Page 1

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation, operation

and maintenance of Traulsen:

Rethermalization Oven

Reach-In Model TRT32 and Roll-In Model TRT32R

This Traulsen unit is built to our highest quality standards. We build our Rethermalization Oven this way as a matter

of pride. This philosophy has made Traulsen the leader in commercial refrigeration since 1938. We thank you for your

choice and condence in Traulsen equipment and we know you will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record le with the service department. In the event of any future questions

you may have, please refer to the model and serial number found on the name tag afxed to the unit. Should you need

service, call us on our toll free number, 800-825-8220 between 7:30 am - 4:30 pm CST, Monday thru Friday. You may also

log onto www.traulsen.com for further information. It is our pleasure to help and assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35898 REV. 11/08 P/N 375-60302-00

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Packaging Page 2

b-Electrical Requirements Page 2

c-Installation Codes & Standards Page 2

d-Location Page 2

e-Electrical Connection Page 2

IV. OPERATION

a-Before First Use Page 3

b-Oven Controls Page 3

c-User Adjustable Parameters Page 3

d-Alarms Page 3

e-Testing The Oven Page 4

f-Operating The Oven Page 4

g-Shutdown Page 5

h-Extended Shutdown Page 5

V. MAINTENANCE

a-Interior Page 5

b-Exterior Page 5

c-Door Gasket (s) Page 5

d-Stainless Steel Care - Cleaning Page 5

e-Preserving And Restoring Page 5

f-Heat Tint Page 6

g-Calibration Procedure Page 6

VI. Wiring Diagram Page 7

VII. Trouble Shooting Guide Page 8

VIII. Service Assistance

a-Service Information Page 8

b-Spare Parts Information Page 8

c-Warranty Registration Page 8

IX. Warranties Page 9

X. Service Parts List Page 10

XI. Retherm & Holding Guide `Page 11

Model Serial

Volts Phase Watts

Amps Cycle

I. THE SERIAL TAG

The serial tag is a permanently afxed label on which

is recorded vital electrical data about your Traulsen

product, as well as the model and serial number. This

tag is located in the exterior back of the cabinet by the

electrical connection.

READING THE SERIAL TAG

• Model = The model # of your Traulsen unit

• Serial = The permanent ID# of your Traulsen unit

• Volts = Voltage

• Phase = Phase

• Watts = Wattage

• Amps = Amps

• Cycle = Cycle

• Agency Labels = Designates agency listings

-1-

Page 3

II. RECEIPT INSPECTION

III. INSTALLATION (cont’d)

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost care

has been taken in crating this product to protect against

damage in transit.

You should carefully inspect your unit for damage during

delivery. If damage is detected, you should save all the

crating materials and make note on the carrier’s Bill Of

Lading describing the damage. A freight claim should be

led immediately. If damage is subsequently noted during or immediately after installation, contact our customer

care team to le a freight claim. There is a fteen (15)

day limit to le freight damage with the carrier. Under no

condition may a damaged unit be returned to Traulsen

without rst obtaining written permission (return authorization). You may contact Hobart/Traulsen customer care

at 800-333-7447 to request a return or le a claim.

III. INSTALLATION

III. a - PACKAGING:

Your unit is packed in a cardboard carton which in turn,

is banded to a wooden pallet.

Remove the banding material holding the carton to the

pallet. Remove the cardboard carton and the plastic bag

covering the cabinet and the banding material holding the

cart to the skid. Metal pan slides and shelves are shipped

under the cabinet, in between the casters (careful not to

discard boxes with other packaging material). Remove

items from boxes and install in the interior of cabinet.

Most exterior stainless steel surfaces have a protective

vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is installed

in place of application peel, remove and discard the

covering from all surfaces.

National Electrical Code (ANSI/NFPA No. 70 latest edition) available from the National Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

Vapor Removal from Cooking Equipment, (NFPA-96, latest edition) available from NFPA.

In Canada, the Traulsen oven system must be installed in accordance with the following local codes:

Canadian Electrical Code available from the Canadian Standards

Association, 5060 Spectrum Way, Mississauga, Ontario, Canada

L4W 5N6.

III. d - LOCATION:

For efcient cabinet operation, choose a location that will provide

easy loading and unloading without interfering with the nal assembly of food orders.

The nal location must allow adequate clearances for servicing

and air circulation for proper operation.

III. e - ELECTRICAL CONNECTION :

WARNING

Before connecting the oven to the power source,

verify that the voltage and phase of the power source are identical

to the voltage and phase information on the data plate.

WARNING

Electrical and grounding connections must comply with the applicable portions of the National Electrical code

and/or other local electrical codes.

WARNING

Do not store or use gasoline or other ammable

vapors or liquids in the vicinity of this or any other appliance.

The cord and plug come with a proper strain relief to prevent unit

from moving away from electrical connection.

III. b - ELECTRICAL REQUIREMENTS:

Verify that the power source matches the serial tag electrical data, before the connection is made. A dedicated

circuit is required for all models. See page 1 for serial

tag location and data.

III. c - INSTALLATION CODES & STANDARDS:

In the United States, the Traulsen oven system must

be installed in accordance with the following state and

local codes:

Refer to the wiring diagram in this manual for proper connection.

