Page 1

Manual 0-2856

82 Benning Street, West Lebanon, NH 03784 USA

(603) 298-5711 • www.thermal-dynamics.com

General Information

The PCH / M-42 RPT Replacement Torches are suitable

for use with various Power Supplies and are connected

using various Adapter Kits purchased separately.

The Torches are supplied with 20 ft (6.1 m), 25 ft (7.6 m)

or 50 ft (15.2 m) Leads as follows:

Description Catalog #

PCH-42R RPT Hand Torches With Standard Handle

70° Head, 20 ft (6.1 m) Leads 7-4226

90° Head, 20 ft (6.1 m) Leads 7-4227

PCH-42ER RPT Hand T orches W ith Ergonomic Handle

70° Head, 20 ft (6.1 m) Leads 7-4220

90° Head, 20 ft (6.1 m) Leads 7-4222

70° Head, 50 ft (15.2 m) Leads 7-4221

90° Head, 50 ft (15.2 m) Leads 7-4223

PCM-42 RPT Machine Torches

180° Head, 25 ft (7.6 m) Leads 7-4224

180° Head, 50 ft (15.2 m) Leads 7-4225

These instructions are supplied to ensure the proper installation of the Replacement T orches. It is recommended

to thoroughly read the instructions first, befor e attempting the installation of the kit.

PCH / M-42 RPT

Replacement Torches

Installation Instructions

General T orch Description

The Replacement T or ches pr ovide cutting capabilities of

up to 40 amperes. In the torch, a single torch lead provides gas from a single source to be used as both the

plasma and secondary gas. The gas flow is divided inside the torch head. Single - gas operation provides a

smaller sized torch and inexpensive operation.

Torch Specifications & Design

Features

The following applies to the Replacement Torches only:

A. Torch Configurations

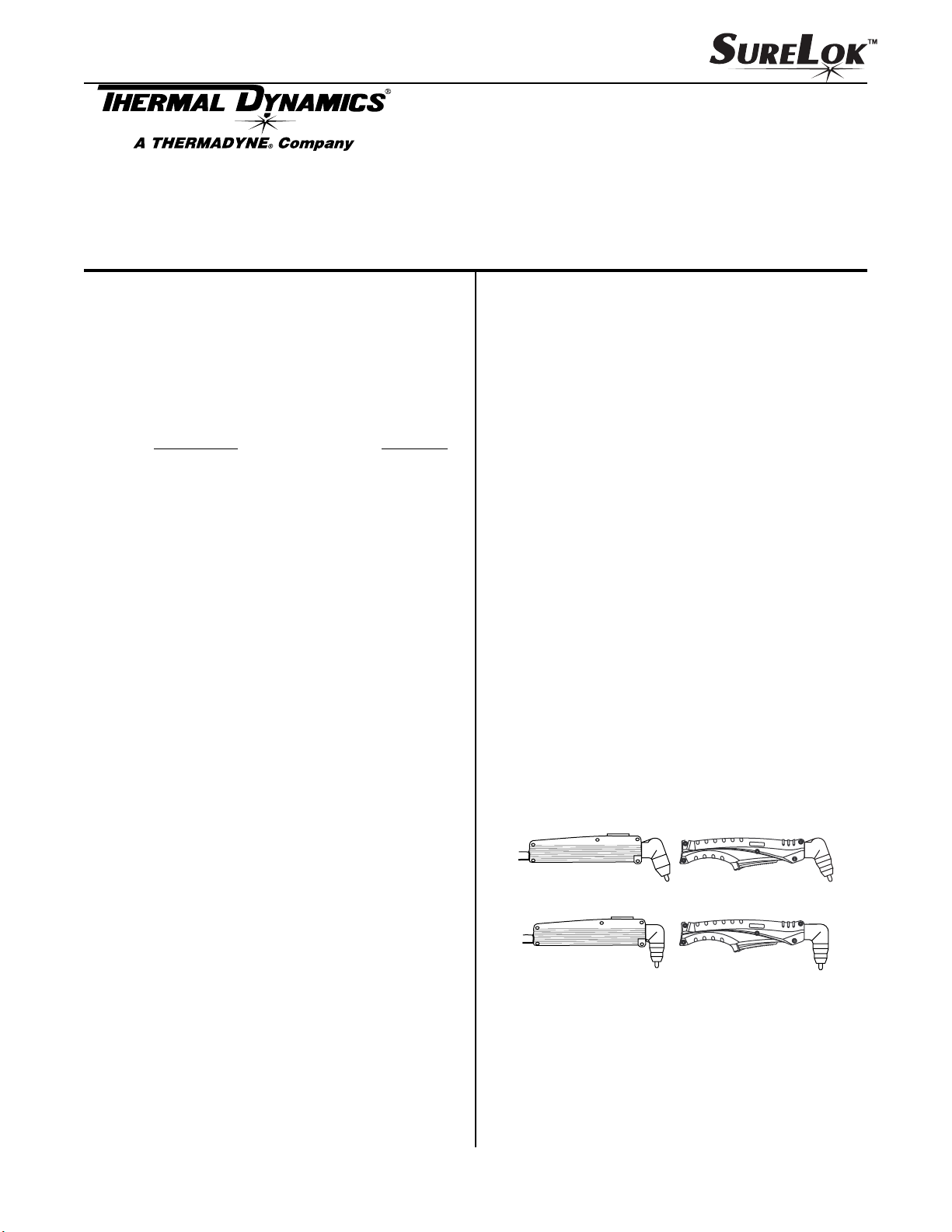

1. Hand T or ches

A vailable with torch head at 70° or 90° to the torch

handle. The hand torches include a torch handle

and torch switch assembly.

