Page 1

DG711 and DG511

Pipe Laser

User Guide

www.surveyinstrumentsales.com

Page 2

DG711 and DG511

Pipe Laser

User Guide

F

Version 1.6

Part Number 1281-0100

Revision C

September 2007

Page 3

Corporate Office

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

(800) 538-7800 (Toll Free in U.S.A.)

+1-937-245-5600 Phone

+1-937-233-9004 Fax

www.trimble.com

Copyright and Trademarks

© 2002-2007, Trimble Navigation

Limited. All rights reserved.

The Globe & Triangle logo, and

Trimble are trademarks of Trimble

Navigation Limited.

All other trademarks are the property

of their respective owners.

Release Notice

This is the September 2007 release

(Revision C) of the DG711 and DG511

Pipe Laser User Guide, part number

1281-0100. It applies to version 1.6 of

the DG711 and DG511 Pipe Laser

software.

The following limited warranties give

you specific legal rights. You may have

others, which vary from

state/jurisdiction to state/jurisdiction.

Hardware Limited Warranty

Trimble Navigation Limited warrants

that this hardware product (the

“Product”) will perform substantially

in accordance with published

specifications and be substantially free

of defects in material and

workmanship for a period of one (1)

year (DG511 Pipe Laser) and two (2)

years (DG711 Pipe Laser) starting

from the date of delivery. The warranty

set forth in this paragraph shall not

apply to software products.

Software License, Limited

Warranty

This Trimble software product,

whether provided as a stand-alone

computer software product, built into

hardware circuitry as firmware,

embedded in flash memory, or stored

on magnetic or other media, (the

“Software”) is licensed and not sold,

and its use is governed by the terms of

the relevant End User License

Agreement (“EULA”) included with

the Software. In the absence of a

separate EULA included with the

Software providing different limited

warranty terms, exclusions and

limitations, the following terms and

conditions shall apply. Trimble

warrants that this Trimble Software

product will substantially conform to

Trimble’s applicable published

specifications for the Software for a

period of ninety (90) days, starting

from the date of delivery.

Warranty Remedies

Trimble's sole liability and your

exclusive remedy under the warranties

set forth above shall be, at Trimble’s

option, to repair or replace any Product

or Software that fails to conform to

such warranty ("Nonconforming

Product") or refund the purchase price

paid by you for any such

Nonconforming Product, upon your

return of any Nonconforming Product

to Trimble in accordance with

Trimble’s standard return material

authorization procedures.

Warranty Exclusions and

Disclaimer

These warranties shall be applied only

in the event and to the extent that the

Products and Software are properly

and correctly installed, configured,

interfaced, maintained, stored, and

operated in accordance with Trimble's

relevant operator's manual and

specifications, and; (ii) the Products

and Software are not modified or

misused. The preceding warranties

shall not apply to, and Trimble shall

not be responsible for defects or

performance problems resulting from

(i) the combination or utilization of the

Product or Software with hardware or

Page 4

software products, information, data,

systems, interfacing or devices not made,

supplied or specified by Trimble; (ii) the

operation of the Product or Software under

any specification other than, or in addition

to, Trimble's standard specifications for its

products; (iii) the unauthorized

modification or use of the Product or

Software; (iv) damage caused by accident,

lightning or other electrical discharge,

fresh or salt water immersion or spray; or

(v) normal wear and tear on consumable

parts (e.g., batteries). Trimble does not

warrant or guarantee the results obtained

through the use of the Product.

THE WARRANTIES ABOVE STATE

T

RIMBLE'S ENTIRE LIABILITY, AND

YOUR EXCLUSIVE REMEDIES,

RELATING TO PERFORMANCE OF THE

PRODUCTS AND SOFTWARE. EXCEPT AS

OTHERWISE EXPRESSLY PROVIDED

HEREIN, THE PRODUCTS, SOFTWARE,

AND ACCOMPANYING

DOCUMENTATION AND MATERIALS

ARE PROVIDED “AS-IS” AND WITHOUT

EXPRESS OR IMPLIED WARRANTY OF

ANY KIND BY EITHER TRIMBLE

NAVIGATION LIMITED OR ANYONE

WHO HAS BEEN INVOLVED IN ITS

CREATION, PRODUCTION,

INSTALLATION, OR DISTRIBUTION

INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, TITLE, AND

NONINFRINGEMENT. THE STATED

EXPRESS WARRANTIES ARE IN LIEU

OF ALL OBLIGATIONS OR

LIABILITIES ON THE PART OF

TRIMBLE ARISING OUT OF, OR IN

CONNECTION WITH, ANY

PRODUCTS OR SOFTWARE. SOME

STATES AND JURISDICTIONS DO

NOT ALLOW LIMITATIONS ON

DURATION OR THE EXCLUSION OF

AN IMPLIED WARRANTY, SO THE

ABOVE LIMITATION MAY NOT

APPLY TO YOU.

TRIMBLE NAVIGATION LIMITED IS

NOT RESPONSIBLE FOR THE

OPERATION OR FAILURE OF

OPERATION OF GPS SATELLITES OR

THE AVAILABILITY OF GPS

SATELLITE SIGNALS.

Limitation of Liability

TRIMBLE’S ENTIRE LIABILITY UNDER

ANY PROVISION HEREIN SHALL BE

LIMITED TO THE AMOUNT PAID BY YOU

FOR THE PRODUCT OR SOFTWARE

LICENSE. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, IN

NO EVENT SHALL TRIMBLE OR ITS

SUPPLIERS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES

WHATSOEVER UNDER ANY

CIRCUMSTANCE OR LEGAL THEORY

RELATING IN ANY WAY TO THE

PRODUCTS, SOFTWARE AND

ACCOMPANYING DOCUMENTATION

AND MATERIALS, (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS PROFITS, BUSINESS

INTERRUPTION, LOSS OF BUSINESS

INFORMATION, OR ANY OTHER

PECUNIARY LOSS), REGARDLESS

WHETHER TRIMBLE HAS BEEN

ADVISED OF THE POSSIBILITY OF ANY

SUCH LOSS AND REGARDLESS OF THE

COURSE OF DEALING WHICH DEVELOPS

OR HAS DEVELOPED BETWEEN YOU

AND TRIMBLE. BECAUSE SOME STATES

AND JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF

LIABILITY FOR CONSEQUENTIAL OR

INCIDENTAL DAMAGES, THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

NOT WITHSTANDING THE ABOVE, IF

YOU PURCHASED THIS PRODUCT OR

SOFTWARE IN THE EUROPEAN

UNION, THE ABOVE WARRANTY

PROVISIONS MAY NOT APPLY.

PLEASE CONTACT YOUR DEALER

FOR APPLICABLE WARRANTY

INFORMATION.

Page 5

Notices

FCC Decleration of Confirmity

Class A Statement – Notice to Users.

This equipment has been tested and

found to comply with the limits for a

Class A digital device, pursuant to Part

15 of the Federal Communication

Commission (FCC) rules. These limits

are designed to provide reasonable

protection against harmful interference

in a commercial environment. This

equipment generates, uses, and can

radiate radio frequency energy and, if

not installed and used in accordance

with the instructions, may cause

harmful interference to radio or

television communication. However,

there is no guarantee that interference

will not occur in a particular

installation. If this equipment does

cause harmful interference to radio or

television reception, which can be

determined by turning the equipment

off and on, the user is encouraged to try

to correct the interference by one or

more of the following measures:

– Reorient or relocate the receiving

antenna.

– Increase the separation between the

equipment and the receiver.

– Connect the equipment into an

outlet on a circuit different from that

to which the receiver is connected.

– Consult the dealer or an experienced

radio/TV technician for help.

Changes and modifications not

expressly approved by the

manufacturer or registrant of this

equipment can void your authority to

operate this equipment under Federal

Communications Commission rules.

Canadian regulatory notice

The digital apparatus does not exceed

the Class AA limits for radio noise for

digital apparatus set out in the Radio

Interference Regulation of the

Canadian Department of

Communications.

EEC regulatory notice

Application of

Council Directive(s)

Manufacturer’s name Trimble Navigation

Manufacturer’s

address

European

representative

address

Model number(s) DG711 and DG511

Conformance to

directive(s)

Equipment

type/environment

Product standards Product meets the limit B

Notice to Our European Union Customers

For product recycling instructions and more information,

please go to: www.trimble.com/environment/summary.html

Recycling in Europe

To recycle Trimble WEEE,

call: +31 497 53 2430, and

ask for the "WEEE associate," or

mail a request for recycling instructions to:

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

89/336/EEC

Limited

5475 Kellenburger Road

Dayton, Ohio

45424-1099, U.S.A.

Tr i mb l e G m b H

Am Prime Parc 11

65479 Raunheim,

Germany

EC Directive 89/336/EEC

using EN55022 and

EN50082-1

ITE/residential,

commercial and light

industrial

and methods of EN55022

Product meets the levels

and methods of

IEC 801-2, 8 kV air, 4 kV

contact

IEC 801-3, 3 V/m 26 to

1000 MHz 80%, @ 1 kHz

IEC 801-4, ac leads 2 kV

Page 6

Safety Information

For detailed installation and operating instructions, follow the instructions

given in this manual for this laser.

Laser Safety 0.0.1

The maximum radiant power

output of this laser is less than

5 mW. Use only the targets

supplied with this product.

Controls are listed on the radiation

control drawings.

Warning – Use of controls

C

To help you comply with your

government regulations, a laser

safety kit is supplied with every

laser. This kit contains operator

qualification cards and a sign that

should be posted near the laser

whenever it is in use.

or adjustments

performance of

procedures other than

those specified may result

in higher dosage of laser

exposure.

As with any visible laser device,

observe the following safety rules:

• Never look directly into a laser

beam or point the beam into the

eyes of others. Set the laser at a

height that prevents the beam from

shining directly into people’s eyes.

• Do not remove any warning

signs from the laser.

• Make sure that only properly

trained people use this product.

• If service is required, which

results in the removal of the outer

protective cover, factory-trained

personnel must perform this.

Certification 0.0.2

The IEC and the United States

Government Center of Devices for

Radiology Health (CDRH) has

classified this laser as a Class

3R/3A laser product. This laser

complies with IEC/EN

60825-1:2001, CDRH 21 CFR

1040.10 and 1040.11.

Page 7

Queries 0.0.3

Battery:

Address any questions you may

have about laser safety to:

Trimble

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

Attention: Quality Assurance

Group, Laser Safety Officer

Phone (937) 233-8921 ext 824 or

(800) 538-7800

Fax (937) 233-9661

Labels 0.0.4

The labels required for this product

are:

Certification and Identification:

DO NOT OPEN

NON-REPLACEABLE BATTERIES

CHARGING TEMPERATURE

RANGE 0

C TO 25˚C

˚

Aperture:

Warning and

Cautions 0.0.5

Warnings and Notes in the text

indicate a level of danger or

concern. Ensure that you follow the

instructions that accompany these

alerts:

Non-Interlocked Protective

Housing:

DANGER

LASER LIGHT

WHEN OPEN.

AVOID DIRECT

EYE EXPOSURE

Danger Logotype:

Warning – A Warning

C

indicates a hazard or an

unsafe practice that could

result in minor injury or

property damage.

Note – A Note indicates important

information unrelated to safety.