At the circuit breaker, turn off power to the circuit to which the

oven system is to be connected.

Check that the oven power ON/OFF switch is in the OFF position.

Connect the power cord from the oven system to the electrical

power source.

At the circuit breaker, turn on power to the circuit.

-2-

Page 4

IV. OPERATION

IV. OPERATION (cont’d)

IV. a - BEFORE FIRST USE:

Thoroughly clean the oven before initial use.

Avoid splashing water into upper areas of the cabinet to

NOTE:

prevent damage to electrical components or connections.

Never spray the unit with a hose.

NOTE:

NOTE:

Never use harsh chemicals or abrasive pads to clean the

cabinet.

Remove the interior side racks and the air tunnel from the cabinet.

Take the interior side racks and the air tunnel from the cabinet.

Use a mild soap and water solution to clean these items.

Wring out the cloth so it is only damp and not soaking wet.

Reassemble oven.

IV. b - OVEN CONTROLS:

The operating control is located in the top front panel. The control contains the following displays, knob or push button (from

left to right):

TIME (IN MINUTES) - Displays set time.

RETHERM TEMP - Displays set Retherm Temperature.

HOLD TEMP - Displays set Hold Temperature.

CABINET TEMP (PROGRAM #) - Displays interior temperature,

displays programming number in programming mode.

ADJ/SET - Knob allows Adjustment and Setting changes.

Adjustable Default Adjustment

Parameters Value Ranges

• rth Lo 1000 1000 - 350

• rth Hi 3500 1000 - 350

• hld Lo 1000 1000 - 250

• hld Hi 2500 1000 - 250

• CAL OffSEt 00 -300 - +30

rth Lo

This is the RETHERM temperature low limit. It sets the

lowest possible limit for the RETHERM temperature.

Adjustments during normal operation may not be made

lower than this parameter setting.

rth Hi

This is the RETHERM temperature high limit. It sets the

highest possible limit for the RETHERM temperature.

Adjustments during normal operation may not be made

higher than this parameter setting.

NOTE:

Some local codes require the use of a ventilation

hood for equipment operating in excess of 2500 degrees

F. Many will allow operation of Rethermalization ovens

at lower temperatures. Please modify this parameter if

needed to meet local codes.

hld Lo

This is the HOLD temperature low limit. It sets the lowest

possible limit for the HOLD temperature. Adjustments

during normal operation may not be made lower than

this parameter setting.

hld Hi

This is the HOLD temperature high limit. It sets the highest possible limit for the HOLD temperature. Adjustments

during normal operation may not be made higher than

this parameter setting.

0

0

0

0

0

START - Button will start the operation/pre-set settings.

IV. c - USER ADJUSTABLE PARAMETERS:

The user’s parameter set menu is entered by turning the oven on

while pushing the START button. The START button must remain

depressed for 4 seconds after power has been applied. The user’s

parameter settings menu is then active. There are 5 adjustable

parameters. Rotate ADJ/SET to change the currently displayed

parameter. Push ADJ/SET to advance to the next parameter. Push

START to accept and save the current parameter settings and

exit the parameter set menu. Normal oven operation is resumed

with the new settings.

-3-

CAL OFFSet

This parameter is a calibration offset and is used in conjunction with a precision thermometer. The cal offset may

be set from -30 to 30 to calibrate the oven temperature

regulation and display.

IV. d - ALARMS:

The oven reports an over temperature condition any time

the oven temperature reaches 400° or higher.

Page 5

IV. OPERATION (cont’d)

IV. OPERATION (cont’d)

When this condition exists the oven will sound an audible alarm by

emitting a triple beep (three quick short beeps) every 2 seconds

and it will ash the message “Err too Hot” on the display to alert

nearby staff. The audible alarm may be temporarily canceled FOR

3 MINUTES by pushing ADJ/SET. After 3 minutes have expired

the oven will begin beeping again. The error message on the

display cannot be canceled. The proper action when this alarm

is present is to turn the oven off and call for service.

IV. e - TESTING THE OVEN:

Before using the oven for the rst time, verify that the oven operates normally.

Check that the oven is connected to the correct power source.

Turn the oven ON at the power switch.

Use the controls to set the HOLDING TEMPERATURE to 1400F.

Check that the oven circulating fans are running.

Check that the heaters ON indicator is lit.

Check that the oven is warming to the displayed holding temperature.

NOTE:

The cooling fans may not operate when the oven is rst

turned on. The cooling fans operate only when the thermostat

to which they are connected requires it.

Set the TIME to 2 hours, Set the RETHERM TEMP to 2500, push

the START BUTTON, check the interior rear of the oven cavity to

determine that the oven is heating.

Push the ADJ/SET knob to cancel the cycle, set the TIME to 0,

set the HOLD TEMP to 2500F, push the START BUTTON.

Check that the RETHERM TEMP display has been blanked and

the HOLD TEMP display is lighted.

Check the interior rear of the oven to ensure that the oven is

heating. If all the functions perform satisfactory, the oven is

ready for operation.

IV. f - OPERATING THE OVEN:

Main Features

Flexibility-Manual setting of the parameters RETHERM TIME,

HOLD TEMP and RETHERM TEMP.