Torches with 20 ft (6.1 m) leads use the standard

handle with top mounted switch or the ergonomics handle with bottom mounted switch.

Torches with 50 ft (15.2 m) leads use only the ergonomics type handle and switch.

70o Hand Torches

A-02540

Supplied Parts

The following parts are supplied:

• PCH-42R, PCH-42ER or PCM-42 RPT Torch With

Leads - 1 each

• Installation Instructions - 1 each

'R' Type

Handle

© 2001 by Thermal Dynamics Corp., Printed in USA

January 23, 2004 1 Manual 0-2856

o

Hand Torches

90

'ER' Type

Handle

Page 2

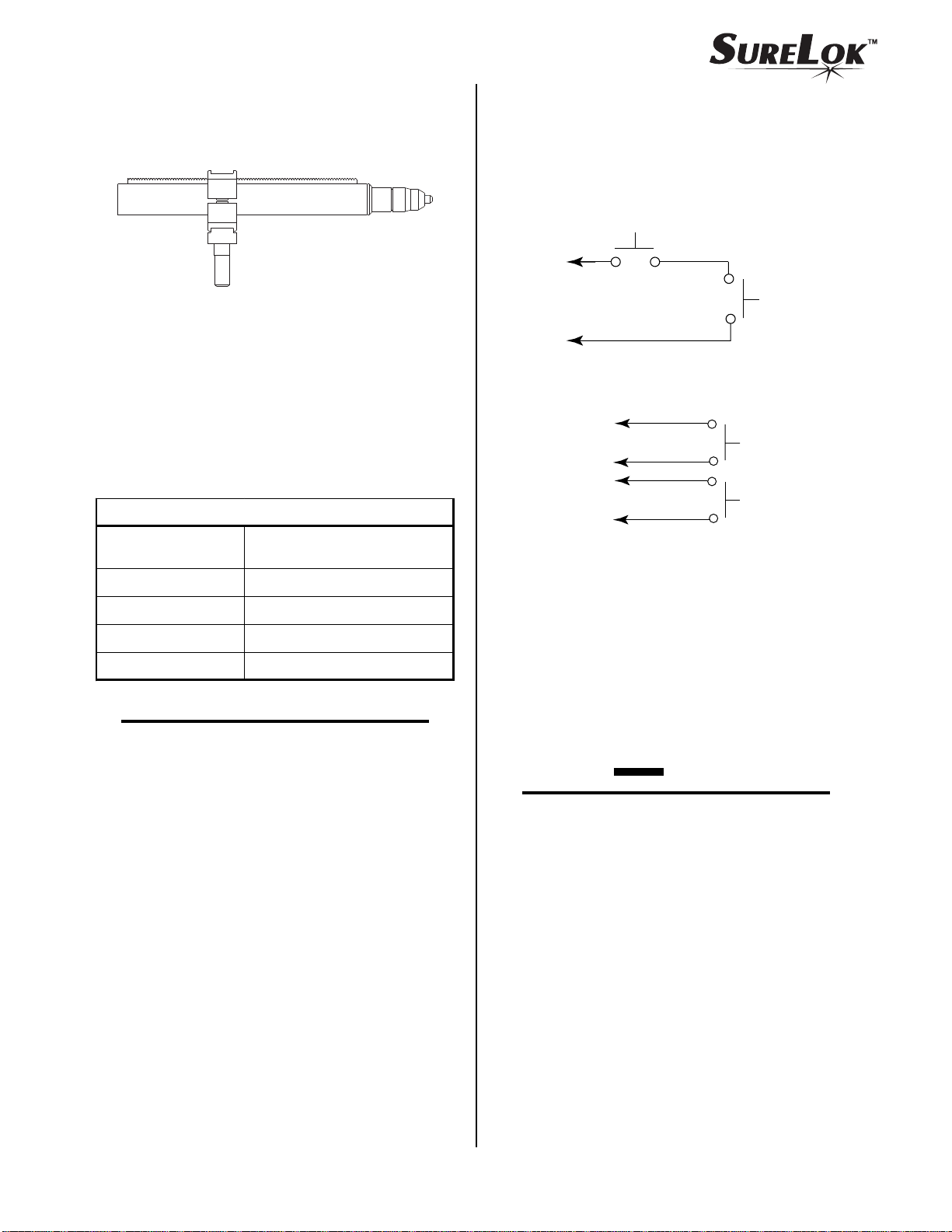

2. Machine T or ches

E. Parts - In - Place (PIP)

Available with fiberglass mounting tube & rack

and phenolic (plastic) pinch block assembly.

B. Torch Leads Lengths

• Hand Torches:

20 ft (6.1 m) or 50 ft (15.2 m)

• Machine Torches:

25 ft (7.6 m) or 50 ft (15.2 m)

C. Torch Ratings

Torch Ratings

Ambient

Temperature

Duty Cy cle

100% @ 40 Amps @ 200 scfh

104° F

(40° C)

A-02812

The torch head has built - in contacts called Parts - In

- Place (PIP). These two contacts are made through

the inside of the shield cup when it is installed. The

torch will fail to operate if these contacts are not made.

