Page 1

perator's Manual

®

0®

A2.41

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

P/N 769-00532 (12/02)

PRINTED IN USA

Page 2

Content Page

Calling Customer Support .................................................... 2

Rules for Safe Operation ..................................................... 3

4now Your Unit ....................................................... 6

Assembly Instructions ....................................................... 7

Operating Instructions ....................................................... 8

Maintenance and Repair Instructions .......................................... 11

Cleaning and Storage ....................................................... 14

Accessories and Replacement Parts ........................................... 14

Troubleshooting Chart ...................................................... 15

Specifications .......................................................... 15

Warranty Information ....................................................... 16

Parts List .................................................... Inside Back Cover

This operator's manual is an important part of your new trimmer. It will help you assemble, prepare and maintain the unit

for best perforrnance, please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the

information from it in the space provided below. ]-his information is very important it you need help from oUt Customer

Support Department or an authorized dealer.

• You can locate the model number Onthe unit. A sample model plate is explained below. For future reference,

please copy the model number and the serial number of the equipment in the space below.

"'odal. : Copy the model and parent

Serial rn umber , .'_.. . part number here: -

MODEL:

ParefltPan Nurnoer

Copy the serial number here:

IIHIIIIIIIHHIIIIIIIIIHIIII

If you have difficulty assembling this product or have any questions regarding the contro!s, operation or maintenance of

this unit, please ca!! the Customer Support Department.

Call 1-800-520,5520 to reach a Customer Support representative. Please have your unit's model number

_'_ and serial number ready when y0u call See previous section to locate this information, yo u will be asked tO

enter the serial number in order to process your call

2

Page 3

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

SYMBOL MEANING ]

DANGER: Failure to Obey a safety warning I

will result in serious injury to yourself or to I

others. Always follow th e safety precautions I

to reduce the risk Of fire, e ectr c shock and

personal injury. J

I SYMBOL MEANING ]

A SAFETY ALERT SYMBOL: Indicates danger,

Aiik warning or caution. Attention is required in

order to avoid serious personal injury. May be

used in conjunction with other symbols or

p ctographs.

NOTE: Advises you of information or instructions Vital

to the operation or maintenance of the

equipment.

READ ALL INSTRUCTIONS

DANGER: When using battery trimmers,

should always be

followed to reduce the risk of fire, electric

shock and personal injury. Carefully read and

understand the entire operators manual

before using your trimmer. Pay close

attention to the operating instructions and

safety warnings.

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Children and teens under the age of 15 must not use

the unit, except for teens guided by an adult.

• Inspect the unit before use. Replace damaged parts.

Check for battery leaks. Make sure all fasteners are in

place and secure. Replace cutting attachment parts

that are cracked, chipped or damaged in any way.

Make sure the cutting attachment is properly installed

and securely fastened. Be sure the cutting attachment

shield is properly attached, and positioned as

recommended. Failure to do so can result in personal

injury to the operator and bystanders, as well as

damage to the unit.

• Avoid dangerous environments. Never operate your

unit in damp or wet conditions. Moisture is a shock

hazard.

• Do not use the unit in the rain.

• Do not handle the unit with wet hands.

[ ,_11L [WARNING: Failure to obey a safety warning ]

,_lk |can result in injury to yourself and others. I

IAlways follow the safety precautions to I

I reduce the risk of fire, electric shock and

| personal injury. |

CAUTION: Failure to obey a Safety warning

may result in property damage or personal

injury to yourself or to others. Always follow I

the safety precautions to reduce the risk of

fre, electric shock and persona njury. J

Use only 0.080 inch (2.03 mm) diameter Genuine

Factory Parts rM replacement line. Never use metal-

reinforced line, wire or rope. These can break off and

become dangerous projectiles.

Be aware of the risk of injury to the head, hands and feet.

Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire or

string. They can be thrown or become entangled in the

cutting attachment. Clear the area of children,

bystanders, and pets. At a minimum, keep all children,

bystanders and pets outside a 50-foot (15 m.) radius;

there still may be a risk to bystanders from thrown

objects. Bystanders should be encouraged to wear

eye protection. If you are approached, stop the motor

and cutting attachment immediately.

This unit was not designed to be used as a

brushcutter. Do not attach or operate this unit with any

type of brushcutting blade or brushcutting attachment.

SAFETY WARNINGS FOR BATTERY TRIMMERS

Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in operating

condition. Be aware of possible hazards even when

the tool is idle. Take care when performing

maintenance or service.

Remove or disconnect the battery before servicing,

cleaning or removing material from the unit.

Only use the charging station provided with your unit.

Do not substitute any other charging equipment. Use

of any other means of charging could cause the

batteries to explode, resulting in possible serious

personal injury.

3

Page 4

• Do not charge the unit in the rain or in wet locations

SAFETY WARNINGS FOR CHARGING STANDS

AND LEAD-ACID BATTERIES

• Before using the charging stand, read all instructions

and cautions in this manual, as well as on the charging

stand, and on the unit.

• Do not expose charger to rain or snow.

• To reduce risk of injury, charge only sealed lead-acid

rechargeable batteries Other types of batteries may

burst, causing personal injury and damage

• To reduce risk of damage to charger body and cord,

pull it by the charger body (not the cord) when

disconnecting the charger

• Make sure the charger cord is located in an area where

it will not be stepped on, tripped over or otherwise

subjected to damage or stress.

• Do not operate the charger with a damaged cord or

plug. If damaged, replaced the charger immediately.