Quick cycle start-Press START at any time during parameter

entry to execute a cycle with the existing parameters displayed.

The only exception to this is during programming of the stored

settings (1 – 9).

Quick cycle abort-Press the ADJ/SET knob at any time during

the retherm cycle to return to the Idle State.

-4-

User programming of the 9 most used cycle parameters.

Fast recall and cycle start of the pre-programmed cycle

parameters.

Very fast recall and cycle start of pre-programmed cycle

#1 parameters.

Manual Setting Features

From the IDLE STATE (TIME is blinking) rotate the ADJ/

SET knob to adjust the retherm time. Press START to accept the currently displayed settings and begin the cycle

or press ADJ/SET to set the currently displayed time and

advance to the RETHERM TEMP setting. RETHERM is

blinking. Rotate the ADJ/SET knob to adjust the retherm

temperature. Press START to begin the cycle or press

ADJ/SET to set the retherm temperature and advance

to the HOLD TEMP setting. HOLD is blinking. Rotate

ADJ/SET to adjust the hold temperature. Press START

to execute the cycle or press ADJ/SET to re-adjust the

three parameters. After a cycle is started press ADJ/SET

at any time to abort the cycle and return to idle.

Pre-Programmed Cycle Feature

From the IDLE STATE (Time Blinking) press and hold

ADJ/SET for 3 seconds. TIME no longer blinks. The

current temperature display TEMP displays “P-1” and

is blinking. TIME, RETHERM and HOLD display the pa-

rameters pre programmed for AUTO CYCLE #1. Press

START to execute a retherm cycle with these parameters

or rotate the ADJ/SET knob to select one of the other

pre-programmed cycle settings (0–9) then press START

. After a cycle is started press ADJ/SET at any time to

abort the cycle and return to idle.

Programming The Pre-Programmed Cycles

From the IDLE STATE (Time Blinking) press and hold

ADJ/SET for 3 seconds. TIME no longer blinks. The

current temperature display TEMP displays “P-1” and

is blinking. If necessary rotate ADJ/SET to the desired

pre-programmed cycle “P-x”. Press and hold ADJ/SET

for 3 seconds. P-x no longer blinks and TIME is blinking.

Rotate ADJ/SET to adjust the retherm time and press

ADJ/SET to accept the retherm time. RETHERM is blinking. Rotate ADJ/SET to adjust the retherm temperature

and press ADJ/SET to accept the retherm temperature.

HOLD is blinking. Rotate ADJ/SET to adjust the hold

temperature and press ADJ/SET to accept the hold temperature. P-x has been updated to the currently displayed

settings and P-x is again blinking. To program another

location rotate ADJ/SET to the desired cycle # then press

and hold ADJ/SET for 3 seconds. To return to IDLE press

and release ADJ/SET. To start a cycle with the currently

displayed settings press START.

Fast cycle Start Using Pre-programmed Setting #1

Press ADJ/SET. While holding ADJ/SET press START.

(see page 11 for Retherm & Holding Guide)

Page 6

IV. OPERATION (cont’d)

V. MAINTENANCE (cont’d)

IV. g - SHUTDOWN:

Turn the Power ON/OFF Switch to OFF position.

IV. h - EXTENDED SHUTDOWN:

Perform the following procedure to shut down the oven for an

extended period of time.

Perform shutdown procedure. Unplug the unit.

Thoroughly clean the oven according to the cleaning procedures in this manual.

Leave the door (s) slightly open to allow ventilation and preservation of the gasket (s).

V. MAINTENANCE

V. a - INTERIOR:

Wash the inside of the compartment with a solution of mild

detergent and warm water.

Rinse thoroughly with warm water.

Wipe dry.

This should be performed based upon a schedule predetermined for your operation.

NOTE:

Leave the compartment door (s) slightly open

(unlatched) when the unit is not in use. Keeping the

gasket under pressure when the unit is not in use can

cause a permanent deformation of the gasket and reduce

its serviceable life.

V. d - STAINLESS STEEL CARE - CLEANING:

Stainless steel contains 70-80% iron, which will rust if

not properly maintained. It also contains 12-30% chromium, which forms an invisible passive, protective lm

that shields against corrosion. If the lm remains intact,

the stainless steel will remain intact.

However, if the lm is damaged, the stainless steel can

break down and rust. To prevent stainless steel breakdown, follow these steps:

Never use any metal tools. Scrappers, les, wire brushes

or scouring pads (except for stainless steel scouring

pads), will mar the surface.

Never use steel wool, which will leave behind particles

that rust.

Never use acid based or chloride-containing cleaning

solutions, which will break down the protective lm.

Never rub in a circular motion.

V. b - EXTERIOR:

Refer to “Stainless Steel Care-Cleaning”.

V. c - Door Gasket (s):

At least once a week, thoroughly clean the gasket sealing

surfaced of the oven door (s) to remove food acids; this action

will ensure maximum gasket life.

NOTE:

Do not use any solvents or sharp instruments to clean

the gasket (s).

Wash the gasket (s) with a cloth moistened with a solution of

mild detergent and warm water.

