Page 1

Operator’s Ready Reference

Page 2

What is plasma?

Plasma is a gas heated to an extremely high temperature and ionized so that it becomes

electrically conductive. Plasma arc cutting uses the plasma as an electrode to transfer a

electrical arc to the work piece. The heat of the arc melts the work piece and the force of the

plasma and shield gases blow away the molten metal to cut the work piece.

Different metals react differently to plasma cutting. Carbon steel can be oxidized, and is usually

cut with a plasma containing oxygen to take advantage of the exothermic process. Higher

levels of oxygen in the plasma result in higher heat and higher rates of oxidation. The result is

a faster and cleaner cut. Stainless steel and aluminum are not subject to rapid oxidation and

depend entirely on the plasma’s heat for the cutting process. Because plasma produces much

higher heat than the oxygen-fuel cutting process, plasma can cut stainless steel and aluminum

quickly and cleanly.

Choosing a plasma process

Thermal Dynamics systems offer a variety of plasma cutting processes for precision and general

purpose cutting. Ultra-Cut systems offer precision cutting as well as conventional cut options.

Auto-Cut O2 systems offer high speed oxygen cutting, precision non-ferrous and conventional

cut options. Auto-Cut systems offer conventional mild steel and precision non-ferrous options.

Process

Plasma Shield

O

2

O

2

N

2

Air

O

2

H2O Precision Non-Ferrous

Mild Steel Precision 50-300 Amps

and High Speed Oxygen Process

Mild Steel Precision at 30 Amps Weld Ready Cut Surface

Used For Advantages

Weld Ready Cut Surface

Best Cut Quality on Stainless

and Aluminum to ¾”

