Page 1

www.trimble.com

HL450 Laserometer

User Guide

EMC Declaration of Conformity

This receiver has been tested and found to comply with the limits for a

Class B digital device for radio noise for digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communication, and is pursuant to part 15 of the Federal Communication

Commission (FCC) rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This receiver generates radio frequency. If it’s not used in accordance

with the instructions, it may cause harmful interference to radio or television reception. Such interference can be determined by turning the receiver off and on. You are encouraged to try eliminating the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the laser and the receiver.

For more information, consult your dealer or an experience

radio/television technician.

CAUTION: Changes or modications to the receiver that are not ex-

pressly approved by Trimble could void authority to use the equipment.

Declaration of Conformity

Application of Council Directive(s): 89/336/EEC

Manufacturer’s Name: Trimble Navigation Ltd.

Manufacturer’s Address: 5475 Kellenburger Road

Dayton, Ohio 45424-1099 U.S.A.

European Representative Address: Trimble GmbH Am Prime Parc 11

65479 Raunheim, Germany

Model Number: HL450

Conformance to Directive(s): EC Directive 89/336/EEC using

EN55022 and EN50082-1

Equipment Type/Environment: ITE/residential, commercial

& light industrial

Product Standards: Product meets the limit B and

methods of EN55022

Product meets the levels and

methods of IEC 801-2, 8 kV air,

4 kV contact IEC 801-3, 3 V/m

26 to 1000 MHz 80%, @ 1 kHz

1. Keypad - Power, Accuracy, Units & Volume switches.

2. Beeper output - Fast, solid & slow audible signal.

3. Bubble Vial - aids in keeping HL450 level.

4. An ti-strobe sensor - Reduces false ind ication f rom

strobe lights.

5. SuperCell Reception Window - 4.0 in / 102 mm of height.

6. Front LCD - Displays elevation, settings and status.

7. On-grade Mark - Aligned with laser center on-grade

reading.

8. Battery Door & Latch for two “AA” batteries.

9. Marking Notch (3.15 in / 80.0 mm from top).

10. Captive Screw Thread

11. Clamp Guides - Dimples align rod clamp.

12. Serial Number / ID Label.

13. Rear LCD - repeats indications of front LCD.

Front view

Rear view

Working Radius: 1 m - 200 m (3 ft - 650 ft)

(Laser dependent):

Laser Detection Height: 102 mm (4“)

Numeric Readout Height: 76 mm (3“)

Accuracy (Dead band):

Fine 1.0 mm 0.05 in 1/16 in

Medium 5.0 mm 0.20 in 1/4 in

Calibration 0.1 mm 0.01 in 1/64 in

Reception Angle: ± 45° minimum

Detectable Spectrum: 610 nm ... 900 nm

Beeper Volumes: Loud = 100+ dBA

Low = 65 dBA

Power Supply: 2 x 1.5 Volt “AA” batteries

Battery Life: 70+ hours

Automatic Shut Off: 30 min

Environmental: Waterproof, Dustproof to IP67

Weight without clamp: 371 g (13.1 oz.)

Dimensions without clamp: 168.0 x 76.0 x 36.0 mm

(6.6” x 3.0” x 1.4”)

Operating Temperature: -20°C...+60°C (-4°F... +140°F)

Storage Temperature: -40°C...+70°C (-40°F...+158°F)

*Specifications subject to change without notice.

Trimble warrants the HL450 to be free of defects in material and

workmanship for a period of three years. (3 year limited, 2 years free

exchange, 3rd year a fee is charged.) Trimble or its authorized service

center will repair or replace, at its option, any defective part, or the entire

product, for which notice has been given during the warranty period. If

required, travel and per diem expenses to and from the place where

repairs are made will be charged to the customer at the prevailing rates.

Customers should send the product to Trimble Navigation Ltd. or the

nearest authorized service center for warranty repairs or exchange,

freight prepaid. Any evidence of negligent, abnormal use, accident,

or any attempt to repair the product by other than factory-authorized

personnel using Trimble certied or recommended parts, automatically

voids the warranty. The foregoing states the entire liability of Trimble

regarding the purchase and use of its equipment. Trimble will not be

held responsible for any consequential loss or damage of any kind. This

warranty is in lieu of all other warranties, except as set forth above,

including any implied warranty merchantability of tness for a particular

purpose, are hereby disclaimed. This warranty is in lieu of all other

warranties, expressed or implied.

Notice to Our European Union Customers

For product recycling instructions and more information,

please go to: www.trimble.com/environment/summary.html

Recycling in Europe

To recycle Trimble WEEE,

call: +31 497 53 2430, and

ask for the “WEEE associate,” or

Mail a request for recycling instructions to:

Trimble Europe BV c/o Menlo Worldwide Logistics

Meerheide 45 5521 DZ Eersel, NL

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

+1-937-245-5600 Phone

www.trimble.com

© 2009, Trimble Navigation Limited. All rights reserved.