Page 8

Contents

1 Introduction

Claim for Damage in Shipment . . . . . . . . . . . . . . 6

Owner’s Record . . . . . . . . . . . . . . . . . . . . . . 6

2 Features and Functions

Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remote Controls . . . . . . . . . . . . . . . . . . . . . 10

Model RC501, 3-Button Remote Control . . . . 10

Model RC502, 7-Button Remote Control . . . . 11

3 Preparation Before Operation

Powering the Laser. . . . . . . . . . . . . . . . . . . . 13

Ni-MH Batteries . . . . . . . . . . . . . . . . . 13

External Power Cable P21 . . . . . . . . . . . . 16

Optional Features . . . . . . . . . . . . . . . . . . . . 18

4 Getting Started

Optional Features Operating Instructions . . . . . . . . 24

5 Applications and Setups

Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Elevation . . . . . . . . . . . . . . . . . . . . . . . . . 30

Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setup, Step-by-Step . . . . . . . . . . . . . . . . . . . 31

Set Grade . . . . . . . . . . . . . . . . . . . . . 31

Set Elevation for Small In-the-Pipe or

Pre-cast Inverts . . . . . . . . . . . . . . . . 32

Elevation of Flat Bottom Manholes . . . . . . . 34

DG711 and DG511 Pipe Laser User Guide i

Page 9

Contents

1230/1237 Heavy Duty Invert Plate . . . . . . . 34

1239 Universal Fixed Pole . . . . . . . . . . . . 35

Setting Line . . . . . . . . . . . . . . . . . . . . 41

First Point Setup (Using Plumb-bob). . . . . . . 41

1211 Laser Plummet Line Setting . . . . . . . . 43

Second Far-Point Alignment . . . . . . . . . . . 43

Setting Line with the Line Set/Check Feature . . 44

Activating the Cross Axis Roll Option . . . . . . 44

Activating Line Set/Check Raise . . . . . . . . . 45

Activating Line Set/Check Lower . . . . . . . . 46

Large Pipe . . . . . . . . . . . . . . . . . . . . 47

In a Manhole . . . . . . . . . . . . . . . . . . . 48

Open Excavations. . . . . . . . . . . . . . . . . 51

Over the Top . . . . . . . . . . . . . . . . . . . 52

6 DG511/711 Additional Accessories

1211 Laser Plummet . . . . . . . . . . . . . . . . . . . 55

1238/1249 Mounting Plates . . . . . . . . . . . . . . . 56

1244 and 1244-1 T-Bars . . . . . . . . . . . . . . . . . 56

Features . . . . . . . . . . . . . . . . . . . . . . 57

Setup Instructions. . . . . . . . . . . . . . . . . 59

Pipe Targets . . . . . . . . . . . . . . . . . . . . . . . 60

Through the Pipe Applications . . . . . . . . . . 60

Over the Top Applications . . . . . . . . . . . . 61

Model 936 Adjustable Pipe Target . . . . . . . . 62

Model 956 Optically Enhanced Universal Target 63

Model 1212 LineLevel . . . . . . . . . . . . . . 63

1232 Precast Invert Adapter . . . . . . . . . . . 64

Model 1214 Line String Adapter . . . . . . . . . 65

ii DG711 and DG511 Pipe Laser User Guide

Page 10

7Refraction

Model 929 Blower Operating Instructions . . . . . . . . 69

8 DG511/711 Troubleshooting

9 Calibration

Checking the Calibration. . . . . . . . . . . . . . . . . 75

Adjusting the Calibration . . . . . . . . . . . . . . . . 77

Grade Check . . . . . . . . . . . . . . . . . . . . . . . 78

Example. . . . . . . . . . . . . . . . . . . . . . 79

10 Maintenance and Care

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Battery Disposal . . . . . . . . . . . . . . . . . . . . . 82

Contents

System Cleaning . . . . . . . . . . . . . . . . . . . . . 82

11 Laser Specifications

Request for Service and Parts . . . . . . . . . . . . . . 86

DG711 and DG511 Pipe Laser User Guide iii

Page 11

Contents

iv DG711 and DG511 Pipe Laser User Guide

Page 12

Introduction 1

CHAPTER

1

Thank you for choosing from the

Trimble family of precision pipe

lasers. You’ve just made a wise

investment in field-proven products

made by Trimble, the world’s

leading manufacturer of laserbased leveling, alignment, and

grade-control systems.

The pipe laser is an easy-to-use

tool that provides underground

contractors line, elevation, and

grade control for installing storm,

sanitary, or other gravity-flow pipe.

This system can also be used for

tunneling, boring, pipe alignment,

or any other application requiring

The pipe laser projects a highly

visible red beam of laser light in a

direction at a predetermined

(grade) for the alignment of

gravity-flow pipe. The laser light is

intercepted by a target. To align the

pipe, you need to position it so that

the pipe laser’s beam is centered in

the target.

line, elevation, and grade control.

DG711 and DG511 Pipe Laser User Guide 5

Page 13

1 Introduction

Included in this manual is

information about setting up,

using, maintaining, and

troubleshooting the laser system.

Use the manual now to learn basic

skills, and use it later for reference.

For the best performance of your

laser system, follow the

maintenance and care

recommendations in this manual.

Be sure to keep this manual in a

convenient place for easy

referencing.

Your comments and suggestions

are welcome; please call the

Trimble Construction Division

listed below for your local,

authorized Trimble office.

Claim for Damage

in Shipment 1.1

The pipe laser system generally

includes a pipe laser, remote

control, laser target, optional

external power cable, operator’s

manual, laser safety kit, carrying

case, rechargeable batteries, and

battery recharger. The components

vary depending on the system that

you purchase.

You should inspect your pipe laser

system as soon as you receive it. It

has been packaged for safe

delivery. If it is damaged in any

way, immediately file a claim with

the carrier or, if insured separately,

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

Phone: (937) 245-5600

(800) 538-7800

Fax: (937) 233-9004

www.trimble.com

with the insurance company.

Owner’s Record 1.2

Be sure to record the serial number

of each component in the space

provided below. Refer to these

numbers if you need to contact

your Trimble dealer regarding any

of these products.

Serial Number________________

Model # ________________

6 DG711 and DG511 Pipe Laser User Guide

Page 14

Features and

CHAPTER

Functions

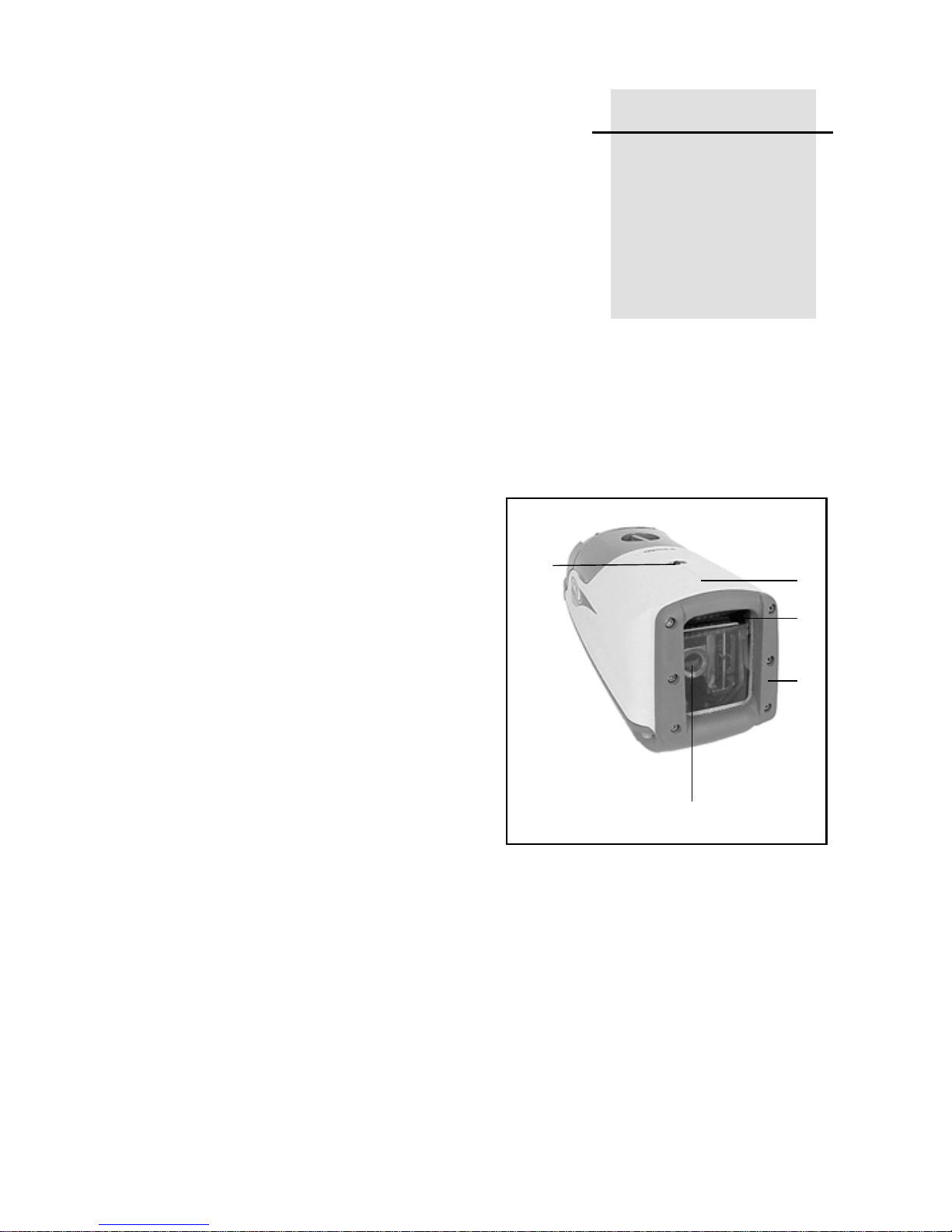

Laser 2.1

1 Beam-Exit Window – provides

a clear window for the laser beam

to exit the pipe laser.

2

2

3

4

2

2 Front and Rear Remote

Receiver Window – receives

signals from models RC501 and

RC502 Remote Control to perform

various keypad functions.

3 Line-Axis Pivot Marker and

LED – identifies the pivot point for

the pipe laser’s line system. The

LED lights for 15 minutes after

turning on the pipe laser or

pressing a control-panel button.

The LED also allows you to align a

transit over the top of the pipe

laser.

20

1

4 Alignment Markers –

correspond with the line system of

the pipe laser. Use them with the

Line Center feature to align the

laser with a distant control point.

DG711 and DG511 Pipe Laser User Guide 7

Page 15

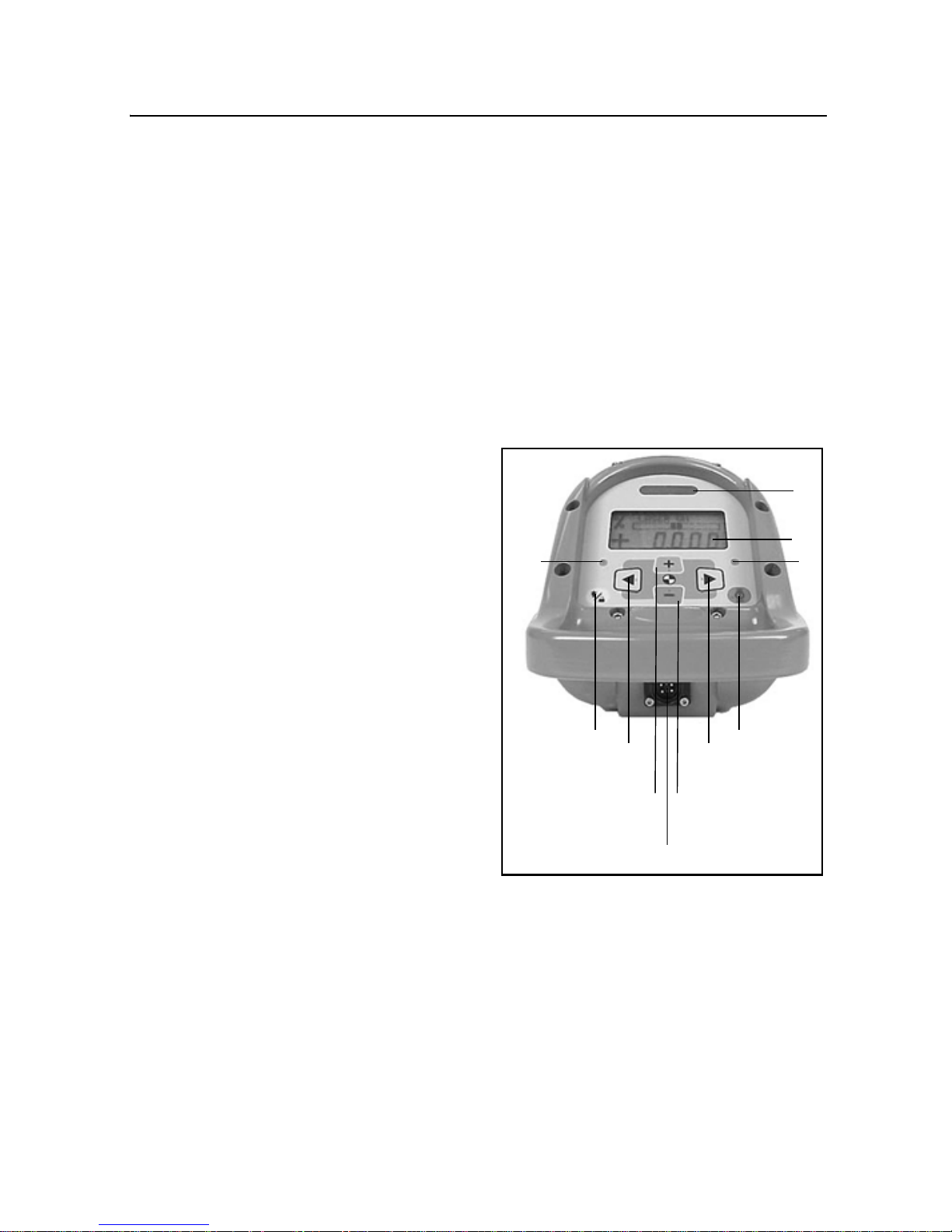

2 Features and Functions

5 Liquid Crystal Display (LCD)

– shows the power, grade, battery,

out-of-level, line position, and

status of the pipe laser.

