Page 1

TWECO®

FUSION™250

Safety and

Operating

Instructions

AIR-COOLED MIG GUN 250 AMP

Tweco.com

English

Canadien Français

Americas Español

Revision: B Issue Date: August 2, 2013 Manual No.: 89200015

IMPORTANT: Included inside - special

instructions for liner replacement.

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on receiving your new Tweco product. We are proud to

have you as our customer and will strive to provide you with the best

service and support in the industry. This product is backed by our extensive

warranty and world-wide service network.

We know you take pride in your work and we feel privileged to provide you

with this high performance product that will help you get the job done.

For more than 75 years Tweco has provided quality products you can trust,

when your reputation is on the line.

YOU ARE IN GOOD COMPANY!

Tweco is a Global Brand of Arc Welding Products for Victor Technologies

Inc. We distinguish ourselves from our competition through marketleading innovation and truly dependable products that will stand the test of

time.

We strive to enhance your productivity, efficiency and welding performance

enabling you to excel in your craft. We design products with the welder in

mind delivering- advanced features, durability, ease of use and ergonomic

comfort.

Above all, we are committed to a safer working environment within the

welding industry. Your satisfaction with this product and its safe operation

is our ultimate concern. Please take the time to read the entire manual,

especially the Safety Precautions.

If you have any questions or concerns regarding your new Tweco product,

please contact our friendly and knowledgeable Customer Service Team at:

1-800-462-2782 (USA) and 1-905-827-4515 (Canada),

or visit us on the web at www.Tweco.com

Page 3

i

WARNINGS

Read and understand this entire Manual and your employer’s safety practices

before installing, operating, or servicing the equipment. While the information

contained in this Manual represents the Manufacturer’s judgment, the Manufacturer

assumes no liability for its use.

Tweco® Fusion 250 AMP MIG Gun

Safety and Operating Instructions

Instruction Guide Number 89200015

Published by:

Victor Technologies, Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.tweco.com

U.S. Customer Care: (800) 426-1888

Canada Customer Care: 905-827-4515

International Customer Care: (940) 381-1212

Copyright © 2012, 2013 Victor Technologies, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss

or damage caused by any error or omission in this Manual, whether such error results from

negligence, accident, or any other cause.

Publication Date: December 17, 2012

Revision Date: August 2, 2013

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

Equipment Serial #:

Page 4

ii

Table of Contents

SECTION 1: SAFETY PRECAUTIONS .........................................................................3

1.01 Safety Precautions .......................................................................... 3

SECTION 2: INTRODUCTION ......................................................................................5

2.01 How to Use this Manual ................................................................... 5

2.02 Receipt of Equipment ....................................................................... 5

2.03 Description ....................................................................................... 5

SECTION 3: MIG GUN SPECIFICATIONS.....................................................................6

3.01 MIG Gun Classification ..................................................................... 6

3.02 Duty Cycles ..................................................................................... 6

3.03 Tweco® fusion 250A MIG Gun Selection guide ................................ 7

3.04 Tweco® Fusion 250A MIG Gun Part Number Identification .............. 7

3.05 Velocity Contact Tip Nozzle Identification .........................................8

3.06 Velocity 250 Amp Conductor Tube Identification ............................. 8

SECTION 4: MIG GUN INSTALLATION ........................................................................9

4.01 Direct Plug MIG Gun Installation ...................................................... 9

4.02 Tweco® MIG-Kwik Connection and Adapter Kit Installation ........... 10

SECTION 5: REPLACEMENT INSTRUCTIONS ...........................................................11

5.01 Replacing Velocity Contact Tip ...................................................... 11

5.02 Replace Conductor Tube ............................................................... 11

5.03 Conduit Identification and Replacement ......................................... 12

5.04 Replacing Handle, trigger .............................................................. 13

SECTION 6: CABLEHOZ® REPAIR ............................................................................14

6.01 Tools Required ............................................................................... 14

6.02 Repair of Cablehoz® ...................................................................... 14

SECTION 7: MAINTENANCE AND TROUBLESHOOTING............................................19

SECTION 8: 250 AMP REPLACEMENT PARTS .........................................................20

8.02 Tweco® Fusion 250 A MIG Gun Parts ............................................ 20

8.02 Tweco® Fusion MIG Gun Consumables ......................................... 22

SECTION 9: STATEMENT OF WARRANTY ................................................................24

9.01 Warranty Schedule .........................................................................24

Global Contact Information ...............................................Rear Cover

Page 5

SAFETY AND OPERATING INSTRUCTIONS

389200015

SECTION 1:

SAFETY PRECAUTIONS

1.01 SAFETY PRECAUTIONS

WARNING

SERIOUS INJURY OR DEATH may result if welding and cutting equipment is not

properly installed, used, and maintained. Misuse of this equipment and other

unsafe practices can be hazardous. The operator, supervisor, and helper must read

and understand the following safety warnings and instructions before installing

or using any welding or cutting equipment, and be aware of the dangers of the

welding or cutting process. Training and proper supervision are important for a

safe work place. Keep these instructions for future use. Additional recommended

safety and operating information is referenced in each section.

WARNING

WARNING: This product contains chemicals, including lead, known to the State

of California to cause birth defects and other reproductive harm. Wash hands

after handling.

ELECTRIC SHOCK CAN CAUSE INJURY OR DEATH

Install and maintain equipment in accordance with the National Electrical Code

(NFPA 70) and local codes. Do not service or repair equipment with power on.

Do not operate equipment with protective insulators or covers removed. Service

or repair to equipment must be done by qualified and/or trained personnel only.

Do not contact electrically live parts. Always wear dry welding gloves that are in

good condition. Aluminized, protective clothing can become part of the electrical

path. Keep oxygen cylinders, chains, wires, ropes, cranes, and hoists away from any part of the

electrical path. All ground connections must be checked periodically to determine if they are

mechanically strong, and electrically adequate for the required current. When engaged in AC

welding/cutting under wet conditions or where perspiration is a factor, the use of automatic

controls for reducing the no load voltage is recommended to reduce shock hazards. Accidental

contact must be prevented when using open circuit voltage exceeding 80 volts AC, or 100 volts

DC by adequate insulation or other means. When welding is to be suspended for any length of

time, such as during lunch or overnight, all electrode holders and electrodes should be removed

from the electrode holder and the power supply should be turned off to prevent accidental

contact. Keep MIG Guns, electrode holders, Tig torches, Plasma torches, and electrodes away

from moisture and water. See safety and operating references 1, 2, and 8.

SMOKE, FUMES, AND GASES CAN BE DANGEROUS TO YOUR HEALTH

Ventilation must be adequate to remove smoke, fumes, and gases during

operation to protect operators and others in the area. Vapors of chlorinated

solvents can form the toxic gas “Phosgene” when exposed to ultraviolet radiation

from an electric arc. All solvents, degreasers, and potential sources of these

vapors must be removed from the operating area. Use air-supplied respirators

if ventilation is not adequate to remove all fumes and gases. Oxygen supports, and vigorously

accelerates fire and should never be used for ventilation. See safety and operating references

1, 2, 3, and 4.

Page 6

4

SAFETY AND OPERATING INSTRUCTIONS

89200015

ARC RAYS, HOT SLAG, AND SPARKS CAN INJURE EYES AND BURN SKIN

Welding and cutting processes produce extreme localized heat and strong

ultraviolet rays. Never attempt to weld/cut without a federally compliant welding

helmet with the proper lens. A number 12 to 14 shade filter lens provides the

best protection against arc radiation. When in a confined area, prevent the

reflected arc rays from entering around the helmet. Approved shielding curtains

and appropriate goggles should be used to provide protection to others in the surrounding area.

Skin should be protected from arc rays, heat, and molten metal. Always wear protective gloves

and clothing. All pockets should be closed and cuffs sewn shut. Leather aprons, sleeves, leggings,

etc. should be worn for out-of-position welding and cutting, or for heavy operations using large

electrodes. Hightop work shoes provide adequate protection from foot burns. For added protection,

use leather spats. Flammable hair preparations should not be used when welding/cutting. Wear

ear plugs to protect ears from sparks. Where work permits, the operator should be enclosed in

an individual booth painted with a low reflective material such as zinc oxide.

See safety and operating references 1, 2, and 3.

WELDING SPARKS CAN CAUSE FIRES AND EXPLOSIONS

Combustibles reached by the arc, flame, flying sparks, hot slag, and heated

materials can cause fire and explosions. Remove combustibles from the work

area and/or provide a fire watch. Avoid oily or greasy clothing as a spark may

ignite them. Have a fire extinguisher nearby, and know how to use it. If welding/

cutting is to be done on a metal wall, partition, ceiling, or roof, precautions must

be taken to prevent ignition of nearby combustibles on the other side. Do not

weld/cut containers that have held combustibles. All hollow spaces, cavities, and containers

should be vented prior to welding/cutting to permit the escape of air or gases. Purging with inert

gas is recommended. Never use oxygen in a welding torch. Use only inert gases or inert gas

mixes as required by the process. Use of combustible compressed gases can cause explosions

resulting in personal injury or death. Arcing against any compressed gas cylinder can cause

cylinder damage or explosion. See safety and operating references 1, 2, 5, 7, and 8.

NOISE CAN DAMAGE HEARING

Noise from the air carbon-arc process can damage your hearing. Wear protective

hearing devices to ensure protection when noise levels exceed OHSA standards.

Adequate hearing protection devices must be worn by operators and surrounding

personnel to ensure personal protection against noise. See safety and operating

references 1, 2, and 6.

SAFETY AND OPERATING REFERENCES

1. Code of Federal Regulations (OSHA) Section 29, Part 1910.95, 132, 133, 134, 139,

251, 252, 253, 254 and 1000. U.S. Government Printing Office, Washington, DC 20402.

2. ANSI Z49.1 “Safety in Welding and Cutting”.

3. ANSI Z87.1 “Practice for Occupational and Educational Eye and Face Protection”.

4. ANSI Z88.2. “Standard Practice for Respiratory Protection”. American National

Standards Institute, 1430 Broadway, New York, NY 10018.

5. AWS F4.1. “Recommended Safe Practices for Welding and Cutting Containers”.

6. AWS C5.3. “Recommended Practices for Air Carbon-Arc Gouging and Cutting”. The

American Welding Society, 550 NW Lejeune Rd., P.O. Box 351040, Miami, FL 33135.

7. NFPA 51B. “Fire Prevention in Cutting and Welding Processes”.

8. NFPA-7. “National Electrical Code”. National Fire Protection Association, Battery Park,

Quincy, MA 02269.

9. CSA W117.2. “Safety in Welding, Cutting and Allied Processes”. Canadian Standards

Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W 1R3.

Page 7

SAFETY AND OPERATING INSTRUCTIONS

589200015

SECTION 2:

INTRODUCTION

2.01 HOW TO USE THIS MANUAL

To ensure safe operation, read the entire manual, including the chapters on safety instructions

and warnings.

Throughout this manual, the words WARNING, CAUTION, and NOTE may appear. Pay particular

attention to the information provided under these headings. These special annotations are

easily recognized as follows:

NOTE

NOTE conveys installation, operation, or maintenance information which is

important but not hazard-related.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

2.02 RECEIPT OF EQUIPMENT

When you receive the equipment, check it against the invoice to make sure it is complete and

inspect the equipment for possible damage due to shipping. If there is any damage, notify the

carrier immediately to file a claim. Furnish complete information concerning damage claims

or shipping errors to the location in your area, listed on the back cover of this manual. Include

a full description of the parts in error.

If you want additional or replacement copies of this manual, please contact Tweco® at the

address and phone number in your area listed on the back cover of this manual. Include the

Manual number (from page i).

2.03 DESCRIPTION

Tweco MIG Guns are furnished with rear connections to fit directly into most Miller®, Lincoln®,

and Euro connection wire feeders. These guns are referred to as Direct Plug MIG Guns. Tweco

MIG guns are also furnished with the time-proven MIG-Kwik connection. The MIG-Kwik

connection, when utilized with a Tweco adapter kit, allows a Tweco MIG gun to be installed on

almost any wire feed system. For a listing of available adapter kits, see the Tweco Adapter Kit

Listing, Form No. TAKL-97, or call Tweco Customer Care.

MILLER is a registered trademark of Miller Electric Mfg. Co.; ESAB is a registered trademark of ESAB AB; LINCOLN is

a registered trademark of LINCOLN Electric Co.; The aforementioned registered trademarks are no way affiliated with

Tweco Products, Inc. or Victor Technologies, Inc. Tweco is a registered trademark of Victor Technologies, Inc.

Page 8

6

SAFETY AND OPERATING INSTRUCTIONS

89200015

SECTION 3:

MIG GUN SPECIFICATIONS

3.01 MIG GUN CLASSIFICATION

Process MIG/MAG welding

Method of Guidance Manually guided

Voltage Class for Welding and Control Circuits L (up to 113 V peak)

Type of Cooling Air or cooling gas

Type of Shielding Gas All types

3.02 DUTY CYCLES

Duty Cycle

MIG Gun

250 AMP

10% 320

35% 290

80% 250

100% 195

The above duty cycles were established by testing under the following parameters:

Parameter MIG (metal inert gas) MAG (metal active gas)

Type of Voltage D.C.

Shielding Gas Argon Argon/CO2 Mixed Gas (80/20, 75/25)

Gas Flow Rate 30-35 CFH (14,2- 16,5 l/m)

Gun Cable Length

10 ft. (3 m)

12 ft. (3,7 m)

15 ft. (4,6 m)

20 ft. (6 m)

25 ft. (7,6 m)

Electrode Polarity Positive

Wire Diameter

Wire (Continuous Electrode) Size

250 amp

.023" (0,6 mm)

.030" (0,8 mm)

.035" (0,9 mm)

.040" (1,0 mm)

.045" (1,2 mm)

.052" (1,3 mm)

3/64” (1,2 mm)

1/16” (1,6 mm)

5/64” (2,0 mm)

3/32” (2,4 mm)

7/64” (2,8 mm)

1/8” (3,2 mm)

Page 9

SAFETY AND OPERATING INSTRUCTIONS

789200015

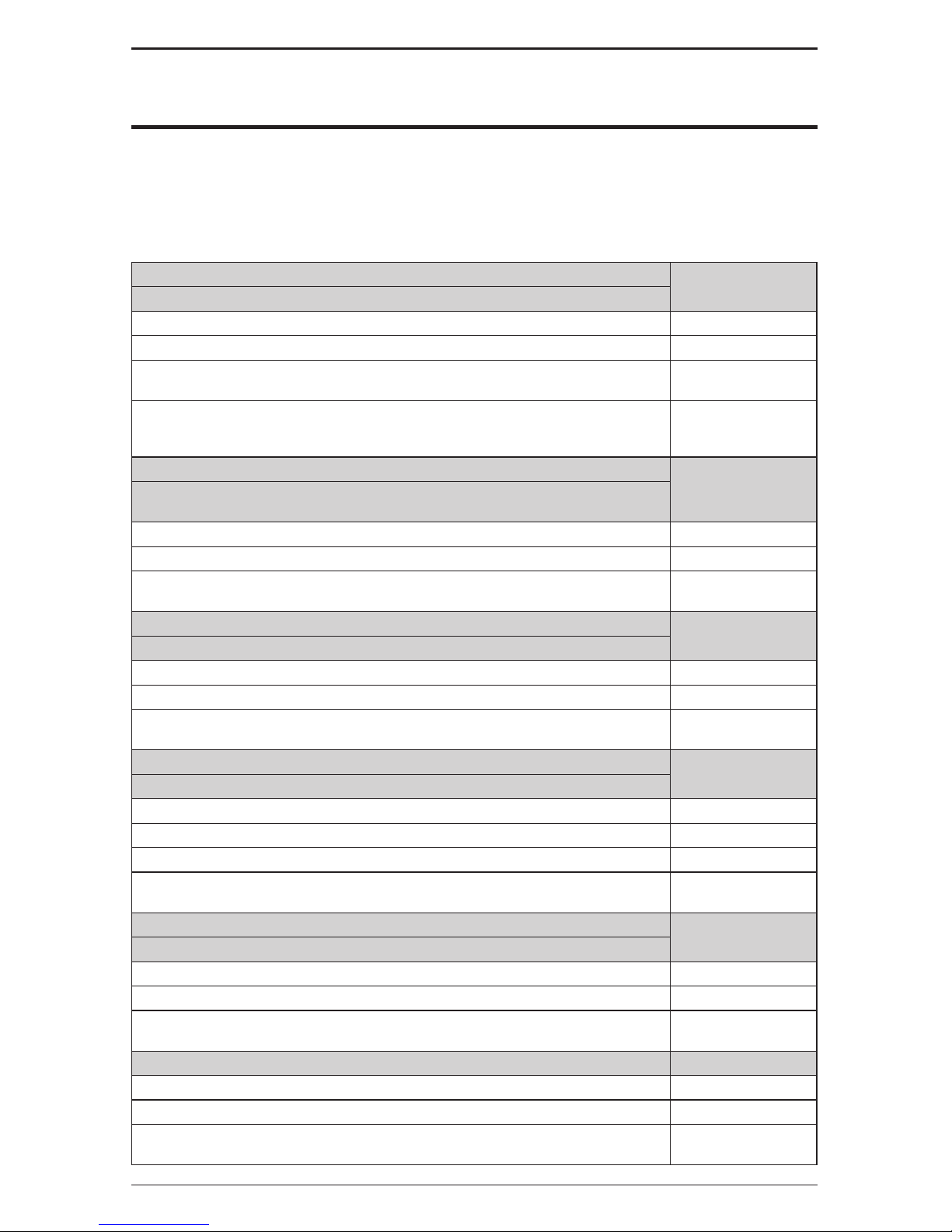

3.03 TWECO® FUSION 250A MIG GUN SELECTION GUIDE

Rear

Connection

250 AMP MIG Gun*

Rear Connector

(Replacement)