Torch Switch

PIP Pin

To Control

Cable Wiring

PIP Pin

Shield Cup

A-00458

PIP Circuit - Machine Torch

To Control

Cable Wiring

A-03540

Torch Switch

PIP Pins

Torch Trigger

Shield Cup

PIP Circuit - Hand Torch

Maxi mu m C u r r e n t

Voltage (V

peak

)

Arc Stri king Voltag e

40 Amps

500V

12 kV

NOTE

Power Supply characteristics will determine material thickness range.

D. Torch Parts

Gas Distributor , Electrode, Tip, Shield Cup

F. Gas Requirement

1. Single Plasma / Secondary Gas

Compressed Air

2. Pressure

70 psi (4.8 bar)

CAUTION

Maximum input gas pressure must not exceed 125

psi (8.6 bar)

3. Total Flow

Cutting: 200 scfh (94.4 lpm)

Gouging: 230 scfh (108.5 lpm)

scfh = standard cubic feet per hour

January 23, 2004 2 Manual 0-2856

Page 3

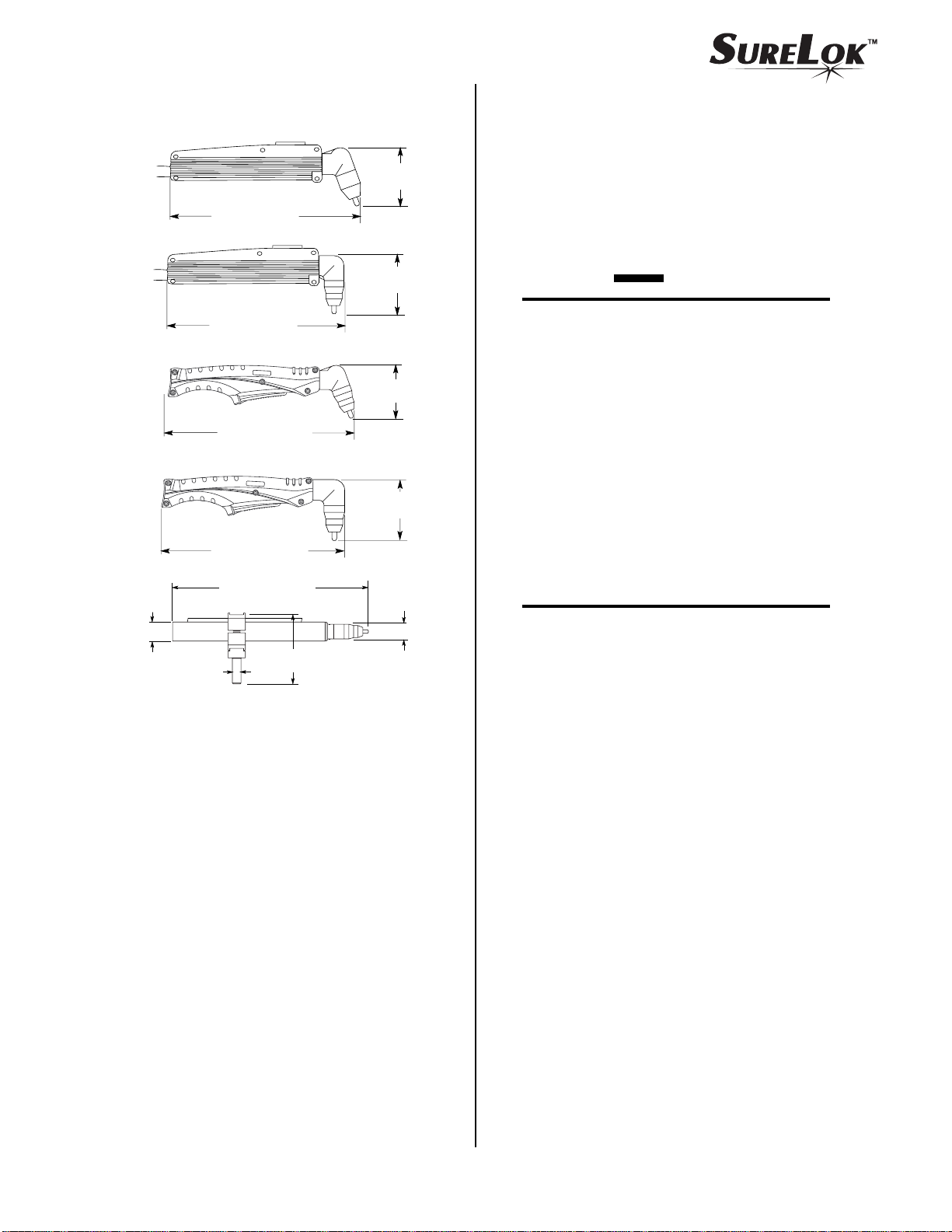

G. Dimensions

2.95 in

(75 mm)

Connecting T orch

1. Follow the instructions supplied with the appro-

priate Adapter Kit to connect the torch lead connections to the Adapter Kit parts for connection

to the Power Supply.

1.4 in

(35.6 mm)

7.98 in (203 mm)

7.31 in (186 mm)

10.5 in (266.7 mm)

9.86 in (250.4 mm)

0.6 in

(15.2 mm)

14.1 in (358 mm)

5.1 in

(130 mm)

3.13 in

(80 mm)

(76.2 mm)

3.18 in

(80.8 mm)

(27.9 mm)

A-03024

3 in

1.1 in

2. Refer to Tor ch Parts Selection and check the torch

for proper parts assembly (see CAUTION).

CAUTION

The torch parts must correspond with the type of

operation. Refer to Torch Parts Selection.

Torch Parts Selection

The type of operation to be done determines the torch

parts to be used.

