Page 1

HEFTY®II STAINLESS

SEMIAUTOMATIC, SOLID STATE CONTROLLED

VOLTAGE SENSING WIRE FEEDER

For the Following Specs:

100052-1

•

OWNER’S MANUAL Number 430429-456 (Rev AB)

Revised June 5, 2000

IMPORTANT: Readtheseinstructionsbeforeinstalling,operating, or servicing this system.

THERMAL ARC INC., TROY, OHIO 45373-1085, U.S.A.

Page 2

430429-456

TABLE OF CONTENTS

INTRODUCTION 1

How To Use This Manual ..................................1-1

Equipment Identification ..................................1-1

Receipt Of Equipment ...................................1-1

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS 2

DESCRIPTION OF EQUIPMENT 3

General ...........................................3-1

Product Specifications ...................................3-1

Features/Benefits ......................................3-2

Meanings Of Markings And Graphical Symbols ......................3-3

Front Panel Controls And Connections ...........................3-4

Internal Controls And Connections (Component Side) ...................3-5

Internal Controls And Connections (Wire Spool Side) ...................3-6

Description Of Feedhead Assembly ............................3-6

Power Source Compatibility ................................3-7

Available Options ......................................3-8

INSTALLATION 4

Connections .........................................4-1

Installation Of Welding Wire Spool .............................4-1

Adjustment Of Spool Tension ................................4-1

Input And Output Wire Guide Installation ..........................4-1

Selection And Installation Of Feed Rolls ..........................4-1

Welding Gun Compatibility And Installation .........................4-2

Threading Wire Into Feedhead ...............................4-2

OPERATION 5

Prewelding Procedure ...................................5-1

Welding Procedure .....................................5-2

Welding In CC Mode vs. CV Mode .............................5-2

Theory Of Operation ....................................5-2

Adjusting Burnback Time ..................................5-2

Calibrating Wire Feed Speed Meter ............................5-3

Protection And Safety Circuits ...............................5-3

MAINTENANCE 6

Cleaning Of The Unit ....................................6-1

Cleaning Of The Feed Rolls ................................6-1

Feedhead Maintenance ...................................6-1

Contactor Maintenance ...................................6-1

Gas Valve Maintenance ..................................6-1

TROUBLESHOOTING 7

Scope ............................................7-1

Safety ............................................7-1

Troubleshooting Hints ....................................7-1

Troubleshooting Guide ...................................7-2

June 5, 2000 Revised Page 1

Page 3

430429-456

TABLE OF CONTENTS

PARTS LIST 8

Equipment Identification ..................................8-1

How To Use This Parts List .................................8-1

DIAGRAMS

WARRANTY

Page 2 November 17, 1999

Page 4

INTRODUCTION

430429-456

INTRODUCTION

How To Use This Manual:

This Owner’s Manual usually applies to just the

underlined specification or part numbers listed on

the cover. If none are underlined, they are all covered by this manual.

Throughout this manual, the words WARNING,

CAUTION, and NOTE may appear. Pay particular

attention to the information provided under these

headings. These special annotationsareeasily recognized as follows:

WARNING gives information regarding possible personal injury. Warnings will be enclosed

in a box such as this.

CAUTION refers to possible equipment

damage. Cautions will be shown in bold

type.

NOTE offers helpful information concerningcertainoperatingprocedures. Notes will

be shown in italics.

appear on a nameplate attached to the control

panel. In some cases, the nameplate may be attached to the rearpanel.Equipment which does not

have a control panelsuch as gunand cable assemblies is identified only by the specification or part

number printed on the shipping container. Record

these numbers for future reference.

Receipt Of Equipment:

When you receivethe equipment, checkit against

the invoice to make sure it is complete and inspect

theequipmentforpossibledamageduetoshipping.

If there is any damage, notify the carrier immediately to file a claim. Furnish complete information

concerning damage claims or shipping errors to

Thermal Arc, Order Department, 2200 Corporate

Drive, Troy, Ohio 45373-1085. Include all equipment identification numbers as described above

along with a full description of the parts in error.

Move the equipment to the installation site before

uncrating the unit. Use care to avoid damaging the

equipment when using bars, hammers, etc., to uncrate the unit.

Equipment Identification:

The unit’s identification number (specification or

part number), model, and serial number usually

Additional copies of this manual may be purchased by contacting Thermal Arc at the address

given above. Include the Owner’s Manual number

and equipment identification numbers.

November 17, 1999 1-1

Page 5

430429-456

INTRODUCTION

This page intentionally left blank.

1-2 November 17, 1999

Page 6

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

ARC WELDING can be hazardous.

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER

WEARERSKEEPAWAY UNTILCONSULTINGYOUR DOCTOR.DONOT LOSETHESEINSTRUCTIONS. READOPE RATING/INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property, if the operator does

not strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned through study and

trainingbeforeusingthis equipment. Anyone not havingextensivetraining in welding and cuttingpracticesshould not attempt to weld. Certain

of the practices apply to equipment connected to power lines; other practices apply to engine driven equipment.

Safe practices are outlined in the American National Standard Z49.1 entitled:

other guides to what you should learn before operating this equipment are listed at the end of these safety precautions.

HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY QUALIFIED PEOPLE.

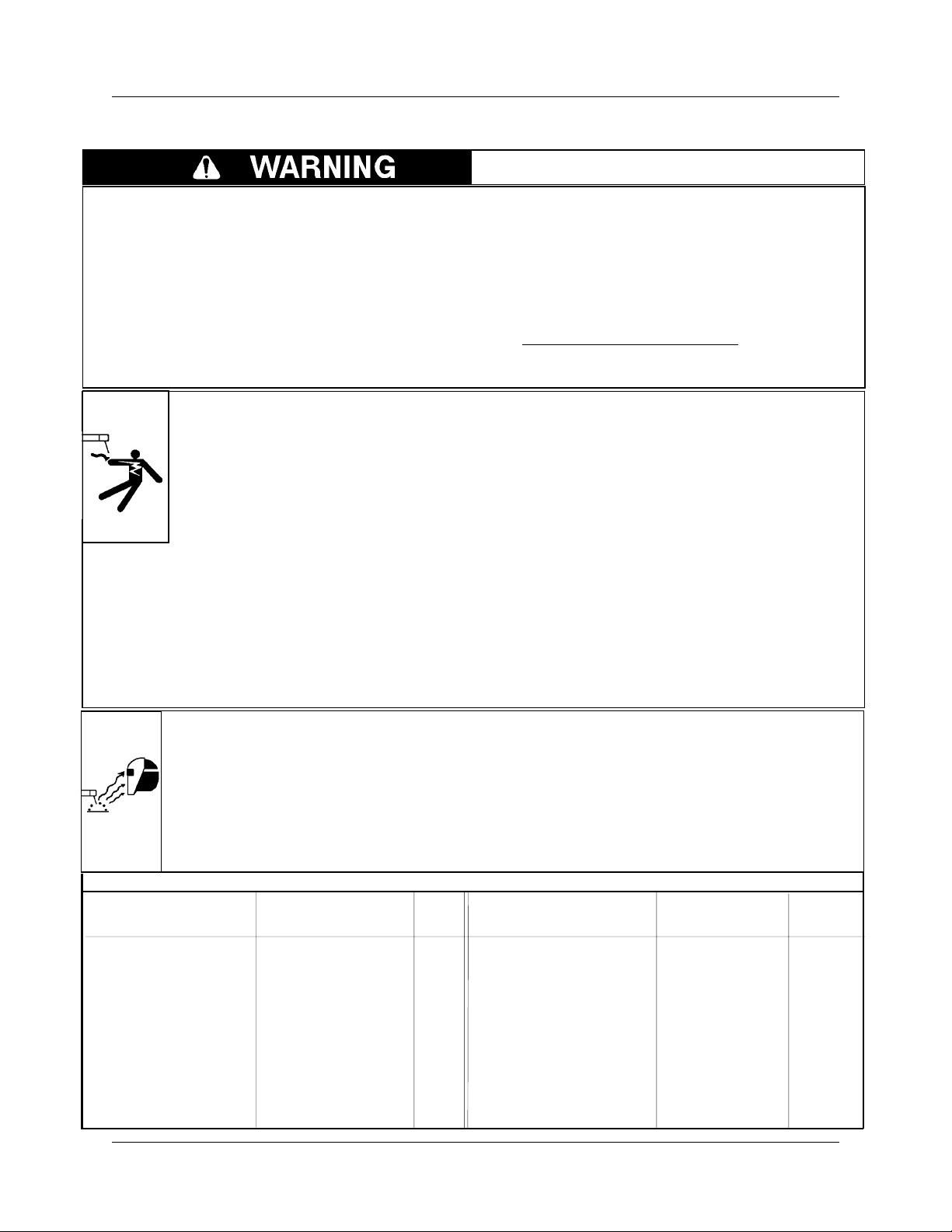

ELECTRIC SHOCK can kill.

Touchingliveelectrical partscancause fatal shocks

or severe burns. The electrode and work circuit is

electricallylivewhenevertheoutputison. The input

power circuit and machine internal circuits are also

livewhen poweris on.In semiautomaticorautomatic

wire welding, the wire, wire reel, drive roll housing,

and all metal parts touching the welding wire are

electrically live. Incorrectly installed or improperly

grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourselffromwork and ground using dryinsulatingmats

or covers.

4. Disconnect input power or stop engine before installing or servicing this equipment. Lock input power disconnect switch open,

or remove line fuses so power cannot be turned on accidentally.

5. Properly install and ground this equipment according to its

Owner’s Manual and national, state, and local codes.

SAFETY IN WELDING AND CUTTING. This publication and

6. Turn off all equipment when not in use. Disconnect power to

equipment if it will be left unattended or out of service.

7. Use fully insulated electrode holders. Never dip holder in water

to cool it or lay it down on the ground or the work surface.Donot

touch holders connected to two welding machines at the same

time or touch other people with the holder or electrode.

8. Do notuse worn, damaged,undersized,or poorly splicedcables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth) ground.

11. Do not touch electrode while in contact with the work (ground)

circuit.