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

10 ft cable 12 ft cable 15 ft cable 20 ft cable 25 ft cable

Tweco

®

FV210-3545

1023-1059

FV212-3545

1023-1060

FV215-3545

1023-1061

FV220-3545

1023-1062

FV225-3545

1023-1063

350-174H

2035-2110

Miller

®

FV210M-3545

1023-1067

FV212M-3545

1023-1068

FV215M-3545

1023-1069

FV220M-3545

1023-1070

FV225M-3545

1023-1071

350-174MH

2035-2111

Lincoln

®

----

FV212L-3545

1023-1084

FV215L-3545

1023-1085

---- ----

350-174LH

2035-2112

Euro-Kwik

FV210X-3545

1023-1089

FV212X-3545

1023-1090

FV215X-3545

1023-1091

----

FV225X-3545

1023-1092

174EX-1

2040-2276

252i

ThermalArc

---- ----

FV215TA3545

1023-1097

---- ----

350-174H

2035-2110

*Rear connector supplied as standard

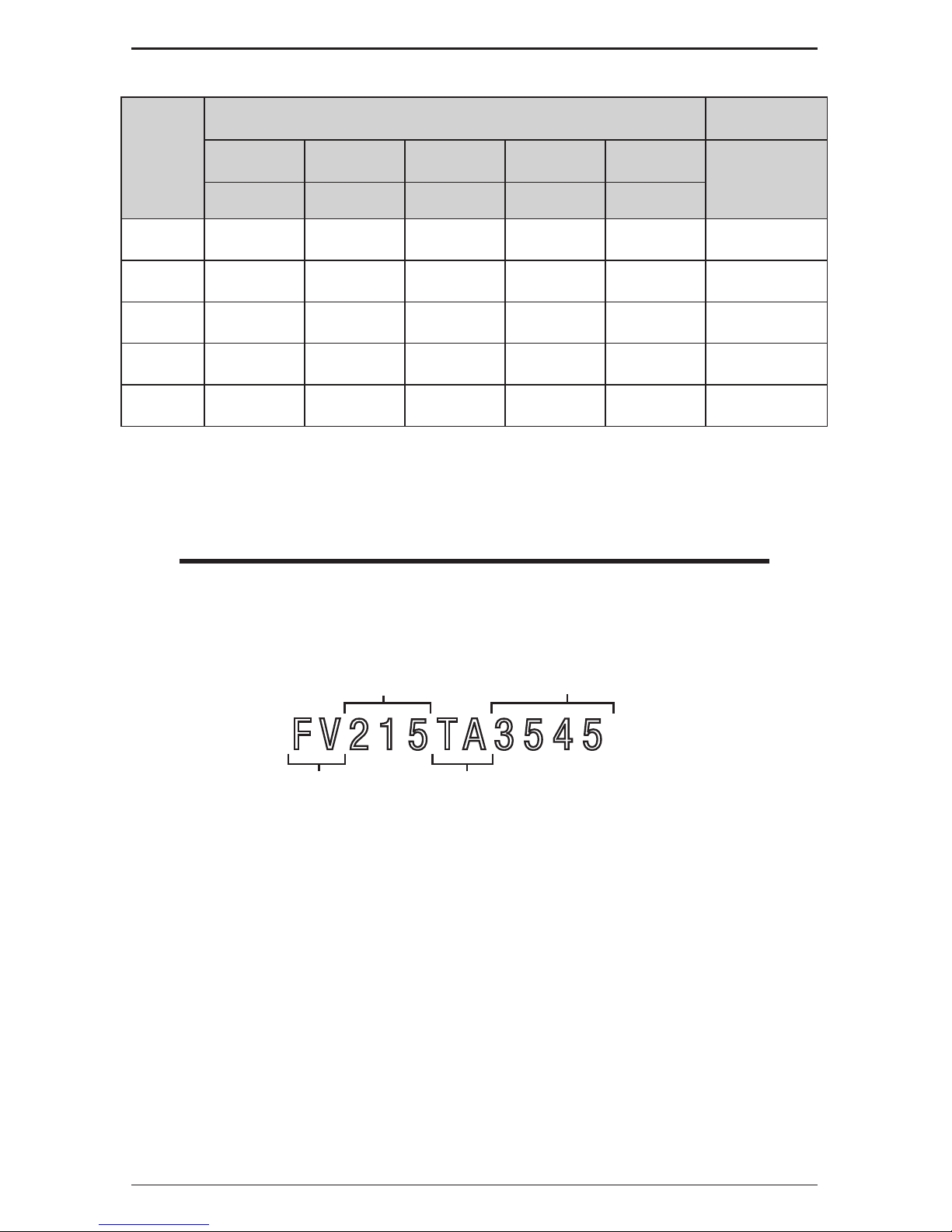

3.04 TWECO FUSION 250A MIG GUN PART NUMBER

IDENTIFICATION

NOTE

Tweco Fusion MIG guns, as a general rule, have a specific nomenclature

incorporated within each part number to help determine the wire size of each

MIG gun.

Example Part Number:

FV215TA3545

T=Tweco

TA=Tweco (Bundle)

L=Lincoln

M=Miller

X, XE=Euro-Kwik

Fusion Velocity

15 foot (5 M) cable

.035"-.045" Wire Capacity

(0,9 mm - 1,2 mm)

So a part number "FV215TA3545" would identify the MIG gun as a: Tweco Fusion 250A MIG

Gun bundle pack with a 8-pin rear connector, 15 foot long cable and having a 0.035" to 0.045"

diameter wire capacity.

So a part number"FV2253545" would identify the MIG gun as a: Tweco Fusion 250A MIG Gun

with a 4-pin Tweco rear connector, 25 foot long cable and having a 0.035" to 0.045" diameter

wire capacity.

MILLER is a registered trademark of Miller Electric Mfg. Co.; ESAB is a registered trademark of ESAB AB; LINCOLN is

a registered trademark of LINCOLN Electric Co.; The aforementioned registered trademarks are no way affiliated with

Tweco Products, Inc. or Victor Technologies, Inc. Tweco is a registered trademark of Victor Technologies, Inc.

Page 10

8

SAFETY AND OPERATING INSTRUCTIONS

89200015

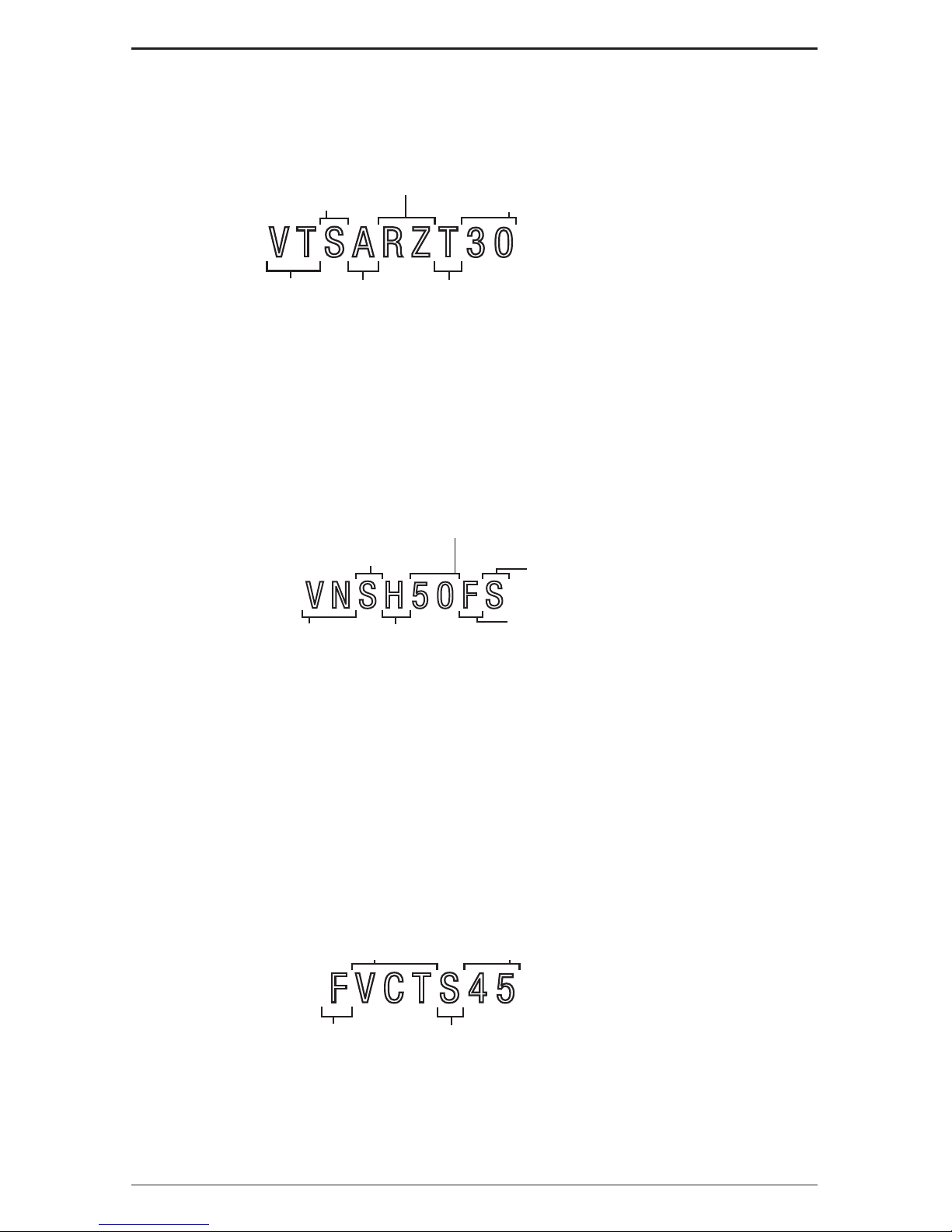

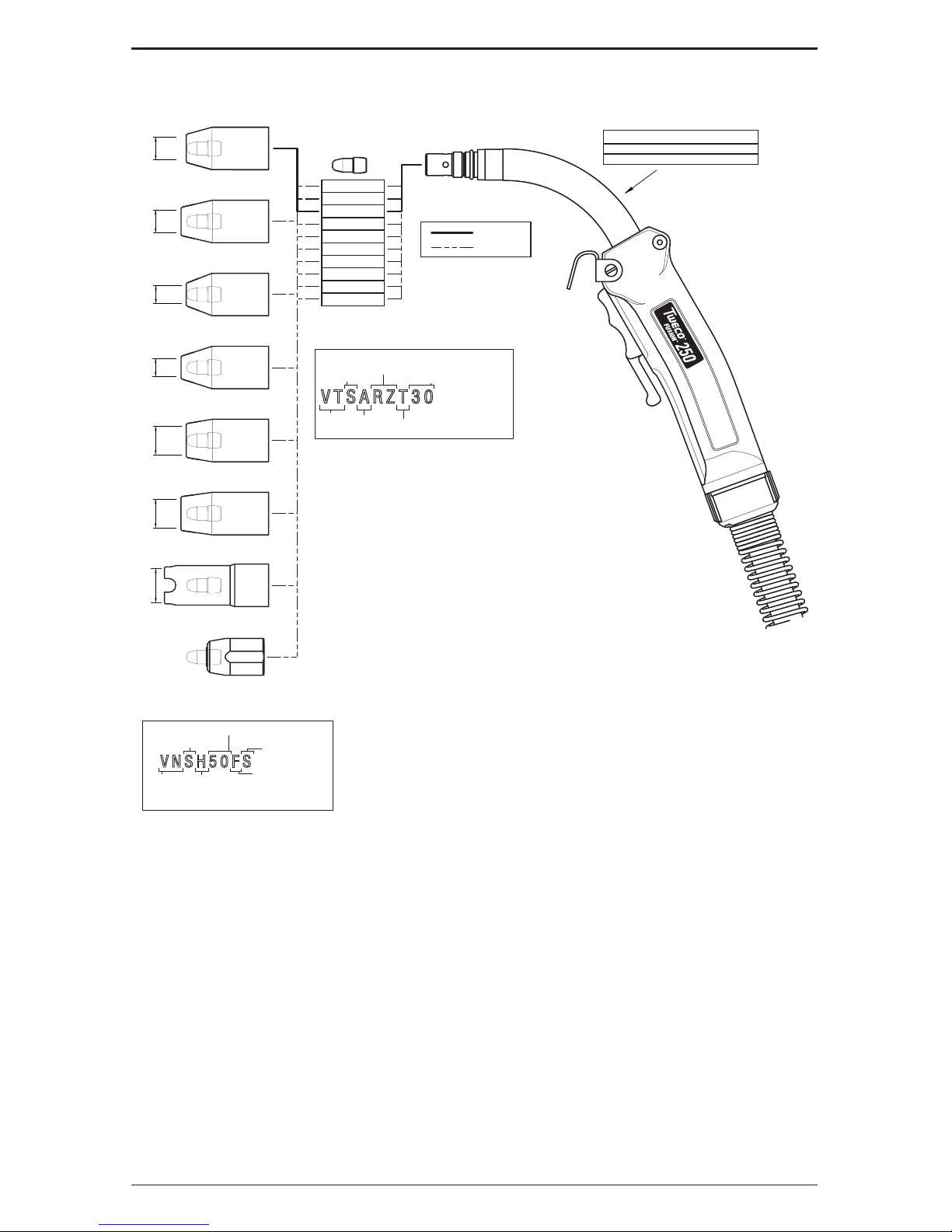

3.04 VELOCITY CONTACT TIP IDENTIFICATION

Velocity Contact Tips may be identified by the tip type and the part number marking for each tip.

Example Part Number:

VTSARZT30

Velocity

Tip

Blank=CU,

RZ=CHROM ZIRC,

RS=SILVER ZIRC

T=Tapered,

Blank=None

S=Small,

M=Medium,

L=Large

A=Aluminum,

Blank=Other

Wire Size: 23=0.023” 116=1/16”

30=0.030” 564=5/64”

35=0.035” 332=3/32”

40=0.040” 764=7/64”

45=0.045” 18=1/8”

52=0.052” 364=3/64”

So a part number "VTSARZT30" would be: Velocity Tip Type, Small Size, Aluminum, RZ Alloy,

Tapered for wire size 0.030" diameter.

A part number "VTM40" would be: Velocity Tip Type, Medium Size, CU, wire size 0.040" diameter.