Torch parts:

Shield Cup, Cutting Tip, Electrode and Gas Distributor

Type of operation:

Drag cutting, standoff cutting or gouging

NOTE

Refer to the section titled T or ch Consumables for

the various torch parts that are used depending on

the application.

I. Direct Contact Hazard

For exposed tip the recommended standoff is 1/8" 3/8" ( 3 - 9 mm).

January 23, 2004 3 Manual 0-2856

Page 4

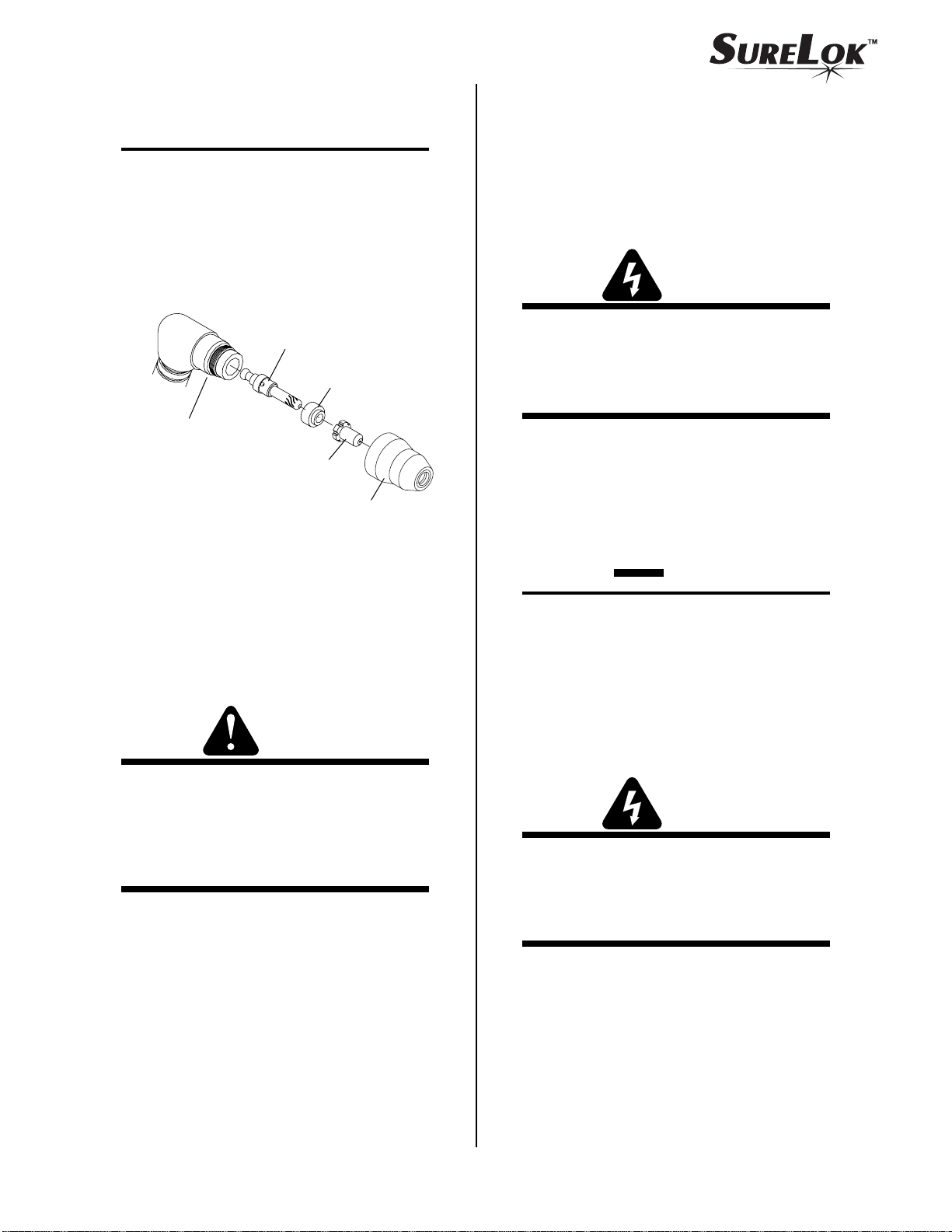

Change the torch parts for a different operation as follows:

NOTE

The shield cup holds the tip and gas distributor in

place. Position the torch with the shield cup facing upward to prevent these parts from falling out

when the cup is removed.

1. Unscrew and remove the shield cup from the torch

head.

General T orc h Maintenance

A. Cleaning T orch

Even with only clean air , eventually the inside of the

torch becomes coated with residue. This buildup can

affect the pilot arc initiation and the overall cut quality of the torch.