Rinse with a fresh cloth moistened in warm water to remove

all traces of detergent.

Wipe dry with a clean dry cloth.

Never apply food oils or petroleum lubricants directly to the

gasket (s); petroleum-based solvents and lubricants will reduce

gasket life.

Leaking and/or damaged or gaskets (s) cause inefcient and

unsatisfactory operation of the unit. Replace any door gasket

(s) that are damage or deformed.

Never leave any food products or salt on the surface.

Many foods are acidic. Salt contains chloride.

For routine cleaning, use warm water, mild soap or detergent and a sponge or soft cloth.

For heavy-duty cleaning, use warm water a de greaser

and a plastic, stainless steel or scotch-brite pad.

Always rinse thoroughly. Always rub gently in the direction of the steel grain.

V. e - PRESERVING AND RESTORING:

Special stainless steel polishing cleaners can preserve

and restore the protective lm.

Preserve the life of stainless steel with a regular application of a high quality stainless steel polishing cleaner as

a nal step to daily cleaning.

If signs of breakdown appear, restore the stainless steel

surface. First, thoroughly clean, rinse and dry surface.

Then, on a daily basis, apply a high-quality stainless steel

polish according to manufacturer’s instructions.

-5-

Page 7

V. MAINTENANCE (cont’d)

V. f - HEAT TINT:

Darkened areas, called “heat tint”, may appear on stainless steel exposed to excessive heat, which causes the

protective lm to thicken. It is unsightly but is not a sign

of permanent damage.

To remove heat tint, follow the routine cleaning procedure.

Stubborn heat tint will require heavy-duty cleaning.

V. g - CALIBRATION PROCEDURE:

All units are tested and calibrated to run precisely as

designed prior to shipment. However, if over time there

becomes a need to calibrate or adjust the sensors please

utilize the procedure noted below.

First, set the CAL OFF Set parameter to 0 using the

procedure described under User Adjustable Parameters.

Place a precision thermometer inside the oven’s cavity.

Turn on the oven and adjust the HOLD Temperature to

160 Degrees. When the oven has reached the set temperature wait another 10 minutes for temperatures to

become homogenous inside the oven, read the precision

thermometer and compare it to the oven’s temperature

display. If the oven’s current temperature display is

greater than the precision thermometer reading, the

CAL OFF Set must be set negative (-) the number of degrees that the oven display is higher than the precision

thermometer reading. If the oven’s current temperature

display is lower, the CAL OFF Set must be set positive

the number of degrees that the oven display is lower than

the precision thermometer reading.

EXAMPLE

The oven’s current temperature display after reaching 160

and a 10 minute wait is 161. The precision thermometer

reading is 164. The CAL OFF Set parameter should be

set to 3.

EXAMPLE

The oven’s current temperature display after reaching 160

and a 10 minute wait is 160. The precision thermometer

reading is 156. The CAL OFF Set parameter should be

set to -4.