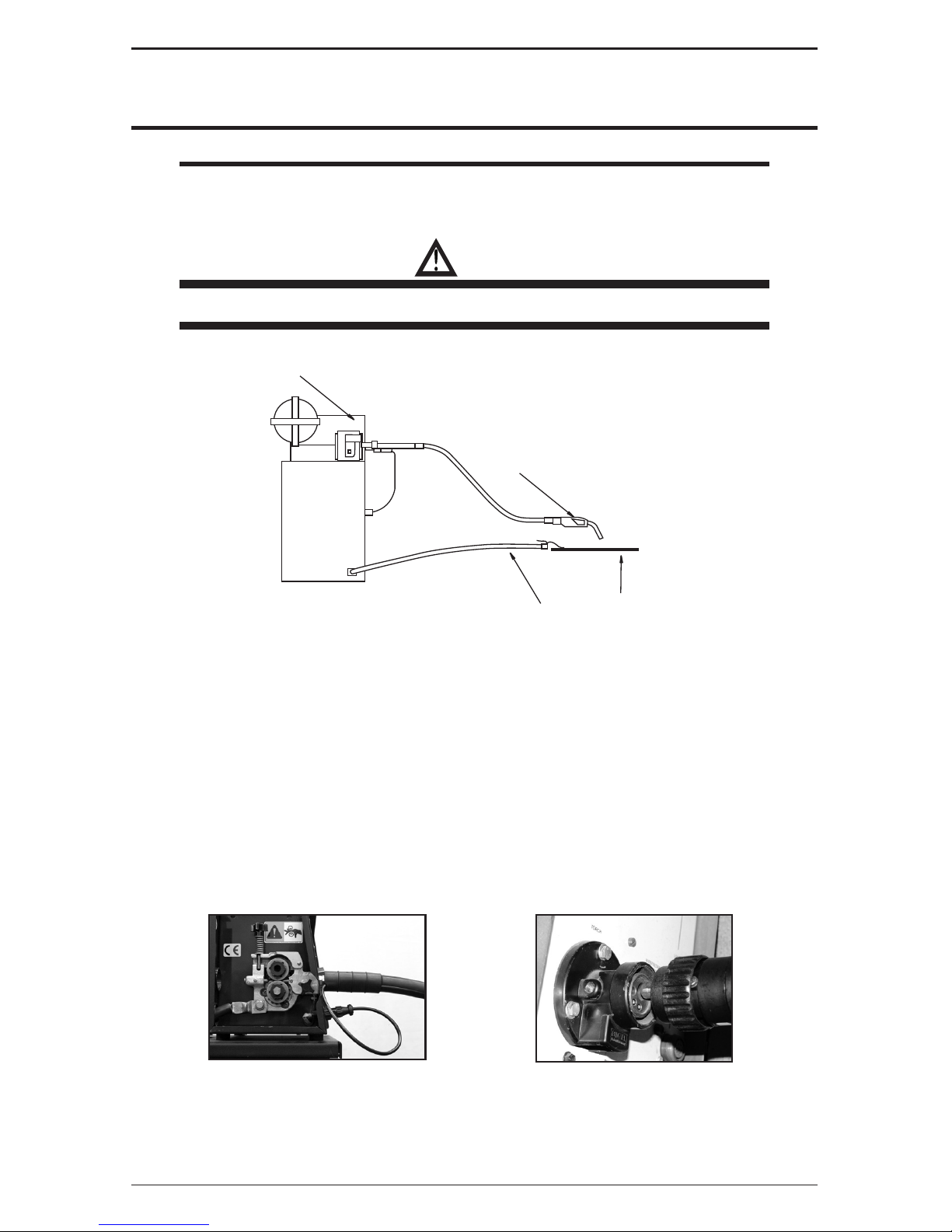

3.05 VELOCITY CONTACT TIP NOZZLE IDENTIFICATION

Nozzles for the Velocity contact tip Tweco Fusion MIG Guns may be identified by their type and part

number marking on each nozzle.

Example Part Number:

Blank=Standard,

H=Heavy Duty

VNSH50FS

Velocity

Nozzle

Blank=Std Recess,

F=Flush,

P=Protrude,

R= Recess ¼” (6.35mm)

FAS=Spot Weld

FC=Flux Core

S=Small Nozzle,

M=Medium Nozzle,

L=Large Nozzle

Orifice Opening Size: 37=3/8” 62=5/8”

50=1/2” 75=3/4”

Blank=Threaded,

S=Slip

So a part number "VNSH50FS" would be: Velocity Nozzle Type, Small Nozzle Size, Heavy Duty,

orifice opening size of 0.50 inch, Flush end, Slip fit.

A part number "VNS50" would be: Velocity Nozzle Type, Small Nozzle Size, Standard Duty,

orifice opening size of 0.50 inch, Standard Recess end, Threaded fit.

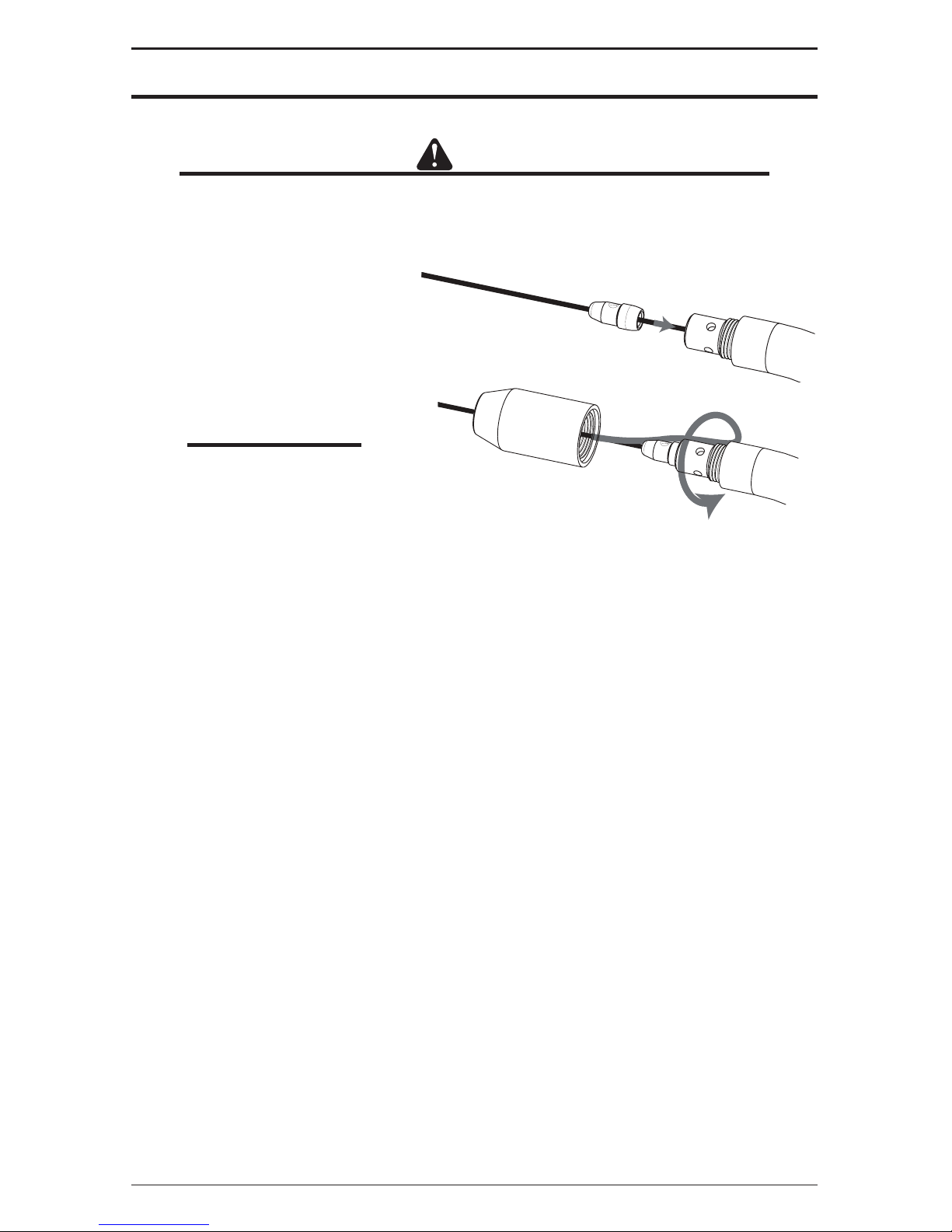

3.06 VELOCITY 250 AMP CONDUCTOR TUBE IDENTIFICATION

Conductor tubes for the Velocity Contact Tip on the Tweco Fusion MIG Guns may be identified by their

type and part number marking on each tube.

Example Part Number:

FVCTS45

Fusion

Velocity

Conductor Tube

Bend Angle: 45˚, 60˚, or 180˚

S=Small Tip,

M=Medium Tip,

L=Large Tip

So a part number "FVCTS45" would be: Tweco Fusion Gun Type, Velocity 250 Amp Conductor

Tube, Small Tip Size, 45 degree bend.

A part number "FVCTM60" would be: Tweco Fusion Gun Type, Velocity 250 Amp Conductor

Tube, Medium Tip Size, 60 degree bend.

Page 11

SAFETY AND OPERATING INSTRUCTIONS

989200015

SECTION 4:

MIG GUN INSTALLATION

NOTE

Be certain that the end user (welder, operator, or helper) reads and understands

these instructions. Be certain that the welder also reads Section 1 “Safety

Precautions.”

WARNING

Electric shock can cause injury or death.

POWER

SOURCE

WIRE FEEDER

GROUND

WORK PIECE

GUN

Figure 1: Standard MIG Gun Installation

4.01 DIRECT PLUG MIG GUN INSTALLATION

Direct plug MIG guns install by directly inserting the rear connector plug into the feeder wire

guide outlet (see figure 2) and tightening the plug retaining screw. All models of MIG guns,

except the Euro-Kwik guns, require a control wire assembly to attach the MIG gun trigger

leads to the feeder. The control wire assemblies plug into the rear connector case of the MIG

gun, and into the control wire receptacle on the feeder. Euro-Kwik connections are installed by

inserting the gun connection into the feeder receptacle, aligning the conduit plug first, then the

gas plug. Push until all fittings are seated, then tighten the nut hand tight as shown in figure 3.

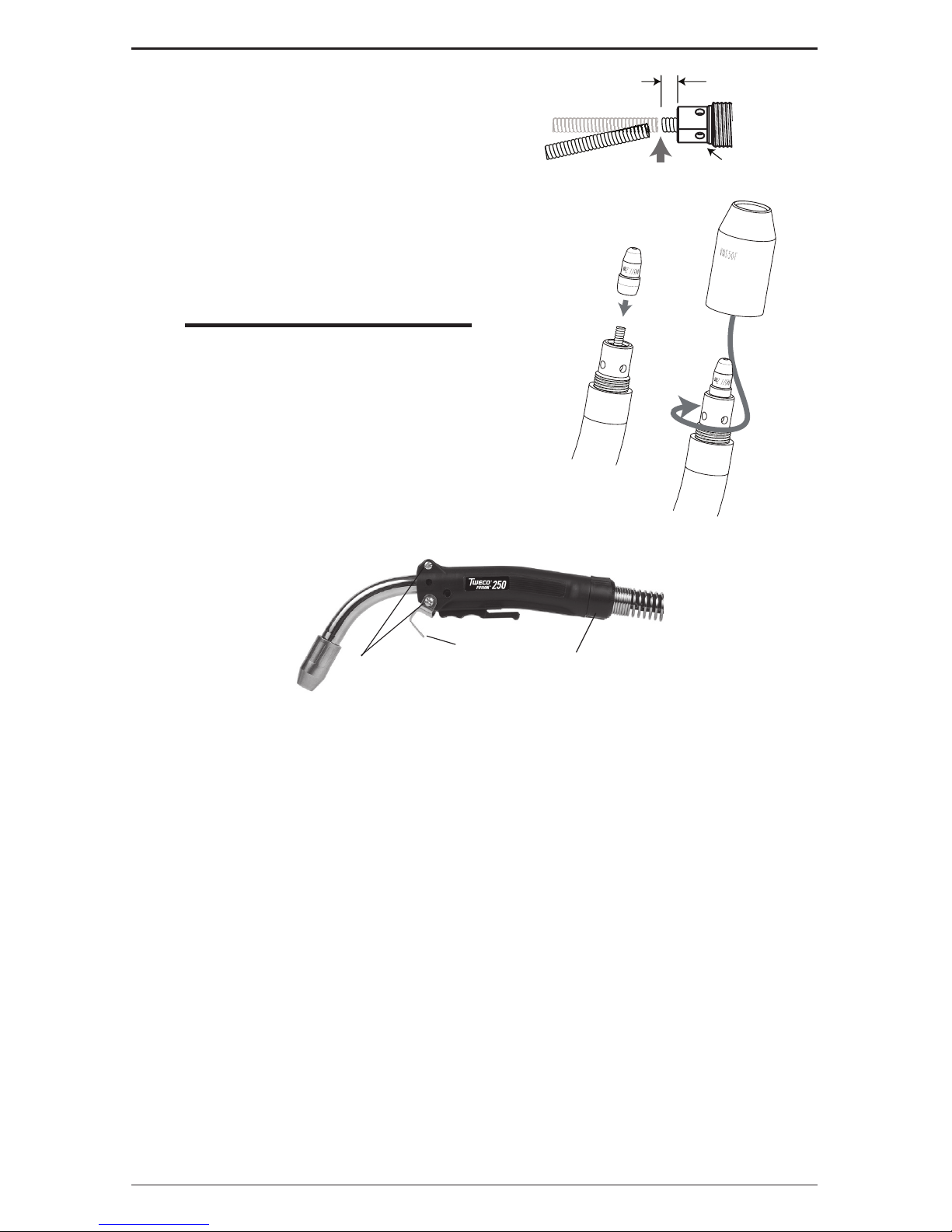

Figure 2

Figure 3

Page 12

10

SAFETY AND OPERATING INSTRUCTIONS

89200015

4.02 TWECO® MIG-KWIK CONNECTION AND ADAPTER KIT

INSTALLATION

Installation of a Tweco MIG gun with a Tweco connector plug, may require an adapter kit. Choose

the correct adapter kit for your wire feeder from the Adapter Kit Listing Form No. TLAK-97 for

more detail. To install, follow the instructions furnished with the adapter kit. Figure 4 shows

the general adapter kit installation.

Receptacle

(TLAK-1 or 6TLAK-1)

Receptacle

(TAK-1 or 6TAK-1)

ADAPTER PLUG

WIRE FEEDER

GAS HOSE

GAS HOSE

POWER CABLE

CONTROL WIRE

MIG GUN

Figure 4

1. Screw adapter plug into the receptacle and tighten.

2. Insert the adapter plug and receptacle into the wire feeder wire guideout. Tighten the

wire guide attachment screw.

3. If needed, attach a proper sized welding cable from the welding power source to the

receptacle power connection.

4. Attach a gas hose to the receptacle and to the feeder gas solenoid.

NOTE

When using an adapter kit, the gas must be attached to the receptacle to provide

gas to the MIG gun. If the feeder gas supply is attached to the feeder wire guideout

block, it must be rerouted to the receptacle.

5. Insert the MIG gun rear connection plug into the receptacle and tighten the attachment

screw.

6. Attach the control wire plug assembly to the wire feeder MIG gun control circuit. Then

plug the flat double female plug into the MIG gun.

The gun should now be installed and ready to feed wire as recommended by the feeder

manufacturer.

Page 13

SAFETY AND OPERATING INSTRUCTIONS

1189200015

SECTION 5: REPLACEMENT INSTRUCTIONS

5.01 REPLACING VELOCITY CONTACT TIP

CAUTION

While nozzle and contact tip are removed, maintain an adequate distance of the

wire from metal objects to avoid burnbacks to conduit or conductor tube.

1. Remove worn nozzle and tip. (Clean nozzle if reusing.)

2. Slide new contact tip over

the conduit end and into the

conductor tube end.

3. Replace the nozzle. Hand tighten

(Nozzle secures tip).

NOTE

For proper operation the

nozzle MUST be tight.

4. Trim wire to desired stick out.

The MIG gun is now ready operation.

5.02 REPLACE CONDUCTOR TUBE

The conductor tube is attached to the Tweco® Fusion handle by two set screws on the side of

the handle. To remove:

1. Remove the front end consumables from the conductor tube.

2. Loosen the conduit liner set screw with a 5/64" Allen wrench (supplied) and then

loosen the socket head cap screw securing the conductor tube in place inside the

handle with a 5/32" Allen wrench.

3. Remove conductor tube.

4. Slide the new tube over the liner and insert into the brass connection within the handle.

Confirm the tube is correctly aligned with the MIG Gun handle and wrench tighten the

socket head cap screw.

5. Tighten the conduit set screw down against the liner. Do not overtighten to avoid

damaging the liner.

6. Re-assemble the front end consumables.

The MIG gun is now ready for operation.

Page 14

12

SAFETY AND OPERATING INSTRUCTIONS

89200015

Conduit liner set screw

Socket head cap screw

5.03 CONDUIT IDENTIFICATION AND REPLACEMENT

The procedure for removal and installation of a wire conduit is similar for all Tweco MIG guns. Conduits

may be identified by the type of conduit stop and the part number marking on each conduit stop.

Example Part Number:

44-116-15

44 Series

1/16" (1,6mm) Wire Capacity

Liner length in feet

Conduit Removal

1. Lay the MIG gun out on a table or on the floor in a straight line. Make sure the gun is

fully extended and all twists in the cable are removed.