6 Backlight/Lock Button –

activates the LCD’s backlight and

line-pivot LED. If you

simultaneously press this button

along with one of the line control

or grade buttons, it locks/unlocks

the control panel, so that the grade

and line system are not

unintentionally changed.

7 Power Button – turns the pipe

laser on/off. Press and hold the

button for about 2 seconds to turn

11 Positive Grade LED – lights

green to show that you have

entered a positive grade into the

pipe laser.

12 Increase Button – increases the

1

grade.

To zero the grade and

change the grade in quick change

mode, press and hold this button

simultaneously with the decrease

button.

2

5

10

11

the unit off.

8 Left Line-Control Button –

1

moves the laser beam to the left

.

To center the line, this button has to

be pressed simultaneously with the

right line.

9 Right Line-Control Button –

1

moves the laser beam to the right

.

To center the line, this button has to

be pressed simultaneously with the

left line.

10 Negative Grade LED – lights

red to show that you have entered a

negative grade into the pipe laser.

13 Decrease Button – decreases

the grade

change the grade in quick change

mode, press and hold this button

simultaneously with the increase

button.

1.

Use this button in combination with others for further operations.

6

8 9

12 13

14

1

. To zero the grade and

7

8 DG711 and DG511 Pipe Laser User Guide

Page 16

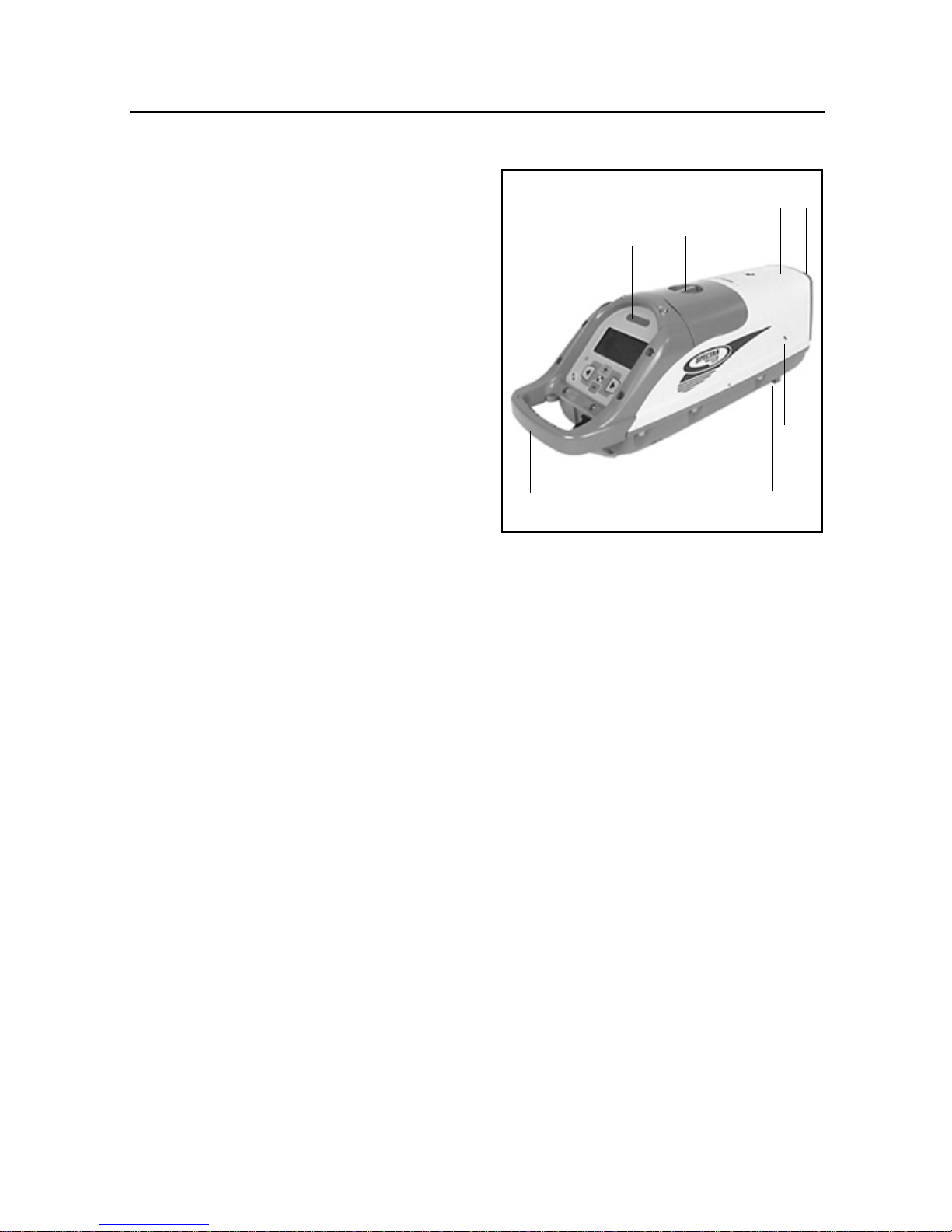

Features and Functions 2

14 External Power Receptacle –

allows the pipe laser to be powered

by an optional external 6–16 VDC

power source.

15 5/8-11 Threaded Mount –

allows the pipe laser to be attached

to various setup accessories.

16 Grade-Axis Pivot Marker –

identifies the pivot point for the

pipe laser’s grade system.

17 Battery Pack – contains non-

replaceable Ni-MH batteries, or a

pack that can hold four replaceable

D-Cell alkaline batteries to power

the pipe laser (depending on

model).

18

20

19

2

17

16

15

18 Handle – allows you to carry

the pipe laser easily and provides a

safety-rope tie-off.

19 Armor Plated Housing – plated

with a special, hardened military

material for unsurpassed

ruggedness and reliability.

20 Protective Rubber Bumper –

protects the front end of the unit by

safeguarding the exit window.

DG711 and DG511 Pipe Laser User Guide 9

Page 17

2 Features and Functions

Remote Controls 2.2

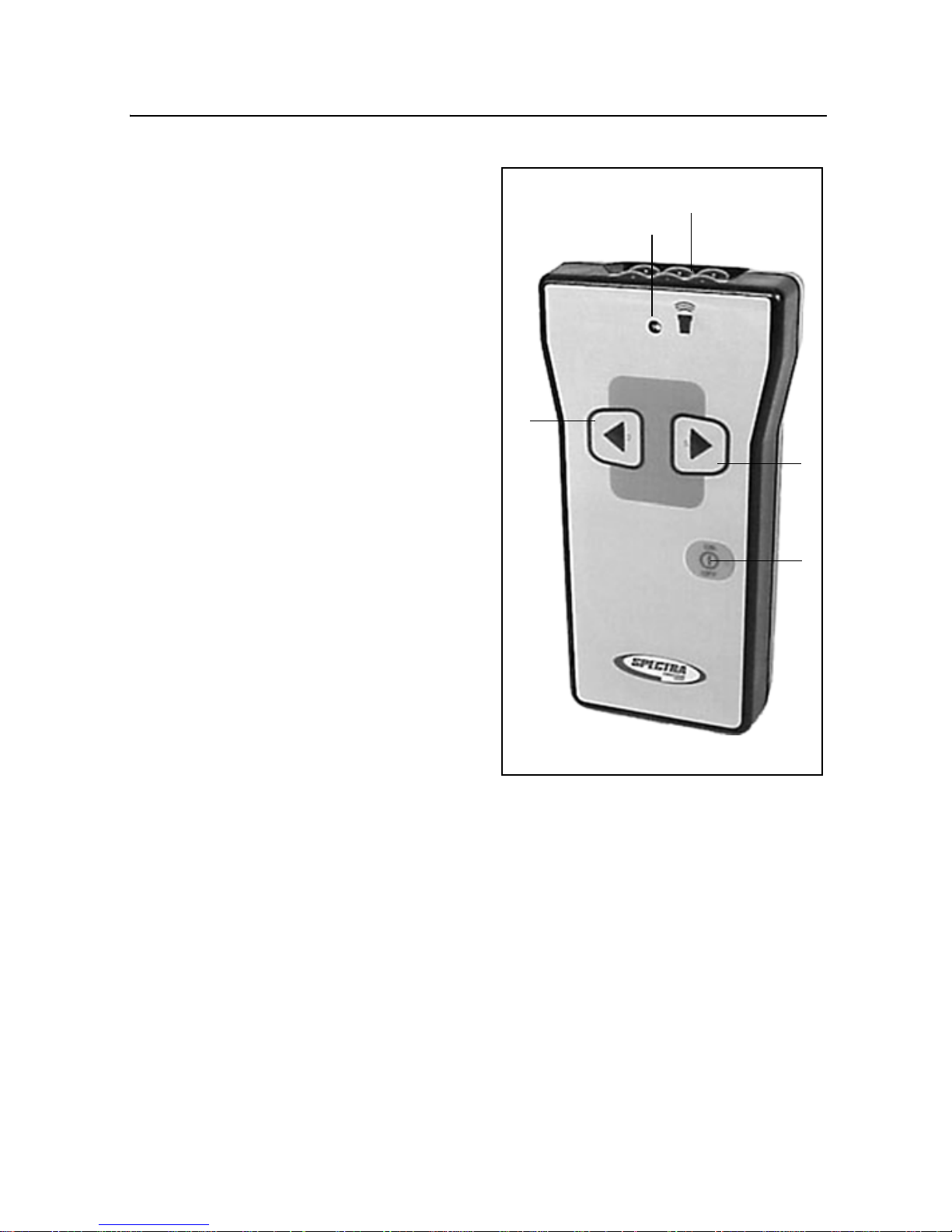

Model RC501, 3-Button

Remote Control 2.2.1

1 Power – turns the pipe laser

on/off. Press and hold the button

for about 2 seconds to turn the unit

off.

2 Left Line-Control Button –

5

4

2

allows you to move the laser beam

to the left.

3 Right Line-Control Button –

allows you to move the laser beam

to the right.

Note – Line Center – Press Left

Line-control and Right

Line-Control simultaneously to

center the line.

4 Status LED - flashes four times

per second when a line button is

pressed or once per second to

indicate that the internal battery is

low.

5 Emission Window – provides

an opening for the infrared signals

3

1

to exit from so that the remote

control and pipe laser can

communicate with each other.