-6-

Page 8

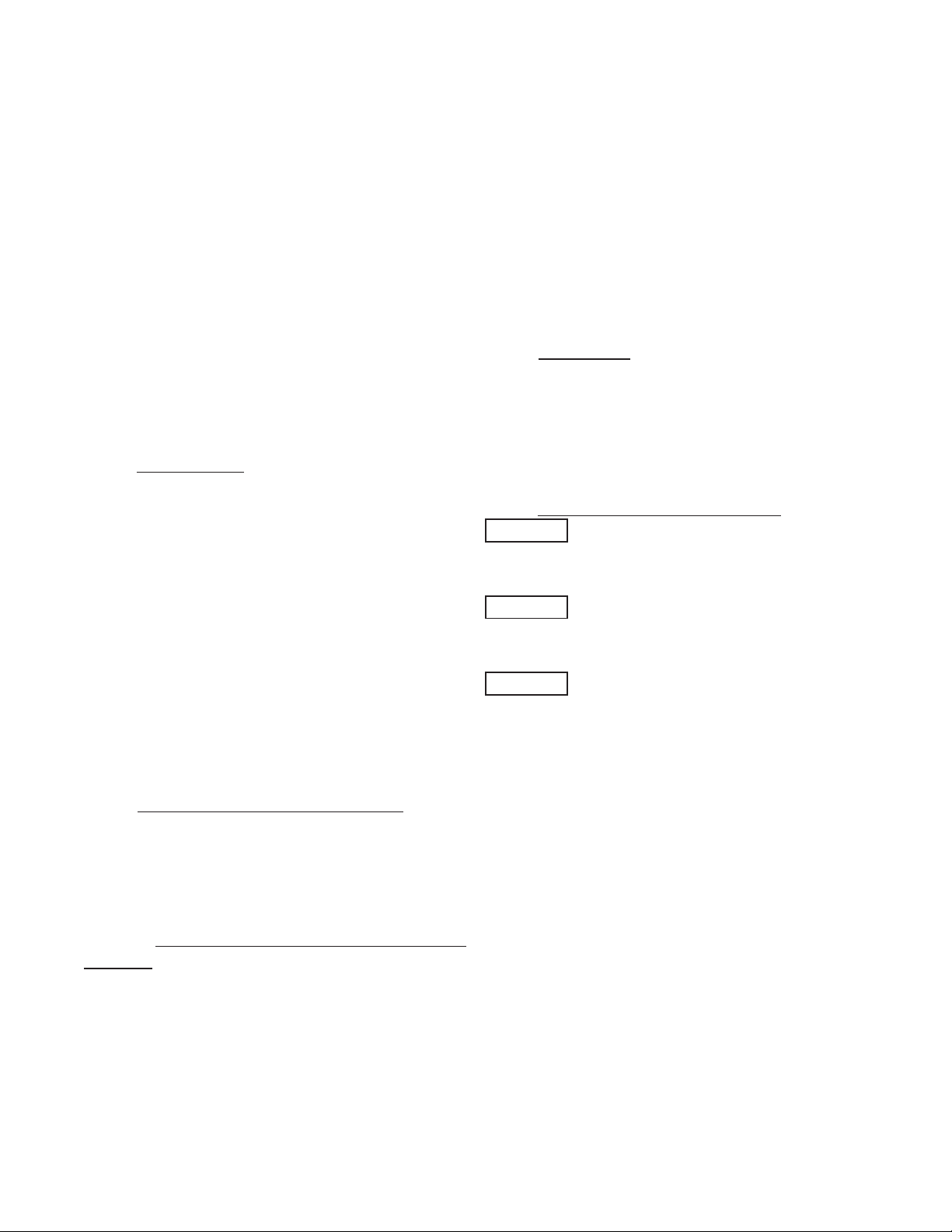

VI. WIRING DIAGRAM

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

CONTACTOR

DISTRIBUTION BLOCK

HEATING

ELEMENT

HEATING

ELEMENT

HEATING

ELEMENT

HEATING

ELEMENT

L2

L1

L1L2

POWER SWITCH

REAR VIEW

FUSE 3A

COOLING FAN

THERMOSTAT

FUSE 3A

IN LINE

TAP

IN LINE

TAP

IN LINE

TAP

12V CLASS II

TRANSFORMER

TERMINAL BLOCK TERMINAL BLOCK

CONTROL AND DISPLAY BOARD

J1-1 J2-1

3 2

START SWITCH

1

1 2 3 4

J4

HI - LIMIT

12VDC

HEATER RELAY

1

2

J3

C

NO NC

BLACK

BLACK

YELLOW

YELLOW

1 2

3 4

6 CONDUCTOR RIBBON

J8

SHAFT ENCODER

T-

T+

2

1

AMP

640250-2

CONTACT PINS

AMP 640252-1 or 770476-1

QTY = 4

QTY = 2

1 2 3 4

AMP

640250-4

# = .25" FASTON, 6 TOTAL

# #

# #

# #

$ $

$ = .125" FASTON, 2 TOTAL

COILCOIL+

RED

YELLOW

K TYPE

THERMOCOUPLE,

GROUNDED

379-60486-00 1

RT-32 WIRING DIAGRAM, 208-240v, 10, 60Hz

Traulsen & Company

4401 Blue Mound Rd., Fort Worth, TX 76106

B

1 12Thursday, July 10, 2008

Title

Size Document Number Rev

Date: Sheet

of

WHITE

BLACK

GREEN

COOLING FAN 1

BLOWER FANBLOWER FAN

COOLING FAN 2

BLOWER FAN

+

.1uF/600V

BLOWER FAN160 OHM

Refer to the wiring diagram below for any service work performed by a qualied technician.

-7-

Page 9

VII. TROUBLE SHOOTING GUIDE

PROBLEM POSSIBLE CAUSE

1. Oven NOT operating. a. Power ON/OFF switch is not on?

b. Oven is not plugged into power source.

c. Fuse is blown.

2. Oven Compartment is NOT heating and

blower motor is operating with power switch on.

3. Oven is warming but cooling fans are NOT

operating.

4. Oven compartment IS NOT heating and blow-

er motor IS operating with power switch ON.

a. Defective connection.

b. Defective wiring.

0

a. Oven is below 150

b. Defective connection or wiring.

c. Defective Fan.

d. Defective Temperature Probe.

a. Oven is below 400F.

b. Missing or defective thermocouple.

c. Defective High-Limit Thermostat.

d. Defective Heating Element.

F.

VIII. SERVICE ASSISTANCE

VIII. a - SERVICE INFORMATION:

If after checking the items in the trouble shooting guide, and the unit is still not operating properly, please contact an authorized Traulsen service agent. You may obtain the name of a service agent from the Tech Service page of our web site:

www.traulsen.com. If service is not satisfactory, please contact our in-house service department at:

Traulsen

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

VIII. b - SPARE PARTS INFORMATION:

To purchase replacement parts or to speak to service support for Traulsen and most Hobart Refrigeration units please

contact our Ft. Worth facility by phone at 800-825-8220 or fax to 817-740-6748 (parts) or 817-740-6757 (service).

