Page 1

Copernicus™ GPS Receiver

Reference Manual

Part Number 58052-00

Revision A

July 2006

Page 2

Corporate Office

Hardware Limited Warranty

Trimble Navigation Limited

935 Stewart Drive

Sunnyvale, CA 94085

U.S.A.

Phone: +1-408-481-8000, 1-800-827-8000

www.trimble.com

Support

+1-800-767-4822 (USA and Canada)

+1-913-338-8225 (International)

Copyright and Trademarks

© 2006 Trimble Navigation Limited. All rights reserved. No

part of this manual may be copied, reproduced, translated, or

reduced to any electronic medium or machine-readable form

for any use other than with the Copernicus™ GPS Receiver.

The Globe & Triangle logo, Trimble, Colossus, FirstGPS, and

Lassen, are trademarks of Trimble Navigation Limited.

The Sextant logo with Trimble is a trademark of Trimble

Navigation Limited, registered in the United States Patent and

Trademark Off ice .

All other trademarks are the property of their respective

owners.

Release Notice

This is the May 2006 release (Revision A) of the Copernicus™

GPS Receiver System Designer Reference Manual, part

number 58052-00.

Trimble warrants that this Trimble hardware product (the

“Product”) shall be free from defects in materials and

workmanship and will substantially conform to Trimble’s

applicable published specifications for the Product for a period

of one (1) year, starting from the date of delivery. The warranty

set forth in this paragraph shall not apply to software/firmware

products.

Software and Firmware License, Limited Warranty

This Trimble software and/or firmware product (the

“Software”) is licensed and not sold. Its use is governed by the

provisions of the applicable End User License Agreement

(“EULA”), if any, included with the Software. In the absence

of a separate EULA included with the Software providing

different limited warranty terms, exclusions, and limitations,

the following terms and conditions shall apply. Trimble

warrants that this Trimble Software product will substantially

conform to Trimble’s applicable published specifications for

the Software for a period of ninety (90) days, starting from the

date of delivery.

Warranty Remedies

Trimble's sole liability and your exclusive remedy under the

warranties set forth above shall be, at Trimble’s option, to

repair or replace any Product or Software that fails to conform

to such warranty (“Nonconforming Product”), or refund the

purchase price paid by you for any such Nonconforming

Product, upon your return of any Nonconforming Product to

Trimble in accordance with Trimble’s standard return material

authorization procedures.

Warranty Exclusions and Disclaimer

The following limited warranties give you specific legal rights.

You may have others, which vary from state/jurisdiction to

state/jurisdiction.

Waste Electrical and Electronic Equipment (WEEE)

Notice

This Trimble product is furnished on an OEM basis. By

incorporating this Trimble product with your finished goods

product(s) you shall be deemed the “producer” of all such

products under any laws, regulations or other statutory scheme

providing for the marking, collection, recycling and/or

disposal of electrical and electronic equipment (collectively,

“WEEE Regulations”) in any jurisdiction whatsoever, (such as

for example national laws implementing EC Directive 2002/96

on waste electrical and electronic equipment, as amended), and

shall be solely responsible for complying with all such

applicable WEEE Regulations.

Restriction on Hazardous Substances

As of July 1, 2006, the Product is compliant in all material

respects with DIRECTIVE 2002/95/EC OF THE EUROPEAN

P ARLIAMENT AND OF THE C OUNCIL of 27 January 2003

on the restriction of the use of certain hazardous substances in

electrical and electronic equipment (RoHS Directive) and

Amendment 2005/618/EC filed under C(2005) 3143, with

exemptions for lead in solder pursuant to Paragraph 7 of the

Annex to the RoHS Directive applied. The foregoing is limited

to Product placed on the market in the Member States of the

European Union on or after 1 July 2006. Trimble has relied on

representations made by its suppliers in certifying this Product

as RoHS compliant.

These warranties shall be applied only in the event and to the

extent that: (i) the Products and Software are properly and

correctly installed, configured, interfaced, maintained, stored,

and operated in accordance with Trimble’s relevant operator's

manual and specifications, and; (ii) the Products and Software

are not modified or misused.

The preceding warranties shall not apply to, and Trimble shall

not be responsible for defects or performance problems

resulting from (i) the combination or utilization of the Product

or Software with products, information, data, systems or

devices not made, supplied or specified by Trimble; (ii) the

operation of the Product or Software under any specification

other than, or in addition to, Trimble's standard specifications

for its products; (iii) the unauthorized modification or use of

the Product or Software; (iv) damage caused by accident,

lightning or other electrical discharge, fresh or salt water

immersion or spray; or (v) normal wear and tear on

consumable parts (e.g., batteries).

Page 3

THE WARRANTIES ABOVE STATE TRIMBLE'S ENTIRE

LIABILITY, AND YOUR EXCLUSIVE REMEDIES, RELATING

TO PERFORMANCE OF THE PRODUCTS AND SOFTWARE.

EXCEPT AS OTHERWISE EXPRESSLY PROVIDED HEREIN,

THE PRODUCTS, SOFTWARE, AND ACCOMPANYING

DOCUMENTATION AND MATERIALS ARE PROVIDED “AS-

IS” AND WITHOUT EXPRESS OR IMPLIED WARRANTY OF

ANY KIND BY EITHER TRIMBLE NAVIGATION LIMITED OR

ANYONE WHO HAS BEEN INVOLVED IN ITS CREATION,

PRODUCTION, INSTALLATION, OR DISTRIBUTION,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, TITLE, AND NONINFRINGEMENT.

THE STATED EXPRESS WARRANTIES ARE IN LIEU OF ALL

OBLIGATIONS OR LIABILITIES ON THE PART OF TRIMBLE

ARISING OUT OF, OR IN CONNECTION WITH, ANY

PRODUCTS OR SOFTWARE. SOME STATES AND

JURISDICTIONS DO NOT ALLOW LIMITATIONS ON

DURATION OR THE EXCLUSION OF AN IMPLIED

WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY

TO YOU.

TRIMBLE NAVIGATION LIMITED IS NOT RESPONSIBLE FOR

THE OPERATION OR FAILURE OF OPERATION OF GPS

SATELLITES OR THE AVAILABILITY OF GPS SATELLITE

SIGNALS.

Limitation of Liability

TRIMBLE’S ENTIRE LIABILITY UNDER ANY PROVISION

HEREIN SHALL BE LIMITED TO THE GREATER OF THE

AMOUNT PAID BY YOU FOR THE PRODUCT OR SOFTWARE

LICENSE OR U.S.$25.00. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL

TRIMBLE OR ITS SUPPLIERS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES WHATSOEVER UNDER ANY CIRCUMSTANCE OR

LEGAL THEORY RELATING IN ANY WAY TO THE

PRODUCTS, SOFTWARE, AND ACCOMPANYING

DOCUMENTATION AND MATERIALS, (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS

INFORMATION, OR ANY OTHER PECUNIARY LOSS),

REGARDLESS OF WHETHER TRIMBLE HAS BEEN ADVISED

OF THE POSSIBILITY OF ANY SUCH LOSS AND

REGARDLESS OF THE COURSE OF DEALING WHICH

DEVELOPS OR HAS DEVELOPED BETWEEN YOU AND

TRIMBLE. BECAUSE SOME STATES AND JURISDICTIONS

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL

DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO

YOU.