2. Remove the nozzle and tip.

NOTE

On Miller® Direct Plug MIG guns, remove the nipple on the end of the connector

plug. On Euro-Kwik connections, remove the conduit retaining cap.

3. Loosen the conduit set screw in the front of the gun. This is usually located at the

front of the handle. Then loosen the conduit set screw in the rear connector plug.

4. Grip the conduit stop and remove the conduit with a twisting motion. On Miller® Direct

Plug MIG guns, twisting the rear of the gun approximately one revolution clockwise

will raise the conduit stop out of the connector plug recess.

Conduit Installation - Velocity Contact Tip Style

WARNING

Failure to follow Conduit Installation Instructions will cause wire feed issues.

1. Uncoil the conduit and lay it in a straight line. Insert the conduit into the rear connector plug.

Push the conduit into the gun with short strokes.

NOTE

If the conduit hangs up gently whip the cable while applying pressure to the

conduit. New liners must be cut to the correct length.

2. When the conduit is completely in the gun, tighten the rear conduit set screw. On Miller®

guns, reinstall the nipple. On Euro-Kwik guns, reinstall the conduit retaining cap.

Page 15

SAFETY AND OPERATING INSTRUCTIONS

1389200015

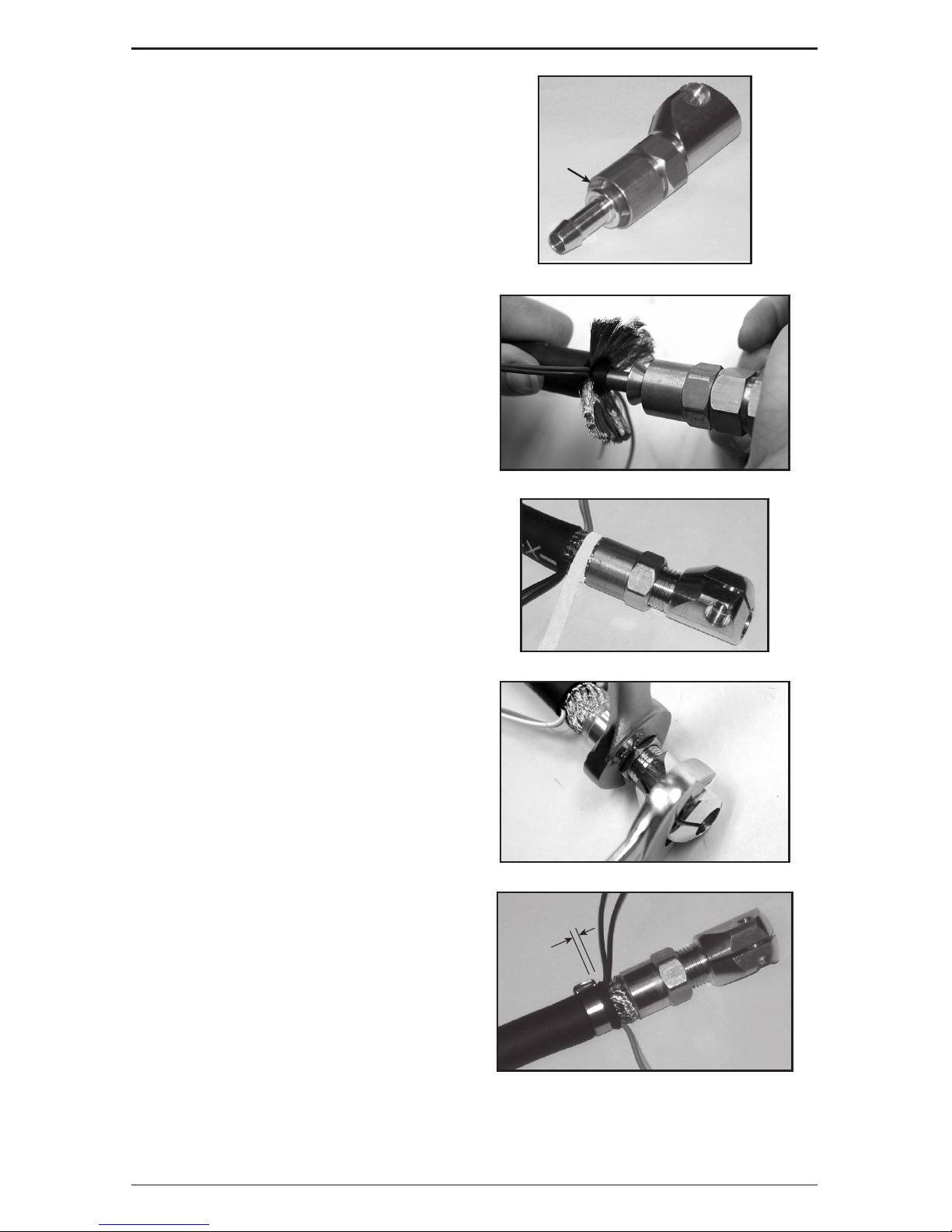

IMPORTANT!

3. The new conduit liner will need to be cut to length.

This can be done by trimming the conduit to the

appropriate length.

1/8” (3,2 mm)

Velocity

Conductor Tube

4. File the cut conduit end to remove burrs.

5. Replace the contact tip.

6. Replace the nozzle. Hand tighten

(Nozzle secures tip).

NOTE

For proper operation the nozzle MUST

be tight.

The MIG gun is now ready to be reinstalled on the

feeder.

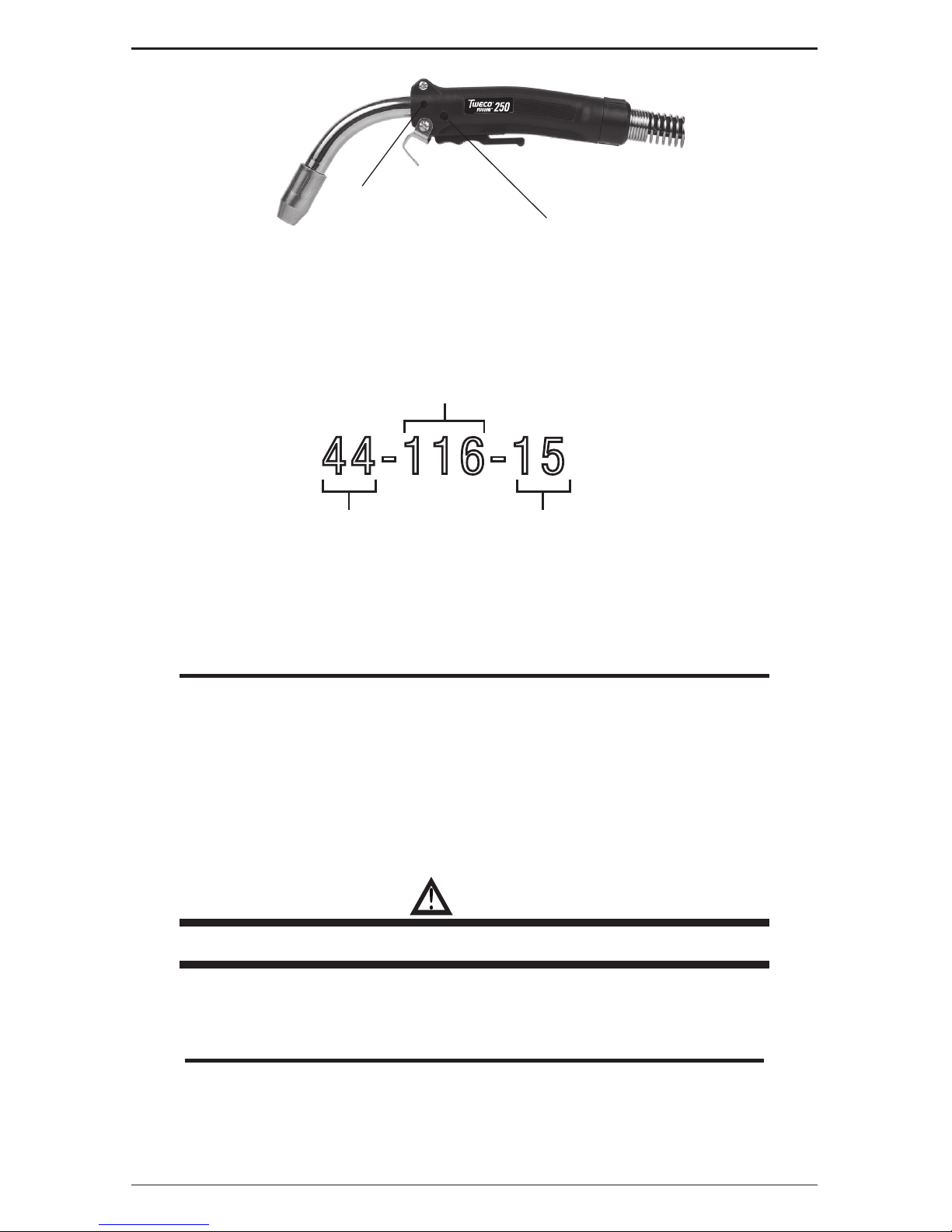

5.04 REPLACING HANDLE, TRIGGER

Remove the MIG gun from the feeder prior to beginning these steps.

Handle screws Back Cap

Gun Hanger

1. Lay MIG gun on side, screw side up and remove both handle screws at the front of the

gun handle.

2. Remove the small screw from the other side of the gun hanger clip and remove the

gun hanger clip being careful to keep all internal components in place.

3. Lay the gun back down on its side and untwist the handle back cap.

4. Remove the top handle half being careful to keep all components in place in the lower

handle half.

5. (Follow this step ONLY if the trigger is to be replaced.) Lift out the molded trigger, the

trigger mechanism, and disconnect the lead wires. Connect the wires to the new trigger

mechanism then place the molded trigger and new trigger in the lower handle half.

6. Place the new top handle half on the old lower handle half and gently flip the gun over.

Replace the old lower handle half with the new lower handle half. Molded trigger should

move within the handle.

7. Flip the gun back to the screw side up and press the handle halves together until they

bottom. Be careful not to pinch the trigger lead wires.

8. Put the gun hanger in place and install the two handle screws. Rotate the gun handle

to the other side and install the small gun hanger clip screw.

9. Slide the Back Cap into place and twist onto the handle end.

The MIG gun is now ready to be reinstalled on the feeder.

Page 16

14

SAFETY AND OPERATING INSTRUCTIONS

89200015

SECTION 6:

CABLEHOZ® REPAIR

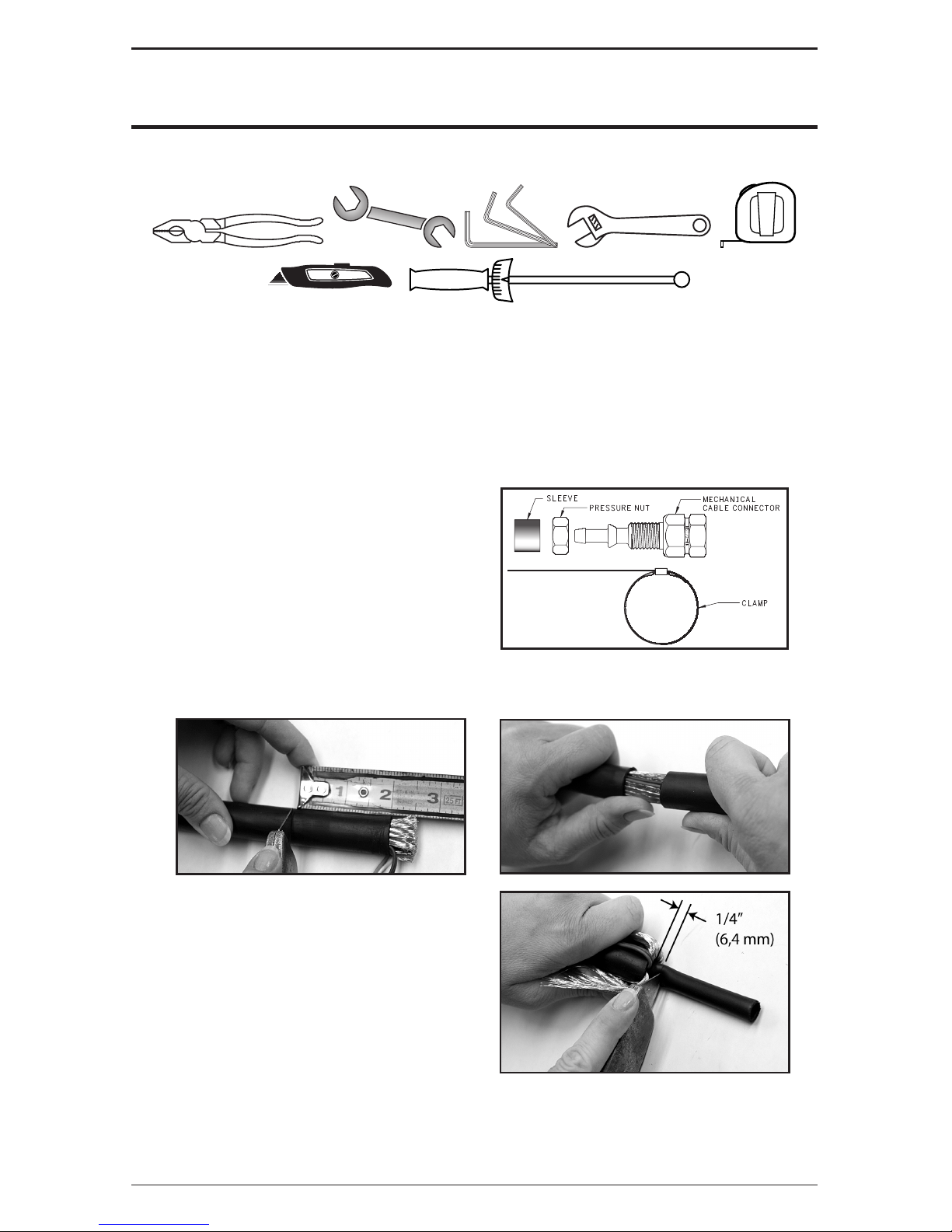

6.01 TOOLS REQUIRED

6.02 REPAIR OF CABLEHOZ®

A. Back-End Repair

1. Disassemble the rear case to expose the rear connector assembly and pull the assembly

away from the rear case.

2. Cut the Cablehoz® to remove the damaged area.

3. Use replacement connector assembly,

Part No. MS172-RK (Stock No. 2060-

2134) on 250 Amp Tweco® Fusion MIG

Guns.

4. Measure back 2-1/2" (63,5 mm) from the end of the Cablehoz and cut away the outer

jacket of the cable, being careful not to cut the copper strands and or lead wires.

5. Pull the copper strands and lead

wires away from the inner core tube

that is exposed and cut away leaving

approximately ¼" (6,35 mm) past the

end of the end of the Cablehoz.

