Troybilt 21AE682L766-2003 Owner’s Manual

0 TRO- ] BIIT°

m m _ iiiiiiiiiiiiiiii1_ _111111111111_1111_

Ope

S a

ual

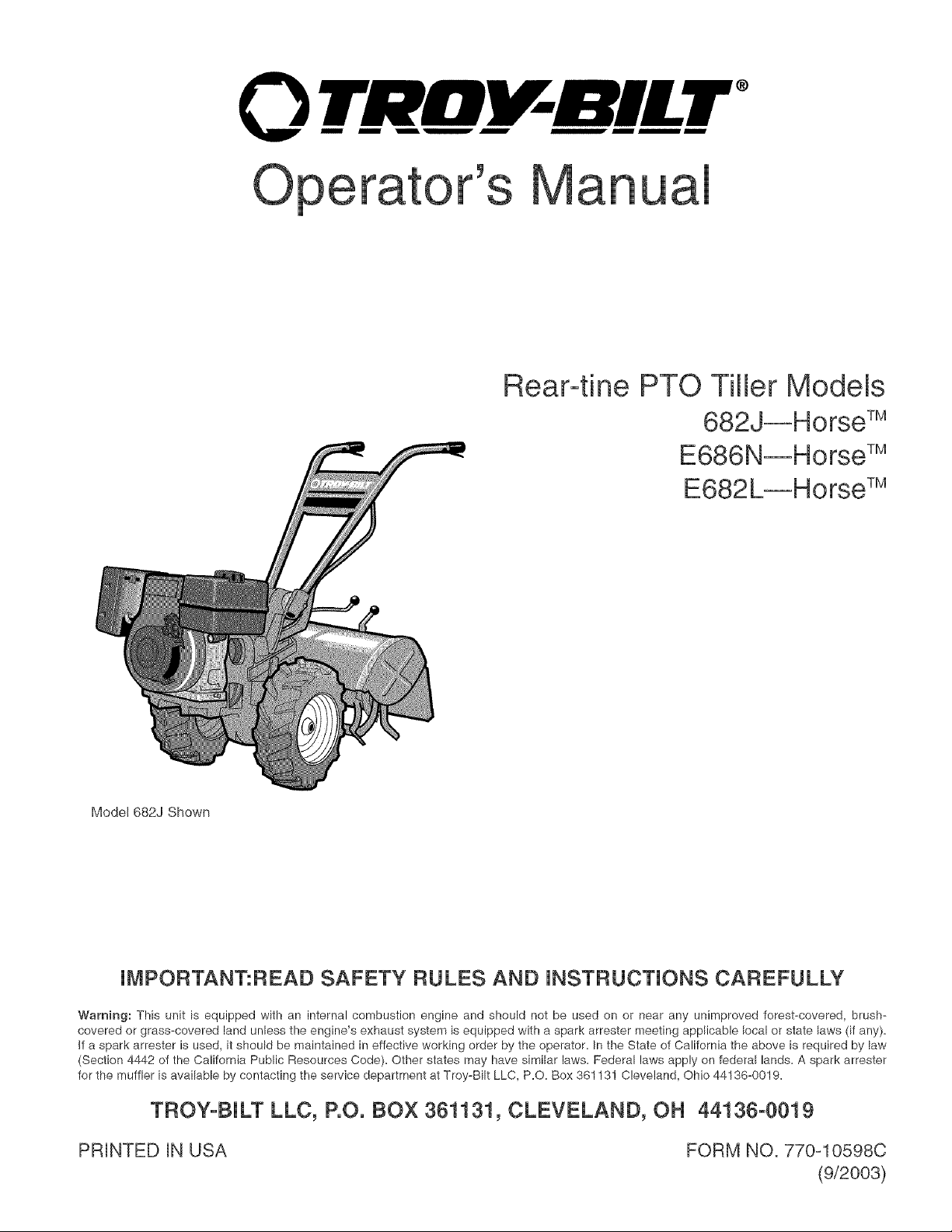

Rear-finePTO TillerModels

Model 682J Shown

iMPORTANT:READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark attester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 36113! Cleveland, Ohio 44136-0019.

TROY-BJLT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FORM NO. 770-10598C

(9/2003)

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 28

Safety 3 Troubleshooting 41

Assembly 6 Attachments & Accessories 43

Features and Controls 11 Parts List 44

Operation 14 Warranty Information Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new rear-tine tiller. It will help you assemble, prepare and maintain

the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by standing behind the unit and looking down at rear surface of the tine shield. This

information will be necessary to use the manufacturer's web site and/or help from the Customer Support

Department or an authorized service dealer.

Copy the model number here:

Copy the serial number here:

O'_,_,_,_X_" TROY-B|LT LL(

www.troybiJt.oom CLEVELAND,0H44136

_. 1 =800=520=552@

P. O. BOX 361131

330=558=7220

CUSTOMERSUPPORT

Pleasedo NOTreturnthe unit to the retailer from where it waspurchased,without first contactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

JO; c _i

o,,fC ,,

,C GW@¢' ./OL _ '0

_ /,. ,# )'{: J . >_:?

_ Y/"0 ,h;;!:_:@OJf3_;ss;4Is,,, "

7i;,C ........................................

EnOine

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regards to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

Section

Safety AmertSymbem

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is pubfished by the

American National Standards Institute.

,_ This is asafetyalertsymbol. It is used inthis

Failureto obeysafety messagescould resultin personal

injury or property damage.

1. Carefullyreadthis Owner'sManual, the

separateEngineOwner's Manual,and any

other literature you mayreceive.Bethor-

oughly familiar with the controls and the

proper useof the tiller and itsengine.

Know how to stop the unit and disengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operate the

tilier without proper instruction.

3.Keepthe areaof operation clearof alI

persons, particulariy chiidren and pets.

4, Keepin mind that the operator or user

is responsible for accidentsor hazards

occurring to other people,their property,

andthemselves.

1, Thoroughly inspect the areawhere the

tiller isto be usedand removealIforeign

objects.

2. Putthe Wheelsfrines/PTO Drive Lever

into NEUTRALbeforestarting the engine.

3. Do not operatethe tiiier without

wearingadequateoutergarments. Avoid

loose garments or jeweirythat could get

caught in moving parts.

4. Do not operatethe tiiier when barefoot

or wearingsandals, sneakers,or fight

footwear. Wear protective footwear that

wiii improve footing on slippery surfaces.

5, Do nottiii near underground electric

cabies,teiephoneiines, pipes or hoses. If

in doubt,contactyour telephoneor utility

company.

manuaiandonthe unit to alert youto

potential hazards. Whenyou seethis symbol,

readand obeythe messagethat foliows it.

6, Warning: Handlefue!with care;it is

highly flammable andits vaporsare

explosive. Besureto takethe following

precautions:

a. Storefue! incontainers specifically

designedfor this purpose.

b. The gascap shall never beremoved

or fue!addedwhiie the engine is

running. Allow the engineto cooI

for severalminutes before adding

fuel.

¢. Keepmatches,cigarettes, cigars,

pipes, openflames, and sparks

away from the fuettank and fueI

container.

d. FiiifueItankoutdoors with extreme

care. Neverfill fueI tank indoors.

Usea funnel orspout to prevent

spiiiage.

e. Replaceali fue!tank and container

caps securely.

f. If fuei isspiiied, do not attemptto

start the engine, but movethe

machineaway from the areaof

spiiiage and avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustments whenengine

is running (unless recommendedby

manufacturer).

1. Donot put hands or feet nearor under

rotating parts. Donot aiiow handsor any

other part ofthe body or clothing nearthe

rotating tines or nearany other moving

part. Thetines beginto rotateforward

A

The engine exhaust from this productcontains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

oncethe enginestarts, the Tines/PTO

Ciutch Leveris in the ENGAGEposition,

the Forward Interlock Leversare squeezed

closed and the Wheelsfrines/PTO Drive

Leveris shifted to FORWARD.Thetines

rotate in Reversewhether the Interlock

Leversare closed or open.

2. Exerciseextremecautionwhen on or

crossing graveldrives, walks, or roads.

Stayalert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine, removethe wire from thespark

piug wire and prevent it from touching the

spark piug. ThorougHy inspect the

machinefor any damageand repair the

damagebefore restarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abhor-

marly,stopthe engine,disconnectthe

spark piugwire and prevent it from

touching the spark piug, andcheck imme-

diatelyfor the cause.Vibration is

generaiiyawarning of trouble.

6. Stopti_eengine,disconnectthe spark

piug wire and prevent it from touching the

spark piugwheneveryou ieavethe

operatingposition, before uncloggingthe

tines, or when makingany repairs, adjust-

ments or inspections.

7, Takeali possible precautions when

leavingmachineunattended.Stopengine.

Disconnectsparkplug wire andmoveit

away from spark piug. Removeignition

key on electdcstart models

Section1: Safety

8. Beforecleaning,repairing, or inspect=

ing, stop the engineand makecertainatI

moving partshavestopped. Disconnect

the spark piug wire and prevent it from

touching the spark piug to prevent acci=

dentaIstarting.

9. The flap on thetine hood must be

down when operatingthe tiiier, unless

using the Hiiier/Furrowerattachment.

10. Neveruse the tiiier unlessproper

guards, piates,or other safetyprotective

devicesareinplace.

11. Do not run engine in an enclosed

area.Engineexhaustcontains carbon

monoxide gas, a deadlypoison that is

odorless, coloriess, and tasteless.

12. Keepchildren and pets away.

13. Neveroperate thetiiier underengine

power if the WheeISpeedLeveris inthe

FREEWHEELposition. In FREEWHEEL,

the wheels wiii not hold thetiiier backand

the revoiving tines could propei the tiiier

rapidly, possibtycausingioss of controi.

AIwaysengagethe WheetSpeedLever in

either FASTor SLOWposition before

starting the engineorengagingthetines

with the WheeIs/Tines/PTODrive Lever.

14. Be aware that the tiller may unexo

pectedlv bounce upward or jamp

forward ifthe tines should strike

extremely hard packedsoil, frozen

ground, or buried obstacles like large

stones, roots, or stumps, ff in doubt

about the tilling conditions,always use

the following operating precautions to

assist you in maintaining control of the

tiller:

a. Walk behind and to one side of the

tiller, using one handon the han-

dlebars. Relax your arm, bnt rise a

secnre handgrip.

b. Use shallower depth regulator

settings, working gradually deeper

with each pass.

c. Use slower wheel, tine and engine

speeds.

d. Clear the tilling area of all large

stones, roots and other debris.

e. Avoid using downward pressureon

handlebars.If need be, use slight

npward pressure to keep the tines

from digging too deeply.

f. Before contacting hard packedsoil

at the endof a row, reduce engine

speed and lift handlebarsto raise

tines out of the soil.

g. Jn an emergency, stoptines and

wheets byshifting the

WheelsiTinesiPTO Drive Lever

intoNEUTRAL.tf you can not

reach the leveror havelostcontrom

of the tiller, let go of the handle=

bars and aHcontroms,go not

attempt to restrain the tiller.

15. Donot overioadthe tiiier's capacity by

attempting to till too deeplyat too fast a

rate.

16. Neveroperatethe tiller at high

transport speedson hard or slippery

surfaces. Look behindandusecare when

backing up.

t7. Donot operatethetiiier on aslope

that istoo steep for safety. Whenon

slopes, slow down andmakesure you

havegood footing. Neverpermit the tiiier

to freewheel down slopes.

18. Neverallow bystandersnearthe unit.

19. Only useattachmentsandaccessories

that areapproved by the manufacturer of

the tiller.

28. Usetiiier attachments and acces-

sories when recommended.

21. Neveroperatethe tiller without good

visibility or iight.

22. Neveroperatethe tiiier if you are

tired, or underthe influence of alcohol,

drugs or medication.

23. Operatorsshali not tamper with the

engine-governor settings on the machine;

the governor controis the maximum safe

operatingspeedto protect the engineand

ali moving partsfrom damagecausedby

overspeed. Authorized service shail be

sought if a problemexists.

24. Donot touch engineparts which may

behot from operation. Letpartscool

downsufficiently.

25. POBON/OANGER--CAUSES

SEVEREBURNS.Thebattery on electric

start models contains suifudc acid. Avoid

contact with skin, eyesor clothing. Keep

out of reachof children.

Antidotes:

External- Flushimmediately with lots of

water.

Internal- Drink largequantities of water

or milk. Follow with milk of magnesia,

beateneggs orvegetableoil. Calla

doctor immediately.

Eyes- Fiushwith water for 15 minutes.

Getprompt medicai attention.

26. DANGER=BATTERIESPRODUCE

EXPLOSIVEGASES. Keepsparks, flame

or smoking materiaisaway. Ventilate

whencharging battery or using inan

enctosedspace. Alwayswear safety

goggteswhen working near battery.

27. Pieaseremember:Youcanalways

stop thetines and wheels by releasingati

controis, or by moving the ignition switch

and/orthrottle control lever on the engine

to OFFor STOP.

28. To ioador unloadthetiller, seethe

instructions in Section4 of this Manual.

29. Useextreme caution when backing or

puliing the machinetowards you.

30. Startthe engine carefuiiy according to

instructions and with feet well awayfrom

the tines.

31. Neverpick up or carry a machine

whiiethe engine is running.

32. When ioading or unioadingthe tiller,

alwaysdisengagetines andusesiower

wheelandenginethrottle speeds. Use

sturdy ramps wideandstrong enoughto

easiiysupport the tiiier (280-to-325 ibs.

dependingon model) and operator.

Nevergo down ramps in FORWARD

drive--the tiiier couid tip forward,

exposingyou to the tines (which should

be disengaged). Always useREVERSE

driveand backdown ramps. Togo up

ramps, use FORWARDdrive and follow

the tiller.

33, The ForwardInterlock SafetySystem

should betested for correct functioning

everytime the tiller or PTOpower unit is

used. SeeSection 4 in this Manual.

34. If using the optional DozerBlade,

either removethe tine attachment, or

disengagethe tines with the Tines/PTO

CiutchLever. Revolvingtines are

dangerous.

Section1: Safety

Maintenance and Sterage

1. Keepthetiiier, attachments and acces-

sories insafeworking condition.

2. Checkali nuts, boits, andscrews at

frequent intervalsfor propertightness to

be surethe equipment is in safe working

condition.

3. Neverstore the tiiier with fue! inthe

fueJtank insidea buiiding where ignition

sources are presentsuch as hot water

and space heaters,furnaces, ciothes

dryers, stoves, electric motors, etc.).

Aiiow engine to cool beforestoring in any

encJosure.

