑1 Accelerator must be in‑

stalled in accordance with the following

instructions:

NOTE

Failure to follow these instructions can result

in ooding of the Accelerator and accidental

tripping due to closure of the ball oat.

Step 1. The Accelerator must be positioned

vertically and trimmed per the arrange‑

ment shown in Figure 4. Apply pipe thread

sealant sparingly to male threads only.

Step 2. The Strainer located at the Accel‑

erator Inlet must be installed with its arrow

pointed towards the Accelerator.

The Check Valve located in the line

Step 3.

between the Accelerator Outlet and the in‑

termediate chamber of the dry pipe valve

must be installed horizontally with its arrow

pointed in the direction of ow to the inter‑

mediate chamber.

The connection to the system pip‑

Step 4.

ing must be located so that drain back wa‑

ter will not ow into the Accelerator piping

and it must be located at a point above the

maximum expected level of the drain back/

condensate water.

If the connection is made to the riser, it must

be located at least two feet above the level

of the dry pipe valve priming water. Con‑

nections to a feed or cross main must be

made either to the side or top of the main.

Step 5. The accelerator/dry pipe valve com‑

bination must be installed in a heated en‑

closure which is maintained at a minimum

temperature of 4°C (40°F). Heat tracing is

not permitted.

Step 6. Close the Accelerator Control Valve

until the Model ACC‑1 Accelerator is ready

to be placed in service.

The Accelerator Control Valve must be

closed during hydrostatic testing of the

system in order to prevent damage to the

Ball Float. After the system is hydrostatically

tested and drained, the Accelerator connec‑

tion to the system must be independently

drained through the Strainer clean‑out

plug by rst removing the Strainer clean‑

out plug and then opening the Accelerator

Control Valve to vent the line.

Setting Procedure

The Model ACC‑1 Accelerator and Dry Pipe

Valve must be reset and restored to service

as soon as possible after an operation.

Follow the procedure indicated below.

Step 1. Close the system main control valve,

the air supply control valve (to the system)

and the Accelerator Control Valve.

Step 2. Open the Inspector’s Test Connec‑

tion and then open the main drain valve as

well as all auxiliary (low point) drains.

Step 3.

close the Inspector’s Test Connection and

all auxiliary drain valves. Leave the main

drain valve open.

Step 4.

with the instructions given in the appropri‑

ate technical data sheet. Restore normal

system air pressure. Leave the main con‑

trol valve closed and the main drain valve

open.

Step 5. While holding the plunger of the

dry pipe valve’s automatic drain valve de‑

pressed, partially open the Accelerator

Control Valve one‑quarter turn and allow

the water in the Accelerator piping to blow

out. After water spray stops discharging,

close the Accelerator Control Valve and

then release the plunger. (This instruction

does not apply when the Model ACC‑1 Ac‑

celerator is being set for the rst time, since

the Accelerator is shipped in the set posi‑

tion. Proceed to Step 6.)

Pressure

(bar)

Pressure

(psi)

1,4 20 24 160

1,7 25 18 116

2,1 30 15 92

2,8 40 10 60

3,5 50 8 48

4,1 60 6 36

TABLE A

DIFFERENTIAL CHAMBER FILL TIMES TO 0,7 bar (10 psi)

After the system has been drained,

Set the dry pipe valve in accordance

Minimum

(seconds)

Step 6. Clean out the Strainer at the Accel‑

erator Inlet.

A clogged strainer can prevent the Accelera‑

tor from properly tripping the dry pipe valve.

Step 7. Slowly remove the Vent Plug locat‑

ed in the front of the Accelerator Cover and

bleed o any residual air pressure in the Dif‑

ferential Chamber.

Step 8. Unscrew (counter‑clockwise rota‑

tion) the knurled Reset Knob at the front of

the Accelerator until it resists further turn‑

ing. A click, which is the sound of the Lever

snapping back into the Set Position, may be

heard. Screw the Reset Knob back in until it

is nger tight.

Do not wrench on the reset Knob, since dam‑

age may result. The Reset Knob will turn with

nger torque only.

Step 9. Replace the Vent Plug.

Step 10. Verify that the system air pressure

has returned to normal.

Step 11. Partially open the Accelerator Con‑

trol Valve just enough to allow air to slowly

pass through the Accelerator Control Valve.

Using a watch, note the time for the pres‑

sure in the Dierential Chamber of the Ac‑

celerator to increase to 0,7 bar (10 psi) after

the Accelerator Control Valve is opened.

The time should be within the range of val‑

ues indicated in Table A for optimum per‑

formance of the Accelerator.