Better Parts Life Than Air

N

2

N

2

Conventional Thin Non-Ferrous

Better Cut Surface Than Air on

Non-Ferrous

Thicker Non-Ferrous

H35 N

2

>¾” Aluminum

>¾” Stainless

Air Air Conventional Mild Steel

Faster Cutting on Thicker SS and

Aluminum

Weld Ready Cut Surface

H35=65%Ar/ 35%H

Economical Cost of Operation

Good Cut Quality

Air Air Conventional Non-Ferrous Economical Cost of Operation

page 2

2

Page 3

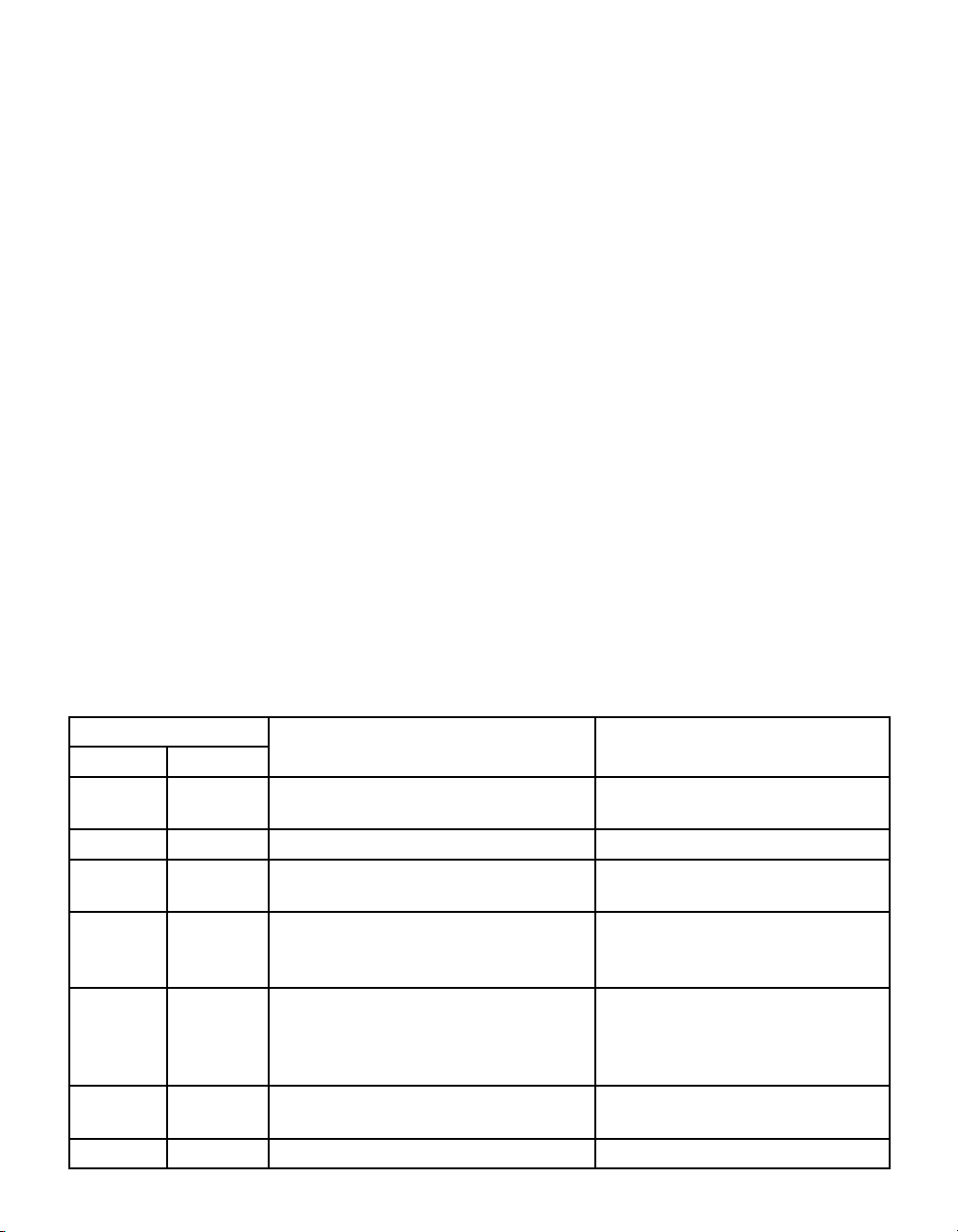

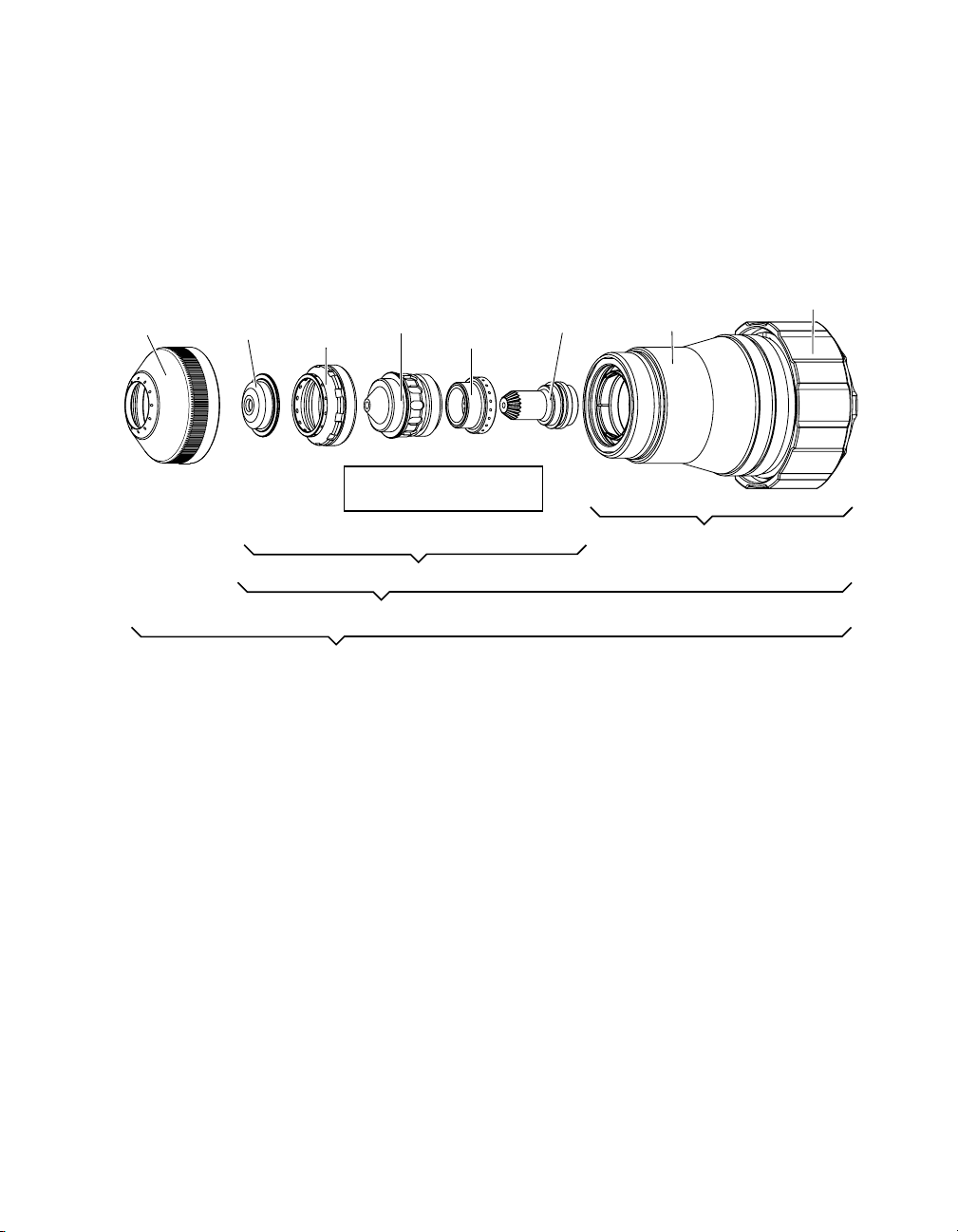

Cut charts

Cartridge

21-1020

Electrode

21-1068

Plasma

Gas Distributor

21-1040

Tip

21-1050

Shield Cap

21-1024

Shield Cup

21-1016

Art # A-06768

Shield

Gas Distributor

21-1082

Thermal Dynamics provides a cut parameters chart for every process and output current combination.

Material

Mild Steel

Current

Level

30A

O2 Plasma / O2 Shield

Process

Consumable Parts

Material

Thickness

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

20 0.036 60 22 120 21 120 128 0.050 130 0.120 0.2 0.058

16 0.060 60 22 120 21 120 143 0.050 60 0.120 0.3 0.070

14 0.075 60 22 120 21 120 145 0.070 45 0.120 0.3 0.072

12 0.105 60 22 120 21 120 148 0.110 40 0.150 0.3 0.074

10 0.135 80 22 120 21 120 154 0.130 30 0.150 0.3 0.085

3/16 0.188 80 22 120 21 120 154 0.120 25 0.150 0.4 0.075

Gas Control

Settings

Material

Thickness

(mm) (Bar) Ball (Bar) Ball (Bar) Volts

1 4.1 22 8.3 21 8.3 130 1.3 3050 3.0 0.2 1.5

2 4.1 22 8.3 21 8.3 145 1.9 1130 3.1 0.3 1.8

3 4.1 22 8.3 21 8.3 150 3.0 910 3.8 0.3 2.0

4 5.5 22 8.3 21 8.3 154 3.2 710 3.8 0.3 2.1

5 5.5 22 8.3 21 8.3 155 3.0 640 3.8 0.4 1.9

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

30A Mild Steel (O2/O2)

Cut Flow Rates /

Pressures

Plasma (O2) Shield (O2)

Cut Flow Rates /

Pressures

Plasma (O2)

Shield (O2)

Torch

Height

(in)

Travel

Speed

(ipm) (in) (sec) (in)

Arc

Voltage

Working

±0.005

Arc Voltage for

Torch Height Control

Travel

Torch

Arc

Voltage

Working

Height

(mm)

±0.1

Speed

(mm/

min)

Initial

Initial

Pierce

Delay

Pierce

Delay

@ Rec.

Speed

Width

@ Rec.

Speed

Piercing

Height

Piercing

Height

(mm) (sec) (mm)

Kerf Size

Kerf

Width

Kerf

Pierce

Data

Plasma Marking

Parameters

15A Arc Current

Burn-through

thicknesses

< 1/16” (0.063”) /

may

occur on

1.6 mm

Pre Flow

Pressure

(N2)

20psi

1.4 bar

Marking (with 30A Mild Steel Parts)

80 psi

5.5 bar

Arc

Voltage

145

Cut Flow Rates /

Pressures

Plasma

Pressure (N2)

Ball Press Ball Press Volts

40 psi

20

2.8 bar

Shield

Pressure N2)

70

page 3

Torch

Working

Height

In ±0.005 /

mm ± 0.1

0.1

2.5

Travel

Speed

ipm /

mm/min

300

7600

Initial

Piercing

Height

In ±0.005 /

mm ± 0.1

0.1

2.5

Pierce

Delay

(sec)

0

Marking

Quality

Degrades

as

Thickness

Decreases.