• Do not operate charger if it has received a sharp blow,

been dropped or has been damaged in any way. If the

charger case is damaged, replace the charger.

• Do not disassemble the charger. The charger is not

serviceable; disassembly may result in a electric shock

or fire.

• To reduce the risk of electric shock, unplug the charger

from the outlet before you clean or service the unit.

• Do not use the charger outdoors.

• Use only the following type and size battery: 12 volt

DC, sealed lead-acid battery (182391).

• Do not dispose of batteries in fire. The cell may

explode. Batteries should be recycled. Consult your

local waste authority for information regarding available

recycling and/or disposal options.

• Exercise care when handling the batteries. Be careful

and avoid shorting the battery with conducting

materials like rings, bracelets and keys. The battery or

conductor may overheat and cause burns.

• Charge the battery in a location where the temperature

is between 50"F (10"C) and 100"F (38"C).

• Do not open or mutilate the battery. Released

electrolyte is corrosive and may cause damage to the

eyes or skin. It may be toxic if swallowed.

WHILE OPERATING

• Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards. Also wear

ear/hearing protection when operating this unit. Wear a

face or dust mask if the operation is dusty. Long sleeve

shirts are recommended.

• Wear heavy, long pants, boots and gloves. Do not

wear loose clothing, jewelry, short pants, sandals or go

barefoot. Secure hair above shoulder level.

• The cutting attachment shield must always be in place

while operating the unit. Do not operate unit without

the trimming lines extended, and the proper line

installed. Do not extend the trimming line beyond the

length of the shield.

• Adjust the D-handle to your size to provide the best grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Do not carry around a unit

with your finger on the trigger switch.

• Use the right tool. Only use this tool for the purpose

intended.

• Do not overreach. Always keep proper footing and

balance.

Always hold the unit with both hands when operating.

Keep a firm grip on both the battery housing grip and

the D-handle.

• Keep hands, face and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it is rotating.

• Do not operate the motor faster than the speed needed

to cut, trim or edge. Do not run the motor at high

speed when you are not cutting.

• Always stop the motor when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign object,

stop the motor immediately and check for damage Do

not operate before repairing damage Do not operate

the unit with loose or damaged parts

• Release the trigger, ensure the lock-off button resets

and allow the motor to stop for maintenance or repair.

• Use only Genuine Factory Parts TM replacement parts

when servicing this unit These parts are available from

your authorized service dealer Do not use

unauthorized parts, accessories or attachments Using

unauthorized parts may lead to serious injury, damage

to the unit and a voided warranty

• Keep the unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

OTHER SAFETY WARNINGS

• Disconnect the unit from the power supply when it is idle,

when you are storing or transporting it, when you are

servicing it, and when you are changing attachments.

• Store the unit in a dry area, locked up to prevent

unauthorized use or damage, and stored in a high

place out of the reach of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use. See the Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