12. Useonlywell-maintained equipment.Repair orreplacedamaged

parts at once.

13. In confined spaces or damp locations, do not use a welder with

AC output unless it is equipped with a voltage reducer. Use

equipment with DC output.

14. Wear a safety harness to prevent falling if working above floor

level.

15. Keep all panels and covers securely in place.

ARC RAYS can burn eyes and skin;

NOISE can damage hearing.

Arc rays from the welding process produce intense

heat and strong ultraviolet rays that can burn eyes

and skin. Noise from some processes can damage

hearing.

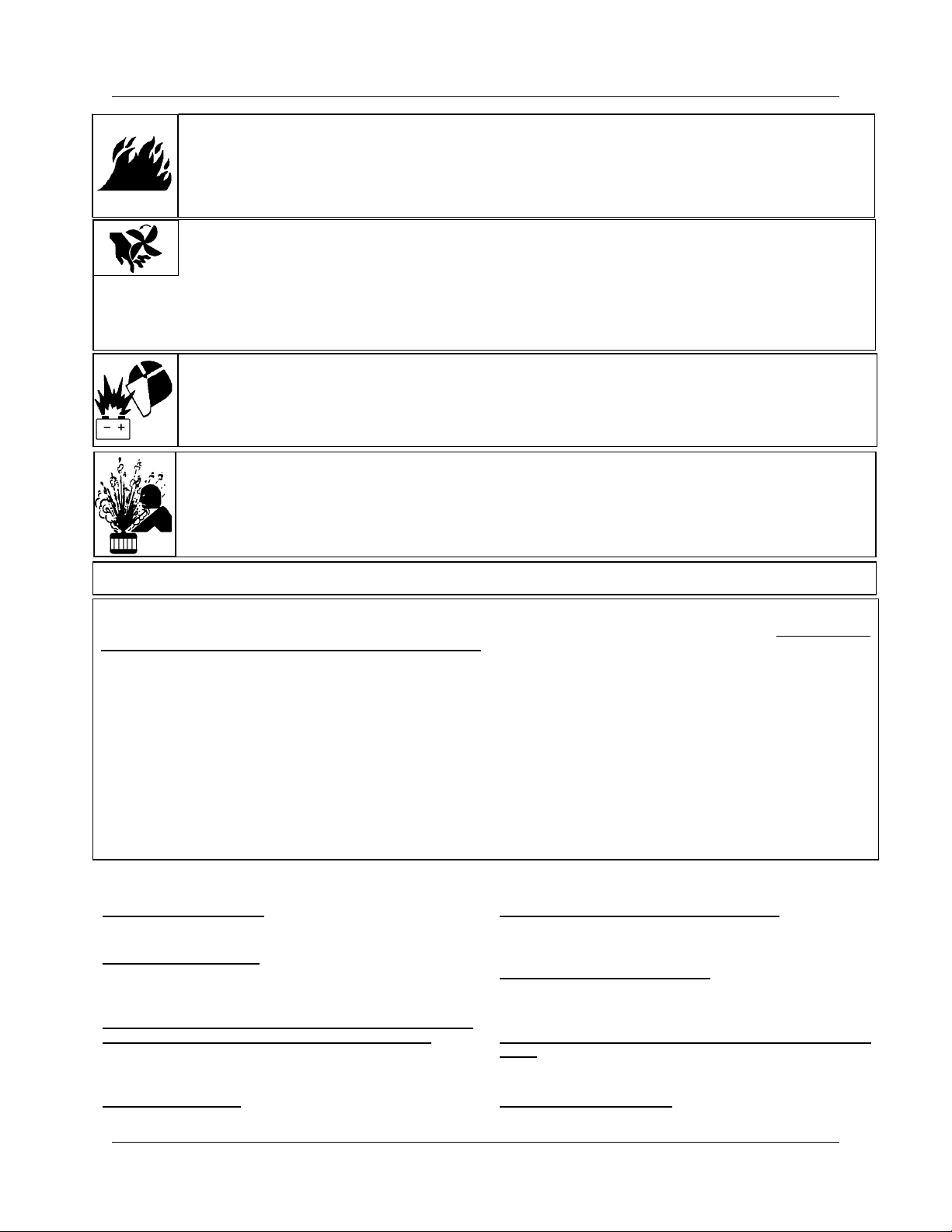

Eye protection filter shade selector for welding or cutting (goggles or helmet), from AWS A6.2-73.

Welding or Cutting

Operation

Torch soldering

Torch brazing

Oxygen cutting

Light

Medium

Heavy

Gas welding

Light

Medium

Heavy

Shielded metal-arc welding

(stick) electrodes

Electrode Size

Metal Thickness

or Welding Current

—

—

Under 1 in., 25 mm

1 to 6 in., 25-150 mm

Over 6 in., 150 mm

Under 1/8 in., 3 mm

1/8 to 1/2 in., 3-12 mm

Over 1/2 in., 12 mm

Under 5/32 in., 4 mm

5/32 to 1/4 in., 4 to 6.4 mm

Over 1/4 in., 6.4 mm

Filter

Shade

No.

2

3or4

3or4

4or5

5or6

4or5

5or6

6or8

10

12

14

1. Wear a welding helmet fitted with a proper shade of filter (see

ANSI Z49.1 listed in Safety Standards) to protect your face and

eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others from flash

and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistant

material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is high.

Welding or Cutting

Operation

Gas metal-arc welding (MIG)

Non-ferrous base metal

Ferrous base metal

Gastungstenarcwelding (TIG)

Atomic hydrogen welding

Carbon arc welding

Plasma arc welding

Carbon arc air gouging

Light

Heavy

Plasma arc cutting

Light

Medium

Heavy

Electrode Size

Metal Thickness

or Welding Current

All

All

All

All

All

All

Under 300 Amp

300 to 400 Amp

Over 400 Amp

May 8, 1996 2-1

Filter

Shade

No.

11

12

12

12

12

12

12

14

9

12

14

Page 7

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

FUMES AND GASES can be hazardous

to your health.

Weldingproducesfumesandgases.Breathingthese

fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breath the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to

remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The

flying sparks and hot metal, weld spatter, hot workpiece, and hot equipment cancausefiresandburns.

Accidental contact of electrode or welding wire to

metal objects can cause sparks, overheating, or fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding arc.

If this is not possible, tightly cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

4. Read the Material Safety Data Sheets (MSDSs) and the manufacturer’s instruction for metals, consumables, coatings, and

cleaners.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Shielding gases used for

welding can displace air causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and raysofthearccanreactwithvapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing an air-supplied respirator. The coatings and any metals

containing these elements can give off toxic fumes if welded.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at

contact tip when not in use.

11. Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap.

FLYING SPARKS AND HOT METAL can

cause injury.

Chipping and grinding cause flying metal. As welds

cool, they can throw off slag.

CYLINDERS can explode if damaged.

Shielding gas cylinderscontaingasunderhighpressure. If damaged, a cylinder can explode. Since gas

cylinders are normally part of the welding process,

be sure to treat them carefully.

1. Protectcompressed gascylinders fromexcessiveheat,mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining

themtoa stationarysupport orequipment cylinderracktoprevent

falling or tipping.

ENGINE EXHAUST GASES can kill.

Engines produce harmful exhaust gases.

1. Wear approved face shield or safety goggles. Side shields recommended.

2. Wear proper body protection to protect skin.

3. Keep cylindersawayfrom any welding orotherelectricalcircuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and

fittings designed for the specific application; maintain them and

associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is

in use or connected for use.

8. Read and follow instructionsoncompressedgas cylinders, associated equipment, and CGA publication P-1 listed in Safety

Standards.

ENGINES can be hazardous.

1. Use equipment outside in open, well-ventilated areas.

2. If used in a closed area, vent engine exhaust outside and away

from any building air intakes.

2-2 May 8, 1996

Page 8

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

ENGINE FUEL can cause fire or

explosion.

Engine fuel is highly flammable.

1. Stop engine before checking or adding fuel.

MOVING PARTS can cause injury.

Moving parts,suchasfans, rotors, and belts cancut

fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and securely

in place.

2. Stop engine before installing or connecting unit.

SPARKS can cause BATTERY GASES

TO EXPLODE; BATTERY ACID can

burn eyes and skin.

Batteriescontain acidandgenerateexplosivegases.

STEAM AND PRESSURIZED HOT

COOLANT can burn face, eyes, and

skin.

The coolantinthe radiator can beveryhot and under

pressure.

WARNING: This product, when used for welding or cutting, produces fumes or gases which contain chemicals known to the State

of California to cause birth defects and, in some cases, cancer. (California Health & Safety Code Sec. 25249.5 et seq.)

NOTE: Considerations About Welding And The Effects Of Low Frequency Electric And Magnetic Fields

The following is a quotation from the General Conclusions Section of the U.S. Congress, Office of Technology Assessment,

of Power Frequency Electric& Magnetic Fields — Background Paper, OTA-BP-E-63 (Washington, DC: U.S. Government Printing Office, May

1989): “... there is now a very large volume of scientific findings based on experiments at the cellular level and from studies with animals and

people which clearly establish that low frequency magnetic fields can interact with, and produce changes in, biological systems. While most of

this work is of very high quality, the results are complex. Current scientific understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet allow us to draw definite conclusions about questions of possible risk or to

offer clear science-based advice on strategies to minimize or avoid potential risks.”

To reduce magnetic fields in the workplace, use the following procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

2. Donotadd fuelwhilesmoking orifunit isnearany sparksoropen

flames.

3. Allow engine to cool before fueling. If possible, check and add

fuel to cold engine before beginning job.

4. Do not overfill tank — allow room for fuel to expand.

5. Do not spill fuel. If fuel is spilled,cleanupbeforestartingengine.

3. Have only qualified people remove guards or covers for mainte-

nance and troubleshooting as necessary.

4. Topreventaccidental starting duringservicing,disconnect nega-

tive (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from moving

parts.

6. Reinstall panels or guards and close doors when servicing is

finished and before starting engine.

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting battery cables.

