Page 1

Accelerating the World of Cooking

TM

Service Manual

FOR THE TURBOCHEF 3240 HIGH H CONVEYOR O VEN

Page 2

Page 3

For further information, call

800.90TURBO

or

+1 214.379.6000

Page 4

The information contained in this manual is important for the proper installation, use, maintenance, and repair of this oven. Follow these procedures and instructions to help ensure satisfactory

baking results and years of trouble-free service.

Errors – descriptive, typographic, or pictorial – are subject to correction. Specifications are subject

to change without notice.

PLEASE CAREFULLY READ THIS MANUAL AND RETAIN IT FOR FUTURE REFERENCE.

Page 5

TABLE OF CONTENTS

Table of Contents

Safety Instructions

Important Safety Information - Please Read First i

General Safety Information i

Preventing Oven Damage i

Reducing Fire Risk ii

Grounding Instructions ii

Power Cord Replacement ii

Specifications and Startup

Oven Overview 1

Certifications 2

Dimensions 2

Oven Construction 2

Theory of Operation 2

Power Specifications 2

Ventilation Requirements 2

Gas Derating 2

Gas Setup 3

Reading the Incoming Gas Pressure (Static) 3

Reading the Gas Pressure at 100% Flame 3

Reading the Gas Pressure at Minimum Flame 4

Reading the Operating Gas Pressure 4

Confirming Proper Closure of all Taps 4

Cleaning

Cleaning the Oven 5

Supplies and Equipment 5

Daily Cleaning Procedures 5

Deep Cleaning Procedures 6-8

Standard Oven Operation

Oven Controls 9

Cooking a Product 10

Editing a Cooking Profile 12

Changing a Cooking Profile’s Name 12

Adjusting the Belt Speed 13

Adjusting the Temperature 13

Adjusting the Top and Bottom Air 13

Page 6

TABLE OF CONTENTS

Oven Modes

Config Mode 15

Smart Card Screen 15

Updating the Firmware 15

Accessing the Fault Count Screen 16

Accessing the Setup Mode 16

Accessing the Test Mode 16

Setup Mode 16

Changing the Display Temperature 16

Edit Option Screen 16

Changing the Display Language 17

Info Screen 17

Test Mode 17

Accessing the Burner Control Screen 18

Manipulating the Top and Bottom Blowers 18

Viewing the Status Indicators 18

Entering a New Serial Number 19

Initiating a Burn-In Test 20

Erasing all Oven Settings 20

Clearing the Fault Counts 20

Viewing the Serial Number 20

Oven Systems

The Control System 21

Control Board 21

Display 21

EMI Filter 21

Fuses 21

High-Limit Thermostat 21

Idle Button 21

Keypad 21

Power Supply - 24VDC (Domestic) 21

Power Supply - 24VDC (International) 22

K3 Relay - Gas 22

K4 Relay - Ignition 22

RTD 23

Smart Card Reader 23

Speaker 23

Thermostat - 120F (Close on Rise) 23

Wire Harness 23

The Conveyor System 23

Gear Drive (Conveyor Motor) 23

Gear Drive (Conveyor Motor) Speed Controller (CMSC) 24

Page 7

TABLE OF CONTENTS

The Blower System 25

Blower Motor 25

Blower Motor Speed Controller (BMSC) 25

The Burner System 26

Air Pressure Switch 26

Burner Transformer 26

Combustion Blower 27

Modulating Gas Valve 27

Ignition Module 27

Troubleshooting

Overview of Troubleshooting 29

Fault Code Descriptions 29

Fault Code Troubleshooting 31

F1: Blower Fault 31

F2: Low Cook Temp 32

F3: No Flame 34

F5: CC Over Temp 36

F6: EC Over Temp 37

F7: RTD Fault 38

F8: High Limit Tripped 38

F9: Belt Fault 39

F10: Air Pressure Switch Fault 40

Non-Fault Code Troubleshooting 41

Cooling System Issue 41

Food Not Cooking Properly 42

No Display 43

No Keypad Input 43

Schematics

Schematic 45

Pin-out 46

Controller Codes 47

Appendix A - Replacing Oven Components

Comprehensive Part List A-1 - A-4

Replacing Items - No Panel Removal Required A-6

Replacing Items - Right End Bell A-8

Replacing Items - Left End Bell A-12

Replacing Items - Burner Compartment Cover A-14

Page 8

i SAFET Y INSTRUCTIONS

Important Safety Information – Please Read First

Improper installation, adjustment, alteration, service, or maintenance of this equipment can cause property

damage, injury, or death. Thoroughly read the installation, operating, and maintenance instructions before

installing or servicing this equipment. Strictly adhere to the following safety information to reduce the

risk of:

- Damage to the oven

- Damage to property near the oven

- Personal injury

- Burns

- Fire

- Electric shock

General Safety Information

a

Use this appliance only for its intended uses as described in this manual.

a

Only qualified service personnel should service this appliance. Contact the nearest authorized service

facility for examination, repair, or adjustment.

a

Always ensure the oven is disconnected from the power supply before servicing, repairing, or adjusting any components or parts.

X

DO NOT place the cord near heated surfaces.

X

DO NOT store or use flammable vapors or liquids (e.g., gasoline) in the vicinity of this appliance.

X

DO NOT allow children to use this appliance.

X

DO NOT place corrosive chemicals or vapors in this appliance. It is not designed for industrial or

laboratory use.

X

DO NOT operate this appliance if it:

-Has a damaged cord, plug, or gas hose

-Is not working properly

-Has been damaged or dropped

X

DO NOT cover or block any openings on this appliance.

X

DO NOT store this appliance outdoors.

X

DO NOT use this appliance near water.

X

DO NOT immerse this appliance or any of its components (e.g., cord, plug, etc.) in water.

X

DO NOT let the cord hang over the edge of a table or counter.

X

DO NOT work near the appliance with long hair, loose clothing, or dangling jewelry.

Preventing Oven Damage

a

When servicing this appliance, do not tear insulation to get to components. Rather, find the edge of

the insulation and remove the tape that holds it in place.

a

Clean the oven daily (page 5).

a

Clean the oven only with TurboChef approved cleaner.

X

DO NOT clean with a water jet.

X

DO NOT slam or mishandle the oven window.

X

DO NOT frequently open and close the window to check the cook status of the food.

X

DO NOT allow cleaning solution or water to remain in the cook cavity longer than necessary.

Page 9

SAFET Y INSTRUCTIONS

ii

Reducing Fire Risk

If materials inside the oven ignite or if smoke is observed,

1.Keep the oven window closed.

2.Turn off the oven.

3.Disconnect the power cord or shut off power at the fuse/circuit breaker panel.

a

Carefully attend the oven if paper, plastic, or other combustible materials are placed inside the oven

to facilitate cooking.

X

DO NOT leave items in the cook cavity when the oven is not in use.

X

DO NOT cook items wrapped in cling wrap or plastic film.

X

DO NOT overcook food.

X

DO NOT store (or use) gasoline or any other flammable vapors or liquids near this appliance.

If a gas leak is noticed,

X

DO NOT attempt to light or operate any appliance.

X

DO NOT operate any electronic device.

a

Immediately use an exterior phone to contact your gas supplier.

a

If you cannot contact your gas supplier, contact your local fire department.

Grounding Instructions

WARNING: Improper grounding increases the risk of electric shock.

This appliance must be grounded. The cord is equipped with a grounding wire and plug, which in the

event of an electrical short circuit, reduce the risk of electric shock by providing an escape wire for the

electric current. The wire must be plugged into an outlet that is properly installed and grounded.

Consult a qualified electrician or serviceman to determine whether or not the appliance is properly

grounded.

X

DO NOT use an extension cord. If the power supply cord is too short, request a qualified electrician

or serviceman to install an outlet near the appliance.

Power Cord Replacement

To avoid potential hazards, only the manufacturer, its service agent, or a similarly-qualified person should

replace a damaged power cord.

Page 10

iii SAFET Y INSTRUCTIONS

This page intentionally

left blank.

Page 11

Specifications and Startup

Page 12

Page 13

SPECIFICATIONS AND STARTUP

1

Overview

Figures 1 and 2. For part numbers, see the

appendix.

1. Air filter, 11.75” x 7.5” (298 mm x

190 mm)

2. Idle button (page 21)

3. Left end bell (page A-12)

4. Right end bell (page A-8)

5. VFD display and keypad (page 21 and A-8)

6. Chain guard

7. Conveyor belt

8. Window (optional feature)

9. Hi-limit reset switch

10. Burner compartment cover

11. Cooling fan tube

12. Air filter, 9” x 3.25” (228 mm x 83 mm)

13. Cooling fan tube access thumb screw

14. Burner compartment cover access screws

15. Power cord and plug (page ii)

16. Rating plate

3

1

4

5

6

7

8

2

9

10

11

12

15

16

13

14

Figure 1: Oven Overview, Front

Figure 2: Oven Overview, Rear

Page 14

2

Certifications

cULus GAS FIRED LISTED, UL EPH, FCC

Dimensions

With End Bells Closed

- Width: 72.13” (1832 mm)

- Depth: w/ window: 55.25” (1403 mm)

- Depth: w/o window: 52.85” (1342 mm)

- Height: 19.00” (483 mm)

With End Bells Open

- Width: 87.53” (2223 mm)

- Depth: w/ window: 59.20” (1504 mm)

- Depth: w/o window: 56.80” (1443 mm)

- Height: 19.00” (483 mm)

Oven Construction

- 430 stainless steel exterior

- 304 stainless steel interior

- Powder coated steel legs

Theory of Operation

The HhC3240 conveyor oven uses two

independently-controlled blower motors to

precisely distribute impinged air into the cook

cavity from the top and bottom, creating a

highly-customizable cooking environment and

more throughput than any other oven its size.