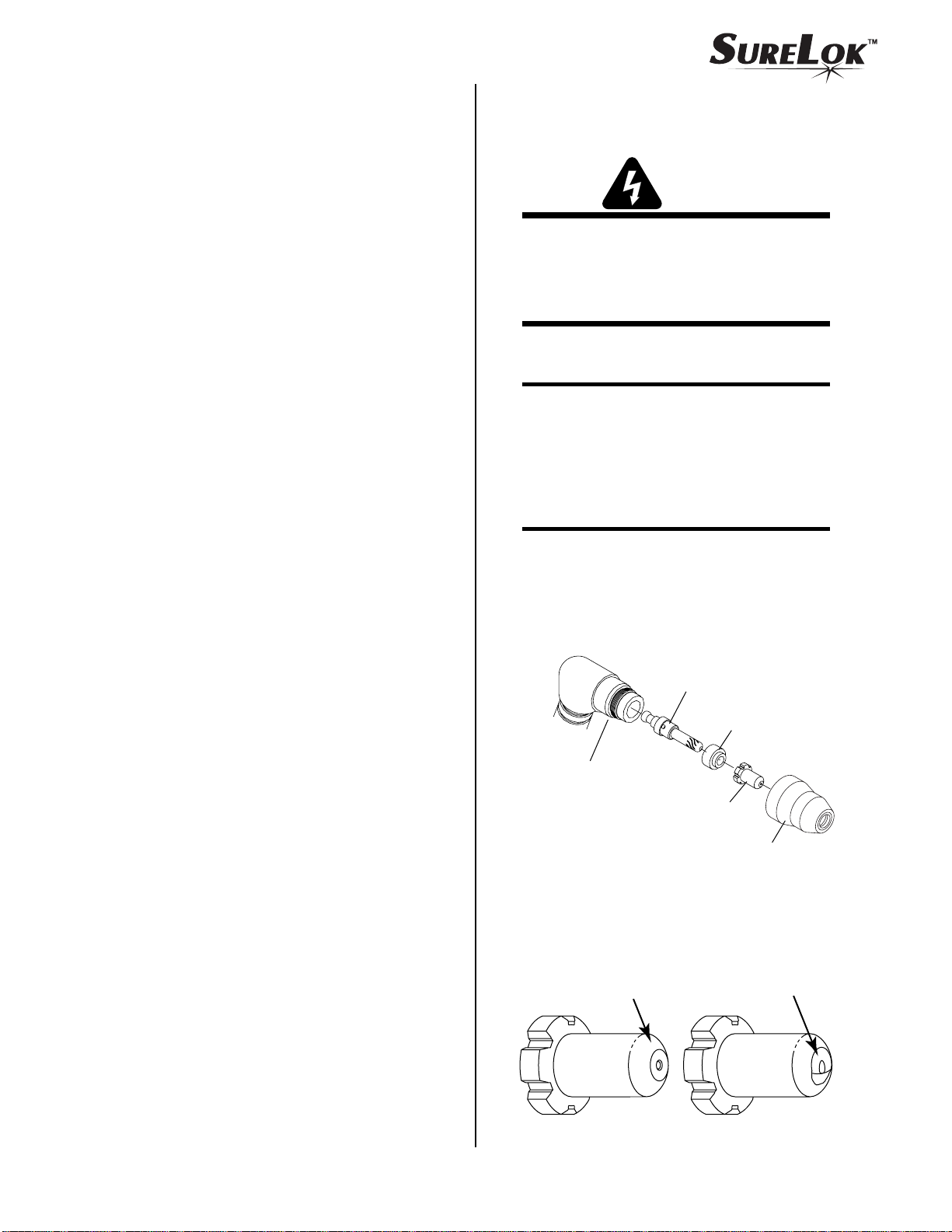

WARNINGS

Electrode

Gas

Distributor

Torch Head Assembly

(70˚ Hand Torch Shown)

Tip

A-03025

Shield Cup

2. Tilt the torch head to r emove the tip and gas distributor .

3. Remove the SureLok Electrode by pulling it straight

out of the Torch Head.

4. Install the SureLok Electrode by pushing it straight

into the torch head until it clicks.

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

The inside of the torch should be cleaned with electrical contact cleaner using a cotton swab or soft wet

rag. In severe cases, the torch can be removed from

the leads and cleaned more thoroughly by pouring

electrical contact cleaner into the torch and blowing

it through with compressed air.

CAUTION

Dry the torch thoroughly before reinstalling.

B. Checking Center Insulator

The center insulator separates the negative and positive

sections of the torch. If the center insulator does not provide adequate resistance, current which is intended for

the pilot arc may be dissipated into the torch head, resulting in torch failure.

The SureLok Electrode can only be used with the

SureLok Torch Head.

WARNINGS

The use of any consumable parts other than

those specified by the Manufacturer may cause

irreparable damage to the torch head.

5. Install the desired gas distributor and tip for the op-

eration into the torch head.

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

6. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

January 23, 2004 4 Manual 0-2856

Page 5

1. Remove the shield cup, tip, gas distributor, and electrode from the torch. Disconnect the tor ch leads from

the power supply to isolate the torch from power supply circuits.

Inspection and Replacement of

Consumable T orch Parts

2. Using an ohmmeter (set to 10K or higher), check for

continuity between the positive and negative torch

fittings. Infinite resistance (no continuity) should be

found. If continuity is found there is a problem in the

Torch or Torch Leads.

Common Operating Faults

The following lists the more common cutting faults and

the possible causes:

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non - Genuine Thermal Dynamics Parts

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Tor ch standoff too high from workpiece

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

Remove the consumable torch parts as follows:

NOTE

The tip and gas distributor are held in place by the

shield cup. Position the torch with the shield cup

facing upward to prevent these parts from falling

out when the cup is removed.

1. Unscrew and remove the shield cup from the torch.

NOTE

Slag built up on the shield cup that cannot be removed may effect the performance of the system.

2. Inspect the cup for damage. Wipe it clean or replace

if damaged.

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non - Genuine Thermal Dynamics Parts

3. Excessive Dross Formation

a. Cutting speed too slow

b. Tor ch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non - Genuine Thermal Dynamics Parts

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Air flow too low (incorrect pressure)

e. Improperly assembled torch

Electrode

Gas

Distributor

Torch Head Assembly

(70˚ Hand Torch Shown)

Tip

A-03025

Shield Cup

3. Remove the tip. Check for excessive wear (indicated

by an elongated or oversized orifice). Clean or replace the tip if necessary.