Page 4

Page 5

Table of Contents

Table of Contents

1 GENERAL DESCRIPTION

Receiver Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Interface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Physical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 INTERFACE CHARACTERISTICS

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Detailed Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Serial Ports Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pulse-Per-Second (PPS) in Copernicus Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 ELECTRICAL SPECIFICATIONS

Absolute Minimum and Maximum Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Normal Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Consumption over Temperature and Voltage . . . . . . . . . . . . . . . . . . . . . . . . 22

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 OPERATING MODES

Copernicus Receiver Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standby Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Monitor Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Changing the RUN/STANDBY modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the XSTANDBY Pin to Switch Modes . . . . . . . . . . . . . . . . . . . . . . . . 25

Using Serial Ports to Switch Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Saving the Almanac into the Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Graceful Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Almanac in Flash Updating Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

18-Hour RTC Roll Over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Copernicus GPS Receiver v

Page 6

Table of Contents

5 COPERNICUS GPS APPLICATION CIRCUITS

Passive antenna—Minimum Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Active Antenna—Full Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Active Antenna—No Antenna Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 RF LAYOUT CONSIDERATIONS

General Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Design considerations for RF Track Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . 37

PCB Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

MIcrostrip Transmission Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Stripline Transmission Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 MECHANICAL SPECIFICATIONS

Mechanical Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Guidelines for soldering the Copernicus module to a PCB. . . . . . . . . . . . . . . . . . . . . 43

Solder mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pad Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Paste Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 PACKAGING

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Tapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9 SHIPPING AND HANDLING

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Moisture Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Floor Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Moisture Precondition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Recommended Baking Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Soldering Paste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Solder Reflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Recommended Soldering Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Optical Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Repeated Reflow Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Wave Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Hand Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Conformal Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Grounding the Metal Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

vi Copernicus GPS Receiver

Page 7

Table of Contents

10 COPERNICUS REFERENCE BOARD

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Copernicus Reference Board Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Copernicus Reference Board Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Copernicus Reference Board I/O and power Connector . . . . . . . . . . . . . . . . . . . . . . 65

Copernicus Reference Board Power Requirement . . . . . . . . . . . . . . . . . . . . . . . . . 65

Copernicus Reference Board Jumper Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Reference Board Component Locations Drawing . . . . . . . . . . . . . . . . . . . . . . . . . 67

11 COPERNICUS STARTER KIT

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Interface Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Serial Port Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Loading the FTDI Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Starter Kit Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Removing the Reference Board from the Interface Unit . . . . . . . . . . . . . . . . . . . . . . 75

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Using a Passive Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pulse-Per-Second (PPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12 FIRMWARE UPGRADE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Software Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Boot Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Firmware Binary File Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Firmware Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Pseudo-code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Pseudo-Code Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Error Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Monitor Interface Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Protocol Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Data Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Monitor Mode Packet Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ENQ, ACK, NAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Packet ID – 0x96 (Boot ROM Version Report) . . . . . . . . . . . . . . . . . . . . . . . 90

Packet ID – 0x8F (Erase Firmware Section). . . . . . . . . . . . . . . . . . . . . . . . . 91

FlashLoader Tool Reference Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

File and Folder Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Source Code Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Compiling and Generating the Executable. . . . . . . . . . . . . . . . . . . . . . . . . . 95

Copernicus GPS Receiver vii

Page 8

Table of Contents

A TRIMBLE STANDARD INTERFACE PROTOCOL (TSIP)

Interface Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Run Mode Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Automatic Output Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Customizing Receiver Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Automatic Position and Velocity Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Initialization Packets to Speed Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Packets Output at Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Timing Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Satellite Data Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Backwards Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Guidelines for Use with Copernicus GPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Recommended TSIP Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 06

Command Packets Sent to the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Report Packets Sent by the Receiver to the User . . . . . . . . . . . . . . . . . . . . . . . . . .108

Key Setup Parameters or Packet BB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Dynamics Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Elevation Mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Signal Level Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Packet Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Packet Descriptions Used in Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Command Packet 0x1E - Clear Battery Backup, then Reset. . . . . . . . . . . . . . . . .113

Command Packet 0x1F - Request Software Versions . . . . . . . . . . . . . . . . . . . .113

Command Packet 0x21 - Request Current Time. . . . . . . . . . . . . . . . . . . . . . .113

Command Packet 0x23 - Initial Position (XYZ ECEF) . . . . . . . . . . . . . . . . . . .113

Command Packet 0x24 - Request GPS Receiver Position Fix Mode . . . . . . . . . . . .114

Command Packet 0x25 - Initiate Soft Reset & Self Test . . . . . . . . . . . . . . . . . .114

Command Packet 0x26 - Request Health . . . . . . . . . . . . . . . . . . . . . . . . . .114

Command Packet 0x27 - Request Signal Levels. . . . . . . . . . . . . . . . . . . . . . .114

Command Packet 0x2B - Initial Position (Latitude, Longitude, Altitude). . . . . . . . . .114

Command Packet 0x2D - Request Oscillator Offset. . . . . . . . . . . . . . . . . . . . .115

Command Packet 0x2E - Set GPS Time. . . . . . . . . . . . . . . . . . . . . . . . . . .115

Command Packet 0x31 - Accurate Initial Position (XYZ ECEF). . . . . . . . . . . . . .115

Command Packet 0x32 - Accurate Initial Position, (Latitude, Longitude, Altitude) . . . .116

Command Packet 0x35 - Set Request I/O Options . . . . . . . . . . . . . . . . . . . . .117

Command Packet 0x37 - Request Status and Values of Last Position and Velocity. . . . .119

Command Packet 0x38 - Request/Load Satellite System Data . . . . . . . . . . . . . . .119

Command Packet 0x3A - Request Last Raw Measurement . . . . . . . . . . . . . . . . .120

Command Packet 0x3C - Request Current Satellite Tracking Status . . . . . . . . . . . .120

Report Packet 0x41 - GPS Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Report Packet 0x42 - Single-Precision Position Fix, XYZ ECEF . . . . . . . . . . . . . .121

Report Packet 0x43 - Velocity Fix, XYZ ECEF . . . . . . . . . . . . . . . . . . . . . . .122

viii Copernicus GPS Receiver

Page 9

Table of Contents

Report Packet 0x45 - Software Version Information . . . . . . . . . . . . . . . . . . . .122

Report Packet 0x46 - Health of Receiver . . . . . . . . . . . . . . . . . . . . . . . . . .123

Report Packet 0x47 - Signal Levels for all Satellites . . . . . . . . . . . . . . . . . . . .123

Report Packet 0x4A - Single Precision LLA Position Fix. . . . . . . . . . . . . . . . . .124

Report Packet 0x4B - Machine/Code ID and Additional Status. . . . . . . . . . . . . . .125

Report Packet 0x4D - Oscillator Offset . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Report Packet 0x4E - Response to Set GPS Time . . . . . . . . . . . . . . . . . . . . . .126

Report Packet 0x55 - I/O Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Report Packet 0x56 - Velocity Fix, East-North-Up (ENU) . . . . . . . . . . . . . . . . .127

Report Packet 0x57 - Information About Last Computed Fix. . . . . . . . . . . . . . . .128

Report Packet 0x58 - Satellite System Data/Acknowledge from Receiver . . . . . . . . .128

Report Packet 0x5A - Raw Measurement Data . . . . . . . . . . . . . . . . . . . . . . .131

Report Packet 0x5C - Satellite Tracking Status . . . . . . . . . . . . . . . . . . . . . . .133

Report Packet 0x6D - All-In-View Satellite Selection. . . . . . . . . . . . . . . . . . . .134

Command Packet 0x7A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Report Packet 0x7B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Command Packet 0x7E - TAIP Message Output . . . . . . . . . . . . . . . . . . . . . .136

Report Packet 0x83 - Double-Precision XYZ Position Fix and Bias Information. . . . . .138

Report Packet 0x84 - Double-Precision LLA Position Fix and Bias Information. . . . . .139

Packets 0x8E and 0x8F - Superpacket . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Command Packet 0xBB - Navigation Configuration . . . . . . . . . . . . . . . . . . . .140

Command Packet 0xBC - Protocol Configuration. . . . . . . . . . . . . . . . . . . . . .141

Command Packet 0xC0 - Graceful Shutdown and Go To Standby Mode . . . . . . . . . .143

TSIP Superpackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Command Packet 8E-4A - Set/Request Copernicus GPS Cable Delay

and PPS Polarity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Command Packet 8E-4A - Set/Request Copernicus GPS Cable Delay

and PPS Polarity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Command Packet 8E-15 - Set/Request Datum. . . . . . . . . . . . . . . . . . . . . . . .146

Command Packet 0x8E-17 - Request Last Position or Auto-Report Position in UTM Single

Precision Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Command Packet 8E-18 - Request Last Position or Auto Report Position in UTM Double

Precision Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Report Packet 0x8F-15 - Current Datum Values. . . . . . . . . . . . . . . . . . . . . . .148

Report Packet 8F-17 - UTM Single Precision Output . . . . . . . . . . . . . . . . . . . .149

Report Packet 8F-18 - UTM Double Precision Output . . . . . . . . . . . . . . . . . . .150

