Trevi Outline, Therm, Traditional Installation Instructions Manual

Installation Instructions

A3000 Trevi Therm built-in thermostatic mixer

A3700 Trevi Outline built-in thermostatic mixer

E3115 Trevi Traditional built-in thermostatic mixer

INSTALLER:

After installation please pass this instruction booklet to user

TREVI SHOWERS

Trevi Outline

Trevi Traditional Trevi Therm

trevi showers.qxd 04/12/03 13:21 Page 1

WATER REGULATIONS

Hot and cold water supply pressures must be

reasonably balanced and from a common

source - both from storage or both from a

supply pipe. (IRN 101). The mixers will function

within specification on unequal pressures up to

a ratio of 5 : 1, but it is not recommended that

the cold supply be connected to the rising main

and hot to the tank fed supply as the pressure

differential is likely to exceed the 5:1 ratio.

The minimum pressure for correct operation is

0.1 bar (1m head - see Figure 5). Pressure head

is measured as the vertical distance between the

bottom of the cold water storage tank which

feeds the hot water system and the highest

point on the shower spray plate.

When installing with a shower pump the use of

a secondary tapping from the cylinder is highly

recommended.

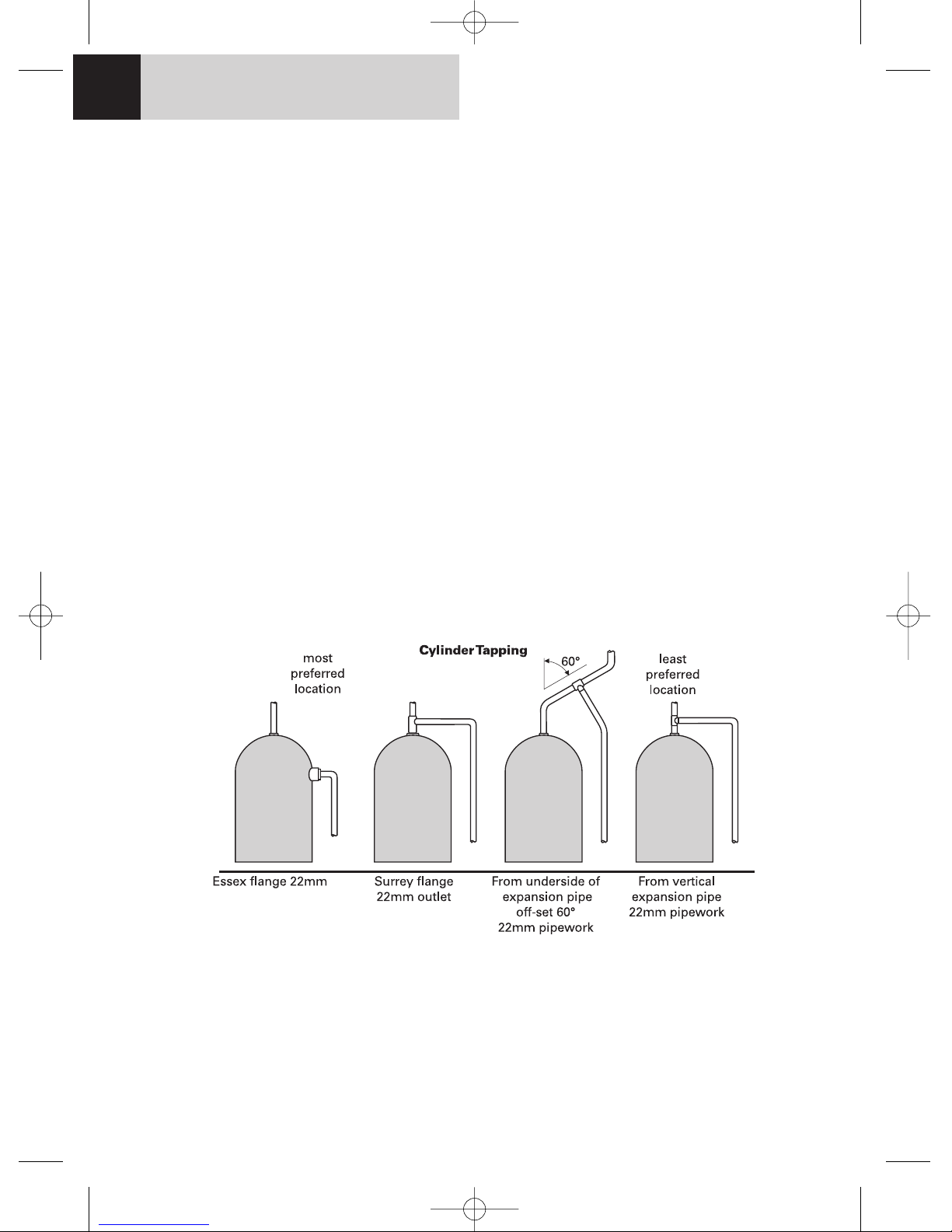

Figure 1 shows the various methods of connecting

the hot water pipe to the cylinder - the most

preferred on the left and the least preferred on

the right.

The fitting should be so installed as to be readily

accessible for examination, repair, replacement or

operation. (IRN 111).

The temperature of the hot water must not exceed

85ºC but the installer’s attention is drawn to code

of practice BS 6700 which recommends that

stored hot water should normally never exceed

65ºC. For correct operation of the valve, a

minimum of 52ºC is required.

GENERAL NOTES

Trevi thermostatic shower mixers are designed to be installed on normal UK low

pressure storage tank fed systems, unvented high pressure systems, modulating

instantaneous water heaters or modulating combination (combi) boilers. They are suitable

for all pumped applications.

Figure 1 Preferred locations of cylinder tapping

1

FOR HEALTHCARE ESTABLISHMENTS

In accordance to NHS model engineering specification DO8 the valve has approval for the following

applications: High pressure -HP-S

Low pressure -LP-S

TMV3 approval number: ETC/227/0903

trevi showers.qxd 04/12/03 13:21 Page 2

When installing on a modulating combination

boiler it is sometimes possible for the interaction of a thermostatic valve with the combi to

cause the boiler to cut out and cut in again with

the result that the water will become alternatively cold and hot. To overcome this, flow

restrictors should be fitted upstream of the

thermostatic valve.

The Do8 approval of this fitting only

applies when installed without the flow

restrictors.