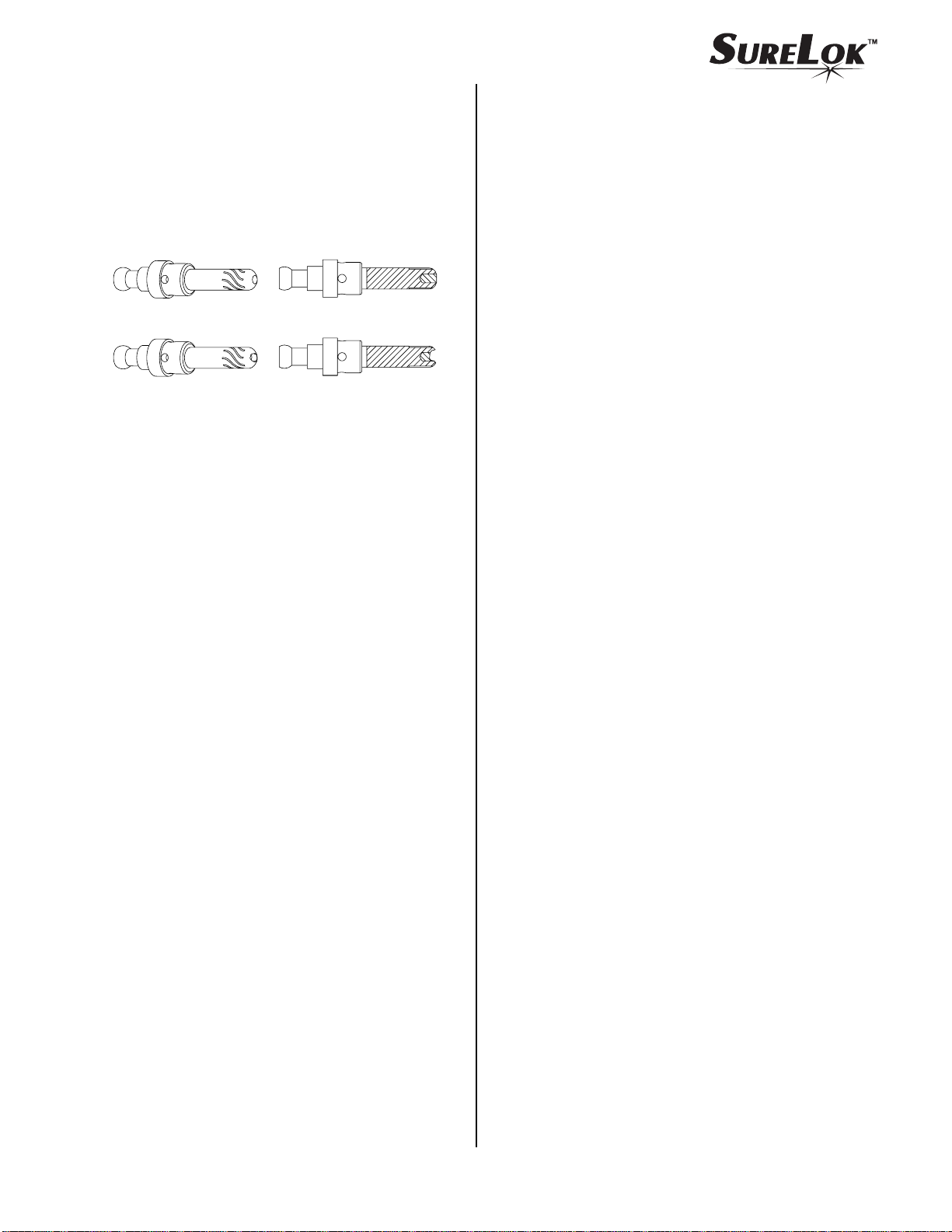

Good Tip

Worn Tip

f. Non - Genuine Thermal Dynamics Parts

A-00323

January 23, 2004 5 Manual 0-2856

Page 6

4. Remove the gas distributor and check for excessive

wear , plugged gas holes, or discoloration. Replace if

necessary.

5. Remove the SureLok Electrode by pulling it straight

out of the Torch Head. Refer to the following figure

and check the face of the electrode for excessive wear .

Electrode Selection

The new SureLok PCH / M-42 RPT Torch offers a new

General Purpose Electrode. The information supplied in

this section is to describe the new electrode.

General Purpose SureLok

Electrode (Cat. No. 9-6542)

New Electrode

A-03026

Worn Electrode

6. Reinstall the SureLok Electrode by pushing it straight

into the torch head until it clicks.

7. Reinstall the gas distributor and tip into the torch head.

8. Hand tighten the shield cup until it is seated on the

torch head. If resistance is felt when installing the

cup, check the threads before proceeding.

• General Purpose - Good performance with all

systems.

• Design of electrode is similar to previous designed

electrodes used in the PCH / M-25, 26, 28, 35, and

40 Torches.

• New patented locking design offers improved

parts life, excellent piloting, improved arc transfer distance and excellent arc characteristics as

compared to older electrode designs.

• The General Purpose electrode is the standard

electrode offered with Sur eLok RPT Replacement

T orches providing good all ar ound characteristics

and performance when applied to the wide range

of older Thermal Dynamics Systems and different manufacturers’ systems.

• New innovative patented "fluted" design.