Command Packet 0x8E-20 - Request Last Fix with Extra Information . . . . . . . . . . .151

Report Packet 0x8F-20 - Last Fix with Extra Information (binary fixed point) . . . . . . .151

Command Packet 0x8E-26 - Non-Volatile Memory Storage . . . . . . . . . . . . . . . .153

Report Packet 0x8F-26 - Non-Volatile Memory Status . . . . . . . . . . . . . . . . . . .154

Datums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Copernicus GPS Receiver ix

Page 10

Table of Contents

B COPERNICUS MONITOR USER’S GUIDE

Copernicus Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

TSIP Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

TSIP Demo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Copernicus Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

TSIP and NMEA Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

C NMEA 0183

The NMEA 0183 Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

NMEA 0183 Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Field Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Exception Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Power-up with No Back-up Data on SRAM. . . . . . . . . . . . . . . . . . . . . . . . .172

Power-up with Back-up Data on SRAM. . . . . . . . . . . . . . . . . . . . . . . . . . .172

Interruption of GPS Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

NMEA 0183 Message Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

NMEA 0183 Message Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

GGA - GPS Fix Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

GLL - Geographic Position - Latitude/Longitude . . . . . . . . . . . . . . . . . . . . . .176

GSA - GPS DOP and Active Satellites . . . . . . . . . . . . . . . . . . . . . . . . . . .176

GSV - GPS Satellites in View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

RMC - Recommended Minimum Specific GPS/Transit Data . . . . . . . . . . . . . . . .177

VTG - Track Made Good and Ground Speed . . . . . . . . . . . . . . . . . . . . . . . .178

ZDA - Time & Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

AH - Almanac Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

AL - Almanac Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

AS - Almanac Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

BA - Antenna Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

CR - Configure Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

DM - Datum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

EM - Enter Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

EP - Ephemeris. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

IO Ionosphere . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

KG - Set Initial Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

NM - Automatic Message Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

PS - PPS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

PT - Serial Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

RT - Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

TF - Receiver Status and Position Fix . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

UT - UTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

VR - Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

x Copernicus GPS Receiver

Page 11

Table of Contents

D TRIMBLE ASCII INTERFACE PROT OCOL (TAIP)

Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Start of a New Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Message Qualifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Message Identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Data String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Vehicle ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Message Delimiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Sample PV Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Time and Distance Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Latitude and Longitude Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Message Data Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

AL Altitude/Up Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

CP Compact Position Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

ID Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

IP Initial Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

LN Long Navigation Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

PR Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

PT Port Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

PV Position/Velocity Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

RM Reporting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

RT Reset Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

ST Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

TM Time/Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

VR Version Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

X1 Extended Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Communication Scheme for TAIP221

Query for Single Sentence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Scheduled Reporting Frequency Interval . . . . . . . . . . . . . . . . . . . . . . . . . .221

The Response to Query or Scheduled Report . . . . . . . . . . . . . . . . . . . . . . . .222

The Set Qualifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Sample Communication Session. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

E TAIP MONITOR USER’S GUIDE

TAIP Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Copernicus GPS Receiver xi

Page 12

Table of Contents

xii Copernicus GPS Receiver

Page 13

List of Figures

List of Figures

Figure 1.1 Copernicus Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

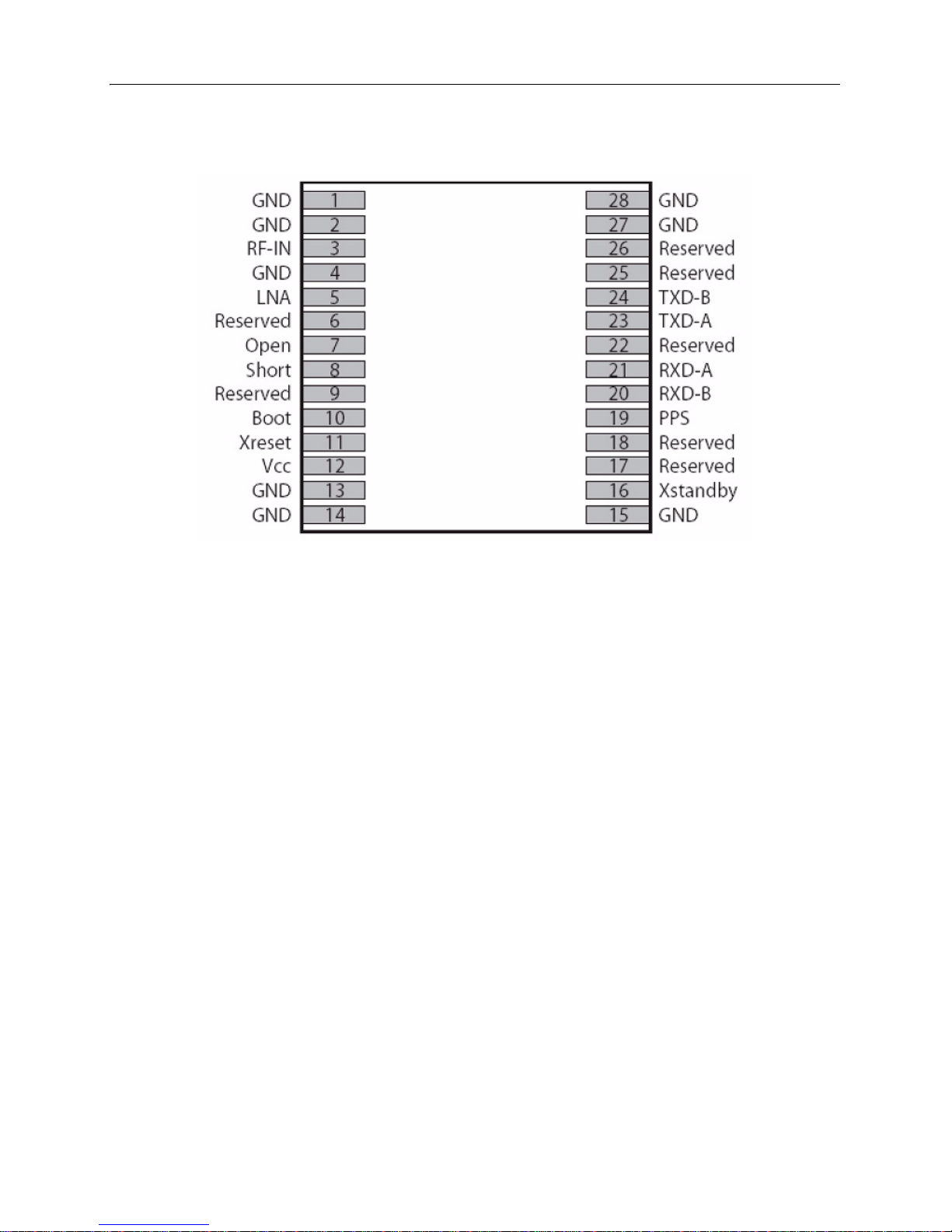

Figure 2.1 Copernicus Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4.1 Current Draw Levels in Standby Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4.2 Issuing three (3) NULL characters for exiting Standby Mode . . . . . . . . . . . . . . 28

Figure 5.1 Application Drawing: Passive Antenna - Minimum Connections . . . . . . . . . . . . 30

Figure 5.2 Passive antenna - HW Activated Standby Mode Available . . . . . . . . . . . . . . . 31

Figure 5.3 Application Drawing: Active antenna - Full connection . . . . . . . . . . . . . . . . . 32

Figure 5.4 Application Drawing: Active antenna - No Antenna Status . . . . . . . . . . . . . . . 34

Figure 6.1 Microstrip Transmission Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 6.2 PCB Microstrip Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 6.3 Stripline Transmission Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 7.1 Copernicus GPS Receiver, Footprint. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 7.2 Copernicus GPS Receiver, Outline Dimensions . . . . . . . . . . . . . . . . . . . . . 42

Figure 7.3 Solder Mask Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 7.4 Pad Pattern Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 7.5 Paste Mask Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 8.1 Copernicus GPS Receiver Packaged in Tape. . . . . . . . . . . . . . . . . . . . . . . 48