4

Page 5

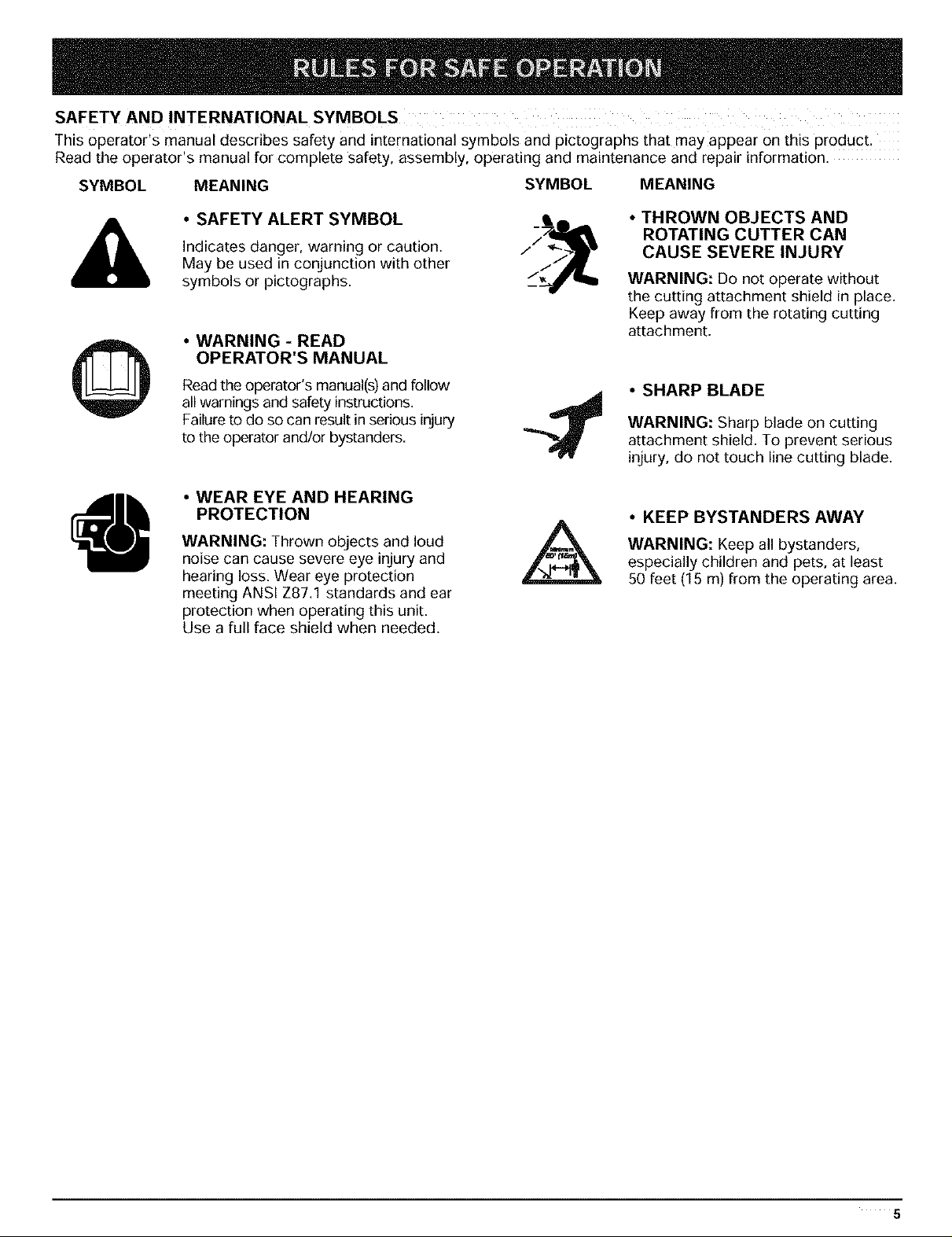

SAFETY AND INTERNATIONAL SYMBOLS

This operato['s manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING SYMBOL MEANING

• THROWN OBJECTS AND

ROTATING CUTTER CAN

Indicates danger, warning or caution. //._

• SAFETY ALERT SYMBOL __

May be used in conjunction with other //

symbols or pictographs.

• WARNING - READ

OPERATOR'S MANUAL

CAUSE SEVERE INJURY

WARNING: Do not operate without

the cutting attachment shield in place.

Keep away from the rotating cutting

attachment.

©

{_ • WEAR EYE AND HEARING

Read the operator's manual(s)and follow

all warnings and safety instructions.

Failureto do so can result in serious injury

to the operator and/or bystanders.

PROTECTION

WARNING: Thrown objectsand loud

noise can cause severe eye injury and

hearing loss. Wear eye protection

meeting ANSI Z87.1 standards and ear

protection when operating this unit.

Use a full face shield when needed.

• SHARP BLADE

WARNING: Sharp blade on cutting

attachment shield. To prevent serious

injury, do not touch line cutting blade.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders,

especially children and pets, at least

50 feet (15 m) from the operating area.

5

Page 6

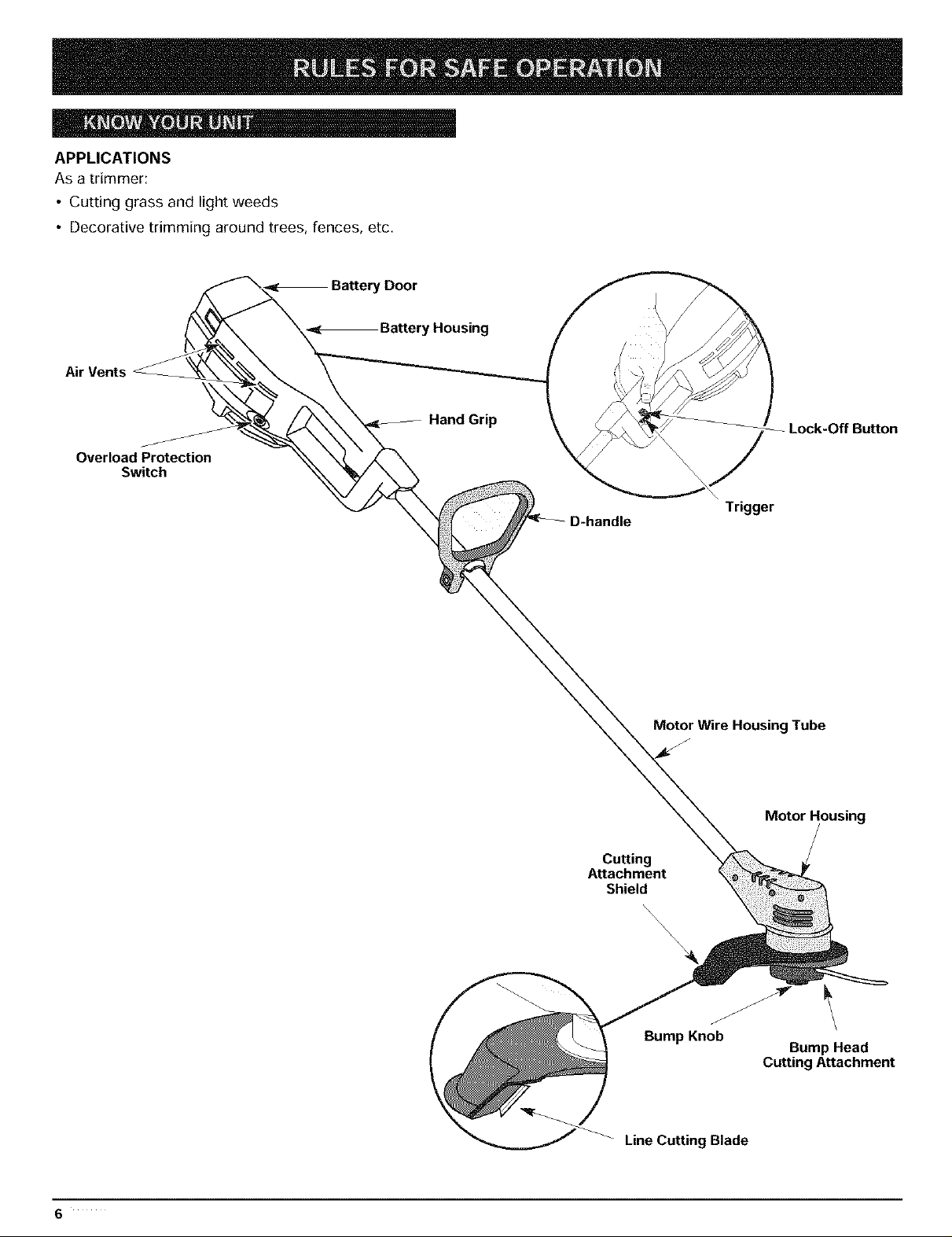

APPLICATIONS

As a trimmer:

• Cutting grass and light weeds

• Decorative trimming around trees, fences, etc.