10 DG711 and DG511 Pipe Laser User Guide

Page 18

Features and Functions 2

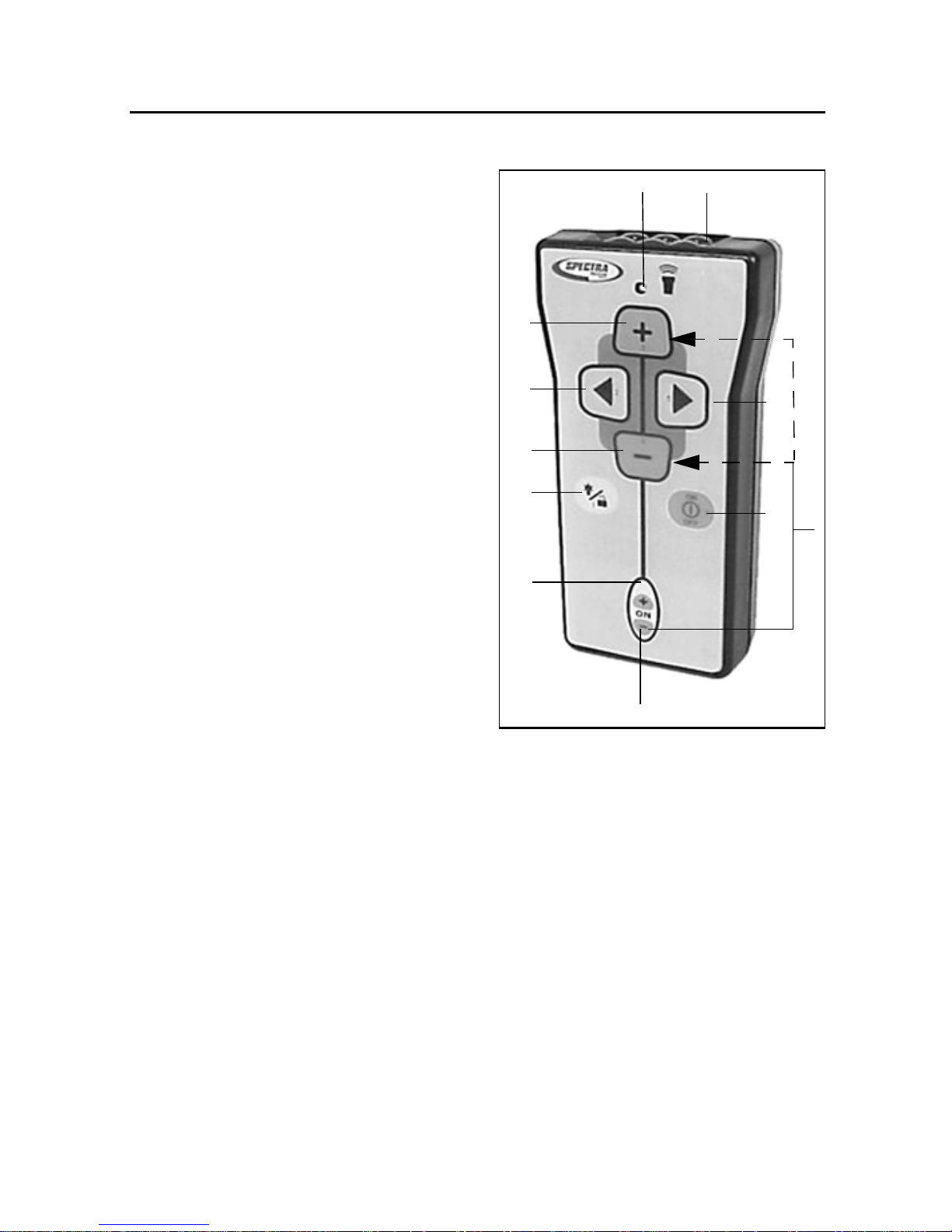

Model RC502, 7-Button

Remote Control

1 Power – turns the pipe laser

on/off. Press and hold the button

for about 2 seconds to turn the unit

off.

2 Grade-Enable LED – flashes

when the grade-enable function is

activated.

3 Grade-Enable Button –

activates/deactivates the increase

and decrease button. Deactivating

the grade-enable function prevents

the pipe laser grade value from

accidentally being changed.

4 Backlight/Lock Button –

2.2.2

8

7

6

5

4

2

10

9

1

11

activates the pipe-laser LCD’s

backlight. If this button is pressed

simultaneously with one of the line

control or grade buttons, it

locks/unlocks the control panel so

that the line and grade system do

not get accidentally changed.

5 Decrease Button – allows you

to decrease the grade.

6 Left Line-Control Button –

allows you to move the laser beam

to the left.

7 Increase Button – allows you to

increase the grade.

3

8 Status LED – flashes four times

per second when a control button is

pressed or once per second to

indicate that the internal battery is

low.

9 Right Line-Control Button –

allows you to move the laser beam

to the right.

10 Emission Window – provides

an opening for the infrared signals

to exit from so that the remote

DG711 and DG511 Pipe Laser User Guide 11

Page 19

2 Features and Functions

control and pipe laser can

communicate with each other.

11 Grade Bump – If the Grade

Enable button and either Grade

button are pressed simultaneously,

the grade changes by one

increment. This function enables

small grade changes for matching

to existing grade.

12 DG711 and DG511 Pipe Laser User Guide

Page 20

Preparation

Before

CHAPTER

Operation

Powering the

Laser 3.1

Ni-MH Batteries 3.1.1

Installing/Removing the

batteries

3

3

clockwise.

1 Turn the battery-pack knob

counterclockwise. Lift the battery

pack from the pipe laser.

2 Plug the battery-pack in place

and turn the battery knob

DG711 and DG511 Pipe Laser User Guide 13

Optional Alkaline Battery

Pack

1 Turn the battery-pack knob

counterclockwise. Lift the battery

pack from the pipe laser.

2 Pull out on the top of the side

clips then push down on them to

release them from the side-clip

catches.

Page 21

3 Preparation Before Operation

3 Pull on the top housing to

separate it from the bottom

housing. Make sure to detach

latches from bottom housing.

4 Install/remove the batteries.

Note – When installing the

batteries, ensure that you take note

of the positive (+) and negative (-)

diagram inside of the housing.

Note – The pipe laser has reverse

polarity protection. If the batteries

are put in wrong, no damage

occurs to the pipe laser but it does

not work. Allow it one minute to

recover after the batteries have

been installed correctly.

5 Put the top housing back on the

7 Put the battery pack in place

and turn the battery-pack knob

clockwise.

bottom housing.

6

6 Position the side clips so that

they hold the top and bottom

housings together securely.

14 DG711 and DG511 Pipe Laser User Guide

Page 22

Preparation Before Operation 3

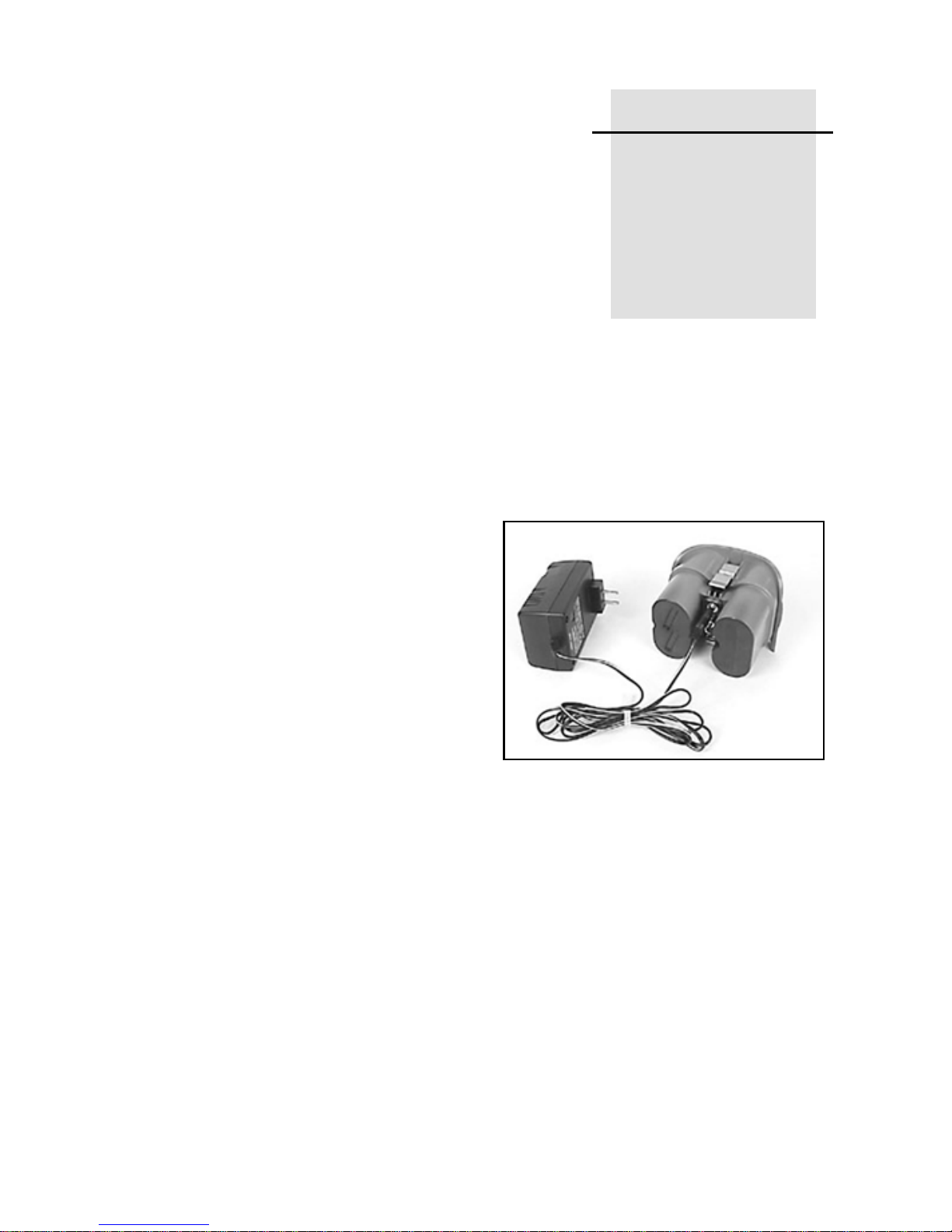

Smart Charger

The charger, to be used ONLY with the Ni-MH battery pack, starts

charging automatically as soon as a battery pack is installed and the charger

is plugged in. The LEDs on the charger indicate the condition shown in

Table 3.1.

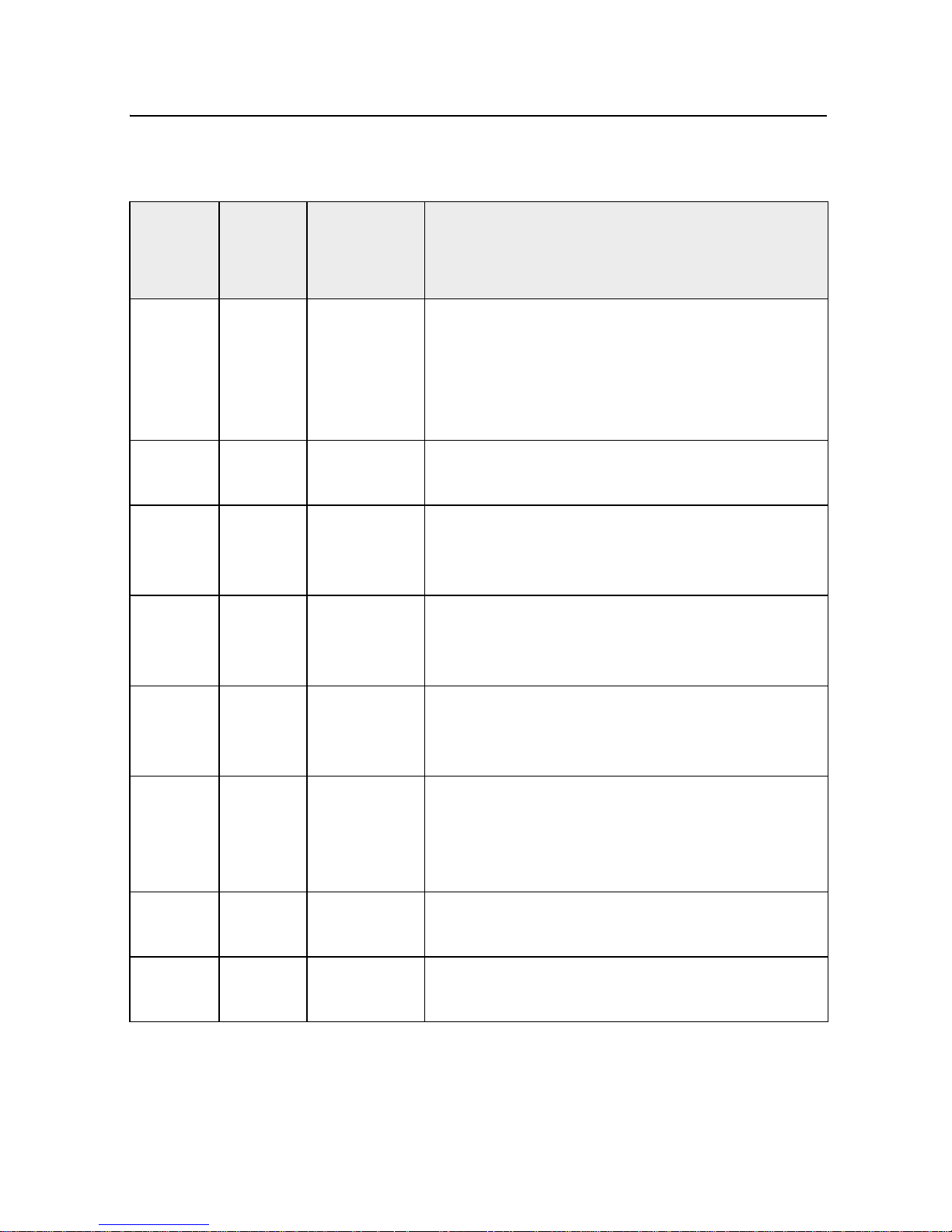

Table 3.1 LED condition

LED condition Description

Red LED On Batteries are charging

Green LED on Batteries are fully charged, and the charger has

switched to trickle charge

Flashing red LED Battery-contact detection (test phase)