3. Do not allow tools to cause sparks when working on a battery.

4. Do not use welder to charge batteries or jump start vehicles.

5. Observe correct polarity (+ and –) on batteries.

1. Do not remove radiator cap when engine is hot. Allow engine to

cool.

2. Wear gloves and put a rag over cap area when removing cap.

3. Allow pressure to escape before completely removing cap.

Biological Effects

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far awayfrom body as

practical.

About Pacemakers:

The above procedures are among those also normally recommended for pacemaker wearers. Consult your doctor for complete information.

PRINCIPAL SAFETY STANDARDS

Safety inWeldingandCutting,ANSI Standard Z49.1, from American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126.

SafetyandHealthStandards, OSHA 29 CFR1910,fromSuperintendent of Documents, U.S. Government Printing Office, Washington,

D.C. 20402.

Recommended Safe Practices for the Preparation for Welding and

CuttingofContainersThatHaveHeldHazardousSubstances,American Welding Society Standard AWS F4.1, from American Welding

Society, 550 N.W. LeJeune Rd., Miami, FL 33126.

National Electrical Code, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet

P-1, from Compressed Gas Association, 1235 Jefferson DavisHighway, Suite 501, Arlington, VA 22202.

Code forSafetyin Welding and Cutting,CSAStandard W117.2, from

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices for Occupation and Educational Eye and Face Protection, ANSI Standard Z87.1, from American National Standards

Institute, 1430 Broadway, New York, NY 10018.

Cutting and Welding Processes, NFPA Standard 51B, from National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

May 8, 1996 2-3

Page 9

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

This page intentionally left blank.

2-4 May 8, 1996

Page 10

PRECAUTIONS DE SECURITE EN SOUDAGE A L'ARC

Instruction 830002

PRECAUTIONS DE SECURITE EN SOUDAGE A L′ARC

LE SOUDAGE A L′ARC EST DANGEREUX

PROTEGEZ-VOUS,AINSI QUE LES AUTRES, CONTRE LES BLESSURESGRAVES POSSIBLES OU LA MORT. NE LAISSEZ PAS LES

ENFANTSS’APPROCHER,NILES PORTEURSDE STIMULATEURCARDIAQUE (AMOINSQU’ILS N’AIENTCONSULTE UNMEDECIN).

CONSERVEZ CES INSTRUCTIONS.LISEZLEMANUELD’OPERATION OU LES INSTRUCTIONS AVANT D’INSTALLER, UTILISER OU

ENTRETENIR CET EQUIPEMENT.

Les produits et procédés de soudage peuvent sauser des blessures graves ou la mort, de même que des dommages au reste du matériel

et à la propriété,sil’utilisateur n’adhère pas strictement à toutes les règles de sécurité et ne prend pas les précautions nécessaires.

En soudage et coupage, des pratiques sécuritaires se sont développées suite à l’expériencepassée. Ces pratiques doivent être apprises

parétude ou entraînement avant d’utiliserl’equipement. Toute personne n’ayant pas suivi un entraînement intensif en soudage et coupage

ne devrait pas tenter de souder. Certaines pratiques concernent les équipements raccordés aux lignes d’alimentation alors que d’autres

s’adressent aux groupes électrogènes.

La norme Z49.1 de l’American National Standard, intitulée “SAFETY IN WELDING AND CUTTING” présente les pratiques sécuritaires à

suivre. Ce document ainsi que d’autres guides que vous devriez connaître avant d’utiliser cet équipement sont présentés à la fin de ces

instructions de sécurité.

SEULES DES PERSONNES QUALIFIEES DOIVENT FAIRE DES TRAVAUX D’INSTALLATION, DE REPARATION, D’ENTRETIEN ET

D’ESSAI.

L’ELECTROCUTION PEUT ETRE

MORTELLE.

Une décharge électrique peut tuer ou brûler gravement. L’électrode et le circuit de soudage sont sous

tension dès la mise en circuit. Le circuit d’alimentation et les circuits internes de l’équipement sont

aussi sous tension dès la mise en marche. En

soudage automatique ou semi-automatique avec

fil, ce dernier, le rouleau ou la bobine de fil, le

logement des galets d’entrainement et toutes les

pièces métalliques en contact avec le fil de soudage

sont sous tension. Un équipement inadéquatement

installé ou inadéquatement mis à la terre est dangereux.

1. Ne touchez pas à des pièces sous tension.

2. Portez des gants et des vêtements isolants, secs et non troués.

3. Isolez-vousdela pièceàsouder et delamise àlaterre aumoyen

de tapis isolants ou autres.

4. Déconnectez la prise d’alimentation de l’équipement ou arrêtez

le moteur avant de l’installer ou d’en faire l’entretien. Bloquez le

commutateurencircuit ouvertou enlevezlesfusibles del’alimentation afin d’éviter une mise en marche accidentelle.

5. Veuillez à installer cet équipement et à le mettre à la terre selon

le manuel d’utilisation et les codes nationaux, provinciaux et

locaux applicables.

LE RAYONNEMENT DE L′ARC PEUT

BRÛLER LES YEUX ET LA PEAU; LE

BRUIT PEUT ENDOMMAGER L′OUIE.

L’arc de soudage produit une chaleur et des

rayons ultraviolets intenses, susceptibles de

brûler les yeux et la peau. Le bruit causé par

certains procédés peut endommager l’ouïe.

1. Portez une casque de soudeur avec filtre oculaire de nuance

appropriée (consultez la norme ANSI Z49 indiquéeci-après)

6. Arrêtez tout équipement après usage. Coupez l’alimentation de

l’équipement s’il est hors d’usage ou inutilisé.

7. N’utilisezque desporte-électrodesbienisolés.Nejamaisplonger

les porte-électrodes dans l’eau pour les refroidir. Ne jamais les

laisser traîner par terre ou sur les pièces à souder. Ne touchez

pas aux porte-électrodes raccordés à deux sources de courant

en même temps. Ne jamais toucher quelqu’un d’autre avec

l’électrode ou le porte-électrode.

8. N’utilisez pas de câbles électriques usés, endommagés, mal

épissés ou de section trop petite.

9. N’enroulez pas de câbles électriques autour de votre corps.

10. N’utilisez qu’une bonne prise de masse pour la mise à la terre

de la pièce à souder.

11. Ne touchez pas à l’électrode lorsqu’en contact avec le circuit de

soudage (terre).

12. N’utilisez que des équipements en bon état. Réparez ou remplacez aussitôt les pièces endommagées.

13. Dans des espacesconfinésoumouillés,n’utilisezpasde source

de courant alternatif, à moins qu’il soit muni d’un réducteur de

tension. Utilisez plutôt une source de courant continu.

14. Portez un harnais de sécurité si vous travaillez en hauteur.

15. Fermez solidement tous les panneaux et les capots.

pour vous protéger le visageetlesyeuxlorsquevoussoudezou

que vous observez l’exécution d’une soudure.

2. Portezdeslunettes desécuritéapprouvées. Des écranslatéraux

sont recommandés.

3. Entourez l’aire de soudage de rideaux ou de cloisons pour

protéger les autres des coups d’arcoudel’éblouissement;

avertissez les observateurs de ne pas regarder l’arc.

4. Portez des vêtements en matériaux ignifuges et durables (laine

et cuir) et des chaussures de sécurité.

5. Portez un casque antibruit ou des bouchons d’oreille approuvés

lorsque le niveau de bruit est élevé.

8-V-96 2-1

Page 11

PRECAUTIONS DE SECURITE EN SOUDAGE A L'ARC

Instruction 830002

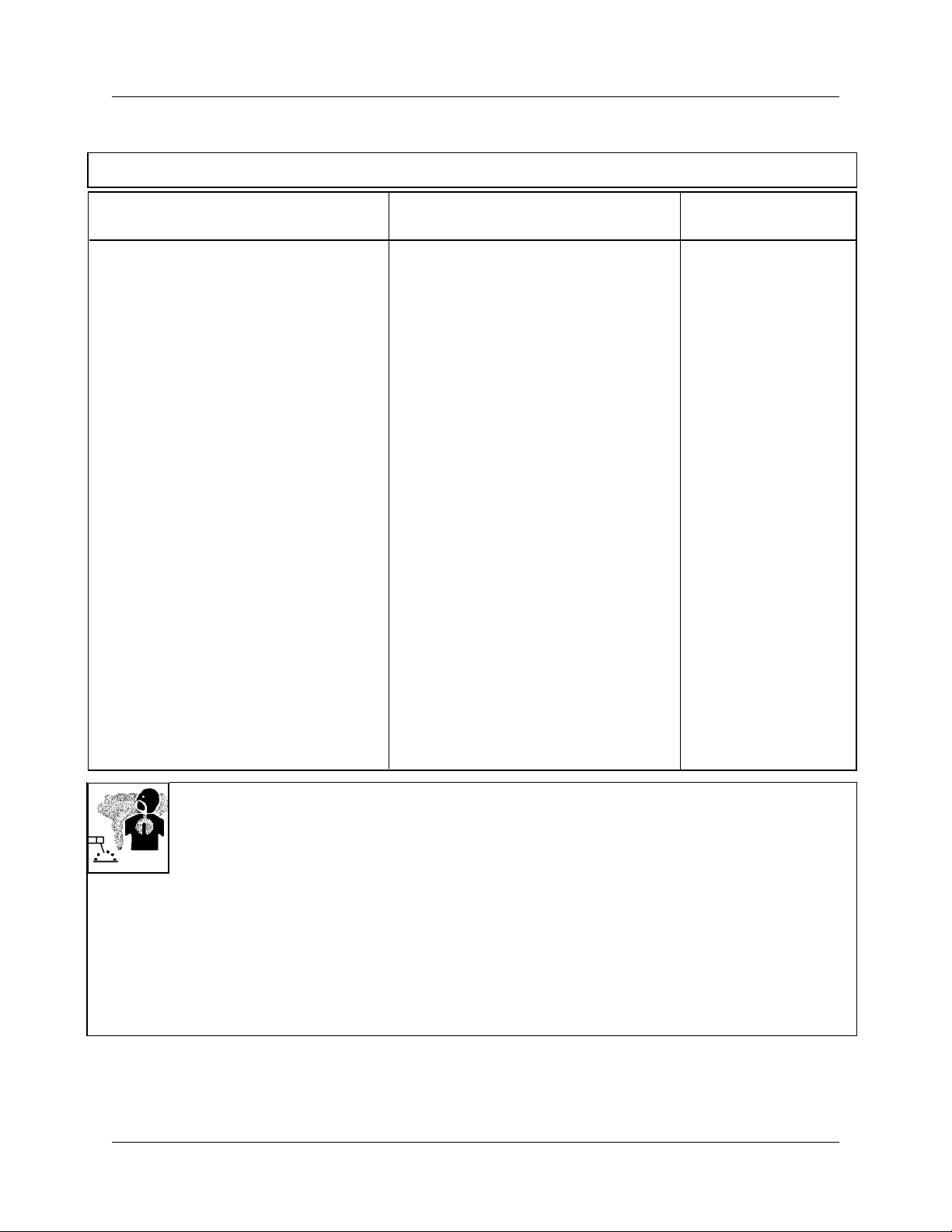

SELECTION DES NUANCES DE FILTRES OCULAIRES POUR LA PROTECTION DES YEUX EN COUPAGE ET SOUDAGE

Opération

de

Coupage ou soudage

Brasage tendre au chalumeau

Brasage fort au chalumeau

Oxycoupage

mince

moyen

épais

Soudage aux gaz

mince

moyen

épais

Soudage à l’arc avec

electrode enrobées (SMAW)