If the time to pressurize the Dierential Cham‑

ber to 0,7 bar (10 psi) is not within the range

of values given in the Table A, then the Ac‑

celerator control Valve should be closed and

the corrective procedure described in the Care

and Maintenance Section followed.

Step 12. When the air pressure in the Dier‑

ential Chamber of the Accelerator is equal

to that in the system, then the Accelerator

is set and ready for service.

Step 13.

Valve and then slowly open the dry pipe

Close the Accelerator Control

Maximum

(seconds)

NOTE

NOTE

NOTE

Page 7

TFP1112_EN Page 7 of 10

valve’s low body drain valve, to bleed o

any excess water above the priming level.

Reclose the low body drain valve, return

system pressure to its normal value, and

then re‑open the Accelerator Control Valve.

Step 14.

valve. Close the main drain valve as soon

as water discharges from the drain connec‑

tion, and then completely open the main

control valve. The re protection system is

now ready for service.

After placing a re protection system in ser‑

vice, notify the proper authorities and advise

those responsible for monitoring proprietary

and/or central station alarms.

Partially open the main control

NOTE

Care and

Maintenance

The following procedures and inspections

should be performed as indicated, in ad‑

dition to any specic requirements of the

NFPA, and any impairment must be imme‑

diately corrected.

The owner is responsible for the inspec‑

tion, testing, and maintenance of their re

protection system and devices in compli‑

ance with this document, as well as with

the applicable standards of the National

Fire Protection Association (e.g., NFPA 25),

in addition to the standards of any author‑

ity having jurisdiction. The installing con‑

tractor or product manufacturer should be

contacted relative to any questions.

It is recommended that automatic sprinkler

systems be inspected, tested, and main‑

tained by a qualied Inspection Service.

The Model ACC‑1 Accelerator must be main‑

tained and serviced in accordance with the

following instructions:

NOTE

If an Accelerator is to be temporarily taken out

of service, then the proper authorities and all

personnel who may be aected must be noti‑

ed.

Before performing an alarm test, notify the

proper authorities and all personnel who may

be aected.

Before closing a re protection system main

control valve for inspection or maintenance

work on the re protection system that it con‑

trols, permission to shut down the aected re

protection system must be obtained from the

proper authorities and all personnel who may

be aected by this action must be notied.

Accelerator Inspection Procedure

It is recommended that the following Accel‑

erator inspection procedure be performed

at least annually, preferably in the fall or

winter of the year. This procedure must

also be used whenever ooding the system

would expose the water to freezing condi‑

tions.

Step 1. Verify that the Reset Knob is

screwed in.

Step 2. Close the system’s main control

valve and open the main drain valve to re‑

lieve the supply pressure to the dry pipe

valve.

Step 3.

Valve is open.

Step 4.

tion. Verify that the time to Accelerator trip

is essentially the same as in previous tests. A

momentary burst of air from the Automatic

Drain Valve indicates that the Accelerator

has tripped.

As the system pressure is decreasing, check for

any sign of water being discharged from the

Accelerator Relief Port.

Step 5. Depress the plunger of the Auto‑

matic Drain Valve. A steady stream of ex‑

hausting air indicates that the Accelerator

has properly latched in the Tripped posi‑

tion.

Step 6. Close the Accelerator Control Valve

and the Inspector’s Test Connection.

Step 7. Clean out the Strainer at the Accel‑

erator inlet.

A clogged strainer can prevent the Accelera‑

tor from properly tripping the dry pipe valve.

Step 8. Reset the Accelerator in accordance

with Steps 7 through 14 of the Setting Pro‑

cedure Section.

System Inspection Procedure

It is recommended that the following Ac‑

celerator and dry pipe valve inspection

procedure be performed at least annu‑

ally, preferably in the spring or summer of

the year. This procedure can only be used

whenever there is no danger that ooding

the system will expose the water to freezing

conditions.

Step 1. Verify that the Reset Knob is

screwed in.

Step 2. Open the Inspector’s Test Connec‑

tion. Verify that tripping of the Accelerator

operates the dry pipe valve and that water

is delivered out of the Inspector’s Test con‑

nection within the elapsed time required

by the authority having jurisdiction.

Verify that the Accelerator Control

Open the Inspector’s Test Connec‑

NOTE

NOTE

NOTE

As the system pressure is decreasing, check for

any sign of water being discharged from the

Accelerator Relief Port.

Reset the accelerator and dry pipe

Step 3.

valve in accordance with the Setting Proce‑

dure Section.

Trouble Shooting

Refer to the following subsections, as appli‑

cable. If the designated instructions do not

remedy the particular problem, refer to the

Accelerator Disassembly and Reassembly

subsection.