Green LED

Red LED

Battery-pack reversed

Battery pack broken, open or unsuitable cells

The batteries are discharging after pressing the

discharge button

Discharge Button: Pressing the

Discharge

Button

button for approximately 2 seconds

the charger automatically

discharges the battery and switches

over to charging. The process of

discharging the battery before

charging should be performed

every three months to help prevent

loss of battery capacity due to

frequent partly discharging.

DG711 and DG511 Pipe Laser User Guide 15

Page 23

3 Preparation Before Operation

Charging Time:

Table 3.2 shows the approximate charging time for 4 to10 batteries with a

7500 mAh capacity.

Table 3.2 Charging time

# of Cells Cell Capacity Approximate Charging Time

4 7500 mAh 10 Hours with smart charger

4 7500 mAh 14 Hours with 12V Cigarette Lighter

Charger Model P22

Recharging the batteries

Note – A sealed Ni-MH battery

pack is offered in most standard

models (P23/P23B).

1 Turn the battery-pack knob

counterclockwise. Lift the battery

pack from the pipe laser.

2 Plug the battery recharger's

single-socket plug into the battery

pack's recharging receptacle.

3 Plug the battery recharger into

an appropriate outlet.

Note – The charger takes 10 hours

to charge the batteries to full

capacity.

Note – To extend battery life, the

charger discharge function should

be performed after every three

months of charging.

Warning – Do not charge

C

the batteries above 45°C

(113°F).

External Power Cable

P21 3.1.2

In case the internal batteries

become discharged and you do not

have spare batteries available, you

can also power the pipe laser using

an optional external power cable.

This can be achieved by using a

DC regulated automotive or

motorcycle battery with the

supplied optional external power

cable on some models. The internal

batteries will not recharge while

you’re using the external power

16 DG711 and DG511 Pipe Laser User Guide

cable.

Page 24

While using the optional external

Preparation Before Operation 3

power cable and 12-V DC battery

to power the pipe laser, you can

remove the internal batteries and

the pipe laser will continue to

operate. The battery pack however

has to be in place in order to cover

the contacts.

Connecting/Disconnecting

the external power cable

Warning – To avo i d

C

damaging the pipe laser

and to prevent the

possibility of creating a

spark at the battery, make

sure the pipe laser is off

before connecting/

disconnecting the external

power cable to/from the

pipe laser.

Warning – An electrical

C

1 Turn the external-power-

receptacle cap counterclockwise

enough to remove it from the

external power receptacle.

Removing the cap exposes the

receptacle.

2 Connect the alligator clips to a

12-V dc automotive or motorcycle

battery noting the correct polarity

(red = positive, black = negative).

3 Insert the plug into the

shock risk may occur if

you connecting/

disconnecting the power

plug or power cable from

the pipe laser with wet

hands. Make sure your

hands are dry when

performing this task.

Warning – Do not

C

connect the pipe laser to a

power generator where

over-voltage can occur. Do

not start the vehicle while

the pipe laser is

connected to the external

battery.

receptacle on the laser.

4 To disconnect the external

power cable from the pipe laser,

remove the plug from the pipe laser

first and then remove the alligator

clips from the battery.

DG711 and DG511 Pipe Laser User Guide 17

Page 25

3 Preparation Before Operation

Optional Features 3.2

The DG511/711 has various

optional features that your

salesman or service personnel may

configure according to your

individual needs.

For more information, contact your

Trimble dealer.

18 DG711 and DG511 Pipe Laser User Guide

Page 26

Getting Started 4

CHAPTER

4

Press the On/Off button to turn on the Laser. Press and hold the button for

about 2 seconds to turn the unit off.

If your laser displays a language other than what you need, consult your

salesman or service center for re-configuration.

The following languages are available:

• English

• Dutch / Netherlands

• French / Francais

• German / Deutsch

• Italian / Italiano

• Japanese

• Portuguese

• Spanish / Espanol

• Swedish /Svensk

• Finnish / Suomi

DG711 and DG511 Pipe Laser User Guide 19

Page 27

4 Getting Started

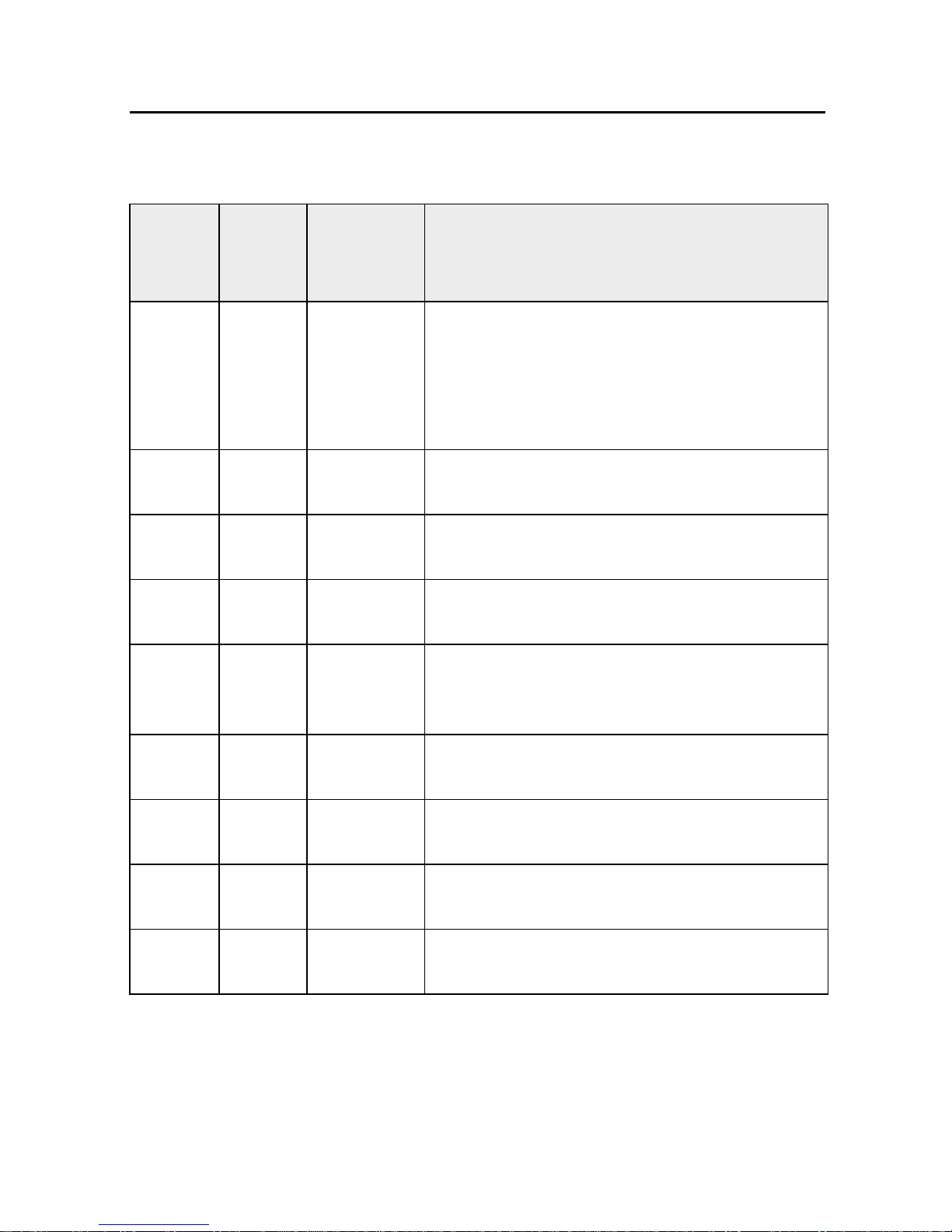

Table 4.1 contains a list of the DG511/711 feature options.

Table 4.1 DG511/711 feature options

DG711 DG511 Main

Features

Options

99

99

Service

Check

Grade

Display

Description

Selects user calibration interval reminder

Floating Displays three (3) significant

digits on grades less than

10%, 2 digits on grades

greater than 10%

Example: 1.234% 12.34%.

Fixed Displays two (2) digit grade.

1.23% or 12.34%

Per Mille Displays grade in millimeters

per meter.

12.34‰

Rise/Run

Slope

99

20 DG711 and DG511 Pipe Laser User Guide

Grade

Entry

Step and

Go

Digit

Select –

Displays grade as Rise / Run =

1.234 rise over 100 ft run

“Step” through grade with

single grade button actuation

or “Go” through grade changes

at an increasing rate.

Enables an individual grade

“Digit” to be “Selected” and

changed until the required

grade is entered.

Page 28

Table 4.1 DG511/711 feature options (Continued)

Getting Started 4

DG711 DG511 Main

Features

Options

99

99

9

99

9

Quick

Grade

Mode

(Grade

Zero)

Grade

Lock

Line

Set/Check

Language Sets user’s local language. For more

Line Alert Flashes the laser beam two times per

Description

Enables instant resetting of the grade to

“Zero” by holding both grade buttons

simultaneously. Continuous holding of

both grade buttons puts the unit in Quick

Grade mode.

Prevents any changes to the grade

system.

Moves the laser vertically to its maximum

limit, which aids in setting line.

information, see page 19.

second if the unit is disturbed after a 5

minute set up period.

99

9

99

99

Line

Center

Line Limit Enables complete movement of the laser

Line Lock Locks out line system controls once the

Low Batt

Warning

Automatically centers Line system when

line is moved to a reference point.

to the left or right line limit.

required line setting is reached.

Flashes laser two times a second

indicating the low battery condition.

DG711 and DG511 Pipe Laser User Guide 21

Page 29

4 Getting Started

Table 4.1 DG511/711 feature options (Continued)

DG711 DG511 Main

Features

Options

99

99

9

99

Steep

Grade

Name Displays owner’s name as entered by local

Power

Saver

(Standby)

Roll Vial

Warn

Description

Disables the self-leveling system but

keeps the laser beam turned on for

applications where you need to manually

point the laser beam at steeper grades

than allowed by the self-leveling system.

dealer.

Turns the laser beam off when not being

used to conserve battery life, but keeps all

other systems operational.

Flashes the laser beam once per second

and the LCD displays that the unit is

beyond its roll leveling range.

9

99

99

99

22 DG711 and DG511 Pipe Laser User Guide

Security When active, the Laser prompts you for a

four-digit password before it will operate.

An incorrect password turns the unit off.

Status When activated, the LCD indicates which

functions have been activated and

displays the status of those activated

functions.

Auto Shut

Down

Calibration

Option

The unit automatically turns off after 15

minutes of an out-of-level condition.

Changes factory default calibration

settings.