Soudage à l’arc sous gaz

avec fil plein (GMAW)

métaux non-ferreux

métaux ferreux

Soudage à l’arc sous gaz

avec électrode de tungstène (GTAW)

Soudage à l’hydrogène

atomique (AHW)

Soudage à l’arc avec

électrode de carbone (CAW)

Soudage à l’arc Plasma (PAW)

Gougeage Air-Arc avec

électrode de carbone

mince

épais

Coupage à l’arc Plasma (PAC)

mince

moyen

épais

( selon AWS A 8.2-73 )

Dimension d’électrode ou

Epaisseur de métal ou

Intensité de courant

toutes conditions

toutes conditions

moins de 1 po. (25 mm)

de 1 à 6 po. (25 à 150 mm)

plus de 6 po. (150 mm)

moins de 1/8 po. (3 mm)

de 1/8 à 1/2 po. (3 à 12 mm)

plus de 1/2 po. (12 mm)

moins de 5/32 po. (4 mm)

de 5/32 à 1/4 po. (4 à 6.4 mm)

plus de 1/4 po. (6.4 mm)

toutes conditions

toutes conditions

toutes conditions

toutes conditions

toutes conditions

toutes dimensions

moins de 300 ampères

de 300 à 400 ampères

plus de 400 ampères

Nuance de

de filtre

oculaire

2

3 ou 4

2 ou 3

4 ou 5

5 ou 6

4 ou 5

5 ou 6

6 ou 8

10

12

14

11

12

12

12

12

12

12

14

12

14

9

LES VAPEURS ET LESFUMEES SONT

DANGEREUSES POUR LA SANTE.

Le soudage dégage des vapeurs et des fumées

dangereuses à respirer.

1. Eloignez la tête des fumées pour éviter de les respirer.

2. A l’intérieur, assurez-vous que l’aire de soudage est bien ventilée ou que les fumées et les vapeurs sont aspirées à l’arc.

3. Si la ventilation est inadequate, portez un respirateur à adduc-

tion d’air approuvé.

4. Lisez les fiches signalétiques et les consignes du fabricant

relatives aux métaux, aux produitsconsummables, aux revêtements et aux produits nettoyants.

5. Ne travaillez dans un espace confiné que s’il est bien ventilé;

sinon, portez un respirateur à adduction d’air. Les gaz protecteurs de soudage peuvent déplacer l’oxygène de l’air et ainsi

causer des malaises ou la mort. Assurez-vous que l’air est

propre à la respiration.

6. Ne soudez pas à proximité d’opérations de dégraissage, de

nettoyage ou de pulvérisation. La chaleur et les rayons de l’arc

peuvent réagir avec des vapeurs et former des gaz hautement

toxiques et irritants.

7. Ne soudez des tôles galvanisées ou plaquées au plomb ou au

cadmium que sileszonesà souder ont été grattées à fond, que

si l’espace est bien ventilé;sinécessaire portez un respirateur

à adductiond’air.Car ces revêtementsettout métal qui contient

cesélémentspeuventdégagerdes fuméestoxiques aumoment

du soudage.

2-2 8-V-96

Page 12

PRECAUTIONS DE SECURITE EN SOUDAGE A L'ARC

Instruction 830002

LE SOUDAGE PEUT CAUSER UN INCENDIE OU UNE EXPLOSION

L’arc produit des étincellies et des projections. Les

particules volantes, le métal chaud, les projections

de soudure et l’équipement surchauffé peuvent

causer un incendie et des brûlures. Le contact

accidentel de l’électrode ou du fil-électrode avec un

objet métallique peut provoquer des étincelles, un échauffement

ou un incendie.

1. Protégez-vous, ainsi que les autres, contre les étincelles et du

métal chaud.

2. Ne soudez pas dans un endroit où des particules volantes ou

des projections peuvent atteindre des matériaux inflammables.

3. Enlevez toutes matières inflammables dans un rayon de 10, 7

mètres autour de l’arc, ou couvrez-les soigneusement avec des

bâches approuvées.

LES ETINCELLES ET LES PROJECTIONS BRULANTES PEU VENT

CAUSER DES BLESSURES.

LES BOUTEILLES EN DOMMAGEES

PEUVENT EXPLOSER

Les bouteilles contiennent des gaz protecteurs

sous haute pression.Desbouteillesendommagées

peuvent exploser. Comme les bouteilles font normalement partie du procédé de soudage, traitezles avec soin.

1. Protégez les bouteilles de gaz comprimé contre les sources de

chaleur intense, les chocs et les arcs de soudage.

2. Enchainez verticalement les bouteilles à un support ou à un

cadre fixe pour les empêcher de tomber ou d’être renversées.

3. Eloignez les bouteilles de tout circuit électrique ou de tout

soudage.

4. Méfiez-vous des projectionsbrulantesde soudage susceptibles

de pénétrerdansdesaires adjacentes pardepetitesouvertures

ou fissures.

5. Méfiez-vous des incendies et gardez un extincteur à portéede

la main.

6. N’oubliez pas qu’une soudure réalisée sur un plafond, un

plancher, une cloison ou une paroi peut enflammer l’autre côté.

7. Ne soudez pas un récipient fermé, tel un réservoir ou un baril.

8. Connectez le câble de soudageleplus près possible delazone

de soudage pour empêcher le courant de suivre un long parcours inconnu, et prévenir ainsi les risques d’électrocution et

d’incendie.

9. Ne dégelez pas les tuyaux avec un source de courant.

10. Otez l’électrode du porte-électrode ou coupezle filautube-contact lorsqu’inutilisé après le soudage.

11. Portez des vêtements protecteurs non huileux, tels des gants

en cuir, une chemise épaisse, un pantalon revers, des bottines

de sécurité et un casque.

Le piquage et le meulage produisent des particules métalliques

volantes. En refroidissant, la soudure peut projeter du éclats de

laitier.

1. Portez un écran facial ou des lunettes protectrices approuvées.

Des écrans latéraux sont recommandés.

2. Portez des vêtements appropriés pour protéger la peau.

4. Empêchez tout contact entre une bouteille et une électrode de

soudage.

5. N’utilisez que des bouteilles de gaz protecteur, des détendeurs,

des boyauxs et des raccords conçus pour chaque application

spécifique; ces équipements et les pièces connexes doivent

être maintenus en bon état.

6. Ne placez pas le visage face à l’ouverture du robinet de la

bouteille lors de son ouverture.

7. Laissez en place le chapeau de bouteille sauf si en utilisation

ou lorsque raccordé pour utilisation.

8. Lisez et respectez les consignes relatives aux bouteilles de gaz

comprimé et aux équipements connexes, ainsi que la publication P-1 de la CGA, identifiée dans la liste de documents

ci-dessous.

LES MOTEURS PEUVENT ETRE DANGEREUX

LES GAZ D’ECHAPPEMENT DES

MOTEURS PEUVENT ETRE MORTELS.

Les moteurs produisent des gaz d’échappement

nocifs.

LE CARBURANT PEUR CAUSER UN INCENDIE OU UNE EXPLOSION.

Le carburant est hautement inflammable.

1. Arrêtez le moteur avant de vérifier le niveau de

carburant ou de faire le plein.

1. Utilisez l’équipement à l’extérieur dans des aires ouvertes et

bien ventilées.

2. Si vous utilisez ces équipements dans un endroit confiné, les

fumées d’échappement doivent être envoyées à l’extérieur, loin

des prises d’air du bâtiment.

2. Ne faites pas le plein en fumant ou proche d’une source

d’étincelles ou d’une flamme nue.

3. Si c’est possible, laissez le moteur refroidir avant de faire le

plein de carburant ou d’en vérifier le niveau au début du

soudage.

4. Ne faites pas le plein de carburant à ras bord: prévoyez de

l’espace pour son expansion.

5. Faitesattentiondene pas renverserdecarburant.Nettoyez tout

carburant renversé avant de faire démarrer le moteur.

8-V-96 2-3

Page 13

PRECAUTIONS DE SECURITE EN SOUDAGE A L'ARC

Instruction 830002

DES PIECES EN MOUVEMENT PEUVENT CAUSER DES BLESSURES.

Despiècesen mouvement,telsdes ventilateurs,des

rotors et des courroies peuvent couper doigts et

mains, ou accrocher des vêtements amples.

1. Assurez-vous que les portes, les panneaux, les capots et les

protecteurs soient bien fermés.

2. Avant d’installer ou de connecter un système,arrêtezlemoteur.

DESETINCELLESPEUVENT FAIREEXPLOSER UN ACCUMULATEUR;

L’ELECTROLYTE D’UN ACCUMULATEUR PEUT BRULER LA PEAU ET

LES YEUX.

