Traulsen Transport Cart Service Manual

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation, operation

and maintenance of Traulsen:

Heated Banquet & Transport Carts

This Traulsen unit is built to our highest quality standards. We build our heated carts this way as a matter of

pride. This philosophy has made Traulsen the leader in commercial refrigeration since 1938. We thank you for

your choice and condence in Traulsen equipment and we know you will receive many years of utility from this

equipment.

All Traulsen units are placed on a permanent record le with the service department. In the event of any future

questions you may have, please refer to the model and serial number found on the name tag afxed to the unit.

Should you need service, call us on our toll free number, 800-825-8220 between 7:30 am - 4:30 pm CST, Monday thru Friday. You may also log onto www.traulsen.com for further information. It is our pleasure to help and

assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35896 REV. 3/09 P/N 375-60299-00

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Packaging Page 2

b-Electrical Requirements Page 2

IV. OPERATION-STANDARD

a-Control Panel Page 2

b-Thermostat Page 2

c- Thermometer Page 2

V. OPERATION-ELECTRONIC/FORCED AIR

a-Control Panel Page 2

b- Temperature Controller Page 3

c- Determining Previous Holding Temperature Page 3

d-Modifying Previous Holding Temperature Page 3

VI. CLEANING THE CABINET Page 3

VII. WIRING DIAGRAMS-STANDARD

a-Standard Page 4

VIII. WIRING DIAGRAMS-ELECTRONIC/FORCED AIR

a-Electronic/Forced Air Page 4

IX. TROUBLE SHOOTING GUIDE Page 5

X. SERVICE ASSISTANCE

a-Service Information Page 5

b-Spare Parts Information Page 5

c-Warranty Registration Page 5

XI. WARRANTIES Page 6

XII. SERVICE PARTS LIST

a-Banquet Cart Page 7

b-Transport Cart Page 8

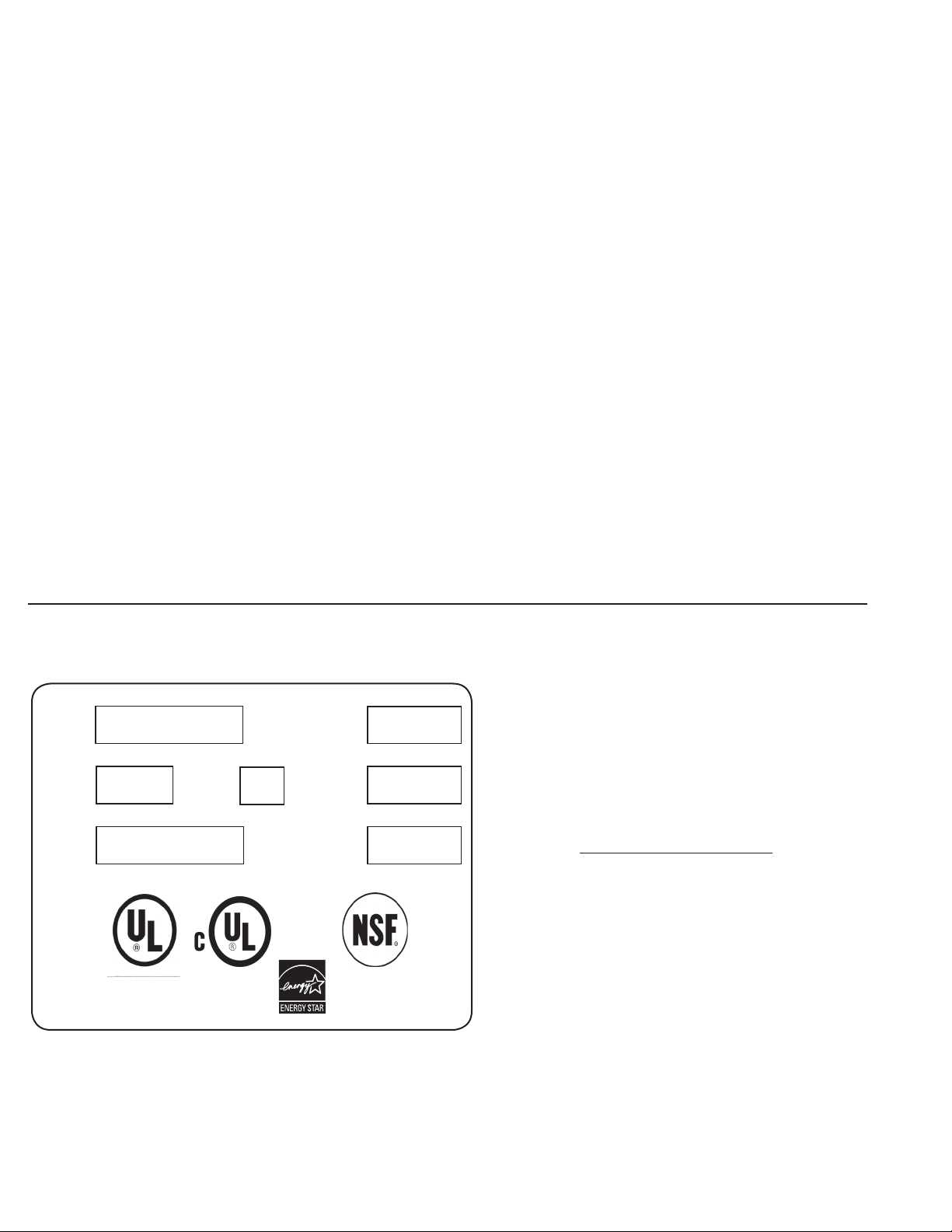

Model Serial

Volts Phase Watts

Amps Cycle

I. THE SERIAL TAG

The serial tag is a permanently afxed label on which is

recorded vital electrical data about your Traulsen product, as well as the model and serial number. This tag is

located in the exterior back top corner on all standard

banquet and transport cart models.

READING THE SERIAL TAG

• Model = The model # of your Traulsen unit