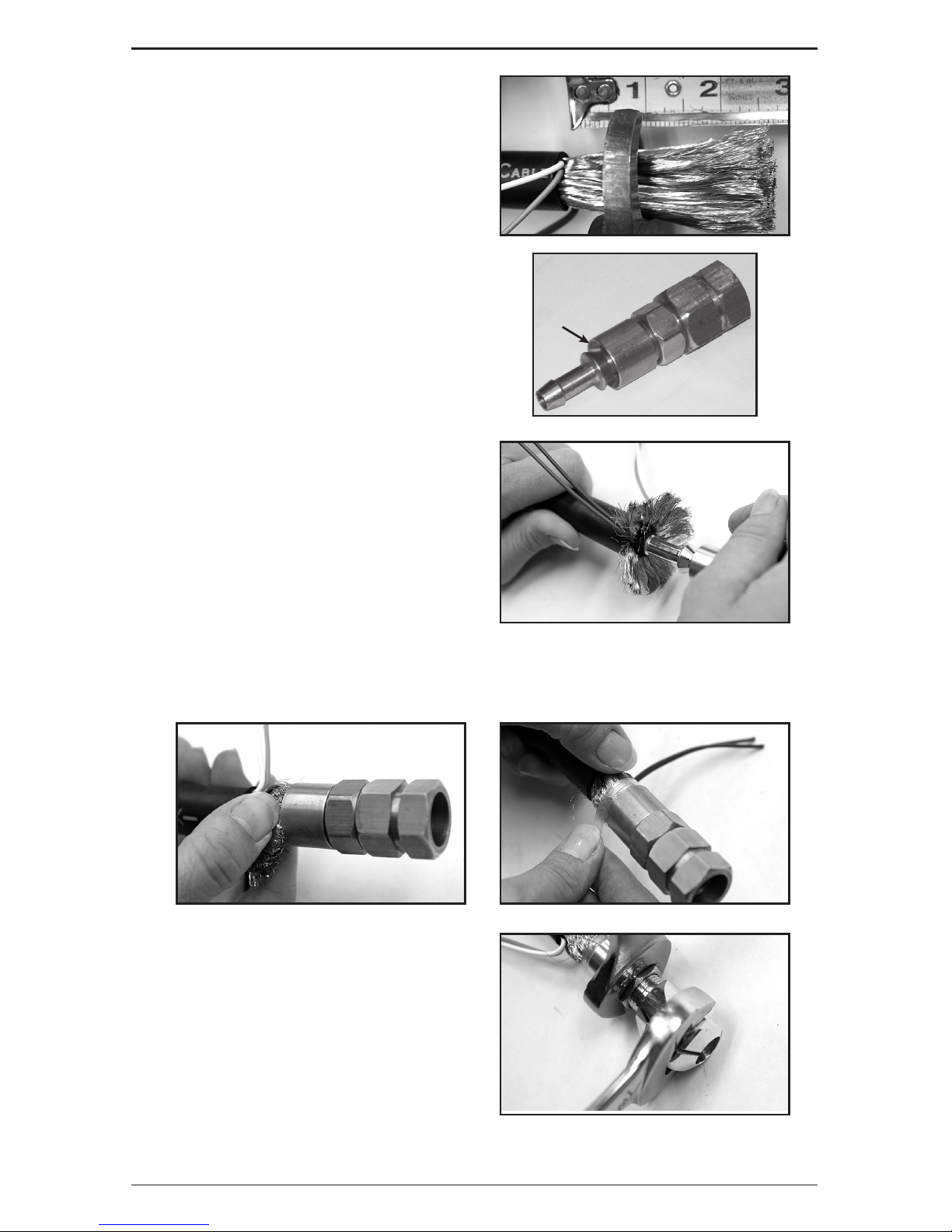

Page 17

SAFETY AND OPERATING INSTRUCTIONS

1589200015

6. Cut the copper strands to a length of ¾"

(19,05 mm) while leaving the wire leads

intact.

7. Thread the pressure nut onto the

replacement rear connector until it

bottoms out and then slide the sleeve

over the connector.

Note: Make sure the bevel is facing the

right direction.

Bevel

8. Insert the replacement connector nipple

into the inner core tube of the Cablehoz.

It is recommended to use a small amount

of non-petroleum based lubricant* to help

the connector to slide into the tube. The

core tube should bottom out against the

shoulder, approximately 15/16" (23,8

mm) onto the connector.

*A small amount of white glue works well.

9. Push the copper strands underneath the sleeve. It is recommended that a 1/8” glass

filament tape be wrapped around the exposed copper to keep the copper strands together

when tightening the pressure nut.

10. Begin to turn the pressure nut counterclockwise which will force the copper

strands & sleeve against and then under

the machined taper on the connector.

Use Torque Wrench and wrench to

perform this task.

11. Torque the pressure nut to 250 inch

pounds, +/-50 inch pounds, (28,2 newton

meters, +/- 5,6 newton meters).

Page 18

16

SAFETY AND OPERATING INSTRUCTIONS

89200015

12. Apply clamp over outside cable and

tighten. Trim excess clamp.

13. Connect lead wires accordingly.

14. Re-assemble the rear case.

Approx.

0.2” (5mm)

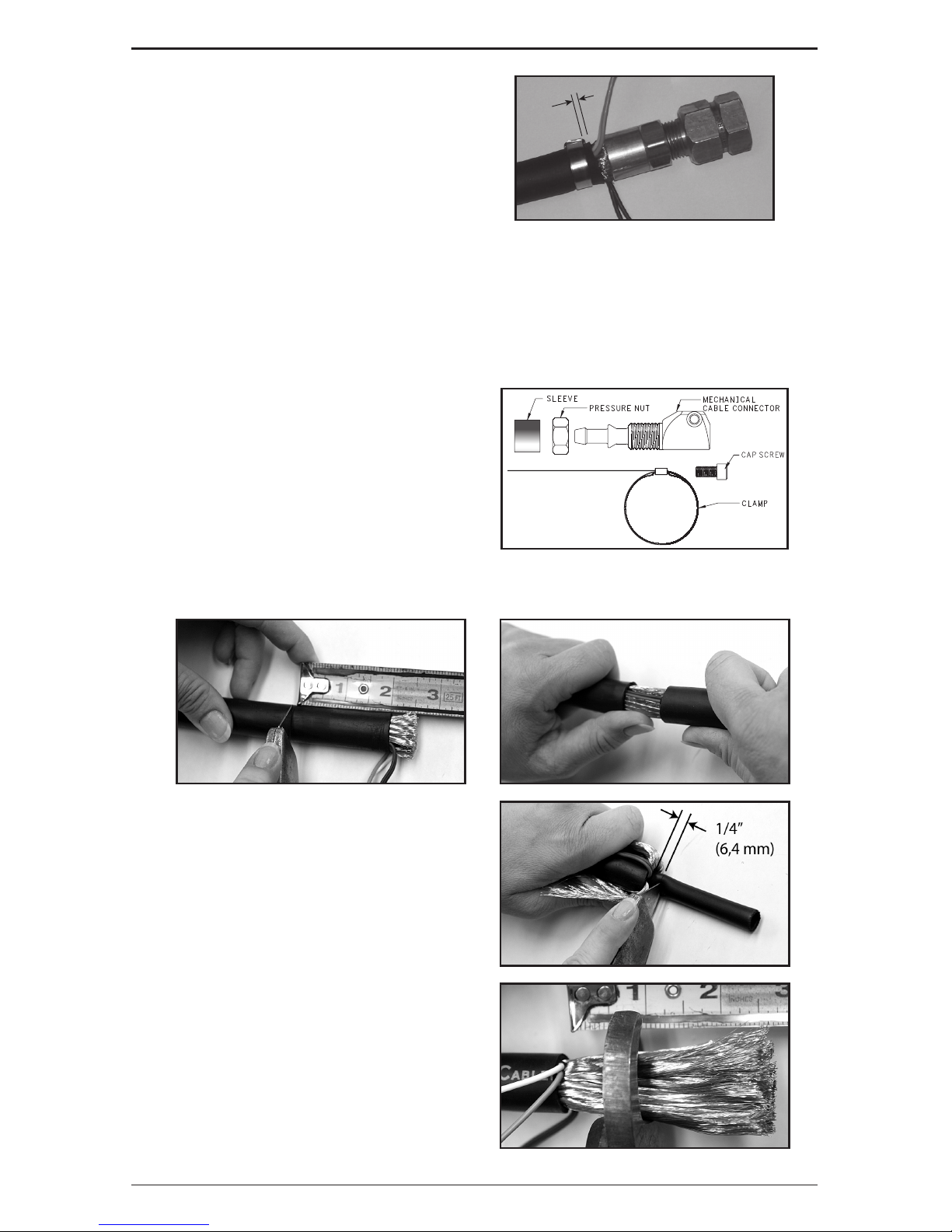

B. Front-End Repair

1. Disassemble the front handle halves to expose the front connector assembly and pull

the assembly from the front handle case.

2. Cut the Cablehoz® to remove the damaged area.

3. Use replacement connector assembly,

Part No. MS102-RK (Stock No. 2060-

2132) on 250 Amp Tweco® Fusion MIG

Guns.

4. Measure back 2-1/2” (63,5 mm) from the end of the Cablehoz and cut away the outer

jacket of the cable, being careful not to cut the copper strands and or lead wires.

5. Pull the copper strands and lead

wires away from the inner core tube

that is exposed and cut away leaving

approximately ¼” (6,35 mm) past the

end of the end of the Cablehoz.

6. Cut the copper strands to a length of ¾”

(19,05 mm) while leaving the wire leads

intact.

Page 19

SAFETY AND OPERATING INSTRUCTIONS

1789200015

7. Thread the pressure nut onto the

replacement front connector until it

bottoms out and then slide the sleeve

over the connector.

Note: Make sure the bevel is facing the

right direction.

Bevel

8. Insert the replacement connector nipple

into the inner core tube of the Cablehoz.

It is recommended to use a small amount

of non-petroleum based lubricant* to help

the connector to slide into the tube. The

core tube should bottom out against the

shoulder, approximately 15/16” (23,8

mm) onto the connector.

*A small amount of white glue works well.

9. Push the copper strands underneath the

sleeve. It is recommended that a 1/8”

glass filament tape be wrapped around

the exposed copper to keep the copper

strands together when tightening the

pressure nut.

10. Begin to turn the pressure nut counterclockwise which will force the copper

strands & sleeve against and then under

the machined taper on the connector.

Use Torque Wrench and wrench to

perform this task.

11. Torque the pressure nut to 250 inch

pounds, +/-50 inch pounds, (28,2 newton

meters, +/- 5,6 newton meters).

12. Apply clamp over outside cable and

tighten. Trim excess clamp.

13. Connect lead wires accordingly.

14. Re-assemble the front end.

Approx.

2” (5mm)

Page 20

18

SAFETY AND OPERATING INSTRUCTIONS

89200015

This page intentionally blank.

Page 21

SAFETY AND OPERATING INSTRUCTIONS

1989200015

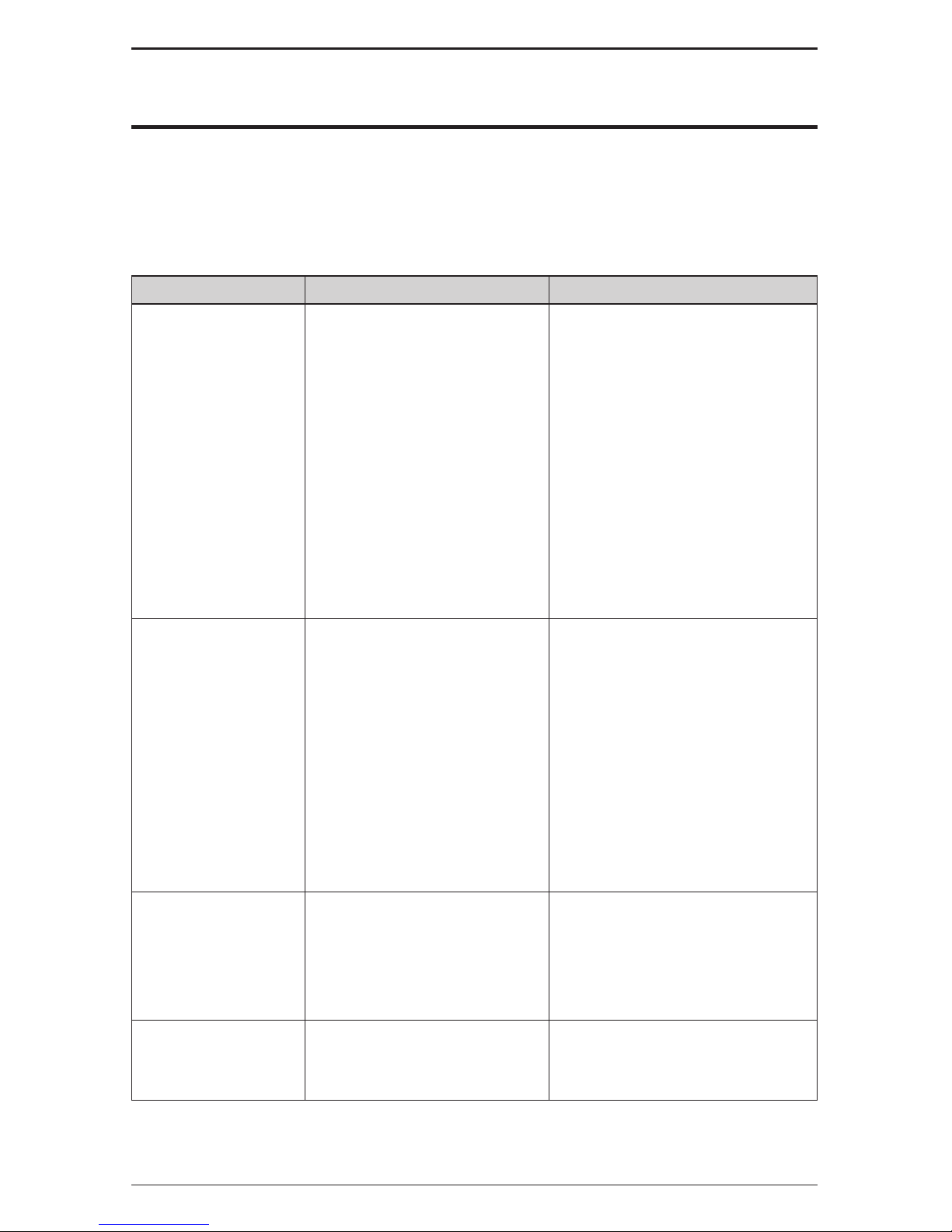

SECTION 7:

MAINTENANCE AND TROUBLESHOOTING

Contact tips and nozzles should be cleaned frequently. Spatter buildup may cause bridging

between nozzle and tip. This could cause electrical shorting between the nozzle and work

piece as well as poor or improper gas flow. Regularly inspect the conductor tube, handle,

cable, and other parts of the MIG Gun for abrasion, cuts, or undue wear. Replace or repair any

parts found deficient.

Problem Possible Cause Corrective Action

Wire feed inconsistent

or not smooth

1. Loose contact tip. 1. Tighten nozzle.

2. Excessively worn contact tip. 2. Replace contact tip.

3. Spatter buildup on end of

contact tip.

3. Clean or replace contact tip.

4. Sharp bends or kinks in

conduit.

4. Straighten or replace conduit.

5. Dirty or plugged conduit. 5. Replace conduit.

6. Conduit pulled back from

contact tip.

6. Reposition conduit and cable.

7. Machine improperly adjusted. 7. Reset machine per machine

and wire manufacturers’

recommendations.

MIG Gun is running hot

1. Loose contact tip. 1. Tighten nozzle.

2. Loose power connections. 2. Inspect complete gun for loose

connections and repair.

3. Loose or undersize ground

cable or ground clamp.

3. Tighten or replace as required.

4. Operating gun above

recommended amperage

rating.

4. Readjust machine to correct

setting for size of gun being used.

5. Operating gun above

recommended duty cycle

rating.

5. Readjust machine to correct

setting for size of gun being used.

Porous weld

1. Poor or improper gas flow. 1. Check gas flow out of gun nozzle.

Check for leaks or restrictions in

gas hoses and connections.

2. Dirty or contaminated wire. 2. Change wire.

3. Base metal contaminated. 3. Replace base metal.

Conduit gets hung-up

inside of the gun

1. Burr on the end of the cut

conduit.

