Page 1

Traulsen Refrigeration

SERVICE MANUAL #07

Instructions For The Troubleshooting

And Repair Of All Traulsen TE-Series

Refrigerated Equipment Stand Models

-NOTICE-

This Manual is prepared for the use of trained Authorized Traulsen Service Agents and should not be used

by those not properly qualified. This manual is not intended to be all encompassing, but is written to

supplement the formal training, on-the-job experience and other product knowledge acquired by Authorized Traulsen Service Agents. Before proceeding with any work, you should read, in its entirety, the repair

procedure you wish to perform to determine if you have the necessary tools, instruments and skills required

to perform the procedure. Procedures for which you do not have the necessary tools, instruments and

skills should be performed only by a trained Authorized Traulsen Service Agent.

Reproduction or other use of this Manual, without the express written consent of Traulsen, is prohibited.

FORM NUMBER TR35896 - REVISED. 4/08

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG 1

II. GENERAL INFORMATION

a. Introduction 2

b. Model Designations 2

c. Wiring Diagrams 2

d. Installation - See Owner’s Manual 2

e. Cleaning 2

f. Tools 2

g. Refrigeration System Theory Of Operation 2

h. Air Flow Requirements 2

i. The Microprocessor Control 2

j. Control Locations 3

k. Specifications 3

l. Operating Data Chart 3

III. REMOVAL & REPLACEMENT OF PARTS

a. Louver Assembly 4

b. Evaporator Housing Cover 4

c. Removing The Drawer 4

d. Removing The Drawer Frame (slides) 4

e. Drawer Gaskets 5

f. Microprocessor Control 5

g. Condensate Drain Pan 5

h. Accessing Start Components 5

IV. REPLACING THE...

a. Condenser Fan Motor and/or Blade 6

b. Condenser Coil 7

c. Evaporator Fan 8

d. Evaporator Coil 9

IV. REPLACING THE... (cont’d)

f. Compressor 10

V. WIRING DIAGRAMS

a. 115V Refrigerator Models 11

VI. SERVICE PROCEDURES & ADJUSTMENTS

a. System Access 12

b. Sweat On Piercing Valves 12

c. Refrigerant Leak Check 12

d. Evacuating System 13

e. Charging System 13

f. System Clean-Up 14

g. Heater Test/Drawer Perimeter Heater 14

VII. ELECTRICAL OPERATION

a. Sequence Of Operation/Normal Operation 14

b. Sequence Of Operation/Defrost Mode 14

c. Component Function 15

d. Installation of Sensors 15

VIII. REPLACEMENT PARTS LISTING 16

IX. TROUBLESHOOTING 17

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

I. THE SERIAL TAG

The serial tag is a permanently affixed sticker on

which is recorded vital electrical and refrigeration data

about your Traulsen product, as well as the model

and serial number. This tag is located on the upper

right interior wall of all TE-Series models.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen

• Model = The model # of your Traulsen

• Volts = Voltage

• Hz = Cycle

• PH = Phase

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit required

• Lights = Light wattage

• Heaters = Heater amperage

• Refrigerant = Refrigerant type used

• Design Pressure = High & low side operating

pressures and refrigerant charge

• Agency Labels = Designates agency listings

-1-

Page 3

II. GENERAL INFORMATION

II. a - INTRODUCTION:

This manual applies to the following Traulsen

models only:

TE036HT, TE048HT, TE060HT, TE065HT, TE072HT

TE084HT, TE096HT, TE110HT, TE125HT &

TE139HT

II. b - MODEL DESIGNATIONS:

TE060HT

Position 1: TE = Traulsen Equipment Stand

Position 2: 036 = 36” Long Model

048 = 48” Long Model

060 = 60” Long Model

Position 3: HT = Refrigerator

II. c - WIRING DIAGRAM:

Refer to the wiring diagram for any service work

performed on this unit. A copy is located on the unit

when shipped. Should you require another copy, or a

wiring diagram for an older production unit, please

contact Traulsen Service at (800) 825-8220, and

provide the model and serial number of the unit

involved (this information is located on the serial

tag, see page one).