Door

Air Vents

Overload Protection

Switch

Battery Housing

Hand Grip

\

- Lock-Off Button

Trigger

Motor Wire Housing Tube

Motor Housing

Cutting

Attachment

Shield

\\\\\\\\\_1_

Bump Knob

Line Cutting Blade

Bump Head

Cutting Attachment

6

Page 7

ADJUSTING THE D-HANDLE

NOTE: The D-handle comes mounted on the backside

of the shaft.

1. Locate the wing nut on the D-Handle. Untighten the

wing nut enough to loosen the D-Handle (Fig. 1).

NOTE: Do not remove wing nut, washer, or bolt.

2. Rotate the D-Handle to the upright position on the

front side of the shaft housing (Fig. 1).

NOTE: The D-handle should slant towards the

powerhead of the unit.

\

\

Wing Nut

MOUNTING THE CHARGING STATION

NOTE: Mount the charging unit and allow the unit to

charge for at least 36 hours prior to first use.

This unit may stay on the charging station continuously

without overcharging. Place the charging station where

the unit is intended to be stored. This should be a cool,

dry and well ventilated place, where the unit can be

locked-up and out of the reach of children.

The unit should be stored and charged in a location

where the temperature is between 50F (10C) and IOOF

(38c).

1. Locate a place for the charging station near a wall

outlet and high enough to keep the unit off the floor.

2,

Locate the wall stud and mount the charging station

to the wall using the three (3) screws provided

(Fig 3). Make sure that the screws enter the wall stud

to provide a secure mount.

Fig. 1

3. Hold the unit in the operating position, if necessary,

reposition the D-handle to the location that provides

the best grip (Fig. 2).

WaOu, lll

Fig. 3

CAUTION: TO prevent injury or damage to I

the unit, the charging station must be

mounted secure y to the wa. J

,

Plug the charger into the wall outlet and wind any

excess wire onto the cord wrap on the charging

station (Fig. 3).

Wall

Stud

Fig, 2

4. Tighten the wing nut until the D-Handle is secure.

7

Page 8

CHARGING THE UNIT

Make sure the charging station is securely fastened to a

wall and the charger is plugged into a working wall

outlet.

NOTE: Allow the unit to charge for at least 36 hours

prior to first use.

1.

Slide the unit down into the charging station until it is

firmly seated (Fig. 4). The barrel connector in the

charging station will insert into the unit. If it doesn't,

refer to Replacing the Charger.

NOTE: The battery will heat up while the unit charges.

Be sure the air vents on the battery housing are

kept clear for proper ventilation (Fig. 4).

3. Charge the battery until the Charging Indicator Dght

on the charger turns from red to green (Fig. 5).

NOTE: The unit's operahng time and the life of the

battery will be shorten if the untt is not fully

charged between uses,

4. Place the unit back on the chargLng station afte/

each use. The unit is designed so that the battery

cannot be overcharged,

Barrel

Connector

Air Vents

Charging

Station

Fig, 4

2.

When the red indicator light on the charger is on, the

battery is being charged (Fig. 5). If the light fails to

come on, check that:

a.

The charger is plugged into a working wall outlet.

b.

The unit is firmly seated into the charging station and

the barrel connector is fully inserted into the unit.

C.

The barrel connector is properly installed in the

charging station. If it isn't, refer to Replacing the

Charger.

d. Power is on at the wall outlet.

NOTE: If the wall outlet is operated by a switch, be sure

the switch is ON.

A l WARNING: If the wall outlet is not Working l

"_, I properly, have the wall outlet checked by a l

qualified electrician. This will help prevent l

.Lserous persona njury.

Charging

Fig. 5

Charging Tips for Maximum Performance

Store and charge the unit where temperatures are

between 50 F (10=C) and 100= F (38 C). Storing the

unit or batteries above 100= F (38 C) will reduce

battery life.

Storage below 50=F (10 C) will not reduce battery

life, but may require a longer charging time.

Store the unit on the charging station when not in

use. The unit is designed so that the battery cannot

be overcharged.

NOTE: The charging indicator light will remain lit when

the unit is properly installed in the charging

station.

Temperature Effects on Charging Time

50 F (10=C) to 100 F (38" C) - Battery will charge

within 24 hours.

40 F (4 C) to 50 F (10 C) - Battery will require up to

48 hours for a full charge.

Below 40" F (4 "C)- Battery will not reach full charge.

NOTE: The unit run time will be reduced when the

battery is not fully charged.

8

Page 9

STARTINGTHEUNIT

1. Press and hold the lock-off button in (Fig. 6). This

allows the trigger to operate.

WARNING: To prevent serious personal l

injury, ensure the lock-off button [esets each I

time the trigger is released. I

Trigger

/

Fig. 6

2. Depress and hold the trigger.

3. Release the lock-off button.

STOPPING THE UNIT

Release the trigger to stop the trimmer.