Water Discharge From Accelerator Relief

Port

Use the following instructions if water is

discharged from the Accelerator Relief Port

during a trip.

Step 1. Verify that the connection from the

Accelerator to the system piping is installed

in accordance with Step 4 of the Installation

Section. Correct if necessary.

Step 2. Investigate for and correct any con‑

dition which could result in an excessive

build‑up of drain back and/or condensate

water.

Step 3.

used to set the Accelerator. Failure to per‑

form Step 5 of the Setting Procedure can

permit a small amount of water to enter the

Pilot Chamber of the Accelerator.

Slow Fill of Dierential Chamber

Use the following instructions if the time to

ll the Dierential Chamber is longer than

the maximum value indicated in Step 11 of

the Setting Procedure Section.

Step 1. Check to see that the Accelerator

was reset per Step 8 of the Setting Proce‑

dure Section.

Step 2. Close the system’s main control

valve and open the main drain valve.

Step 3.

age past the Accelerator Pressure Gauge,

Vent, and Restriction Access Plug connec‑

tions.

Step 4.

age past the Reset Knob and Cover Gasket.

Step 5. Close the Accelerator Control Valve.

Step 6. Gently insert an M2 (3/32”) or small‑

er diameter probe into the Relief Port. If

the probe can be inserted more than 6 mm

(1/4”) then the Lever has not reset and the

Accelerator must be disassembled for inter‑

nal inspection. See the instructions for Ac‑

celerator Disassembly and Reassembly.

Review procedures which were

Check for any sign of external leak‑

Check for any sign of external leak‑

Page 8

Page 8 of 10 TFP1112_EN

Step 7. Slowly remove the Accelerator Vent

Plug to bleed all pressure from the Dier‑

ential Chamber and then slowly remove the

Restriction Access Plug to bleed all pressure

from the Pilot Chamber.

Step 8. Replace the Restriction and then

the Restriction Access Plug.

Step 9. Place the re protection system

back in service in accordance with Steps 9

through 14 of the SettingProcedure Sec‑

tion.

Unexplained Accelerator Trip

Use the following instructions if there is an

unexplained accidental trip of the Accelera‑

tor.

Step 1. Verify that the connection from the

Accelerator to the system piping is installed

in accordance with Step 4 of the Installation

Section. Correct if necessary.

Step 2. Verify the time to ll the Dierential

Chamber as described in Step 11 of the Set‑

ting Procedure Section. If the time to ll the

Dierential Chamber to 0,7 bar (10 psi) is

longer than the maximum indicated value,

then follow the instructions given under

“Slow Fill of Dierential Chamber”.

Step 3.

Chamber is within the indicated range of

values, then investigate for and correct any

condition which could result in excessive

leakage of system air pressure.

Fast Fill of Dierential Chamber or Long

Time to Accelerator Trip

Use the following instructions if the time to

ll the Dierential Chamber is shorter than

the minimum value indicated in Step 11 of

the Setting Procedure Section. This proce‑

dure should also be followed if the time to

Accelerator trip (following opening of the

Inspector’s Test Connection) is signicantly

longer than expected.

Step 1. Close the system’s main control

valve and open the main drain valve.

Step 2. Close the Accelerator Control Valve.

Step 3.

Plug to bleed all pressure from the Dier‑

ential Chamber and then slowly remove the

Restriction Access Plug to bleed all pressure

from the Pilot Chamber.

Step 4.

the tightness of the Restriction.

Step 5. Inspect the Restriction’s O‑ring seal.

The O‑ring must be replaced if there are any

signs of nicks, cuts, or deterioration due to

age. Replace the Restriction after cleaning

and lubricating its O‑ring with a non‑petro

leum based grease (such as Dow Corning

If the time to ll the Dierential

Slowly remove the Accelerator Vent

Using a slotted screw driver, check

FS3452). Replace the Vent Plug and Restric‑

tion Access Plug.

Step 6. If the Restriction and its O‑ring are

found to be in good condition, then it is

likely that there is leakage past the Plunger.

Remove the Cover from the Base. Check

that the six screws securing the Upper Dia‑

phragm Plate to the Cover are tight.

Inspect the Upper Diaphragm for any sign

of cracks, pin holes or deterioration due

to age. Replace the Plunger if there is any

possibility of leakage past the Upper Dia‑

phragm.

Step 7. Reassemble the Accelerator and

place the re protection system back in ser‑

vice in accordance with Steps 10 through

14 of the Setting Procedure Section.

Air Leakage Out Automatic Drain

If there is leakage of air out the Automatic

Drain of the dry pipe valve, after the Accel‑

erator and dry pipe valve have been placed

in service, then it will be necessary to rst

determine whether the leakage is past the

Accelerator or the dry pipe valve.