Page 4

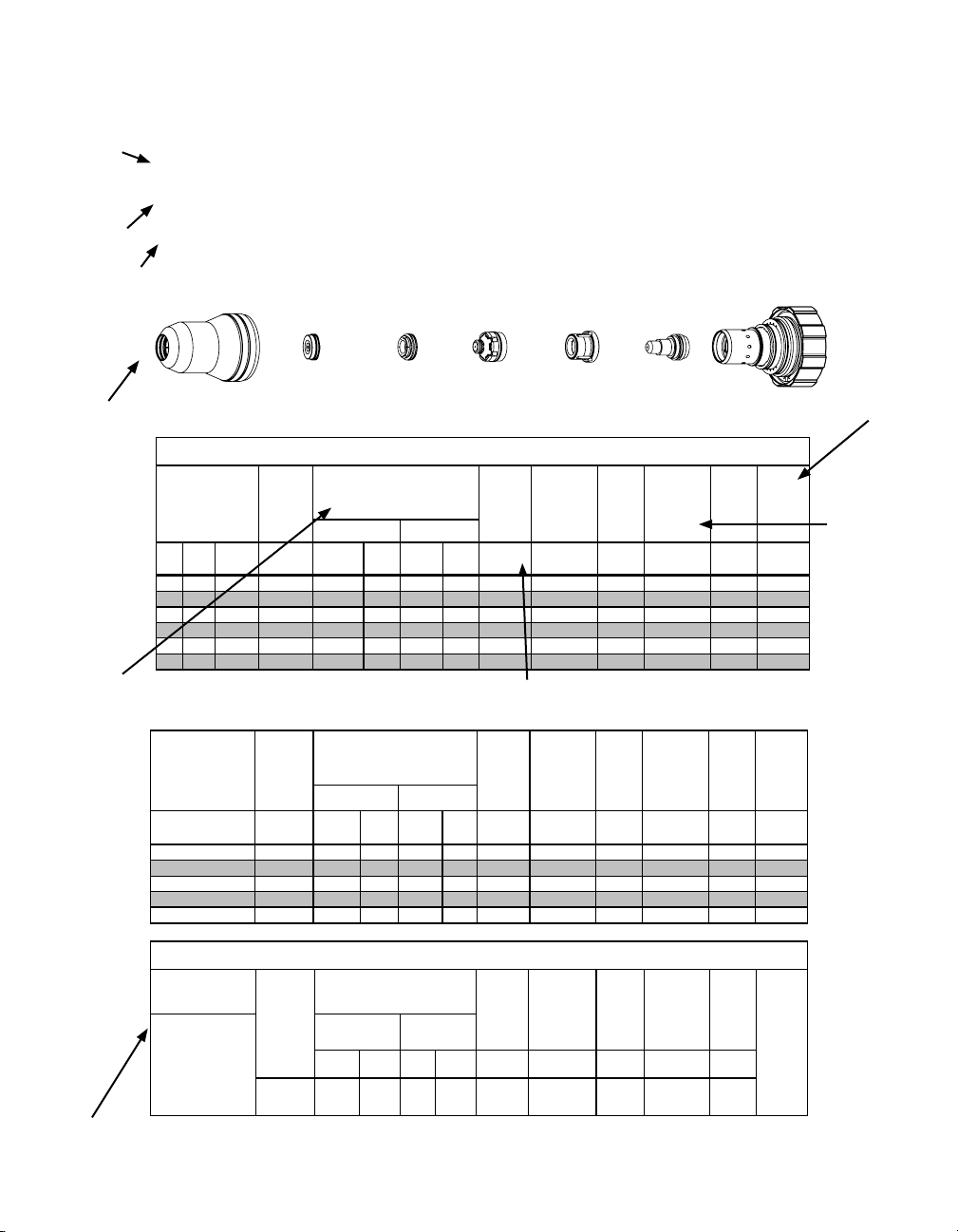

Consumable parts

Cartridge Covers

Upper O-Ring

on Torch Tip

Shield Cap Protrudes

0.063-0.083" (1.6 - 2.1 mm)

Electrode

Plasma Gas

Distributor

Tip

Shield Gas

Distributor

Shield Cap

Upper O-Ring

on Tip

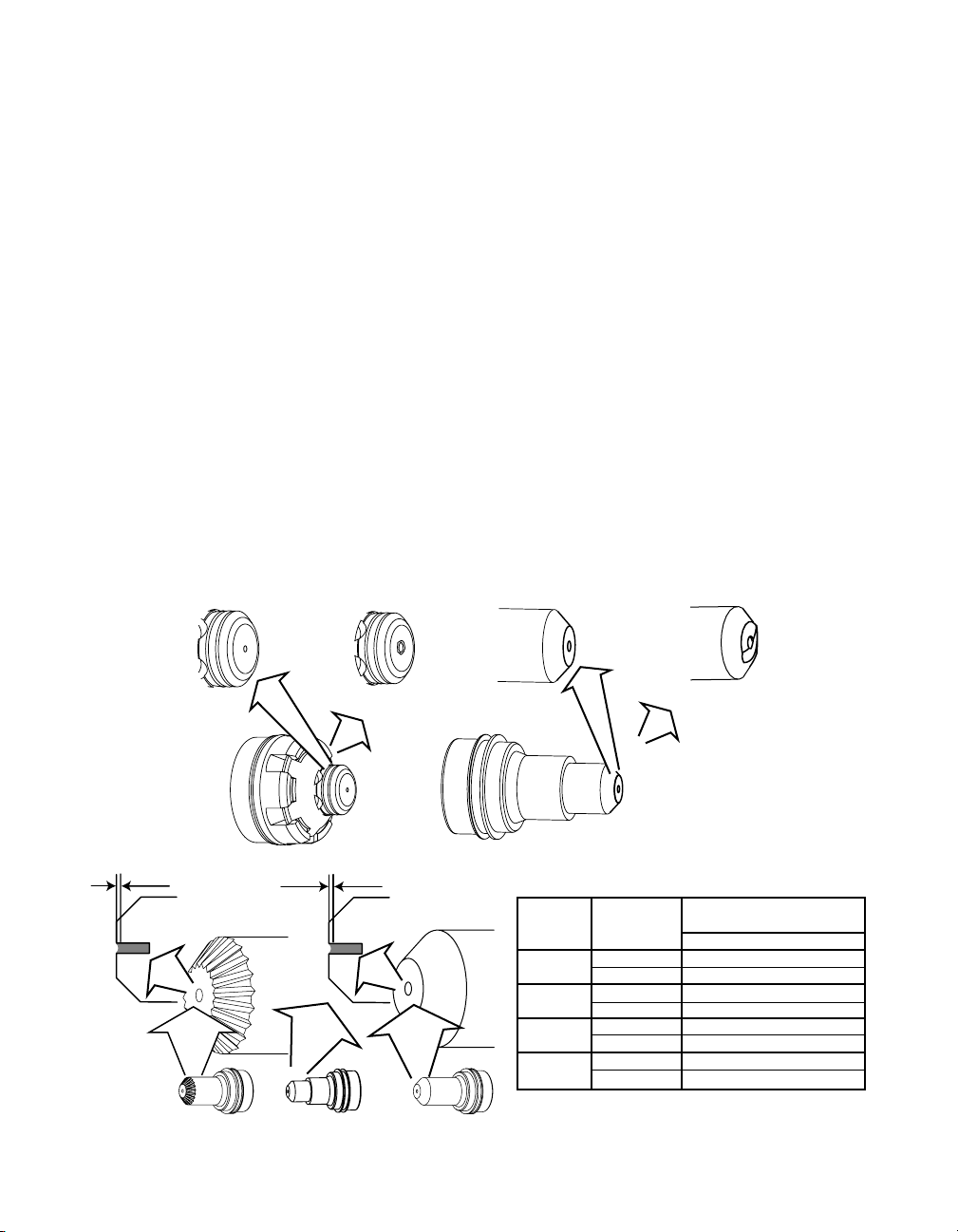

1: Stack Parts

2: Press Cartridge onto Stacked Parts

4: Check Shield Cap Protrusion

Art # A-04716

No Gaps

Between Parts

3: Thread Shield Cup onto Cartridge

Shield Cap

Shield Cup

Parts selection

Consumable parts are specifically designed to perform in specific conditions. Using the

wrong consumable parts will result in short parts life and poor cut quality. Use the cut charts to

determine which consumable parts to use in any specific application.

Installing consumable parts

The XT torch is a precision instrument. Take care when installing consumable parts to keep the

parts clean and free from any contamination that might cause a gas or coolant leak inside the

consumable parts cartridge.

Assembly Sequence, 30-150 Amp Consumables

7.04 Torch Consumables Installation

Do not install consumables into the Cartridge

while the Cartridge is attached to the Torch Head.

Keep foreign materials out of the consumables and Cartridge.

Handle all parts carefully to avoid damage,

which may affect torch performance.