Power Specifications

Electrical

Gas

-Volume: Maximum input per cavity

85k BTU (25kW [Gross])

-Min. Pressure (Nat, LP, I2H, I2E, I

2E+

, I2L, and I3P):

6” W.C. (152.4 mm H2O / 14.94 mb)

-Max. Pressure (Nat, LP, I2H, I2E, I

2E+

, I2L, and I3P):

14” W.C. (350.6 mm H2O / 34.87 mb)

-Burner Pressure (Nat, LP, I2H, I2E, I

2E+

, and I3P):

3.5” W.C. (88.9 mm H2O / 8.71 mb)

-Burner Pressure (I2L):

4.0” W.C. (101.6 mm H2O / 9.96 mb)

Ventilation Requirements

The TurboChef model HhC3240 conveyor oven

must be operated underneath a Type I or II hood.

Always adhere to local building and gas codes.

Local code is the prevailing authority for determining hood size and CFM.

Gas Derating

Contact TurboChef with questions regarding elevations and necessary adjustments.

SPECIFICATIONS AND STARTUP

19.00”

(483mm)

19.00”

(483mm)

Figure 3: Dimensions

North America EU / Asia

Phase

1 Phase 1 Phase

Voltage

208/240 VAC 220-240 VAC

Frequency

50/60 Hz 50/60 Hz

Current Draw

8 Amp 8 Amp

Supply

3 Wire (L+L+G) 3 Wire (L+L+G)

Breakers

20 amp 16 amp

Plug

NEMA L620 IEC, 309 3 PIN

Page 15

SPECIFICATIONS AND STARTUP

3

Gas Setup

A digital manometer that will read 0.10” WC

(2.54 mmH2O, 0.249 mb) must be used to

properly set all pressures. If the minimum

pressure is not set correctly, the oven temperature

will slowly rise in stand-by mode and eventually

cause cooking issues as well as trip the high limit

temperature switch. Digital manometers (HHC-

3001) are available through TurboChef; call

800.90

TURBO (+1 214-379-6000) for pricing and

availability.

For information on accessing the

burner control, see page 18.

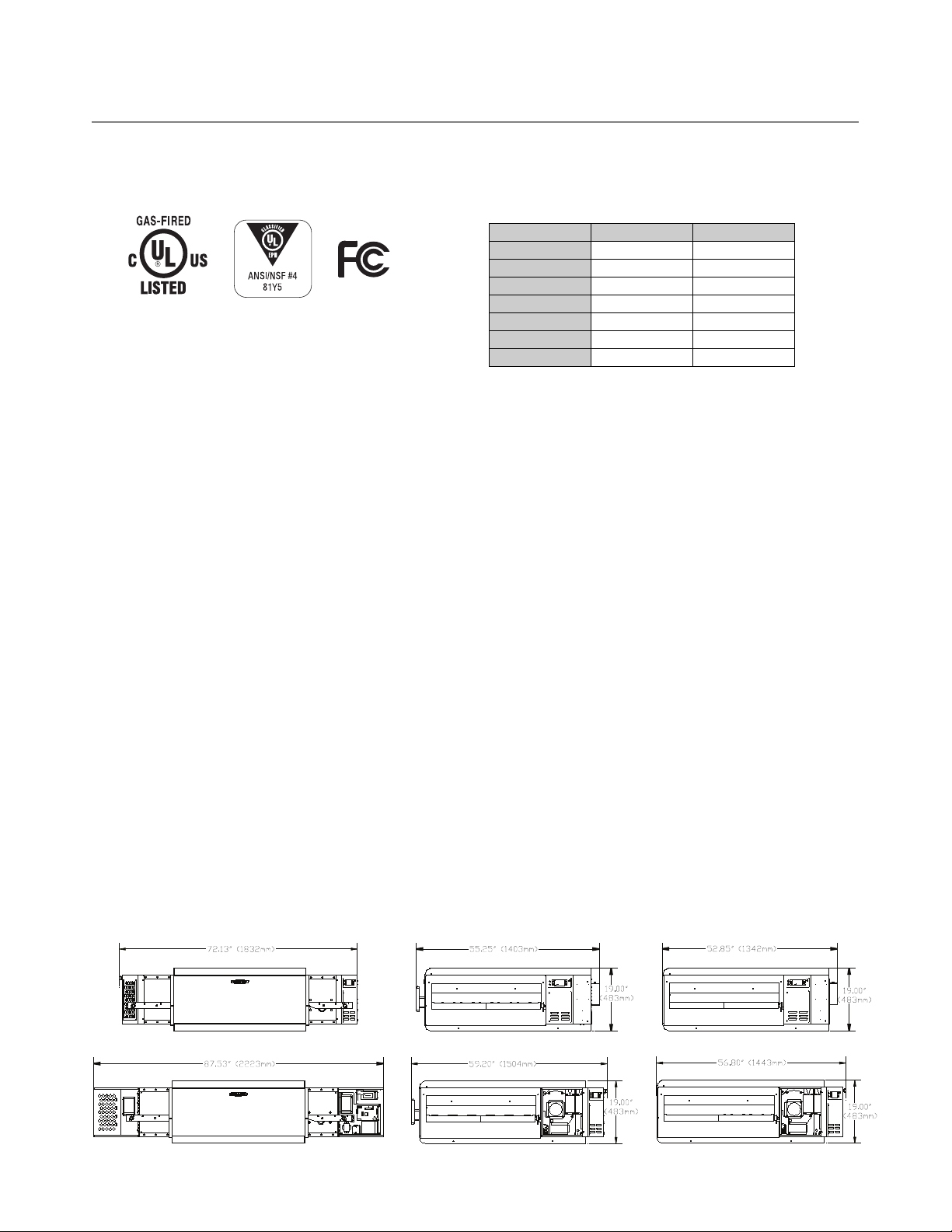

Reading the Incoming Gas Pressure

(Static)

1. Ensure the oven and all the equipment in the

piping system are off (pilot lights are

acceptable).

2. Remove the burner compartment cover and

cooling fan tube (refer to page 1).

3. Remove the screw from the upper tap of the

gas valve.

4. Attach the digital manometer to the upper

tap of the gas valve (Figure 4). This tap will

show the incoming pressure before the

internal regulator of the gas valve.

5. The pressures must be no less than 6” W.C.

(152.4 mmH

2

O, 14.94 mb) and no more

than 14” W.C. (350.6 mmH2O, 34.87 mb).

Otherwise, severe damage to the equipment

can occur.

6. Reattach the screw to the upper tap of the

gas valve.

Reading the Gas Pressure at 100%

Flame

1. Ensure the oven is on.

2. Select a cooking profile.

3. Remove the screw from the lower tap of the

gas valve.

4. During warmup (both fan speeds are at 65%

and the oven is at 100% flame), attach the

manometer to the lower tap of the gas valve

(Figure 4).

5. Verify that the maximum operating pressure is

3.5” W.C. (88.9 mmH

2

O, 8.71 mb)

, unless

operating I2Lgas.

NOTE: I

2L

gas requires a pressure of 4” W.C.

(101.6 mmH2O, 9.96 mb).

6. If not, use an 8mm nut driver to adjust the

8mm nut (Figure 4) until the manometer

reads 3.5” W.C. (88.9 mmH

2

O, 8.71 mb)

,

unless operating I2Lgas, as noted above (turn

clockwise to increase the pressure, counterclockwise to decrease the pressure).

7. Reattach the screw to the lower tap of the

gas valve.

Figure 4: Gas Valve

Red/White

Wires

Upper Tap

Lower Tap

8mm nut

5mm nut

Page 16

4 SPECIFICATIONS AND STARTUP

Reading the Gas Pressure at Minimum

Flame

1. Remove either the red or white wire

(Figure 4).

2. Attach the electric manometer to the lower

tap of the gas valve (Figure 4).

3. Verify that the minimum operating pressure is

0.10” W.C. (2.54 mmH2O, 0.249 mb).

4. If not, use a 5mm nut driver to adjust the

5mm nut until the electric manometer reads

0.10” W.C. (2.54 mmH2O, 0.249 mb) (turn

clockwise to increase the pressure, counterclockwise to decrease the pressure).

5. Reconnect the wire you removed.

6. If adjustments were made, re-check 100%

flame pressure (see adjacent procedure).

Reading the Operating Gas Pressure

1. Ensure the oven is on.

2. Select a cooking profile (page 10).

3. Remove the screw from the upper tap of the

gas valve.

4. During warmup (both fan speeds are at 65%

and the oven is at 100% flame), attach the

manometer to the upper tap of the gas valve

(Figure 4).

5. Ensure that the pressure is no less than 6”

W.C. (152.4 mmH2O, 14.94 mb)and no

more than 14” W.C. (350.6 mmH2O,

34.87 mb).

6. Reattach the screw to the upper tap of the

gas valve.

Confirming Proper Closure of all Taps

Additional testing may be required - always

adhere to local gas codes and required methods of

leakage testing in the immediate location (refer to

the regulations in force in the country in which

the appliance is being installed). The prevailing

authority is the local code (or regulations).

1. Turn on the gas supply.

2. Spray all gas connections with a soap

solution.