Close the Accelerator Control Valve. Slowly

remove the Accelerator Vent Plug to bleed

all pressure from the Dierential Chamber

and then slowly remove the Restriction Ac‑

cess Plug to bleed all pressure from the Pi‑

lot Chamber.

If leakage out the Automatic Drain persists

then refer to the dry pipe valve Technical

Data Sheet for maintenance instructions. If

leakage out of the Automatic Drain stops,

then the Accelerator will have to be taken

out of service and the Accelerator Plug Seat

removed for cleaning of the seat and the

lower O‑ring area on the Exhaust Valve.

Accelerator Disassembly and Reassembly (For Internal Inspection As Necessary)

Step 1. Close the system’s main control

valve and open the main drain valve.

Step 2. Close the Accelerator Control Valve.

Slowly remove the Accelerator Vent

Step 3.

Plug to bleed all pressure from the Dier‑

ential Chamber and then slowly remove the

Restriction Access Plug to bleed all pressure

from the Pilot Chamber.

Break the union connections at the

Step 4.

Inlet and Outlet of the Accelerator and re‑

move it from the line. Plug the connection

to the intermediate chamber of the dry

pipe valve and place the re protection sys‑

tem in service while the Accelerator is out

for maintenance.

‑

Step 5. Remove the eight screws hold‑

ing the Cover to the Base and remove the

Cover.

Step 6. Remove the six screws holding the

Upper Diaphragm Plate to the Cover. Re‑

move the Plunger and inspect the Upper

Diaphragm to be sure that it is exible and

free from physical damage or deterioration

due to age.

Check the Jam Nut to assure that it is as‑

sembled tightly to its Screw. Remount the

Plunger and Upper Diaphragm Plate taking

care to cross‑tighten the screws uniformly.

Step 7. Replace the Restriction if it has been

wetted. Clean and lubricate the Restriction

O‑ring seal with a non‑petroleum based

grease (such as Dow Corning FS3452).

Replace the Vent Plug and Restriction Ac‑

cess Plug.

Step 8. Remove the Retaining Ring from the

Upper Plug portion of the Exhaust Valve.

Remove the four screws holding the Pivot

Plate. Remove the sub‑assembly of the Le

ver and Pivot Plate, the Exhaust Valve, the

Anti‑Flood Valve and the Relief Valve.

Step 9. Inspect the Lower Diaphragm to be

sure that it is exible and free from physical

damage or deterioration due to age.

Step 10. Check to see that the Exhaust

Valve components are securely assembled

together. Only tighten by gripping the ats

using an open end type wrench.

Step 11. Inspect the O‑ring on the Lower

Plug. It must be replaced if there are any

signs of nicks, cuts or deterioration.

Step 12. Inspect the Relief and Anti‑Flood

Valves. If either is bent or nicked it must be

replaced.

Step 13.

The catch leaf should extend 8 to 10 mm

(5/16 to 3/8”) in the free state.

Step 14.

move the O‑ring and Seal Washer. Carefully

clean the O‑ring and Seal Washer seating

surfaces in the valve seat and Accelerator

Base. If the O‑ring or Seal Washer is nicked,

cut, or shows signs of deterioration, it must

be replaced.

Step 15. Replace the Seal Washer in the

Accelerator Base. Apply a thin lm of Dow

Corning FS3452 Fluorosilicone Grease to

the valve seat. Place the O‑ring in its seat

(the lubricant will hold it in place) and then

thread the Relief Valve Seat into the Body

with 13,5 to 20 Nm (10 to 15 ft.lbs.) of

torque.

Remove and inspect the Latch.

Remove the Relief Valve Seat. Re‑

‑

Page 9

TFP1112_EN Page 9 of 10

Step 16. Remove the Anti‑Flood Seat As‑

sembly w/Ball Float. Check for damaged

parts and for freedom of Ball movement. If

parts are damaged or inoperative, the As‑

sembly must be replaced.

Step 17. After checking the Anti‑Flood Seat

Assembly w/Ball Float, lubricate the O‑ring

with a thin lm of Dow Corning FS3452

Fluorosilicone Grease, and thread the As‑

sembly into the Body with 13,5 to 20 Nm

(10 to 15 ft.lbs.) of torque.

Step 18. Remove the Reset Knob. Carefully

clean the O‑ring and its seating surface. If

the O‑ring is cut, nicked, or shows signs of

deterioration it must be replaced. Lubricate

the O‑ring with a thin lm of Dow Corning

FS3452 Fluorosilicone Grease.