Figure 8.2 Reel Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 8.3 Tape Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 8.4 Feeding Direction Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 9.1 Moisture Precondition Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 9.2 Recommended Soldering Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 10.1 Copernicus Reference Board, Frontside . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 10.2 Copernicus Reference Board, Backside . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 10.3 Copernicus Reference Board Block Diagram . . . . . . . . . . . . . . . . . . . . . . 62

Figure 10.4 Copernicus Reference Board Schematic (Page 1) . . . . . . . . . . . . . . . . . . . . 63

Figure 10.5 Copernicus Reference Board Schematic (Page 2) . . . . . . . . . . . . . . . . . . . . 64

Figure 10.6 Copernicus Reference Board Schematic (Page 3) . . . . . . . . . . . . . . . . . . . . 64

Figure 10.7 Copernicus Reference Board, Top Side . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 10.8 Copernicus Reference Board Schematic, Bottom Side. . . . . . . . . . . . . . . . . . 67

Figure 11.1 Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 11.2 AC/DC Power Supply Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 11.3 USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 11.4 Front side of the Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 11.5 Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 11.6 Conxall Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 11.7 Connecting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Copernicus GPS Receiver xiii

Page 14

List of Figures

Figure B.1 Copernicus Monitor Serial Port Selection . . . . . . . . . . . . . . . . . . . . . . . .165

Figure B.2 Copernicus Monitor - Main Window. . . . . . . . . . . . . . . . . . . . . . . . . . .165

Figure E.1 TAIP Monitor - Serial Port Selection. . . . . . . . . . . . . . . . . . . . . . . . . . .226

Figure E.2 TAIP Monitor - Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

xiv Copernicus GPS Receiver

Page 15

CHAPTER

1

GENERAL DESCRIPTION 1

In this chapter:

• Receiver Overview

•Starter Kit

• Key Features

• Block Diagram

• Performance Specifications

• Interface Characteristics

• Electrical Characteristics

• Physical Characteristics

• Environmental Specifications

• Ordering Information

Page 16

1 GENERAL DESCRIPTION

1.1 Receiver Overview

Trimble's Copernicus™ GPS receiver delivers proven performance and Trimble quality

for a new generation of position-enabled products. It features the Trimble revolutionary

TrimCore™ software technology for extremely fast startup times and high performance in

foliage canopy, multipath and urban canyon environments.

Designed for the demands of automated, pick and place, high-volume production

processes, the Copernicus module is a complete 12-channel GPS receiver in a 19mm x

19mm x 2.54mm, thumbnail-sized shielded unit. The small, thin, single-sided module is

packaged in tape and reel for pick and place manufacturing processes; 28 reflowsolderable edge castellations provide interface to your design without costly I/O and RF

connectors. Each module is manufactured and factory tested to Trimble's highest quality

standards.

The ultra-sensitive Copernicus GPS receiver can acquire GPS satellite signals and

generate fast position fixes with high accuracy in extremely challenging environments and

under poor signal conditions. The module consumes less than 94 mW typically at full

power with continuous tracking. The Copernicus GPS receiver has been designed to meet

restrictions on the use of hazardous substances under the RoHS European Directive.

The Copernicus GPS module is a complete drop-in, ready-to-go receiver that provides

position, velocity and time data in a choice of three protocols. Trimble's powerful TSIP

protocol offers complete control over receiver operation and provides detailed satellite

information. The TAIP protocol is an easy-to-use ASCII protocol designed specifically for

track and trace applications. The bi-directional NMEA 0183 v3.0 protocol offers industrystandard data messages and a command set for easy interface to mapping software.

Compatible with active or passive antenna designs, the Copernicus GPS receiver is perfect

for portable handheld, battery-powered applications. The receiver's small size and low

power requirement make it ideal for use in Bluetooth appliances, sport accessories,

personal navigators, cameras, computer and communication peripherals, as well as,

vehicle and asset tracking, navigation, and security applications.

1.2 Starter Kit

The Copernicus Starter Kit provides everything you need to get started integrating stateof-the-art GPS capability into your application. The kit includes the reference interface

board, which gives designers a visual layout of the Copernicus module on a PCB including

the RF signal trace and RF connector, as well as the I/O connections of the 28 signal pins.

Also included are a power converter, power adapter, GPS antennas, and the software for

the user to readily evaluate the ease of adding Copernicus GPS to an application.

6 Copernicus GPS Receiver

Page 17

1.3 Key Features

• Thumbnail-sized: 19 mm W x 19 mm L (0.75" W x 0.75" L)

• Ultra-thin design: 2.54 mm H (0.1")

• Fast manufacturing: Pick & place assembly, Tape & reel packaging, Reflow

solderable

• No I/O or RF connector; 28 Edge castellations

• Ultra-low power usage: less than 94 mW (typical)

• Highly sensitive:

−152 dBm Tracking Sensitivity

−142 dBm Acquisition Sensitivity

• Fast TTFF (cold start): 39 sec

• Supports active or passive antenna designs

• 12-channel simultaneous operation

• Supports NMEA 0183, TSIP and TAIP protoc ols

GENERAL DESCRIPTION 1

• Reference board and starter kit available

• RoHS compliant (Lead-free)

• High quality, low price

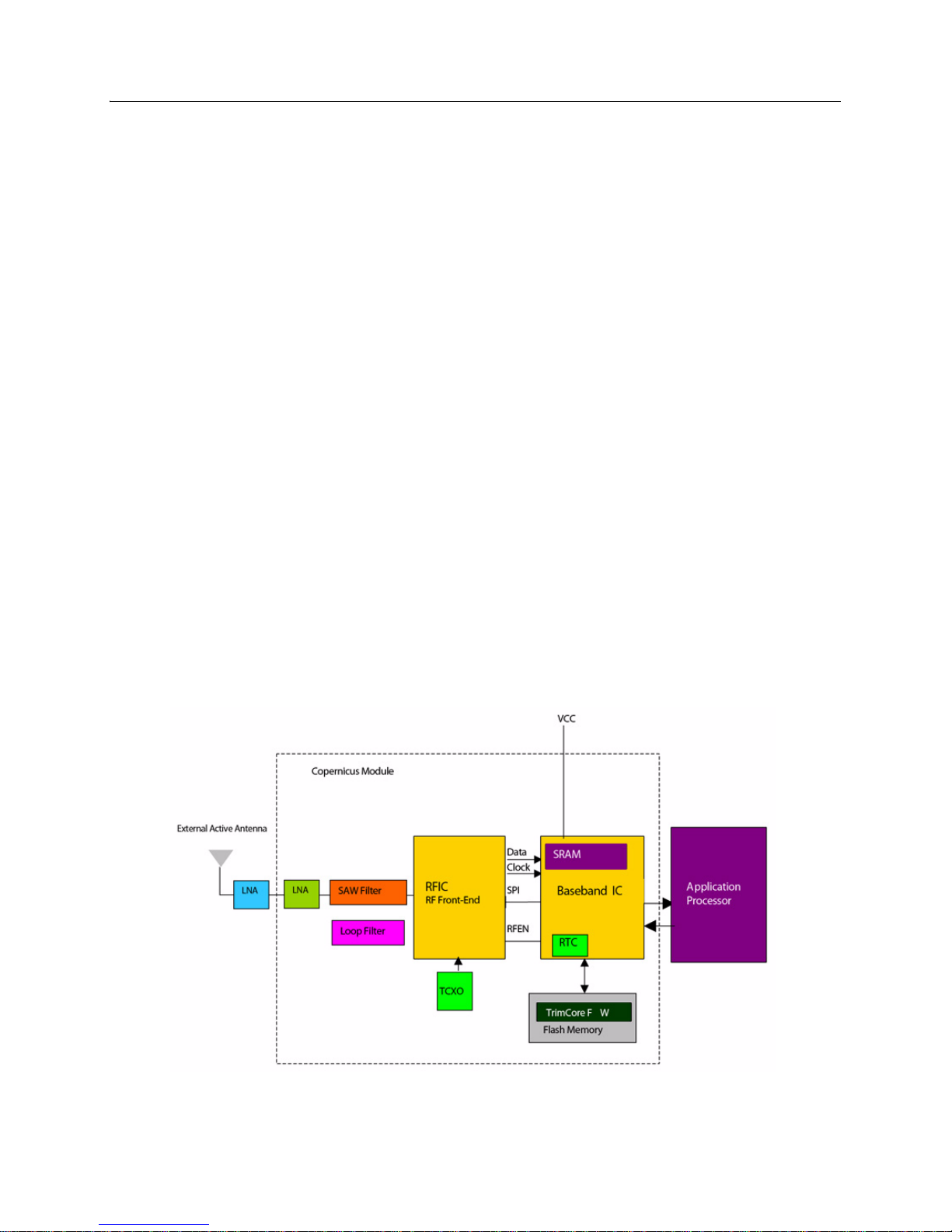

1.3.1 Block Diagram

Figure 1.1 Copernicus Block Diagram

Copernicus GPS Receiver 7

Page 18

1 GENERAL DESCRIPTION

1.4 Performance Specifications

Performance Specifications

L1 (1575.42 MHz) frequency, C/A code, 12-channel, continuous

tracking receiver

Update Rate

TSIP 1 Hz

NMEA 1 Hz

TAIP 1 Hz

Accuracy

Horizontal <3 meters (50%), <8 meters

Altitude <10 meters (50%), <16 meters

Velocity 0.06 m/sec

PPS (static) ±50 nanoseconds

Acquisition (Autonomous Operation)