-If growing soap bubbles are observed, a leak

-is present. Immediately shut off the gas

-supply.

-If no growth occurs, the connections are

-intact. Turn off the gas supply.

Page 17

Cleaning

Page 18

Page 19

CLEANING

5

Cleaning the Oven

Follow the steps below daily to help maintain

your HhC oven.

Daily Cleaning Procedures

Supplies and Equipment

TurboChef-approved oven cleaner, nylon scrub

pad, cleaning towels, disposable gloves

Step 1: Prepare the Oven

-Press the back/off key (page 9) to turn the oven off.

-Ensure cooling down has completed.

CAUTION: Injury can occur if oven is not allowed to cool properly

before cleaning. DO NOT attempt to clean until the “cooling down”

message has disappeared.

Step 2: Remove and Clean the End Trays

-Remove both end trays.

-Wash and rinse both end trays, then dry them with a clean towel.

-Reinstall the end trays.

Step 3: Remove and Clean the Crumb Trays

-Slide out and remove both crumb trays.

-Wash and rinse both crumb trays, then dry them with a clean towel.

-Reinstall the crumb trays.

Step 4: Remove and Clean the Filters

-Remove the filters, both of which are located on the left side of the oven.

-Wash and rinse both filters, then dry them with a clean towel.

+ If a filter is torn or damaged, replace with a new filter (page A-2 for

part number).

CAUTION: DO NOT operate the oven without the filters in place.

Step 5: Clean the Oven Exterior

-Wipe the oven exterior and window with a clean, damp towel.

-The oven is ready to turn on.

Step 1

Step 2

Step 3

Step 4

Step 5

Page 20

6 CLEANING

Deep Cleaning Procedures

TurboChef recommends deep cleaning the oven once a month (or more frequently depending on

use) to ensure optimal performance. Use only TurboChef-approved cleaner. Using any other

cleaning product can damage critical parts and may void the oven’s warranty.

Step 1: Prepare the Oven

-Press the back/off key (page 9) to turn the oven off.

-Ensure cooling down has completed.

CAUTION: Injury can occur if oven is not allowed to cool properly

before cleaning. DO NOT attempt to clean until the “cooling down”

message has disappeared.

Step 2: Remove and Clean the End Trays

-Remove both end trays.

-Wash and rinse the end trays, then dry them with a clean towel.

Step 3: Remove and Clean the Crumb Trays

-Slide out and remove both crumb trays.

-Wash and rinse both crumb trays, then dry them with a clean towel.

Step 4: Remove and Clean the Filters

-Remove the filters, both of which are located on the left side of the oven.

-Wash and rinse both filters, then dry them with a clean towel.

+ If a filter is torn or damaged, replace with a new filter (page A-2 for

part number).

CAUTION: DO NOT operate the oven without the filters in place.

Step 5: Remove and Clean the Chain Guard

-Remove the guard that covers the conveyor drive chain.

-Wash and rinse the chain guard, then dry it with a clean towel.

Step 6: Remove and Clean the Upper End Panels

-Remove both upper end panels from each end of the oven.

-Wash and rinse the upper end panels, then dry them with a clean towel.

WARNING: Lock all four casters before removing the conveyor, lower

plenum assembly, and upper nozzle plate. Physical injury or damage to

equipment can occur if the casters are not locked.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Page 21

CLEANING

7

Step 7: Remove and Clean the Conveyor (requires TWO people)

-Position one person at each end of the conveyor.

-Lift the conveyor assembly up and then towards the left side of the oven until

the conveyor drive chain has enough slack for removal.

-Remove the conveyor drive chain.

WARNING: Never attempt to remove the conveyor with fewer than 2 people.

-Lift the conveyor and push it through the right side of the oven for removal.

-Wash, rinse, and dry the conveyor with a clean towel.

Step 8: Remove and Clean the Lower End Panels

-Remove both lower end panels from each end of the oven.

-Wash and rinse the lower end panels, then dry them with a clean towel.

Step 9: Remove and Clean the Upper Nozzle Plate

-Remove the thumbscrew holding the upper nozzle plate in place on the right side

-of the oven (located between the two handles). If the right side upper air diverter is

-incorrectly positioned in front of the lip of the upper nozzle plate, remove the right

-side upper air diverter.

-Spray the upper nozzle plate with TurboChef Oven Cleaner to break apart any

-heavy stains. Allow cleaner to penetrate stains for five minutes.

-Scrub the upper nozzle plate with a nylon scrub pad.

-Rinse the upper nozzle plate with water and wipe it with a clean, damp towel.

WARNING: Be sure to THOROUGHLY remove all cleaner residue.

Step 10: Remove and Clean the Right and Left Lower Air Diverters

-Remove the four thumbscrews from the right side lower air diverter.

-Remove the right side lower air diverter.

-Remove the two thumbscrews from the left side lower air diverter.

-Remove the left side lower air diverter.

-Wash and rinse the lower air diverters, then dry them with a clean towel.

Step 11: Remove and Clean the Lower Plenum Assembly

-Remove the lower plenum assembly from the right side of the oven.

-Spray the lower plenum assembly with TurboChef Oven Cleaner to break

-apart any heavy stains. Allow cleaner to penetrate stains for five minutes.

-Scrub the lower plenum assembly with a nylon scrub pad.

-Rinse the lower plenum assembly with water and wipe it with a clean, damp towel.

WARNING: Be sure to THOROUGHLY remove all cleaner residue.

Step 7

Step 8

Step 9

Step 10

Step 11

Right

Left

Page 22

8 CLEANING

Step 12: Clean the Oven Interior

-Spray the bottom and sides of the oven interior with TurboChef Oven Cleaner to

break apart any heavy stains. Allow cleaner to penetrate stains for five minutes.

-Scrub the oven interior with a nylon scrub pad.

-Wipe the oven interior with a clean, damp towel.

WARNING: Be sure to THOROUGHLY remove all cleaner residue.

Step 13: Reinstall the Oven Components

-Reinstall the lower plenum assembly (if upper nozzle plate was cleaned,

-reinstall now).

-Reinstall the lower end panels.

-Reinstall the conveyor and chain.

-Reinstall the upper end panels.

-Reinstall the chain guard, filters, and crumb trays.

Step 14: Clean the Oven Exterior

-Wipe the oven exterior and window with a clean, damp towel.

-The oven is ready to turn on.

Step 13

Step 14

Step 12

Page 23

Standard Oven Operation

Page 24

Page 25

9

STANDARD OVEN OPERATION

Oven Controls

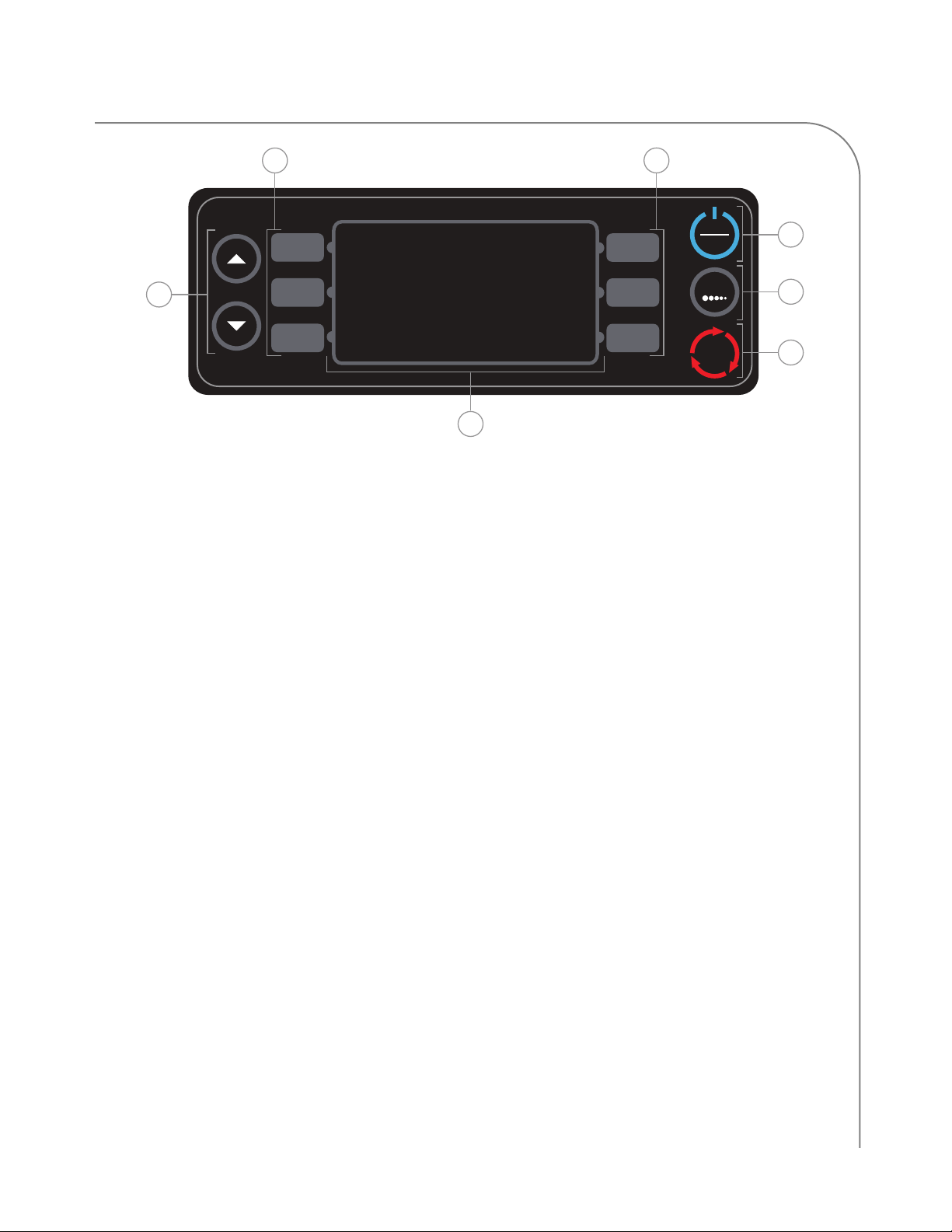

Figure 5

1. Display

The display shows current oven operation

and/or user programming information.