• Serial = The permanent ID# of your Traulsen unit

• Volts = Voltage

• Phase = Phase

• Watts = Wattage

• Amps = Amps

• Cycle = Cycle

• Agency Labels = Designates agency listings

-1-

II. RECEIPT INSPECTION

IV. OPERATION-STANDARD

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost care

has been taken in crating this product to protect against

damage in transit.

You should carefully inspect your unit for damage during

delivery. If damage is detected, you should save all the

crating materials and make note on the carrier’s Bill Of

Lading describing the damage. A freight claim should be

led immediately. If damage is subsequently noted during or immediately after installation, contact our customer

care team to le a freight claim. There is a fteen (15)

day limit to le freight damage with the carrier. Under no

condition may a damaged unit be returned to Traulsen

without rst obtaining written permission (return authorization). You may contact Hobart/Traulsen customer care

at 800-333-7447 to request a return or le a claim.

III. INSTALLATION

III. a - PACKAGING:

Your unit is packed in a cardboard carton which in turn,

is banded to a wooden pallet.

IV. a - CONTROL PANEL:

The control panel contains a dual indicator operating light with

both amber and red lamps, a dial thermometer, and a full range

thermostat.

After the cart is connected to an appropriated power source, the

operator will notice that the red indicator light is illuminated. This

light will continue to be on as long as the cabinet is connected

to the power source.

IV. b - THERMOSTAT:

Rotate the thermostat knob so that it points to the number 5. This

will cause heating elements to start heating. When this occurs

the amber light will be illuminated. This light will stay on as long

as the heating elements are engaged. Once the predetermined

temperature is achieved, the heating elements will begin to cycle.

During this period the amber light will turn on and off.

IV. c- THERMOMETER:

As the elements are heating , the thermometer will begin to

move and indicate the interior temperature of the cabinet. At the

number 5 setting the thermometer should indicate an average

temperature of approximately 1500 degrees F.