Reacquisition 2 sec

Hot Start 9 sec

Warm Start 35 sec

Cold Start 39 sec

Out of the Box 41 sec

Sensitivity

Tracking -152 dBm

Acquisition -142 dBm

Operational

Speed Limit 515 m/s

(90%)

(90%)

1.5 Interface Characteristics

Interface Characteristics

Connectors 28 surface mount edge castellations

Serial Port 2 serial ports (transmit/receive)

PPS 3.0 V CMOS-compatible TTL-level pulse,

Protocols Supports TSIP*, TAIP** and NMEA*** 0183

The following abbreviations are used to refer to the interface protocols:

• Trimble Standard Interface Protocol, TSIP

• Trimble ASCII Interface Protocol, TAIP

• National Marine Electronics Association, NMEA

8 Copernicus GPS Receiver

once per second

v3.0 Bi-directional NMEA Messages

Page 19

1.6 Electrical Characteristics

Electrical Specifications

Prime Power +2.7 VDC to 3.3 VDC

Power Consumption (typ.) 30.7 mA (82.9 mW) @ 2.7 V

Backup Power +2.7 VDC to +3.3 VDC

Ripple Noise Max 50 mV, peak-to-peak from 1 Hz to 1 MHz

1.7 Physical Characteristics

Physical Specifications

Enclosure Metal shield

Dimensions 19 mm W x 19 mm L x 2.54 mm H (0.75" W x

Weight 1.7 grams (0.06 ounce) including shield

GENERAL DESCRIPTION 1

(typ.) 31.3 mA (93.9 mW) @ 3.0 V

0.75" L x 0.1" H)

1.8 Environmental S pecifications

Electrical Specifications

Operating Temperature -40° C to +85° C

Storage Temperature -55° C to +105° C

Vibration 0.008 g2/Hz 5 Hz to 20 Hz

Operating Humidity 5% to 95% R.H. non-condensing, at +60° C

0.05 g2/Hz 20 Hz to 100 Hz

-3 dB/octave 100 Hz to 900 Hz

Copernicus GPS Receiver 9

Page 20

1 GENERAL DESCRIPTION

1.9 Ordering Information

Ordering Information

Copernicus GPS Receiver Module Single module in metal enclos u re

Reference Board P/N 58054-00

Starter Kit Non-RoHS: PN 58050-00

P/N 58048-00

Copernicus GPS module mounted on a carrier

board with I/O and RF connectors for evaluation

purposes, including the RF circuitry with the

antenna open detection, as well as antenna short

detection and protection.

RoHS (Lead-free version): P/N 58050-05

Includes Copernicus Reference Board

mounted on interface motherboard in a

durable metal enclosure, AC/DC power

converter, compact magnetic-mount GPS

antenna, serial interface cable, cigarette

lighter adapter, TSIP, NMEA, and TAIP

protocols, software toolkit and manual on

CD-ROM.

10 Copernicus GPS Receiver

Page 21

CHAPTER

2

INTERFACE CHARACTERISTICS 2

In this chapter:

• Pin Assignments

• Pin Description

• Protocols

• Serial Ports Default Settings

• Pulse-Per-Second (PPS) in Copernicus Receiver

Page 22

2 INTERFACE CHARACTERISTICS

2.1 Pin Assignments

Figure 2.1 Copernicus Pin Assignments

12 Copernicus GPS Receiver

Page 23

INTERFACE CHARACTERISTICS 2

2.2 Pin Description

T able 2.1 Pin Description

Pin Name Description Function Note

1 GND Ground G Signal ground. Connect to common ground.

2 GND RF Ground G One of two RF grounds adjacent to RF input.

Connect to RF ground system.

3 RF Input GPS RF input I 50-ohm unbalanced (coaxial) RF input.

4 GND RF Ground G One of two RF grounds adjacent to RF input.

Connect to RF ground system.

5 LNA_XEN LNA Enable O Can be used with active antennas only. Active

low logic level signal to control external LNA.

6 Reserved Reserved I/O Do not connect.

7 OPEN Antenna OPEN I Logic level from external antenna detection

circuit. See “Antenna Detect Truth Table”.

8 SHORT Antenna SHORT I Logic level from external antenna detection

circuit. See “Antenna Detect Truth Table”.

9 Reserved Reserved I Connect to VCC.

10 Reserved Reserved I Connect to VCC.

1 1 XRESET Reset I Active low logic level reset. Connect to VCC with

or without a pullup resistor, if not used.

12 VCC Supply voltage P Module power supply 2.7 - 3.3 VDC

13 GND Ground G Signal ground. Connect to common ground.

14 GND Ground G Signal ground. Connect to common ground.

15 GND Ground G Signal ground. Connect to common ground.

16 XST ANDBY Run/Standby I Selects “RUN” or “STANDBY” mode. Connect to

VCC if not used (run only).

17 Reserved Reserved I/O Do not connect.

18 Reserved Reserved I/O Do not connect.

19 PPS Pulse per second O Logic level timing signal at 1 Hz. Do not connect

if not used.

20 RXD_B Serial port B receive I Logic level secondary serial port receive.

21 RXD_A Serial port A receive I Logic level primary serial port receive.

22 Reserved Reserved I/O Do not connect.

23 TXD_A Serial port A transmit O Logic level primary serial port transmit.

24 TXD_B Serial port B transmit O Logic level secondary serial port transmit.

25 Reserved Reserved I/O Do not connect.

26 Reserved Reserved I/O Do not connect.

27 GND Ground G Signal ground. Connect to common ground.

28 GND Ground G Signal ground. Connect to common ground.

Index: G: Ground; I: Input; O: Output; P: Power

Copernicus GPS Receiver 13

Page 24

2 INTERFACE CHARACTERISTICS

2.2.1 Detailed Pin Descriptions

RF Input

This pin is the 50 ohm unbalanced GPS RF input. It can be used with active or passive

antennas.

Passive antennas: This pin may be connected by a low-loss 50 ohm unbalanced

transmission system to the passive GPS antenna if loss is minimal (< 2 dB).

Active Antennas: It can also be connected to the output of an external low-noise amplifier,

which is amplifying GPS signals from an antenna. The gain of the LNA must be great

enough to overcome transmission losses from the LNA output to this pin. The

specification for noise figure for the module is < 3 dB at room temperature and < 4 dB

over the specified temperature range, -40 to +85 C. The external LNA must be located

such that the loss from the GPS antenna connection to the LNA input is minimized,

preferably < 1 dB. The noise figure of the LNA should be as low as possible, preferably

< 2 dB. The specifications are provided so that a cascaded noise figure design calculation

can be used. Active antennas must be powered with a single bias-Tee circuit. (See

applications circuits in Chapter 5.)

LNA_XEN

This logic level output can be used to control power to an external LNA or other circuitry.

The logic of this signal is such that when the module is running (not in standby), this signal

is low. During “STANDBY” mode, this signal is high. This pin may be used to control the

gate of a p-channel FET used as a switch.