Les accumulateur s contiennent de l’électr oly te

acide et dégagent des vapeurs explosives.

LA VAPEUR ET LE LIQUIDE DE REFROIDISSEMENT BRULANT SOUS

PRESSION PEU VENT BRULER LA

PEAU ET LES YEUX.

Le liquide de refroidissement d’un radiateur peut

être brûlant et sous pression.

3. Seules des personnes qualifiées doivent démonter des protecteurs ou des capots pour faire l’entretien ou le dépannage

nécessaire.

4. Pour empêcher un démarrage accidentel pendant l’entretien,

débranchez le câble d’accumulateur à la borne négative.

5. N’approchez pas les mains ou les cheveux de pièces en mouvement; elles peuvent aussi accrocher des vêtements amples

et des outils.

6. Réinstallez les capots ou les protecteurs et fermez les portes

après des travaux d’entretien et avant de faire démarrer le

moteur.

1. Portez toujours un écran facial en travaillant sur un accumulateur.

2. Arrêtez le moteur avant de connecter ou de déconnecter des

câbles d’accumulateur.

3. N’utilisez que des outils anti-étincelles pour travailler sur un

accumulateur.

4. N’utilisez pas une source de courant de soudage pour charger

un accumulateur ou survolter momentanément un véhicule.

5. Utilisez la polarité correcte (+ et –) de l’accumulateur.

1. N’ôtez pas le bouchon de radiateur tant que le moteur n’est pas

refroidi.

2. Mettez desgantsetposezun torchon sur le bouchon pourl’ôter.

3. Laissez la pression s’échapper avant d’ôter complètement le

bouchon.

PRINCIPALES NORMES DE SECURITE

SafetyinWeldingandCutting, normeANSI Z49.1,AmericanWelding

Society, 550 N.W. LeJeune Rd., Miami, FL 33128.

Safety and Health Standards, OSHA 29 CFR 1910, Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402.

Recommended Safe Practices for the Preparation for Welding and

CuttingofContainersThatHaveHeldHazardousSubstances,norme

AWS F4.1, American Welding Society, 550 N.W. LeJeune Rd.,

Miami, FL 33128.

National Electrical Code, norme 70 NFPA, National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, document P-1,

Compressed Gas Association, 1235 JeffersonDavisHighway,Suite

501, Arlington, VA 22202.

Code for Safety in Welding and Cutting, norme CSA W117.2 Association canadienne de normalisation, Standards Sales, 276 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices for Occupation and Educational Eye and Face Protection, norme ANSI Z87.1, American National Standards Institute,

1430 Broadway, New York, NY 10018.

Cutting and Welding Processes, norme 51B NFPA, National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

2-4 8-V-96

Page 14

DESCRIPTION OF EQUIPMENT

DESCRIPTION OF EQUIPMENT

430429-456

General:

The HEFTY II STAINLESS is a portable, solid state

controlled,voltage sensing wire feederthat operates on

arc voltage and can be usedwithmostconstant voltage

(CV)andconstant current(CC)DC-typepowersources.

Theonlyconnectionrequiredbetweenthepowersource

and the wire feeder is the welding cable.

The unique design of this wire feeder allows operation in a constant wire feed speed mode when

used with CV power sources, and in a voltage

sensing wire feed speed mode (wire feed speed

varies with respect to arc voltage) when used with

CC power sources.

The stainless steel case totally encloses the solid

state control circuitry, welding wire, and wire drive

system. A hinged, latched door allows quick and

easy access to the welding wire and feedhead

assembly that features quick change, gear-driven

feed rolls and a hand operated knob for clamping

the welding gun into the feedhead.

The HEFTY II STAINLESS comes with an abundance of standard features, which include: (1)

on/off rocker switch, (2) wire feed speed control

knob, (3) inch/purge switch, (4) carrying handle, (5)

contactor, (6) gas valve, (7) CC/CV mode switch,

(8) input circuit breaker forcomplete system protection, (9) electronic controlled protection circuitry to

protect against an undervoltage, an overvoltage, a

voltage spike, a shorted or locked motor, a shorted

contactor coil, and a shorted gas valve, (10) electroniccontrolleddynamicbrake, (11) electroniccontrolled current limit to motor, (12) electronic

controlledstart circuit for improved arc starting,(13)

low voltage gun trigger circuit for operator safety,

and (14) a feed roll kit for 0.035 and 0.045 size filler

wire.

The HEFTY II STAINLESS has been designed to

comply with CSA NRTL/C and NEMA EW 3 standards.

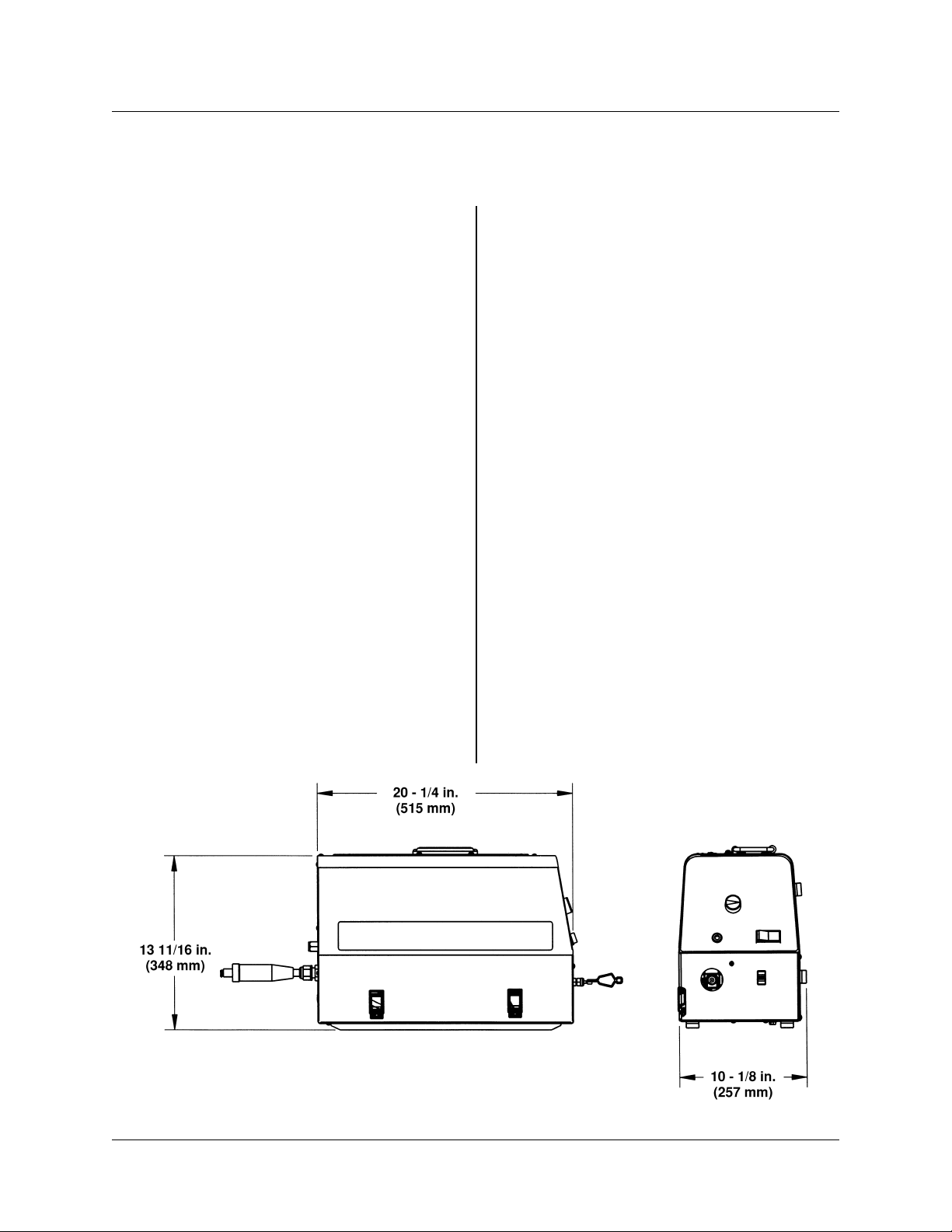

Product Specifications:

Input Voltage Range ..........................15 - 100 VDC

Input Frequency..................................... 0 Hz (DC)

Maximum Input Current.............................. 8 Amps

Wire Speed Range

(Dependent On Arc Voltage).......... 50 - 700 IPM

..................................................... (1.3 - 17.8 MPM)

Wire Sizes ........................................ 0.024 - 5/64"

......................................................... (0.6 - 2.0 mm)

Maximum Wire Spool Capacity...... 12" (304.8 mm)

....................................................... 30Lbs. (13.6 kg)

Feed Rolls............................. 2 (Both Gear Driven)

Welding Current (I)........... 330A at 60% Duty Cycle

Welding Gun Diameter....................... 5/8" Nominal

Maximum Shielding Gas Inlet Pressure ....... 75 PSI

Weight (Less Wire)...................... 38 Lbs. (17.2 kg)

Approvals.......................................... CSA NRTL/C

........................................................... NEMA EW 3

Figure 3-1 Dimensional Information

June 5, 2000 Revised 3-1

Page 15

430429-456

DESCRIPTION OF EQUIPMENT

Features/Benefits:

1. Operates On Arc Voltage

2. Voltage Sensing Control Circuit With

CC/CV Switch

3. Solid State Circuitry

4. Polarity Insensitive

5. Electronic Controlled Start Circuit

6. Electronic Brake

7. Standard Contactor

8. Standard Gas Valve

9. Powerful, Permanent Magnet DC Drive

Motor

A. Can be used with most constant current (CC) or con-

stant voltage (CV) DC-type power sources

B. No control cables required

A. Allows voltagesensingwirefeedspeedoperationwhen

used with CC power sources

B. Allows constant wire feed speed operation when used

with CV power sources

A. Improves wire speed accuracy

B. Compensates for motor load variations

C. Providescurrentlimittocontactor, gas valve,andmotor

A. Operates on either straight or reverse polarity

A. Enhances arc starting performance with CC power

sources

A. Solid state control of an electronic brake offers quick

stopping of the motor to prevent wire overrun

A. Allows the weldingwiretoremainelectrically“cold”until

the gun switch trigger is depressed

B. Increases operator safety

A. Controls the “on/off” flow of shielding gas

A. Accommodatesthefastspeed demands of small diameter

wire

B. Accommodates the low speed,hightorquedemandsof

large diameter wire

10. Replaceable Motor Brushes

11. Needle Bearing Construction On Motor

Output Shaft

12. Input Circuit Breaker

13. Electronic Controlled Protection Circuitry

14. Stainless Steel Case

15. Standard Inch/Purge Switch

16. Carrying Handle

17. Quick Change Feed Rolls

18. Gun Clamp Knob

19. Feed Roll Pressure Release

A. Provides economical means of extending motor life

A. Reduces friction and extends bearing life over a

sleeving bearing

A. Ensures complete system protection

A. Protects electronics from undervoltage, overvoltage,

and voltage spikes.