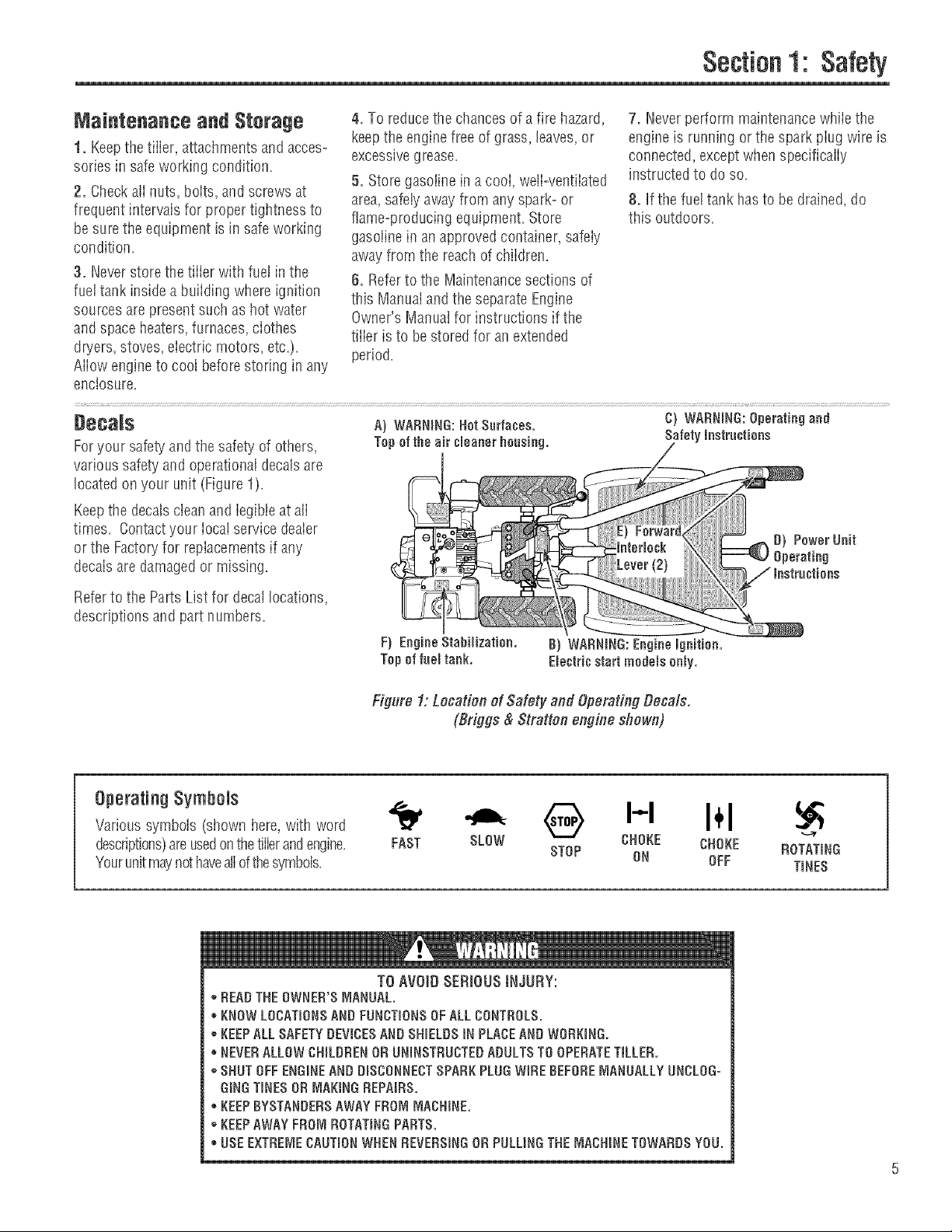

Deca_$ A) WARNmNG:HotSurfaces. C) WARNING:Operatingand

Foryour safetyand the safety of others, Tepeftheair umeanerheusing. Safetymnstruutiens

various safety and operationaldecalsare

located on your unit (Figure 1).

Keepthe decalscleanand legibleat all

times. Contactyour Iocai service dealer

or the Factoryfor repiacementsif any

decals are damagedor missing.

4. To reducethe chancesof a fire hazard,

keepthe enginefreeof grass, leaves, or

excessivegrease.

5. Storegasoiine in a cooi, weJi-ventiiated

area,safetyawayfrom any spark-or

flame-producing equipment. Store

gasolinein anapprovedcontainer, safeiy

awayfrom the reach of chiidren.

6. Referto the Maintenancesections of

this Manuaiandthe separate Engine

Owner's Manualfor instructions if the

tilier is to be stored for an extended

period.

7. Neverperform maintenancewhiiethe

engine is running or the spark piug wire is

connected,exceptwhen specifically

instructed to do so.

8, If the fuel tank hasto be drained, do

this outdoors.

Referto the PartsList for decallocations,

descriptions andpart numbers.

Operating Symbols

Varioussymbols (shown here,with word

descriptions)areusedonthetillerandengine=

Yourunitmaynot haveaiiofthesymbols=

oDEAD THEOWNER'SMANUAL.

KNOW LOCATmONSAND FUNCTmONSOFALLCONTHOLS.

*KEEPALLSAFETYDEVICESAND SHmELDSiNPLACEAND WORKmNG.

NEVERALLOW CHmLDRENOR UNBNSTRUCTEDADULTSTO OPERATETILLED.

*SHUT OFFENGINEAND DmSCONNECTSPARKPLUG WIHEBEFOREMANUALLYUNCLOG=

GiNGTINESOR MAKINGHEPAIRS.

- KEEPBYSTANDERSAWAYFROMMACHINE.

*KEEPAWAYFROM ROTATmNGPARTS.

USE EXTHEI_,_ECAUTmONWHEN HEVEHSmNGOH PULLINGTHEMACHINETOWARDS YOU.

Figure 1: Location of Safety and Operating Decals.

(Briggs & Stratten engine shown)

• @ H I÷1

CHOKE CHOKE HOTATING

FAST SLOW STOP ON OFF TmNES

TO AVOID SERIOUS INJURY:

Section

To preventpersonal injury or property

damage, do not start the engine until

aJJ assembly steps are complete and

you have read and understand the

safety and operatinginstructionsinthis

manual

introduction

Carefuiiyfoiiow these assembiy steps to

correctly prepareyour tiiier for use. It is

recommendedthat you readthis Section

in its entirety beforebeginning assembly.

NOTE:Threedifferent Horse modeltiiiers

are covered in this Manual.Use oniythe

information applicableto your model.

Tiiier engines vary by model.Your engine

mayappear differently than thosefound

in illustrations of this manual.

inspect Unit

h_spectthe unit andcartonfor damage

immediately after deiivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them ofthe

damageandrequestinstructions for fiiing

a claim. To protect your rights, putyour

ciaim inwriting and maiIacopyto the

carrier within 15 days after the unit has

been delivered.Contact us atthe Factory

if you needassistanceinthis matter.

STEP1: Unpacking instructions

NOTE:Donot severelybend any ofthe

control cableson the unit.

1. The tiiier is heavy. Donot attemptto

removeit from tire shipping piatform until

instructed to do so in these Assembly

steps.

2. RemoveaiI ueassembtedparts from

the carton. Thehardware bag is included

in your literature packaging.

3. Checkthat you havethe items iisted

below (contact your local dealeror the

Factoryif any items are missing or

damaged).

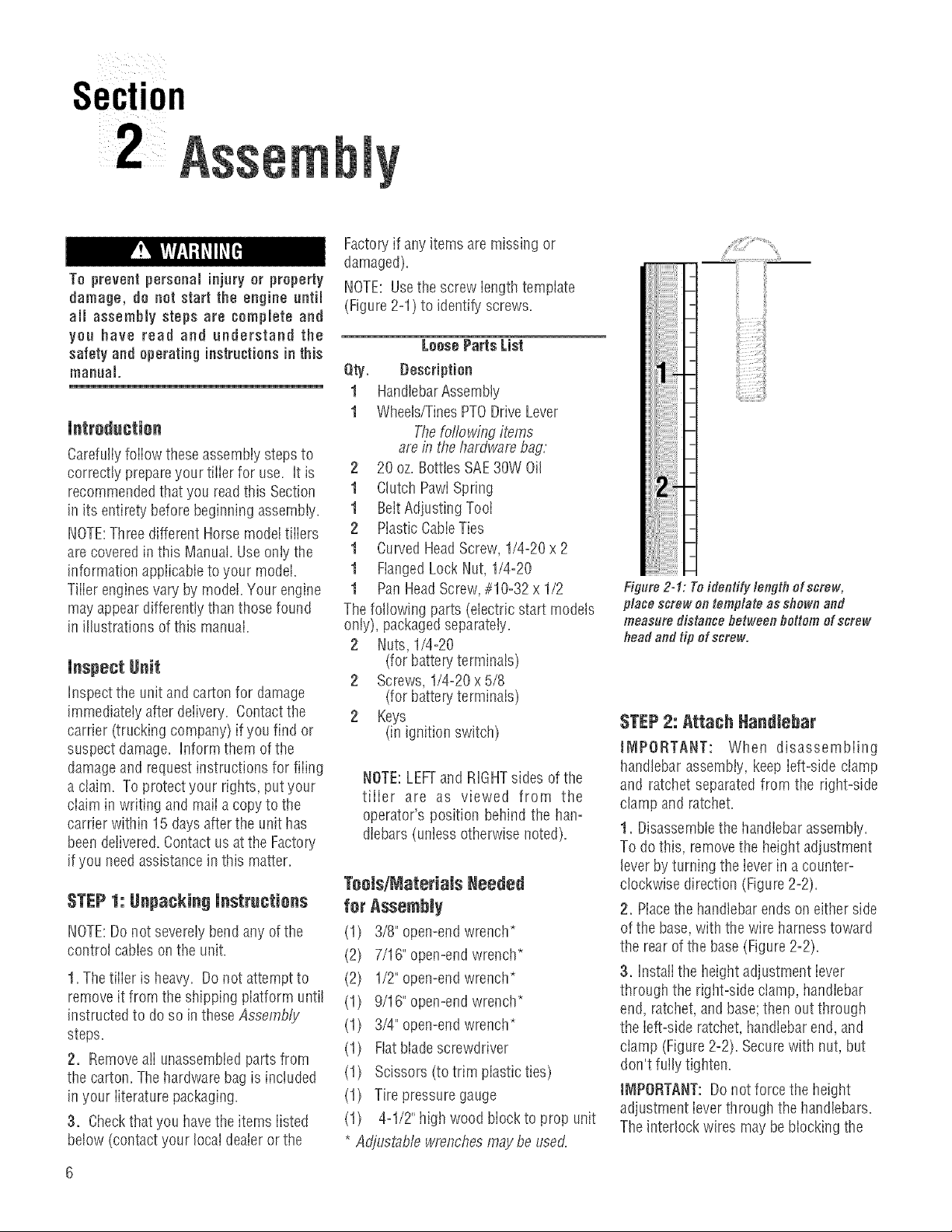

NOTE: Usethe screw iength template

(Figure2-1) to identify screws.

LoosePartsList

Qty. Bescription

1 HandlebarAssembly

1 Wheels/TinesPTODrive Lever

Thefor'towingitems

are in thehardware bag:

2 20 oz. BotttesSAE30W Oil

1 Clutch PawiSpring

1 BeltAdjustingTooI

2 PiasticCabieTies

1 Curved HeadScrew, 1/4-20 x 2

1 FlangedLock Nut, 1/4-20

1 PanHeadScrew,#10-32 x 1/2

The following parts (electric start models

only), packagedseparately.

2 Nuts, 1/4-20

(for battery terminals)

2 Screws, 1/4-20x5/8

(for battery terminals)

2 Keys

(in ignition switch)

NOTE:LEFTand RIGHTsides of the

tiller are as viewed from the

operator's position behind the han=

dlebars (unless otherwise noted).

Toels/MateriaJs Needed

for Assembly

(1) 3/8" open-endwrench*

(2) 7/16" open-endwrench*

(2) 1/2" open-endwrench*

(1) 9/16" open-endwrench*

(1) 3/4" open-endwrench*

(1) Fiatblade screwdriver

(1) Scissors (to trim plastic ties)

(1) Tire pressuregauge

(1) 4-1/2"high wood block to prop unit

* Adjustable wrenchesmaybeused.

Fi lure 2-1: Toidentify lengthof screw,

place screw on template as shown and

measure distance between bottom of screw

head andtip of screw.

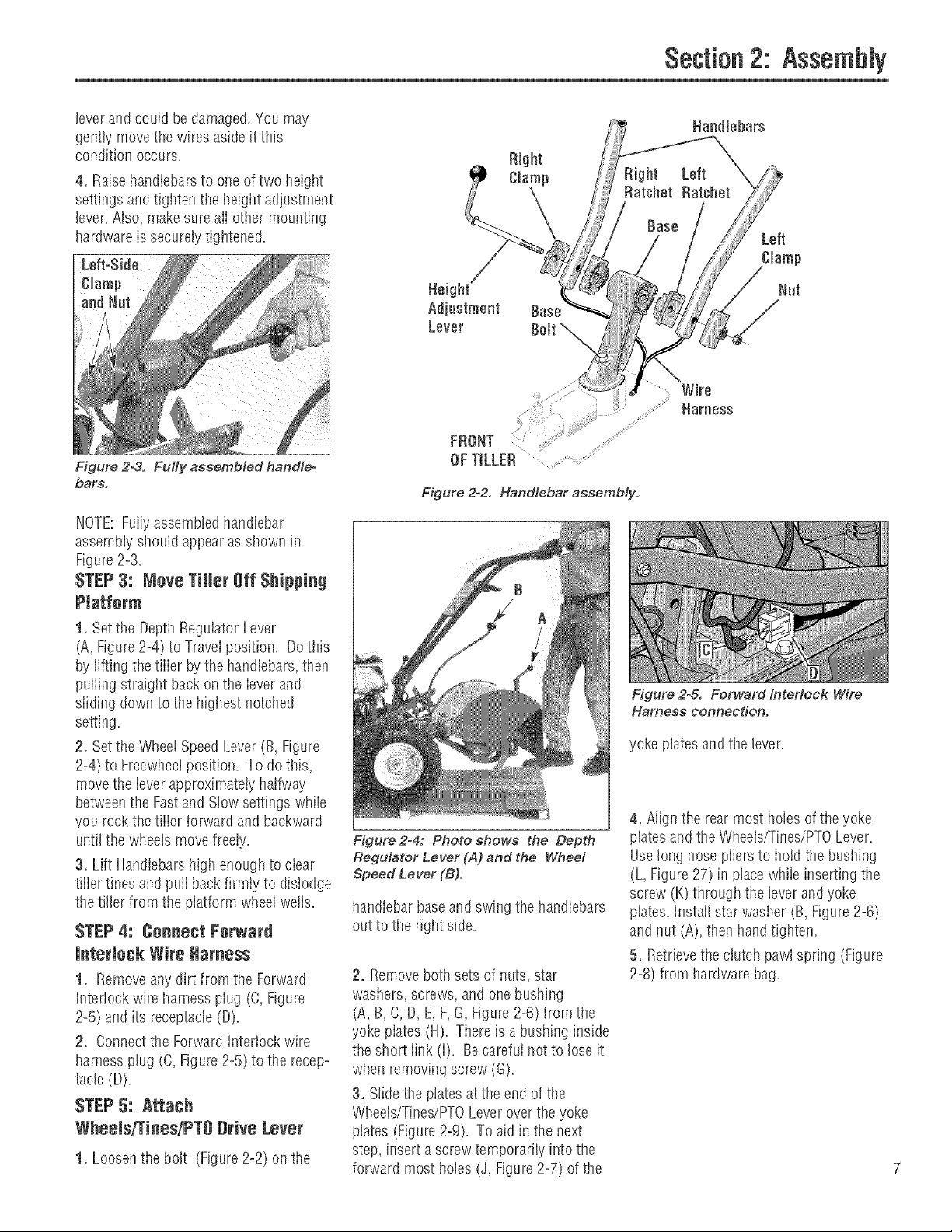

STEP2: Attach Nandlebar

JNIPORTANT: When disassembling

handlebar assembly, keep ieft-side clamp

and ratchet separated from the right-side

clamp andratchet.