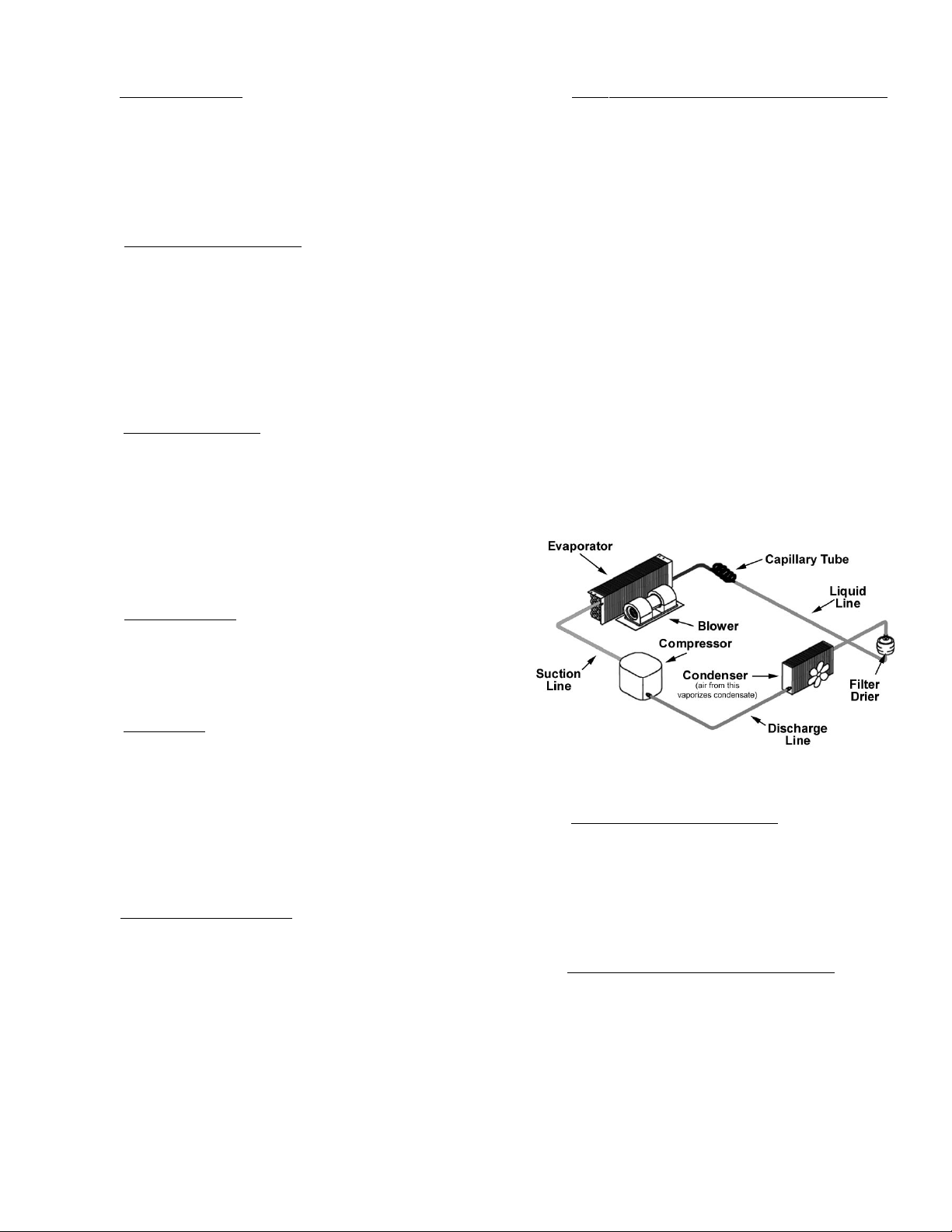

II. g - REF’N SYSTEM - THEORY OF OPERATION:

The refrigeration system is the mechanism whereby

heat is transferred from the cabinet to the outside air.

It works under the principle that the heat moves from

hot to cold as it tries to establish equilibrium.

The microprocessor control signals a need for heat to

be removed from the cabinet. The compressor begins

by compressing the refrigerant gas as it is discharged.

The high pressure refrigerant now circulates through

the condenser, removing heat from the refrigerant and

condensing it into a liquid. From there the refrigerant

flows to the filter drier which removes all traces of

moisture and particles from the system.

After the filter drier, the refrigerant passes through a

“metering device.” Traulsen uses a capillary tube to

regulate the flow of refrigerant into the evaporator

coils.

In the evaporator coil, heat is transferred from the

cabinet to the refrigerant, which changes from a cold

liquid to a warm low pressure gas. When the desired

cabinet air temperature has been reached, the

microprocessor control shuts off the compressor.

II. d - INSTALLATION:

Generally TE-Series refrigeration products are installed

by the dealer, or others contracted by the dealer or

owner. Detailed installation instructions are included

along with each unit when shipped.

II. e - CLEANING:

Detailed cleaning instructions are included with each

unit, however special care MUST be given to the

condenser coil. The condenser coil must be cleaned

at a minimum of every six months. This can be done

with a vacuum cleaner using a brush attachment, or a

stiff brush or wisk broom. For more information please

refer to

Manual.

II. f - TOOL REQUIREMENTS:

For most jobs a standard set of hand tools, a VOM and

AC current tester, along with a temperature tester or

thermometer are adequate. However in some cases

the following additional tools may be required as well:

“Section V.a” of the TE-Series Owner’s

• Refrigeration Guage Manifold

• Refrigeration Reclaiming Equipment

• Acetylene Torch

• Anti-Static Grounding Kit (TL 84919)

• Nitrogen Bottle With Gauges

• Thin 5/16” Open End Wrench

• Refrigerant Reclaim Unit

Fig. 1 - The Refrigeration System

II. h - AIR FLOW REQUIREMENTS:

To assure optimum performance, the condensing unit

of your Traulsen unit MUST have an adequate supply

of air for cooling purposes. Therefore, the operating

location must allow a minimum of 12” clearance in

front of the louvers to allow for unrestricted air flow to

the condensing unit.

II. i - THE MICROPROCESSOR CONTROL:

For detailed information on replacement, repair or

adjustment of the INTELA-TRAUL® microprocessor

control please refer to it’s service manual (form

number TR35705).