Page 30

Table 4.1 DG511/711 feature options (Continued)

Getting Started 4

DG711 DG511 Main

Features

Options

9

9

9

Grade

Bump

Rental

Timer

Description

The RC502 Remote Control can be used

to change current grade setting by one

value where matching of an existing grade

is required.

Shows the number of hours the unit was

rented. It can be set to 00000 hours for

new rental customers.

9 Line Scan Causes the line system to move completly

to the left or right limit without the need for

the operator to conntinuously hold down

the line switches.

DG711 and DG511 Pipe Laser User Guide 23

Page 31

4 Getting Started

Optional Features Operating Instructions4.1

Table 4.2 details operation instructions for the optional features.

Table 4.2 Optional features

Option Operating Instructions

User preferences

Language No instructions required.

Service Check At the preset time (3, 6, 12, or 24 months) a message

will appear on the display informing the user that a unit

inspection is recommended.

System Status Quickly press and release the ON/OFF button to display

the system's status.

Name The entered name will appear for 3 seconds when first

turned on.

Security The selected 4-digit password must be entered when

prompted on power up, or the laser will turn itself off.

24 DG711 and DG511 Pipe Laser User Guide

Page 32

Getting Started 4

Table 4.2 Optional features (Continued)

Option Operating Instructions

Line Preferences

Line Set / Check 1 The manhole should be placed and dirt for the 1st 2

pipe joints excavated. A stake indicating the pipeline

direction should be placed at the end of the

excavation (usually this is done when the job is

initially laid out).

2 Place the unit in the manhole outlet, without the

first pipe joint installed.

3 To adjust the laser before line set, at the laser

press and release the ON/OFF and “+” GRADE

buttons (buttons 3 and 6) in sequence. Adjust the

roll of the unit until the roll indicator is centered.

Press and release the ON/OFF button to resume

normal operation.

4 To start line set using the remote, first press and

release the grade enable key. Then,

simultaneously, press and release the ON/OFF

and "+" GRADE button. Once the laser beam

approaches the line grade stake, use the remote

control to adjust the beam up or down (Buttons 3

and 4) or left and right (buttons 2 and 5) until it is

centered on the line stake.

5 Press and release the ON/OFF button on the

remote (button 6) to take the unit out of the line

set/check mode and resume normal operation at

your desired grade. Setup is complete.

DG711 and DG511 Pipe Laser User Guide 25

Page 33

4 Getting Started

Table 4.2 Optional features (Continued)

Option Operating Instructions

Line Alert The laser beam will blink twice every second, followed

by a 1 second pause, if the laser receives a bump or

excessive vibration after its initial setup, indicating line

may need reset. To reset to normal operation, press any

button on the laser or remote control.

Line Scan To move the line position to the extreme right or left

(such as a severe dogleg right or left manhole setup),

simultaneously press the ON/OFF and LINE RIGHT

(button 5) or LINE LEFT (button 2) buttons.

Line Reference To set a second line point and save it, move the line to

the desired location and press line buttons (#2 and 5)

along with the decrease button (#4) and hold for 1

second. Press buttons #2 and #5 for 1 second to move

the move line to the the saved position.

Grade Preferences

Grade Display

Fixed*

Grade Display

Per Mille*

Grade Display

Slope*

Grade Display*

Floating

Displays grade as a percent, to 2 decimal places

(1.23% or 12.34%)

Displays grade as millimeters rise or fall in 1 meter

(12.34%o)

Displays grade as the straight calculation of rise over

run (0.01234, or a 1.234 rise over a 100 run).

Displays grade as a percent, to 3 decimal places under

10% and 2 decimal places at 10% and over (1.234% or

12.34%).

Note – Only one Grade Display Mode can be selected.

26 DG711 and DG511 Pipe Laser User Guide

Page 34

Table 4.2 Optional features (Continued)

Option Operating Instructions

Getting Started 4

Grade Entry,

Step and Go

Grade Entry,

Digit Select

Press the + GRADE (button 3) or - GRADE (button 4)

and grade will increase or decrease accordingly. The

longer each button is held down the faster grade will

increase or decrease.

1 Press the + GRADE (button 3) or - GRADE

(button 4) to initiate a grade change. All grade digits

will appear and the grade polarity (+ or -) sign will

blink.

2 Use the + GRADE or - GRADE buttons to change

the blinking character to the desired polarity or

digit.

3 Use the LEFT or RIGHT line buttons (button 2 or

button 4) to select which digit to change.

4 When all digits have been changed to the desired

amount, press button 1 (backlight button) to store

the new value and resume normal operation.

(Grade Zero)

Quick Change

Mode

1 Press and hold both grade buttons to zero the

grade.

2 Continuous holding of the grade buttons

increments grade in 1% increments, until 10% is

reached.

3 Once 10% is reached, grade increments in 5%

increments until 40% is reached.

4 Once 40% is reached, grade reverts to -15%.

5 Once -15% is reached, grade reverts to -10%.

6 Once -10% is reached, grade increases in 1%

increments until 0% is reached.

Once 0% is reached, the process repeats.

DG711 and DG511 Pipe Laser User Guide 27

Page 35

4 Getting Started

Table 4.2 Optional features (Continued)

Option Operating Instructions

Steep Grade Press and hold button 1 for five seconds until “STEEP

GRADE” appears.

Use button 3 or 4 to manually point the beam up or

down, and button 2 or 5 (line buttons) to move the beam

left or right to the desired position.

Grade Bump The RC502 Remote Control is used to change current

grade setting by one value where matching of an

existing grade is required.

Power Management

Low Battery

Warning

Power Saver

(Standby)

Flashes the laser 2 times per second to indicate

batteries are getting low.

On the RC502 remote control, press buttons 1 and 6

simultaneously. The laser beam will turn off while all

internal functions remain on, typically doubling the

battery life. To restore the laser beam to instantly begin

to work, press buttons 1 and 6 simultaneously again.

Auto Shut Down The unit automatically turns off after 15 minutes of an

out-of-level condition.

28 DG711 and DG511 Pipe Laser User Guide

Page 36

Applications

CHAPTER

and Setups

This chapter describes three

fundamentals for using the Model

DG511/711 to install gravity flow

pipe; they are Grade, Elevation,

and Line, otherwise known as

G-E-L.

To install gravity flow pipe, the

pipe is set to a percentage of

Grade that has been determined by

Manhole

stake

Elevation

5

5

Manhole

stake

Line

Grade

some engineered plans. The gravity

flow pipe is designed to be set to

some engineered Elevation.

Finally, the gravity flow pipe will

be installed between two designed

points, therefore defining Line.

DG711 and DG511 Pipe Laser User Guide 29

Page 37

5 Applications and Setups

Grade 5.1

Grade establishes the slope of the

pipe and is generally displayed in

percent (%). A rise of 1 m (1ft)

over a run of 100 m (100 ft ) equals

1.00%.

After setting Grade into the unit,

the laser automatically slopes the

The process for setting up the

Model DG511/711 remains the

same. The laser beam shall be

sloped to match the plans. The

Elevation of the pipe or cut to

invert is given from the plans at

which the laser shall be used to

control that elevation, and finally

set the laser on Line to match the

orientation of the pipe run.

After all have been set, installing

pipe is accomplished by inserting a

laser target into new pipe sections

and then aligning the pipe until the

laser targets’ bull’s-eye is centered

on the beam.

beam to match the slope of the pipe

and maintains its slope if disturbed.

Note – Some engineering plans list

the pipe’s grade on a per foot or

per meter basis. Before using your

Model DG511/711, transfer the

engineered slope information into

the Laser according to the Grade

Display Mode feature. Consult

your salesman or service personnel

for Grade Display Mode

configuration.

Elevation 5.2

Depending on the application and

jobsite conditions, you can set the

30 DG711 and DG511 Pipe Laser User Guide

laser to an elevation that matches

the centerline of the pipe, at some

distance above the pipe’s invert, or

set it over the top of the pipe.

Page 38

Applications and Setups 5

When setting the laser, a surveyed

manhole grade hub must be

available to set the laser at the

proper elevation and the pipe will

be installed at the correct elevation.

Line 5.3

Line ensures proper direction of

the pipe run between manholes

according to the engineered plans.

Once Grade, Elevation, and Line

are set, the laser will be projected

at the proper grade, elevation, and

line for the pipe run. After a little

practice, it normally takes about 5

minutes to set up the laser and start

Setup, Step-by-

Step 5.4

Set Grade 5.4.1

1 Press the positive or negative

grade button to set the Laser at the

correct grade as determined by the

engineered plans.

2 Engineering plans sometimes

list the pipe rise/fall on a per foot

or per meter basis. To ensure that

the correct grade display format is

entered into your DG511/711, see

the Grade Display mode

information in Table 4.1 on

page 20.

laying pipe.

Laser beam Pipe invert Always constant distance

DG711 and DG511 Pipe Laser User Guide 31

Page 39

5 Applications and Setups

Set Elevation for Small

In-the-Pipe or Pre-cast

Inverts 5.4.2

1 The laser automatically centers

in the 150 mm (6 inch) diameter

3 Use the following chart to

determine how to set up the laser

so the laser beam is centered in the

following pipe sizes.

pipe and pre-cast inverts without

additional accessories.

2 The laser automatically centers

in 200 mm (8 inch) diameter pipe

with the 1238 mounting plate.

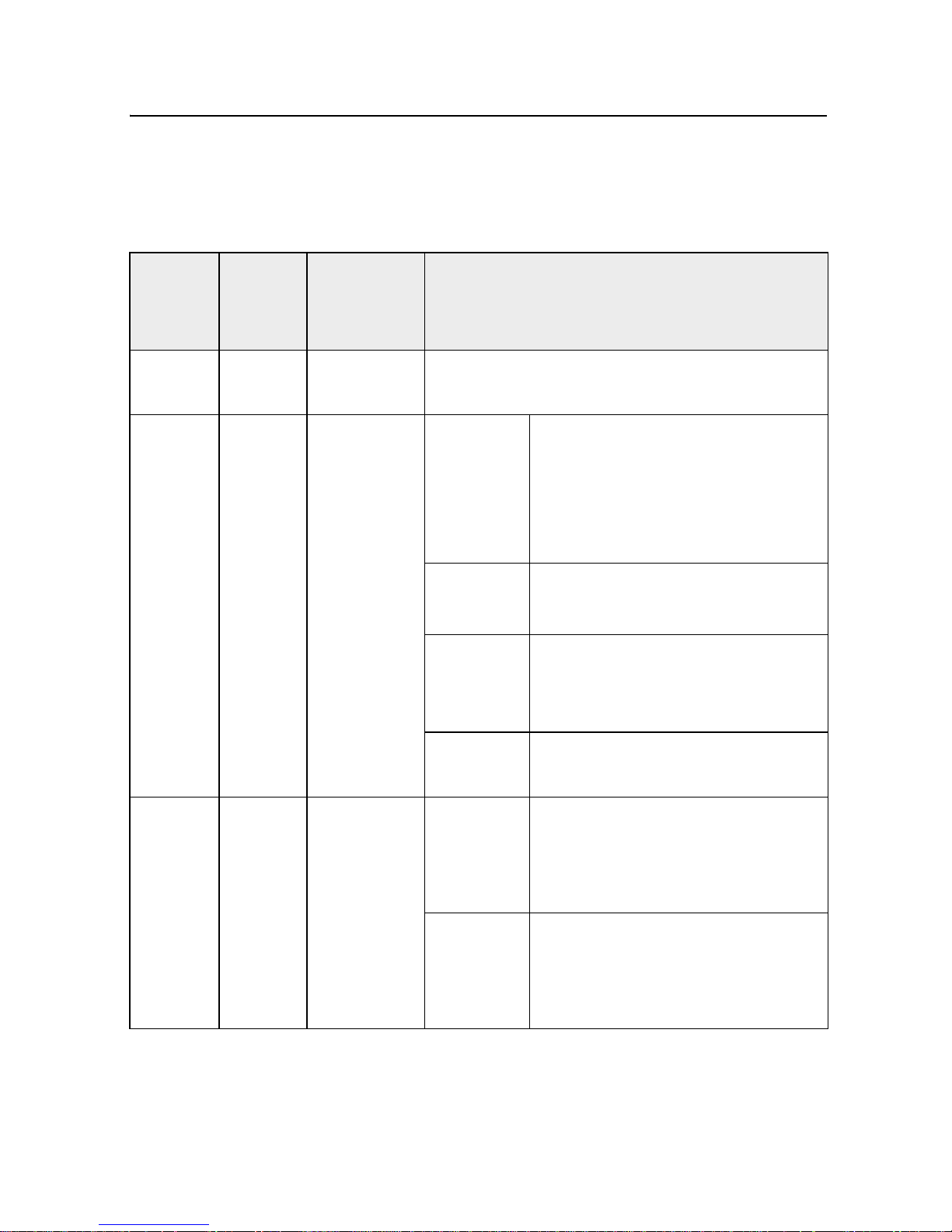

Table 5.1 Mounting Plates Setups

Pipe Diameter Required Mounting Accessories

1228 1230/1237 1238 1249 Setup

150 mm or 6 inch None 1

200 mm or 8 inch Legs Up

225 mm or 9 inch Legs Up

250 mm or 10 inch Legs Up

300 mm or 12 inch Legs Down

400 mm or 15 inch Legs Down

9

9

9

9

9

2

3

4

5

6

32 DG711 and DG511 Pipe Laser User Guide

Page 40

Applications and Setups 5

Illustration

Setup 1228 1230/1237 1238 1249

1

2

3

4

5

6

DG711 and DG511 Pipe Laser User Guide 33

Page 41

5 Applications and Setups

Elevation of Flat Bottom

Manholes 5.4.3

1 When a laser is to be set on a

flat surface where the laser beam is

not centered in the pipe, use model

1230/1237 Heavy Duty Trivet

Plate and 1239 Universal Fixed

Pole.