1. Install the consumables as follows:

WARNINGS

Art # A-03887

page 4

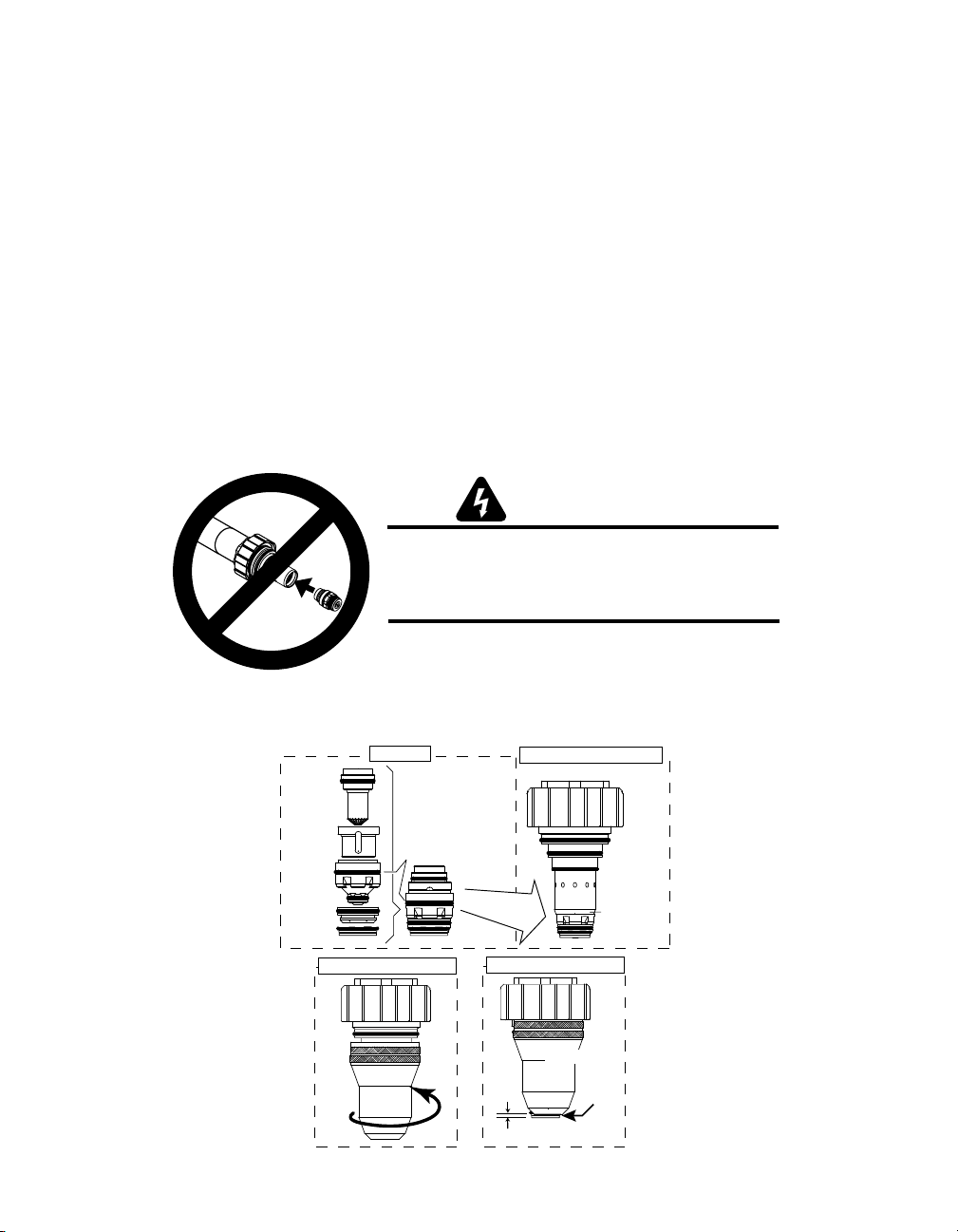

Page 5

Tip

Electrode

Plasma Gas

Distributor

Shield Cap

Shield Gas

Distributor

Shield Retainer

Shield Cup

Assembly sequence:

Cartridge

1

2

3

4

Art # A-07424

Assembly Sequence, 200/300 Amp Consumables

To ensure proper assembly of the torch cartridge:

1. Place the cartridge assembly on a clean, flat surface

2. Assemble the consumable parts from electrode to shield cap.

3. Install the consumable parts in the cartridge

4. Install the shield retainer to complete the cartridge assebly.

page 5

Page 6

Consumable Parts Life

Tips and electrodes wear under normal usage. Tips and electrodes should be

changed before failure to avoid damaging the other consumable parts or the material to be

cut. Optimum life will vary according to specific cutting conditions. Keep a count of cuts

per set of tip and electrode in a given application to establish the most effective time to

change consumable parts sets. The pilot arc is more erosive to the tip and electrode than

the cutting arc is, so an application that demands more pilot and pierce sequences will erode

consumable parts faster than an application that uses longer cuts but fewer arc starts.

Tip – Tips wear as the arc erodes the tip orifice. When the tip is no longer round or has

become enlarged, it should be replaced. Tip life is best when cuts are made at optimum

speed. Cutting too fast or too slow causes the arc to bend and biases erosion, resulting

in an orifice that is oval shaped.

Electrodes – The electrode wears from the hafnium or tungsten insert at the end of the

electrode. The face of the insert is liquefied by the heat of the arc and droplets erode from

the insert as cutting progresses. Proper gas flow will support longer electrode life.

An electrode should be replaced when the electrode insert is pitted to a depth of 1/16 inch

(see chart below).