To source parts locally follow instructions below for nearest location:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

3. Select Locate Parts (left side of screen)

4. Click on State desired

To source service support locally follow instructions below for nearest authorized service agent:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

4. Click on State desired

VIII. c - WARRANTY REGISTRATION:

The warranties for your new Traulsen unit may be registered with us by contacting our Ft. Worth facility by phone at 800825-8220 or you may register on line:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

3. Select Warranty Registration Form (left side of screen)

4. Fill out information requested

5. Select Submit to complete unit warranty registration

Note: When calling for spare parts or service support, please make sure you have model and serial number of unit available.

-8-

Page 10

IX. WARRANTIES

STANDARD DOMESTIC WARRANTY

TRAULSEN warrants new equipment to the original purchaser, when installed within the United States against defective

material and workmanship for one (1) year from the date of original installation. Under this warranty, TRAULSEN, will repair

or replace, at its option, including service and labor, all parts found to be defective and subject to this warranty.

Lifetime parts warranty on door hinges and door latch.

This warranty does not apply to damage resulting from re, water, burglary, accident, abuse, misuse, transit, acts of God,

terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

THERE ARE NO ORAL, STATUTORY OR IMPLIED WARRANTIES APPLICABLE TO TRAULSEN, INCLUDING BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE WHICH

EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY

FOR CONSEQUENTIAL OR SPECIAL DAMAGES, GROWING OUT OF OR WITH RESPECT TO THE EQUIPMENT OR ITS

SALE, OPERATION OR USE, AND TRAULSEN NEITHER ASSUMES NOR AUTHORIZES ANYONE ELSE TO ASSUME FOR

IT ANY OBLIGATION OR LIABILITY IN CONNECTION WITH THE EQUIPMENT OR ITS SALE, OPERATION OR USE OTHER

THAN AS STATED HEREIN.

INTERNATIONAL COMMERCIAL WARRANTY

TRAULSEN warrants to the original purchaser, new equipment to be manufactured and sold by, it to be free from defects in material and workmanship under

normal use and service for a period of one (1) year from date of shipment. Under this warranty, TRAULSEN will reimburse the purchaser for the replacement of

any part of said equipment, which then proves to be defective. This warranty does not apply to damage resulting from re, water, burglary, accident, abuse,

misuse, transit, acts of God, terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date of original installation not to exceed Fifteen (15)

months from date of shipment from factory, TRAULSEN:

will replace, F.O.B. factory, any defective parts normally subject to warranty.

will not cover the cost of packing, freight or labor such costs being the sole responsibility of the dealer/end user.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND CONSTITUTES

TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON REMOTE MODELS.

(for Canadian warranties see domestic US warranty)