1. Disassemblethe handlebarassembly.

To do this, removethe heightadjustment

leverbyturning the ieverinacounter-

clockwise direction (Figure2=2).

2. Placethe handlebarends on either side

ofthe base,with the wire harnesstoward

the rearof the base(Figure2-2).

3. Instalithe heightadjustment iever

through the rigirt-side clamp, handlebar

end, ratchet,and base;then out through

the left-side ratchet,handlebarend,and

clamp (Figure2=2).Securewith nut, but

don't fully tighten.

t_IPORTANT: Do not force the height

adjustment ieverthrough the handlebars.

The interlock wires maybeblockingthe

leverandcould bedamaged.You may

gentiy movethe wires aside if this

condition occurs.

4. Raisehandlebars to one of two height

settings andtiglrten the height adjustment

lever. Also, makesureali other mounting

hardware is securelytightened.

Left-Side

Clamp

and Nat

Figure 2=3. Fully assembled handle-

bars.

Section2: Assembly

Right

Clamp

Left

Clamp

Nat

Wire

Harness

FRONT

OFTILLER

Figure 2-2. Handlebar assembly.

NOTE:Fullyassembledhandlebar

assembly should appearas shown in

Figure2=3.

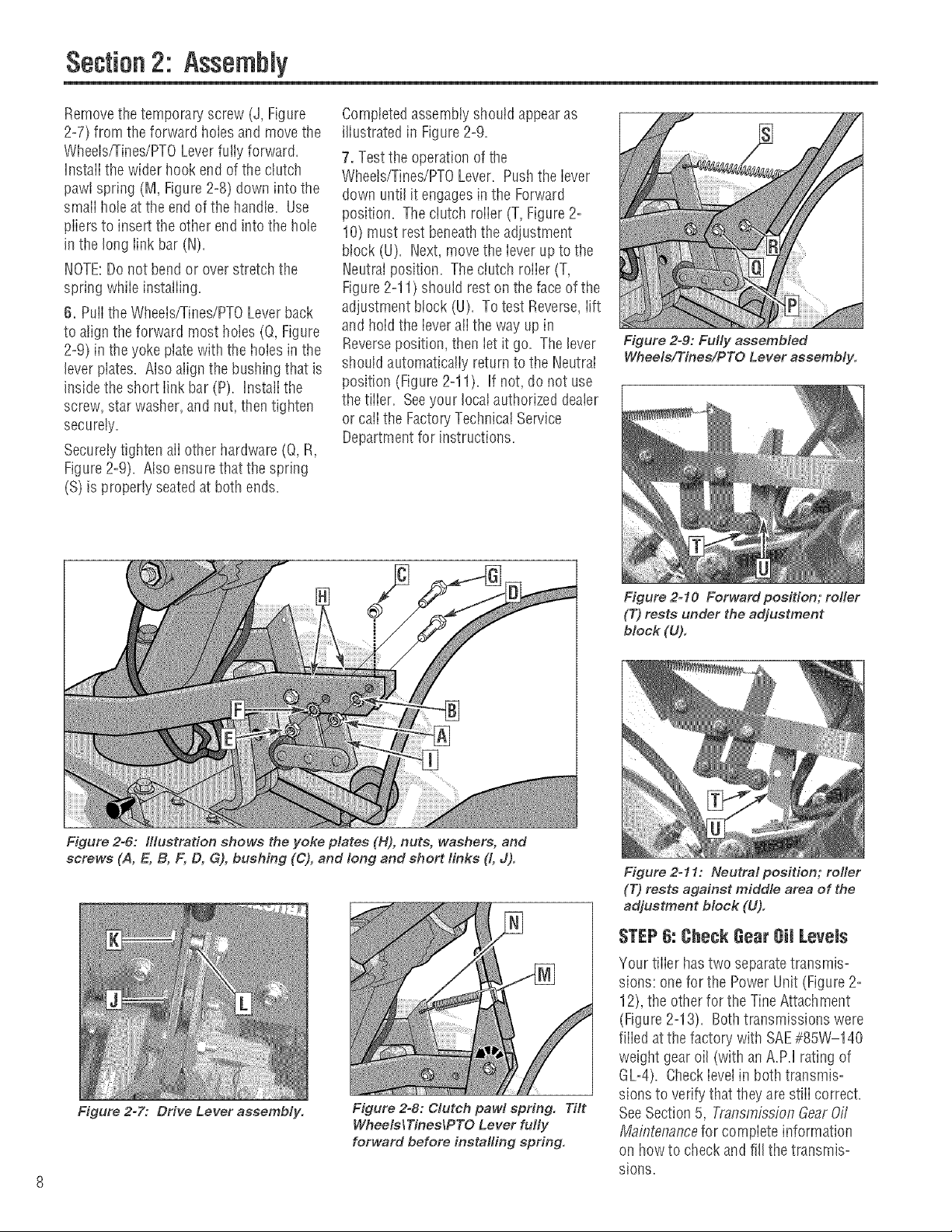

STEP3: Meve Tiller Off Shipping

Piatferm

1. Setthe DepthRegulator Lever

(A, Figure2=4)to Travelposition. Dothis

by lifting the tiiier bythe handiebars,then

puiiing straight back on the ievm and

siiding down to the highest notched

setting.

2. Setthe WheetSpeed Lever(B, Figure

2=4)to Freewheelposition. To do this,

movethe ieverapproximately halfway

betweenthe Fastand Siow settingswhiie

you rockthe tiiim forward andbackward

untilthe wheeis movefreely.

3. Lift Handlebarshigh enoughto ciear

tiiier tines and pull back firmty to dislodge

the tiller from the platform wheel wells.

STEP4: Cenneet Ferward

Figure2-4: Photo shows the Depth

Regulator Lever (A) and the Wheel

Speed Lever (B).

handIebarbaseand swing the handlebars

out to the dglrt side.

interlock Wire Harness

1. Removeany dirt from the Forward

Interlock wire harness plug (C, Figure

2=5)and its receptacle(D).

2. Connectthe ForwardIntmiock wire

harness plug (C,Figure2=5)to the recepo

tacle (D).

STEP5: Attach

Wheels/Tines/PT8 Drive Lever

1. Loosenthe bolt (Figure2=2)on the 7

2. Removeboth sets of nuts, star

washers, screws, and one bushing

(A, B, C, D, E,F,G, Figure2=6)from the

yoke piates (H). Thereis a bushing inside

the si_ortlink (i). Becarefuinot to loseit

when removing screw (G).

3. Siide the ptatesat the end of the

Wheeis/Tines/PTOLeveroverthe yoke

plates (Figure2-9). To aidin the next

step, insert ascrew temporarily into the

forward most holes (J, Figure2=7)of the

Figure 2=& Forward Interlock Wire

Harness connection.

yoke plates and the lever.

4. Align the rear most holes of theyoke

platesand the Wheets/Tines/PTOLever.

Uselong nosepiiers to hold the bushing

(L, Figure 27) in placewhile inserting the

screw (K) througtl the lever andyoke

plates.Install star wasller (B, Figure2=6)

and nut (A), then handtighten.

5. Retrievethe clutch pawl spring (Figure

2=8)from hardwarebag.

Section2: Assembly

Removethe temporary screw (J, Figure

2=7)from the forward holes andmovethe

Wheelsffines/PTO Lever fuliy forward.

[nstalI the wider hook end of the dutch

pawt spring (M, Figure2=8)down into the

smaii holeatthe end of the handle. Use

piiers to insertthe other endinto the hole

in the long link bar (N).

NOTE:Do not bend or overstretch the

spring while instailing.

6. Pull the Wheets/Tines/PTOLeverback

to align the forward most holes (O,Figure

2=9)in the yoke plate with the holesin the

lever plates. Also align the bushing that is

insidethe short link bar (P). [nstalI the

screw, star washer, and nut, then tighten

securely.

Securelytighten all other hardware (Q,R,

Figure2=9). Also ensurethat the spring

(S) is properly seatedat both ends.

Completedassembly should appearas

illustrated in Figure2-9.

7. Test the operation of the

Wheets/Tines/PTOLever. Pushthe iever

down until it engagesinthe Forward

position. The clutch roller (T,Figure2o

10) must rest beneaththe adjustment

block (U). Next, movethe iever up to the

Neutral position. The clutch rolier (T,

Figure2=11)shouid reston the faceof the

adjustment block (U). To test Reverse,iift

and hoid the iever aii the way up in

Reverseposition, then iet it go. Thelever

should automaticaliy return to the Neutrai

position (Figure2=11). If not, do not use

the tiiier. Seeyour local authorized dealer

or carlthe FactoryTechnicalService

Departmentfor instructions.

Figure 2-9: Fully assembled

Wheels/Tines/PTO Lever assembly.

Figure 2=6: Illustration shows the yoke plates (H), nuts, washers, and

screws (A, E, B, F, D, G), bushing (C), and long and short finks (t, J).

Figure 2=7: Drive Lever assembly.

Figure 2=8: Clutch pawl spring. Tilt

WheelslTineslPTO Lever fully

forward before installing spring.

Figure 2=10 Forward position; roller

(7")rests under the adjustment

block (U).

Figure 2=11: Neutral position; rofler

(T) rests against middle area of the

adjustment block (U).

STEP6: CheckGearOil Levels

'four tiller hastwo separatetransmis=

sions: one for the PowerUnit (Figure 2-

12), the other for the TineAttachment

(Figure2-13). Bothtransmissions were

fiiied at the factory with SAE#85W-140

weight gear oil (withanA.PJ rating of

GU4). CheckieveIin both transmis-

sions to verify that theyarestiii correct.

SeeSection5, TransmissionGearOff

MaflTtenancefor compiete information

on howto checkandfill the transmiso

sions.

Section2: Assembly

iMPORTANT: Checkgear oii ievet in both

transmissions after the first 2 hours of

new tiiier operation, then every 30

operating hours thereafter. SeeSection5

for instructions.

Figure 2=12: Checking oil level on

Power Unit Transmission.

Figure 2o13: Checking oil level on

Tine Attachment Transmission.

STEP7: Add Motor Oil to Engine

1. Beforeadding motor oii, park thetiller

oil ieveiground. Levelthe engine by

placing asturdy block underthetines or

the tines depth regulator bar.

2. Referto the EngineOwner's ManuaI

provided with your tiiier for detaiiedinfor-

mation onhow to add motor oil and for

motor oilspecifications.

IMPORTANT:Two 20 oz. bottles of motor

oii areincluded with your tiiier. Checkthe

oii ievei as instructed in the Engine

Owner's Manual provided with your tiiier

BEFOREpouring the full amount of each

bottle into the engine.

iMPORTANT:

° Changeengine oil after first 2 hours of

new operation.

. Checkengine oii ieve! every 5 hours of

operation or each use.

STEP8: Attach Engiee Throttle

Lever and Cable

Forshipping purposes,the throttie cabie,

together with the throttie iever, is wound

around the engine. Carefuiiyunwind the

cable. If the throttle controi iabetis

covered with aclearprotective coating,

peel it off.

To avoid electric shock from a short

circait (electric start tiJJers only), never

allow the throttle cabte to roach the

battery. Route cabte below the battery,

on the outside of the batteryholder.

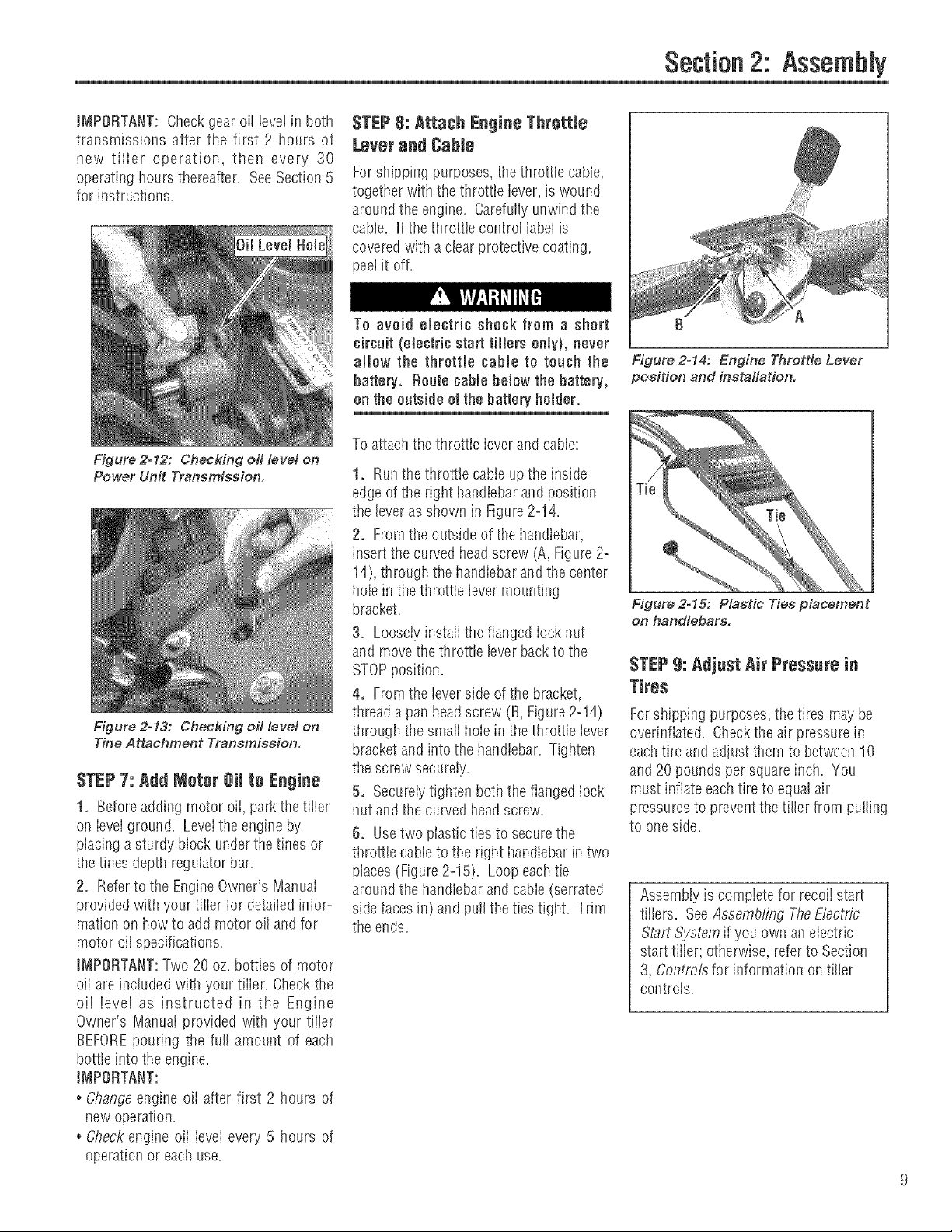

To attach thethrottle leverand cable:

1. Runthe throttle cableupthe inside

edge of the right handlebarand position

the lever as shown in Figure2=14.