2. Conduit liner has kinks.

1. Remove the burr with a file.

2. Replace conduit.

Page 22

20

SAFETY AND OPERATING INSTRUCTIONS

89200015

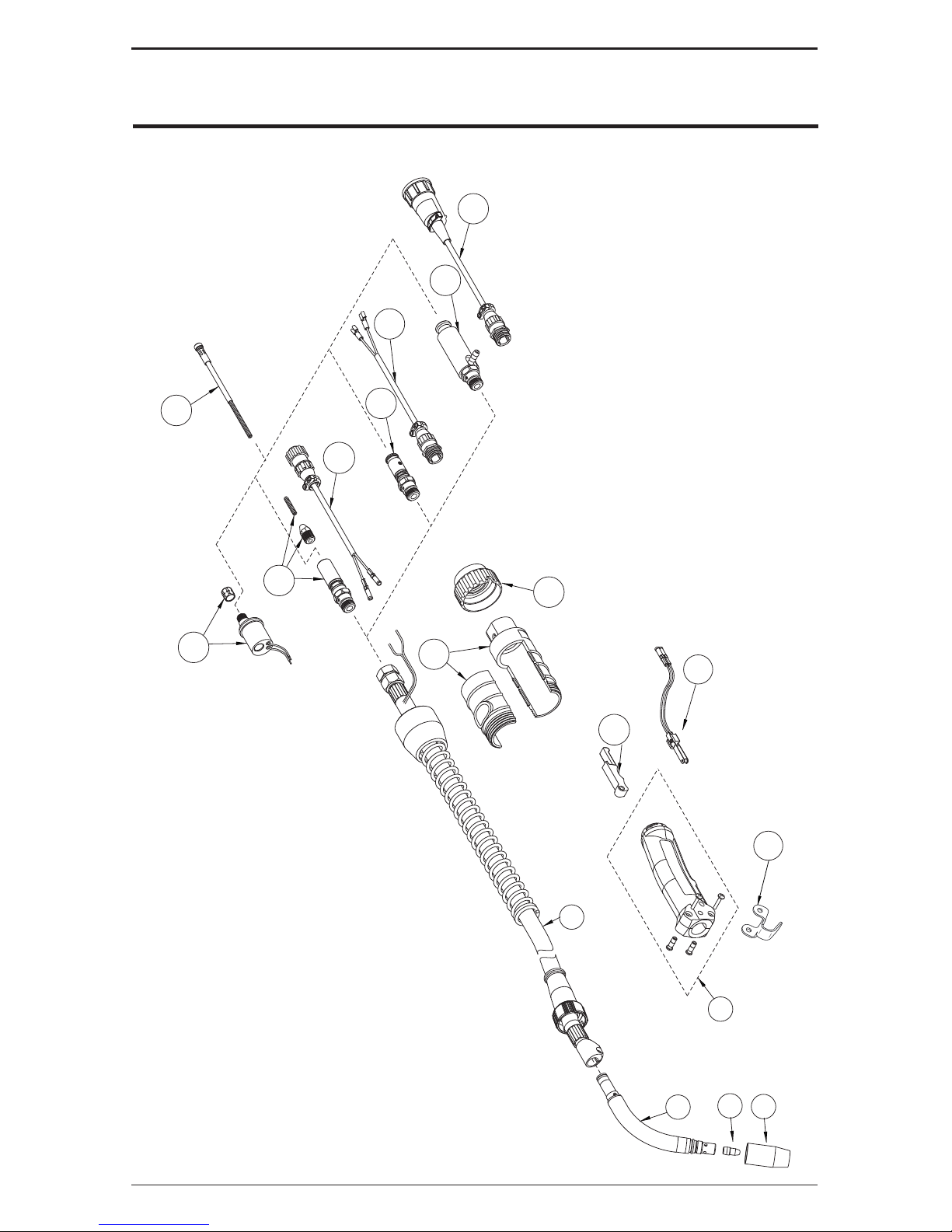

SECTION 8:

250 AMP REPLACEMENT PARTS

8.02 TWECO® FUSION 250 A MIG GUN PARTS

13b

13a

10a

11a

12a

11

10

12

13

14

9

2

5

7

8

6

1

15

Page 23

SAFETY AND OPERATING INSTRUCTIONS

2189200015

Item No. Part No. Stock No. Description

1*

VNS-50 1220-1201 Velocity Nozzle

VNS-50F 1220-1200 Flush Velocity Nozzle

VNS-62 1220-1203 Velocity Nozzle

VNS-62F 1220-1202 Flush Velocity Nozzle

VNS-37 1220-1206 Velocity Nozzle

VNS-37F 1220-1204 Flush Velocity Nozzle

VNS-75FAS 1220-1205 Spot Welding Velocity Nozzle

** **

2*

VTS-23 1110-1308 0.023” Velocity Contact Tip

VTS-30 1110-1309 0.030” Velocity Contact Tip

VTS-35 1110-1310 0.035” Velocity Contact Tip

VTS-40 1110-1311 0.040” Velocity Contact Tip

VTS-45 1110-1312 0.045” Velocity Contact Tip

VTSA-364 1110-1313 3/64” Velocity Contact Tip (for Aluminmum)

VTS-52 1110-1314 0.052” Velocity Contact Tip

VTS-116 1110-1315 1/16” Velocity Contact Tip

VTSA-116 1110-1317 1/16” Velocity Contact Tip (for Aluminmum)

VTS-564 1110-1316 5/64” Velocity Contact Tip

** **

5*

FVCT-S45 1620-1369 Velocity 45° Conductor Tube

FVCT-S60 1620-1368 Velocity 60° Conductor Tube

6 F84 2060-2126 Handle – Standard

7 ELC94 2060-2647 Trigger– Standard

8 ELC94-BL 2060-2671 Trigger Blade Assembly

9

NS

MS210 1720-2115 Cablehoz® Assembly - 10 ft (3 m)

MS212 1720-2116 Cablehoz Assembly - 12 ft (4 m)

MS215 1720-2117 Cablehoz Assembly - 15 ft (5 m)

MS225 1720-2118 Cablehoz Assembly - 25 ft (8 m)

MS212X 1720-2107 Cablehoz Assembly, Euro-Kwik - 12 ft (4 m)

MS215X 1720-2108 Cablehoz Assembly, Euro-Kwik - 15 ft (5 m)

MS225X 1720-2109 Cablehoz Assembly, Euro-Kwik - 25 ft (8 m)

9a MS102-RK 2060-2132 Cablehoz Front Mechanical Connector Replacement Kit

9b MS172-RK 2060-2134 Cablehoz Rear Mechanical Connector Replacement Kit

9c 172X-M 2020-2181 Cablehoz Rear Mechanical Connector Replacement Kit For Euro-Style

10

10a 350-174MH 2035-2111 Miller® Rear Connector

10b WM-354M 2030-2075 Miller Control Wire & Plug

11

11a 350-174H 2035-2110 Tweco® Rear Connector

11b MS354-TAJ 2060-2139 Tweco Control Wire

12

12a 350-174LH 2035-2112 Lincoln® Rear Connector

12b MS-354DS-LJ 2060-2137 Lincoln Control Wire & Plug

13

174EX-1 2040-2276 Euro-Kwik Connection Assy

13a 174X-2 2040-2177 Euro-Kwik Nut

13b X6RC 2060-2006 Euro-Kwik Connector Case

14 ** ** Conduit

15 152 2020-2152 Gun Hanger

NS = Not Shown

** Refer to Tweco Catalog No. for specific parts.

* Patent Pending

MILLER is a registered trademark of Miller Electric Mfg. Co.; ESAB is a registered trademark of ESAB AB; LINCOLN is

a registered trademark of LINCOLN Electric Co.; The aforementioned registered trademarks are no way affiliated with

Tweco Products, Inc. or Victor Technologies, Inc. Tweco is a registered trademark of Victor Technologies, Inc.

Page 24

22

SAFETY AND OPERATING INSTRUCTIONS

89200015

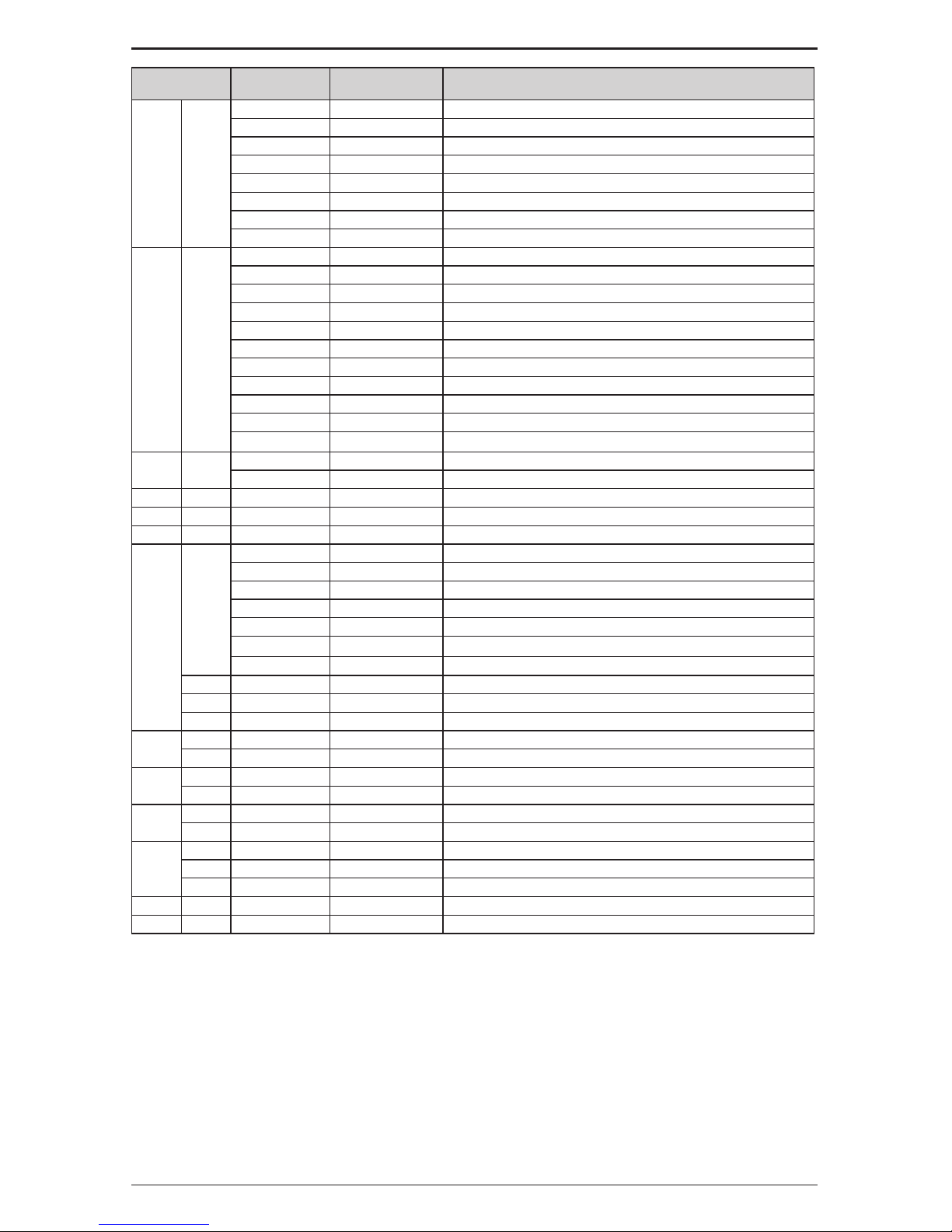

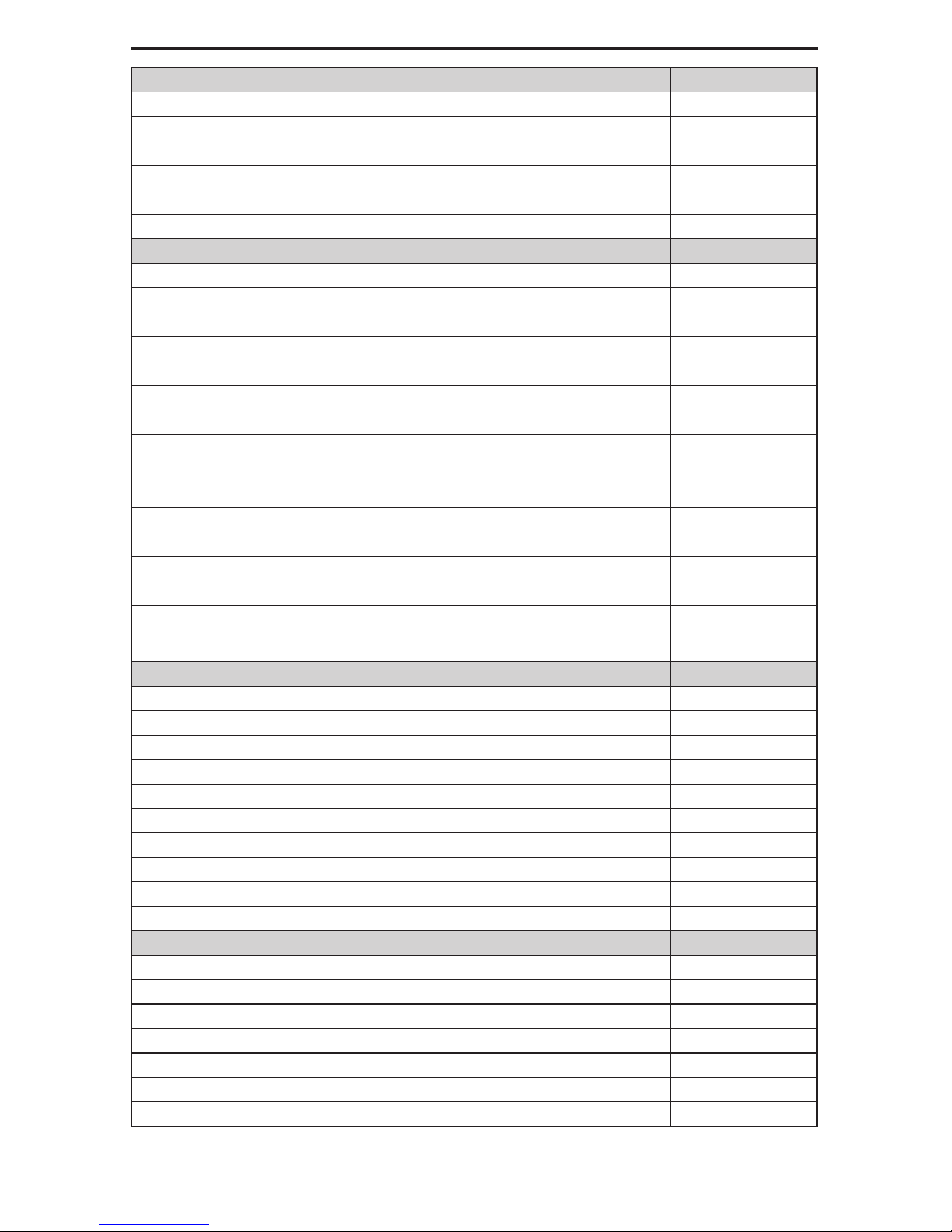

8.02 TWECO® FUSION MIG GUN CONSUMABLES

VNS-50F

5/8” (15,9 mm)

VNS-37

3/8” (9,5 mm)5/8” (15,9 mm)

VNS-75FAS

VNS-50

1/2” (12,7 mm) 1/2” (12,7 mm)

VNS-37F

3/8” (9,5 mm)

VNS-62F

VNS-62

3/4” (19,1 mm)

60° FVCTS60

45° FVCTS45

VTSARZT30

Velocity

Tip

Blank=CU,

RZ=CHROM ZIR,

RS=SILVER ZIR

T=Tapered,

Blank=None

S=Small,

M=Medium,

L=Large

A=Alum,

Blank=Other

Wire Size: 23=0.023” 116=1/16”

30=0.030” 564=5/64”

35=0.035” 332=3/32”

40=0.040” 764=7/64”

45=0.045” 18=1/8”

52=0.052” 364=3/64”

Blank=Standard,

H=Heavy Duty

VNSH50FS

Velocity

Nozzle

Blank=Std Recess,

F=Flush,

P=Protrude,

R= Recess ¼” (6.35mm)

FAS=Spot Weld

S=Small Nozzle,

M=Medium Nozzle,

L=Large Nozzle

Orifice Opening Size: 37=3/8” 62=5/8”

50=1/2” 75=3/4”

Blank=Threaded,

S=Slip

VELOCITY CONTAC T TIP IDENTIFICATION

VELOCITY NOZZLE IDENTIFICATION

Velocity

Nozzle

Velocity

Contact Tip

VTS-23

VTS-45

VTSA-116

VTS-564

VTS-52

VTS-116

VTS-364

VTS-35

VTS-40

VTS-30

Replacement Conductor Tubes

250A MIG GUN

OPTIONAL

STANDARD

VNS-FC

Page 25

SAFETY AND OPERATING INSTRUCTIONS

2389200015

This page intentionally blank.

Page 26

24

SAFETY AND OPERATING INSTRUCTIONS

89200015

SECTION 9:

STATEMENT OF WARRANTY

9.01 WARRANTY SCHEDULE

The warranty is effective below for the time stated in the Warranty Schedule beginning on the

date that the authorized distributor delivers the products to the purchaser. Victor Technologies,

Inc. reserves the right to request documented evidence of date of purchase.

Engine Driven Welders

Parts / Labor

Scout®, Rraider®, Explorer

™

Original Main Power Stators and Inductors 3 years / 3 years

Original Main Power Rectifiers, Control P.C. Boards 3 years / 3 years

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Power Switch Semi-Conductors

1 year / 1 year

Engines and Associated Components are NOT Warranted by Thermal Arc®, Although Most are Warranted by

the Engine Manufacturer. SEE THE ENGINE MANUFACTURERS’ WARRANTY FOR DETAILS.