-2-

Page 4

II. GENERAL INFORMATION (cont’d)

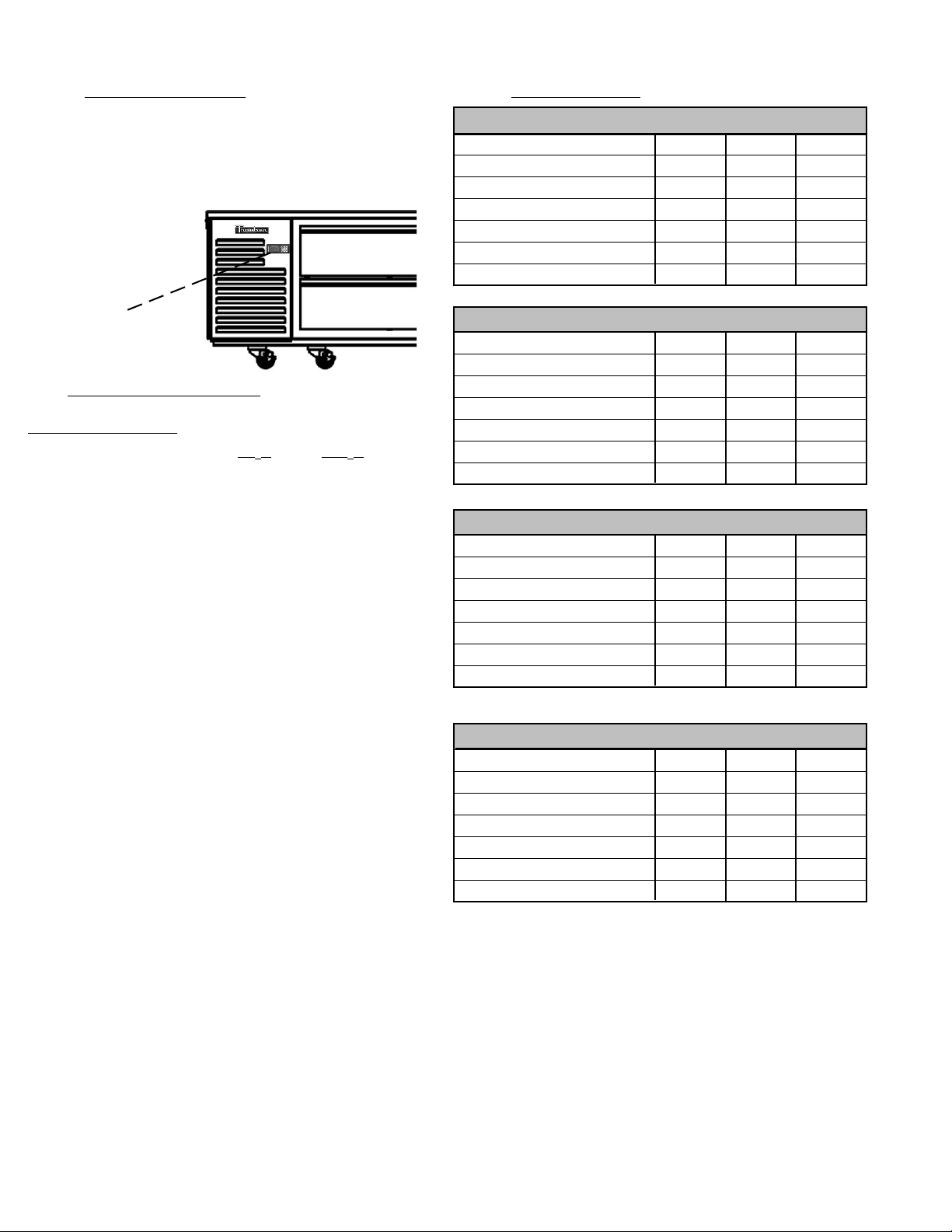

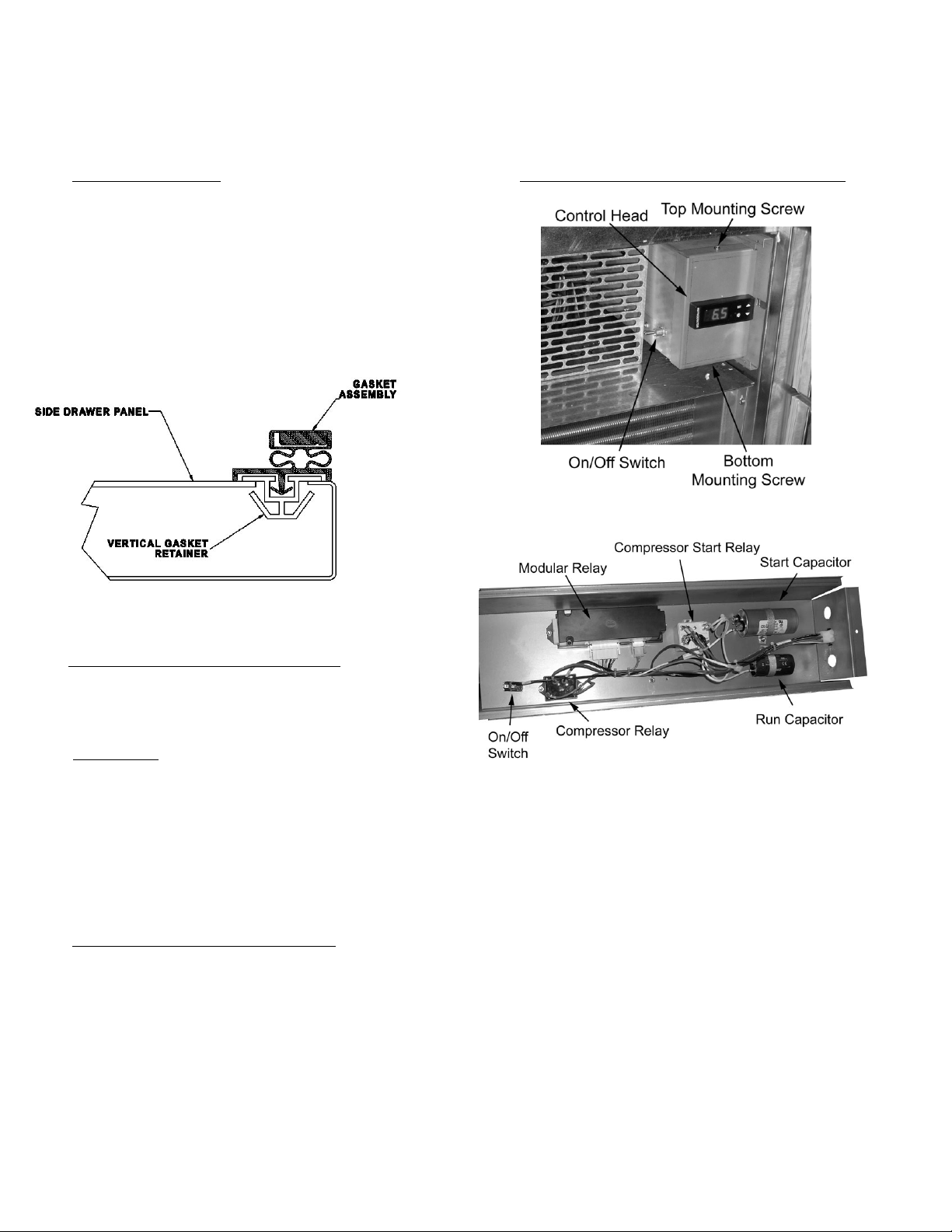

II. j - CONTROL LOCATION:

On all TE-Series refrigerator models, the microprocessor control is located on the louver assembly.

The louvers/refrigeration system are mounted standard

on the left side, but as an option are available mounted

on the right (see figure 2).