2. Soft Keys

Six soft keys are on the oven controls, three on

the left (L1, L2, L3, where L1 = top) and three

on the right (R1, R2, R3, where R1 = top).

Press a soft key to select the option/command

that is adjacent to it on the screen.

3. Up and Down Keys

When the oven is in the OVEN OFF MODE, use

the up key to access the CONFIG MODE (page

15). Use the down key to access cooking

profiles 5-8.

When the oven is in TEST MODE (page 17),

press the down key to access the second screen

of options. Press the up key to go back to the

first page.

Press the up and down keys to also change

option settings, where applicable

4. Back/Off Key

Depending on the mode the oven is in, the

back/off key will return the oven to the

previous screen or turn the oven off.

5. Idle Key

The idle key activates the IDLE MODE (page 12).

6. Emergency Stop Key

The emergency stop key shuts down the conveyor and burner, at which time the display

shows the belts halted screen. From the belts

halted screen, press the back/off key to turn the

conveyor back on and send the oven to the

COOLING DOWN MODE (page 11).

DO NOT use the emergency stop key as a

general on/off switch.

IDLE

BACK

OFF

E

M

E

R

G

E

N

C

Y

S

T

O

P

High h Conveyor

by TurboC hef

TM

2

2

3

4

5

6

1

Figure 5: Oven Controls

Page 26

Cooking a Product

This section explains how to cook a food

product by describing the “standard operation”

modes through which the oven progresses

(Figure 6).

-MODE 1: Oven Off

-MODE 2: Belt Speed Select

-MODE 3: Lighting

-MODE 4: Warming

-MODE 5: Soaking

-

MODE 6: Cooking

-

MODE 7: Cooling Down

-MODE 8: Idle

-

MODE 9: Cool To Light

NOTE:

MODES 8 and 9 are not part of a

“standard” cooking cycle. They only occur when

the user intervenes as described on page 12.

Mode 1: Oven Off

Mode during which all cooking components are

off and the oven temperature has receded below

150°F (66°C), but the display and keypad

remain on. The user can access cooking profiles

1-4 on this screen (1) or press the down key to

access cooking profiles 5-8.

Happens When...

-Power is supplied to the oven.

-The oven completes

MODE 7.

-The user presses the down key while-accessing

-The CONFIG MODE (refer to page 15 for more

information).

Goes To...

-MODE 2 when the user selects a cooking profile

(soft keys L1, L3, R1, or R3).

-CONFIG MODE when the user presses the up key.

Mode 2: Belt Speed Select

Mode during which the user selects the desired

belt speed.

NOTE: If a different key is pressed, the oven

will ask if you wish to continue or return to the

belt speed select screen. If you select continue,

the oven will not save the belt speed.

Happens When...

-The user selects a cooking profile from MODE

1 or 7.

Goes To...

-MODE 3 when the user selects a belt speed and

the set cooking temperature is higher than the

oven’s current temperature.

PROFILE 1

PROFILE 2

PROFILE 3

COOLING DOWN

OVEN TCC = 425F

PROFILE 4

LUNCH

BELT F

2:00

BELT R

3:00

TOP AIR 100%

SET

COOL TO LIGHT

OVEN TCC = 425F

400F

BTM AIR 100%

BREAKFAST

LUNCH

DINNER

OVEN OFF

DESSERT

BREAKFAST

5:00

3:00

LUNCH

DINNER

2:00

3:20

4:00

BELT SPEED

2:45

2:00 2:30

DESSERT

BREAKFAST

BELT F

5:00

BELT R

3:20

TOP AIR 80 %

SET

COOKING

475F

BTM AIR 100 %

BREAKFAST

BELT F

5:00

BELT R

3:20

TOP AIR 40 %

SET

LIGHTING

OVEN TCC = 72F

475F

BTM AIR 40 %

BREAKFAST

BELT F

5:00

BELT R

3:20

TOP AIR 60 %

SET

WARMUP

OVEN TCC = 275F

475F

BTM AIR 60 %

BREAKFAST

BELT F

5:00

BELT R

3:20

TOP AIR 80 %

SET

SOAKING

TIME LEFT = 5:00

475F

BTM AIR 100 %

1

2

3 6

5

9

4

BREAKFAST

BELT F

5:00

BELT R

3:20

TOP AIR 30%

SET

OVEN IDLE

PRESS ANY KEY

475F

BTM AIR 30%

8

BREAKFAST

LUNCH

DINNER

COOLING DOWN

OVEN TCC = 425F

DESSERT

7

STANDARD OVEN OPERATION

Figure 6: Cooking Modes

10

Page 27

11

STANDARD OVEN OPERATION

-MODE 9 when the user selects a belt speed and

the set cooking temperature is lower than the

oven’s current temperature.

Mode 3: Lighting

Mode during which the ignition module applies

voltage to the spark rod to start the burner.

Happens When...

-The user selects a belt speed from MODE 2.

Goes To...

-MODE 4 when the control board receives a

signal from the flame sensor that a flame is

present.

-

MODE 6 if the oven’s current temperature is

within 25°F (14°C) of the oven’s set

temperature.

Mode 4: Warming

Mode during which the oven warms to the preset cooking temperature defined by the cooking

profile that was selected.

Happens When...

-MODE 3 successfully completes, and the oven’s

temperature at the beginning of warmup was

not within (less than) 25°F (14°C) of the

oven’s set temperature.

Goes To...

-MODE 5 once the oven has reached the

temperature defined by the selected cooking

profile.

-MODE 7 when the user presses the back/off key

-and the oven is above 150°F (66°C).

Mode 5: Soaking

Mode during which the oven has completed

warming up and automatically allows an

additional five minutes for the oven cavity

surfaces to warm.

Happens When...

-MODE 4 completes (within 5°F [3°C] of set

point)

Goes To...

-MODE 6 when soaking completes.

-MODE 7 when the user presses the back/off key

-and the oven is above 150°F (66°C).

Mode 6: Cooking

Mode during which the oven is ready to cook.

The user can place food on the conveyor to

cook, or edit cook settings if the full edit or flex

option is enabled. See page 12 for more

information on full edit and flex options.

Happens When...

-MODE 5 completes.

-MODE 3 completes, if the oven’s current

temperature is within 25°F (14°C) of the oven’s

set temperature.

-The user presses the idle key, up key, down

key, or any soft key during MODE 8.

Goes To...

-MODE 7 when the user presses the back/off key.

-MODE 8 when the user presses the idle key.

-MODE 4 if the temperature drops 25°F (14°C)

or more below the set point.

-

MODE 9 if temperature rises 25°F (14°C) or

more above the set point.

Mode 7: Cooling Down

Mode during which the burner assembly shuts

off to allow the oven to cool.

Happens When...

-The user presses the back/off key from

-MODES 3 or 4 (and the oven temperature is

above 150°F [66°C]), or from MODES 5, 6, 8,

or 9.

Goes To...

-MODE 1 when the oven temperature has

receded below 150°F (66°C).

-MODE 2 when the user selects a cooking

profile.

Page 28

12

Mode 8: Idle

Mode during which both blowers are reduced

to 30% to save power. All other oven

components remain the same.

Happens When...

-The user presses the idle key from MODE 6.

Goes To...

-MODE 6 when the user presses the idle key, up

key, down key, or any soft key.

-MODE 7 when the user presses the back/off key.

Mode 9: Cool to Light

Mode during which the burner assembly shuts

off to allow the oven to cool to the set cooking

temperature defined by the profile that was

selected.

Happens When...

-The user selects a cooking profile from

MODE

1 or 7 that has a set cooking temperature lower

than the oven’s current temperature.

Goes To...

-

MODE 3 when the oven has cooled to the set

temperature of the current cooking profile.

-MODE 7 when the user presses the back/off key.

Editing a Cooking Profile

To edit a cooking profile, the oven must be in

the COOKING MODE and the full edit or flex

option must be enabled. For more information

on selecting between full edit, rigid, and flex

options, see Edit Options Screen on page 16.

When the rigid option is enabled, the soft keys

displayed in Figure 7 are disabled and no menu

editing is allowed.

When the full edit option is enabled, a cooking

profile is fully customizable and all changes are

saved once the oven returns to the OVEN OFF or

COOLING DOWN MODE.

When the flex option is enabled, a cooking

profile is customizable within flex option

limitations (as described in the following

sections), and all changes will reset when the

oven returns to the OVEN OFF or COOLING

DOWN MODE.

This section assumes that the full edit option is

enabled (except where otherwise noted) and

that a cooking profile has been enabled.

Changing a Cooking Profile’s Name

The full edit option must be enabled to change

a cooking profile’s name.