Open/Short Pins

If using an active antenna, Trimble recommends that the user implement an antenna

detection circuit with short circuit protection. There are two pins provided for reporting the

antenna status: OPEN and SHORT.

The following logic level inputs may be used with a detection circuit (with or without

protection) to monitor the status of the external LNA of an active antenna by the module.

The truth table for the logic of these signals is provided below. These input pins conform

to the Input / Output Pin threshold levels specified in Table 3.2.

14 Copernicus GPS Receiver

Page 25

INTERFACE CHARACTERISTICS 2

Table 2.2 Antenna Status Truth Table

Condition of logic signals

ANTENNA REPORTS SHORT OPEN

Antenna Open Reported 1 1

Antenna Normal Reported 1 0

Antenna Shorted Reported 0 0

Undefined 0 1

If using a passive antenna and the SHORT and OPEN pins are floating, the receiver will

report an open condition. If a normal condition from the receiver is desired when using a

passive antenna, set the logic levels of the SHORT pin High and the OPEN pin Low.

XRESET

This logic-level, active low input is used to issue hardware or power-on reset to the

module. It may be connected to external logic or to a processor to issue reset, if desired. To

reset the module, take this pin low for at least 100 microseconds. This pin must be tied to

VCC with a resistance of less than 10 K Ohms if not used.

The hardware reset deletes all the information saved in SRAM (position time, almanac,

ephemeris and customers' user set configurations if not previously saved in non-volatile

Flash memory) and restarts the Copernicus receiver.

VCC

This is the primary voltage supply pin for the module. This pin also provides power during

Standby Mode (Backup Mode). If it is desired to have separate power supplies for main

power and Standby Mode (Backup Mode) power, an external diode-pair must be provided.

XSTANDBY

This logic level input is used to control the RUN/STANDBY state of the module. If this

signal is high, the unit will run normally. If this signal is low, the unit will go to

“STANDBY” mode.

PPS

Pulse-per-second. This logic level output provides a 1 Hz timing signal to external devices.

The positive going 4.2 usec pulse delay is controllable by firmware packet 0x35. This

output meets the Input / Output Pin Threshold Specifications in Table 3.2.

RXD_A and RXD_B

These logic level inputs are the primary (A) and secondary (B) serial port receive lines

(data input to the module). These inputs meet the Input / Output Pin Threshold

Specifications in Table 3.2. The baud rate for the two ports is under firmware control.

Copernicus GPS Receiver 15

Page 26

2 INTERFACE CHARACTERISTICS

TXD_A and TXD_B

These logic level outputs are the primary (A) and secondary (B) serial port transmit lines

(data moving away from the module). These outputs meet the Input / Output Pin Threshold

Specifications in Table 3.2. The baud rate for the two ports is under firmware control.

Reserved Pins

There are 8 reserved pins on the Copernicus GPS Receiver. For the recommended pin

connections for these reserved pins, please refer to Table 2.1.

2.3 Protocols

T able 2.3 Copernicus GPS Receiver Available protocols

Protocols Specification Direction Serial Port Support

NMEA NMEA 0183 v3.0; Bi-directional

with extended NMEA sentences

TSIP (Trimble S tandard

Interface Protocol)

T AIP (Trimble ASCII

Interface Protocol)

Trimble propriety binary protocol Input / Output Both Serial Ports

Trimble propriety ASCII protocol Input / Output Both Serial Ports

Input / Output Both Serial Ports

16 Copernicus GPS Receiver

Page 27

INTERFACE CHARACTERISTICS 2

2.4 Serial Ports Default Settings

Copernicus GPS receiver supports two serial ports. The default settings are provided in the

table below.

Table 2.4 Copernicu s GPS Receiver Serial ports default set tin gs

Port Port Direction Pin # Protocol Characteristics

Baud Rate Data Bits* Parity* Stop Bits* Flow Control *

A TXD-A 23 TSIP-Out 38.4 K 8 None 1 NO

RXD-A 21 TSIP-IN 38.4 K 8 None 1 NO

B TXD-B 24 NMEA-Out 4800 8 None 1 NO

RXD-B 20 NMEA-IN 4800 8 None 1 NO

* Data Bits, Parity, Stop Bits and Flow Control are not configurable. Only Protocol and Baud rates are configurable by

the user.

Note – Detailed descriptions of the protocols are defined in the Appendices.

Copernicus GPS Receiver 17

Page 28

2 INTERFACE CHARACTERISTICS

2.5 Pulse-Per-Second (PPS) in Copernicus Receiver

The Copernicus GPS receiver provides a CMOS compatible TTL level Pulse-Per-Second

(PPS). The PPS is a positive pulse available on pin 19 of Copernicus GPS Receiver. The

rising edge of the PPS pulse is synchronized with respect to UTC. The timing accuracy is

±50 nanoseconds when valid position fixes are being reported.

The rising edge of the pulse is typically less than 6 nanoseconds. The distributed

impedance of the attached signal line and input circuit can affect the pulse shape and rise

time. The PPS can drive a load up to 1mA without damaging the module. The falling edge

of the pulse should not be used.

The Copernicus' default PPS output mode is Always On, sometimes called or “Early PPS”.

In Always On mode, PPS is output immediately after main power is applied. The PPS is

driven by the Real Time Clock (RTC) until the receiver acquires GPS time from the

satellite and begins outputting fixes. In Always On mode, the PPS continues even if the

receiver loses GPS lock. The drift of the PPS, when the Copernicus GPS receiver is not

tracking satellites, is unspecified and should not be used for synchronization.

The PPS output modes can be controlled with TSIP packet 0x35 and NMEA “PS” Packet.

The modes are Always On (default), Fix Based, or Always Off. Cable delay compensation

is available through the use of TSIP packet 0x8E-4A and NMEA “PS” Packet.

After a specific mode is selected, it can be stored in non-volatile memory (FLASH) using

TSIP command 0x8E-26.

Note – PPS can be configured as positive or negative polarity; factory default is positive.

The PPS pulse width is also configurable; factory default is 4.2 microseconds.

18 Copernicus GPS Receiver

Page 29

CHAPTER

3

ELECTRICAL SPECIFICATIONS 3

In this chapter:

• Absolute Minimum and Maximum Limits

• Normal Operating Conditions

• Power Consumption over Temperature and Voltage

• ESD Protection

Page 30

3 ELECTRICAL SPECIFICATIONS

3.1 Absolute Minimum and Maximum Limits

Absolute maximum ratings indicate conditions beyond which permanent damage to the

device may occur. Electrical specifications shall not apply when operating the device

outside its rated operating conditions.

Table 3.1 Copernicus GPS Receiver, Absolute Limits

Parameter Min Max Unit

Power Supply

Power Supply Voltage (VCC) on Pin 12

STANDBY Voltage (VCC) on Pin 12 *

Antenna

Input Power at RF Input +10 dBm

Input Gain at RF Input 0 (passive antenna) 36 dB

* See the application note on STANDBY circuitry

Table 3.2 Input / Output Pin Threshold levels

Input / Output Pin Threshold levels

Input Pin Voltage (RXD-A, RXD-B, Open, Short, Reserved Pins, Xreset, Xstandby)

Status Min Max Unit

High 2.0 3.6 V

Low 0 0.8 V

Output Pin Voltage (TXD-A, TXD-B, LNA_XEN)

Status Min Max Unit

High (loh = 1 mA) 0.8 * VCC VCC

Low (lol = 1 mA) 0 0.22 * VCC V

-0.3 3 .6 V

-0.3 3.6 V

3.2 Normal Operating Conditions

Minimum and maximum limits apply over full operating temperature range unless

otherwise noted.