Fig. 2

Control Location

II. k -

OPERATING DATA CHART:

Refrigerated Models (cabinet temperature set at 38°F)

Ambient 70°F 100°F

Suction Pressure 35 PSIG 50 PSIG

Suction Temperature 3°F16°F

Discharge Pressure 200 PSIG 295 PSIG

Discharge Temperature 88°F115°F

II. l - SPECIFICATIONS:

TE-Series Refrigerated Equipment Stands

TE036 TE048 TE060

Horsepower 1/3 HP 1/3 HP 1/3 HP

Condensing Unit - BTU/HR 2440 2440 2440

Condensing Unit Amp Draw 4.5 4.5 4.9

Fan, Lights, Etc. Amp Draw 0.6 0.6 1.1

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 14.0 14.5 16.0

TE-Series Refrigerated Equipment Stands

TE065 TE072 TE084

Horsepower 1/3 HP 1/3 HP 1/3 HP

Condensing Unit - BTU/HR 2440 2440 2440

Condensing Unit Amp Draw 4.9 4.9 4.9

Fan, Lights, Etc. Amp Draw 1.1 1.1 1.1

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 16.5 16.5 17.0

TE-Series Refrigerated Equipment Stands

TE096 TE110 TE125

Horsepower 1/2 HP 1/2 HP 1/2 HP

Condensing Unit - BTU/HR 4090 4090 4090

Condensing Unit Amp Draw 9.6 9.6 9.6

Fan, Lights, Etc. Amp Draw 1.5 1.5 1.5

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 20.0 20.0 20.0

TE-Series Refrigerated Equipment Stands

TE139

Horsepower 1/2 HP

Condensing Unit - BTU/HR 4090

Condensing Unit Amp Draw 9.6

Fan, Lights, Etc. Amp Draw 1.9

Refrigerant R-404A

Refrigerant Charge (oz.) 21.0

-3-

Page 5

III. REMOVAL & REPLACEMENT OF BASIC PARTS

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE

AND FOLLOW LOCKOUT/TAGOUT PROCEDURES.

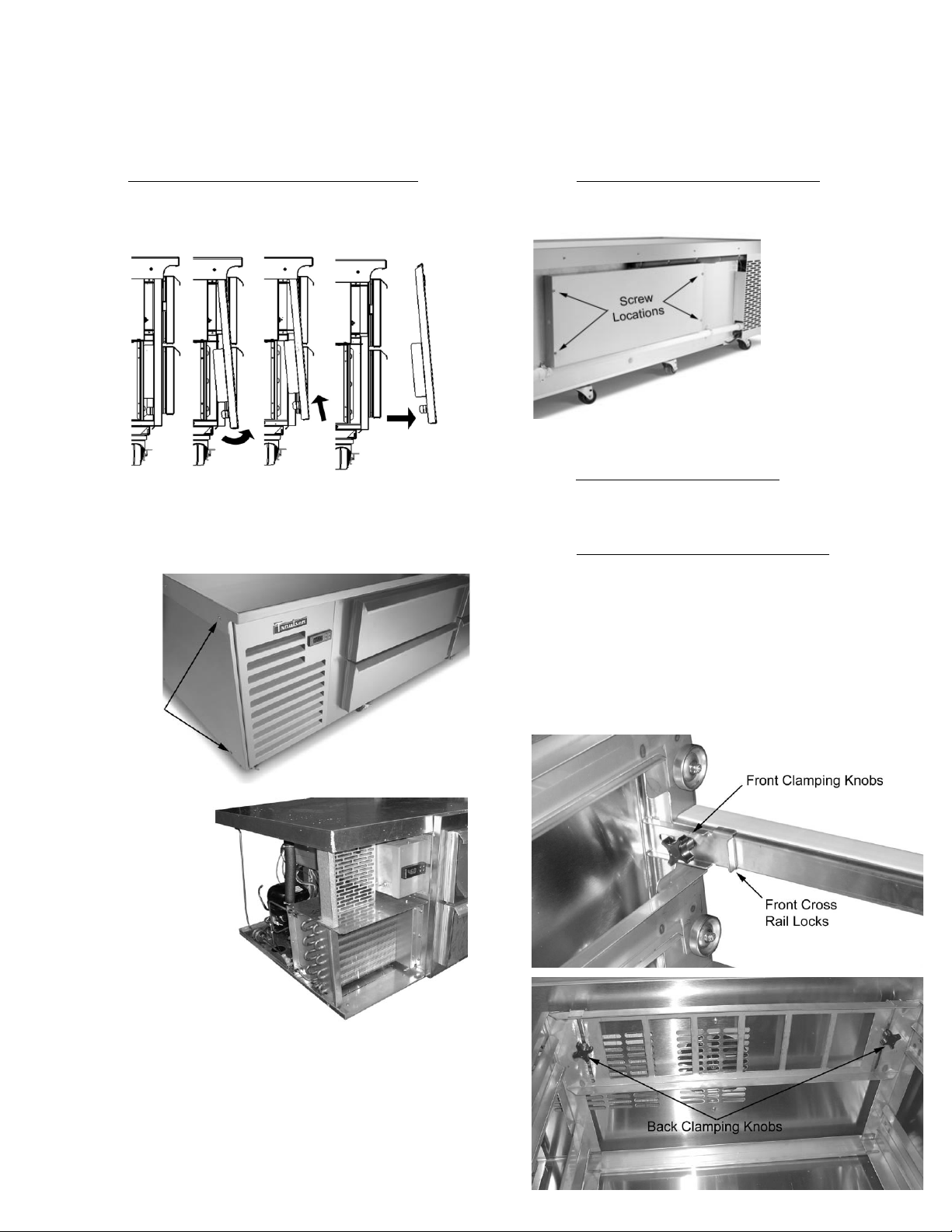

III. a - LOUVER ASSEMBLY/SYSTEM ACCESS:

To remove the louver assembly first place your hands

under the louver panel and lift this up off the bracket

and then away from the cabinet face (see figure 3).

Fig. 3

To gain full access to the refrigeration system from

the side, remove the cover by removing the bottom

screws (see figures 4 & 5).

Fig. 4

Screw

Locations

EVAPORATOR HOUSING COVER:

III. b Remove the back cover by removing the four screws

which secure this to the cabinet (see figure 6).

Fig. 6

Reverse the procedure when done to reinstall.

III. c -

REMOVING THE DRAWERS:

Remove the drawer(s) from the drawer frame by lifting

up on the drawer, and then pulling out.