2. Fromthe outside of the handlebar,

insert the curved headscrew (A,Figure2=

14),through the handlebarand the center

hole in thethrottie levermounting

bracket.

3. Loosely instaii the flanged iocknut

and movethe throttle leverbacktothe

STOPposition.

4. Fromthe leverside of the bracket,

thread a pall headscrew (B, Figure 2=14)

through the smaiihoiein the throttle iever

bracket and into the handlebar. Tighten

the screw securely.

5. Secureiytighten both theflanged lock

nut and the curvedheadscrew.

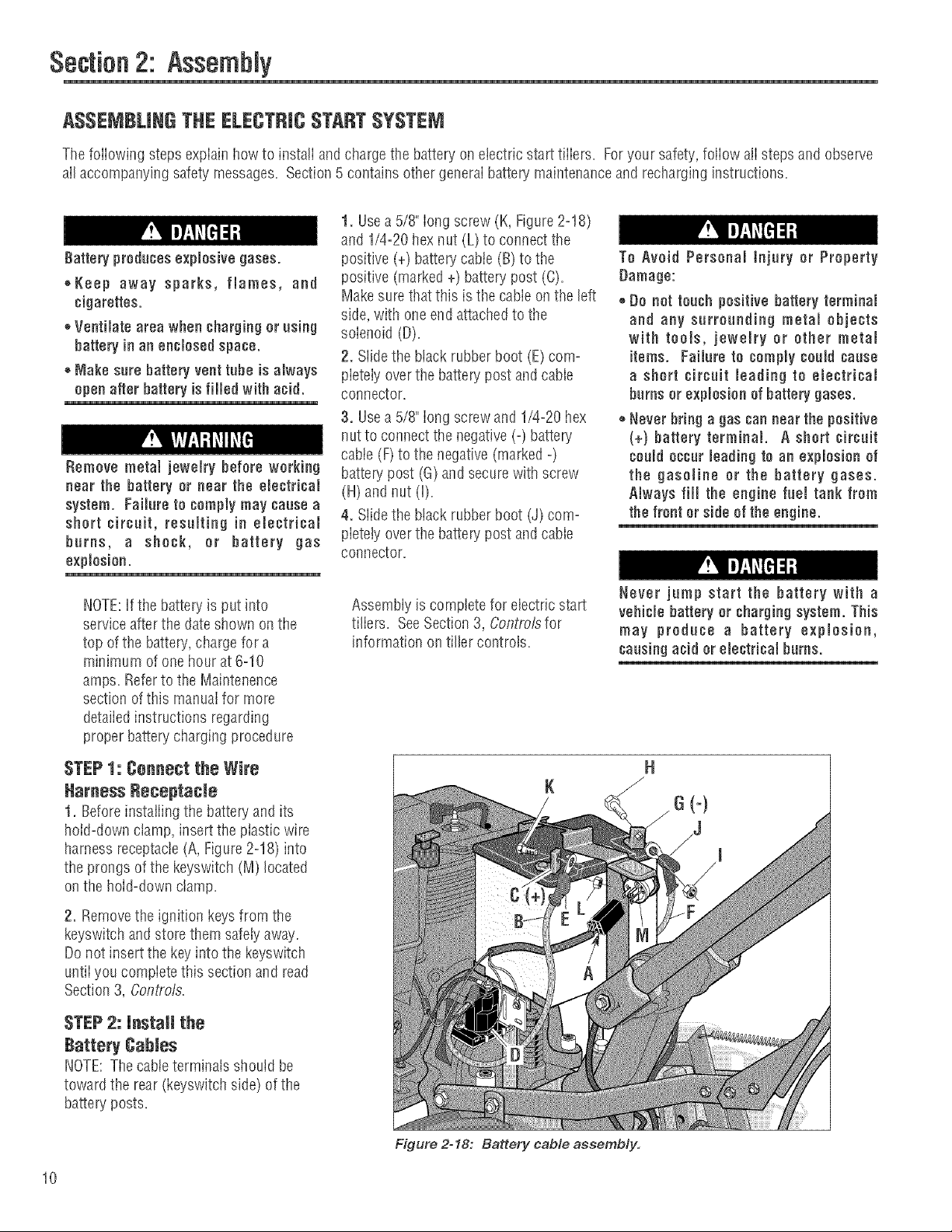

6. Usetwo plastic tiesto securethe

throttle cableto the right handlebar intwo

places (Figure2=15). Loop eachtie

around the handlebar and cable (serrated

side faces in) andpulIthe ties tight. Trim

the ends.

f} A

Figure 2-14: Engine Throttle Lever

position and installation.

Figure 2o15: Plastic Ties placement

on handlebars.

STEP9: Adjust Air Pressurein

Tires

Forshipping purposes,the tires maybe

overinflated. Checkthe air pressure in

eachtire and adjust themto between10

and 20pounds per squareinch. You

must inflate each tire to equalair

pressuresto prevent thetiller from pulling

to one side.

Assembiy is compiete for recoiistart

tiilers. SeeAssembling TheElectric

Start System if you own an electric

start tiller; otherwise, refer to Section

3, Controlsfor information oil tiller

controls.

Section2: Assembly

ASSEMBLINGTHE ELECTRICSTARTSYSTEM

ThefoiiowJngsteps expiaiu howto Jnstaliandchargethe battery on electrJcstart tJiiers. Foryour safety',foliow alisteps and observe

all accompanying safety messages=Section5 contains other generalbattep/maintenance and recharginginstructions=

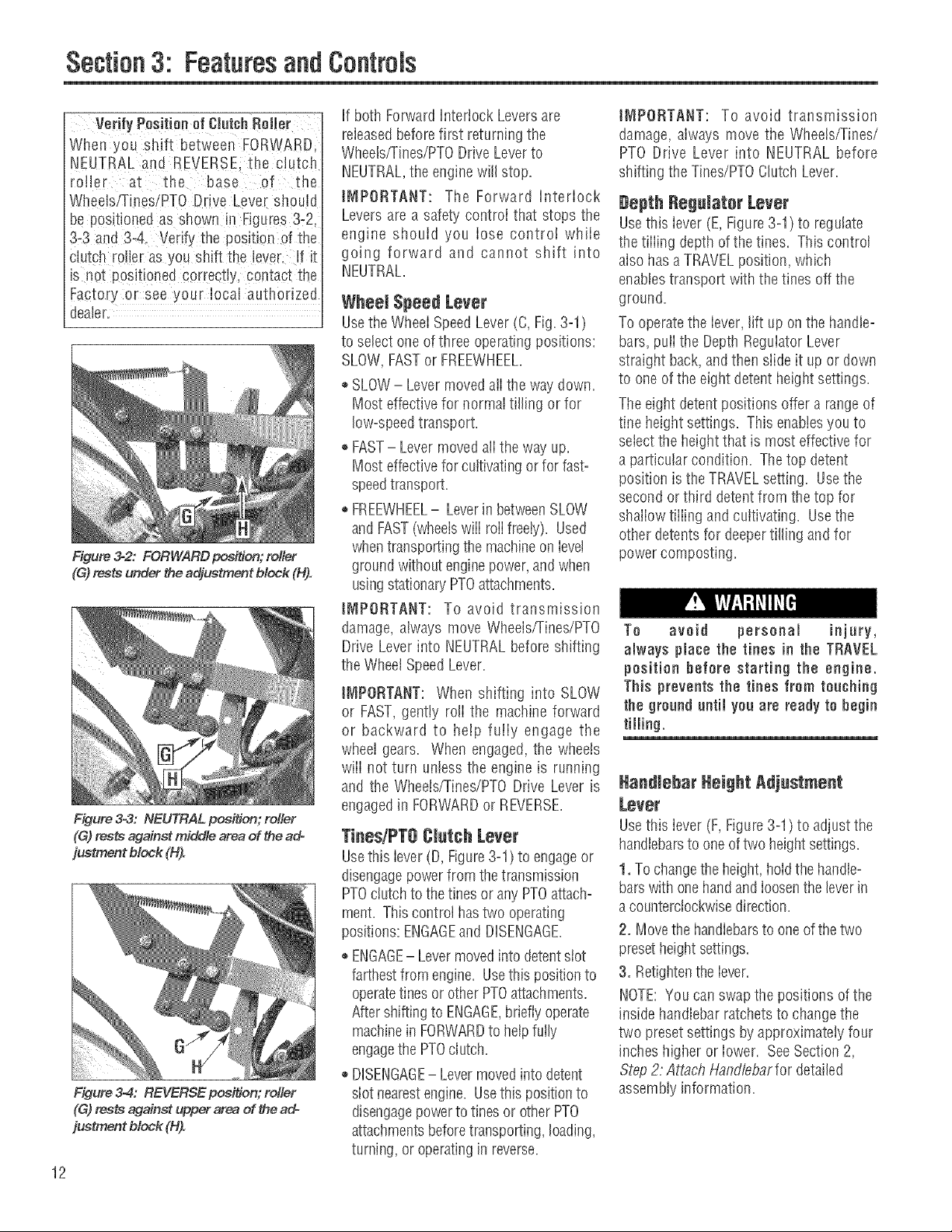

1. Usea 5/8" long screw (K, Figure2=18)

and 1/4=20hexnut (L)to connectthe

Battery producesexplosive gases.

++Keep away sparks, flames, and

cigarettes.

++Ventilate area when chargingor using

battery in an enclosed space.

®Make sure battery vent tube is always

openafter battery is filled with acid.

Remove metal jewemrybefore working

near the battery or near the electrical

system. Failure to comply may cause a

short circuit, resulting in emectfical

burns, a shock, or battery gas

explosion.

positive (+) battery cabte(B)to the

positive (marked +) battery post (C).

Makesurethatthis is the cabie on the left

side, with oneend attachedto the

solenoid (D).

2. Slidethe black rubberboot (E)corn=

pietely overthe batterypost and cable

connector.

3. Usea 5/8" iong screwand 1/4=20hex

nut to connectthe negative(-) battep/

cable (F)to the negative (marked-)

batte_' post (G) andsecurewith screw

(H)andnut (I)=

4. Slidethe black rubberboot (J) corn=

pietetyoverthe battery post and cable

connector.

To Avoid Personal tnjury or Property

Damage:

+Do not touch positivebattery terminal

and any surrounding metal objects

with tools, jewelry or other metai

items. Failure to comply could cause

a short circuit leading to electrical

burns or explosion of battery gases.

++Never bring a gas can near the positive

(+) battery terminal. A short circuit

could occur leading to an explosion of

the gasoline or the battery gases.

Always fill the engine fuel tank from

the front or side of the engine.

NOTE:Ifthe battery is put into

serviceafterthe dateshown on the

top ofthe battery,charge for a

minimum of onehourat 6=10

amps. Referto the Maintenence

section of this manualfor more

detailedinstructions regarding

proper batterycharging procedure

STEP1: Connect the Wire

Harness Beeeptacie

t. Beforeinstaiiing the batteryand its

hold-down clamp, insertthe plastic wire

harness receptacle(A,Figure2-18)into

the prongs of the keyswitch (M) located

on the hoW-downctamp.

2. Removethe ignition keysfrom the

keyswitch and store themsafelyaway.

Donot insert the keyinto the keyswitch

untiiyou compietethis section and read

Section 3, Contro/s.

STEP2: install the

Battery Cables

NOTE:The cableterminals should be

toward the rear (keyswitch side) of the

battery posts.

Assembly is complete for electric start

tiliers. SeeSection 3, Controlsfor

information on tiller controls.

Never jump start the battery with a

vehiclebattery or chargingsystem. This

may produce a battery explosion,

causing acid orelectrical burns.

10

Figure 2o18: Battery cable assembly.

Section

3 =ea u

Before operating your machine,

¢arefuJJy read and understand aJJ

safety, controls, operating instructions

in this Manual, the separate Engine

Owner's Manual and on the decals on

the machine.

Failure to fellow these instructionscan

result inseriuus persunalinjury.

Jntreduetion

This section describes the location and

function of the controls andfeatures on

your tiiier. Referto Section 4, Operation

for detaiiedoperating instructions.

Practiceusingthese controis, with the

engine shut off, untiiyou completely

understandthe operation ofthe controls

and feelconfident with eachof them.

iMPORTANT:Referto the separateengine

manufacturer's Engine Owner's Manuai

for information about the controls on the

engine.

NOTE:Aiireferencesto ieft,right, front

and rearof the machineare basedon a

position behindthe handiebarsandfacing

forward.

PTO Attachments Feature

In addition to powerful tiiiing capabiiity,

you can quickly convert your machine

into a PTO(PowerTake=Off)PowerUnit

that is capable of towing or powering

various TROY-BILTattachments,

You canaccessthis capabiiity by

removing the tines attachment (powered

bythe PTOPower Unit). The PTOPower

Unit isthen avaiiabtefor enginepowered

attachments,or for puiiing ortowing non-

poweredattachments. SeeSection 4,

PTOPower Unitfor detaiiedinformation

on instaiiingand operatingTROY-BILT

PTOattachments.