T able 3.3 Copernicus GPS Receiver Normal Operating Conditions

Parameter Conditions Min Typ Max Unit

Primary Supply Voltage * 2.7 3.3 * V

Current Draw Continuous

Tracking,

Power Consumption

Continuous Tracking,

20 Copernicus GPS Receiver

Max: 85

Min: -40 °C, 2.7V

Typ: 25 °C, 3.0 V

Max: 85 °C, 3.3 V

Min: -40 °C, 2.7V

Typ: 25 °C, 3.0 V

°C, 3.3 V

23.9 34.8 38.3 mA

79 93.9 115 mW

Page 31

ELECTRICAL SPECIFICATIONS 3

Parameter Conditions Min Typ Max Unit

Power Consumption

Absolute Maximum

50

165

mA

mW

Current Draw **

Standby Mode

Max: 85 °C,

Min: -40 °C

7.1 8.5 60 uA

Typ: 25 °C, 3.0 V

Current Draw Standby

Mode RTC Service

30

Please see section

mA

Serial Port Activity

Supply Ripple Noise 1Hz to 1MHz

50

mVpp

GPS TCXO

1

mVpp

Frequency +/-5kHz

Hardware RESET Assert XRESET pin to

100 us

clear STANDBY memory

* The user can use one source of power on Pin 12 (VCC) for both main and Standby power.

** If using two sources of power, the Main and Standby power must be connected to VCC via an external diode-pair.

During the Standby Mode, the main power can be removed so the unit can be run on Standby power. Standby power

must be at least 0.3V less than main power. The voltage at Pin 12 must be 2.7V to 3.3V including the diode voltage drop.

(See Chapter 5 for information on application circuits.)

Copernicus GPS Receiver 21

Page 32

3 ELECTRICAL SPECIFICATIONS

3.3 Power Consumption over Temperature and Voltage

Run Mode

(Tracking with Almanac Complete): < 90 mW average @ 2.7 VDC, -40 to 85 C

Standby Mode: < 30 uW @ 3.0 VDC, typical at 25 C, < 200 uW under all conditions

except during service time for the 18-hour real time clock roll over. (See Chapter 4 for

more information.)

Table 3.4 Copernicus GPS Receiver Power Consumption

At 2.7 volts

Avg Current (mA) Avg power consumption (mW)

-40 C 29.7 80.2

Room Temp 30.7 82.9

85 C 31.5 85.1

At 3.0 volts

Avg Current (mA) Avg power consumption (mW)

-40 C 30.3 90.9

Room Temp 31.3 93.4

85 C 34.9 104.7

At 3.3 volts

Avg Current (mA) Avg power consumption (mW)

-40 C 31.5 104

Room temp 31.4 104

85 C 31.9 105

3.4 ESD Protection

All inputs and outputs are protected to +/-500 volts ESD level. If a higher level of

compliance is required, additional electrostatic and surge protection must be added.

22 Copernicus GPS Receiver

Page 33

CHAPTER

4

OPERATING MODES 4

In this chapter:

• Copernicus Receiver Operating Modes

• Run Mode

• Standby Mode

• Monitor Mode

• Changing the RUN/STANDBY modes

• Saving the Almanac into the Flash Memory

Page 34

4 OPERATING MODES

4.1 Copernicus Receiver Operating Modes

Table 4.1 Copernicu s GPS Receiver Operating Modes

Operating Modes Description

Run Mode Continuous tracking or normal mode

Standby Mode Backup power or low power mode

Monitor Mode Flash upgrading mode

4.2 Run Mode

The RUN mode is the continuous tracking or the normal mode.

4.3 Standby Mode

The Copernicus GPS receiver provides a Standby Mode, in which the module's RAM

memory is kept alive and the real-time clock is running while the rest of the receiver is

turned off. RAM memory is used to store the GPS almanac, ephemeris and last position.

Using this information, together with the time information provided by the real-time clock,

the receiver normally provides faster startup times. The type of start-up after Standby

Mode depends on the state of the receiver prior to entering Standby Mode and on the

length of time the receiver spent in the Standby Mode.

If the receiver has almanac, ephemeris, and position information before entering Standby

Mode, and the time spent in Standby Mode is less than two hours, the receiver will

typically perform a hot start.

If the receiver has all of the information listed above, but the time spent in Standby Mode

is more than two hours, the receiver will typically perform a warm start.

GPS almanac can also be stored in non-volatile Flash memory. Even without time or

ephemeris, the receiver can use almanac stored in Flash memory to shorten the start-up

time. In all cases, the receiver will use all of the available information to do the fastest

start-up possible.

In the Standby Mode, the power consumption of the unit is very low. Please see Table 7 for

the power requirement specifications in the Standby Mode. Please refer to section 5.3 for

the application note on how to power the receiver from battery in the Standby Mode.

4.4 Monitor Mode

Monitor Mode is the operating mode for upgrading the firmware stored in the Flash

memory. For details regarding the firmware upgrading process, please refer to the

Firmware Upgrading Section of this manual.

24 Copernicus GPS Receiver

Page 35

4.5 Changing the RUN/STANDBY modes

Copernicus provides the user with two methods of switching the receiver between RUN

and STANDBY modes:

1. Using the XSTANDBY pin or

2. Using the serial ports under user control

Note – Only one method can be used at a time. If you are using the

XSTANDBY pin, you should not use the serial ports for controlling the

modes. If you are using the serial port option, the XSTANDBY pin should

always be held high. You cannot use serial po rts to switch to RUN mode if

the XSTANDBY pin was used to enter STANDBY mode.

4.5.1 Using the XSTANDBY Pin to Switch Modes

The first method for putting the receiver into Standby Mode or exiting this mode back to

the Run Mode is through the pin XSTANDBY, pin #16. As long as the pin is held high, the

receiver will operate normally in Run Mode.

Entering Standby Mode

OPERAT ING MODES 4

When the pin is taken low, the receiver will go to the STANDBY mode.

Exiting Standby Mode

When the pin is taken high again, the receiver will warm restart and return to normal

operation.

Note – Excessive noise on the XST ANDBY pin could trigger the receiver to

reset (see Table 3.2).

4.5.2 Using Serial Ports to Switch Modes

Entering Standby Mode: The second method for putting the receiver into Standby Mode is

using TSIP packet 0xC0 or NMEA packet RT to command the unit into Standby Mode.

Exiting Standby Mode: In this case there are two possible conditions that would trigger the

receiver to reset and operate normally again:

1. Serial Port Activity

2. Exit after X elapsed seconds.

Copernicus GPS Receiver 25

Page 36

4 OPERATING MODES

Serial Port Activity

When the receiver enters Standby Mode through the software protocol commands, the first

condition for exiting Standby Mode is using serial port A activity or serial port B activity.

The condition is identical for both ports A and B.

To ensure the receiver detects and responds to serial port activity, issue a NULL character

on the selected serial port to bring the unit out of Standby Mode. In Standby Mode, the

receiver samples for serial port activity at a rate of 32.768 kHz. A NULL character will

bring the selected RX line low for 9 bits so even at the highest baud rate of 115200, a

NULL character should be detectable at the sample rate.

There are two exceptions where serial activity may not trigger the unit to exit Standby

Mode:

• During the 3 seconds following the command to enter Standby Mode.

The Copernicus GPS receiver may not detect serial port activity during the 3

seconds immediately after receiving a software command to enter Standby Mode.

During that 3 seconds, the unit is processing the shut-down command and will

ignore serial port activity. Therefore the minimum time between issuing the shutdown command and the use of serial port activity to return the unit to Run mode is 3

seconds. Standby time cannot be less than 3 seconds.

• During the 10 msec RTC service time.

During the 10 msec RTC service time, there exists a 91.6 μsec window where the

receiver cannot detect serial port activity. Using a series of three NULL characters

in a row should ensure that the unit responds.(See 18-Hour RTC Roll Over, on

page 28 for an explanation of the RTC service time.)

Exit after X elapsed seconds.

The second condition that will trigger the receiver to exit Standby Mode is the elapse of a

pre-defined time. When the receiver is placed into the Standby Mode using protocol

commands, the receiver can be made to exit the S tandby Mode after a defined el apsed time

using TSIP command Packet 0xC0 or NMEA packet R T. In this case, the user specifies the

number of seconds the receiver should stay in Standby Mode. After this time has elapse d ,

the unit will perform a reset and start operating normally.

Note – These conditions are provided to the receiver in the serial

command packet, and the user can specify any combination of these

conditions as desired. For exiting the Standby Mode, either of the 2

methods can be applied. The first one that occurs will bring the receiver to

the RUN mode to start normal operations.

26 Copernicus GPS Receiver

Page 37

4.6 Saving the Almanac into the Flash Memory

Almanac information contained in RAM can be saved into the Flash Memory by issuing

the “Graceful Shutdown” command.