Step 19. Reassemble the Accelerator in the

following order.

a. Thread the Reset Knob into the Base n

ger tight.

b. Set the Anti‑Flood Valve (with Retain

ing Ring in place) and the Compression

Spring into their seat.

c. Set the Exhaust Valve in place.

d. Slide the Relief Valve into the slot at the

end of the Lever and then remount the

sub‑assembly of the Lever and Pivot

Plate in the Base, taking care to cross‑

tighten the screws uniformly.

e. Replace the Retaining Ring on the Up

per Plug.

f. Push the Anti‑Flood Valve end of the Le

ver down and release it twice to assure

that there is no binding.

g. Replace the Latch making sure that the

notch in the bottom straddles the Reset

Knob and that the tabs at the top are

seated in the Base. Place the Lever in

the Tripped (latched) position.

h. Place the Cover upside down. Set the

Cover Gasket in place and then push

all eight screws through the Gasket to

assist in assembling the Cover to the

Base.

i. Align the Cover with the Base and tight

en all of the screws uniformly.

j. Replace the Vent Plug and the Restric

tion Access Plug.

k. Reinstall the Accelerator and return the

system to service in accordance with

the Setting Procedure Section.

Limited Warranty

Products manufactured by Tyco Fire & Build‑

ing Products (TFBP) are warranted solely to

the original Buyer for ten (10) years against

defects in material and workmanship when

paid for and properly installed and main‑

tained under normal use and service. This

warranty will expire ten (10) years from

date of shipment by TFBP. No warranty is

given for products or components manu‑

factured by companies not aliated by

ownership with TFBP or for products and

components which have been subject to

misuse, improper installation, corrosion, or

which have not been installed, maintained,

modied or repaired in accordance with ap‑

plicable Standards of the National Fire Pro‑

tection Association, and/or the standards

of any other Authorities Having Jurisdic‑

tion. Materials found by TFBP to be defec‑

‑

tive shall be either repaired or replaced, at

TFBP’s sole option. TFBP neither assumes,

‑

nor authorizes any person to assume for it,

any other obligation in connection with the

sale of products or parts of products. TFBP

shall not be responsible for sprinkler system

design errors or inaccurate or incomplete

information supplied by Buyer or Buyer’s

representatives.

In no event shall TFBP be liable, in contract,

tort, strict liability or under any other le‑

gal theory, for incidental, indirect, special

‑

or consequential damages, including but

not limited to labor charges, regardless of

whether TFBP was informed about the pos‑

‑

sibility of such damages, and in no event

shall TFBP’s liability exceed an amount

equal to the sales price.

The foregoing warranty is made in lieu of

any and all other warranties express or

implied, including warranties of merchant‑

ability and tness for a particular purpose.

This limited warranty sets forth the exclu‑

sive remedy for claims based on failure of

or defect in products, materials or compo‑

nents, whether the claim is made in con‑

tract, tort, strict liability or any other legal

theory.

‑

This warranty will apply to the full extent

permitted by law. The invalidity, in whole or

‑

part, of any portion of this warranty will not

aect the remainder.

Ordering

Procedure

Orders for the ACC‑1 Accelerator, trim and

replacement parts must include the descrip‑

tion and Part Number (P/N). The Complete

Model ACC‑1 Accelerator Package includes

the Accelerator and Basic Galvanized Trim.

Complete Package:

Specify: Complete Model ACC‑1 Accelera‑

tor Package,

................................................. P/N 52‑311‑2‑002.

Accelerator Only:

Specify: Model ACC‑1 Accelerator,

................................................. P/N 52‑311‑1‑001.

Basic Galvanized Trim Only:

Specify: Model ACC‑1 Accelerator, Basic

Galvanized Trim for DN100 & 150 (4 & 6“)

Model DPV‑1 Dry Pipe Valves,

................................................. P/N 52‑311‑2‑010.

Replacement Parts for Accelerator:

(Specify description) for use with Model

ACC‑1 Accelerator,

................................................. P/N (see Figure 3).

Replacement Trim Parts:

Specify: (specify description),

.................................................. P/N (see Figure 4)

Page 10

Page 10 of 10 TFP1112_EN

Note: This document is a translated document. Translations of any materials into languages other than English are intended

solely as a convenience to the non‑English‑reading public. Translation accuracy is neither guaranteed nor implied. If any ques‑

tions arise related to the accuracy of the information contained in the translation, please refer to the English version of docu‑

ment TFP1112 which is the ocial version of the document. Any discrepancies or dierences created in the translation are not

binding and have no legal eect for compliance, enforcement or any other purposes. www.quicksilvertranslate.com.

TYCO FIRE & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

Loading...

Loading...