OVERLOAD PROTECTION SWITCH

This unit is equipped with an overload protection switch

to prevent overheating damage to the motor.

If the switch pops out:

1. Release the trigger and allow the unit to cool for a

minute.

2. Press the overload switch to reset. Resume

operation (Fig. 7).

If the switch pops again shortly after the first time:

1. Allow the unit to cool for 15 to 30 minutes.

2. After the unit has cooled, press the overload switch

to reset. Resume operation

If the switch does not stay in or continues to pop out

during operation, take the unit to an authorized service

dealer for repair.

Overload

Protection

Switch

]

Fig. 7

HOLDING THE UNIT

WARNING: Dress properly to reduce the risk

of injury when operating this unit. Do not wear

loose clothing or jewelry. Wear eye and

ear/hearing protection. Wear heavy, long

pants, boots and gloves. Do not "wear short

pants, sandals or go barefoot.

Before operating the unit, stand in the operating position

and check that:

• The operator is wearing eye protection and proper

clothing.

• The operator's right arm is slightly bent, the right hand

holding the housing grip.

• With a straight left arm, the left hand holding the

D-handle.

• The unit is at waist level.

• The trimmer bump head is parallel to the ground and

easily contacts the material to be cut without the

operator having to bend over (Fig. 8).

J_

Fig. 8

l_ ' WARNING: To prevent serious injury, do n0t '

l carry the unit with YOU!finger On the trigger • I

9

Page 10

OPERATINGTHETRIMMER

and body protection to reduce the risk of

WARNING:Always wear eye, hearing, foot

injury when operating this Unit I

Clear the area to be cut before each use Remove all

objects such as rocks, broken glass, nails, wire, or string

which can be thrown or become entangled in the cutting

attachment Clear the area of children, bystanders, and

pets At a minimum, keep all children, bystanders and

pets outside a 50 feet (15m) radius; there still may be a

risk to bystanders from thrown objects Bystanders

should be encouraged to wear eye protection If you are

approached, stop the motor and cutting attachment

immediately

NOTE: Remove protective tape from the line cut-off

blade before operating trimmer

ADJUSTING TRIMMING LINE LENGTH

The bump head allows the operator to release more

trimming line without stopping the motor. As line

becomes frayed or worn, additional line can be released

by lightly tapping the trimming head on the ground while

operating the trimmer (Fig. 9).

\

Bump Head

\

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting attachment parallel to the ground

• Do not force the cutting attachment Allow the tip of the

J

line to do the cutting, especially along walls Cutting with

more than the tip will reduce cutting efficiency and may

overload the motor

• Cut grass over 8 inches (200 mm) by working from top

to bottom in small increments to avoid premature line

wear or motor drag

• Cut from right to left whenever possible Cutting to the left

improves the unit's cutting efficiency Clippings are

thrown away from the operator

• Slowly move the trimmer into and out of the cutting

area at the desired height Move either in a forward-

backward or side-to-side motion Cutting shorter

lengths produces the best results

• Trim only when grass and weeds are dry

• The life of your cutting line is dependent upon:

• Following the trimming techniques previously explained

• What vegetation is cut

• Where vegetation is cut

For example, the line will wear faster when trimming against

a foundation wall as opposed to trimming around a tree

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences and more

Rotate the whole unit so that the cutting attachment is at

a 30 ° angle to the ground (Fig 10)

44J

Fig, 9

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult as cutting

line becomes shorter.

A I CAUTION: DOnot remove or alter the line I

"_, I cutting blade assembly. Excessive line length will I

make the unit overheat. This may lead to serious

persona njury or damage to the un t.

Each time the head is bumped, approximately 1 inch

(25.4 mm) of trimming line is released. A blade in the

string guard will cut the line if excess line is released.

For best results, tap the head on bare ground or hard

soil. If line release is attempted in tall grass, the motor

may overheat. Always keep the trimming line fully

extended. Line release becomes more difficult as the

cutting line becomes shorter.

10

44J

Fig. 10

Page 11

Thewarrantyonthisunitdoesnotcoveritemsthathave

beensubjectedtooperatorabuseornegligence.To

receivefullvaluefromthewarranty,theoperatormust

maintaintheunitasinstructedinthisoperator'smanual.

NOTE: Always clean the inner reel, outer spool and shaft

before reassembling the bump head.

WARNING: Battery tools do not have to be

plugged into an electrical outlet; therefore, they

are always in operating condition. To prevent

serious personal injury, take extra precautions

and care when cleaning, performing

maintenance and service, or when changing

the cutting attachment or other attachments.

injury,remove or disconnectthebatteryI

I_[WARNING: To prevent serious personal I

beforeservicing,cleaningor removing

mater a from the un t.

SERVICING DOUBLE INSULATED UNITS

This unit is double-insulated. In a double-insulated unit,

two systems of insulation are provided instead of

grounding. There is no grounding provided and no

means of grounding should be added to this unit.

Extreme care and knowledge of the system is required

when servicing a double-insulated unit. Service should

be performed by qualified service personnel only.

Replacement parts for a double-insulated unit must be

identical to the parts they replace. Refer any repair to an

authorized service dealer. A double-insulated unit is

marked with the words "double insulation" or "double

insulated."

LINE INSTALLATION

Always use genuine Genuine Factory PartsTM 0.080 in.

(2.03 ram.) replacement line. Using line other than

specified may cause the unit to overheat or fail.

Press Tabs

Outer _7 _/_

Fig. 11

4.