1. From the cooking screen (Figure 7), press

L1 to access the name change screen

(Figure 8).

2. Change the name of the cooking profile.

- The up key moves up through the

available characters. e.g. A,B,C…

- The down key moves down through the

available characters e.g. A,+,-, ,9,8,…

- INS (L1) inserts a space.

- DEL (R1) deletes the selected character.

STANDARD OVEN OPERATION

PROFILE 1

BELT F

5:00

BELT R

3:20

TOP AIR 80 %

SET

COOKING

475F

BTM AIR 100 %

INS

CANCEL

DEL

<--- --->

SAVE

[PROFILE 1 ]

Figure 7: Cooking Screen

Figure 8: Name Change Screen

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

Page 29

13

- ---> (R1) moves the cursor to the right.

The cursor starts at the far left character.

If ---> is pressed when the cursor is on the

far right character, the cursor moves to the

far left character.

- <--- (L1) moves the cursor to the left. The

cursor starts at the far left character.

If <--- is pressed when the cursor is on the

far left character, the cursor moves to the

far right character.

3. Press save (R3) to save the changes or cancel

(L3) to cancel any changes.

Adjusting the Belt Speed

Figure 7

The High h Conveyor Oven can accommodate

either one or two conveyor belts. The oven will

automatically detect the number of conveyor

belts installed and display the option to change

the speed of each conveyor belt independently.

1. Press the soft key adjacent to the conveyor

belt you wish to adjust (press L2 for the

front belt [Belt F] or L3 for the rear belt

[Belt R]).

2. Adjust the time it takes for the conveyor

belt to completely cycle through the oven.

- The up key increases bake time in

5-second increments.

+ Flex option enabled: the user can only

increase the time up to an additional

15 seconds.

- The down key decreases bake time in

5-second increments.

+Flex option enabled: the user cannot

decrease the time by more than 15

seconds.

3. Press the soft key adjacent to the belt that

was adjusted to exit the belt speed controls.

Adjusting the Temperature

Figure 7

1. Press R2 to access the temperature controls.

2. Adjust the temperature.

- Press the up key to increase the

temperature in 5°F/5°C increments.

+Flex option enabled: the user can only

increase the temperature up to an

additional 10°F/5°C.

- Press the down key to decrease the

temperature in 5°F/°5C increments.

+Flex option enabled: the user cannot

decrease the temperature by more than

10°F/5°C.

3. Press R2 again to exit the temperature

controls.

Adjusting the Top and Bottom Air

Figure 7

1. Press R1 to access the top air controls, or

R3 to access the bottom air controls.

2. Adjust the air speed.

- Press the up key to increase the air speed

in 5% increments up to 100%.

+Flex option enabled: the user can only

increase the air speed by up to an

additional 15%.

- Press the down key to decrease the air

speed in 5% increments down to 30%.

+Flex option enabled: the user cannot

decrease the air speed by more than

15%.

- Press the soft key again to exit the air

controls.

STANDARD OVEN OPERATION

Page 30

14 STANDARD OVEN OPERATION

This page intentionally

left blank.

Page 31

Oven Modes

Page 32

Page 33

15

The Config Mode

The CONFIG MODE (Figure 9) serves four main

purposes:

1. To access the smart card screen.

2. To access the fault count screen.

3. To access the SETUP MODE.

4. To access the TEST MODE.

To access the CONFIG MODE, press the up key

from the OVEN OFF MODE.

Smart Card Screen

The smart card screen allows the user to

-Load a menu from smart card to oven.

-Save a menu from oven to smart card.

To load or save a menu,

1. Press L3 (Figure 9) to access the smart card

screen (Figure 10).

2. Insert a smart card into the smart card slot

(Figures 11 and 12), with the gold chip

facing the inside of the oven.

3. Load or save a menu.

- Press R1 to load a menu from the smart

card to the oven (Figure 10).

- Press R2 to save a menu from the oven to

the smart card (Figure 10).

Updating the Firmware

From the oven off screen,

1. Insert the gray smart card (see Figure 11)

with the gold chip facing the inside of the

oven. If multiple smart cards are required,

they will be labeled in sequence - ensure the

correct sequence is followed.

2. From the COOLING DOWN or OVEN OFF

MODE, press and hold the idle key until the

oven resets (approximately 5 seconds). The

display will go blank until the upload is

complete.

3. When the oven beeps one long high tone,

the load was successful. If a second card

was provided, insert it.

4. When the oven restarts and the display

turns on, the update is complete. Remove

the smart card.

NOTE: If the update is unsuccessful, the

display will remain off and the oven will beep

one long, low tone. If this occurs, repeat the

above procedure. If the update fails multiple

times, a smart card may be damaged. Contact

TurboChef to obtain a new smart card.

INSERT SMART CARD

PRESS [BACK] TO EXIT

OVEN MODES

Figure 11 Smart Card slot location

SMARTCARD

FAULTS

CONFIG MENU

SETUP

TEST MODE

Figure 9: Config Mode

LOAD FROM CARD

SMARTCARD

SAVE TO CARD

Figure 10: Smart Card Screen

Figure 12: Insert Smart Card Screen

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

Page 34

Accessing the Fault Count Screen

Refer to page 29 for fault descriptions.

From the

CONFIG MODE (Figure 9, page 15),

press R1 to access the fault count screen (Figure

13). The oven will display the number of faults

that have occurred since the oven fault counts

were last cleared (page 20), the oven’s software

was last updated (page 15), or the oven was last

returned to the manufacturer’s default settings

(page 20).

Accessing the Setup Mode

From the CONFIG MODE (Figure 9, page 15),

press L1 to access the SETUP MODE. The SETUP

MODE allows the user to customize several oven

settings - see below for more details.

Accessing the Test Mode

From the CONFIG MODE (Figure 9, page 15),

press R3 to access the TEST MODE. The TEST

MODE gives the service agent the ability to

diagnose oven problems and perform other service related tasks. See page 17 for more information on the TEST MODE.

Setup Mode

Figure 14

The SETUP MODE serves four main purposes:

1. To change the display temperature.

2. To access the edit option screen.

3. To change the display language.

4. To access the info screen.

To access the SETUP MODE, press the up key

from the OVEN OFF or COOLING DOWN MODE

(to access the CONFIG MODE), and then press L1.

Changing the Display Temperature

The oven can display the temperature in either

Celsius or Fahrenheit units. To change the

display temperature, press L1 in

SETUP MODE

(Figure 14).

Edit Option Screen

The edit option screen (Figure 16) allows the

user to switch between full edit, rigid, and flex

options. For more information on the different

edit options, see Editing a Cooking Profile on

page 12.

To access the edit option screen,

1. Press L3 (Figure 14) to access the password

screen (Figure 15).

2. Input the password

6 6 3 3 by pressing the

soft key adjacent to the appropriate number.

To change the edit option (Figure 16),

-Press L1 to select the full edit option.

-Press L2 to select the rigid option.

-Press L3 to select the flex option.

1

2

3

4

5

<6633>

6

ENTER PASSWORD

Figure 15: Password Screen

FULL EDIT*

RIGID

FLEX

EDIT OPTION

Figure 16: Edit Option Screen

DEGS F

EDIT/RIGID/FLEX

ENGLISH

SETUP MENU

INFO

Figure 14: Setup Mode

16 OVEN MODES

F1: 0

F2: 0

F3: 0

F4: 0

F5: 0

F6: 0

F7: 0

F8: 0

F9: 0

F10: 0

FAULT COUNTS

Figure 13: Fault Counts Screen

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

Page 35

17

OVEN MODES

Changing the Display Language

NOTE: This feature is not available on all oven

models.

From the setup menu screen, press R1 to

change the language (Figure 14):

-English

-French

-German

-Spanish

Info Screen

The info screen (Figure 17) is used to display

the following information in an easy to access

place:

- The oven’s serial number

- The oven’s electrical compartment

temperature

- The oven’s voltage

- The total time the oven has been on

- The total time the oven has been idle

- The oven’s software version

To access the info screen, press R3 within the

SETUP MODE.

Test Mode

Figures 18-19

The TEST MODE serves six main purposes:

1. To test individual oven components.

2. To view oven information.

3. To reset oven parameters.

4. To input a new serial number.

5. To perform a burn-in test.

NOTE: When the oven is in

TEST MODE, the

burner does not operate unless a burn-in test is

being performed.

To access the

TEST MODE,

1. Press the up key from the

OVEN OFF or

COOLING DOWN MODE to access the

CONFIG MODE.

2. Press the R3 soft key.

3. Input the password

2 4 3 3 (Figure 20).

The TEST MODE consists of two screens (Figures

18 and 19). Use the up and down keys to

navigate between them.

From screen 1 of the TEST MODE, the user can:

-Access the burner control screen.

-Manipulate the top and bottom blowers.

-View the status indicators.

From screen 2 of the TEST MODE, the user can:

-Input a new serial number

-Initiate a burn-in test

-Erase all oven settings

-Enable/disable maintenance mode*

-Clear the fault counts

* The maintenance mode will show

temperature, burner operation, and other

diagnostics while the oven is running.