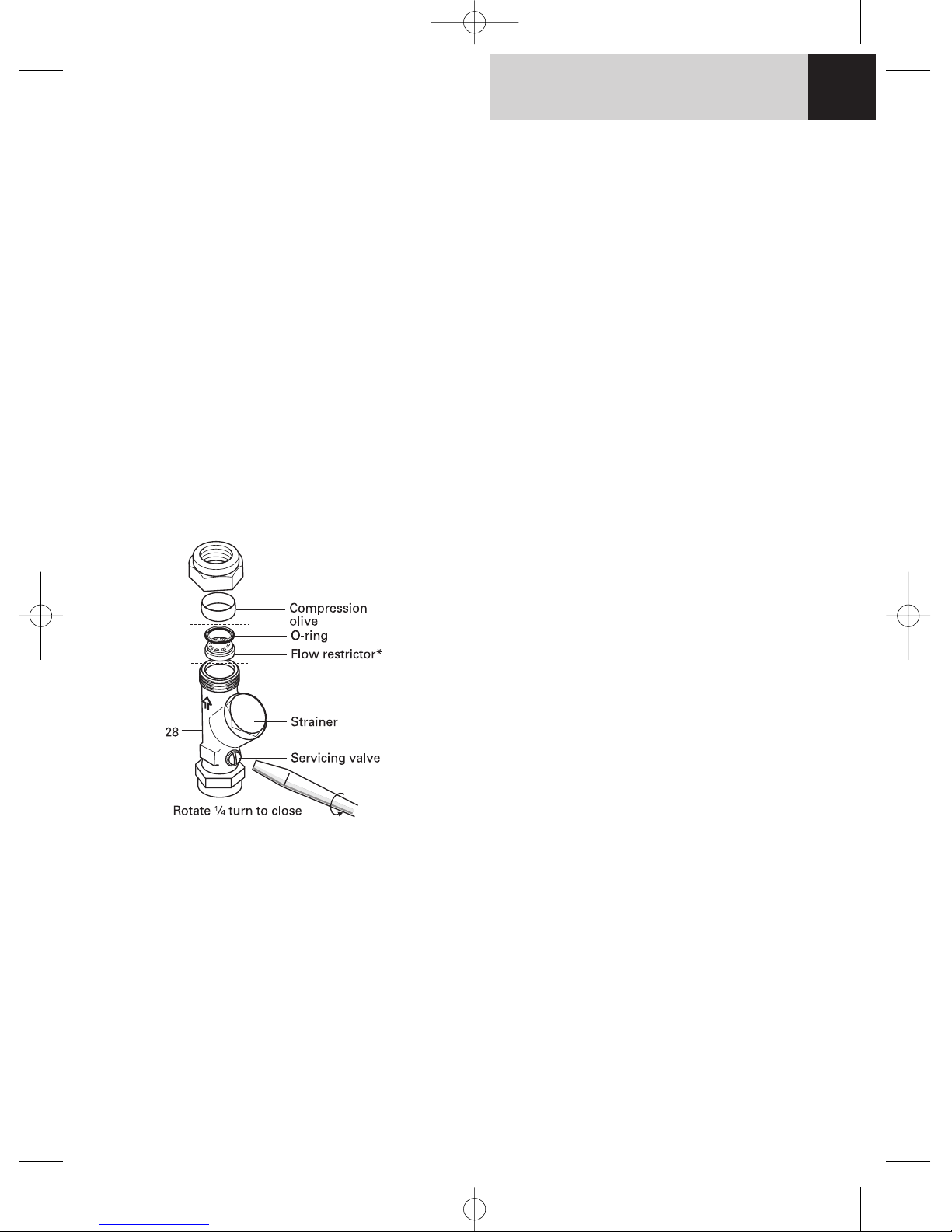

Trevi supply in-line strainers/servicing valves (28)

which include these flow restrictors. These

should be inserted in the downstream side of

the servicing valve as shown on Figure 2. It is

essential that they are positioned the right way

round as shown in the sketch. Remove the compression nut and olive from the outlet side of

the Isolating valve and place the restrictor in the

outlet. Push to the bottom of the recess. Fit Oring in the visible rebate around the edge of the

restrictor and push home until it is fully in the

rebate. Use the tip of a small screwdriver or similar to achieve this.

Servicing valves should be fitted as close as is

practical to the shower valve.