Check the indexing teeth on the inner reel and outer

spool for wear (Fig. 12). If necessary, remove burrs

or replace the reel and spool.

Indexing Teeth \

\

I [WARNING: Never use metal-reinforced line,

become dangerous project es.

There are two methods to replace the trimmer line:

• Wind the inner reel with new line

• Install a prewound inner reel

Winding the Existing Reel

1. Remove the bump head cover by pressing in both

bump head cover tabs visible on either side of the

bump head outer spool (Fig. 11).

NOTE: The spring will push the cover up when the tabs

release.

2. Remove the inner reel and spring (Fig. 11).

3. Use a clean cloth to wipe the inner surface of the

outer spool (Fig. 11).

wire chain or rope. These can break off and

Fig. 12

.

Take approximately 12 feet (3.6 m) of new trimming

line and insert one end of the line into the hole in the

inner reel (Fig. 13).

6.

Wind the line, in even and tight layers, onto the reel

(Fig. 13). Wind the line in the direction indicated on

the inner reel.

NOTE: Failure to wind the line in the direction indicated

will cause the bump head to operate incorrectly.

Fig. 13

11

Page 12

7. Insert the end of the line into one of the two holding

slots (Fig. 14).

Slot

Fig. 14

8. Insert the end of the line through the eyelet in the

outer spool (Fig. 15).

/'/*

ii!i:iiii i! ::

Fig. 15

9. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

10. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 16).

11. Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

into place.

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

INSTALLING A PREWOUND REEL

Always use genuine replacement line. Using larger line

then the specified may make the motor overheat or fail.

1. Remove the bump head cover by pressing in both

bump head cover tabs visible on either side of the

bump head outer spool (Fig. 11).

NOTE: The spring will push the cover up when the tabs

release.

2.

Remove the old inner reel and spring from the outer

spool (Fig. 11).

3.

Remove the spring from the old inner reel

(Fig. 11).

4.

Use a clean cloth to wipe the inner surface of the

outer spool (Fig. 12).

5.

Insert the end of the line, on the prewound reel,

through the eyelet in the outer spool (Fig. 15).

6. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

7. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 16).

.

Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

into place.

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

12

\

Fig. 16

Page 13

BATTERY PACK REPLACEMENT

.,,_ To preserve natural resources, please recycle

\_,_f or dispose of properly. THIS PRODUCT

ICONTAINS A SEALED LEAD-ACID BATTERY

Pb AND MUST BE DISPOSED OF PROPERLY.

Local, State, Or federal laws may prohibit

disposal of sealed lead-acid batteries in

ordinary trash. Consult your local waste

authority for information regarding available

recycling and/or disposal options.

Removing the Battery

I. Push the two latches on the side of the battery housing

door in and swing the door down. Unhook the door

from the slot on the bottom of the battery housing by

lifting up and away. Set the door aside (Fig. 17).

Battery Housing I_f/_he_Door

WARNING: If the battery pack has signs of

leakage, do not touch. Do not open or

mutilate the battery. Released electrolyte is

corrosive and may cause damage to the eyes

or skin. To avoid serious injury, take the unit

to an authorized service dealer for repair.

Installing the Battery

1. Slide the battery into the battery housing until the

battery retaining latch locks the battery into place

(Fig 18).

2. Reinstall the door by hooking over the slot on the

bottom of the battery housing. Swing the battery

housing door closed until the two latches snap into

place.

For best performance when reinstalling the battery:

• Check the battery terminals for corrosion and clean

them if necessary. Clean the terminals using a dry

scrubbing pad and wipe clean with a dry cloth. Never

use liquids to clean terminals.

• Check the battery casing for signs of damage and

replace it if needed.

NOTE: If you clean or replace the battery, apply a small

amount of electrically conductive grease to the

terminals only. This grease is available at any

local electronics store. Do not use automotive or

beating grease.

Hook

Fig. 17

2. Push down on the battery retaining latch while

pulling battery out (Fig. 18).

NOTE: You might notice grease on the terminal contacts

when the battery is removed. This is normal.

Battery

O Ret lining Latch

o

[ !

Fig. 18

Storing the Battery Pack

If you are removing the battery for replacement or for

storage, cover the battery pack's terminals with heavy

duty electrical tape.

WARNING: Do not attempt to destroy or

disassemble battery or remove any of its

components. Sealed lead-acid batteries must

be recycled or disposed of properly. Never

touch both terminals with metal objects

and/or body parts, a short circuit may result.

Keep away from children. Failure to comply

with these warnings could result in fire and/or

serious personal injury.