Replace the Gas Distributor if it is charred or cracked

Replace the Gas Disributor if the flange is damaged in any way

Replace the tip and/or electrode if they are worn

Torch

Electrodes

Good Tip

Worn Tip

Good Electrode

page 6

Worn Electrode

Art # A-04745_AB

Amperage Plasma Gas Recommended Wear Depth

for Replacement

30

50

70

100

Inch mm

O2 0.04 1

Air 0.04 2

O2 0.04 1

Air 0.08 2

O2 0.04 1

Air 0.08 2

O2 0.04 1

H35 0.08 2

Art # A-04704_AB

Page 7

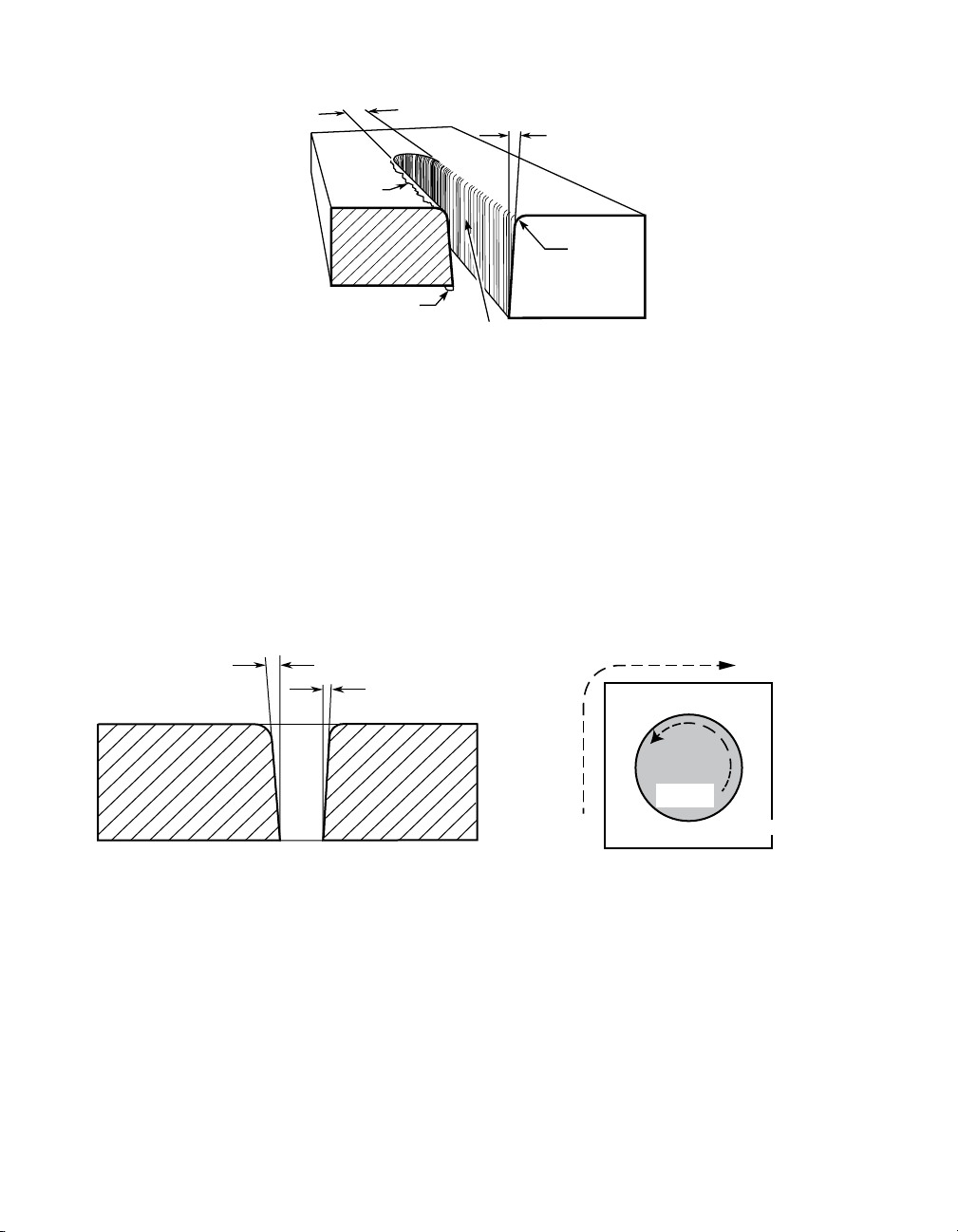

Cut characteristics

Kerf Width

Cut Surface

Bevel Angle

Top

Spatter

Top Edge

Rounding

Dross

Build-Up

Cut Surface

Drag Lines

Cut Surface – Cut surface is influenced by process and positioner precision more than by other

parameters. For smoothest cut face on different materials, use: mild steel – oxygen plasma

Direction of cut – The plasma has a clockwise swirl as it exits the torch tip. Considering the

direction of torch travel, the right side of the cut will always show less bevel and top edge

rounding than the left side. Program cuts so that the right side will be on the finished part and

the left side will be scrap.

A-00007

stainless < ¾’ – nitrogen / WMS

> ¾” – H35 / nitrogen

aluminum < ¾’ – nitrogen /WMS

> ¾” – H35 / nitrogen

Left Side

Cut Angle

Right Side

Cut Angle

A-00512

Clockwise

Scrap

Counter-

Clockwise

Scrap

Workpiece

Art # A-04182

Top edge rounding – Caused by the heat of the plasma arc at the top surface of the cut.

Proper torch height control can minimize or eliminate top edge rounding. Excessive top

edge rounding is often a sign that torch cutting height should be lower.

Top spatter – Top spatter is caused by fast cutting or by too high a torch height setting.

Reducing cut speed or lowering torch cutting height will reduce top spatter. Top spatter is

easy to remove.

Bottom dross – Molten metal may build up on the bottom of the plate. Faster cut speeds

reduce bottom dross as less material is melted. Bottom dross that is easy to remove is an

indication of slow cutting speed. Bottom dross that is difficult to remove or requires grinding

is an indication of too fast cut speed.

page 7

Page 8

Kerf – Kerf width is specified in the cut charts and can be calculated into cut programs.

The kerf width is related to tip orifice size and higher current cutting will produce a wider kerf.

Higher torch height will also result in a wider kerf.

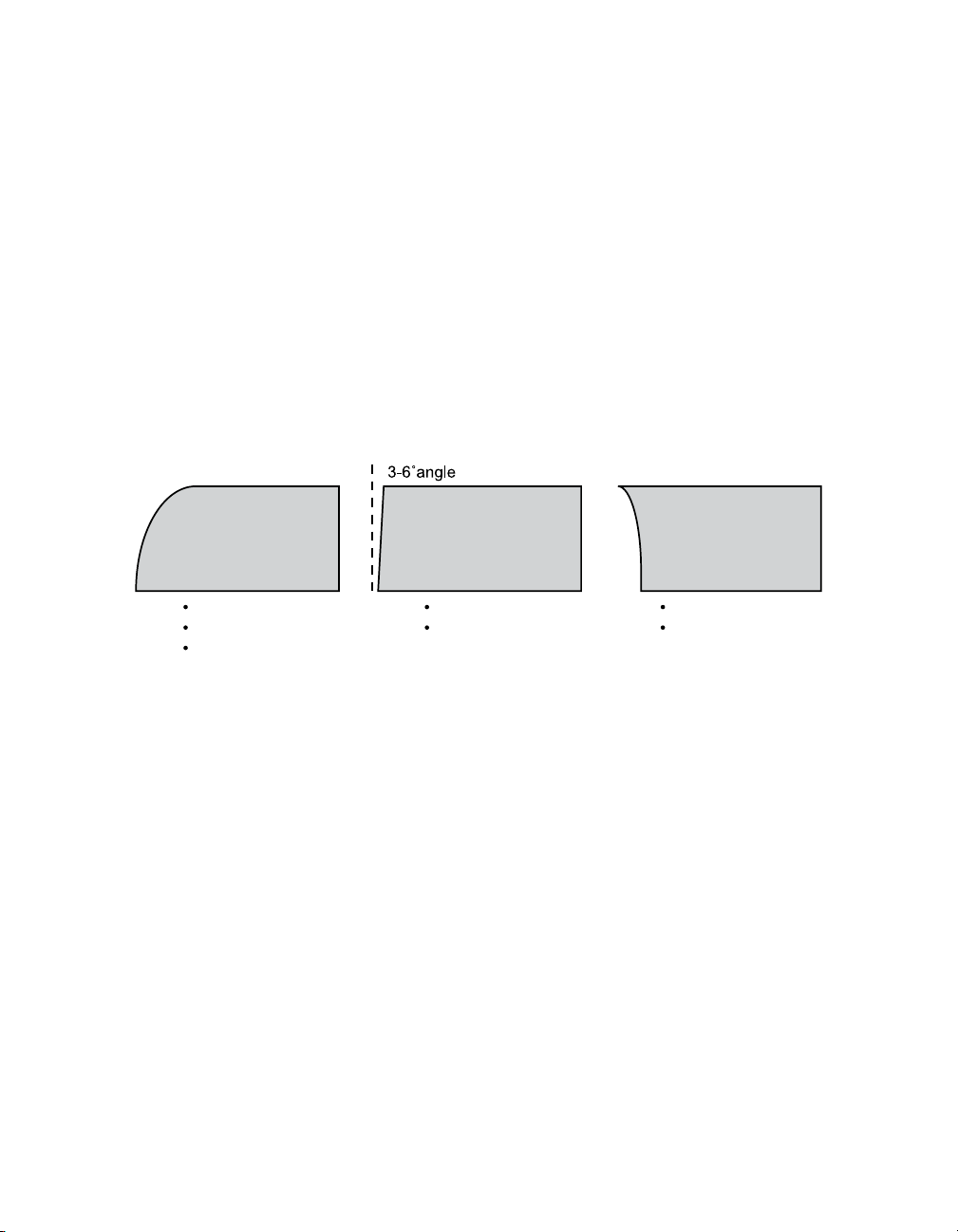

Bevel angle – Precision cut processes produce bevel angle in the 0-3° range. Conventional

plasma cutting will produce larger bevel angles. Proper torch height control will produce the

smallest bevel angle, as well as improved kerf width and minimal top edge rounding. A slower

cut speed can be used when cutting circles and corners to reduce bevel.