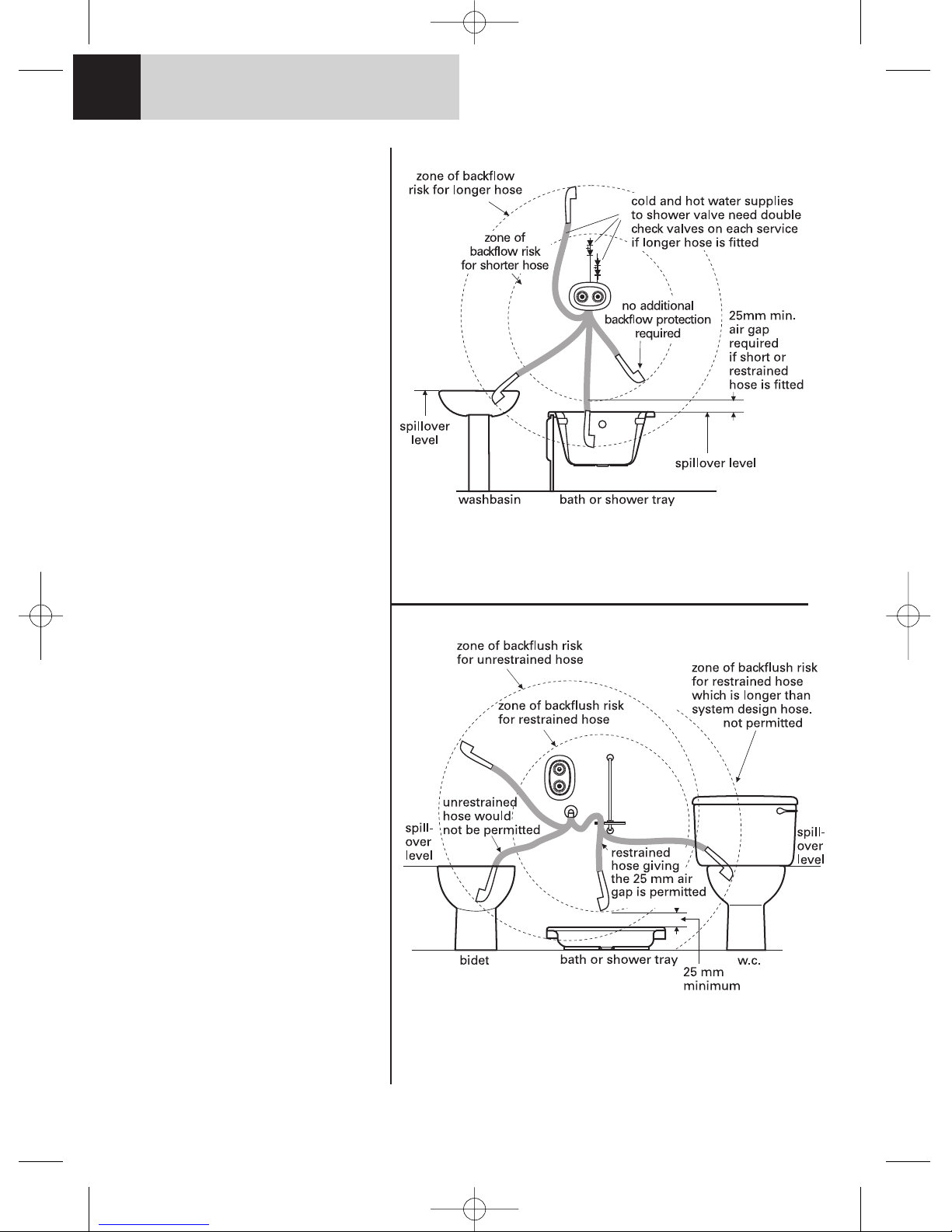

CATEGORIES OF RISK

The water regulations published in 1999* take a

new approach to backflow in that they look at

different categories of risk. The installer must

assess the risk from the various categories of

fluid in adjacent appliances before determining

the level of backflow protection required for a

particular installation. Figures 3 & 4 describe the

protection required in various installations.

CATEGORY 3 RISK

Water in a shower tray, basin or bathtub is

considered to be a fluid category 3 risk which is

a fluid which represents a slight health hazard if

it were to find it’s way back into the supply pipe.

For this reason it must not be possible for any

flexible shower head to be able to enter any adjacent washbasin, bath or shower tray unless

appropriate protection is employed. (See Figure 3).

Figure 2 in-line filter and service valve

showing restrictor

*A guide to the Water Supply (Water fittings) Regulations 1999 and the Water Byelaws 2000, Scotland is

published by WRAS (Water Regulations Advisory Scheme) Fern Close, Pen-y-Fan Industrial Estate, Oakdale, Newport, NP11 3EH.

ISBN 0-9539708-0-9.

WATER REGULATIONS 2

Table 1 Conditions for normal use

Operating pressure range: High Pressure Low Pressure

Maximum static pressure - Bar 10 10

Flow pressure hot and cold - Bar 1 to 5 0.2 to 1

Hot supply temperature - °C 52 to 65 52 to 65

Cold supply temperature - °C 5 to 20 5 to 20

Temperature differential characteristic (TDC) °C 10 10

Valves operating outside of these conditions cannot guaranteed to perform as type 3.