B. Protects electronics from a shorted or locked motor

C. Protects electronics from a shorted contactor coil

D. Protects electronics from a shorted gas valve coil

A. Provides strength in a small, portable, light weight

package

B. Allows easy access for difficult to reach jobs

A. Allows “cold” inching of wire at set wire feed speed

B. Allows purging of gas without running wire

A. Promotes portability

A. Allows operator to change feed rolls without the use of

tools

B. Both feed rollsare gear drivenfor better feeding ofwire

A. Allows operator to secure welding gun without the use

of tools

A. Allows operator to adjust feed roll pressure without the

use of tools

B. Allows operator to change feed rolls or wire while

retaining preset feed roll pressure

3-2 November 17, 1999

Page 16

Meanings Of Markings And Graphical Symbols:

Signifies an OFF position

Signifies an ON position

Signifies voltage input

Signifies a wire feed function

Signifies a voltage or voltage control

430429-456

DESCRIPTION OF EQUIPMENT

Signifies amperage

Signifies cycles per second

Signifies a welding gun

Signifies the feeding of wire towards the work piece with output voltage off

Signifies a purging of gas

Signifies a constant voltage characteristic

Signifies a constant current (drooping) characteristic

Signifies a circuit breaker in an electrical circuit

I

I

X

June 5, 2000 Revised 3-3

Signifies welding current

Signifies duty cycle

Page 17

430429-456

DESCRIPTION OF EQUIPMENT

Signifies a percentage

Signifies an analog meter function

Front Panel Controls And

Connections:

See Figure 3-2 for details.

1. WELDING GUN CABLE CONNECTION - The

welding gun cable is connected to the wire feeder

at this point. Connections must be tight; otherwise,

arcing or overheating could result.

2. WIRE FEED SPEED CONTROL - This knob

controls the wire feed speed. The wire feed speed

control can be adjustedduringsetup or actual welding.

3. ARC VOLTAGE CONTROL (OPTIONAL) This knob controls the arc voltage from the power

source. The arc voltage control can be adjusted

during setup or actual welding.

NOTE: The power source must be in the

remote position for this function to work.

4. ARC VOLTAGE METER (OPTIONAL) - The

arc voltage meter displaystheactual voltage output

of the power source.

5. WIRE FEED SPEED METER (OPTIONAL) Thewirefeedspeedmeterdisplaystheactualwirefeed

speed output of the wire feeder.

6. POWER ON/OFF SWITCH - This switch controls input power only to the wire feeder and not to

the power source.

Figure 3-2 Front Panel Controls And Connections

3-4 November 17, 1999

Page 18

Internal Controls And

Connections (Component Side):

See Figure 3-3 for details.

7. CC/CV MODE SWITCH - TheCC position provides a voltage sensing wire feed speed mode of

operation for use with constant current (CC) power

sources. The CV position provides a constant wire

feed speed mode of operation for use with constant

voltage (CV) power sources.

NOTE: This switch does not select a CC or

CV mode of operation. The mode ofoperationissetbythe type of power source being

used.

8. INPUT CIRCUIT BREAKER - This circuit

breakerprovidescompletesystemprotection for the

wire feeder in the case of a fault or overload condition.

430429-456

DESCRIPTION OF EQUIPMENT

9. 12 VDC DRIVER PCB - The 12 VDC driver

printed circuit board (PCB) is primarily responsible

for controlling the contactor and gas valve.

10. MOTOR CONTROL PCB - The motor control

printed circuit board (PCB) is primarily responsible

for controlling the output speed of the motor.

11. CONTACTOR - The contactor controls the

“on/off” flow of weld current from the power source.

When the contactor is open, the welding wire is

electrically“cold.” Whenthecontactorisclosed,the

welding wire is electrically “hot.”

CAUTION: The contactor is rated for

330 amps of weld current at a 60% duty

cycle. Exceeding the current or duty cycle ratings will damage or shorten the

life of the contactor.

12. GAS VALVE - The gas valve controls the

“on/off” flow of shielding gas through the welding

gun.

Figure 3-3 Internal Controls And Connections

(Component Side)

June 5, 2000 Revised 3-5

Page 19

430429-456

DESCRIPTION OF EQUIPMENT

Figure 3-4 Internal Controls And Connections

(Wire Spool Side)

Internal Controls And

Connections (Wire Spool Side):

See Figure 3-4 for details.

13. WELD CABLE CONNECTION -This is where

the weld cable from the power source connects to

the wire feeder. Connections must be tight; otherwise, arcing or overheating could result.

NOTE: The mating connector for the weld

cable connection has been supplied with

the unit and is located in the owner’s manual bag.

14. GAS VALVE INLET -Thisiswhere the shielding gas hose (if used) is connected to the wire

feeder.

15. HUB TENSION BOLT - The hub tension bolt

is used to adjust the wire spool tension which acts

as a mechanical brake to assist in the stopping of

the welding wire at the completion of a weld.

16. INCH/PURGE SWITCH - Depressing the inch

portion of the switch will feed wire at a speed set by

the wire feed speed control. The wire will not be

electrically “hot” when using the inch switch. Depressing the purge portion of the switch will allow

shielding gas to flow out of the welding gun without

feeding wire.

17. GUN SWITCH RECEPTACLE - The gun

switch receptacle accepts the welding gun control

wires. The gun switch receptacle is where a gun

switch closure is inputted to the wire feeder.

18. VOLTAGE SENSING LEAD - This lead

serves as an input power connection point for the

wire feeder and must be connected to the work

piece for proper operation. If the voltage sensing

lead from the wire feeder and the weld cable from

the power source are not connected to the work

piece, the wire feeder will not work.

Description Of Feedhead

Assembly:

See Figure 3-5 for details.

19. LOWER RETAINING KNOB - This knob is

usedtosecure the drive feed roll. Remove thisknob

to change the drive feed roll.

20. INPUT WIRE GUIDE - This guide is required

to direct the welding wire from the wire spool to the

drive feed roll.

21. INPUT GUIDE LOCKSCREW - Tighten this

screw to secure the input wire guide.

22. SPRING TENSION KNOB - Use the spring

tension knob to adjust the amount of force the

bearing feed roll exerts on the welding wire.

23. UPPER RETAINING KNOB - This knob is

used to secure the bearing feed roll. Remove this

knob to change the bearing feed roll.

24. OUTPUT GUIDE LOCKSCREW - Tighten

this screw to secure the output wire guide.

3-6 November 17, 1999

Page 20

430429-456

DESCRIPTION OF EQUIPMENT

Figure 3-5 Feedhead Assembly

25. GUN CLAMP KNOB - Tighten this knob to

secure the welding gun to the wire feeder.

26. OUTPUT WIRE GUIDE - This guide is required to direct the welding wire from the drive feed

roll to the welding gun cable.

Power Source Compatibility:

Since the HEFTY II STAINLESS operates on arc

voltage, it will work with most constant current (CC)

or constant voltage (CV) DC-type power sources.

When connected to a HEFTY II STAINLESS, the

maximum allowed open circuitvoltage (OCV) ofthe

power source is 100 VDC. Open circuit voltages

exceeding 100 VDC will damage or shorten the life

of the unit.

NOTE: Because of the high open circuit

voltage associated with most CC power

June 5, 2000 Revised 3-7

sources, it is recommended to place the

HEFTY

OFF position when not welding. This procedurewillprolongthelifeof electrical componentsconnectedtothepowerinput lines.

When using the HEFTY II STAINLESS, there

must be at least 15 VDC between the output terminals of the power source during standby and while

welding. Otherwise, the unit will not have enough

input voltage to operate properly.

A contac t or is a sta ndard component of the

HEFTY II STAINLESS and allows the welding wire

to remain electrically “cold” until the gun switch

trigger is depressed. This contactor is rated for 330

amps of welding current at a 60% duty cycle. If the

weld current or duty cycle rating is exceeded, the

contactor will be damaged or its life shortened.

II

STAINLESS power switch in the

Page 21

430429-456

DESCRIPTION OF EQUIPMENT

Available Options:

Thefollowing options are available for use with the

HEFTY II STAINLESS. Some optionsare kits while

others are individual items.

1. Spool Adapter - 10# 375585

2. Spool Adapter - 15# 375864-1

3. Coil Adapter - 14# 375942A

4. Feed Roll Kits

(See Diagrams Chapter) 171435-x

5. Control Pot Shaft Friction Lock 402663

6. Flowmeter Kit 870258

7. Tweco Gun Adapter 870144

8. Remote Voltage Control Kits

14 Pin Amphenol, 100’ 870259-1

19 Pin Amphenol, 100’ 870259-2

9. Dinse Connector Coversion Kit 870257

10. Wire Feed Speed

and Arc Voltage Meters 870260

3-8 November 17, 1999

Page 22

INSTALLATION

430429-456

INSTALLATION

Connections:

See the System Outline drawing (170091) in the

Diagrams chapter of this manual for details.

CAUTION: Make sure all connections

are tight; otherwise, arcing or overheating could result.

1. Connect a weld cablefromthe power source to

the weld cable connection of the wire feeder.

2. Connect a weld cablefromthe power source to

the work connection.