-9-

Page 11

X. SERVICE PARTS LIST

DESCRIPTION PART NUMBER

BLOCK TERMINAL (INTERNAL DISTRIBUTION) AD-206-2000-0

BLOCK, TERMINAL (POWER CONNECT) AD-206-1000-0

BOLT, RETAINING RACK (PACK OF 4) WP-305

CONTACTOR, 3POLE-50AMP(208/240V) AD-260-6000-COR

CORD, POWER 208/240V AD-161-3000-0

ELEMENT, OVEN 208/240V/1900W AD-280-1000-0

FAN, COOLING 208/240V AD-305-2000-0

FUSE, 3 AMP AD-207-0000-0

GASKET, DOOR (PER FOOT) WP-302

GRATE, RETURN AIR AD-266-0000-0

GUARD, FAN AD-253-0000-0

CASTER, RIGID WP-114-6R

CASTER, SWIVEL WITH BRAKES WP-114-6S

SHELF, WIRE WP-019

HANDLE, SIDE AD-307-1000-0

HINGE, DOOR AD-306-1000-0

HOLDER, FUSE AD-210-0000-0

HOLDER, PROBE (TEMPERATURE) 1/4” AD-150-1

LATCH, DOOR CHROME WP-215

MOTOR, BLOWER (208/240V) AD-301-2000-0

RACK, MEAT (INSERT FOR SHEET PAN 18”X26”) AD-400

STRAIN RELIEF, POWER CORD AD-252-2000-00

SUPPRESSER, ORANGE (W/RESISTOR) AD-135-0000-0

SWITCH, ROCKER AD-213

THERMOSTAT, COOLING FAN W/BRACKET AD-251-0000-0

THERMOSTAT, HIGH-LIMIT AD-241-0000-0

VENT, SCREEN AD-253-10000-0

PRINTED CIRCUIT BOARD ASSEMBLY 950-60420-00

ENCODER 336-10148-00

TRANSFORMER 337-60169-03

RELAY 336-10149-00

PUSH BUTTON 337-60425-00

CONTROL KNOB 336-10147-01

STAND OFFS FOR BOARD MOUNTING (6-6/32X.250) 351-60059-250

-10-

Page 12

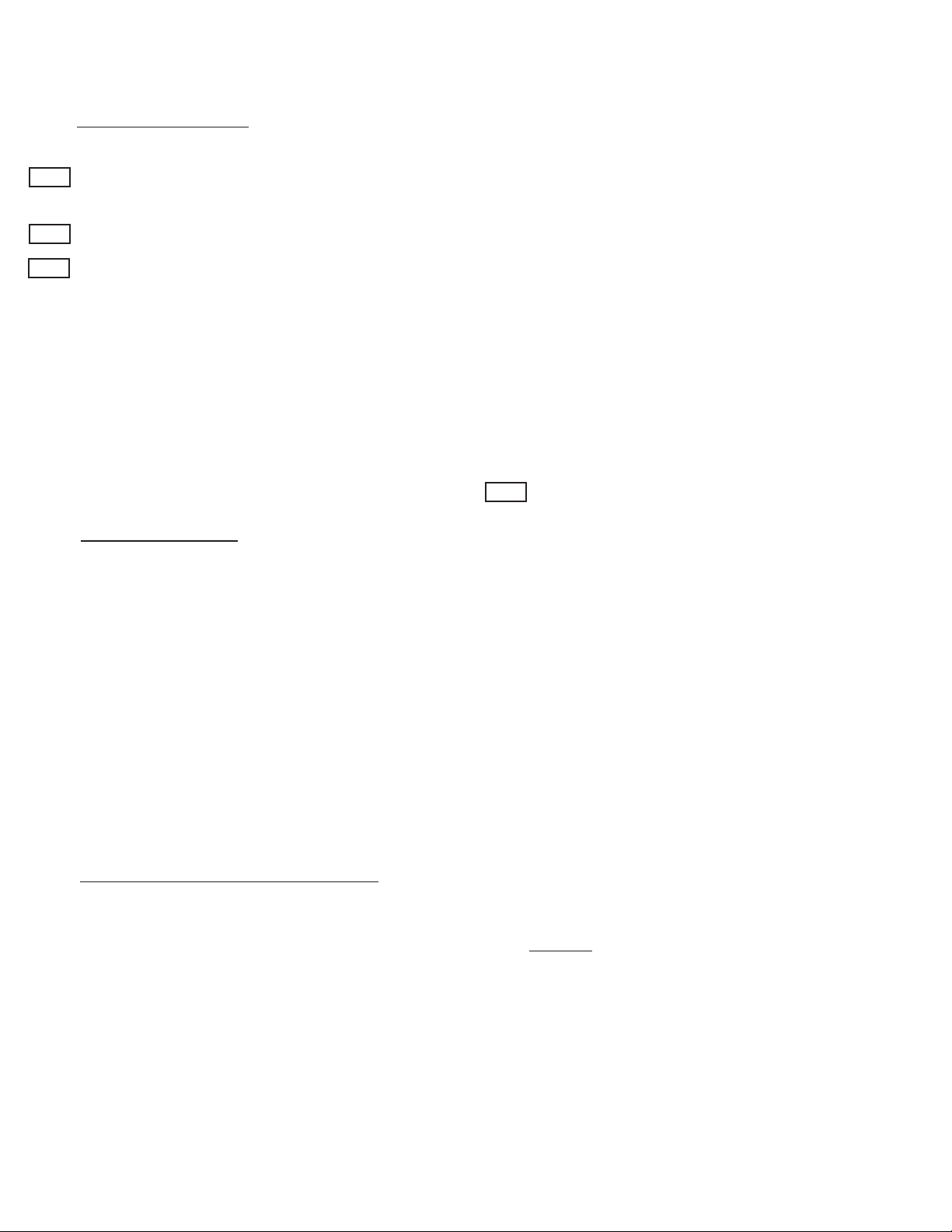

Max.

Cook Cook Hold Internal Loading Guidelines

Product Details/Weight Time Temp Hold Time Temp Temp 2 per shelf on 4 shelves

Prime Rib USDA #109, 20 lbs. 5 hrs 225°F4 hrs min 140°F 135°F3 per shelf on 6 shelves

Boneless Ribeye USDA #112A, 12 lbs. 3 hrs 225°F4 hrs min 140°F 135°F2 per shelf on 4 shelves

Top Round USDA #168, 18-20 lbs. 4-1/2-5 hrs 225°F4 hrs min 140°F 130°F2 per shelf on 4 shelves

Steamship Round USDA #160, 60 lbs. 10 hrs 225°F4 hrs min 140°F 130°F1 per shelf on 2 shelves

Bottom Round USDA #170, 20 lbs. 5 hrs 225°F 8 hrs 140°F 130°F2 per shelf on 4 shelves

Boneless Strip Loin USDA #180, 12 lbs. 3 hrs 225°F 4 hrs 140°F 130°F3 per shelf on 6 shelves

Whole Tenderloin USDA #190, 4-6 lbs. 2-1/2 hrs 225°F2 hrs min 140°F 130°F4 per shelf on 8 shelves

Top Sirloin Butt USDA #184, 12-14 lbs. 3 hrs 225°F4 hrs min 140°F 135°F3 per shelf on 4 shelves

Beef Short Ribs 10 lbs. 4 hrs 225°F4 hrs min 155°F 165°F1 per shelf on 6 shelves

Cubed Steaks 10 lbs. 4 hrs 225°F3 hrs min 160°F 180°F1 per shelf on 6 shelves

Beef Back Ribs 30 lbs. 5 hrs 225°F 4 hrs 160°F 175°F4 per shelf on 6 shelves

Beef Stew 10 lbs. (stew meat) 4 hrs 225°F 6 hrs

1

150°F 140°F1 per shelf on 6 shelves

Corned Beef 12 lbs. 4 hrs 250°F4 hrs min 150°F 165°F2 per shelf on 6 shelves

Frozen Burgers 4-5 oz. 45 min 225°F4 hrs max 150°F 165°F 24 per shelf on 14 shelves