See the Engine

Manufacturers’ Warranty for

Details

GMAW/FCAW (MIG) Welding Equipment

Parts / Labor

Fabricator® 131, 181, 190, 210, 251, 281; Fabstar® 4030; PowerMaster® 320SP, 350, 350P,

400SP, 500SP, 500, 500P; Excel-Arc® 6045; Wire Feeders: Ultrafeed®, Porta-feed

®

Original Main Power Transformer and Inductor 5 years / 3 years

Original Main Power Rectifiers, Control P.C. Boards, Power Switch Semi-Conductors 3 years / 3 years

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Electric Motors

1 year / 1 year

GTAW (TIG) & Multi-process Inverter Welding Equipment

Parts / Labor

160TS, 300TS, 400TS, 185AC/DC, 200AC/DC, 300AC/DC, 400GTSW, 400MST, 300MST, 400MSTP

Original Main Power Magnetics 5 years / 3 years

Original Main Power Rectifiers, Control P.C. Boards, Power Switch Semi-Conductors 3 years / 3 years

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Electric Motors

1 year / 1 year

Plasma Welding Equipment

Parts / Labor

Ultima® 150

Original Main Power Magnetics 5 years / 3 years

Original Main Power Rectifiers, Control P.C. Boards, Power Switch Semi-Conductors 3 years / 3 years

Welding Console, Weld Controller, Weld Timer 3 years / 3 years

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Electric Motors, Coolant Recirculators

1 year / 1 year

SMAW (Stick) Welding Equipment

Parts / Labor

Dragster™ 85

Original Main Power Magnetics 1 year / 1 year

Original Main Power Rectifiers, Control P.C. Boards 1 year / 1 year

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Power Switch Semi-Conductors

1 year / 1 year

160S, 300S, 400S Parts / Labor

Original Main Power Magnetics 5 years / 3 years

Original Main Power Rectifiers, Control P.C. Boards 3 years / 3 years

All Other Original Circuits and Components Including, but not Limited to, Relays, Switches, Contactors,

Solenoids, Fans, Power Switch Semi-Conductors

1 year / 1 year

Page 27

SAFETY AND OPERATING INSTRUCTIONS

2589200015

General Arc Equipment Parts / Labor

Water Recirculators 1 year / 1 year

Plasma Welding Torches 180 days / 180 days

Gas Regulators (Supplied with Power Sources) 180 days / NA

MIG and TIG Torches (Supplied with Power Sources) 90 days / NA

Replacement Repair Parts 90 days / NA

MIG, TIG and Plasma Welding Torch Consumable Items NA / NA

Gas Welding and Cutting Equipment Parts / Labor

Victor® Professional 5 years / NA

Oxygen Conservers 2 years / NA

Aluminum Cylinders Lifetime / NA

Cutting Machine Motors 1 year / NA

HP&I Brass Regulators/Manifolds 2 years / NA

HP&I Stainless Regulators/Manifolds 1 year / NA

HP&I Corrosive Gas Regulators/Manifolds 90 days / NA

TurboTorch

®

3 years / NA

CutSkill

®

2 years / NA

Steel Cylinders 1 year / NA

Victor Medical 6 years / NA

Victor VSP 2 years / NA

Firepower® MIG Welders 5-2-1 years / NA

Transformers 5 years / NA

Parts Used in Rental Applications

1 year from date sold

by seller to authorized

distributor

MIG Torches and Arc Accessories Parts / Labor

Arcair® N6000 90 days / NA

Spool and Pull Guns 90 days / NA

Robotic Deflection Mounts 90 days / NA

QRM-100 Anti-Spatter Applicator 90 days / NA

TC and TCV Water Coolers 1 year / NA

TSC-96 Smoke Collector 1 year / NA

ESG-1, EPG-CR2 Control Boxes for Spool & Pull Guns 1 year / NA

QRC-2000 Nozzle Cleaning Stations 1 year / 1 year

QRC-3000 UltraSonic Cleaning Stations 2 years / 2 years

All other products 30 days from date purchaser purchases from seller. 30 days / NA

Plasma Cutting Systems Parts / Labor

Automated Plasma 2 years / 1 year

CutMaster

™

3 years / 3 years

PakMaster® XL PLUS 3 years / 1 year

Drag-Gun

®

1 year / 1 year

Drag-Gun Plus 2 years / 1 year

Torches 1 year / 1 year

Consoles, Control Equipment, Heat Exchangers and Accessory Equipment 1 year / 1 year

Page 28

© 2012 Victor Technologies International, Inc. www.victortechnologies.com Printed in Mexico

THE AMERICAS

Denton, TX USA

U.S. Customer Care

Ph: 1-800-426-1888 (tollfree)

Fax: 1-800-535-0557 (tollfree)

International Customer Care

Ph: 1-940-381-1212

Fax: 1-940-483-8178

Miami, FL USA

Sales Office, Latin America

Ph: 1-954-727-8371

Fax: 1-954-727-8376

Oakville, Ontario, Canada

Canada Customer Care

Ph: 1-905-827-4515

Fax: 1-800-588-1714 (tollfree)

EUROPE

Chorley, United Kingdom

Customer Care

Ph: +44 1257-261755

Fax: +44 1257-224800

Milan, Italy

Customer Care

Ph: +39 0236546801

Fax: +39 0236546840

ASIA/PACIFIC

Cikarang, Indonesia

Customer Care

Ph: 6221-8990-6095

Fax: 6221-8990-6096

Rawang, Malaysia

Customer Care

Ph: +603 6092-2988

Fax: +603 6092-1085

Melbourne, Australia

Australia Customer Care

Ph: 1300-654-674 (tollfree)

Ph: 61-3-9474-7400

Fax: 61-3-9474-7391

International

Ph: 61-3-9474-7508

Fax: 61-3-9474-7488

Shanghai, China

Sales Office

Ph: +86 21-64072626

Fax: +86 21-64483032

Singapore

Sales Office

Ph: +65 6832-8066

Fax: +65 6763-5812

U.S. Customer Care: 800-426-1888 / fax 800-535-0557

Canada Customer Care: 905-827-4515 / fax 800-588-1714

International Customer Care: 940-381-1212 / fax 940-483-8178

INNOVATION TO SHAPE THE WORLD

™

T ECHNOLOGIES

™

Page 29

TWECO®

FUSION™250

Guide de

sécurité et

d’utilisation

PISTOLET DE MIG À REFROIDISSEMENT PAR AIR

250 A

Tweco.com

English

Canadien Français

Americas Español

Révision : B Date de publication : 2 août 2013 Manuel no. : 89200015FC

IMPORTANT : Instructions spéciales de

remplacement du conduit

Page 30

NOUS APPRÉCIONS VOTRE FIDÉLITÉ!

Félicitations pour avoir reçu votre nouveau produit Tweco. Nous sommes

fiers de vous avoir comme client et nous nous efforcerons de vous fournir

le meilleur service possible et d’apporter notre soutien à l’industrie. Ce

produit est couvert par notre garantie étendue et par notre réseau de

service dans le monde entier.

Nous savons que vous êtes fier de votre travail et nous nous sentons

privilégiés de vous offrir ce produit de haute performance qui vous aidera à

accomplir votre tâche.

Cela fait plus de 75 ans que Tweco fournit des produits de qualité sur lequel

vous pouvez compter quand votre réputation en dépend.

VOUS ÊTES EN BONNE COMPAGNIE!

Tweco est une Marque mondiale de produits de Soudage à l’arc de Victor

Technologies Inc. Nous nous distinguons de nos concurrents par une

innovation qui domine le marché et avec des produits réellement fiables qui

résisteront à l’épreuve du temps.

Nous nous efforçons d’améliorer vos performances en matière de

productivité, d’efficacité et de soudure vous permettant ainsi d’exceller

dans votre métier. Nous concevons les produits en pensant au soudeur

et en offrant des fonctionnalités avancées, ainsi que durabilité, facilité

d’utilisation et confort ergonomique.

Et surtout, nous sommes engagés à un environnement de travail plus sûr

au sein de l’industrie du soudage. Notre préoccupation principale est que

vous soyez satisfait de ce produit et qu’il fonctionne en toute sécurité.

Veuillez prendre le temps de lire le manuel en entier, en particulier les

Précautions de sécurité.

Si vous avez des questions ou des préoccupations au sujet de votre

nouveau produit Tweco, veuillez contacter notre équipe sympathique et

compétente de service à la clientèle au :

1-800-462-2782 (États-Unis) et au 1-905-827-4515 (Canada),

ou visitez-nous sur notre site Web à www.Tweco.com

Page 31

i

!

AVERTISSEMENT

Lisez et comprenez tout le Manuel et les pratiques de sécurité de l’utilisateur

avant l’installation, le fonctionnement ou l’entretien de l’équipement.

Même si les informations contenues dans ce Manuel représentent le meilleur

jugement du Fabricant, celui-ci n’assume aucune responsabilité pour son usage.

Pistolet de FUSION 250 A MIG

Guide d'installation et d'utilisation

Numéro du Manuel d’Instructions pour : 89200015FC

Publié par :

Victor Technologies International, Inc.

2800 Airport Rd.

Denton, TX. 76207

(940) 566-2000

www.tweco.com

Assistance clientèle américaine: (800) 426-1888

Assistance clientèle de Canada: 905-827-4515

Assistance clientèle internationale: (940) 381-1212

Copyright © 2012, 2013 Victor Technologies International, Inc.

Tous droits réservés.

La reproduction, de tout ou partie de ce manuel, sans l’autorisation écrite de l’éditeur, est

interdite.

L’éditeur n’assume pas et dément toute responsabilité pour perte ou dommage causés à une

partie par erreur ou omission dans ce manuel, si une telle erreur résulte d’une négligence,

d’un accident, ou de toute autre cause.

Date de Parution : 17 décembre 2012

Révisé le : 2 août 2013

Complétez les informations suivantes à des fins de garantie :

Lieu D’achat :

Date D’achat :

Numéro de :

Page 32

ii

Table des matières

CHAPITRE 1: PRECAUTIONS DE SECURITE ..............................................................3

1.01 Mesures de sécurité ......................................................................... 3

CHAPITRE 2: INTRODUCTION ....................................................................................6

2.01 Comment utiliser ce manuel ............................................................ 6

2.02 Réception de l’équipement ............................................................... 6

2.03 Description ....................................................................................... 6

CHAPITRE 3: CARACTÉRISTIQUES DE PISTOLET DE MIG .........................................7

3.01 Classification du pistolet MIG .......................................................... 7

3.02 Facteurs de marche ..........................................................................7

3.03 Guide de choix de pistolet de Fusion TwecoMD 250 A MIG ................ 8

3.04 Identification de parties de fusil de MIG de 250 A Tweco Fusion ..... 8

3.05 Identification des buses pour les Velocity ........................................ 9

3.06 Identification du tube conducteur de 250 A Velocity ...................... 10

CHAPITRE 4: INSTALLATION DE PISTOLET DE TWECOMD DE FUSION MIG ..............11

4.01 Installation d'un pistolet de MIG à branchement direct .................. 11

4.02 Installation d'un connecteur et d'un ensemble adaptateur

MIG-Kwik TwecoMD ........................................................................ 12

CHAPITRE 5: INSTRUCTIONS DE RECHANGE ..........................................................13

5.01 Mise en place d'un Velocity tube-contact ......................................13

5.02 Remplacer le tube conducteur ....................................................... 13

5.03 Identification de conduits de type .................................................. 14

5.04 Remplacer le manche, la détente ................................................... 15

CHAPITRE 6: RÉPARATION DU CABLEHOZMD ..........................................................16

6.01 Outils requis ................................................................................... 16

6.02 Réparation du CablehozMD ............................................................. 16

CHAPITRE 7: ENTRETIEN ET DÉPANNAGE ..............................................................21

CHAPITRE 8: PIÈCES DE RECHANGE POUR 250 A ..................................................22

8.01 Pièces de rechange pour 250 A TwecoMD Fusion MIG .................... 22

8.02 Consommables pour pistolet de TwecoMD Fusion MIG ................... 24

CHAPITRE 9: DÉCLARATION DE GARANTIE ............................................................26

9.01 Période de validité de la garantie .................................................... 26

L'information globale de contact de service

à la clientèle ..........................................................Couverture arrière

Page 33

GUIDE D'INSTALLATION ET D'UTILISATION

389200015FC

CHAPITRE 1:

PRECAUTIONS DE SECURITE

1.01 MESURES DE SÉCURITÉ

!

AVERTISSEMENT

DES BLESSURES GRAVES OU MORTELLES peuvent résulter d’une installation,

d’un usage ou d’un entretien inadéquat de l’équipement de soudage et de

découpage. Une mauvaise utilisation de cet équipement et d’autres pratiques

risquées peuvent être dangereuses. L’opérateur, le superviseur et l’aide doivent

lire et comprendre les avertissements et les instructions de sécurité suivantes

avant d’installer ou d’utiliser tout équipement de soudage ou de découpage et être

conscients des dangers inhérents aux processus de soudage et de découpage.

Une formation et une supervision adaptées sont importantes pour assurer un lieu

de travail sûr. Gardez ces instructions pour une utilisation future. Chaque section

comporte des informations supplémentaires de sécurité et de fonctionnement.

!

AVERTISSEMENT

AVERTISSEMENT : Ce produit contient des produits chimiques, notamment du

plomb, reconnu par l'État de la Californie pour causer des malformations congénitales

et d'autres dommages touchant le système reproductif. Se laver les mains après

manipulation.

UN CHOC ÉLECTRIQUE PEUT CAUSER DES BLESSURES OU LA MORT

L’installation et l’entretien de l’équipement doivent être conformes au Code national

de l’électricité NFPA 70 et aux codes locaux. N’effectuez pas l’entretien ou la

réparation d’équipement en marche. N’opérez pas l’équipement sans isolateurs

ou caches de protection. L’entretien ou la réparation de l’équipement doivent être

effectués uniquement par un technicien qualifié ou par du personnel formé.

Ne touchez pas aux pièces électriques chargées. Portez toujours des gants de soudage au sec

et en bon état. Les vêtements de protection aluminisés peuvent devenir une partie du chemin

électrique. Éloignez les bouteilles d’oxygène, les chaînes, les câbles métalliques, les appareils

de levage, les treuils et les élévateurs de toute partie du circuit électrique. Toutes les liaisons de

terre doivent être vérifiées périodiquement pour déterminer si elles sont solides et appropriées au

courant demandé. En cas de soudage ou de découpage en courant alternatif dans des conditions

d’humidité ou de chaleur où l’opérateur risque de transpirer, il est recommandé d’utiliser des

contrôles automatiques pour réduire la tension à vide et ainsi diminuer les risques de choc

électrique. Lorsque le procédé de soudage et de découpage exige des valeurs de tension en

circuit ouvert dans des machines à courant alternatif supérieur à 80 volts ou dans des machines

à courant continu supérieur à 100 volts, il faut prendre des mesures pour empêcher un contact

accidentel en prévoyant une isolation adéquate ou d autres moyens. Lorsqu’il faut interrompre

les activités de soudage pendant un certain temps, à l’heure du repas ou la nuit, par exemple, il

faut enlever toutes les électrodes du porte-électrode et mettre hors tension l’alimentation pour

éviter tout contact accidentel. Gardez les pistolets MIG, les porte-électrodes, les torches TIG, les

torches à plasma et les électrodes loin de l’humidité et de l’eau. Voir les références en matière

de sécurité et d’utilisation n° 1, 2 et 8.

Page 34

4

GUIDE D'INSTALLATION ET D'UTILISATION

89200015FC

LA FUMÉE, LES ÉMANATIONS ET LES GAZ PEUVENT ÊTRE DANGEREUX POUR VOTRE SANTÉ

La ventilation doit être suffisante pour enlever la fumée, les émanations et les

gaz pendant le fonctionnement de la torche afin protéger les opérateurs et les

autres personnes présentes dans la zone. Les vapeurs de solvants chlorés peuvent

former un gaz toxique appelé « Phosgène » si elles sont exposées au rayonnement

ultraviolet d un arc électrique. Il faut enlever de la zone de travail tous les solvants,

décapants et sources potentielles de ces vapeurs. Servez-vous d’appareils respiratoires à

adduction d’air si la ventilation n’est pas suffisante pour enlever toutes les émanations et gaz.

L’oxygène alimente les incendies et en accélère la propagation il ne faut jamais l’utiliser à

des fins de ventilation. Voir les références en matière de sécurité et d’utilisation n° 1, 2,

3 et 4.