3. Connect the voltage sensing leadfrom the wire

feeder to the work connection.

WARNING: ELECTRIC SHOCK

CAN KILL! DO NOT touch the

metal portions of the voltage

sensing lead when the power

source output is on.

4. Make the proper gas line connection from the

gas supply to the wire feeder gas valve (if gas will

be used).

5. Attach the welding gun to the wire feeder.

6. Connect the welding gun switch leads to the

wirefeeder gun switch receptaclelocatedinsidethe

case of the wire feeder.

Installation Of Welding Wire

Spool:

See Figures 3-4 and 3-5.

NOTE:Thewirespoolhub suppliedwiththe

unit is provided for mounting a 30 pound

spool of wire. Optional adapters are availableallowinga10or15pound spool of wire

or a 14 pound coil of wire to be used.

1. Remove the wire spool hub nut by turning

counterclockwise.

2. Slide the spool of wire over the wire spool hub,

makingsurethatthe alignmentpinonthehubenters

the hole in the backside of the wire spool.

3. Replace the wire spool hub nut and turn clockwise to a snug position.

NOTE: Install thewelding wire spoolso the

wire feeds from thebottom of thespoolinto

the input wire guide.

Adjustment Of Spool Tension:

Adjust the wire spool tension so the wire will feed

freely into the input wire guide. However, the spool

of welding wire must not “coast” when wire feeding

stops. To adjust the wire spool tension, tighten or

loosen the hub tensionboltaccordingly (See Figure

3-4).

NOTE:Excessive tightening of the hub tension bolt will result in a shorter motor life.

Input And Output Wire Guide

Installation:

Refer to Figure 3-5.

Install the input wire guide (the longer one) by

loosening the input guide lockscrew and inserting

the guide into the hole in the feedhead assembly.

The recessed end of the guide should be towards

the wire spool. Adjust the guide so that it is clear of

the feed rollsand tighten theinput guide lockscrew.

Install the output wire guide (with the conical end

towards the feed rolls) in the same manner as the

input guide. The conical end of the guide should be

as close to the feed rolls as practical. Tighten the

output guide lockscrew.

NOTE: Before tightening the inputand output guide lockscrews, install the drive feed

roll to help in the alignment of the wire

guides.

Selection And Installation Of

Feed Rolls:

NOTE: See feed roll kit drawing (supplied

in the Diagrams chapter) to order feed roll

kits. Kit includes a bearing roll, a drive roll,

an input wire guide, and an output wire

guide for a specific wire type and size.

For installation of feed rolls, refer to Figure 3-3.

Forselection of feed roll styles,referto Figure 4-1.

November 17, 1999 4-1

Page 23

430429-456

INSTALLATION

Style 1 feed rolls consist of a flat, smooth bearing

roll and a double, smooth, vee grooved drive roll.

They feed .024 - .068" hard and tubular wire.

Style 2 feed rolls consist of a flat, knurled bearing

roll and a double, smooth, vee grooved drive roll.

They feed .030 - .045" hard and tubular wire.

Style 3 feed rolls consist of a double, knurled, vee

grooved bearing roll and a double, knurled, vee

grooved drive roll. They feed .045 - 5/64" hard and

tubular wire.

Style 4 feed rolls consist of double, cog bearing

and drive rolls. They feed .045 - .068" tubular wire.

Style 5 feed rolls consist of double, U-grooved

bearing and drive rolls. They feed .035 - 3/64" soft

wire.

NOTE: All grooved feed rolls have their

wire size or range stamped on the side of

the roll. On rolls with different size grooves,

the outer (visible when installed) stamped

wire size indicates the groove in use.

Bearing feed rolls are installed by unscrewing the

upper retaining knob and removing the idler gear.

Thebearingfeedrollretainingknobisthenremoved

from the idler gear, and the bearing feed roll is

placed over thelobes on the idlergear. The bearing

feed roll retaining knob is replaced, andthis assembly is returned and secured with the upper retaining

knob.

Drivefeed rolls are installed by removing the lower

retaining knob, placing the drive feed roll over the

lobes on thedrive gear, and securing with the lower

retaining knob.

NOTE: Installation of all styles of feed rolls

for this feeder is identical.

and connect the welding gun control wires to the

gun switch receptacle.

NOTE: Before inserting the welding gun

into the feedhead, make sure the gun

clamp does not extend into the feedhead;

otherwise,the welding gun cannot beproperly inserted.

Threading Wire Into Feedhead:

Refer to Figure 3-5.

WARNING: ELECTRIC SHOCK

CAN KILL! Make certain the

power source and wire feeder

are turned OFF. Do not turn the

power ON until told to do so in

these instructions.

CAUTION: Use care when handling the

spooled wire as the wire tends to “unravel” when loosened from the spool.

Grasp the end of the wire firmly, and

don’t let it get away fromyou.Makesure

that the end of the wire is straight and

free of burrs.

1. Placeendoftheweldingwireintotheinputwire

guide. Feed it through the guide and over the drive

roll groove closest to the feedhead casting.

2. Passthewirethroughthe outputwireguideand

into the welding gun assembly.

3. Lock in position with the spring tension knob.

To adjust the amount of force the bearing feed roll

exerts on the welding wire, turn the spring tension

knob clockwise for increasedforce or counterclockwise for decreased force.

Welding Gun Compatibility And

Installation:

Refer to Figures 3-4 and 3-5.

The HEFTY II STAINLESS wire feeder is designed to be used with most welding guns. In some

cases, a special adapter may be required.

To install the welding gun, simply loosen the gun

clamp knob and insert the welding gun into the

feedhead until it stops. Tighten the gun clamp knob

4-2 November 17, 1999

NOTE: If the force applied tothe wireistoo

great, the welding wirewill “bird nest” inthe

feedhead and not feed properly.

4. Turn the welding machine and wire feeder

ON,andsetthewirefeedspeedcontrolto midrange

(See Figure 3-2). Remove contact tube from welding gun. See Gun Manual. Press the gun switch or

INCH switch until wire feeds out past the gun nozzle. Place contacttube over thewire and screwinto

place and tighten. Cut wire off at about 1/4 inch (6

mm) from the nozzle.

Page 24

430429-456

INSTALLATION

WARNING: The welding wire is electrically “Hot” if wire is fed by depressing

gunswitch. Electrodecontact to workpiece will causean arcwith gun switch

depressed.

NOTE: Number stamped on Side “A” indicates the wire size of Groove “B” and vice versa.

Figure 4-1 Feed Roll Styles

November 17, 1999 4-3

Page 25

430429-456

INSTALLATION

This page intentionally left blank.

4-4 November 17, 1999

Page 26

OPERATION

430429-456

OPERATION

Prewelding Procedure:

Follow all installation instructions for the welding

power source, the welding gun, and the HEFTY ΙΙ

STAINLESS wire feeder before attempting to

weld.

1. Make sure all necessary connections have

been made (Refer to “Connections” in the Installation chapter of this manual).

2. Turn ON the powersource and the wirefeeder.

3. Set the CC/CV modeswitch on the wire feeder

to the proper position (See CC/CV Mode Switch in

the Internal Controls And Connections section of

this manual).

4. If shielding gaswill be used, depress the purge

switch or gun switch and adjust the flow of gas.

WARNING: If the gun switch is

depressed, the wire feeder will

feed electrically “hot” welding

wire. If this “hot” welding wire

touches the work piece, a welding arc will be established.

5. Depress the inch switch or gun switch and

adjust the wire feed speed to the desired value by

meansof the wire feed speed control.Thewirefeed

speed control can beadjustedduring setup or while

welding.

WARNING: If the gun switch is

depressed, the wire feeder will

feed electrically “hot” welding

wire. If this “hot” welding wire

touches the work piece, a welding arc will be established.

6. Adjust the voltage control (on a CV machine)

or current control (on a CC machine) to the desired

value. The voltage or current control can be adjusted during setup or while welding.

7. If using a CV power source, the output contactor on the power source will have to be energized.

In most cases, this will require ajumpertobeadded

tothepowersourceoraswitchonthepowersource

to be turned on. Read the power source owner’s

manual for proper connections or settings required.

ON

Gun Switch

Gas Valve

Wire Feed

Power Source

Figure 5-1 Functional Timing Diagram

November 17, 1999 5-1

OFF

ON

OFF

ON

OFF

ON

OFF

Page 27

430429-456

OPERATION

Welding Procedure:

WARNING: In semiautomatic or

automatic wire welding, the

welding wire, wire reel (if used),

input guide, feed rolls, output

guide, feedhead, and welding

gun metalparts are all ELECTRICALLY “HOT”.

Refer to Figure 5-1.

1. To start the weld, position the welding gun

above the work piece and depress the gun switch

trigger. The solid state control then enables the gas

valve, wire feed motor, and power source.

The solid state control of a “slow run-in” circuit

automatically reduces the initial wire feed speed

when operating witha CC power source. This initial

reductioninwirefeedspeedwillcompensateforthe

high open circuit voltage associatedwith CC power

sources and improve arc starting performance.

WELDING IN CV MODE

When welding witha constant voltage(CV) power

source, changes in wire feed speed willaffect welding current. Changes in wire feed speed can be

obtained by adjusting the wire feed speed control

knob.

To adjust the amount of welding voltage from the

CV power source, a control knob on the power

source or an “optional” control knob on the wire

feeder will have to be adjusted.

2. To end the weld, release the gunswitch trigger

while pulling the welding gun away from the work

piece. The solid state control then disables the gas

valve, wire feed motor, and power source.

NOTE: After the weld is completed, it is

recommendedto pullthe welding gun away

from the work while releasing the gun

switch. This allows the welding arc to partially extinguish at the work piece which

reduces the arcing at the contactor contacts.Usingthis procedurewilllengthenthe

life of the contactor contacts especially

when welding at high amperage.

3. At the end ofthe work day orwhen welding has

been completed, it is recommended that thegas be

SHUTOFF at the cylinder, and the wire feeder and

power source be turned OFF.

Welding In CC Mode vs. CV

Mode:

Refer to the CC/CV Mode Switch located in the

Internal Controls And Connections section of this

manual for further details.