January 23, 2004 6 Manual 0-2856

Page 7

January 23, 2004 7 Manual 0-2856

Page 8

Replacement Hand Torch Parts With Standard Handle (Non - Ergonomic)

Item # Qty Description Catalog #

1 2 PIP (Parts - In - Place) Pins 9-5723

2 2 O - Ring 8-0533

3 1 Assembly, Basic Head

70° Head 9-8442

90° Head 9-8443

(For complete Torch Head Assembly refer to Complete Assembly Replacement)

4 1 Handle, Split, Two Parts (Includes Items #9 - 11) 9-6291

5 1 Lead Assembly, 20 ft (6.1 m) Length (Includes Item #6) 4-2980

6 1 Switch, Torch 9-1058

7 1 #6-32 x 3/16 Phillips Pan Head Screw See Note

8 1 #6 Internal Star Washer See Note

9 1 Button, Split Holder 8-4256

10 2 Spring 9-6292

11 6 #2-56 x 5/16" Phillips Pan Head Screw See Note

NOTE: Item can be purchased locally.

January 23, 2004 8 Manual 0-2856

Page 9

PCH-42R RPT

3

4

9

10

10

2

8

6

4

11

7

5

1

Requires Adapter Kit

For Proper Installation

Art # A-03549

January 23, 2004 9 Manual 0-2856

Page 10

Replacement Hand Torch Parts With Ergonomic Handle

Item # Qty Description Catalog #

1 1 Assembly, Basic Head

70° Head 9-8442

90° Head 9-8443

2 2 PIP (Parts - In - Place) Pins 9-5723

3 1 #6-32 x 3/16" Phillips Pan Head Screw See Note

4 1 #6 Internal Star Washer See Note

1 Ergonomic Handle, Split, with Trigger (includes items #5 - 12) 9-8076

5 1 Trigger, Lexan, Orange 9-8059

6 1 Handle 9-8060

7 1 Spring, 0.390 O.D. x 0.750 9-8061

8 1 Torch Handle Socket Head Cap Screw Kit (5 pcs 6-32 x 1/2" ) 9-8062

9 1 Assembly, Torch Switch 9-8063

10 1 Negative / Plasma Lead Insulation Sleeving 9-8056

11 3 Pin Housing (Used with item #12) 9-8111

12 3 Pin 9-8101

13 3 Socket Housing (Used with item #14) 9-8112

14 3 Socket 9-8102

15 1 Lead Assembly, including items No. 6, 8, and 9

20 ft (7.6 m) Length 4-2989

50 ft (15.2 m) Length 4-2986

NOTE: Item can be purchased locally.

January 23, 2004 10 Manual 0-2856

Page 11

PCH-42ER RPT

6

10

13 & 14

4

3

11 & 12

7

1

2

Requires Adapter Kit

For Proper Installation

5

9

6

8

15

Art # A-03547

January 23, 2004 11 Manual 0-2856

Page 12

Replacement Machine Torch Parts With Pinch Block Mounting Parts

Item # Qty Description Catalog #

1 1 Assembly, PIP (Parts - In - Place) Pins and Wire 9-5723

2 1 Assembly, Basic Head, Machine (Includes items #3 & 4) 9-8444

3 1 #6-32 x 1/16 Phillips Pan Head Screw See Note 1

4 1 #6 Internal Star Washer See Note 1

5 1 Lead Assembly

25 ft (7.6 m) Length 4-2987

50 ft (15.2 m) Length 4-2988

6 1 Positioning T ube With Rack, Fiberglass 9-7835

7 2 Body, Mounting, Pinch Block 9-4513

8 1 Pin, Mounting, Pinch Block 9-4521

9 1 Torch Holder Sleeve 7-2896

10 3 #10-32 x 5/8" Phillips Pan Head Screw See Note 1

11 2 #10-32 x 32 x 1 1/4 Lg Phillips Pan Head Screw See Note 1

12 2 #10-32 Regular Nylon Lock Nut See Note 1

13 1 T or ch Contr ol Cable

Standard - Start / Stop Control Only 9-8098

Optional - CNC / Remote Pendant Control (Adapter Kit) - See Note 2 7-3448

NOTES

1. Item can be purchased locally.

2. For use on Thermal Dynamics Products only.

January 23, 2004 12 Manual 0-2856

Page 13

PCM-42 RPT

11

7

6

10

2

4

1

3

8

7

12

9

5

Requires Adapter Kit

For Proper Installation

13

Optional

CNC/Remote Control

(Start/Stop Control Only)

Standard

Art #A-03548

January 23, 2004 13 Manual 0-2856

Page 14

Complete Assembly Replacement

NOTE

All Complete Torch and Lead Assemblies require a Torch Adapter Kit for proper installation of the Torch.

Description Catalog #

Hand Torches with Two Piece Standard Handle:

PCH-42R RPT 70° Hand Torch, 20 ft (6.1 m) Leads 7-4226

PCH-42R RPT 90° Hand Torch, 20 ft (6.1 m) Leads 7-4227

Hand Torches with Two Piece Ergonomic Handle:

PCH-42ER RPT 70° Hand Torch, 20 ft (6.1 m) Leads 7-4220

PCH-42ER RPT 90° Hand Torch, 20 ft (6.1 m) Leads 7-4222

PCH-42ER RPT 70° Hand Torch, 50 ft (15.2 m) Leads 7-4221

PCH-42ER RPT 90° Hand Torch, 50 ft (15.2 m) Leads 7-4223

Machine Torches with Unshielded Leads (Fiberglass Mounting Tube with Rack & Pinch Block Assembly):

PCM-42 RPT Machine Torch, 25 ft (7.6 m) Leads 7-4224

PCM-42 RPT Machine Torch, 50 ft (15.2 m) Leads 7-4225

January 23, 2004 14 Manual 0-2856

Page 15

Torch Consumables

WARNINGS

Use only the parts shown. Do Not attempt to use older parts that are not shown.