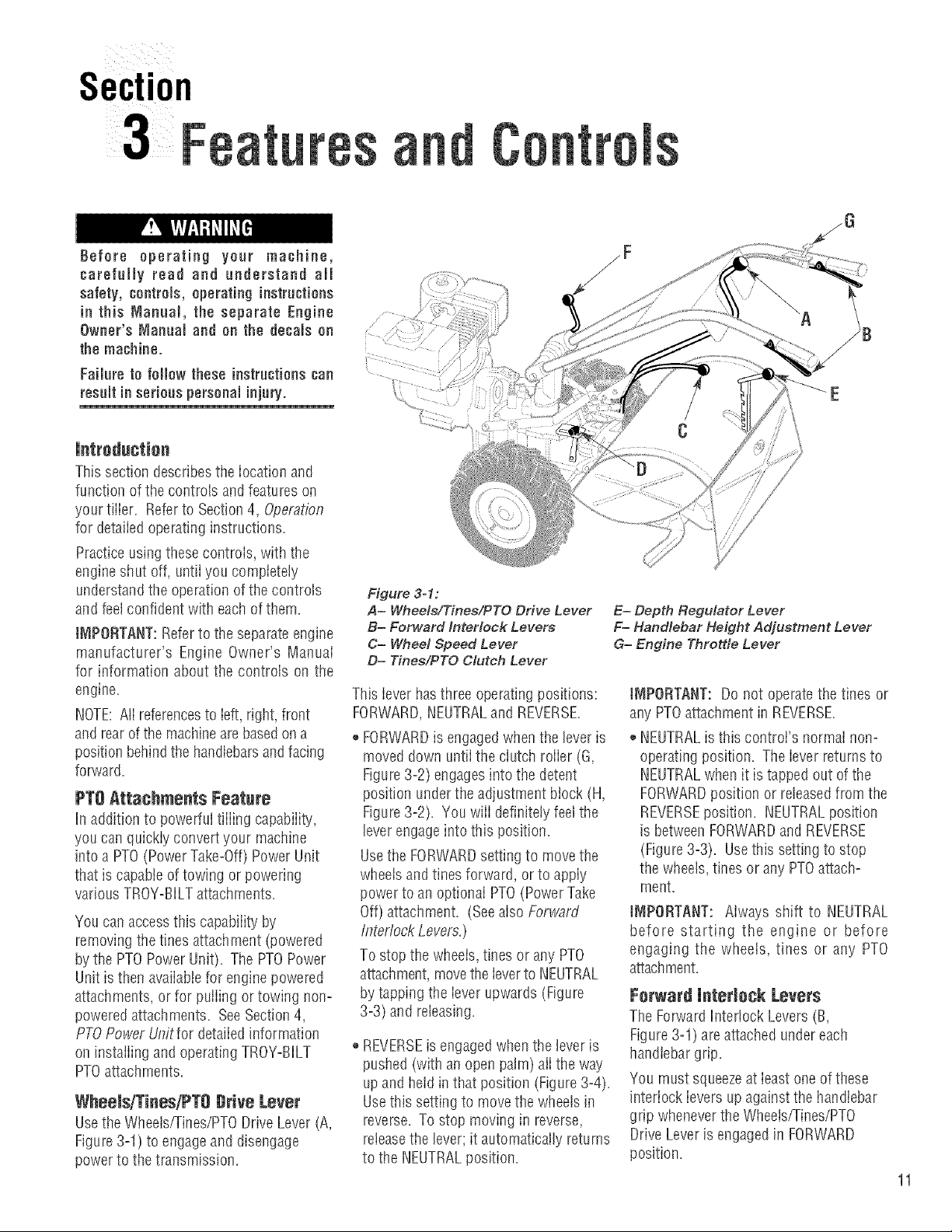

Wheelo/TiueoiPTODrive Lever

Usethe VVheets/Tines/PTODrive Lever (A,

Figure3-1) to engageand disengage

powerto thetransmission.

Figure 3-1:

A= Whee/s/Tinee/PTO Drive Lever

B= Forward Interlock Levers

C= Wheel Speed Lever

D= Tines/PTO Clutch Lever

This lever has three operating positions:

FORWARD,NEUTRALand REVERSE.

,, FORWARDis engagedwhenthe leveris

moved down untilthe clutch roller (G,

Figure3-2) engagesinto the detent

position underthe adjustment block (H,

Figure3-2). You wilI definitely feelthe

leverengageinto this position.

Usethe FORWARDsetting to movethe

wheels andtines forward, or to apply

power to an optional PTO(Power Take

Off) attachment. (Seealso Forward

Interlock Levers.)

To stop the wheeis,tines or any PTO

attachment,movethe Ieverto NEUTRAL

by tapping the iever upwards(Figure

3=3)and releasing.

REVERSEis engagedwhenthe lever is

pushed (with an open palm) aiithe way

up and heid inthat position (Figure 3-4).

Usethis setting to movethe wheetsin

reverse. To stop moving in reverse,

reteasethe lever; it automatically returns

to the NEUTRALposition.

/F

E= Depth Regulator Lever

F= Handlebar Height Adjustment Lever

G= Engine Throtde Lever

JNIPOflTANT: Do not operatethe tines or

any PTOattachment in REVERSE.

NEUTRALis this control's normai non-

operating position. Theiever returns to

NEUTRALwhen it is tappedout of the

FORWARDposition or releasedfrom the

REVERSEposition. NEUTRALposition

is betweenFORWARDandREVERSE

(Figure3-3). Usethis setting to stop

the wheels, tines orany PTOattach-

ment.

IMPORTANT: Always shift to NEUTRAL

before starting the engine or before

engaging the wheels, tines or any PTO

attachment.

Forward interlock Levers

The Forward h_ter!ockLevers(B,

Figure3-1) areattached undereach

handlebargrip.

You must squeezeat ieastoneof these

interlock ievers up against the handlebar

grip wheneverthe Wheets/Tines/PTO

Drive Leveris engagedin FORWARD

position.

11

Section3: FeaturesandControls

Yer!fy Pos!tion of Clutch Roller

When you sNft between FORWABDI

NEUTRAL and REVERSEI the clutch

roller at the base of the

Wheeb!Tines/PTO Drive Lever should

be pesitiobed as shown in Eigures3_2,

3:3 and 3'4, Verify the position Ofthe

clutch roller as you shift the bver_ If it

is not POSitbnedcorrect!y, contact the

Faptory or see your local authorized Wheel Speed Lever

dealer.

Figure 32: FORWARD pos_on; rotier

(G)rests under the adjustment block (H).

Figure 3-3: NEUTRAL position; relier

(G) rests against middle area of the ado

justment block (H).

Figure 3-4: REVERSE position; relier

(G) rests against upper area of the ad-

justment block (H).

12

If both Forward Interlock Leversare

releasedbefore first returning the

Wheels/rines/PTO Drive Leverto

NEUTRAL,the enginewill stop.

iMPORTANT: The Forward Interlock

Levers are a safety control that stops the

engine should you lose control while

going forward and cannot shift into

NEUTRAL.

Usethe Wheel SpeedLever(C,Fig.3-1)

to select oneofthree operatingpositions:

SLOW,FASTor FREEWHEEL.

* SLOW- LevermovedalIthe waydown.

Most effective for normal tilling or for

low-speedtransport.

®FAST- Lever moved all the way up.

Most effective for cultivating or for fast-

speedtransport.

FREEWHEEL- Leverin betweenSLOW

and FAST(wheelswill rollfreely). Used

whentransporting the machineonlevel

ground withoutenginepower,andwhen

usingstationaryPTOattachments.

IMPORTANT: To avoid transmission

damage, always move Wheels/Tines/PTO

Drive Lever into NEUTRALbefore shifting

the Wheel SpeedLever.

IMPORTANT: When shifting into SLOW

or FAST,gently roll the machine forward

or backward to help fully engage the

wheel gears. When engaged, the wheels

will not turn unless the engine is running

and the Wheets/Tines/PTODrive Lever is

engagedin FORWARDor REVERSE.

TinesiPT8 CJutchLever

Usethis lever(D, Figure3-1) to engageor

disengagepowerfrom thetransmission

PTOclutchto the tines or any PTOattach-

ment. Thiscontrol has two operating

positions: ENGAGEand DISENGAGE.

ENGAGE- Levermovedinto detentstot

farthestfrom engine. Usethis positionto

operatetinesor other PTOattachments.

Aftershifting to ENGAGE,brieflyoperate

machinein FORWARDto helpfully

engagethe PTOclutch.

,, DISENGAGE- Levermovedinto detent

slot nearestengine. Usethis positionto

disengagepowerto tines or otherPTO

attachmentsbeforetransporting, loading,

turning, or operatinginreverse.

IMPORTANT: To avoid transmission

damage, always move the Wheels/Tines/

PTO Drive Lever into NEUTRAL before

shifting the Tines/PTOClutch Lever.

#epth Regalater Lever

Usethis lever (E, Figure3-1) to regulate

the tiiiing depthof the tines. This control

alsohasa TRAVELposition, which

enablestransport withthe tines off the

ground.

To operate the lever, rift up on the handle-

bars, pulIthe DepthRegulatorLever

straight back, and then slide it up or down

to one of the eight detent height settings.

The eight detentpositions offer a rangeof

tine heightsettings. This enabbs you to

selectthe heightthat is most effectivefor

a particular condition. The top detent

position isthe TRAVELsetting. Usethe

second or third detent from the top for

shallow tilling and cultivating. Usethe

other @tents for deepertilling and for

powercomposting.

To avoid personal injury,

always place the tines in the TRAVEL

position before starting the engine.

This preventsthe tines from touching

the gronnd nntil yon are ready to begin

tilling.

Handlebar Height Adjustment

Lever

Usethis lever (F, Figure3-1) to adjustthe

handlebarsto oneoftwo heightsettings.

1, To changethe height, hoidthehandb-

barswithonehandandioosenthe leverin

acounterclockwisedirection.

2. Movethe handiebarsto oneofthe two

presetheightsettings.

3. Retightentheiever.

NOTE:Youcan swapthe positions of the

insidehandlebarratchetsto changethe

two presetsettings by approximately four

inches higiler or iower. SeeSection2,

Step2: Attach Handfebarfor detailed

assembly information.

The tiller handlebars can be swung out

300to the right side for use only with the

PTOChipper/Shredder attachment. This

is done by looseningthe mounting bott

on the handlebar base, Never operate

your tiller or attachments, otherthan the

PTOChipper/Shredder, with the handleo

bars in the right side position. Doing so

could result in unsafe handling and

personalinjury.

Engine Throttle Lever

Usethe throttle lever(G, Figure3-1)to

adjust engine speedaswell asto start

and stop the engine.

Movethe leveraway from the STOP

position before starting the engine.

Enginespeedsare variableand range

betweenthe FASTandSLOW. Usethe

STOPposition to turn the engine off.

NOTE:A secondarythrottle leveris

located on the front ofthe 8HPandIOHP

engines. AseparateOn/Offswitch may

alsobeavailableontheengine. (See

EngineOwner'sManualfor information.)

Keyswitch Starter

Thekeyswitchstarter on electricstart

models (A, Figure3-5) hasthree

positions: OFF,RUNand START. Turn

the keyto STARTto start the engine.

Releasethe keyand

it wilI returnto the

RUNposition. Turn

the keyto OFFto

stop the engine,

(Another way to

stop the engine is to

move the engine

throttle leverto the Figure 3-5

STOPposition,)

Section3: FeaturesandControls

Engine Controls

Referto the enginemanufacturer's Engine

Owner's Manual (included in thetiller lit-

erature package)to identify the controls

on your engine.

IMPORTANT:An engine On/Offswitch, a

secondary throttle control, a choke lever

and a fue! iine shut-off controi may be

located on the engine, Refer to your

Engine Owner's Manual for detailed

information.

To avoid serioae personal injury or

damage to equipment, do not start your

engine at this time. Complete starting

instructionsare desoNbed in Section 4,

Operation.

13

Section

Before operating your machine,

carefullyread and understand all safety

(Section 1), ¢ontrots (Section 3) and

operating instrnotions (Section 4) in

this Manual, in the separate Engine

Owner's Manual and on the deoamson

themachine.

FaUnre to follow these instructionscan

resnlt inserious personaminjury,

Readthis Section ofthe manual

thoroughiy beforeyou start the engine.

Then,take the timeto famiiiarizeyourself

with the basic operation of the tilbr

before using it in your garden. Findan

open, level areaand practice usingthe

tiibr controis without the tines engaging

the soii (put tines in Travelsetting--

Section 3, Depth RegulatorLeve,9. Onty

after you've becomecompieteiy famiiiar

with the tflier shoutd you begin using it in

the garden.

Your tiller and its optional PTO Power

Unit attachments are capable of

oansingsefions injury to nntrained or

carelessoperators.

To avoid serious personal injury or

property damage, read the Owner's

Manual that is provided with any

optionaJ accessories or attachments

before using the tiller or PTO Power

Unit.

Break-in i)peration

Perform the following maintenanceduring

the first hours of newoperation (see

MaflTtenanceSectionin this Manuaiand

maintenanceinformation in the Engine

Owner's Manuai).

1, Changeengineoii after first 2 hours of

newengineoperation.

Figure: 4=1

2. After the first 2 hours of new

operation,checkthe gear oiI levelsinthe

PTOPower Unit and the tine attachment

transmissions.

3. Checkfor loose or missing hardware

on unit. Tighten or replaceasneeded.

4. Checktension on forward drivebelt

after first 2 hours of operation.

Starting and Stopping the Engine

Thefollowing stepsdescribehow to start

and stop the engine.

IMPORTANT: Do not attempt to engage

the tines, wheels, or any PTOattachment

untii you have read ali of the operating

instructions in this Section. Atso review

the safety rubs in Section 1, Safety and

the tiller and engine controls information

in Section 3, Featuresand Controls.

Pro=StartChecklist

Makethe following checks and perform

the following services beforestarting the

engine.

1. Readthe Safetyand Confl'otsSections

inthis Manual Readthe separate Engine

Owner'sManuai provided by the engine

manufacturer.

2, Check unit for looseor missing

hardware. Serviceas required.

3, Checkengine oil level. SeeEngine

Owner's Manual.

4. Shift the Wheeis/Tines/PTODriveiever

(Figure4-2) into NEUTRALposition. See

Section3, Controls for more information

on this iever.

5, Check Safety'Guards. AIIguards and

covers must besecurelyin place.

6, Check air cieaner. SeeEngineOwner's

Manual.

7. Attach sparkpiug wire to spark piug.

8, Check EngineCooling System. Clear

cooiing fins and air intakescreen of

debris.

g. Sebct High/Low Belt Speedrange.

10. Adjust HandlebarHeight.

11, FilIthe fuettank with gasolinein

accordancewith the directions in the

separateEngineOwner's Manual. Foliow

alIinstructions andsafetyrules carefully.

GASOUNEIS HIGHLY FLANJNIABLEAND

iTS VAPORSAREE×PLOSIVE.

Follow gasoline safety rules in this

Manual (Section 1) and in the separate

EngineOwner's N_annaJ.

Failure to folJow gasoline safety instruc-

tions can resuJt in serious personal

injnryandproperty damage.