WELDING IN CC MODE

When welding with a constant current (CC) power

source, changes in wire feed speed will affect welding voltage.

To adjust the amount of welding current from the

CC power source, a control knob on the power

source or an “optional” control knob on the wire

feeder will have to be adjusted.

Theory Of Operation:

Refer to the Connection and Schematic Diagram

in the Diagrams chapter of this manual.

Input power is supplied through the on/off switch

(S1) and input circuit breaker (CB1) to the bridge

rectifier(CR1).CR1ensures that the proper polarity

inputvoltage is fed into thep.c.boardsindependent

of the welding polarity.

When the gunswitch on the welding gun ispulled,

ashortisprovidedonthegunswitchreceptacle(J4)

causing the wire feed motor (B1) to turn feeding

wire, the gas valve (L1) to open allowing gas flow,

and the contactor (K1) to close making the welding

wire electrically “hot.”

When the gun switch on the welding gun is released, the short on the gun switch receptacle is

removed causing the wire feed motor to stop feeding wire, the gas valve to close stopping gas flow,

and the contactor to open making the welding wire

electrically “cold.”

Adjusting Burnback Time:

Burnback time is set at the factory, but the motor

control printed circuit board contains a component

that permits adjustment of burnback time.

Burnback time relates to the amount of welding

wire remaining at the end of the welding gun after

the welding process ends. Increasing burnback

time results in less wire remaining at the end of the

welding gun at the end of the weld. Decreasing

burnback time results in more wire remaining at the

end of the welding gun after the welding process

ends.

5-2 November 17, 1999

Page 28

PROCEDURE:

430429-456

OPERATION

1. Place the CC/CV mode switch in the CV

position.

WARNING: ELECTRIC SHOCK

CAN KILL. Make certain the

power source and wire feeder

are both turned OFF before beginning the procedure.

1. Using a 1/4" nut driver or socket, remove the

exterior cover to expose the motor control

printed circuit board (See Figure 5-2).

2. Locate component R68 (“Burnback”) on the

motor control printed circuit board (See Figure 5-2). The best procedure is to make only

slight adjustments until the amount of burnback is acceptable. Component R68 has a

single turn (360°) range of adjustment.

To increase burnback time, adjust component R68 clockwise.

To decrease burnback time, adjust component R68 counterclockwise.

3. Replace the exterior cover.

Calibrating Wire Feed Speed

Meter:

The motor control printed circuit board contains a

component that permits calibration of the wire feed

speed displayed on the analog meter. If the wire

feeder was ordered with a wire feed speed meter

installed, the meter was calibrated at the factory.

However, the wire feed speed meter will have to

be calibrated or recalibrated if one of the following

occur:

• A wire feed speed meter is installed in the

field as an option.

• The motor control printed circuit board is

replaced.

• The drive motor is replaced.

PROCEDURE:

WARNING: ELECTRIC SHOCK

CAN KILL. While calibrating the

wire feed speed meter, voltages

as high as the open circuit voltage of the power source will be

exposed. Use caution, and follow all instructions accordingly.

2. Using a 1/4" nut driver or socket, remove the

exterior cover to expose the motor control

printed circuit board (See Figure 5-2).

3. Adjust the wire feed speed control knob to

position 5.

4. Cut off the welding wire at the tip of the

welding gun.

5. Depress the inch switch or the gun switch on

the welding gun for exactly 15 seconds.

6. Cut off the welding wire at the tip of the

welding gun and accurately measure.

7. Use the formula below to calculate the wire

feed speed in inches per minute (IPM):

IPM = 4 x Wire LengthMeasured In Step

#6

(For Example: If 125 inches of wire feeds in 15

seconds, multiply 125 x 4 = 500 inches per

minute)

8. Now, with the inch or gun switch depressed,

adjust component R46 on the motorcontrol

printed circuit board until the analog meter

displays the IPM calculatedin Step #7 (See

Figure 5-2).

9. Replace the exterior cover.

10. Place the CC/CV mode switchin the proper

position (See “Internal Controls And Connections” section of this manual).

Protection And Safety Circuits:

The following protection and safety circuits come

standard with this wire feeder and are designed to

protect (by disabling the wire feeder) against unfavorable operation and/or equipment damage.

1. Undervoltage Protection - If theinput voltage

drops below the specified voltage range for

an extended period of time, an electronic

circuit will activate, and the wire feeder will

not operate. The undervoltageprotection circuit will automatically deactivate when the

input voltage enters an acceptable range.

2. Overvoltage Protection - If the input voltage

rises above the specified voltage range for

an extended period of time, an electronic

circuit will activate, and the wire feeder will

not operate. The overvoltage protection circuit will automatically deactivate when the

input voltage enters an acceptable range.

November 17, 1999 5-3

Page 29

430429-456

OPERATION

3. Input Current Protection - If the input current

risesabovethespecifiedmaximuminputcurrent for an extended period of time, the input

circuit breaker will trip, and the wire feeder

will not operate. The input circuit breaker will

have to be manually reset if it were to trip.

4. Motor Overcurrent Protection - If the drive

motor becomes locked or shorted, an electronic circuit will activate, and the motor will

not operate. If this circuit activates, a light on

themotorcontrolprintedcircuitboardlabeled

“Fault 2" will turn on (See Figure 5-2). The

motor overcurrent protection circuit will have

to be manually reset by placing the power

switch on the wire feeder in the off position

for at least 60 seconds.

CAUTION: If thisprotection circuit

activates and the drive motor is

notlocked,thedrivemotorismost

likely shorted and will have to be

replaced (See “Troubleshooting

Guide” section of this manual).

5. Contactor And Gas Valve Overcurrent Protection - If the contactor or gas valve becomes shorted, an electronic circuit will

activate, and both the contactor and gas

valve will not operate. If this circuit activates,

a light on the 12 VDC driver printed circuit

board labeled “Fault 1" will turn on. The contactor and gas valve overcurrent protection

circuit will have to be manually reset by placingthe power switch onthewirefeeder in the

off position for at least 60 seconds.

CAUTION: If this protection circuit

activates, the contact or or gas

valve is most likely shorted and

one or both will have to be replaced (See “Troubleshooting

Guide" section of this manual).

R2 (-)

R12 (+)

R46

WIRE FEED SPEED (WFS)

ADJUSTMENT

CR14

FAULT 2 LED

R68

BURNBACK ADJUSTMENT

Figure 5-2 Motor Control Printed

Circuit Board

5-4 November 17, 1999

Page 30

MAINTENANCE

430429-456

MAINTENANCE

Cleaning Of The Unit:

About every 6 months, remove the exterior cover

to expose the printed circuit boards and other components. Using a vacuum cleaner or clean, dry,

compressed air of not more than 25 psi (172 kPa)

pressure, vacuum or blow outtheinterior of the wire

feeder. While the exterior cover is removed, check

all electrical components for loose connections and

correct if necessary.

Cleaning Of The Feed Rolls:

About every 3 months, clean the grooves on the

feed rolls using a small wire brush. If the feed roll

has a smooth surface, wipe off the feed roll with a

clean, dry cloth. After cleaning thefeed rolls, tighten

the upper and lower feed roll retaining knobs accordingly.

Feedhead Maintenance:

See Figure 6-1 for details.

Gas Valve Maintenance:

See Figure 6-2 for details.

Foreignmaterial inside the valve body isthemajor

cause of gas valve failure or improper operation.

Foreignmaterialusuallyenters thevalvebodywhen

disconnected gas lines are allowed to come in

contact with the floor or ground before being connected or reconnected to the gas valve.

In general, sluggish operation and/or gas leakage

are signs the gas valve needs to be cleaned internally. To cleanthe gas valve internally, follow these

simple steps:

NOTE: Before disassembly of the gas

valve, take note of the orientation of inlet

(markedIN) and outlet portswithrespectto

electrical connections. The reassembled

gas valve should have the same orientation.

1. Remove input power from the wire feeder, and

depressurize the gas valve.

2. Remove the gas valve from the wire feeder.

Figure 6-1

The only point of maintenance in the feedhead

assembly is the motor brushes.Inspect these about

every 400 hours of operation. When either brush is

worn to about 1/4" (6.35 mm), both brushes should

be replaced.

CAUTION: Neglect in brush maintenance may cause damage to the drive

motor commutator resulting in ashorter

motor operating life.

Contactor Maintenance:

Regularly examine the contacts on the contactor.

When any contact is worn down to the copper bus

bar, the contactor should be replaced.

3. Remove the (2) bracket screws and bracket

from the yoke of the gas valve.

4. Slip the yoke (containing coil) off the plugnut/core tube sub-assembly.

5. Remove the plugnut/core tube sub-assembly

with the body gasket attached.

6. Remove the core assembly and core spring.

7. All parts should now be inspected for foreign

material and cleaned with a lint-free cloth. Do not

nick or scratch any internal parts of the gas valve.

8. Reassemble the gas valve in reverse order of

disassembly paying careful attention to Figure 6-2.

NOTE: Tighten (2) bracket screws evenly

to insure proper body gasket compression.

Torque bracket screws to 20 inch-pounds.

9. Assemble the gas valve to the wire feeder.

NOTE: It may be necessary to apply pipe

compound sparingly to the gas adapter

male threads only.Do not applycompound

to female threads of gas valve or first two

threadsofmalefittings. Also,makesurethe

June 5, 2000 Revised 6-1

Page 31

430429-456

MAINTENANCE

inlet port (marked IN) side of the gas valve

is connected to the main gas supply; otherwise, the gas valve will leak.

After maintenance, operate the gas valve a few

timestobe sure of proper operation. If the gas valve

continues to show signs of improper operation,

replace the gas valve assembly.

Figure 6-2 Gas Valve Assembly

6-2 June 5, 2000 Revised

Page 32

TROUBLESHOOTING

430429-456

TROUBLESHOOTING

Scope:

The troubleshooting guide is intended to be used

by qualified service technicians. The troubleshootingguide contains information which can beusedto

diagnose and correct unsatisfactory operation or

failureofthe various components of the wire feeder.

Each symptom of trouble is followed by a list of

probable causes and the procedure necessary to