III. d - REMOVING THE DRAWER FRAME:

Once the drawer(s) have been removed, the drawer

frame module can also be removed by loosening the

front and back clamping knobs (2 of each), located on

the cross-rail and liner locks (see figures 7 & 8). Slide

the front cross-rail locks towards the center of the

drawer frame module and allow the liner locks to drop

down from the top of the liner.Pull the drawer frame

module forward, tip forward and pull out. The entire

frame assembly is now free to slide out of the cabinet.

Fig. 5

Side System

Access

When finished, lower the louver assembly into

position and replace the side panel. Secure these in

place using the previously removed screws.

Fig. 7

Fig. 8

-4-

Page 6

III. REMOVAL & REPLACEMENT OF BASIC PARTS (cont’d)

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE

AND FOLLOW LOCKOUT/TAGOUT PROCEDURES.

III. e - DRAWER GASKETS:

To remove the gasket to be replaced, grasp it firmly by

one corner and pull it out. Before attempting to install

a new gasket, both the unit and the gasket itself must

be at room temperature. Insert the four corners first

by using a rubber mallet (or hammer with a block of

wood). After the corners are properly inserted, work

your way towards the center from both ends by gently

hitting with a mallet until the gasket is completely

seated in place (see figure 9 for gasket cross section).

Fig. 9

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

III. h - ACCESSING START COMPONENTS (cont’d):

Fig. 10

III. f - THE MICROPROCESSOR CONTROL:

To remove the microprocessor controller from the unit

in which it was installed, please refer to section “V” of

your INTELA-TRAUL® Master Service Manual.

III. g - DRAIN PAN:

To remove the drain pan, begin by removing the

evaporator housing cover as outlined in section “III.

c.” Next, remove the screws and brackets which

secure the drain pan, and remove the drain tube from

the drain pan. Finish by sliding the drain pan out from

under the coil.

Reverse the procedure to install.

III. h - ACCESSING START COMPONENTS:

The start components are located behind the front

louver, inside a metal tray.

To access the start components, first remove the

louver assembly as shown in section III. a. Next loosen

the top set screw (see figure 10). and remove the molex

connection in the back of the box to gain access to

the back set screw. Slide the electrical box out the

font on its tracks.

Fig. 11

See figure 11 for component detail.

-5-

Page 7

IV. a - REPLACING THE CONDENSER FAN MOTOR AND/OR BLADE

STEP 1: Remove the louver assembly as outlined in

section “III. a” to gain access through left side.

STEP 2: Remove the screws holding the fan motor

bracket to the compressor mounting base (see

illustration 1).

STEP 3: Remove the blade from the motor shaft by

removing the nut (see illustration 2).

NOTE: Install the concave side of the fan blade

toward the motor.

NOTE: If the blade is all that is being replaced,

stop here and reverse procedure to install.

STEP 4: Remove the mounting bracket from the motor

(see illustration 3).

STEP 5: Disconnect the lead wires at the compressor

junction box.

STEP 6: Reverse the procedure to install.

STEP 7: Reconnect power to the unit.

WARNINGS:

1) DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

Illustration 01

STEP 8: Reset the microprocessor control defrost time

settings to the correct time of day.

\

Illustration 02

Illustration 03

-6-

Page 8

IV. b - REPLACING THE CONDENSER COIL

WARNINGS:

1) DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

2) THIS PROCEDURE REQUIRES THE USE OF REFRIGERANTS. BE CERTAIN THE WORK AREA IS WELL

VENTILATED. SAFETY GOGGLES AND GLOVES

SHALL BE WORN SINCE REFRIGERANTS MAY CAUSE

BURNS TO THE SKIN.

STEP 1: Remove the louver assembly as outlined in

section “III. a”.

STEP 2: Recover the refrigerant in the system

following the current EPA Guidelines for

refrigerant recovery.

NOTE: The use of reclaiming equipment is

required.

STEP 3: Disconnect the input and output lines to the

condenser coil at the soldered joints closest

to the condenser.

STEP 4: Remove the four (4) screws which secure the

condenser coil to the mounting brackets (see

illustration 1).

STEP 5: Remove the condenser coil.

STEP 6: Reverse the procedure to install the new

condenser coil.

STEP 7: Install a new drier.

Illustration 01

STEP 8: Charge the refrigeration system as outlined

under “CHARGING SYSTEM” in “SERVICE

PROCEDUES AND ADJUSTMENTS.”

STEP 9: Reconnect power to the unit.

STEP 10: Reset the microprocessor control defrost time

settings to the correct time of the day.

-7-

Page 9

IV. c - REPLACING THE EVAPORATOR FAN

STEP 1: Begin by removing the back cover by first

removing the four screws which secure this to

the cabinet (see illustration 1).

All evaporators and fans are located along the

back wall of the cabinet and best accessed

from the rear (see illustration 2).

STEP 2: Remove the holding rod and unhook the rod

from the other end. This evaporator fan can

then be lifted away from the assembly (see

illustration 3).

STEP 3: Disconnect the wires from the assembly.

STEP 4: Reverse the procedure to install the new

evaporator fan.

STEP 5: Reconnect power to the unit.

STEP 6: Reset the microprocessor control defrost time

settings to the correct time of the day.

WARNINGS:

1) DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

Illustration 01

Illustration 02

Illustration 03

-8-

Page 10

IV. d - REPLACING THE EVAPORATOR COIL

WARNINGS:

1) DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

2) THIS PROCEDURE REQUIRES THE USE OF REFRIGERANTS. BE CERTAIN THE WORK AREA IS WELL

VENTILATED. SAFETY GOGGLES AND GLOVES

SHALL BE WORN SINCE REFRIGERANTS MAY CAUSE

BURNS TO THE SKIN.

STEP 1: Remove evaporator housing cover as outlined

in section “III. b”.

STEP 2: Recover the refrigerant in the system

following the current EPA Guidelines for

refrigerant recovery.

NOTE: The use of reclaiming equipment is

required.

STEP 3: Remove the screws which secure the

evaporator to the mounting brackets.

STEP 4: Disconnect the evaporator output line.

STEP 5: Unsolder the liquid line leading into the

capillary tube.