14

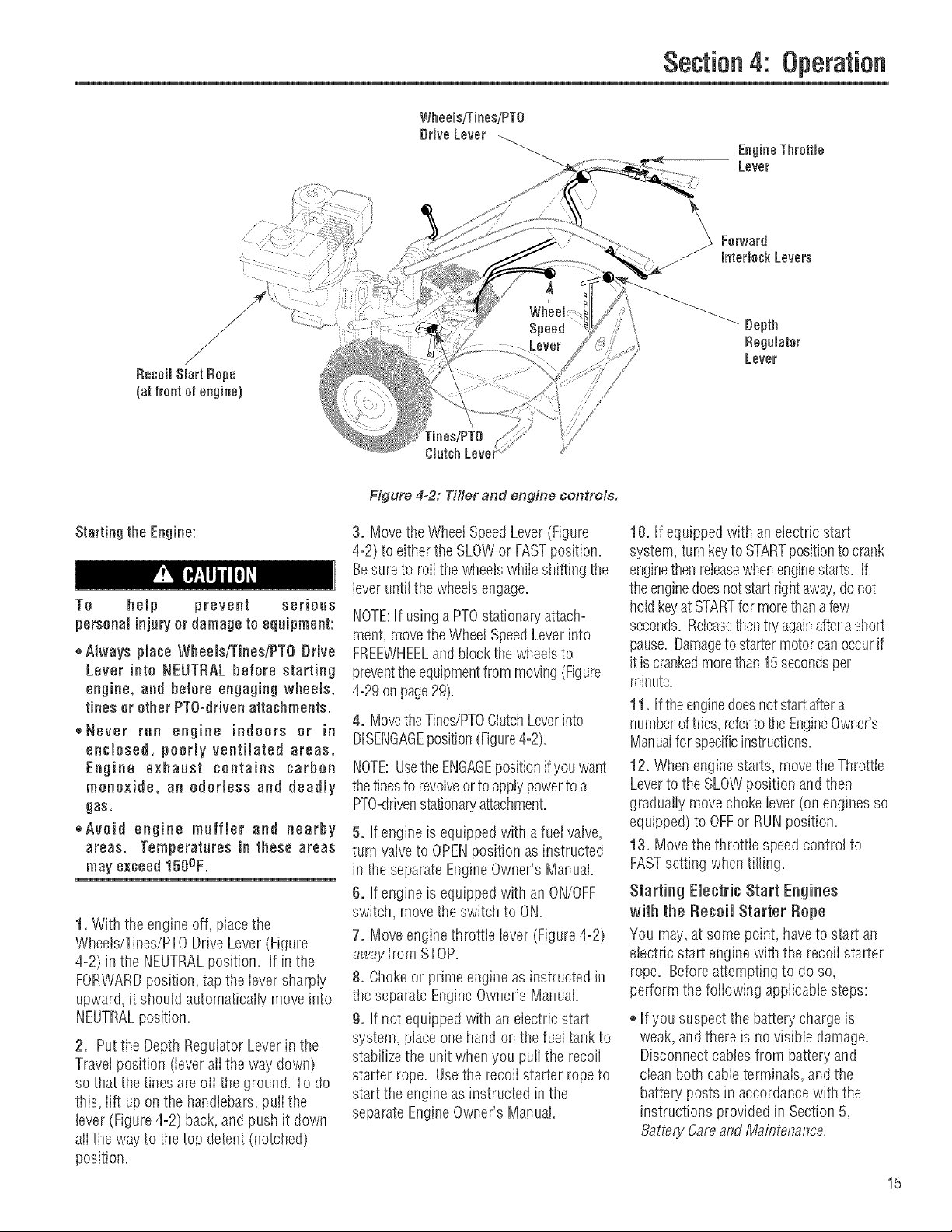

Figure 4-2: Tiller and engine controls.

Section4: Operation

EngineThrottle

Lever

Forward

interlockLevers

Depth

RegaJatar

Lever

Starting the Engine:

To help prevent serious

personalinjuryor damage to equipment:

,_Always place Wheels/Tines/PTO[}rive

Lever into NEUTRAL before starting

engine, and before engaging wheels,

tines orether PTO=dfivenattachments.

,,Never run engine indoors or in

enclosed, poorly ventihted areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas,

,,Avoid engine muffler and nearby

areas. Temperatares in these areas

may exceed150OF.

1. With the engineoff, placethe

Wheets/Tines/PTODrive Lever (Figure

4=2)in the NEUTRALposition. If in the

FORWARDposition, tap the iever sharply

upward, it should automatically move into

NEUTRALposition.

2. Putthe DepthRegulator Leverinthe

Travel position (leveralI the way down)

so that the tines areoffthe ground. To do

this, lift up on the handlebars,pulI the

lever (Figure 4-2) back,and push it down

ali the way to the top detent (notched)

position.

3. Movethe WheelSpeedLever(Figure

4=2)to either theSLOWor FASTposition.

Besureto rolithe wheelswhiie shifting the

leveruntil thewheelsengage.

NOTE:If usingaPTOstationaryattach°

meet,movethe WheelSpeedLeverinto

FREEWHEELandblock the wheelsto

preventthe equipmentfrom moving(Figure

4=29onpage29).

4. MovetheTines/PTOClutchLeverinto

DISENGAGEposition(Figure4=2).

NOTE:UsetheENGAGEpositionifyou want

thetinesto revolveor to applypowerto a

PTO=ddvenstationap./attachment.

5. If engine is equippedwith a fuel valve,

turn valveto OPENposition as instructed

in the separateEngineOwner'sManual.

6. If engine is equippedwith an ON/OFF

switch, move the switchto ON.

7. Moveengine throttie lever (Figure4=2)

away from STOP.

8. Chokeor prime engineasinstructed in

the separateEngineOwner's Manual.

9. If not equippedwith an electric start

system, placeone hand on the fueltankto

stabiiizethe unitwhen you pu!I the recoii

starter rope. Usethe recoii starter ropeto

start the engineasinstructed in the

separateEngineOwner's Manual.

10. If equipped with an electric start

system, turnkeyto STARTpositionto crank

enginethenreleasewhenenginestarts. If

theenginedoesnotstart rightaway,donot

holdkeyatSTARTfor morethana few

seconds. Releasethentry againafterashort

pause. Damageto startermotorcan occurif

itiscrankedmorethan15secondsper

minute.

11. Ifthe enginedoesnotstart aftera

numberoftries,refertotheEngineOwner's

Manualforspecificinstructions.

12. When engine starts, movetheThrottle

Leverto the SLOWposition andthen

graduatiy movechoke iever (onenginesso

equipped) to OFFor RUN position.

13. Movethe throttle speedcontrol to

FASTsetting whentilling.

Starting Electric Start Engines

with the Re€ell Starter Repe

You may,at some point, haveto start an

etectric start engine with the recoii starter

rope. Beforeattemptingto do so,

perform the foiiowing appiicabiesteps:

®Ifyoususpectthe battery chargeis

weak,andthere is no visible damage.

Disconnectcabtes from batteryand

cieanboth cableterminais, and the

batten' posts in accordancewith the

instructions providedin Section5,

BatteryCareand Maintenance.

15

Section4: Operation

Reconnectthe cables and securely

tighten to battery posts. Theenginewiii

rechargethe battery if the battery is still

good.

o If you suspectthe batteris "dead", or if

the batteryis damaged, disconnect,and

remove it. Haveit checkedby a

quaIifiedtechnician.

®If battery hasbeen removed,wrap cable

terminals at endof positive cable with

electricaItapeandsecurethe cableto

the batterybracket.Thiswill prevent

electricaldischarge.

Beforepuffingthe recoil starter rope,

turn the keyswitchto the RUN position.

Move theThrottle Leverawayfrom

STOPposition andset the choke as

applicable.See EngineOwner's Manual.

Cold Weather Operation

Whentemperaturesfail below40% eo

the following s_ensto protectyour

engine ana transmission from _amage:

1. Referto the EngineOwner's Manual

for motor oil specifications for cold

weather operation. Usewinter blend

gasoline

2. Warm up the enginebefore putting it

undera load.

3. Usewinter-blenDgasoline,

4. Usethe correct weight gearoil in PTO

PowerUnit[ransmission.

5. Warm up thetransmission c2earoil as

follows: With engine running, moye

Wheel SpeedLever(Figure4-2) to

FREEWHEEL_thenblock wheelssothey

can't roll, put Tines/PTOClutch Le/or

into DISENBAGE.then squeezeone of

the ForwardInterlock Leversandsnift

the Wheels!Tines!PTODrive Leverto

FORWARD.

6. if wheelsarefrozen to the grounD,

melt ice with warm water.

Stepping the Engine and Tiller

1. Tostop the wheels andtines, movethe

Wheets/Tines/PTODrive Lever into

NEUTRALposition andthen releaseboth

ForwardInterlock Levers.

16

2. Move the engineThrottle Leverto the

STOPposition. Thenonelectric start

models,turn the keyto OFF. Removethe

keyfor safekeeping.

NOTE:Theengine may havea separate

Throttle Control LeverandON/OFFswitch

onthe engine. Thesecontrols can also be

usedto stopthe engine. Seethe Engine

Owner'smanuai for information specific

to your engine.

Operating the Tiller

Whenfirst practicing, keepthe Tines/PTO

CiutchLeverin DISENGAGEposition and

the Wheel SpeedLeverin SLOWposition.

To avoid serious personal injury or

damage to equipment:

,_Always placeWheelsiTiees/PTO Drive

Lever in NEUTRAL before starting

engine, and before engaging wheels,

tines orother PTOattachments.

®Be sure there are no obstacles behind

you before moving inreverse.

* Wheels/TinesiPTO Drive Lever should

automatically return to NEUTRAL

when released from REVERSE

position, tf it does not, move lever to

NEUTRAL manually and discontinue

use until you adjust the lever. See

Seotion 5, Checking and Adjustind

Reverse Drive System.

,,No reverse motion should occur if

Wheels[TinesiPTO Drive Lever is not

held up in REVERSE. See Section 5,

Checkiflg and Adjustind Reverse

Drive System for adjustment steps.

Do not use tiller unless properly

adjusted.

,, Always return to NEUTRALand let all

motion stop before shifting to

FORWARDor REVERSE.

Thefoiiowing pagesprovideguidelines

for using your tiiier effectively and safely

in various gardening applications. Be

sure to readTf/ling Tips& Techniques,in

this Section, beforeyou actually putthe

tines into the soii.

This isa traditional standard=rotating-tine

(SRT)tiiier with forward rotating tines. It

operatesin a compietely different manner

than counter-rotating-tine (CRT)tillers, or

from front-fine tillers.

lVleving the Tiller Forward and Tilling

1. Start the engineandgraduatiyincrease

enginespeedto FAST(seeStarting the

Engine,this Section).

The Forward Interlock Safety System is

designed for the operator'ssafety. Do

not disoonneot or attempt to defeat the

purpose of the system, if the system

malfunctions, immediatelycontactyour

IDeal authorized dealer or the

TROY=BtLTTeohnical Service Depart =

meet for assistance. Do not use the

tiller or the PTO power unit until the

Forward hterlook Safety System is

functioning properly. Always test the

system before asing the tiller or PTO

power anit.

2. Test the Forward Interlock Safety

System. See TestingForward interlock

System,this Section.

Keep away from rotating tines. Rotating

tines will caase injury.

3. When practicing,setthe Depth

Regulator Leverto Travelposition.

Otherwise,set the DepthRegulatorLever

to a desireddepth.

4. MoveTines/PTOClutchLever to

ENGAGEposition if you wantthetines to

turn. If practicing, leavein DISENGAGE.

tNIPORTANT: Do not move Tines/PTO

Ciutch Lever to ENGAGE unless

Wheels/Tines/PTO Drive Lever is in

NEUTRAL Tiller damagemayoccur!

5. To movethe tiller forward andengage

the tines, squeezeand hold eitherForward

Interlock Lever(Figure4-3) against the

handlebargrip, then movethe

Wheels/Tines/PTODrive Leverdown to

FORWARDposition.

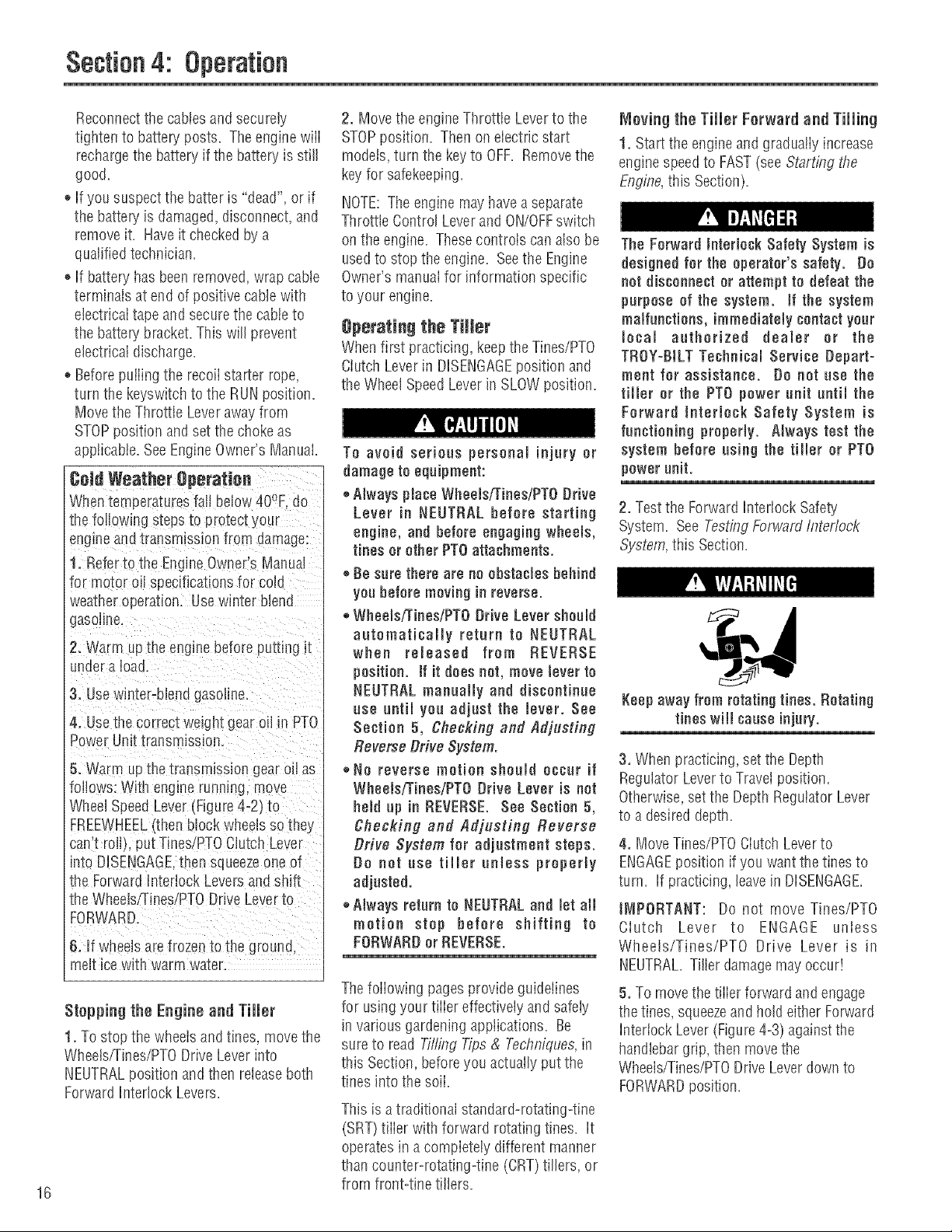

Figure 4=3: Moving tiller forward:

squeeze one Forward interlock Lever

and then move Wheels/Tines/PTO

Drive Lever down to FORWARD.

6. Whenthetiller movesforward, reiax

and ietthe wheels power the tiiier along

whiie the tines dig. Walk behind andto

one side of the tifler. Watkonthe side

that is notyettilled (Figure4-4). Usea

firm grip on the handlebarsbut keepyour

arm relaxed,

JNtPORTANT:Letthe tiiier move aheadat

its own pace. Do not push it ahead--this

reduces operator controi and tiiiing effi=

ciency. Do not push handlebarsdown in

an attempt to dig deeper-- this takes

weigilt off the wheels, reduces traction,

and causes the tines to try to propel the

tiller.