INPUT SN

BURN-IN

ERASE/CLEAR

208V

TEST PAGE 2

CLEAR FAULTS

MAINT ON

Figure 19: Test Mode Screen 2

BURNER CTRL

BELT CTRL

TOP AIR

TEST PAGE 1

BOT AIR

D EC27 45% 100% 23.9V 0.0V450F

R 1 2 _ H _ _ _ _ – – – – – _ _ _ O _ _ T B T B – F – – – –

Figure 18: Test Mode Screen 1

1

2

3

4

5

<2433>

6

ENTER PASSWORD

Figure 20: Password Screen

EC=82F 208V

RUN: 65432 HR

IDLE: 12345 HR

INFO

SERIAL_NUMBER

SOFTWARE VERSION

Figure 17: Info Screen

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

Page 36

18 OVEN MODES

Accessing the Burner Control Screen

From screen 1 of the TEST MODE (Figure 18,

page 17), press L1 to access the burner control

screen (Figure 21).

Use this mode to set gas pressures (see page 3).

To change the burner’s setting,

-Press L1 to set the burner to full (or to

-light the burner).

-Press L2 to set the burner to low.

-Press R1 to turn the burner off.

Accessing the Belt Control Screen

From TEST MODE screen 1 (Figure 18, page 17),

press L2 to access the belt control screen (Figure

22). Use this mode to verify the belts work correctly. The number after the belt speed shows

the pulses read by the HES. The percentage is

the amount of drive being asked of the CMSC

(100% = 10V).

To change the belt’s setting,

-Press L1 to turn the belts off.

-Press L2 to access the belt F controls.

-Press L3 to access the belt R controls.

Manipulating the Top and Bottom

Blowers

Figure 18, page 17.

The user can change the speed of the top and

bottom blowers independently. To change the

speed of the blowers,

1. From screen 1 of the TEST MODE, press R1

to access the top blower or R2 to access the

bottom blower.

2. Press the up or down keys to change the

speed of the selected blower in 5%

increments. The percentage of air cannot go

below 30% or above 100%.

Viewing the Status Indicators

Figure 21

The status indicators are located at the bottom

of TEST MODE screen 1 and the burner control

screen. The status indicators are split into two

display lines.

Top Display Line

The top display line shows values relating to

oven components. The letters a-g below and on

Figure 23 indicate the different top display line

status indicators, which are explained below.

a Shows which key is currently pressed.

-U = up key

-D = down key

-a = L1

-b = L2

-c = L3

-f = R1

-g = R2

-h = R3

-P = back/off key

-I = idle key

-S = emergency stop key

b Shows the temperature within the electrical

compartment (temperature displayed in

Celsius only).

c Shows the temperature within the cook

chamber.

d Shows the % value to which the gas valve is

set.

BURN FULL (LIGHT)

BURN LOW

BURN OFF

BURNER CTRL

TCC = 475F

D EC27 45% 100% 23.9V 0.0V450F

R 1 2 _ H _ _ _ _ – – – – – _ _ _ O _ _ T B T B – F – – – –

Figure 21: Burner Control Screen

L1

L2

L3

R1

R2

R3

BELTS OFF

10:25 1920 36%

BELT F

BELT CTRL

BELT R

12:30 1343 31%

Figure 22: Belt Control Screen

Page 37

OVEN MODES

19

e Shows whether or not the igniter is on.

0% = OFF, 100% = ON.

f Shows the voltage of the power supply.

Bottom Display Line

The bottom display line shows enabled inputs

and outputs on the control board. The numbers

1-10 indicate the different bottom display line,

which are explained below.

NOTE: A “-” or “_” displayed on the bottom

display line denotes values that are not

applicable to this oven.

1 “R” represents the real time clock pulse

used by the control board to time oven

functions. The “R” will blink once per

second.

2 The “1” shows that the rear belt’s conveyor

motor’s Hall Effect Sensor (HES) is sending

a pulse to the control board.

3 The “2” shows that the front belt’s

conveyor motor’s HES is sending a pulse to

the control board.

4 The “H” will only be missing during an F3:

Flameout fault.

5 The “O” will only be missing during an F8:

High Limit Tripped fault.

6 The first “T” is displayed while the top air

BMSC reports an ok status to the control

board.

7 The first “B” is displayed while the bottom

air BMSC reports an ok status to the

control board.

8 The second “T” is displayed while the top

air BMSC is enabled and receiving a

command.

9 The second “B” is displayed while the

bottom air BMSC is enabled and receiving

a command.

Entering a New Serial Number

Figure 24

1. Press L1 (Figure 19, page 17) on screen 2 of

the

TEST MODE to access the input new

serial number screen.

2. Enter the new serial number.

-The up key moves up through the

-available characters. i.e. A,B,C…

-The down key moves down through the

-available characters i.e. A,+,-, ,9,8,…

- INS (L1) inserts a space.

- DEL (R1) deletes the selected character.

- ---> (R2) moves the cursor to the right.

-The cursor starts at the far left character. If

- ----> is pressed when the cursor is on the

-far right character, the cursor moves to the

-far left character.

- <--- (L2) moves the cursor to the left. The

-cursor starts at the far left character, if <---

-is pressed when the cursor is on the far left

-character, the cursor moves to the-far right

-character.

3. Press save (R3) to save the changes or

cancel (L3) to cancel any changes.

D EC27 45% 100% 23.9V 0.0V450F

R 1 2 _ H _ _ _ _ – – – – – _ _ _ O _ _ T B T B – F – – – –

a b c d e f g

1 2 3 4 5 6 7 89 10

Figure 23: Status Indicator Explanation

INS

CANCEL

DEL

<--- --->

SAVE

[ ]

Figure 24: Enter New Serial Number Screen

L1

L2

L3

R1

R2

R3

Page 38

Initiating a Burn-In Test

NOTE: Burn-in tests are for manufacturing use

only. DO NOT initiate a burn-in test unless

expressly instructed by TurboChef.

To initiate a burn-in test, Press L2 (Figure 19,

page 17) on screen 2 of the TEST MODE.

The burn-in test (Figure 25) runs the oven for

45 minutes to ensure correct oven operation.

When the burn-in test completes, the burn-in

complete screen (Figure 26) appears. Press any

key to send the oven to the COOLING DOWN

MODE. If the burn-in test fails, the applicable

error code will appear and the oven will return to

the COOLING DOWN or OVEN OFF MODE.

Erasing all Oven Settings

To erase all oven settings and return the oven to

the manufacturer defaults, press L3 (Figure 19,

page 17) on screen 2 of the TEST MODE. The

oven will ask you to confirm this action (Figure

27); press R3 to confirm or the back/off key to

cancel.

CAUTION: Settings cannot be retrieved

once the erase option is confirmed.

Clearing the Fault Counts

To clear the fault counts (reset all fault counts to

0), press R3 (Figure 19, page 17) on screen 2 of

the test mode. The oven will ask you to confirm

this action (Figure 28), press R3 to confirm or

the back/off key to cancel

CAUTION: Fault counts cannot be

retrieved once the erase option is

confirmed.

Viewing the Serial Number

The serial number is located at the bottom of

screen 2 of the TEST MODE (Figure 19, page 17).

CAUTION: Write this number down

before replacing the I/O control board.

Replacing the I/O control board will erase

this number from the oven’s memory.

If replacing a control board, see page 19 for reentering the serial number.

20 OVEN MODES

Continue?

CLEAR FAULTS?

Figure 28: Confirm Clear Fault Counts Screen

BREAKFAST

BELT F

5:00

BELT R

3:20 100%

TOP AIR 80 %

SET

COOKING

OVEN TCC = 475F

475F

BTM AIR 100 %

Burn-In in Progress

Time Left = 42:37

Figure 25: Burn-In Test Screen

Continue?

ERASE ALL?

Figure 27: Confirm Erase All Screen

BURN-IN COMPLETE

OVEN TCC = 475F

PRESS ANY KEY TO CONTINUE

Figure 26: Burn-In Passed Screen

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

L1

L2

L3

R1

R2

R3

Page 39

Oven Systems

Page 40

Page 41

21

OVEN SYSTEMS

The Control System

This section contains information about the

following components:

-Control Board

-Display

-EMI Filter

-Fuses

-High-limit Thermostat

-Idle Button

-Keypad

-Power Supply - 24VDC (Domestic)

-Power Supply - 24VDC (International)

-Relay (K3 - Gas)

-Relay (K4 - Ignition)

-RTD

-Smart Card Reader

-Speaker

-Thermostat - 120ºF (Close on Rise)

-Wire Harness

This section also contains testing procedures for

the following components:

-Power Supply - 24VDC (Domestic)

-Power Supply - 24VDC (International)

-Relay (K3 - Gas)

-Relay (K4 - Ignition)

-RTD

Control Board

The control board is powered by the 24 VDC

power supply, and sends control voltage to all

the relays. See page 45 for a schematic. 24

VDC can be measured at the J9 connector, pins

19 and 8. See pages 45-47.

Display

The vacuum fluorescent display is the primary

user interface, and is powered by the control

board using 5 VDC. Its input voltage can be

tested at J7, pins 1 and 3 (page 45).

EMI Filter

The EMI filter helps suppress the amount of

RF “noise” emitted by the oven, also filtering

noise from entering the controls.

Fuses

The control circuit is ultimately protected by

two 20-amp class CC fuses, which are in the

line-voltage circuit (incoming voltage). The

fuses are designed to blow in case of an overcurrent situation.

High-Limit Thermostat

The high limit thermostat is a 3-pole, manual

reset thermostat with a trip point of 572ºF

(300ºC). The thermostat interrupts power to

both the ignition module and the closed circuit

of the I/O control board.

Idle Button

The Idle Button places the oven in idle mode,

slowing the blowers to 30%. When lit, idle

mode is active.

Keypad

The keypad is an 11-key membrane switch.