Fresh Ham

2

12 lbs. 6 hrs 250°F 4 hrs 160°F 165°F4 per shelf on 4 shelves

Cooked Cured Ham 12 lbs. 4 hrs 250°F 4 hrs 160°F 135°F2 per shelf on 4 shelves

Pork Back Ribs USDA #422, 10 lbs. 4 hrs 250°F 3 hrs 160°F 175°F36 per shelf on 8 shelves

Pork Spare Ribs 30 lbs. 4 hrs 255°F 4 hrs 160°F 175°F35 per shelf on 6 shelves

Fresh Sausages 10 lbs. 2 hrs 225°F5 hrs max 160°F 175°F 52 per shelf on 6 shelves

Pre-Cooked Sausage 10 lbs. 1-3/4 hrs 250°F5 hrs max 160°F 160°F 52 per shelf on 8 shelves

Roast Suckling Pig 30 lbs. 6 hrs 250°F3 hrs min 160°F 170°F41 per shelf on 4 shelves

Bacon 40 min 350°F n/a n/a n/a 33 per shelf on 14 shelves

Chicken Wings 10 lbs. 45 min 350°F n/a 150°F 165°F 80 per shelf on 8 shelves

Chicken Pieces 8 pcs. per 3-1/2 lb. bird 2-1/4 hrs 250°F 1 hr max 150°F 170°F8 per shelf on 6 shelves

Whole Chickens 3-1/4 lbs. 2-1/2 hrs 250°F5 hrs max 150°F 170°F56 per shelf on 6 shelves

Rottisserie Chicken 2-3/4 lbs. 2-1/2 hrs 375°F 1 hr max 160°F 170°F36 per shelf on 6 shelves

Whole Turkeys 20 lbs. 5 hrs 250°F5 hrs max 170°F 170°F62 per shelf on 4 shelves

Turkey Breast

7

10 lbs. 4 hrs 250°F 1 hr 160°F 160°F33 per shelf on 4 shelves

Roast Duckling 4 lbs. 1-1/2 hrs 350°F3 hrs max 160°F 170°F36 per shelf on 6 shelves

Rack of Lamb 10 lbs. 3-1/2 hrs 250°F3 hrs max 140°F 140°F 14 per shelf on 8 shelves

Braised Lamb Shanks 4 hrs 250°F4 hrs min 160°F 180°F31 per shelf on 8 shelves

Fish Filets 4-6 oz. 40 min 225°F4 hrs max 160°F 160°F 32 per shelf on 8 shelves

Sheet Cakes 18” x 26” 1-1/4 hrs 300°F n/a n/a 190°F1 per shelf on 8 shelves

Kaiser Rolls 35 min 350°F n/a n/a 190°F 15 per shelf on 8 shelves

Italian Bread 40 min 350°F n/a n/a 190°F6 per shelf on 8 shelves

Cookies Various Types 20-35 min 325°F n/a n/a n/a 24 per shelf on 14 shelves

Pies with Top Crust Various Types, 9” dia. 1-1/4 hrs 350°F n/a n/a n/a 3 per shelf on 8 shelves

Dinner Rolls 30 min 350°F n/a n/a n/a 42 per shelf on 8 shelves

Clear Soups 12” x 20” Pans 3 hrs 250°F Overnight 160°F 175°F1 per shelf on 6 shelves

Frozen Pizzas 18” diameter 40 min 350°F2 hrs max 160°F 175°F62 per shelf on 8 shelves

Baked Potatoes 12” x 20” Pans 1-1/4 hr 350°F 1-1/2 hrs 170°F 200°F 30 per shelf on 8 shelves

Rice 1 Quart Dry 2 hrs 250°F 18 hrs max 150°F 160°F1 per shelf on 8 shelves

Frozen Entrees 1 Quart Dry 3 hrs 250

°

F Overnight 160°F 165°F2 per shelf on 8 shelves

1= Overnight 2= Short Shank #402 or Bone Rolled Tied #402B 3= Internal holding temp 150°F 4= Internal holding temp 155°F

5= Internal holding temp 140°F 6= Internal holding temp 160°F 7= Bone In

Traulsen’s Guide to Retherm & Holding

The below information is intended for use as a general reference only when using the Traulsen retherm oven. Please note

that as products vary, as well as other elements such as altitude, so shall actual cooking times and temperatures. These

should be adjusted as needed based upon your actual experience, and finished product temperatures should be verified

manually prior to serving in order to insure food safety.

© Traulsen 2008 - All Rights Reserved. Revised 10/08

NOTE: For preheating please allow 1-minute for every ten degrees needed above current displayed cabinet temperature.

XI. Retherm & Holding Guide

-11-

Page 13

Notes

Page 14

Notes

Page 15

Notes

Page 16

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen

4401 Blue Moud Road Fort Worth, TX 76106

Phone (800) 825-8220 Fax (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

© 2008 Traulsen - All Rights Reserved

Loading...

Loading...