Approval only applies when the valves are installed without the flow restrictors

illustrated in Figure 2.

trevi showers.qxd 04/12/03 13:21 Page 3

If it is desired to allow the hand spray

to be used inside say a bathtub or a

basin it is essential that double check

valves be fitted to the inlet on both

hot and cold supplies to the thermostatic valve. Alternatively single check

valves can be fitted at the inlets and

an additional check valve should be

fitted in the valve outlet.

No check valves need be fitted if

the hand spray is prevented from

reaching closer than 25mm of the

spill over level of any such fixture.

CATEGORY 5 RISK

Water in a Sink, WC or Bidet is

considered to be a fluid category 5

risk which is a fluid which represents

a serious health hazard if it were to

find it’s way back into the supply

pipe. For this reason it must not be

possible for any flexible shower head

to be able to enter any adjacent Sink,

WC or Bidet. If the flexible hose to be

fitted could reach into any such

vessel, the requirements to the

system design are so onerous it is

better not to fit a flexible. Rather, a

fixed overhead showerhead should

be considered. (See Figure 4).

It will also be seen that this risk could

change should the hose be taken out

of the restraining device or should a

longer replacement hose be fitted at

a later date. Installers and householders are advised to take account

of these factors when fitting replacement hoses.

For pumped applications the pipe

supplying the pump must not in

addition supply an ascending spray

bidet.