2 Using this system, the elevation

of the laser beam can be set by

either measuring down from a

grade offset hub outside the trench

or up from the floor of the manhole

to the beam.

3 The 1239 Universal Fixed

Trivet has both cm/mm and

1230/1237 Heavy Duty

Invert Plate 5.4.4

The invert plates model 1230

(English) and 1237 (Metric) are

one piece cast aluminum support

plates that provides automatic self-

centering of the Laser in 250 mm

(10 in.), 300 mm (12 in.) or 400

mm (15 in.) pipe diameters. The

invert plates are used along with

the 1239 Universal Fixed Pole for

setups on the manhole bottom,

outside of the manhole or in pipes

larger than 400 mm (15 in.)

diameter.

tenths/hundredths scales for setting

the beam elevation.

34 DG711 and DG511 Pipe Laser User Guide

Page 42

Applications and Setups 5

1239 Universal Fixed

Pole

The 1239 Universal Fixed Pole

supports a laser at a predetermined

elevation above the invert. Use the

1239 with the 1228 Universal

Adjustable Invert Plate, 1230/1237

Heavy Duty Invert Plates, or 1244

T-Bar Assembly.

Features:

1 Pole Clamp #1 – slides onto the

vertical pole and is secured with

the pole clamp’s handle.

2 Top Pole Scale (TPS) –

determines the distance between

the top of the pole to the center of

5.4.5

1239 universal

fixed pole mounted

on 1230/1237 heavy

duty invert plate

Clamp #1

Clamp #2

the laser beam.

3 Mounting Plate Scale (MPS) –

determines the distance between

the center of the laser beam and the

bottom of the Model Mounting

Plate. This scale is represented

with down arrows next to the scale

numbers.

DG711 and DG511 Pipe Laser User Guide 35

Page 43

5 Applications and Setups

Method 1: Using the Top Pole

Scale (TPS)

Grade rod set on top of the Fixed

Pole.

Note – First decide the laser

beam’s elevation above the invert.

1 Record the “cut-to-invert”

information from the grade hub.

2 Set up an automatic level and

measure its elevation (HI) above

the grade hub.

3 Set a grade rod on top of the

Fixed Pole and record the

measurement with the automatic

level.

4 Subtract the desired laser beam

elevation above the pipe’s invert.

5 Calculate the TPS setting.

Rod reading

on grade

hub

Rod reading on top

of fixed pole

HIn

Laser beam distance

above invert

36 DG711 and DG511 Pipe Laser User Guide

Cut to invert

Page 44

Applications and Setups 5

The laser is now at the proper

working elevation.

Surveyor rod

Grade hub

Table 5.2 Example 1: Setting the Grade Rod on top of the Top Pole

Scale

Step Description Metric Ft / Inch

Step 1 Decide what elevation the laser

0.152 m 0.5 ft

beam shall be used above the

invert.

Step 2 Record the “Cut to Invert”

0.805 m 2.64 ft

information from the grade hub.

Step 3 Measure the elevation (HI) of the

1.128 m 3.70 ft

optical instrument above the

grade hub.

Step 4 Subtract the measured distance

-1.635 m -5.38 ft

from the optical instrument to the

top of 1239 Universal Fixed Pole

Step 5 Subtract the desired elevation of

-0.152 m -0.50 ft

the laser beam above the pipe’s

invert.

DG711 and DG511 Pipe Laser User Guide 37

Page 45

5 Applications and Setups

Table 5.2 Example 1: Setting the Grade Rod on top of the Top Pole

Scale (Continued)

Step Description Metric Ft / Inch

Step 6 Calculated TPS = 0.805 m

1.128 m

-1.635 m

-0.152 m

0.146 m

2.64 ft

3.70 ft

-5.38 ft

-0.50 ft

0.46 ft

Step 7 Adjust the pole clamp until the reading edge is aligned with the

TPS reading (0.146 m or 0.46 ft)

Step 8 The laser beam is now set at your desired working elevation

(152.4 mm / 6 inches / 0.5 ft ) above the invert of the proposed

pipe.

38 DG711 and DG511 Pipe Laser User Guide

Page 46

14.6cm (0.46')

1.128m (3.70')

CI = 0.805m

(2.64')

Applications and Setups 5

HIn = 1.933m (6.34')

1.635m (5.38')

0.152m (0.5')

A

Rod reading set on

top of fixed pole

A

AKS = 1.933m (6.34') - 0.152m (.5') - 1.635m (5.38') = 0.146m (0.46')

Method 2: Setting Grade Rod

on Top of Laser

Note – Using this method, the

offset distance of 70 mm (0.23 ft)

between the top of the Laser

housing and the center of the laser

beam will be used.

1 Decide what elevation of the

laser beam shall be used above the

invert.

2 Record the “cut-to-invert”

information from the grade hub.

Rod reading on top of laser

DG711 and DG511 Pipe Laser User Guide 39

Page 47

5 Applications and Setups

3 Set up an automatic level and

measure the elevation of the

automatic level above grade hub.

4 Add elevation measurement of

instrument to “cut-to-invert” from

grade hub.

5 Subtract the desired working of

elevation of laser beam above

invert.

6 Subtract the beam offset

(70 mm / 0.23 ft).

7 Calculate new rod reading.

8 Set the rod on top of the laser

and adjust the elevation of the laser

until the correct rod reading is

9 The laser beam is now at the

proper working elevation.

Rod reading

on grade hub

Rod reading

HIn

Laser beam distance

above invert

on top of laser

Cut to invert

observed.

Table 5.3 Example 2: Setting Grade Rod on Top of Laser

Step Description Metric Ft / Inch

Step 1 Decide what elevation the laser beam

shall be used above the invert.

Step 2 Record the “cut-to-invert” information

from the grade hub.

Step 3 Measure the elevation (HI) of the

optical instrument above the grade

hub.

Step 4 Add elevation measurement of

instrument to “cut-to-invert” from grade

hub.

0.152 m 0.5 ft

0.805 m 2.64 ft

1.128 m 3.70 ft

1.635 m 5.38 ft

40 DG711 and DG511 Pipe Laser User Guide

Page 48

Applications and Setups 5

Table 5.3 Example 2: Setting Grade Rod on Top of Laser

Step Description Metric Ft / Inch

Step 5 Subtract the desired elevation of laser

beam above the pipe’s invert.

Step 6 Subtract beam offset (70 mm / 0.23 ft). -.070 m -0.23 ft

Step 7 Calculated Rod Reading = 0.805 m

Step 8 Set the rod on top of the Laser and

adjust elevation until the correct rod

reading is observed.

Step 9 The laser beam is now set at your desired working elevation

(152.4 mm / 6 inches / 0.5 ft) above the invert of the proposed

pipe.

-0.152 m -0.50 ft

2.64 ft

1.128 m

-0.152 m

-0.070 m

1.711 m

1.711 m 5.61 ft

3.70 ft

-0.50 ft

-0.23 ft

5.61 ft

Setting Line 5.4.6

The principle for setting line is

always the same. The laser is

positioned over the starting point

of the pipe run then aimed to the

second control point on line. The

further your second point is from

the laser, the more accurate your

line will be.

DG711 and DG511 Pipe Laser User Guide 41

First Point Setup (Using

Plumb-bob) 5.4.7

Whether using the laser in the

invert or attached to the various

mounting plates the goal is to

always set the laser’s line axis

bull’s-eye target over the vertical

centerline of the pipe.

Page 49

5 Applications and Setups

This is accomplished by one of the

following methods:

1 Place the bull’s-eye target

under a plumb bob that has been

transferred from an offset grade

hub.

2 If using a transit or theodolite,

align the bull’s-eye target to the

vertical cross hair of the transit’s

telescope.

3 If the bull’s-eye target cannot

be seen, use the plus sign on the

positive grade button to align the

target to the vertical cross hair of

the transit.

4 In an over-the-top setup, set the

laser on a tripod and plumb bob

them over the first grade stake.

42 DG711 and DG511 Pipe Laser User Guide

Page 50

Applications and Setups 5

1211 Laser Plummet

Line Setting

The laser plummet may be used in

place of the Plumb-bob by

attaching it under the tripod or

manhole mount.

1 Position the laser plummet over

the laser’s bull’s-eye reflective

target into the manhole mount or

tripod replacing the 5/8 x11

attachment thread.

2 Quickly turn the product upside

down to activate the compensator

and turn the power switch "on".

3 If the bull’s-eye target cannot

be seen, align the Laser Plummet

to the plus sign on the positive

5.4.8

Second Far-Point

Alignment

1 Simultaneously press both Left

and Right Line buttons to center

the laser’s ±10° of line travel.

2 Press either Line button to align

the laser beam to the second

control point. If using a wireless

remote control, point the remote

towards the laser and press the

appropriate line button.

Note – Line speed increases the

longer you press the line button. To

slow the line speed, release the line

button then press again.

Next manhole

5.4.9

grade button on the keypad or

anywhere along the center of the

laser.

4 In an over-the-top setup, set the

laser on a tripod and align the

Laser Plummet over the first grade

stake.

DG711 and DG511 Pipe Laser User Guide 43

Page 51

5 Applications and Setups

Setting Line with the

Line Set/Check Featu

re 5.4.10

The Line Set / Check feature,

available with the DG711, can be

used to align the beam to a forward

grade hub by moving the laser to

its maximum leveling limit then

returning it to the original grade

setting. Line Set/Check is

beneficial for setting line if a

manhole mount or transit is not

available.

Note – Before using Line

Set/Check, the Laser must be

accurately positioned for crossaxis roll to ensure that the laser

beam will track plumb. Consult

your salesman or service personnel

to activate the Line Set/Check

feature.

Activating the Cross

Axis Roll Option 5.4.11

1 Quickly press and release the

ON/OFF button to enter the Laser’s

Status mode.

2 While the Battery gauge is

displayed, press and release either

Grade button to display the Laser’s

cross axis roll position.

3 If the Laser is being used in a

pre-cast invert, roll the unit until

the cross-axis roll indicator is

centered and display indicates two

arrows pointing at each other (roll

center) instead of multiple arrows

pointing to the left or to the right.

4 Quickly press and release the

ON/OFF button to return to the

grade display.

5 If the Laser is being used with a

1228 on a flat surface, the Laser

44 DG711 and DG511 Pipe Laser User Guide

must be attached perpendicular

(90°) to the 1228 Universal

Mounting Plate.

6 The footscrews used with the

1230/1237 plate can be used to

help center the roll indicator and

display indicates two arrows

pointing at each other.

Page 52

Activating Line

Applications and Setups 5

Set/Check Raise

1 Simultaneously press the

5.4.12

ON/OFF and the “+” Grade button

to activate Line Set/Check.