Remove the banding material holding the carton to the

pallet. Remove the cardboard carton and the plastic bag

covering the cabinet and the banding material holding the

cart to the skid. Metal pan slides and shelves are shipped

under the cabinet, in between the casters (careful not to

discard boxes with other packaging material). Remove

items from boxes and install in the interior of cabinet.

NOTE: Prior to use, remove cardboard insert located

under the heat cover in the interior of the cabinet.

Most exterior stainless steel surfaces have a protective

vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is installed

in place of application peel, remove and discard the

covering from all surfaces.

III. b - ELECTRICAL REQUIREMENTS:

Verify that the power source matches the serial tag electrical data, before the connection is made. A dedicated

circuit is required for all models. See page 1 for serial

tag location and data.

NOTE: The temperature in any heated cabinet will uctuate as

the heating elements cycle on and off. The thermostat setting will

supply an average temperature air temperature to keep food at a

proper serving temperature. However, the operator should always

test the food product itself to insure proper temperatures.

REMEMBER: The greater the thermostat number setting the

higher the cabinet temperature and the lower the thermostat

number setting the lower the cabinet temperature.

V. OPERATION-ELECTRONIC/

FORCED AIR

V. a - CONTROL PANEL:

The control panel contains an ON/OFF switch, and a full range

electronic temperature controller.

Turn the ON/OFF switch to the ON position. The interior air

circulating fans will immediately start, the LED on the electronic

temperature controller will display.

NOTE: Pre-heat the cabinet at 135 degrees for 30-45

minutes prior to use.

-2-

V. OPERATION-ELECTRONIC/

FORCED AIR

VI. CLEANING THE CABINET

V. b - TEMPERATURE CONTROLLER:

The electronic temperature controller is extremely precise. The

controller has a “ SET” button to allow for modifying temperature

settings, LED display, and “UP” & “DOWN” buttons for either

increasing or decreasing the desired holding temperature.

V. c - DETERMINING THE PREVIOUS HOLDING TEMPERATURE:

Turn the ON/OFF switch to the “ON” position.

The controller LED will ash for a few seconds and then display

the air temperature of the unit.

A small indicator light in the upper left corner of the controller

LED window will illuminate indicating the unit is heating.

Depress and immediately release the “SET” button on the controller. The LED will display the last temperature setting for a

period of 5 seconds. After 5 seconds the LED will display the

air temperature in the unit.

If the displayed temperature setting is that which is desired no

further action is required by the operator.

The interior of the cabinet should be cleaned whenever

a food spill occurs. Use a mild soap and water to clean.

If using plate racks (supplied by others) they should be

removed and cleaned in a sink as necessary. Never use

harsh chemicals or abrasive pads to clean the cabinet.

The cabinet will preheat to the temperature setting and maintain

that temperature during the holding cycle.

V. d - MODIFYING THE PREVIOUS HOLDING TEMPERATURE:

Turn the ON/OFF switch in the “ON” Position.

Depress the “SET” button for at least 2 seconds. The controller

will immediately enter the “change” mode allowing the operator

to modify the holding temperature required. The LED will begin

ashing.

To increase the desired holding temperature simply depress the

“UP” button until the desired temperature is displayed and release

or to decrease the desired temperature depress the “DOWN”

button until the desired holding temperature is displayed and

release.

Depress the “SET” button after modifying the temperature. This

will lock-in the revised temperature setting.

NOTE: THE CONTROLLER HAS BUILT-IN SELF DIAGNOSTIC

FEATURES FOR TROUBLE SHOOTING.

NOTE: The temperature in any heated cabinet will uctuate as

the heating elements cycle on and off. The thermostat setting

will provide an average air temperature in the cabinet. However,

the operator should always monitor the food product to insure

that it remain at proper temperature.

-3-

Loading...

Loading...