Effect of Height Control Settings – General Purpose Cut

Correct Voltage

High Voltage

Positive Bevel

Wide Kerf

Top Dross

Minimal Bevel

Normal Kerf

Low Voltage

Negative Bevel

Wide Kerf

Nitride contamination – Air plasma cutting will produce nitride contamination of the cut face

on carbon steel and stainless steel. Nitride contaminated surfaces will require grinding before

welding to eliminate weld porosity. The depth of the contamination will be close to the Heat

Affected Zone, between .005 and .010” in depth.

Nitride contamination can be eliminated by using a process other than air plasma;

oxygen plasma for carbon steel, H35 or nitrogen/WMS for non-ferrous materials.

Cut speed – Cut charts specify a cut speed that will produce high quality cut performance.

Any plasma system can cut at faster or slower speeds, but cut performance will be affected.

Cut speed should be reduced for corners and tight curves to reduce bevel and corner rounding.

Optimum cut speeds produce a trailing arc which will be visible in the slight arc lines

visible in the cut face. Arc lines are useful for evaluating cut speed on mild steel, but less so

for aluminum and stainless steel. Arc lines that trail at less than 15° indicate that cut speed is

in the optimum range when air or oxygen plasma processes are used. Optimum cut quality in

precision cutting processes will result in arc lines that are near vertical. A slow cut speed may

show arc lines that angle forward and a fast cut speed will show arc lines at a sharper angle

relative to the top of the plate.

page 8

Page 9

Aluminum

Cut Speed Too Fast

Cut drag lines are more than 15 degrees trailing the torch (torch movement right to left)

High speed bottom dross, easy to remove

Cut Speed Correct

Cut drag lines trail are visible, but cut surface is smooth. No dross

Cut Speed Too Slow

Cut drag lines are more pronounced and cut surface is rougher

page 9

Page 10

Stainless Steel (H35 plasma)

Cut Speed Too Fast

Gold heat discoloration swept in both directions

Cut drag lines more than 15 degrees trailing

High speed bottom dross, hard to remove

Cut Speed Correct

Smooth cut surface

No dross

Cut Speed Too Slow

Heat discoloration is concentrated in the bottom half of the cut

Hard bottom dross, hard to remove

page 10

Page 11

Mild Steel (O2 plasma)

Cut Speed Too Fast

Trailing cut drag lines

Light bottom dross, hard to remove, some top splatter

Cut Speed Correct

Cut drag lines near vertical

No dross

Cut Speed Too Slow

Cut drag lines lead the torch

Heavy bottom dross, easy to remove

page 11

Page 12

Mild Steel (Air plasma)

Cut Speed Too Fast

Cut drag lines curve and trail torch movement

High speed bottom dross, hard to remove

Cut Speed Correct

Cut drag lines near vertical

Minimal dross

Cut Speed Too Slow

Cut drag lines vertical or leading the torch head

Thicker bottom dross, easy to remove

page 12

Page 13

Piercing

Lead-out

Overcut

Corner

Pierce

Lead-in

Piercing causes the molten metal to form a puddle on top of the plate. On thicker plate,

pierce height is calculated to keep the torch away from the plate so that the molten metal does

not adhere to the consumable parts and shorten parts life. Hold pierce height as the cutting

table starts movement to allow the torch to clear the pierce puddle before moving to cut height.

Using the Inova height controller, this is done using the Set Pierce Time function on the edit

screen.

Lead-in and lead-out

Lead-in and lead-out should be calculated to allow the torch to move to cut height

before starting the final piece contour of the cut and to move away from the final piece before

beginning end of cut current ramp down.

Corners

The cutting arc normally trails the torch tip orifice. When the torch makes an abrupt

change in direction this trailing arc cannot change direction as quickly at the bottom of the cut

as at the top of the cut. This results in undercutting of sharp corners. 2 techniques can be used

to minimize this effect.

1. Use cut-outs – Overcut past the corner of the shape, then return and cross over the cut line to

achieve a square corner. Triangular or looped overcuts are commonly used.

2. Use the CNC corner slowdown function to hold torch height as it enters and leaves

the corner. As the speed decreases, the arc voltage will increase, driving the torch

down, so corner slowdown will lock out the height controller during the corner cut,

keeping the torch at the programmed height, regardless of arc voltage variations.

page 13

Page 14

Cutting Circles

Pierce

Lead-in

Overrun

at end

of cut

Circle cutting demands precise motion control and circle cut quality will vary as the circle

diameter approaches the thickness of the plate. In general, a circle that is equal in diameter

to the thickness of the plate being cut is the minimum circle diameter possible. Cut quality will

decrease markedly when the circle diameter is less than 1.5 times the thickness of the plate

being cut.

For maximum circle cut quality:

1. Slow down cut speed. Smaller circles may require a cut speed that is 60-50% of the

speed specified in system cut charts. A slower cut speed will eliminate trailing arc and allow the

arc to cut at closer to 0° of bevel.

2. Maintain constant cut height through the circle. This may require locking out the height

controller. As the cut speed slows, arc voltage increases and the height controller tends to drive

the torch down, changing cut bevel. Avoid torch height movement by locking out the height

controller during the circle cut.

3. Start the cut in the center of the circle and use a 90° lead-in to the circle. When the

positioner is in top running condition, a 90° lead-in will produce less distortion at the circle

initiation. A cutting table with backlash may produce a better cut when a radial lead-in is used.

4. End the cut by overburning the circle cut line rather than by using a lead-out. Time the

cut to end just as the arc completes the circle. A lead out or too much of an overburn will cause

the arc to cut more of the outside of the circle and cause a distortion at the point where the

circle cut is completed. Many CNC systems use and advanced off feature to ramp down cutting

current end of cut. Use of the CNC’s advanced off feature will improve circle cutting.

page 14

Page 15

N2/Water Mist Secondary

In this process, tap water is used instead of a shield gas. The water is vaporized as

it passes through the torch head and a portion of the molecules separate onto hydrogen and

oxygen. This vapor protects the cut surface from ambient air contamination and eliminates

nitriding in the cut surface.

Cutting with the N2/WMS process is economically efficient and produces genuine

precision cut quality over a broad range of non-ferrous applications.

Considerations:

• Water supply should be at least 55 psi.

• Hard water will leave mineral deposits, just as it does in sinks and faucets. A standard

water softening filter will prevent mineral deposits that can interfere with water flow in the

torch passages.

• Ohmic sensing to establish initial torch height is ineffective when water is present.

The ohmic clip should be removed from the torch for N2/WMS cutting. The ohmic sensing

system will sense the level of any water on the plate rather than the true position of the plate.

®™

Underwater Cutting

Cutting under water is used by some operators to capture smoke and reduce flash and noise.

Cutting under water is possible with Ultra-Cut and Auto-Cut systems.

Considerations:

• Cutting under water will reduce cut capacity and speed by up to 30%

• The cooling effect of water on the bottom of the plate will facilitate formation of dross

• Cutting aluminum under or over water releases hydrogen, which can explode

• Cutting with N2/WMS process is not recommended

• The water in the table will become contaminated with cut residue and can be a toxic waste

page 15

Page 16

Power Supply Status Codes

Art # A-04862

AC Indicator

Temp Indicator

Gas Indicator

DC Indicator

Status Indicator

Auto-Cut and Ultra-Cut systems display system status codes that are useful for

optimizing system performance and for troubleshooting. The status code is displayed on

the power supply front panel.

AC Power Indicator:

Indicates AC power is being supplied to the system when the

ON/OFF switch is in ON position. When switch is first set to

ON, the indicator will blink, indicating gas purge at power on.