NOTE: When removing the capillary tube care must

be taken toheat protect. Heat sink or wrap a

cold, dampcloth over the capillary tube to

protect it from overheating.

NOTE: Inspect the end of the liquid line after

disassembly, it could become plugged with

solder.

STEP 6: Remove the evaporator coil and capillary tube

from the unit.

STEP 7: Reverse the procedure to install the new

evaporator coil and capillary tube.

STEP 8: Install a new drier.

STEP 9: Charge the refrigeration system as outlined

under “CHARGING SYSTEM” in “SERVICE

PROCEDUES AND ADJUSTMENTS.”

STEP 10: Reconnect power to the unit.

STEP 11: Reset the microprocessor control defrost time

settings to the correct time of day.

-9-

Page 11

IV. e - REPLACING THE COMPRESSOR

NOTE: Compressor models will vary with each cabinet

model, but the basic removal instructions can be followed.

STEP 1: Recover the refrigerant in the system

following the current EPA Guidelines for

refrigerant recovery.

NOTE: The use of reclaiming equipment is required.

STEP 2: Remove the compressor junction box cover.

STEP 3: Disconnect all wire leads coming into the

junction box.

STEP 4: Disconnect the discharge and suction lines to

the compressor (see illustration 1).

STEP 5: Remove the compressor which is secured by

either four (4) nuts or pins.

STEP 6: Install the new compressor and connect the

input and output lines.

STEP 7: Connect the lead wires at the junction box.

WARNINGS:

1) DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT/TAGOUT

PROCEDURES.

2) THIS PROCEDURE REQUIRES THE USE OF REFRIGERANTS. BE CERTAIN THE WORK AREA IS WELL

VENTILATED. SAFETY GOGGLES AND GLOVES

SHALL BE WORN SINCE REFRIGERANTS MAY CAUSE

BURNS TO THE SKIN.

STEP 8: Install a new drier.

STEP 9: Charge the refrigeration system as outlined

under “CHARGING SYSTEM” in “SERVICE

PROCEDUES AND ADJUSTMENTS.”

STEP 10: Reconnect power to the unit.

STEP 11: Reset the microprocessor control defrost time

settings to the correct time of day.

Illustration 01

-10-

Page 12

V. WIRING DIAGRAM

-11-

Page 13

VI. SERVICE PROCEDURES & ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASUREMENTS WHILE

POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

VI. a - SYSTEM ACCESS:

All external indicators should be checked as part of

system diagnosis before determining the

refrigerant pressures. Improper access may expose

the refrigerant to contaminates and non-condensables

which will result in system failure.

VI. b - SWEAT-ON PIERCING VALVES:

NOTE: Sweat-on piercing valves are used for system

diagnostics, but may be left on after service is

complete. They may be installed while the system is

fully charged.

1) Place one piercing valve on the compressor

process tube and one on the liquid line process tube.

Follow the installation instructions provided by the

manufacturer of the piercing valve.

2) When complete, follow the guidelines as outlined

under “LEAK CHECK” and “EVACUATING SYSTEM.”

VI. c - REFRIGERANT LEAK CHECK:

DISCONNECT THE ELECTRICAL POWER TO THE

MACHINE AT THE MAIN CIRCUIT BOX. PLACE A TAG

ON THE CIRCUIT BOX INDICATING THE CIRCUIT IS

BEING SERVICED.

THIS PROCEDURE REQUIRES THE USE OF

REFRIGERANTS. BE CERTAIN THE WORK AREA IS

WELL VENTILATED. SAFETY GOGGLES AND

GLOVES SHALL BE WORN SINCE REFRIGERANTS

MAY CAUSE BURNS TO THE SKIN.

NOTE: The use of R-22 in small quantities is

recommended as a trace gas for leak detection.

NOTE: This leak check procedure is to be used only

after the refrigerant has been properly reclaimed.

1) Access the refrigeration system (note: see section

“V. a - SYSTEM ACCESS”).

2) Attach gauge manifold set to the system, low side

to process tube on the compressor and the high side

to the process tube.

3) Connect refrigerant bottle to the center of gauge

manifold and open the valve on the bottle. Bleed

charging hose at the manifold gauge to remove air from

the system.

4) Open valve on low side of gauge manifold and

charge system with one ounce of R-22.

5) Close low side valve on gauge manifold and the

valve on the refrigerant bottle.

6) Disconnect refrigerant bottle and connect nitrogen

bottle.

VI. c - REFRIGERANT LEAK CHECK (cont’d):

NOTE: The use of a nitrogen requlator is required.

7) Set output valve on nitrogen valve to 120 psi.

8) Open nitrogen bottle valve and low side gauge

manifold valve. Allow pressure to equalize.

9) Shut off both valves and disconnect nitrogen bottle.

10) Use a leak detector or a thick soapy solution and

check for leaks at all tubing connections.

A - If leaks are found, repair leaks and repeat process.

B - If no leaks are found, evacuate system as outlined

in section “V. d - EVACUATING SYSTEM”).

11) Charge the system by weighing in the exact charge

and check for proper operation.

VI. d - EVACUATING SYSTEM:

Introduction - Refrigeration reclaiming equipment is

required. Our goal in system evacuation is to remove

all the non-condensables possible. No evacuation

method will remove 100% of the moisture and air from

within the refrigeration circuit. Because of this,

guidelines and methods must be developed and

adhered to ensuring only harmless amounts of

contaminants remain in the system.

GUIDELINES

WARNING - DO NOT PRESSURIZE SYSTEM ABOVE

150 PSIG. PRIOR TO EVACUATION OR DURING LEAK

TEST PROCEDURES.

• Use only a two stage vacuum pump (2 CFM or

greater) and electronic micron.

• Evacuate from high and low sides of the system.

• No chemical additive or alcohols are to be used to

“dry up” a system.

• Blow down of system with DRY NITROGEN prior to

evacuation is acceptable and many times desirable.

See “System Clean-Up.”

• Evacuate to 200 microns.

PROCEDURE

WARNING: DISCONNECT THE ELECTRICAL POWER

TO THE MACHINE AT THE MAIN CIRCUIT BOX. PLACE

A TAG ON THE CIRCUIT BOX INDICATING THE

CIRCUIT IS BEING SERVICED.