13

Page 14

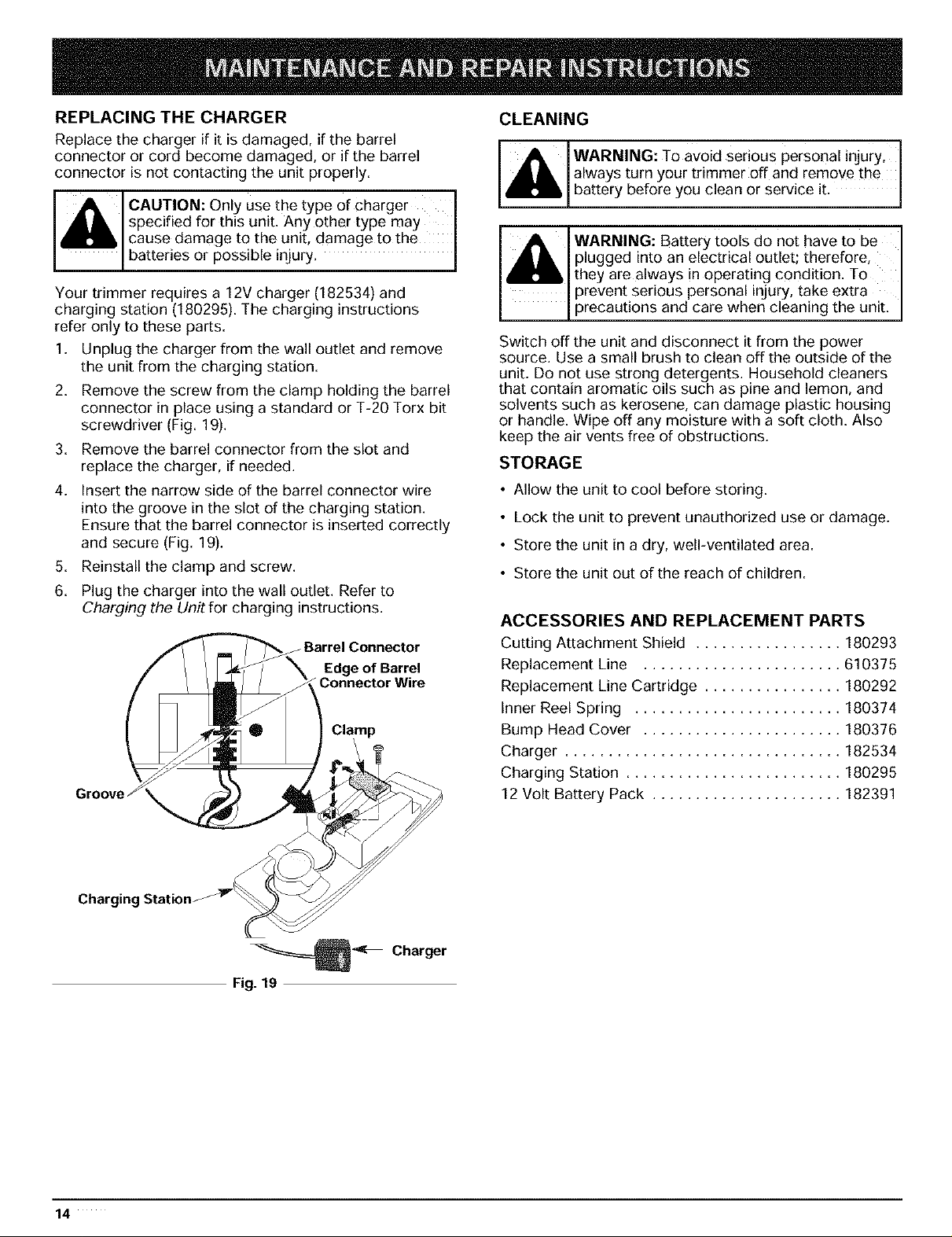

REPLACING THE CHARGER

Replace the charger if it is damaged, if the barrel

connector or cord become damaged, or if the barrel

connector is not contacting the unit properly.

CAUTION: Only use the type of charger

specified for this unit. Any other type may

cause damage to the unit, damage to the

batteries or possible injury.

Your trimmer requires a 12V charger (182534) and

charging station (180295). The charging instructions

refer only to these parts.

1. Unplug the charger from the wall outlet and remove

the unit from the charging station.

2. Remove the screw from the clamp holding the barrel

connector in place using a standard or T-20 Torx bit

screwdriver (Fig. 19).

3. Remove the barrel connector from the slot and

replace the charger, if needed.

4. Insert the narrow side of the barrel connector wire

into the groove in the slot of the charging station.

Ensure that the barrel connector is inserted correctly

and secure (Fig. 19).

5. Reinstall the clamp and screw.

6. Plug the charger into the wall outlet. Refer to

Charging the Unit for charging instructions.

J Barrel Connector

Edge of Barrel

Connector Wire

Clamp

CLEANING

WARNING: To avoid serious personal injury,

always turn your trimmer off and remove the

battery before you c ean or serv ce t. J

WARNING: Battery tools do not have to be

plugged into an electrical outlet; therefore, I

they are always in operating condition. To

prevent serious personal injury, take extra

precaut ons and care when c ean ng the un t.

Switch off the unit and disconnect it from the power

source. Use a small brush to clean off the outside of the

unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth. Also

keep the air vents free of obstructions.

STORAGE

• Allow the unit to cool before storing.

• Lock the unit to prevent unauthorized use or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

ACCESSORIES AND REPLACEMENT PARTS

Cutting Attachment Shield ................. 180293

Replacement Line ....................... 610375

Replacement Line Cartridge ................ 180292

Inner Reel Spring ........................ 180374

Bump Head Cover ....................... 180376

Charger ................................ 182534

Charging Station ......................... 180295

12 Volt Battery Pack ...................... 182391

14

Charging

_ Charger

Fig. 19

Page 15

CAUSE

ACTION

Battery is not charged

Overload protection switch has popped

CAUSE

No power to charger or battery

Battery has failed

CAUSE

Cutting attachment bound with grass

Cutting attachment out of line

Inner reel bound up

Cutting attachment dirty

Line welded

Line twisted when refilled

Not enough line is exposed

Charge the battery

Reset overload protection switch

ACTION

Check charger and charging station

Replace the battery

ACTION

Stop the unit and clean cutting attachment

Refill with new line

Replace the inner reel

Clean inner reel and outer spool

Disassemble, remove the welded section

and rewind the line

Disassemble and rewind the line

Push the Bump Knob and pull out line until

4 inches (102 mm.) of line is outside of the

cutting attachment

Motor .................................................................................................................................................. 12 Volt DC, 15 Amps

Battery ......................................................................................................................................... Sealed Lead-Acid, 12 Volt

Motor Wire Housing Tube ............................................................................................................................ Aluminum Tube

Unit Weight (With battery, cutting attachment shield and D-handle) ...................................................... 10.2 Ibs. (4.63 kg.)