TEMP Indicator:

Normally OFF. Indicator will come ON when the internal

temperature sensors detect temperatures above normal limits.

Let the unit cool before continuing operation.

GAS Indicator:

Normally ON. Indicates adequate gas pressure for

operation in the system.

Status Indicator:

DC Indicator:

Indicates the power supply is generating output DC voltage.

Show system status. The number of flashes indicates the

status.

Refer to the Status Code Section for details. On power supply start-up, the indicator

flashes to show the revision level of the operating software installed in the system.

page 16

Page 17

The Status Indicator flashes a 2 part code that indicates the status of the system.

When the Status Indicator is dark the system is ready to cut. It is normal for the Status Indicator

to flash when the GCM mode switch is placed in set mode. At system start up, the Status

Indicator flashes a 2 part code to indicate the CCM firmware version that is loaded into the

system. This code appears only once at start up. During normal operation the Status Indicator

may flash a code indicating an error or a condition that should be corrected. Some codes will

cause the system to cease operation to prevent damage to the hardware. Other codes will not

cause the system to cease operation, but will continue until the condition which caused the code

to initiate is changed.

Status codes appear in a 2 part sequence. The Status Indicator will flash a number of

times to indicate the first number in the code sequence, then pause for 1.2 seconds and flash

the second number of the code. After 4 seconds, the code sequence will repeat.

Example: The Status Indicator blinks 4 times, pauses, then blinks 3 times.

This code (4-3) indicates overheating coolant and will continue until the condition is corrected.

Status Indicator Codes

Fault Code Key

Error

Code

1-1 System not Enabled or

1-2 Pilot Ignition Failure Pilot did not start within 15 seconds.

1-3 Lost Pilot Pilot went out without shutoff signal; Preflow

1-4 Loss of Transfer Arc transfer (>50 ms.) then arc lost with START still

1-5 Off the Plate Function not currently enabled

1-6 Pilot Timed out w/o

1-7 Tip Saver Function not currently enabled.

1-8 Possible Shorted Torch Detected tip voltage too close to electrode voltage.

Error Remedy / Comments

Plasma Enable Off ; External E-Stop Activated or

Missing AC Input Phase

Transfer

CCM TB1-1&2 jumper missing; Missing AC Phase;

No power to GCM 2000 or 2010 Gas Control,

check GCM control cable connected, reset CP4

or CP5 circuit breaker in power supply, blown fuse

F19 in GCM.

Preflow pressure too high; Defective Arc Starter

pressure too high; cut current set too low for

consumables.

on. Standoff too high; Current set too low.

Must transfer from Pilot to Cutting Arc in 85 ms.

(SW8-1 OFF) or 3 sec. (SW8-1 ON). Standoff too

high or void in work under torch; cut current too low

for consumables; Preflow pressure too low.

Plasma flow/pressure too low; Plasma leak; cut

current too high; shorted torch body; consumable

parts worn out.

page 17

Page 18

Fault Code Key

Error

Code

Error Remedy / Comments

2-1 Missing Phase Blown fuse, Broken or loose connection on power cable

Inverter(s) not configured correctly for input voltage;

2-2 Wrong input voltage

Inverter or Pilot

2-3

Regulator Over

Temperature

Power Supply not

2-4

Ready

2-5 DC Output Low

Primary over current

2-6

fault

2-7 Unexpected current

Unexpected current

2-8

in pilot circuit

Unexpected current

2-9

in work lead

Poor power quality (brownouts, dropouts); Input power capacity

/ wiring too small causing voltage drop; broken or loose power

cable connections.

Failed fan; Ambient above 40 deg C. (104 F); Blocked airflow

Defective inverter

Output less than 60 VDC; Defective inverter, shorted output;

Shorted pilot regulator (chopper); CCM voltage sense (J6) wire

open or disconnected.

Over current detected in inverter primary circuit, remove power

to reset; defective inverter; voltage surge;

Current >20A in work or pilot leads before pilot ignition; Possible

shorted torch; Defective current sensor.

Current > 5A in pilot circuit; wrong or mismatched consumables;

Pilot lead shorted to negative in torch tube; Possible shorted

torch

Current > 5A in work lead; Short to chassis in RAS; Negative

lead short to ground.

page 18

Page 19

Error

Code

3-10

Error Remedy / Comments

Gas Control

Communication fault,

3-1

Cannot establish

Communication with

gas control.

Gas Control

Communication reply

fault, connection was

3-2

established but CCM

did receive a reply to

a process request.

3-3 Gas Pressure Low

Gas Control not

3-4

ready

Gas Control Protocol

3-5

Fault

Invalid Current

3-6

Control level from

GCM

Gas Control returns

3-7

wrong command

sequence

CCM and Gas

Control type

3-8

(Autocut-Ultracut)

mismatch

Gas Control

3-9

Communication reply

fault

Warning. -- Gas

Control firmware

needs update

Fault Code Key

If GCM 1000: Control cable not connected or Basic ID signal

open. GCM 2010 & 2000: Dirt on fiber ends or in connectors,

blow out with clean dry air; fiber not locked into connector;

sharp bends in fiber; fiber defective; Gas Control PCB defective,

replace. CCM defective, replace.

Gas Control did not reply to signal from CCM in allowed time.

Dirt on fiber ends or in connectors, blow out with clean dry

air; fiber not locked into connector; sharp bends in fiber; fiber

defective. If problem persists Gas Control PCB likely defective,

replace board.

If GCM 1000, Plasma < 15 PSI; faulty or disconnected pressure

SW. If GCM2010_AG, GCM2000_AC or later or Gas Control

has been updated with 19X2219_AG or later PCB: Plasma or

Shield input out of range 105-135. If GCM2010_AG,

GCM2000_AC or later or Gas Control has been updated with

19X2219_AG or later PCB: Plasma or Shield input out of range

105-135 PSI; Unplugged or Faulty pressure sensor.

Purging; not in RUN mode; Gas Control faulty, replace PCB.

Application error or firmware compatibility fault

GCM sent output current level outside the range of the power

supply, Check firmware compatibility

Check firmware compatibility

Install correct CCM or Gas Control for system

Reply not compatible with request; Check firmware compatibility

System will function but control may not be optimized for best

performance / consumable life

page 19

Page 20

Fault Code Key

Er r o r

Code

Error Remedy / Comments

4-1 Coolant Level low fault Check coolant level, add as needed.

Low coolant flow

after power on purge.

Not cutting:

< 0.7 gal/min for 15 sec;

4-2

Cutting: flow between

0.35 to 0.7 gal/min for 3

sec. or immediately if

< 0.35gal/min;

Coolant overheated

4-3

(>70 deg. C, 158 deg F)

Coolant System not

ready. During power on

4-4

purge / priming, flow did

not reach 0.35 gal/min

for at least 5 seconds

Low Coolant Level

4-5

- Warning

Suction leak introducing air into coolant, suspect rear panel

filter seal; clogged filter; defective pump.

Coolant fan failed; radiator fins clogged with dirt; Ambient

temperature > 40 deg C.

If new installation recycle power to restart

pump, may take a few times to fill hoses;

Damaged torch coolant tube; Suction leak introducing air

into coolant, suspect rear panel filter seal; clogged filter;

defective pump.

While cutting detected low coolant level, does not stop cut.

Add coolant as required.

page 20

Page 21

Error

Code

Error Remedy / Comments

CANBUS Failure to

5-1

Acknowledge fault.

CANBUS Off due to

5-2

excessive data errors;

CANBUS data error

warning. Errors

5-3

increasing, will soon

fault.