Reorder PN 1277-3950 (11/09)

Specications Warranty

N324

8

9

10

11

12

13

3

5

6

4

1

2

7

Page 2

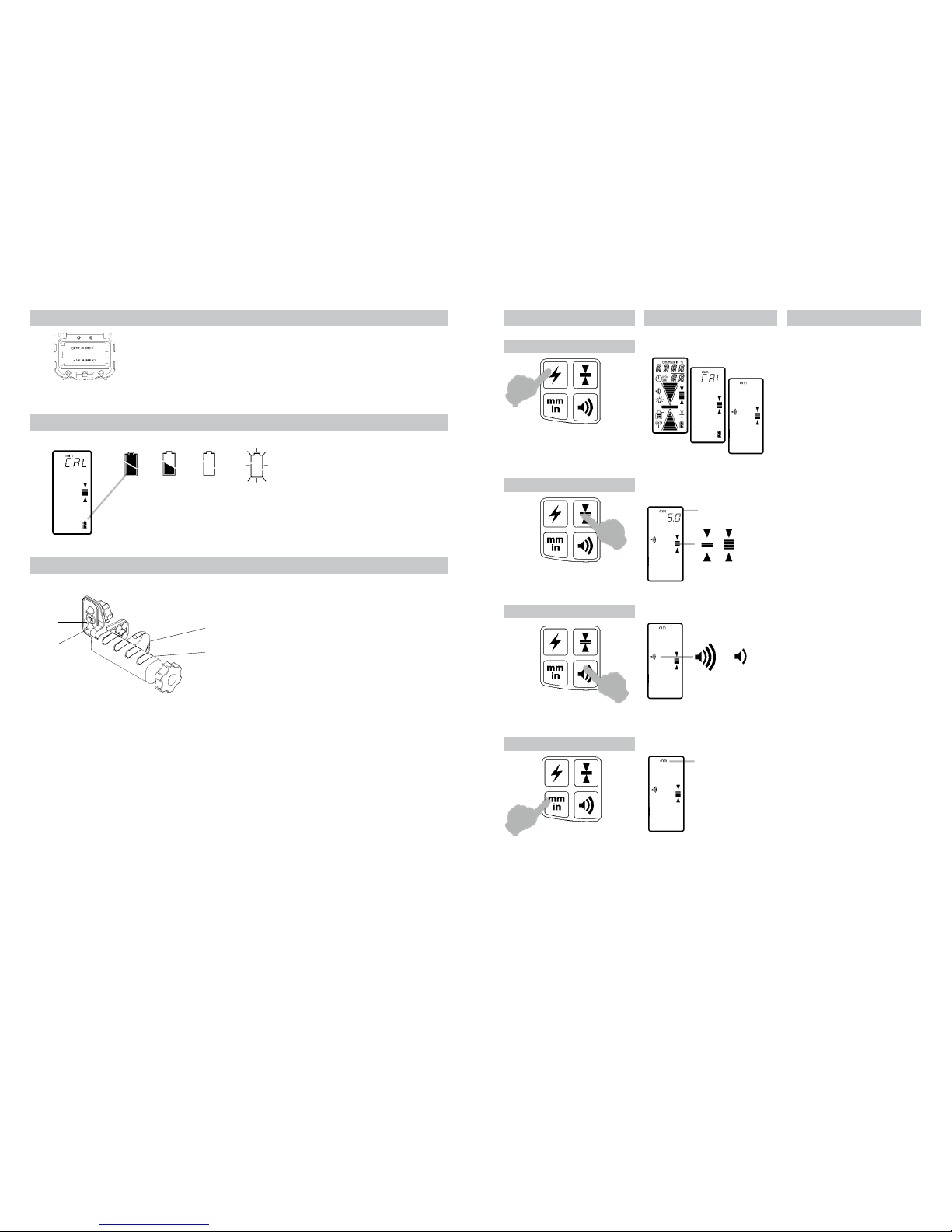

Action Display Remarks

Initialization:

1. Test of LCD and beeper

2. CAL: Calibration (3 sec.)

3. Unit is ready for use.

(Do no t power u p the uni t in a la ser beam

or str obe. If d etected, the unit will disp lay

“E200” and revert to the previous

calibration.)

Accuracy in mm:

1.0 5.0

1

2

3

Turn power ON/OFF

Press to turn p ower ON. Press and hold

for 2 seconds to turn power OFF.

The sel ected unit of measure d etermines

the displayed deadband (accuracy).

The cur rent accura cy is stored in memory

and will be retained when the unit is turned

off or when batteries are replaced.

Press once to display current setting;

push again to scroll through options.

Select accuracy

The cur rent unit o f measure is stored in

memory and will be retained wh en the unit

is turned off or when batteries are replaced.

mm - in - frac - ft

Press once to display current setting,

additional pushes to scroll through options.

Select units of measure

The current beeper

volume is store d in

memory and will be

retained when the unit is

turned off or when batteries are replaced.

Beeper

Loud

Beeper

Low

(No symbol)

Select beeper volume

Press once to change current setting

(A beep confirms the selected volume.)

Beeper

Off

Battery Status

Flashing -

Change

Batteries

Outline -

Approx.

30 Minutes

Remaining

Full -

Batteries

OK

Half -

Initial

Warning

1. Open the battery door using a coin or similar pry device to release the battery door tab.

2. Insert two AA batteries noting the plus (+) and minus (-) diagrams inside the battery housing.

3. Close the battery door. Push down until it “clicks” into the locked position.

Installing the Batteries

Captive Rod Clamp Screw - attaches to the back of detector.1.

Alignment Points (2) - help secure and align rod clamp.2.

Clamping Screw Knob - secures clamp to rods by moving the traveling jaw. 3.

Clockwise tightens; Counterclockwise loosens.

Reference Bar - top of bar is aligned with on-grade. 4.

Traveling Jaw - moving jaw grips tightly to rods.5.

Rod Clamp

4

3

2

1

5

Loading...

Loading...