The use of any consumable parts other than those specified by the Manufacturer may cause irreparable

damage to the torch head.

Cutting Consumables

A-03027

SureLok

Electrode

9-6542 MaximumLife™

SureLok

Electrode

Gas

Distributor

9-6507

Gas

Distributor

MaximumLife™ Tips

Air

Drag - 20A

9-6504

Standoff - 40A

9-6500

Drag - 40A

9-6501

Gouging Consumables

MaximumLife™ Tip

Air

Shield Cups

MaximumLife™

9-6503

9-6003

9-6004

A-03439

Shield Cups

9-6542 MaximumLife™

9-6507

9-6502

9-6003

MaximumLife™

9-6503

Patented SureLok™ Technology

January 23, 2004 15 Manual 0-2856

Page 16

W ARNING - Replacing Original Machine Torch with RPT Mechanized Torch

Thermal Dynamics RPT mechanized torches have two control wires that are used for Parts - In - Place (PIP) only.

Do not connect these PIP connections directly into any start input because when the torch parts are in place, the

start signal will always be energized. If the torch parts are not in place but ar e subsequently installed with the start

signal energized, the shield cup will complete the start circuit and the unit will immediately transfer a pilot arc.

Standard Torch Control Cable For Start / Stop Only Mechanized Systems

NOTE

T o Torch

Control Device

NOTE: These wires are not present

in all configurations. If present,

leave them connected together.

Standard T orch

Control Cable

Control Connector

Plug with Connectors

types of connectors or plugs.

To Power Supply

Control Connector

Art # A-03763

Optional Torch Control Cable For CNC / Remote Pendant Systems

This option is to be used with Thermal Dynamics XR's, XL's and XL Plus Systems Only

To Torch

Control wires have various

Control Device

Torch Control

Cable

Torch Control

Connectors

Control Connector

Plug with Connectors

NOTE: These wires are

not present in all

configurations.

If present, leave them

connected together.

To Power Supply

Control Connector

Control Shield

Connector

Torch Lead

Assembly

Lead Shield

Connector

Connectors only on

Shielded Leads

Art # A-03819

NOTE

Shielded Leads are available only for Thermal Dynamics Product and are not to be installed on any other pr oducts.

January 23, 2004 16 Manual 0-2856

Page 17

Wiring Diagram

Optional Torch Control Cable For CNC / Remote Pendant Systems

Shield

Return

Power Supply

Control

OK-To-Move

Relay

A-02821

2

1

3

4

12

14

13

Torch Control

Cable Connector

Mate & Lock

Connectors

Torch Leads

Mate & Lock

Connectors

Remote Pendant/CNC

Cable Connector

Torch Head

PIP Pin

PIP Pin

3

4

12

14

13

Shield Cup

Control

OK-To-Move

Pendant Ground

NOTE

Every effort has been made to provide complete and accurate information in this manual. However, the

publisher does not assume and hereby disclaims any liability to any party for any loss or damage caused

by errors or omissions in this Manual, whether such errors result fr om negligence, accident, or any other

cause.

January 23, 2004 17 Manual 0-2856

Page 18

Statement of Warranty

LIMITED WARRANTY: Thermal Dynamics® Corporation (hereinafter “Thermal”) warrants that its products will

be free of defects in workmanship or material. Should any failure to conform to this warranty appear within the time

period applicable to the Thermal products as stated below, Thermal shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and maintained in accordance with Thermal’s specifications, instructions, recommendations and recognized standard industry practice, and not subject to misuse, repair,

neglect, alteration, or accident, correct such defects by suitable repair or replacement, at Thermal’s sole option, of

any components or parts of the product determined by Thermal to be defective.

This warranty is exclusive and is in lieu of any warranty of merchantability or fitness for a particular purpose.

LIMITATION OF LIABILITY: Thermal shall not under any circumstances be liable for special or consequential

damages, such as, but not limited to, damage or loss of purchased or replacement goods, or claims of customers of

distributor (hereinafter “Purchaser”) for service interruption. The remedies of the Purchaser set forth herein are

exclusive and the liability of Thermal with respect to any contract, or anything done in connection therewith such as

the performance or breach thereof, or from the manufactur e, sale, delivery, resale, or use of any goods covered by or

furnished by Thermal whether arising out of contract, negligence, strict tort, or under any warranty, or otherwise,

shall not, except as expressly provided herein, exceed the price of the goods upon which such liability is based.

This warranty becomes invalid if replacement parts or accessories are used which may impair the safety or

performance of any Thermal Product.

This warranty becomes invalid if the product is sold by non - authorized persons.

All SureLok™ RPT Torches have a one year Parts & Labor warranty

Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal

Dynamics® repair facility within thirty (30) days of the repair. No transportation costs of any kind will be paid

under this warranty. Transportation charges to send pr oducts to an authorized warranty r epair facility shall be the

responsibility of the customer. All returned goods shall be at the customer’s risk and expense.

Thermal Dynamics Corporation

82 Benning Street

West Lebanon, NH 03784 USA

Telephone: 603-298-5711

www.thermal-dynamics.com

January 23, 2004 18 Manual 0-2856

Loading...

Loading...