5-4 CCM Message not sent

CCM Analog

6-1

Voltage Error

CCM ADC

6-2

or DAC error

Coolant Flow too High

6-3

error, flow > 2.7 gal/min

CCM Data Memory

6-4

error

Fault Code Key

If GCM 1000, Basic ID signal missing; Other gas controls,

Fiber disconnected or broken, Transceiver (what fiber plugs

into) fault, replace Gas control PCB or CCM

Dirt on fiber ends or in connectors, blow out with clean dry

air; fiber not locked into connector; sharp bends in fiber; fiber

defective;

Dirt on fiber ends or in connectors, blow out with clean dry

air; fiber not locked into connector; sharp bends in fiber; fiber

defective;

Dirt on fiber ends or in connectors, blow out with clean dry

air; fiber not locked into connector; sharp bends in fiber; fiber

defective; CANBUS hardware error (CCM or Gas Control

PCB)

Replace CCM

Replace CCM

Torch coolant tube broken or missing; CCM fault, replace

CCM

Replace CCM

page 21

Page 22

Scheduled Maintenance

O-Rings

Art # A-04066

Cat. No. 8-0539

Cat. No. 8-3487

Cat. No. 8-0530

Torch Head

Cat. No. 9-9041

O-Ring, Cat. No. 8-0544

Inner O-Ring (Cat. No. 8-0545)

Location (Under Locking Ring)

O-Ring, Cat. No. 8-0540

Art # A-04071

Snap Ring

Cartridge Assembly

Lubricate Torch Cartridge O-Rings

Lubricate all three O-Rings on the Cartridge Assembly and all three O-Rings on the Torch

Head periodically with O-Ring Lubricant supplied. Remove the snap ring on the cartridge

assembly and slide the locking ring downward for access to the O-Ring under the locking ring.

Use only Thermal Dynamics No. 9-4893 O-Ring Oxygen Compatable Lubricant (Christo Lube MCG-129)

with this torch part. Use of other lubricants may cause irreparable damage to the torch.

An O-ring replacement kit with both torch and cartridge rings is available, catalog number 9-9488.

Coolant

Torch coolant becomes conductive with use and eventually will cause a shorted torch

condition. Torch coolant should be replaced every six months. Also remove and clean the

external coolant filter and the smaller filter located near the flow sensor.

Torch coolant is available pre-mixed or as concentrate.

Catalog Number Description

7-3580 Extra-Cool™ 25/75 10°F / -12°C

7-3581 Ultra-Cool™ 50/50 -27°F / -33°C

7-3582 Extreme-Cool™

7-3523 De-l Water™ 32°F / 0°C

CAUTION

Propylene Glycol/

Deionized Water Mix

Concentrate to be mixed

with De-l™ Water

Freeze Protection

-65°F / -51°C

page 22

Page 23

Periodic Maintenance

No

Yes

Yes

Are Parts New

or Used?

Are Parts fully

assembled into

the Torch?

Unsure?

Disassembly fully

and re-assemble

the Torch Properly.

See Installation Manual.

Replace Torch Head

Is the Torch Damaged?

Replace Consumable

Cartridge and Shield Cup.

Torch still leaks?

Remove and Lubricate

all O-rings on Torch Head,

Consumables Cartridge,

and Consumables.

Re-assemble Torch.

Still leaks?

The parts probably are worn out.

See chart for approximate life expectancy.

The torch may be damaged. See page

to determine if head damage has occurred.

Order Coolant

Tube Replacement Kit

Leaking from

Coolant Supply or

Coolant Return?

Yes

Yes

Yes

No

Return

Supply

Used

Order Coolant

Check Valve

Kit 9-4846

New

Torch leaks

Are Torch

Consumable Parts

Installed?

Daily

Check coolant level; add coolant as needed.

Check gas hose connections and pressures.

Check cooling fan; clean as needed.

Monthly

Check cooling fan and radiator; clean as needed.

Check gas hoses for cracks, leaks, or abrasions.

Replace as needed.

Check all electrical connections for cracks or abrasion.

Replace as needed.

Clean water filter (if using H20 Mist).

Six Months

Replace coolant filter.

Clean coolant tank.

Vacuum out any dust buildup inside power supply.

Power Supply Maintenance Schedule

Troubleshooting Torch Coolant Leaks

page 23

Page 24

Technical Service Contact Numbers

Thermal Dynamics Technical Service is available for telephone or e-mail

support. Technicians are available to assist with installation, application and

repair issues.

Technical Service Toll Free – 1-800-PLASMA2 (752-7622)

Automation Technical Service – 1-888-832-3477

Automation Customer Care – 1-866-279-2628

General Customer Care – 1-800-PLASMA1 (752-7621)

E-mail - tdctech@thermadyne.com

www.thermal-dynamics.com

U.S. Customer Care: ARCAIR

FIREPOWER® .................800-858-4232 / FAX 800-535-0557 TDC AUTOMATION ..................866-279-2628 / FAX 800-221-4401

TURBOTORCH

®

/ STOODY® / THERMAL ARC® / THERMAL DYNAMICS® / TWECO® / VICTOR

®

............. 800-238-0282 / FAX 800-535-0557 VICTOR MEDICAL .................... 800-382-8187 / FAX 800-535-0557

®

................... 800-426-1888 / FAX 800-535-0557

VICTOR SPECIALTY PRODUCTS ...................800-569-0547 / FAX 800-535-0557

Canada Customer Care: 905-827-4515 / FAX 800-588-1714 • International Customer Care: 905-827-9777 / FAX 905-827-9797

CIGWELD Customer Care: 1300-654-674 / FAX 613+ 9474-7391 • www.thermadyne.com

A Global Cutting & Welding Market Leader

W O R LD H EA DQ UA R T ER S: 1 60 52 S wi ng l ey Ri dg e Ro ad , S u i te 3 00 • S t. Lo ui s, M is so ur i 63 01 7 U .S .A .

THE AMERICAS EUROPE ASIA/PACIFIC

Denton, TX USA

U.S. Customer Care

Ph: (1) 800-426-1888

Fax: (1) 800-535-0557

Miami, FL USA

Sales Office, Latin America

Ph: (1) 954-727-8371

Fax: (1) 954-727-8376

Form No. 63-2823 (5/13/08) © Thermadyne Industries, Inc., 2008 www.thermadyne.com Printed in U.S.A.

Oakville, Ontario, Canada

Canada Customer Care

Ph: (1) 905-827-4515

Fax: (1) 800-588-1714

International Customer Care

Ph: (1) 905-827-9777

Fax: (1) 905-827-9797

Chorley, United Kingdom

Customer Care

Ph: (44) 1257-261755

Fax: (44) 1257-224800

Milan, Italy

Customer Care

Ph: (39) 0236546801

Fax: (39) 0236546840

Cikarang, Indonesia

Customer Care

Ph: 62 21+ 8983-0011 / 0012

Fax: 62 21+ 893-6067

Osaka, Japan

Sales Office

Ph: 816-4809-8411

Fax: 816-4809-8412

Melbourne, Australia

Australia Customer Care:

Ph: 1300-654-674

Fax: 613+ 9474-7391

International:

Ph: 613+ 9474-7508

Fax: 613+ 9474-7488

Rawang, Malaysia

Customer Care

Ph: 603+ 6092-2988

Fax: 603+ 6092-1085

Shanghai, China

Sales Office

Ph: 86 21+ 6280-1273

Fax: 86 21+ 3226-0955

Singapore

Sales Office

Ph: 65+ 6832-8066

Fax: 65+ 6763-5812

™

Loading...

Loading...