Cutting Mechanism ............................................................................................................................................. Bump Head

Line Spool Diameter ...................................................................................................................................... 3 in (76.2 mm)

Trimming Line Diameter ......................................................................................................................... 0.080 in (2.03 mm.)

Cutting Path Diameter ................................................................................................................................. 10 in. (254 mm)

15

Page 16

®

REPLACEMENT PARTS-MODEL TB55B

12 VOLT BATTERY TRIMMER

(_ PPN 41AET55G063

Item Part NO.

1 791q82696

2 791-182542

3 753_04354

4 753-04355

5 79%182391

6 79%182699

7 79%182702

8 79%182724

9 79%181482

10 79%180150

11 79%182318

12 79%180364

13 791_180365

14 79%180367

15 791q53064

16 791_181587

17 753_04356

18 753_04357

19 79%180369

20 79%182715

21 79%180372

22 79%180374

23 79%180375

24 79%180292

25 79%180376

26 79%180293

27 79%180377

28 79%182469

29 791-182534

30 791q80295

Item Part NO.

31 791q80378

32 791_182709

33 753_04007

Description

Battery Door

Foam Pad

Right Battery Housing

Left Battery Housing

12 Volt Batterry

Battery Latch

Terminal Spacer

Wiring Harness Assembly

Housing Screw

Switch Assembly (includes 11 )

Trigger

Lock-Off Button

Circuit Breaker

Motor Wire Tube

D_Handle (includes 16)

Handle Hardware

Left Motor Housing

Right Motor Housing

Spacer

Motor with Shaft

Outer Spool and Eyelet/Motor Fan

Spring

Screw

Inner Reel with .080" Line

Reel Cover

Guard and Blade Assembly

Blade Assembly

Guard Screw

12 Volt Charger

Charging Station Stand (includes 31 & 32)

Description

Barrel Clamp with Screw

Mounting Screw

Front Battery Pads

@

@

@

CAUTION: Only authorized service I

technicians should perform adjustments to

doub e- nsu ated un ts.

_tional Accessories

791_610375 Replacement Line (,080 Diameter)

791_180327 Bump Head Assembly (includes 21_25)

E19

Page 17

MANUFACTURER'S LIMITED WARRANTY FOR:

O TROII BIIT"

The limited warranty set forth below is given by Troy-Bilt

LLC with respect to new merchandise purchased and used

in the United States, its possessions and territories.

Troy-Bilt LLC warrants this product against defects in

material and workmanship for a period of two (2) years

commencing on the date of original purchase and will, at its

option, repair or replace, free of charge, any part found to

be defective in material or workmanship. This limited

warranty shall only apply if this product has been operated

and maintained in accordance with the Operator's Manual

furnished with the product, and has not been subject to

misuse, abuse, commercial use, neglect, accident,

improper maintenance, alteration, vandalism, theft, fire,

water or damage because of other peril or natural disaster.

Damage resulting from the installation or use of any

accessory or attachment not approved by Troy-Bilt LLC for

use with the product(s) covered by this manual will void

your warranty as to any resulting damage. This warranty is

limited to ninety (90) days from the date of original retail

purchase for any Troy-Bilt product that is used for rental or

commercial purposes, or any other income-producing

purpose.

HOW TO OBTAIN SERVICE: Warranty service is

available, WITH PROOF OF PURCHASE THROUGH

YOUR LOCAL AUTHORIZED SERVICE DEALER. To locate

the dealer in your area, visit our website at www.troybilt.com,

check for a listing in the Yellow Pages, call 1-800-520-

5520 or write to P.O. Box 361131, Cleveland, OH 44136-

0019.

This limited warranty does not provide coverage in

the following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments,

Filters

B. Wear items - Bump Knobs, Outer Spools, Cutting

Line, Inner Reels, Starter Pulley, Starter Ropes, Drive

Belts

C. Troy-Bilt LLC does not extend any warranty for

PsrOducts sold or exported outside of the United

rates of America, its possessions and territories,

except those sold through Troy-Bilt's authorized

channels of export distribution.

Troy-Bilt LLC reserves the right to change or improve the

design of any Troy-Bilt Product without assuming any

obligation to modify any product previously manufactured.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind Troy-Bilt LLC During the period of

the Warranty, the exclusive remedy is repair or

replacement of the product as set forth above. (Some

states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to

you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. Troy-

Bilt LLC shall not be liable for incidental or

consequential loss or damages including, without

limitation, expenses incurred for substitute or

replacement lawn care services, for transportation or

for related expenses, or for rental expenses to

temporarily replace a warranted product. (Some states

do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold.

Alteration of the safety features of the product shall void

this Warranty. You assume the risk and liability for loss,

damage, or injury to you and your property and/or to

others and their property arising out of the use or misuse

or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty

gives you specific legal rights, and you may also have

other rights which vary from state to state.

To locate your nearest service dealer dial 1-800-520-5520.

Troy-Bilt LLC

RO. Box 361131

Cleveland, OH 44136-0019

16

Loading...

Loading...