Power Supply - 24VDC (Domestic)

The power supply - 24VDC (domestic) converts line voltage (208-240 VAC) to 24 VDC.

Line voltage (208-240 VAC) is connected to

terminals 1 & 4 (jumper between terminals 2

& 3, terminal 5 is not used). The resistance

from terminals 1 to 4 (with wires disconnected)

is 20.7

W. The output (24 VDC) is on

terminals “+OUT” (power = good) and “OUT” (power = bad).

Testing Procedure

1. Disconnect line voltage from the unit.

2. Take a resistance reading on terminals

1 & 4.

a) If terminal resistance is correct

(20.7

W):

-Apply line voltage to the unit.

-Check for line voltage (208-240 VAC)

-at terminals 1 & 4.

Page 42

22 OVEN SYSTEMS

b) If terminal resistance is incorrect,

replace the power supply.

3. If correct voltage is present, disconnect the

output wires and check output (-OUT &

+OUT) for 24 VDC.

4. If voltage is present with output wires

disconnected and not present when the

wires are connected, inspect the wire

harness for damage or shorts.

5. If the wire harness is intact and undamaged,

the power supply is damaged or defective

and must be replaced (page A-8).

Power Supply - 24VDC (International)

The power supply - 24VDC (international)

converts line voltage to 24 VDC. Line voltage is

connected to terminals L & N. The output (24

VDC) is on terminals “-V” and “+V”.

Testing Procedure

1. Check for line voltage (208-240 VAC) at

terminals L & N.

2. If correct voltage is present, check output

(-V & +V) for 24 VDC (with output wires

disconnected).

3. If voltage is present with output wires

disconnected and not present when the

wires are connected, inspect the wire

harness for damage or shorts (page 45).

4. If wire harness is intact and undamaged,

the power supply - 24VDC (international)

is damaged or defective and must be

replaced (page A-8).

K3 Relay - Gas

The K3 relay is a single pole, double throw

relay with a 24 VDC coil. The coil resistance is

577

W and the contact rating is 20A at 240

VAC. When 24 VDC is applied to the coil, the

normally open contacts (7 & 4 or C & NO)

close applying line voltage to the burner transformer and the combustion blower.

Testing Procedure

1. Disconnect line voltage to the unit.

2. Take a resistance reading of the coil.

3. If coil resistance is correct (577

W):

a) Apply line voltage to the unit.

b) Check for 24 VDC at the coil of the

relay when the unit is calling for heat.

c) Check the state of the contacts.

-If the normally open contacts (7 & 4

-or C & NO) are closed when coil

-voltage is applied, the K3 relay is

-functioning normally.

-If the normally open contacts (7 & 4

-or C & NO are not closed when coil

-voltage is applied, the K3 relay is

-malfunctioning and must be replaced

-(page A-8).

4. If the coil resistance is incorrect, replace the

K3 relay.

K4 Relay - Ignition

The K4 relay is a single pole, double throw

relay with a 24 VAC coil. The coil resistance is

585 k

W and the contact rating is 20 A at 240

VAC. When 24 VAC is applied to the coil, the

normally open contacts (7 & 4 or C & NO)

close and the normally closed contacts (7 & 1

or C & NC) open.

The K4 relay uses the normally closed contacts.

If 24 VAC is applied to the ignition module

and 1.5 uA minimum is not maintained, the

ignition module applies 24 VAC to the relay

and the contacts open. When the contacts open

the I/O control board shows an “F3 No Flame”

fault.

Testing Procedure

1. Disconnect line voltage to the unit.

2. Take a resistance reading of the K4 coil.

Page 43

OVEN SYSTEMS

23

3. If coil resistance is correct (585 k W):

a) Apply line voltage to the unit.

b) Check for 24 VAC at the coil of the

relay when the unit is calling for heat.

c) Check the state of the contacts.

-If the normally open contacts (7 & 4

-or C & NO) are closed and the

-normally closed contacts (7 & 1 or C

-& NC) are open when coil voltage is

-applied, the K4 relay is functioning

-normally.

-If the normally open contacts (7 & 4

-or C & NO) are not closed and/or the

-normally closed contacts (7 & 1 or C

-& NC) are not open when coil voltage

-is applied, the K4 relay is

-malfunctioning and must be replaced.

4. If the coil resistance is incorrect, replace the

K4 relay (page A-14).

RTD

The RTD is a resistance temperature detector

used to detect the cavity temperature.

Testing Procedure

1. Disconnect the RTD from the I/O control

board.

2. Place the RTD in a bowl of ice water for 2

minutes.

3. Take a resistance reading of the RTD.

4. If RTD resistance is not 100

W, RTD is

defective and must be replaced.

NOTE: Use Figure 29, page 24 to determine

resistance readings at temperatures other than

freezing.

Smart Card Reader

The smart card reader allows the oven operator

to load a menu/firmware update from a smart

card. A menu that already exists in the oven can

also be saved to a smart card. For instructions,

see page 15.

Speaker

The speaker is separate from the control board,

and provides audible feedback to the oven operator whenever a key is pressed or a fault occurs.

Thermostat - 120ºF (Close on Rise)

The cooling fan thermostat actuates the cooling

fans when the temperature in the left end bell

reaches 120ºF (49ºC).

Wire Harness

The wire harness distributes power to the oven’s

electrical components. See page 45 for a

schematic.

The Conveyor System

This section contains information about the

following components, as well as testing

procedures:

- Gear Drive (Conveyor Motor)

- Gear Drive (Conveyor Motor) Speed

Controller (CMSC)

Gear Drive (Conveyor Motor)

The conveyor motor is a 1550 RPM, 3-phase

motor with a built in Hall Effect Sensor. The

speed of the conveyor motor is controlled by the

voltage frequency applied to the windings from

the CMSC. The Hall Effect Sensor sends a DC

pulse back to the control board to verify motor

speed. The control board uses these pulses to

determine the output DC voltage to the

CMSC.

Conveyor ovens with a split-belt configuration

will contain separate gear motors and speed controllers for each belt.

Testing Procedure

1. Disconnect line voltage from the unit.

2. Take a resistance reading of the motor

windings and use Figure 30, page 24 to

verify that the resistance readings are correct.

Page 44

To From Description Expected Resistance

White Grey Winding (A-B)

215-217 W

White Black Winding (A-C)

215-217 W

Grey Black Winding (B-C)

215-217 W

Black, Brown, or

Blue

Green

Windings to

chassis

Open

Figure 30: Conveyor Motor Ohm Chart

24 OVEN SYSTEMS

3. If the resistance readings are correct,

reconnect the motor wiring and then apply

line voltage to the unit and check for

voltage applied to the motor windings.

4. If no voltage is present, ensure the CMSC is

operating properly (see below).

5. If CMSC is operating properly, inspect the

wire harness for damage or shorts.

6. If the wire harness is intact and undamaged,

and the CMSC is operating properly, the

gear drive is damaged or defective and must

be replaced (page A-8).

Gear Drive (Conveyor Motor) Speed

Controller (CMSC)

The CMSC converts single-phase line voltage

to a three-phase output. The speed of the gear

drive is controlled by the frequency output of

the CMSC. The CMSC receives an input

voltage (0-10 VDC) from the control board

and adjusts the frequency output to the gear

drive.

Testing Procedure

WARNING: Capacitors within the CMSC

can retain charge after power is removed.

Exercise extreme caution when handling the

terminals.

WARNING: DO NOT connect incoming

AC power to output terminals U, V, or W.

This will seriously damage the Conveyor

Motor Speed Controller.

1. Ensure that no faults appear on the display

of the CMSC during oven operation. The

control will display the frequency output if

the system is operating correctly.

2. Check the input voltage on terminals L1 &

L2 and the DC voltage input on terminals

0V & AI (0.1-10 VDC).

3. Check ohms of motor (Figure 30).

4. If no voltage is present, inspect the wire

harness for damage or shorts (page 45).

5. If wire harness is intact and undamaged,

the CMSC is damaged or defective and

must be replaced.

ºF 0º +20º +40º +60º +80º +100º +120º +140º +160º +180º +200º

0º

90.03W 97.39W 101.74W 106.07W 110.38W 114.68W 118.97W 123.24W 127.50W 131.74W 135.97W

+200º

135.97W 140.18W 144.38W 148.57W 152.74W 159.90W 161.04W 165.17W 169.29W 173.39W 177.47W

+400º

177.47W 181.54W 185.60W 189.64W 193.67W 197.69W 201.69W 205.67W 209.64W 213.60W 217.54W

+600º

217.54W 221.47W 225.38W 229.28W 233.17W 237.04W 240.90W 244.74W 248.57W 252.38W 256.18W

ºC 0º +10º +20º +30º +40º +50º +60º +70º +80º +90º +100º

0º

100.00W 103.90W 107.79W 111.67W 115.54W 119.40W 123.24W 127.07W 130.89W 134.70W 138.50W

+100º

138.50W 142.29W 146.06W 149.82W 153.58W 157.31W 161.04W 164.76W 168.46W 172.16W 175.84W

+200º

175.84W 175.91W 183.17W 186.82W 190.45W 194.07W 197.69W 201.29W 204.88W 208.45W 212.02W

+300º

212.02W 215.57W 219.12W 222.65W 226.17W 229.67W 233.17W 236.65W 240.13W 243.59W 247.04W

Figure 29: Temperature/Resistance Relationship Class B. Resistance @ 0ºC = 100.0, Alpha = 0.003850

Page 45

OVEN SYSTEMS

Accessing Parameters

WARNING: DO NOT perform this

procedure unless instructed by

TurboChef.Changing the parameters to

other than those preset by TurboChef can

damage critical oven components.