L LES RAYONS DE L’ARC, LES SCORIES ET LES ÉTINCELLES CHAUDS PEUVENT BLESSER

LES YEUX ET BRÛLER LA PEAU

Les procédés de soudage et de découpage produisent une chaleur extrême

localisée et de puissants rayons ultraviolets. N’essayez jamais de souder ou

de couper sans casque soudage conforme aux normes du gouvernement

fédéral et muni d’une lentille appropriée. Des lentilles à filtre de numéro 12

à 14 fournissent la meilleure protection contre le rayonnement de l’arc. Dans

un endroit confiné, il faut éviter que les rayons reflétés de l’arc n’entrent autour du casque. Il

faut utiliser des rideaux de protection approuvés et des lunettes de protection appropriées pour

protéger les autres personnes se trouvant aux abords. Il faut aussi protéger la peau nue des

rayons de l’arc, de la chaleur et du métal fondu. Portez toujours des gants et des vêtements

de protection. Toutes les poches doivent être fermées et les manchettes, cousues. Il faut porter

un tablier, des manches, des guêtres, etc. en cuir pour effectuer de soudage ou de découpage

et dans le cas des activités intensives nécessitant de grandes électrodes. Les chaussures de

sécurité montantes fournissent une protection suffisante contre les brûlures aux pieds. Pour

obtenir une plus grande protection, portez des guêtres en cuir. Il ne faut pas utiliser de produits

capillaires inflammables avant d’effectuer des activités de soudage ou de découpage. Portez

des bouchons d’oreilles pour vous protéger les oreilles des étincelles. Lorsqu’il est possible

de le faire dans la zone de travail, l’opérateur doit s’isoler dans une cabine individuelle recouverte

d’un revêtement à faible réflectivité, comme l’oxyde de zinc. Voir les références en matière

de sécurité et d’utilisation n° 1, 2 et 3.

LES ÉTINCELLES DE SOUDAGE PEUVENT CAUSER DES INCENDIES ET DES EXPLOSIONS

Les combustibles atteints par l’arc, les flammes, les vols d’étincelles, les scories

chaudes et les matériaux chauffés peuvent causer des incendies et des explosions.

Enlevez les combustibles de la zone de travail ou mettez en place du personnel

de surveillance. Évitez les vêtements huileux ou graisseux, car une étincelle peut

y mettre le feu. Ayez un extincteur à proximité et sachez comment l’utiliser. Si

l’activité de soudage ou de découpage doit être fait contre un mur, une cloison, un plafond ou un

toit, il faut prendre des précautions pour d’enflammer des combustibles qui se trouveraient à

proximité, de l’autre côté. Ne soudez pas et ne coupez pas de conteneurs ayant contenu des

combustibles. Il faut aérer tous les espaces creux, les cavités et les conteneurs avant de les

soumettre au soudage ou au découpage afin d’évacuer tout l’air ou le gaz qui peut s’y trouver. Il

est recommandé d’effectuer une purge avec du gaz inerte. N’utilisez jamais d’oxygène dans une

tête de soudage. N’utilisez que des gaz inertes ou des mélanges de gaz inertes, conformément

aux exigences du procédé. L’utilisation de gaz combustibles comprimés peut causer des explosions

entraînant des blessures ou la mort. Le fait d’utiliser l’arc sur une bouteille de gaz comprimé peut

endommager la bouteille ou causer une explosion. Voir les références en matière de sécurité

et d’utilisation n° 1, 2, 5, 7 et 8.

Page 35

GUIDE D'INSTALLATION ET D'UTILISATION

589200015FC

LE BRUIT PEUT ENDOMMAGER L’OUÏE

Le bruit du procédé de l’arc avec électrode en carbone et jet d’air peut endommager

l’ouïe. Portez un dispositif de protection de l’ouïe pour vous protéger lorsque le

niveau de bruit dépasse les normes de l’OSHA. Les opérateurs et le personnel aux

abords doivent porter un dispositif de protection de l’ouïe approprié pour les protéger

efficacement contre le bruit. Voir les références en matière de sécurité et

d’utilisation n° 1, 2 et 6.

RÉFÉRENCES EN MATIÈRE DE SÉCURITÉ ET D’UTILISATION

1. Code of Federal Regulations (OSHA), section 29, partie 1910.95, 132, 133, 134,

139, 251, 252, 253, 254 et 1000. U.S. Government Printing Office, Washington, DC

20402.

2. ANSI Z49.1 « Safety in Welding and Cutting ».

3. ANSI Z87.1 « Practice for Occupational and Educational Eye and Face Protection ».

4. ANSI Z88.2. « Standard Practice for Respiratory Protection ». American National

Standards Institute, 1430 Broadway, New York, NY 10018.

5. AWS F4.1. « Recommended Safe Practices for Welding and Cutting Containers ».

6. AWS C5.3. « Recommended Practices for Air Carbon-Arc Gouging and Cutting ». The

American Welding Society, 550 NW Lejeune Rd., P.O. Box 351040, Miami, FL 33135.

7. NFPA 51B. « Fire Prevention in Cutting and Welding Processes ».

8. NFPA-7. « National Electrical Code » (code national de l’électricité). National Fire

Protection Association, Battery Park, Quincy, MA 02269.

9. CSA W117.2. « Règles de sécurité en soudage, coupage et procédés connexes ».

Association canadienne de normalisation, 178 boul. Rexdale, Rexdale, Ontario,

Canada M9W 1R3.

Page 36

6

GUIDE D'INSTALLATION ET D'UTILISATION

89200015FC

CHAPITRE 2: INTRODUCTION

2.01 COMMENT UTILISER CE MANUEL

Pour assurer une exploitation sécuritaire de l’appareil, lire le manuel dans son intégralité,

notamment le chapitre concernant les directives de sécurité et les avertissements.

Tout au long du manuel, vous retrouverez les mots AVERTISSEMENT, MISE EN GARDE et

REMARQUE. Soyez particulièrement attentif aux renseignements fournis sous ces symboles.

Ces symboles spéciaux se reconnaissent facilement comme suit :

AVIS

L’avis donne de conseils d’installation ou des informations d’entretien qui

sontimportants mais n’impliquent pas derisques.

MISE EN GARDE

La mention d’mise en garde indique une situation potentiellement dangereuse

qui, sans précautions, peut entraîner des dom.

!

AVERTISSEMENT

L’avertissement indique une situation potentiellement dangereuse qui, sans

précautions, peut entraîner des dommages graves voire mortels.

2.02 RÉCEPTION DE L’ÉQUIPEMENT

À la réception de l’appareil, vérifiez le contenu en le comparant aux articles décrits sur la

facture pour vous assurer d’avoir tous les composants et inspectez l’appareil à la recherche

d’éventuels dommages provoqués par l’expédition. En cas de dommage, avisez le transporteur

immédiatement pour procéder à une réclamation. Fournissez tous les renseignements

nécessaires relatifs à une réclamation concernant un dommage ou une erreur de livraison.

Utilisez les coordonnées de l’emplacement le plus près de chez vous, répertorié à la troisième

couverture du manuel. Inscrivez tous les numéros d’identification de l’appareil comme décrit

ci-dessus et fournissez une description complète de la pièce défectueuse ou de l’erreur à la

livraison.

Pour recevoir des exemplaires supplémentaires ou de remplacement de ce manuel, veuillez

communiquer avec TwecoMD à l'adresse et au numéro de téléphone correspondant à votre

région, lesquels sont présentés sur la couverture arrière de ce manuel. Spécifiez le numéro

du manuel (inscrit à la page i). Il vous est aussi possible de télécharger un exemplaire de ce

manuel à partir de notre site Web www.tweco.com.

2.03 DESCRIPTION

Les pistolets MIG Tweco sont dotés de connexions arrières permettant de les brancher

directement dans la plupart des têtes de soudage MillerMD, LincolnMD et Euro. Ces pistolets sont

des pistolets MIG à branchement direct. Les pistolets MIG Tweco sont également munis de la

connexion MIG-Kwik, qui est reconnue depuis longtemps. La connexion MIG-Kwik, lorsqu'elle

est utilisée avec un jeu d'adaptateurs, permet d'installer un pistolet MIG Tweco sur presque

toutes les têtes de soudage. Pour une liste des jeux d'adaptateurs offerts, consulter la liste des

jeux d'adaptateurs Tweco (formulaire n° TAKL-97) ou appeler le service à la clientèle Tweco.

MILLER est une marque déposée de Miller Electric Mfg. Co.; ESAB est une marque déposée d'ESAB AB ; LINCOLN

est une marque déposée de LINCOLN Electric Co.; Les marques déposées mentionnées ci-dessus ne sont aucune

manière filiale avec Tweco Products, Inc. ou Victor Technologies. Tweco est une marque déposée de Victor Technologies.

Page 37

GUIDE D'INSTALLATION ET D'UTILISATION

789200015FC

CHAPITRE 3:

CARACTÉRISTIQUES DE PISTOLET DE MIG

3.01 CLASSIFICATION DU PISTOLET MIG

Procédé Soudage MIG/MAG

Méthode de guidage Guidage manuel

Classe de tension pour les circuits de soudage

et de commande

L (crête de 113 V)

Type de refroidissement Air ou gaz de refroidissement

Type de Gaz de protection Tous les types

3.02 FACTEURS DE MARCHE

Facteurs de

Marche

Pistolet de MIG

250 AMP

10% 320

35% 290

80% 250

100% 195

Les cycles de travail ci-dessus ont été établis expérimentalement, avec les paramètres suivants :

Paramètre MIG

(protection gazeuse inerte)

MAG

(protection gazeuse active)

Type de tension C.C. (D.C.)

Gaz de protection Argon Gaz mixte argon/CO2 (80/20, 75/25)

Débit gazeux de 30 à 35 pi³/h (de 14,2 à 16,5 l/m)

Longueur du câble du

pistolet

3 m (10 pieds)

3,7 m (12 pieds)

4,6 m (15 pieds)

6 m (20 pieds)

7,6 m (25 pieds)

Polarité de l'électrode Positif

Diamètre du fil

Taille du fil (électrode continue)

250 A

0,6 mm (0,023 po)

0,8 mm (0,030 po)

0,9 mm (0,035 po)

1,0 mm (0,040 po)

1,2 mm (0,045 po)

1,3 mm (0,052 po)

1,2 mm (3/64 po)

1,6 mm (1/16 po)

2,0 mm (5/64 po)

2,4 mm (3/32 po)

2,8 mm (7/64 po)

3,2 mm (1/8 po)

Page 38

8

GUIDE D'INSTALLATION ET D'UTILISATION

89200015FC

3.03 GUIDE DE CHOIX DE PISTOLET DE FUSION TWECOMD 250 A

MIG

Connecteur

arrière

PISTOLET DE 250 A MIG*

Connecteur

arrière

(Remplacement)

No de pièce

No de stock

No de pièce

No de stock

No de pièce

No de stock

No de pièce

No de stock

No de pièce

No de stock

No de pièce

No de stock

10 câble de

pied

12 câble de

pied

15 câble de

pied

20 câble de

pied

25 câble de

pied

Tweco

MD

(4-épingles)

FV210-3545

1023-1059

FV212-3545

1023-1060

FV215-3545

1023-1061

FV220-3545

1023-1062

FV225-3545

1023-1063

350-174H

2035-2110

Miller

MD

FV210M-3545

1023-1067

FV212M-3545

1023-1068

FV215M-3545

1023-1069

FV220M-3545

1023-1070

FV225M-3545

1023-1071

350-174MH

2035-2111

Lincoln

MD

----

FV212L-3545

1023-1084

FV215L-3545

1023-1085

---- ----

350-174LH

2035-2112

Euro-Kwik

FV210X-3545

1023-1089

FV212X-3545

1023-1090

FV215X-3545

1023-1091

----

FV225X-3545

1023-1092

174EX-1

2040-2276

252i

ThermalArc

---- ----

FV215TA3545

1023-1097

---- ----

350-174H

2035-2110

*Le connecteur arrière est fourni de série

3.04 IDENTIFICATION DE PARTIES DE FUSIL DE MIG DE 250A

TWECO FUSION

AVIS

Les fusils de MIG de Fusion de Tweco, en règle général, avoir une nomenclature

spécifique incorporée dans chaque numéro de pièce pour aider détermine la taille

de fil de chaque fusil de MIG.

Exemple de numéro de pièce :

FV215TA3545

T=Tweco

TA=Tweco (Paquet)

L=Lincoln

M=Miller

X, XE=Euro-Kwik

Fusion Velocity

4,6 M (15 pied) câble pour 250 A,

0,9 mm - 1,2 mm Télégraphier la Capacité

(.035 po -.045 po)

Si un numéro de pièce « FV215TA3545 » identifierait le fusil de MIG comme un : le Fusil de MIG

DE 250A de Fusion de Tweco le tas de paquet avec un connecteur postérieur de 8 épingles,

4,6 M (15 pied) le câble long et ayant un 0,9 mm à 1,2 mm (0,035 po à 0,045 po) la capacité

de fil de diamètre.

Si un numéro de pièce « FV2253545 » identifierait le fusil de MIG comme un : le Fusil de MIG

DE 250A de Fusion de Tweco avec un Tweco de 4 épingles le connecteur postérieur, 7,6 M

(25 pied) le câble long et ayant un 0,9 mm à 1,2 mm (0,035 po à 0,045 po) la capacité de fil

de diamètre.

MILLER est une marque déposée de Miller Electric Mfg. Co.; ESAB est une marque déposée d'ESAB AB ; LINCOLN

est une marque déposée de LINCOLN Electric Co.; Les marques déposées mentionnées ci-dessus ne sont aucune

manière filiale avec Tweco Products, Inc. ou Victor Technologies. Tweco est une marque déposée de Victor Technologies.

Page 39

GUIDE D'INSTALLATION ET D'UTILISATION

989200015FC

3.04 IDENTIFICATION DES VELOCITY TUBES-CONTACTS

Les Velocity tubes-contacts peuvent être identifiés par le type de tube-contact et le numéro de pièce

inscrit sur chaque tube-contact.

Exemple de numéro de pièce :

VTSARZT30

Tube contact

de type Velocity

Vide =CUIVRE,

RZ=Chrome-Zirconium,

RS=Argent-Zirconium

Vide = aucun

T = en pointe (Tapered),

S=petit,

M=moyen,

L=gros

A = aluminium,

Vide = autre

Dimension du fil : 23=0,023 po 116=1/16 po

30=0,030 po 564=5/64 po

35=0,035 po 332=3/32 po

40=0,040 po 764=7/64 po

45=0,045 po 18=1/8 po

52=0,052 po 364=3/64 po

Ainsi, par exemple, le numéro de pièce « VTSARZT30 » signifierait : type de bout de Velocity, petit,

aluminium, alliage chrome-zirconium, en pointe pour les fils ayant un diamètre de 0,030 po.

Le numéro de pièce « VTMA40 » signifierait quant à lui : type de bout de Velocity, moyen,

aluminium, cuivre, pour les fils ayant un diamètre de 0,040 po.

3.05 IDENTIFICATION DES BUSES POUR LES VELOCITY

Les buses pour les pistolets de MIG munis des Velocity tubes-contacts peuvent être identifiées par

leur type et le numéro de pièce inscrit sur chacune des buses.

Exemple de numéro de pièce :

Vide = standard,

H = robuste

VNSH50FS

Buse creuse

de type Velocity

Vide = en retrait standard

F = affleurante

P = en saillie

R = en retrait de 6,35 mm (¼ po)

FAS=point de soudure

FC=Noyau de flux

S=petite buse,

M=buse moyenne,

L=grosse buse

Diamètre intérieur

de l’orifice : 37=3/8 po 62=5/8 po

50=1/2 po 75=3/4 po

Vide = enfilée

S = coulissante

Ainsi, par exemple, le numéro de pièce « VNSH50FS » signifierait : type de buse creuse de

Velocity, petite buse, pour usage robuste, diamètre intérieur de l'orifice de 0,50 po, embout

affleurant, Glisser la crise.

Page 40

10

GUIDE D'INSTALLATION ET D'UTILISATION

89200015FC

Le numéro de pièce « VNS50 » signifierait quant à lui : type de buse creuse de Velocity, petite

buse, pour usage normal, diamètre intérieur de l'orifice de 0,50 po, embout en retrait standard,

Enfiler la crise.

3.06 IDENTIFICATION DU TUBE CONDUCTEUR DE 250 A VELOCITY

Les tubes conducteurs pour le tube-contact Velocity des pistolets MIG Tweco Fusion peuvent être

identifiés à l'aide du type et du numéro de pièce figurant sur chaque tube.

Exemple de numéro de pièce :

S=petit tube (Small Tip),

M=tube moyen (Medium Tip),

L=gros tube (Large Tip)

FVCTS45

Fusion

Tube conducteur

Velocity

Angle de cintrage : 45°, 60° ou 180°

Ainsi, le numéro de pièce « FVCTS45 » signifierait : Pistolet Tweco Fusion, tube conducteur de

250 A Velocity, petit tube, angle de pliage de 45 degrés.