Figure 3 Illustration of backflow risk from fluid

Category 3 risk

WATER REGULATIONS3

Figure 4 Illustration of backflow risk from fluid

Category 5 risk

trevi showers.qxd 04/12/03 13:21 Page 4

GRAVITY/PUMPED SYSTEMS

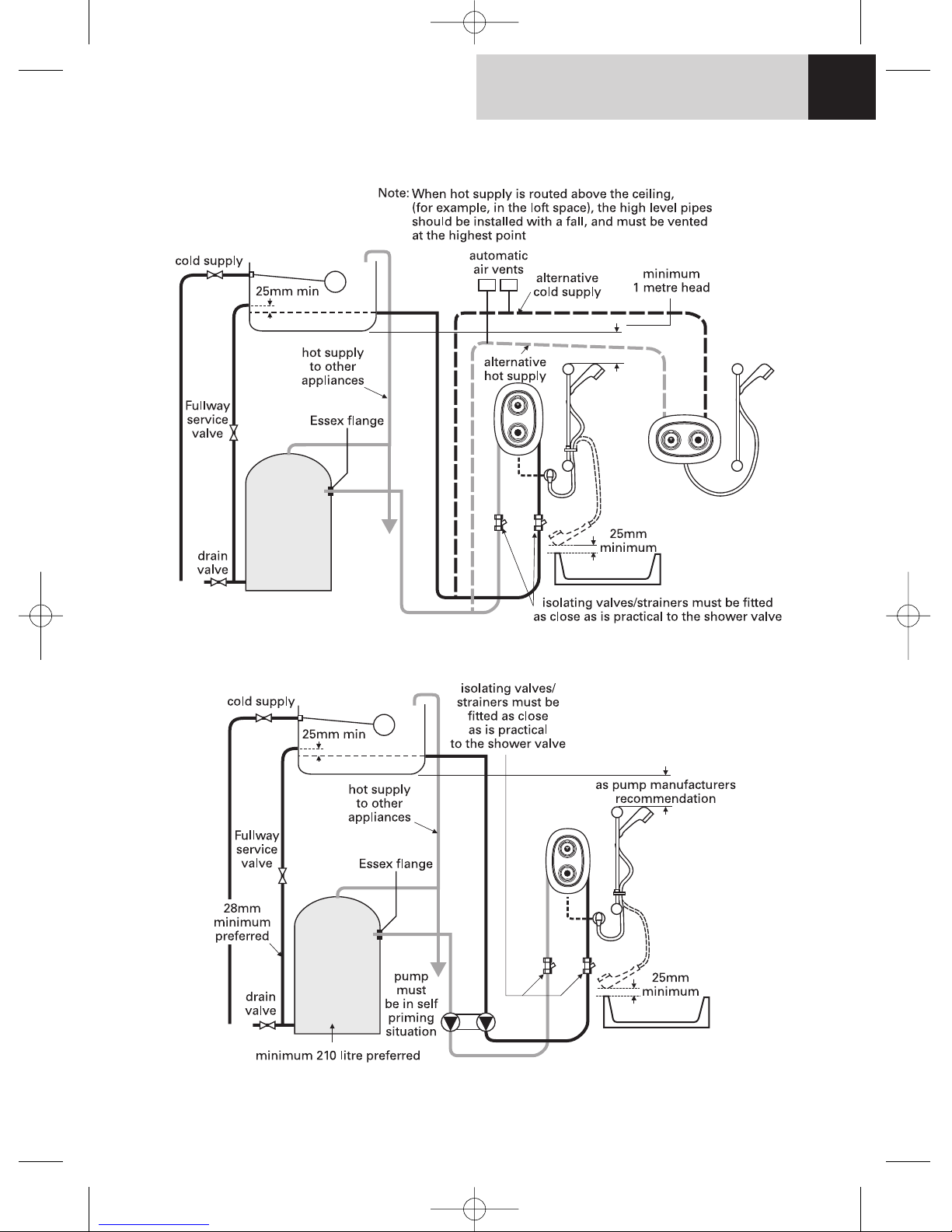

Figure 5 Recommended system layout for gravity applications

Figure 6 Recommended pumped system layout

GRAVITY & PUMPED SYSTEMS 4

trevi showers.qxd 04/12/03 13:21 Page 5

Loading...

Loading...