NOTE: “Motor Rated Speed” (07) is RPM of

motor before gearbox, not after.

1. Open the right end bell (page 1).

2. Locate the CMSC (page A-8).

3. Press the

M key.

4. Use the and keys to navigate the

parameters.

5. Press the M key to access the parameter

shown on the CMSC display.

6. Use the and keys to manipulate the

parameter.

7. Press the M key to return to the parameter

selection.

8. Repeat steps 4-7 to manipulate other

parameters as needed.

The Blower System

This section contains information about and

testing procedures for the following

components:

-Blower Motor

-Blower Motor Speed Controller (BMSC)

Blower Motor

The main blowers are 3400 RPM, 3-phase

blower motors. The speed of the blower motor

is controlled by the voltage frequency applied to

the motor windings from the blower motor

speed controller (BMSC).

Testing Procedure

1. Disconnect line voltage from the unit.

2. Take a resistance reading of the motor

windings and use Figure 31 to verify the

resistance readings are correct.

3. If the resistance readings are correct,

reconnect motor wiring and then apply

line voltage to the unit and check for

voltage applied to the motor windings.

4. If no voltage is present, ensure the BMSC is

operating properly (see below).

5. If BMSC is operating properly, inspect the

wire harness for damage or shorts (page 45).

6. If wire harness is intact and undamaged and

the BMSC is operating properly, the blower

motor is damaged or defective and must be

replaced (page A-8 = lower, A-12 = upper).

Blower Motor Speed Controller (BMSC)

The BMSC converts single-phase line voltage

(208-240 VAC) to a three-phase output. The

speed of the blower motor is controlled by the

frequency output of the BMSC. The BMSC

receives an input voltage (0-10 VDC) from the

I/O control board and adjusts the frequency

output to the blower motor.

Testing Procedure

CAUTION: Capacitors on the BMSC

may retain charge after power is removed.

To discharge capacitors for further safety,

short B+ and B- together.

WARNING: DO NOT connect

incoming AC power to output terminals

U, V, or W or terminals B+ or B-. This

will seriously damage the BMSC.

1. Ensure that no faults appear on the display

during the operation of the BMSC. The

control will display the frequency output if

the system is operating correctly.

25

To From Description Expected Resistance

Blue Brown Winding (A-B)

5.1-5.5 W

Blue White Winding (A-C)

5.1-5.5 W

Brown White Winding (B-C)

5.1-5.5 W

Blue, Brown, or

White

Green

Windings to

chassis

Open

Figure 31: Blower Motor Ohm Chart (Motor Windings)

Page 46

2. Check the input voltage on terminals L1

& L2 (208-240 VAC) and the DC voltage

input on terminals 2 & 5 (0.1-10 VDC).

3. If no voltage is present, inspect the wire

harness for damage or shorts (page 45).

4. If wire harness is intact and undamaged,

the BMSC is damaged or defective and

must be replaced (page A-8 = lower, A-12 =

upper).

Accessing Parameters

WARNING: DO NOT perform this

procedure unless instructed by

TurboChef.Changing the parameters to

other than those preset by TurboChef can

damage critical oven components.

1. Open the right or left end bell depending

on which BMSC requires testing

(page 1, A-1).

2. Locate the BMSC (page A-1).

3. Press the MODE key.

4. Use the keys to navigate the parameters.

5. Press the MODE key to access the parameter

shown on the BMSC display.

6. Use the keys to manipulate the

parameter.

7. Press the MODE key to return to the

parameter selection.

8. Repeat steps 4-7 to manipulate other

parameters as needed.

The Burner System

This section contains information about and

testing procedures for the following

components:

- Air Pressure Switch

- Burner Transformer

- Combustion Blower

- Modulating Gas Valve

- Ignition Module

Air Pressure Switch

The air pressure switch contacts close when a

0.1in WC (2.54mm WC) differential exists

between the two ports. The air pressure switch

has one negative port and one positive. The air

tube from the combustion blower is attached to

the positive port. The air tube must not be damaged in any way (cracked or split). The connection must be tight at the combustion blower and

the switch itself to ensure proper operation of the

air pressure switch.

Testing Procedure

1. Attach a digital manometer to the air tube

coming from the combustion blower.

2. A reading above 0.1in WC (2.54mm WC)

is required to close the contacts. If the

reading is below 0.1in WC (2.54mm WC),

check the combustion blower operation.

Burner Transformer

The burner transformer converts incoming line

voltage to 24 VAC output.

Testing Procedure

1. Disconnect line voltage to the burner

transformer.

2. Remove the burner transformer lead wires.

3. Check the resistance of the primary and

secondary windings, refer to Figure 33, to

determine if the transformer is functioning

properly.

4. Set up the wire configuration for 208 or 240:

- 208 VAC installation: connect wire B

(blue) to wire C (blue). Figure 32, below, is

configured for 208 VAC operation.

- 240 VAC installation: connect wire A (red)

to wire C (blue).

26 OVEN SYSTEMS

B

C

A

Figure 32: Burner Transformer Wires

Page 47

OVEN SYSTEMS

27

Combustion Blower

The combustion blower is a 3000 RPM, 208240 VAC, 0.33 A, 50/60 hz, blower motor.

The winding resistance is 92

W. The combus-

tion blower receives line voltage (208-240 VAC)

from the K3 relay. Once the combustion blower

reaches full speed, the air pressure switch closes,

applying 24 VAC to the ignition module.

Testing Procedure

1. Disconnect line voltage from the unit.

2. Take a resistance reading of the winding;

resistance should be 92

W. If resistance

is incorrect, the combustion blower is

damaged or defective and must be replaced

(page A-14).

3. Apply line voltage to the unit and check for

line voltage (208-240 VAC) applied to the

winding when the unit is calling for heat

and the K3 relay is closed.

4. If no voltage is present, inspect the wire

harness for damage or shorts (page 45).

5. If the wire harness is intact and undamaged,

the combustion blower is damaged or

defective and must be replaced (page A-14).

Modulating Gas Valve

The modulating gas valve is a combination gas

valve with a 24 VAC primary solenoid valve

and 0.1-10 VDC modulating valve. The

primary solenoid valve receives 24 VAC from

the ignition module. The resistance of the

primary solenoid valve is 535 k

W. The

modulating valve receives 0.1-10 VDC from

the control board. The resistance of the

modulating valve is 44

W. The modulating

valve has an adjustment shaft that adjusts the

high and low flame pressure.

Testing Procedure

NOTE: See page 3 for instructions on adjusting

the high and low flame gas pressure.

1. Disconnect line voltage from the unit.

2. Take a resistance reading of both coils,

resistances should be 535k W and 44

W. If resistance is incorrect, the gas

valve is damaged or defective and must be

replaced (page A-14).

3. During warmup and cook mode, apply

line voltage to the unit and check for 24

VAC at the primary solenoid coil and

0.1-10 VDC at the modulating valve coil.

4. If no voltage is present, inspect the wire

harness for damage or shorts (page 45).

5. Check for 24 VAC leaving the ignition

module (see Figure 35, page 28)

6. If wire harness is intact and undamaged,

the modulating gas valve is damaged or

defective and must be replaced (Pipe and

valve assembly, page A-14).

Ignition Module

The ignition module generates 30,000 V at the

spark igniter stud for direct ignition of the main

burner when 24 VAC is applied. The module

senses the presence of the burner flame and

discontinues the ignition spark.

If the burner fails to ignite within 6 seconds,

the module goes into safety lockout. If the

burner does not maintain 1.5 DC uA minimum, the timed trial for ignition (6 seconds) is

repeated and safety lockout occurs. If safety

lockout occurs, power must be removed from

the module before it can be restarted.

Testing Procedure

NOTE: The ignition module is different in

domestic and international model ovens. Figure

34 shows the differences in the terminal labels

between the two models.

To From Expected Resistance

Primary

Black White (240 VAC Input)

28.1 W

Black Blue (240 VAC Input)

53.1 W

Black Red (240 VAC Input)

62.4 W

Secondary

Yellow Yellow

0.80 W

Figure 33: Burner Transformer Ohm Chart

Page 48

28

1. Shut off the gas supply.

2. Disconnect the wire spark cable from the

stud terminal of the ignition module. This

will isolate the burner spark rod from the

ignition module.

3. Using a different wire spark cable (ensure

that the cable is not damaged in any way),

attach one end to the stud terminal of the

ignition module.

4. Touch the other end of the ignition cable to

the ground terminal of the ignition module

(DO NOT remove the existing ground lead

from the ignition module).

5. Apply power to the ignition module.

6. Before the ignition module goes into a

safety lockout (6 seconds), slowly move the

end away from the ground terminal. A

spark length of 1/8” (3 mm) or more

indicates good ignition voltage. If there is

no arc or the maximum spark length is less

than 1/8” (3 mm), and the input voltage to

the ignition module is 20-25 VAC, the

ignition module is damaged or defective

and must be replaced (page A-14).

Testing Procedure for Testing Flame Rectification

Figure 35

1. Ensure the oven is in the off or cooling down

mode (page 10).

2. Remove the flame signal ground wire from

the ignition module.

3. Connect a DC multipurpose meter that is

able to read micro amps (uA) in series with

the flame signal ground wire.

-Connect the red (+) meter lead to the free