Note – For RC502 7-Button

Remote Control users, the ± Grade

enable key must be pressed and the

Red Grade enable LED must be

blinking before the remote will

active Line Set/Check.

2 To stop Line Set/Check as it

approaches the line point, press

either Grade button.

3 To continue raising grade,

simultaneously press the ON/OFF

and the “+” Grade button.

4 If you overshoot and wish to

lower grade, simultaneously press

the ON/OFF and the “-” Grade

button.

5 Once the line position is set,

press and release the ON/OFF

button to return the laser beam to

your original grade setting.

Grade enable key

DG711 and DG511 Pipe Laser User Guide 45

Page 53

5 Applications and Setups

Activating Line

Set/Check Lower 5.4.13

1 Use Line Set/Check Lower

when the laser is set on a tripod for

over the pipe applications.

2 Simultaneously press the

ON/OFF and the “-” Grade button

to activate Grade Lower.

Laying Pipe/Setup

1 First Day Setups – Use the line

buttons to align the laser to the next

manhole.

2 Second day setups – Select a

target that can establish the

centerline or distance above the

Level vial

Undisturbed pipe

set at correct grade

elevation & line

invert in your pipe. Set the target in

the last pipe checked to the correct

grade, elevation, and line.

3 Align the laser to the target

using the line buttons on the laser

or using the wireless remote.

4 Lay Pipe – set the target in each

new section of pipe and adjust the

pipe until the laser intersects the

target’s bull’s-eye.

Next manhole

46 DG711 and DG511 Pipe Laser User Guide

Page 54

Large Pipe 5.4.14

The laser can be set directly on the

flow line using the various

mounting plates or a 1244 T-bar for

increased stability and an

unobstructed flow line.

1 Set Grade Elevation, and Line

into the Laser for large pipe

applications.

2 Set an adjustment pipe target so

that the targets’ bull’s-eye is at the

same distance above the invert as

your laser.

Applications and Setups 5

3 Place the pipe target in the last

section of the pipe that has been

checked to be at the correct grade,

elevation and line.

4 Adjust the pipe target until it’s

level vial reads level.

5 Align the laser to the target’s

bull’s-eye using the line buttons on

the laser or the Wireless Remote.

6 Lay Pipe – Set the target in

each new section of the pipe and

adjust the pipe until the laser

intersects the target’s bull’s-eye

while the target is level.

Level

vial

DG711 and DG511 Pipe Laser User Guide 47

Page 55

5 Applications and Setups

laser is projected down the center

of the pipe.

1 Set the laser support in the

manhole and attach it to the

support.

2 Adjust the laser to the chosen

height above the invert and on the

vertical centerline of the exit hole

for the proposed pipe.

3 Point the laser towards the next

manhole.

4 Hold an engineering rule on the

vertical centerline and adjust the

In a Manhole 5.4.15

The laser can be set up in a

manhole using a transit to

accurately set line. The transit is

laser’s height to the desired height

above the invert.

30.5 cm

Laser beam

(12 in.)

pipe

30.5 cm dia

(12 in.)

15 cm radius

(6 in.)

plumbed over the laser on a mount

that clamps to the manhole. The

48 DG711 and DG511 Pipe Laser User Guide

Page 56

Applications and Setups 5

Line (transit method)

1 Set a manhole mount and

transit on the manhole.

2 Clamp the manhole mount base

to the side of the manhole to

establish a stable transit support.

3 Secure the vertical arm into the

an optical plummet, adjust the

horizontal arm to position the

transit’s optical plummet over

the lasers’ bull’s-eye target.

b Plumb Bob: If your transit

does not have an optical

plummet, suspend a plumb bob

from the transit, and align it

over the lasers’ bull’s-eye

target.

manhole mount base.

4 Assemble the horizontal arm,

horizontal clamp, and vertical

support clamp to the vertical arm

and position over the top of the

laser.

5 Attach your transit to the

5/8 × 11 threaded adapter in the

horizontal arm.

6 Transit Alignment – You may

position your transit over the

laser’s bull’s-eye target in one of

the following methods:

a Use the Laser Plummet and

if your transit is equipped with

7 After rough positioning the

transit over the bull’s-eye target,

use the transit's leveling base to

accurately adjust the transit to the

bull’s-eye target.

8 Once the transit is set over the

lasers’ bull’s-eye target, sight the

transit on the centerline of the next

manhole and lock the scope on

line.

DG711 and DG511 Pipe Laser User Guide 49

Page 57

5 Applications and Setups

Next manhole

B

A

9 Plunge the scope into the trench

and set a stake on line 6–8 m (20–

25 ft) from the first manhole.

10 Use the line buttons to intersect

the stake with the laser beam.

Note – This method assumes that

the manhole was set at the correct

elevation. If there is any question

as to the manhole accuracy, check

the manhole and pipe invert

elevation and transfer an offset to

check the line of pipe entering or

exiting the manhole.

On Top of the Pipe

11 Look through the transit at the

stake and readjust the beam until it

is aligned with the vertical

crosshair of the transit.

Transit

crosshairs

No No

12 Lay pipe – Set the pipe target in

Laser spot

Ye s

each new section of pipe and adjust

the pipe until it intersects the

target’s bull’s-eye.

Vertical centerline

1 Line – Set the laser until it is

over the vertical centerline of the

pipe and pointing toward the next

manhole.

Note – It may be necessary to

support the Laser with extra

gravel, dirt, or sub-base material.

2 Set an adjustable pipe target

(Model 936 or 956) so that the

target’s bull’s-eye is at the same

distance above the pipe as your

laser beam.

50 DG711 and DG511 Pipe Laser User Guide

Page 58

Applications and Setups 5

3 Place the pipe target on top of

the last section of pipe that has

been checked to be at the correct

grade, elevation, and line.

Level vial

Undisturbed pipe

set at correct grade

elevation & line

4 Adjust the pipe target until its

level vial reads the target is level.

5 Align the laser to the targets’

bull’s-eye using the line buttons on

the laser or the Wireless Remote.

6 Lay Pipe – Set the target on top

of each new section of pipe and

adjust the pipe until the laser

intersects the targets’ bull’s-eye

while the target is level.

Open Excavations 5.4.16

Next manhole

B

A

1 Set a transit over the first point

on the proposed pipeline behind

the manhole where the pipe run

starts.

2 Align the transit to the next

manhole and lock the transit on

line.

3 Plunge the transit into the open

excavation where the manhole will

be placed.

4 Set the mounting plate and the

1239 Universal Fixed Pole on

stable sub-base material in the

open excavation and on line.

5 Grade – Enter grade into the

Laser.

6 Attach the laser to the 1239

Universal Fixed Pole.

7 Sight through the transit at the

laser.

DG711 and DG511 Pipe Laser User Guide 51

Page 59

5 Applications and Setups

8 Adjust the laser and the

mounting plate until the bull’s-eye

target or “+” symbol on the

positive grade button is aligned

with the transit’s vertical crosshair.

9 Elevation – Determine the

correct elevation for the invert of

the proposed pipe.

10 Determine if you wish to set the

laser beam on the centerline of the

pipe or at a constant distance above

the flow line.

11 Adjust the laser until you are at

the chosen height above the invert.

12 Set an adjustable pipe target

(Model 936 or 956) so that the

target’s bull’s-eye is at the same

distance above the invert as your

laser beam.

13 Plunge the transit into the open

excavation and set a stake on line

6–8 m (20–25 ft) from the next

manhole.

14 Line – Look through the transit

at the next stake; align the laser to

the vertical crosshair of the transit

using the Line buttons on the laser

or the Wireless Remote

Transit

crosshairs

No NoYe s

15 Lay Pipe – Set the target in

Laser spot

each new section of pipe and adjust

the pipe until the laser intersects

the target’s bull’s-eye while the

target is level.

Over the Top 5.4.17

The laser can be set on a tripod or

mounting plate above the

excavation on the pipe itself. A

laser target is mounted on a pole

and is adjusted to give the correct

distance from the beam to the pipe

invert. For accurate line control, a

level vial can be attached to the

pole to ensure that the target is held

vertically. This is an excellent

setup for shallow cuts for trenches

where water is present.

1 Attach the laser to a tripod

having a 5/8 inch x 11 thread.

52 DG711 and DG511 Pipe Laser User Guide

Page 60

Applications and Setups 5

2 Set the tripod and laser on line

behind the first manhole and

ensure the system is level.

3 Suspend a plumb bob from the

tripod or use a Laser Plummet over

the first point.

4 Transfer the elevation into the

manhole using a level, transit, or

with your laser set to 0.00% grade.

5 Set a stake on the centerline of

the pipe so the top of the stake is at

invert elevation.

6 Use the wireless remote to

position the beam on the rod as you

take your readings.

Rod reading = 6.48

Cut-to-invert = 4.51

Set to = 10.99

Laser beam

7 Add your grade rod reading to

your cut-to-invert reading.

8 Set a target on rod at this

distance. For example:

Instrument method-manhole

Grade rod

reading

Grade hub

C.I.

10.99

Pipe

invert

DG711 and DG511 Pipe Laser User Guide 53

Page 61

5 Applications and Setups

54 DG711 and DG511 Pipe Laser User Guide

Page 62

DG511/711

Additional

CHAPTER

Accessories

1211 Laser

Plummet 6.1

Replaces the 5/8-11 bell housing in

manhole mounts or tripods, and

provides a self plumbed laser dot

that can be quickly positioned over

6

6

Note – You must turn the 1211

upside down then right-side up just

prior to each use. For setup and

operating instructions, see the

1211 operator’s manual.

the plumb point. This greatly

reduces first day setup time.

The 1211 has a self-plumbing

range of 10 degrees, a bright 635nm beam, safety lanyard, shock

bumpers, and operates off two

AAA batteries (included). The

1211 includes operating

instructions and a carrying pouch

with belt loop.

DG711 and DG511 Pipe Laser User Guide 55

Page 63

6 DG511/711 Additional Accessories

1238/1249 Mounting Plates 6.2

Allows the laser to automatically center in an 200 mm (8 inch) diameter

pipe using 1238 mounting plate and 225 mm (9 inch) diameter pipe using a

1249 mounting plate.

1244 and 1244-1

Use the 1244 with a 1239

Universal Fixed Pole for precast

T-Bars 6.3

invert setups for unobstructed

The 1244 T-Bar is a mounting

support system for using a laser in

large diameter pipe, manholes, or

open excavated trenches where

high stability and a variable

elevation adjustment is required.

Pipe Diameter Application Recommended T-Bar

1.07 to 2.03 m (42 – 80 inch) 1244

0.83 to 1.58 m (33 – 66 inch) 1244-1

flowlines.

Also use the 1244 in large diameter

pipe to place the laser beam

parallel to the pipe’s centerline.

56 DG711 and DG511 Pipe Laser User Guide

Page 64

DG511/711 Additional Accessories 6

1

2

3

5

4

Note – Both models can be shortened for use in smaller diameter pipes and

manholes. The speed release handle provides 13 cm (5 inches) of fine

adjustment range.

Features 6.3.1

1 Mounting Plate – supports the

laser or the 1239 Universal Fixed

Pole.

2 Locking Pin – holds the

extension bar in place.

3 Extension Bar – allows for 25

mm (one-inch) coarse adjustments

in the T-Bar’s overall length.

4 Speed Release Handle –

tightens the T-Bar into place and

allows for quick release.

5 Horizontal Lock Knob – allows

the mounting plate to slide freely

along the extension bar and

positions the laser on line.

Reverse the Teflon reading edge

assembly when used with the

T-Bar by unthreading the three

screws fastening the assembly to

the pole clamp. Reverse the unit

wing nut capturing screw on the

pole clamp as necessary based on

whether the pole is mounted above

or below the T-Bar.

DG711 and DG511 Pipe Laser User Guide 57

Page 65

6 DG511/711 Additional Accessories

Fixed pole

Locking pin

Screws

Te fl on

reading

edge

Horizontal

lock

Adjustable

pole lock

58 DG711 and DG511 Pipe Laser User Guide

Page 66

Setup Instructions 6.3.2

1 Attach the vertical pole to the

T-B ar.

2 Adjust the length of the T-Bar

using the locking pin to fit your