WARNING: THIS PROCEDURE REQUIRES THE USE OF

REFRIGERANTS. BE CERTAIN THE WORK AREA IS

WELL VENTILATED. SAFETY GOGGLES AND

GLOVES SHALL BE WORN SINCE REFRIGERANTS

MAY CAUSE BURNS TO THE SKIN.

-12-

Page 14

VI. SERVICE PROCEDURES & ADJUSTMENTS (cont’d)

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASUREMENTS WHILE

POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

VI. d - EVACUATING SYSTEM/GUIDELINES (cont’d):

1) Access the refrigeration system as outlined under

“SYSTEM ACCESS.”

2) Connect low (blue) side of gauge manifold to

schrader valve on compressor process line and high

(red) side of gauge manifold to schrader valve on

filter/drier process line.

3) Connect center line of gauge manifold to vacuum

pump.

4) Turn vacuum pump on and open both sides of gauge

manifold.

5) Pull a vacuum to 200 microns.

6) Break the vacuum with 3 psig of dry nitrogen.

7) Repeat steps 5 and 6.

8) Pull vacuum to 200 microns.

9) Charge system and check for proper operation.

VI. e - CHARGING SYSTEM:

WARNING: DISCONNECT THE ELECTRICAL POWER

TO THE MACHINE AT THE MAIN CIRCUIT BOX. PLACE

A TAG ON THE CIRCUIT BOX INDICATING THE

CIRCUIT IS BEING SERVICED.

WARNING: THIS PROCEDURE REQUIRES THE USE OF

REFRIGERANTS. BE CERTAIN THE WORK AREA IS

WELL VENTILATED. SAFETY GOGGLES AND

GLOVES SHALL BE WORN SINCE REFRIGERANTS

MAY CAUSE BURNS TO THE SKIN.

1) Access the refrigeration system.

2) Attach gauge manifold set to system, low side to

process tube on the compressor and the high side to

the process tube on the drier.

NOTE: See “SYSTEM ACCESS.”

3) Be sure the system is properly leak checked and

evacuated before charging as outlined under “LEAK

CHECK” and “EVACUATING SYSTEM.”

4) Make certain both valves are closed on the gauge

manifold. Open the valve on the bottle. Bleed

charging hose at the manifold gauge to remove air.

NOTE: Initially charge system through high side to

prevent liquid refrigerant from reaching compressor.

5) Open the high side gauge valve (red). Allow

refrigerant to flow into the system until the nameplate

charge is reached or until the high side will not accept

any more refrigerant. At this point, shut the gauge

and bottle valves.

6) Reconnect power to the unit and check for proper

operation and high pressure leaks.

VI. e - CHARGING SYSTEM (cont’d):

7) Add the remaining amount of refrigeration charge

through the low side with the compressor running.

8) Check for proper operation and leaks.

9) Disconnect power to the unit and replace any

covers removed.

VI. f - SYSTEM CLEAN UP/INTRODUCTION:

When a compressor burn-out or moisture infiltration

is encountered, the service person must make the

determination as to the degree of system contamination. Normally a compressor burn-out will fit into one

of three catagories:

• CONTAINED - compressor oil not acidic, no oil dis

coloration.

• CONTAMINATED COMPRESSOR - oil acidic,

discoloration of oil, contamination limited to

compressor.

• MASSIVE CONTAMINATION - contaminated oil

and/or refrigerant pumped through system.

CONTAINED

1) Replacement of liquid line drier.

2) Install suction filter drier for clean up and then

remove it when service is complete. Usually within

48-hours.

3) Replacement of compressor.

4) Evacuation (to 200 microns).

5) Charge by weight.

CONTAMINATED COMPRESSOR

The “contaminated compressor” requires the same

procedure as the “contained” burn-out. Plus, the

system must be flushed with nitrogen after the

compressor and drier has been removed.

-13-

Page 15

VI. SERVICE PROCEDURES & ADJUSTMENTS (cont’d)

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR MEASUREMENTS WHILE

POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE

NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

VI. f - SYSTEM CLEAN UP/INTRODUCTION (cont’d):

MASSIVE CONTAMINATION

The replacement compressor MUST NOT be installed

until after system clean-up procedures have been

completed.

1) Remove the burned-out compressor as outlined

under “COMPRESSOR” in “Section IV. f”.

2) Remove the capillary tube metering device.

3) Purge nitrogen through the high and low sides of

system until moisture and contaminated oil has been

removed from the remaining components of the

system.

4) Reassemble refrigeration system and add a CW style

liquid drier and a suction line drier.

5) Purge nitrogen through the high and low sides of

system for 5 minutes.

6) Evacuate refrigeration as outlined under

“EVACUATING SYSTEM” for 30 minutes. Repeat

nitrogen purge and evacuate two more times.

7) Charge system as outlined under “CHARGING

SYSTEM”. Allow for the increased liquid capacity of

the liquid line drier.

8) Reconnect power and check for proper operation.

9) Disconnect power and install any panels removed.

MASSIVE CONTAMINATION (cont’d):

10) Return between 24 and 48 hours to recover gas,

replace liquid line drier with a CW style drier. Remove

the suction drier, but do not replace.

11) Evacuate and charge system as outlined under

“EVACUATING SYSTEM” and “CHARGING SYSTEM .

VI. g - HEATER TEST - DRAWER PERIMETER HEATER:

1) Access the heater wire around the drawer frame.

2) Plug the unit in and verify 120 volt supply to the

heater.

3) The reading should be .25 amp.

VII. ELECTRICAL OPERATION

VII. a - NORMAL OPERATION:

1. Conditions

a) Unit connected to correct voltage (check using a

volt meter).

b) Microprocessor off cycle defrost settings correct.

c) Condensing unit controlled by the microprocessor

control.

d) Cabinet at desired temperature.

e) Door perimeter heaters are powered 100% of the

time as preset by the factory (this can be adjusted

using the microprocessor control).

f) Evaporator fan powered.

g) Microprocessor control operating correctly.

2. Cabinet temperature rises above set temperature.

a) Microprocessor control initiates compressor

operation.

b) Evaporator fan should be ON all the time.