Stopping Forward Motion and Tines

1. To stop forward motion, tap

Wheels/Tines/PTODriveLeverupward

into NEUTRAL.Then releasethe Forward

Interlock Levers. Thewheelsandtines

wiii stop and the enginewill continue

running.

2. in an emergency, reieaseaiI of the

controi ievers. This stops forward motion

and shuts-off the engine.

To Help Avoid Personal injury or

Damage to Equipment:

®Be sure no obstacles are behind you

before operatingthe tiller in REVERSE.

® Disengage the tines, reduce engine

speed, and move the Wheel Speed

Lever to SLOW position before

operating in REVERSE. Avoid using

FAST wheel speed until you are

familiar with backing the tiller.

1

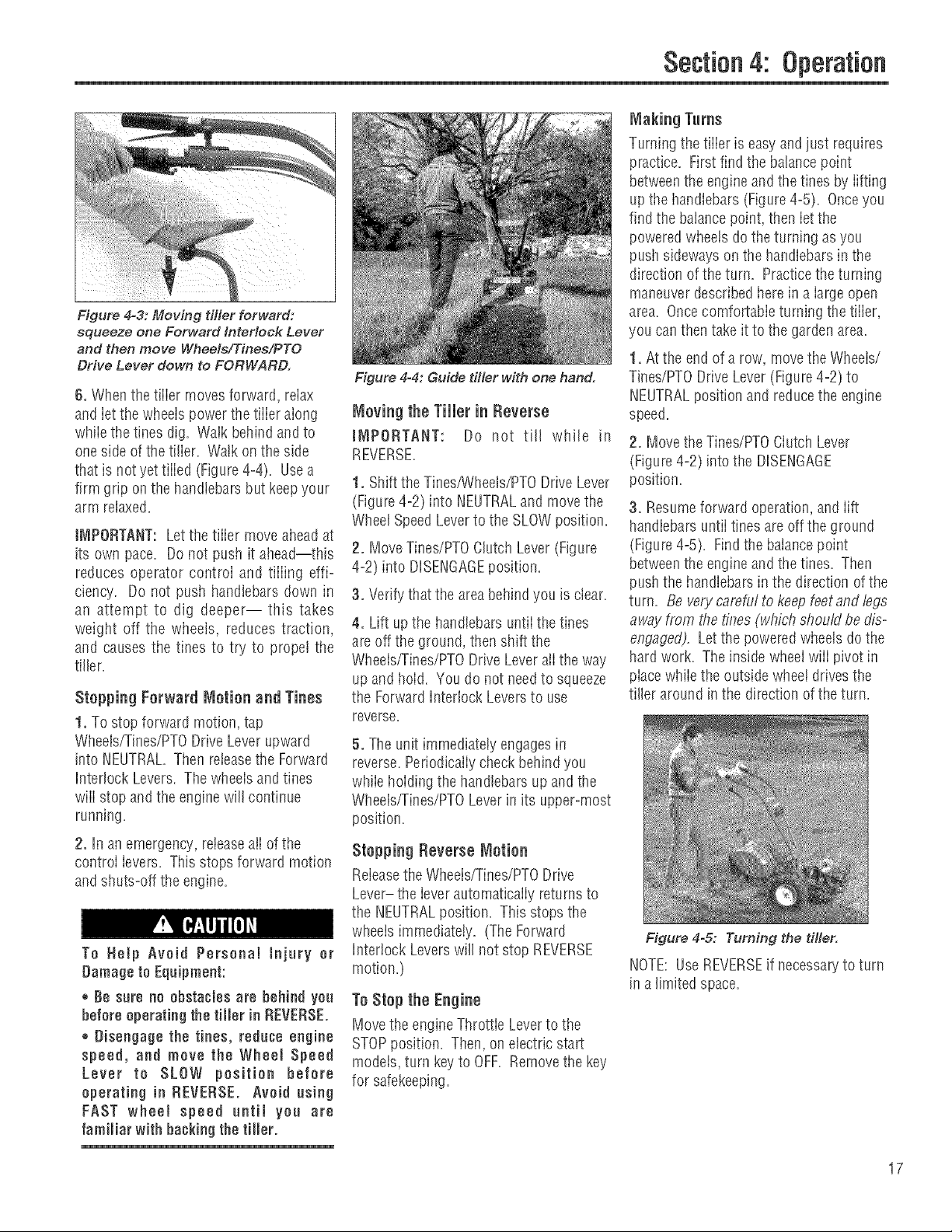

Figure 4=4: Guide tMer with one hand.

Moving the Tiller in Reverse

tN_PORTANT: Do not till while in

REVERSE,

1. Shift the Tines/Wheels/PTODrive Lever

(Figure4=2)into NEUTRALand movethe

WheetSpeedLever to the SLOWposition.

2. Move Tines/PTOClutch Lever(Figure

4-2) into DISENGAGEposition.

3. Verify that the areabehindyou is clear.

4. Lift upthe handlebarsuntii tile tines

are off theground, thenshift the

Wheeisffines/PTO Drive Lever aii the way

up andhoW. Youdo not needto squeeze

the Forward Interlock Leversto use

reverse.

5. Theunit immediatelyengages in

reverse.Periodicaliycheckbehind you

whiie hewing the handlebarsupandthe

Wheelsfrines/PTO Leverin its upper-most

position.

Stopping Reverse Motion

Releasethe Wheels/Tines/PTODrive

Lever- the ieverautomaticaiiy returnsto

the NEUTRALposition. Thisstops tile

wheeis immediately. (The Forward

Interlock Leverswill not stop REVERSE

motion.)

To Stop the Engine

Move the engineThrottleLeverto the

STOPposition. Then,on electric start

models, turn keyto OFF. Removethe key

for safekeeping.

Section4: Operation

Making Turns

Turningthe tiiier is easyand just requires

practice. First find the balancepoint

betweenthe engineandthe tines by iifting

up the handlebars (Figure4°5). Onceyou

find the balancepoint, then iet the

poweredwheets dothe turning as you

push sideways on the handlebarsin the

direction of the turn. Practicetheturning

maneuverdescribed herein a iarge open

area. Oncecomfortabie turning the tiiier,

you can then take it to the gardenarea.

1. Atthe end of a row, movethe Wheeis/

Tines/PTODrive Lever(Figure4-2) to

NEUTRALposition and reducethe engine

speed.

2. Movethe Tines/PTOClutch Lever

(Figure4-2) into the DISENGAGE

position.

3, Resumeforward operation,andlift

handlebars until tinesareoffthe ground

(Figure4°5). Find the balancepoint

betweentile engine andthe tines. Then

push the handlebarsin the direction of the

turn. Be vely camfuf to keep feet and legs

away from the fines (which should be dis°

engaged). Letthe poweredwheelsdothe

hard work. The inside wheelwiii pivot in

placewhiie the outside wheei drivesthe

tifler around inthe direction ofthe turn.

Figure 4-5: Turning the tiller.

NOTE:UseREVERSEif necessaryto turn

in alimited space.

17

Section4:

4. When the turn is complete, shift to

NEUTRALand lower the handlebars=

Move Tines/PTOCiutcil Leverbackto

ENGAGEposition and resumeforward

operation.

Transporting The Tiller Around

Year Property

Whenthe engine is running, thetiiieSs

poweredwheatsmake moving the tiiier to

and from the gardeneasy. If the engineis

not running set the WheelSpeedLeverto

FREEWHEELposition to roll thetiller to

another location.

To help avoid personal injury from

revolving tines, always pat the

TinesiPTOCtutsh Lever in DISENGAGE

position before transporting, loading,or

unloading tiller.

1. Placethe Tines/PTOClutch Leverin

DISENGAGEposition.

2. MoveDepthRegulatorLeverdownalI the

wayintotheTravelsetting.

3. If using engine powel; move Wheel

SpeedLeverto either SLOWor FAST,and

usethe Wheeis/Tinee/PTODrive Leverto

drivethe wheats.

4. If the engineis stopped, move Wheel

SpeedLeverto FREEWHEEL,and

manually pushtiller.

Tenting the Forward

lnterinsk Safety System

TheForwardInterlock Safety System is

designedto shut the tiiier engineoff

immediately if you iosecontroi and

cannot stop moving FORWARDby

shifting theWheets/Tines/PTODriveLever

into NEUTRAL=Whenyou releaseboth

Forward Interiock Levers,they send

ground to the ignition systemthereby

stopping the engine. Squeezingone or

both ievers up against the handlebars

enabiesthe ignition system; therefore,

you must squeezeat ieast one lever

wheneverthe Wheeis/Tines/PTODrive

Leveris engagedin FORWARD=

iNIPORTANT: The interlock system aiso

prevents the engine from starting if the

Wheets/Tines/PTODrive Lever is engaged

in FORWARD.

18

The Forward Interlock Safety System is

designed for the operator's safety. De

net dissonnect or attempt to defeat the

purpose of the system, if the system

maJfnnetions, immediatelycontactyour

local anthorized dealer or the

TROY=BtLTTeshnisal Service Depart =

meet for assistance. Do not use the

filler or the PTO power unit until the

Forward hterlesk Safety System is

functioning properly. Always test the

system before using the tiller or PTO

powerunit.

How to Cheek the interlock System

The Forward Interlock System has an

electro=mechanicaldesign,and so is

subject to normal wearandpossible mat=

function. Checkthe system for proper

operationeachtime prior to usingthe

tiller or PTOpower unit.

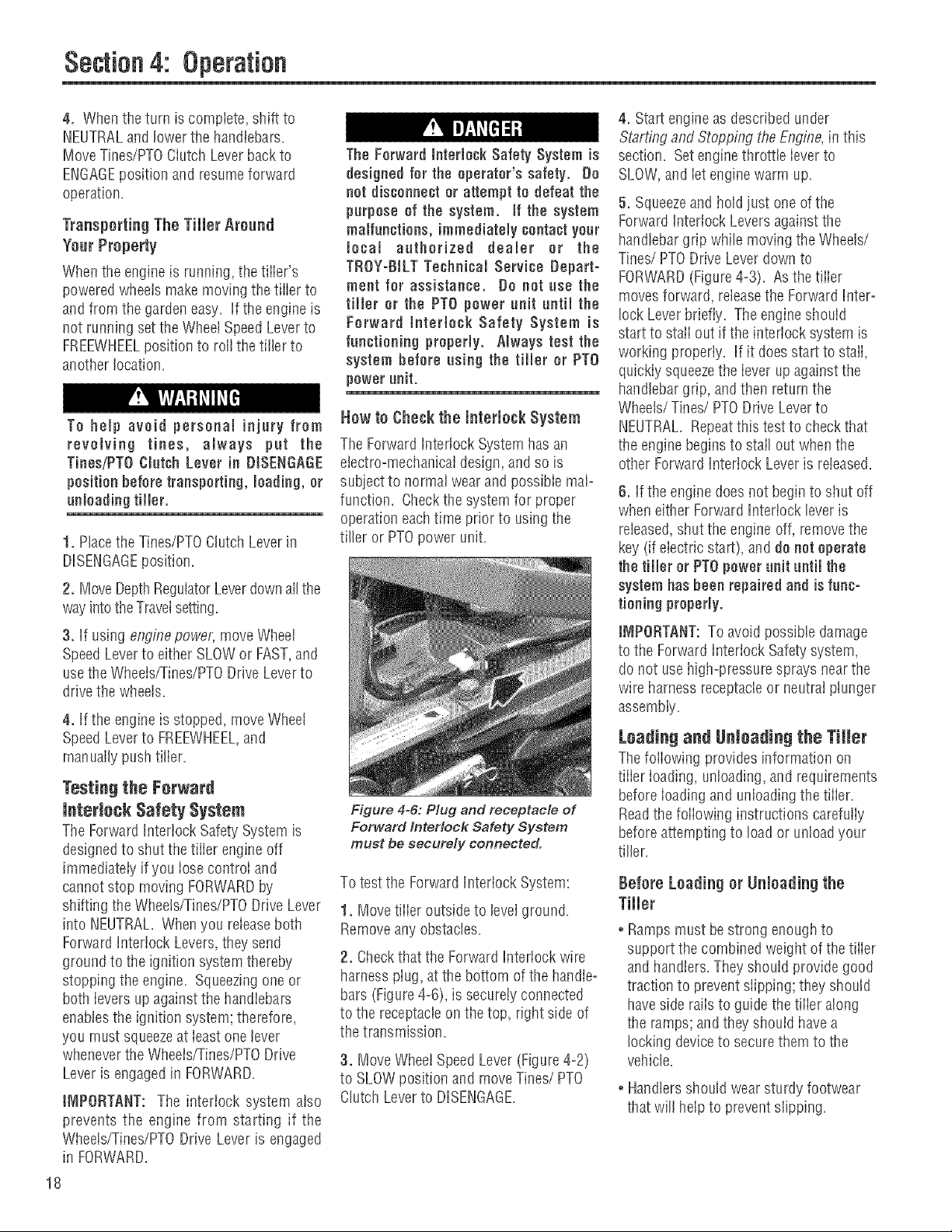

Figure 4-6: Plug and receptacle of

Forward Interlock Safety System

must be securely connected.

To test the Forward Interlock System:

1. Movetiller outside to levelground.

Removeany obstacles.

2. Checkthat the Forward Interlock wire

harnessplug, at the bottom of the handle°

bars (Figure4°6), is securely connected

to the receptacieon the top, right side of

the transmission.

3. Move WheeiSpeedLever(Figure4=2)

to SLOWposition and moveTines/PTO

Clutch Leverto DISENGAGE.

4. Start engine as describedunder

Starting and Stopping theEngine,in this

section. Setenginethrottle ieverto

SLOW,and iet enginewarm up.

5. Squeezeand holdjust oneof the

ForwardInterlock Leversagainst tire

handlebargrip while moving the Wheels/

Tines/PTO DriveLeverdown to

FORWARD(Figure4-3). Asthe tiiier

movesforward, releasethe Forward Inter°

lock Leverbriefly. Theengineshould

start to staiiout if the interiock system is

working properly. If it doesstart to stali,

quickiysqueezethe iever up against the

handlebargrip, and then return the

Wheels/Tines/PTO Drive Leverto

NEUTRAL.Repeatthis test to checkthat

the engine begins to stail out when the

other ForwardInterlock Lever is released.

6. If the engine does not begin to shut off

when either ForwardInterlocklever is

released,shut the engine off, removethe

key (if electric start), anddenet operate

the tiller or PTOpower unit until the

system has beenrepaired and isfuns=

tioning properly.

IMPORTANT:Toavoid possible damage

to the ForwardInterlock Safetysystem,

do not use high=pressuresprays nearthe

wire harness receptacleor neutrai plunger

assembly.

Loading and gnlnading the Tiiiet

Thefollowing provides information on

tiiier ioading, unloading, and requirements

beforeioadingand unloadingthe tiiier.

Readthe foiiowing instructions carefuliy

beforeattemptingto loador unloadyour

tiller.

Before Leading or Unloading the

Tiller

° Rampsmust bestrong enoughto

support the combined weight of the tiiier

and handlers.They should provide good

traction to preventslipping;they should

haveside raiisto guidethetiiier along

the ramps; andthey shouid have a

locking deviceto securethemto the

vehicle.