4.6.1 Graceful Shutdown

The “Graceful Shutdown” command is issued by using TSIP packet 0xC0 or NMEA

command “RT” with “store RAM to flash” flag enabled. After storing the almanac to the

Flash Memory, the unit will perform a reset. The reset type will depend on the other

“Graceful Shutdown” command parameters. On start-up, the unit will use the almanac

from RAM first. If RAM is not available, the unit will use the almanac from the Flash

Memory.

4.6.2 Almanac in Flash Updating Process

The unit automatically updates the almanac in RAM from satellite data. It does NOT

update the almanac in the Flash Memory automatically . To update the almanac in the Flash

Memory , the “Graceful Shutdown” command must be issued to the unit.

OPERAT ING MODES 4

Copernicus GPS Receiver 27

Page 38

4 OPERATING MODES

4.7 18-Hour RTC Roll Over

If the Standby Mode lasts longer than 18 hours, a special condition will occur. The realtime clock has a maximum time count of 18 hours, so that every 18 hours the receiver must

briefly power on the processor and read the elapsed time before the real-time clock rolls

over.

The Diagram below describes the Copernicus current draw levels after initiating a Standby

Command, as well as the service time for the 18-hour real time clock roll over.

IMAGE TO COME

Figure 4.1 Current Draw Levels in Standby Mode

During the 10 msec RTC service is time, there exists a 91.6 μsec window where the

receiver cannot detect state transitions on the RX pins. If NULL characters are being used

to bring the unit out of Standby as described earlier, using three NULL characters in a row

should ensure that one of the NULL characters happens outside of the vulnerable window

so that the serial port activity is detected.

3 Null

= 70 μsec

Figure 4.2 Issuing three (3) NULL characters for exiting Standby Mode

91.6

μsec

28 Copernicus GPS Receiver

Page 39

CHAPTER

5

COPERNICUS GPS APPLICATION

CIRCUITS

In this chapter:

• Passive antenna—Minimum Connections

• Active Antenna—Full Connection

• Active Antenna—No Antenna Status

5

Page 40

5 COPERNICUS GPS APPLICATION CIRCUITS

5.1 Passive antenna—Minimum Connections

IMAGE TO COME

Figure 5.1 Application Drawing: Passive Antenna - Minimum Connections

This is the minimum connection set for Copernicus GPS Receiver. The following

describes the schematic:

• A passive antenna is used. The Copernicus has an on-board LNA and an Automatic

Gain Control circuit.

• The Pin LNA_XEN is not necessary and not connected.

• No Antenna open and short detection or protection is provided.

• If the Open (Pin 7) and Short (Pin 8) are kept unconnected (floating), the

Copernicus reports an open antenna condition. If a normal condition report is

desired, tie Open low and Short high. (See Table 2.2).

• There is no HW reset ability through the pin XRESET, since XRESET pin is tied

High to VCC.

• There is no HW initiated Standby Mode through the Pin XSTANDBY, since

XSTANDBY pin is tied High to VCC. The software serial command to Standby

Mode will still apply.

• There is no separate power for STANDBY power.

• One serial port is utilized.

30 Copernicus GPS Receiver

Page 41

COPERNICUS GPS APPLICA TION CIRCUITS 5

Figure 5.2 Passive antenna - HW Activated Standby Mode Available

Following is a description of the schematic:

• Passive Antenna is used. Copernicus has an on-board LNA and an Automatic Gain

Control circuit.

• The Pin LNA_XEN is not necessary and not connected.

• There is no HW reset ability through the pin XRESET, since XRESET pin is tied

High to VCC.

• HW initiated Standby Mode through the Pin XSTANDBY is possible, since

XSTANDBY pin is not tied High to VCC. The software serial command to Standby

Mode can still be used as a second method to force the module into Standby Mode.

• There is no separate power for STANDBY power.

• One serial port is utilized.

• No Antenna open and short detection or protection is provided. When Open (Pin 7)

and Short (Pin 8) are kept unconnected (floating), the Copernicus reports an open

antenna condition. If a normal condition is desired, tie Open Low and Short High.

Please also refer to the Table 2 - Antenna Status Truth Table.

Copernicus GPS Receiver 31

Page 42

5 COPERNICUS GPS APPLICATION CIRCUITS

5.2 Active Antenna—Full Connection

Figure 5.3 Application Drawing: Active antenna - Full connection

In the following you will find a description of this schematic with antenna detection, when

using a second source to power the unit when in Standby Mode:

• An active antenna is used.

• The Pin LNA_XEN is connected.

• HW reset ability through the pin XRESET is possible, since XRESET pin is not tied

High to VCC.

• HW initiated Standby Mode through the Pin XSTANDBY is possible, since

XSTANDBY pin is not tied High to VCC. Serial Command to Standby Mode can

still apply as the second method to force the module to Standby Mode.

• A second power source for the standby voltage is applied. Please see the Note

below.

• Both serial ports are utilized.

• Antenna open and short detection and protection is provided. The combination of

the two pins Open (Pin 7) and Short (Pin 8) report the antenna status (see Table 2.2).

Note – When using two power sources, main and standby, an external diode pair must be

used to OR the Vcc and Vbackup power to ensure that the voltage at the module VCC pin

is always 2.7-3.3 VDC.

32 Copernicus GPS Receiver

Page 43

COPERNICUS GPS APPLICA TION CIRCUITS 5

Table 5.1 Active Antenna Components

Component Description Manufacturer Part Number

C1 18 PF, 0402 capacitor, C0G KEMET C0402C180J5GAC

C2 0.1 uF, 0402 capacitor, X7R CAL-CHIP GMC04X7R104K16NTLF

J1 MCX Connector Johnson Components 133-3711-312

L1 100 nH, 0603 inductor, surface

Coil Craft 0603CS - R10XJLU

mount

Q2 PNP Transistor Central Semiconductor MMBT404A (MMBTA70LT1

may be used if 12 Volt back

voltage tolerance is not

required)

Q3 NPN Transistor Philips MMBT3904

Q4 PNP Transistor Philips MMBT3906

Q5 PNP Transistor Philips MMBT3906

U1 Dual schottky diode Diodes Inc. BAT 54 CT

Copernicus GPS Receiver 33

Page 44

5 COPERNICUS GPS APPLICATION CIRCUITS

5.3 Active Antenna—No Antenna Status

Figure 5.4 Application Drawing: Active antenna - No Antenna Status

Following is a description of this schematic without antenna detection or a separate power

source for Standby Mode:

• An active Antenna is used.

• The Pin LNA_XEN is not connected.

• There is no HW reset ability through the pin XRESET, since XRESET pin is tied

High to VCC.

• HW initiated Standby Mode through the Pin XSTANDBY is possible, since

XSTANDBY pin is not tied High to VCC. Serial Command to Standby Mode can

still apply as the second method to force the module to Standby Mode.

• There is no separate power for STANDBY power.

• Both serial ports are utilized.

• Antenna open and short detection or protection is not provided. If pins 7 and 8 are

left floating, they will cause the unit to report an antenna open condition (see

Table 2.2).

34 Copernicus GPS Receiver

Page 45

CHAPTER

6

RF LAYOUT CONSIDERATIONS 6

In this chapter:

• General Recommendations

• Design considerations for RF Track Topologies

• PCB Considerations

6. RF LAYOUT CONSIDERATIONS

Page 46

6 RF LAYOUT CONSIDERATIONS

6.1 General Recommendations

The design of the RF transmission line that connects the GPS antenna to the Copernicus

GPS receiver is critical to system performance. If the overall RF system is not

implemented correctly, the Copernicus GPS receiver performance may be degraded.

The radio frequency (RF) input on the Copernicus GPS module is a 50 ohm, unbalanced

input. There are ground castellations, pins 2 and 4, on both sides of the RF input

castellation, on pin 3. This RF input may be connected to the output of an LNA which has

a GPS antenna at its input or to a passive antenna via a low-loss 50 ohm, unbalanced

transmission line system.

In the case where the GPS antenna must be located any significant distance from the

Copernicus GPS module, the use of an LNA at the antenna location is necessary to