° Handlersshould wear sturdy footwear

that will help to preventslipping.

Section4: Operation

oTurn the vehicle'sengineoff and apply

its parking brake.

o Positionthe ioading vehicie so that the

rampangieis asflat as possibie (the

less inclineto the ramp, the better).

Leading the Tiller

1. Use ioading ramps that arestrong and

wide enough to safely hold the weight of

the tiiier andthe operator combined--

your tiller weighs between280 and 325

Ibs,

2. Move theTines/PTOClutch Lever

(Figure4-2) into DISENGAGEposition.

3. Setthe Depth Regulator iever(Figure

4-2) to the Travelposition.

4. Move WheelSpeedLever (Figure4-2)

into SLOWposition and reducethe

enginethrottle speed.

5. Sisiftthe Wheelsfrines/PTO Lever

(Figure4-2) into FORWARDposition and

foiiow the tiiier upthe ramps (Figure4-7).

Checkthe wheelsasyou movethe tiiier

forward. Ensurethat they move up the

center of each ramp.

6. Preventtiiier from roiiing in vehicie.

LeaveWheei SpeedLeverin FASTor

SLOWposition, chock wheels with blocks

and tie down the tiller.

Figure 4=7: To go up ramps, use

unmeadingthe Tiller

iMPORTANT:fgeverunloadtire tiiier in

FORWARDdrive, Thetiiier couid tip

forward andexposeyou to the tines

(which shouid be disengagedas

instructed).

1. Use loading ramps that arestrong and

wide enough to safely hotdtire weight of

the tiller andthe operator combined--

your tiller weigirs between280 and 325

Ibs.

2. Movethe Tines/PT0 Ciutch Lever

(Figure4-2) to DISENGAGEposition.

3. Setthe DepthRegulator Lever (Figure

4-2) to the Travelposition.

4. MoveWheel SpeedLever (Figure4-2)

to SLOWposition and reducethe engine

throttle speed.

IMPORTANT: Look behind you before

you back down the rampto ensurethat ali

is clear. Whiie descending,keepchecking

for obstacies behindyou.

5. Moveand hold tire Wheets/Tines/PTO

Leverinto REVERSEdrive and backdown

the ramps (Figure4°8). Checkthe wheets

asyou movethe tiiier backward. Ensure

that they movedown the centerof each

ramp.

Figure 4-8: To go down ramps, use

REVERSE drive.

Changing Speed Brits

Your tiller hastwo belt-drivenspeed

ranges- HIGH RANGEandLOWRANGE

- you pick one or the other by deciding

which setof pulleygrooves to movethe

forward beltinto. By moving the belt

from onespeed rangeinto the other, in

combination with the FASTand SLOW

wheelspeeds,you obtain a choice of four

different forward wheel speedsand two

different tine speeds.

To help avoid serioas personal injary,

stop the engine, remove the ignition

key, disconnect spark plug wire and

move the wire away from the spark

plug, and let engine and muffler cod

down before changing belt speeds.

Changingthe belt from LOWrangeinto

HIGHrange (or backagain) is a matter of

moving the belt from oneset of puliey

grooves to asecond set of pulleygrooves.

This changeis done quickiy and without

tools (Figures4-9 through 4-13).

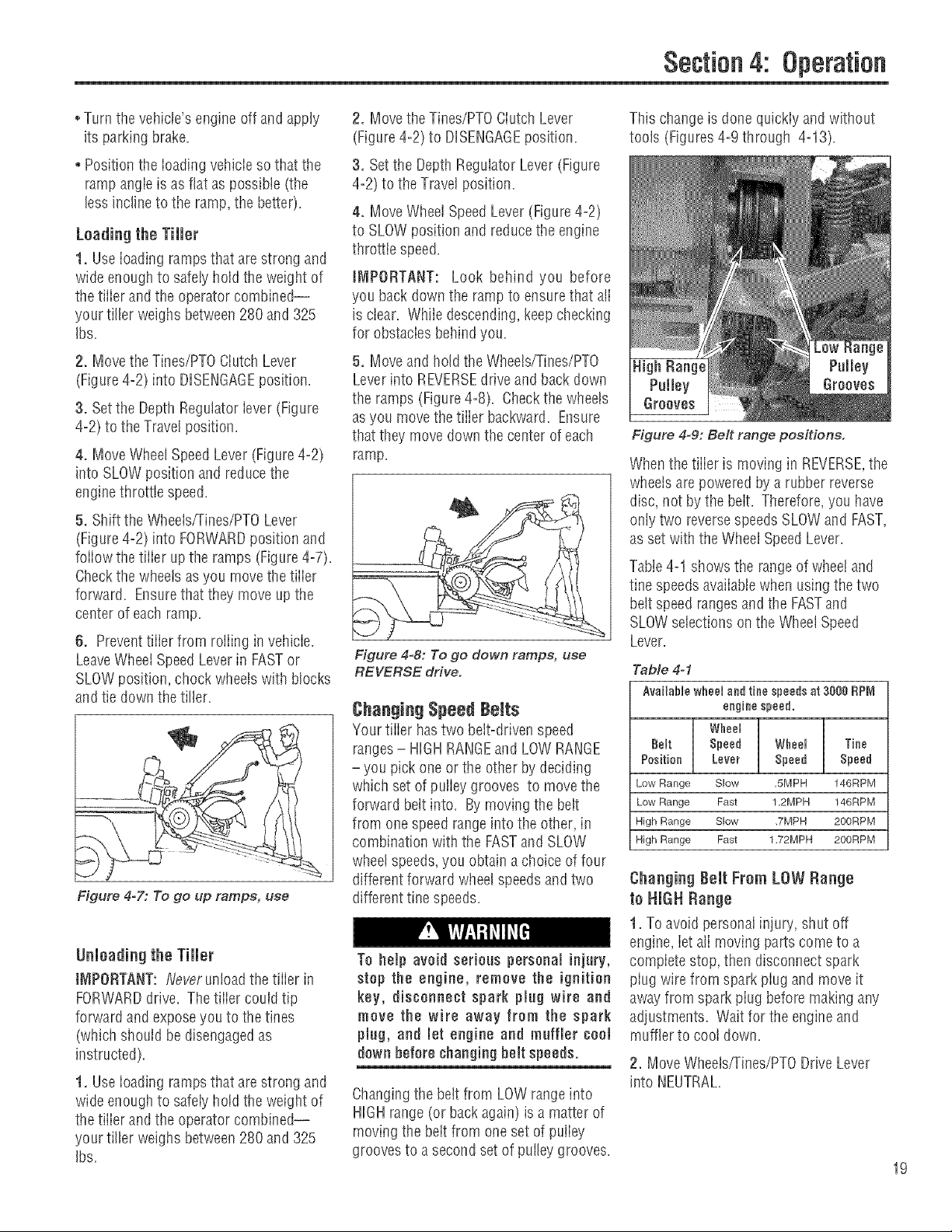

Figure 4=9: Belt range positions.

Whenthe tiller is moving in REVERSE,the

wheels are powered by a rubberreverse

disc, not by the belt. Therefore, you have

onlytwo reversespeedsSLOWand FAST,

as set with the WheelSpeedLever.

Table4-1 shows the range of wheeiand

tine speeds availablewhen usingthe two

bdt speed rangesand the FASTand

SLOWselections onthe WheelSpeed

Lever.

Table 4-1

Available wheel and tine speeds at 3888 RP_

engine speed.

Wheel

Belt Speed Wheel Tine

Position Lever Speed Speed

Low Range Slow ,5MPH 146RPM

Low Range Fast 12MPH 146RPM

High Range Slow ,7MPH 200RPM

High Range Fast 1,72MPH 200RPM

Changing Belt From LOW Range

in HIGH Range

1. To avoid personalinjury, shut off

engine, iet alimoving partscometo a

compiete stop, then disconnect spark

piug wire from spark piug and move it

away from spark piug before making any

adjustments. Wait for the engineand

muffler to cooIdown.

2. Move Wheels,rrines/PTODrive Lever

into NEUTRAL.

19

Section4: Operation

The HiGH speed belt range position

combined with a FAST wheel speed

setting propels the tiller at the fastest

pace. Reduce the enginethrottle speed

when starting outto help avoid personal

injury or propertydamage if using this

speed combination.

3. Kneelon fefiside of tiller. To create

beit slack, reachoverto right side ofthe

pulieys and push in atthe center of the

beit with a finger. At the sametime, use

your ieft hand to work the belt part=way

onto the iower=fronttransmission pulley

groove (Figure 4=10).

4. Goto right sideof tiller and finish

seatingthe beit.

5. Stiil holding the iever up in REVERSE

position, and working from the ieft side of

thetiiier, move the beit from the lower=

front transmission grooveto the lower-

reartransmission groove.

6. Goto the right side of the tiiier and

finish seatingthe belt (Figure4-13).

Figure 4-11: Low range to high

range. Shows moving belt from top=

rear groove onto top-front groove.

7. Checkboth sides of the high range

puiiey grooves to verify that the belt is

properly seated.

Changing Belt Frem HiGH Range te

LOW Range

1. To avoid personal injury,shut off

engine,iet aii movingparts cometo a

complete stop, then disconnect spark

plug wire from spark piug and movewire

away from sparkpiug before making any

adjustments. Letengineand muffler cool.

2. Move the Wheels/Tines/PTODrive

Leverinto NEUTRAL.

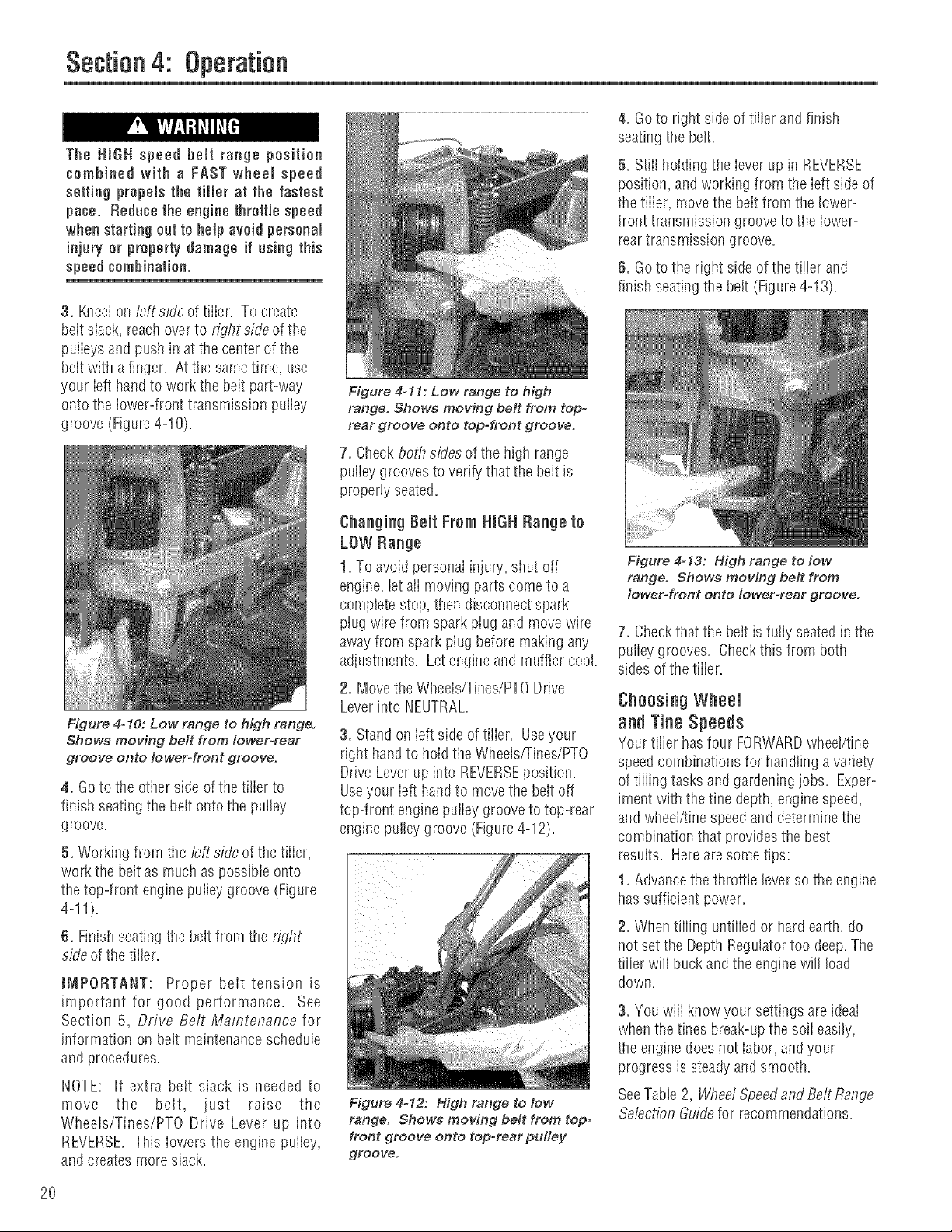

Figure 4o10: Low range to high range.

Shows moving belt from lower-rear

groove onto IowerWront groove.

3. Standon Ieftside of tiiier. Useyour

right handto holdthe Wheels/Tines/PTO

Drive Leverupinto REVERSEposition.

4. Goto the other side ofthe tilier to Useyour ieft handto movethe belt off

finish seatingthe belt onto the putley top-front enginepuiiey groovetotop-rear

groove, engine pulleygroove (Figure4-12).

5. Working from the left sideof the tiller, _ ::::

work the bett as muchaspossibie onto

thetop-front enginepulley groove (Figure

4-11).

6. Finish seatingthe beltfrom the right

sideof thetiller.

JNIPORTANT: Proper beittension is

important for good performance. See

Section 5, Drive Belt Maintenance for

information on belt maintenance schedule

and procedures.

NOTE: If extra belt slack is needed to

move the belt, just raise the

Wheels/Tines/PTO Drive Lever up into

REVERSE.This iowers the engine puiley,

and createsmore slack.

Figure 4-12: High range to low

range. Shows moving belt from top-

front groove onto top-rear pulley

groove.

Figure 4-13: High range to low

range. Shows moving belt from

Iowet=front onto Io wet-rear groo re.

7. Checkthat the bett is fully seatedin the

pulley grooves. Checkthis from both

sides of the tiiier.

Choosing Wheel

and TineSpeeds

Your tilier hasfour FORWARDwheei/tine

speedcombinationsfor handling avariety

of tiiiing tasksandgardeningjobs. Exper-

iment withthe fine depth, enginespeed,

and wheel/finespeedand determine the

combination that provides the best

results. Hereare some tips:

1. Advancethe throttle leverso the engine

hassufficient power.

2. Whentiffing untiiied or hard earth, do

not set the DepthRegulatortoo deep.The

tiiier will buckandthe engine will load

down.

3. You will know your settings areideal

whenthe tines break-upthe soil easily,

the enginedoes not iabor, andyour

progress is steadyandsmooth.

SeeTable2, Wbee/Speedand BettRange

Se/ectionGuidefor recommendations.

2O

Loading...

Loading...