3. Set temperature is met.

a) Conditions return to those outlined in step 1.

VII. b - DEFROST MODE:

1. Conditions

a) Unit operating in normal mode.

2. Defrost initiated by the microprocessor control (an

off-cycle defrost should occur every 60-minutes).

3. Defrost terminated by either: 1) Evaporator Coil

Temperature or 2) Maximum Set Time Interval.

4. Cabinet returns to normal operation.

a) Temperature controlled by the microprocessor

control.

b) Evaporator fan stays ON, evaporator coil will reach

desired temperature.

-14-

Page 16

VII. c - COMPONENT FUNCTION:

Compressor: Pumps refrigerant thru refrigeration system components and

Condenser Fan: Draws air across condenser coil to aid in removing heat from the

Evaporator Fan: Draws air from the cabinet and pulls the air thru the evaporator coil.

Start Capacitor: Stores electrical charge which helps start the compressor motor.

Run Capacitor: Helps keep the compressor motor running after starting.

Microprocessor Control: Performs the functions of the 1) defrost timer, 2) high limit switch,

Drawer Perimeter Heater: Heats drawer opening to prevent condensation from forming.

Contactor Relay: Controls voltage to compressor motors.

VII. ELECTRICAL OPERATION

compresses the low pressure vapor into high pressure vapor.

refrigerant and moves air across compressor to aid in cooling the

compressor.

3) thermometer and 4) thermostat.

VII. d - INSTALLATION OF THE SENSORS:

There are two sensors used inside the

cabinet. The first one is the Cabinet Sensor

that is used to cycle the compressor on and

off at the correct temperature. The cabinet

sensor is mounted between the two coils

just below the top of the cabinet thru the

1/2” holes in the back wall and the tip should

be 1” inside the cabinet. Refer to the

drawing below. The part number for the

Cabinet Sensor is 337-60405-03.

Insert sensor inside the cabinet thru

1/2” holes in back wall

1” inside cabinet

The Evaporator Coil Sensor is to be mounted

in the evaporator, in the center of the coil

and fully inserted into the coil until only the

wire is visible and then pinch the fins around

the cable to hold it in place. The part

number for the Evaporator Coil Sensor is

337-60406-03.

Fully insert probe

into coil

The third sensor used is a Liquid Line

Sensor. This sensor is to be installed on

the liquid line as it comes out of the

condenser coil. The part number for this

sensor is 337-60407-01.

Attach sensor to the

liquid line using the

wrap

When the condensing temperature reaches

140°F or greater the control will display

“CLN-FIL.” Should the condensing

temperature increase to 160°F the

compressor will automatically shut off.

When the liquid line temperature drops

below 140°F the compressor will restart and

when the line temperature drops to 120°F

the alarm will reset.

Center

of Coil

.756 between 1

and 2nd hair bend

-15-

st

Page 17

VIII. REPLACEMENT PARTS LISTING

NOTE: Part numbers listed are for standard products as currently manufactured. For products manufactured

as other than standard, or for older production units, please contact the factory.

PART NO. NAME OF PART

SER-60536-00 4” High Caster w/o Lock

SER-60536-01 4” High Caster with Lock

550-10053-00 Drawer Assembly

550-10057-00 Drawer Face

550-10059-00 Drawer Frame

SER-60537-00 Drawer Frame Insert

341-60176-02 Drawer Gasket

344-60155-00 Drawer Roller

(all models except TE036HT, TE060HT, TE065HT, TE125HT &

550-10054-00 Drawer Assembly

550-10058-00 Drawer Face

550-10060-00 Drawer Frame

SER-60537-01 Drawer Frame Insert

341-60176-03 Drawer Gasket

344-60155-00 Drawer Roller

550-10067-00 Drawer Assembly

550-10076-00 Drawer Face

550-10077-00 Drawer Frame

SER-60537-03 Drawer Frame Insert

341-60176-04 Drawer Gasket

344-60155-00 Drawer Roller

550-10074-00 Drawer Assembly

550-10069-00 Drawer Face

550-10070-00 Drawer Frame

SER-60537-02 Drawer Frame Insert

341-60176-01 Drawer Gasket

344-60155-00 Drawer Roller

CABINET SUPPORTS

DRAWER PARTS

(models TE036HT & TE065HT)

DRAWER PARTS

TE072HT)

DRAWER PARTS

(models TE060HT & TE125HT)

DRAWER PARTS

(model TE072HT only)

PART NO. NAME OF PART

COMPRESSORS

321-60225-00 For Models TE036HT thru TE084HT

321-60226-00 For Models TE096HT thru TE139HT

MISC. SYSTEM COMPONENTS

323-60088-00 Suction Heat Exchange Evap 9” Coil

350-10000-00 Suction Heat Exchange Evap 18” Coil

322-60048-00 Evaporator Coil 9”

322-60050-01 Evaporator Coil 18”

325-60103-00 Liquid Line Drier

325-60144-00 Condenser Fan Motor Assembly

325-60145-00 Evaporator Fan Motor Assembly

325-60135-00 Condenser Fan Blade

338-60050-00 Condenser Fan Motor

701-61119-00 Spring Rod 9” Evaporator Coil

701-61119-01 Spring Rod 18” Evaporator Coil

337-60360-01 Compressor Relay

MISC. CABINET PARTS

337-60346-00 ON/OFF Power Switch

509-50118-00 Marine Top for TE036HT

509-50118-01 Marine Top for TE048HT

509-50118-02 Marine Top for TE060HT

509-50118-03 Marine Top for TE065HT

509-50118-04 Marine Top for TE072HT

509-50118-05 Marine Top for TE084HT

509-50118-06 Marine Top for TE096HT

509-50118-07 Marine Top for TE110HT

509-50118-08 Marine Top for TE125HT

509-50118-09 Marine Top for TE139HT

LOUVER PANELS

500-70075-00 For System on Left

500-70075-01 For System on Right

CONTROL PARTS

337-60403-00 Control Head

337-60405-03 Cabinet Temp Sensor

337-60406-03 Coil Temp Sensor

337-60407-01 Liquid Line Sensor

337-60317-00 Relay Module

-16-

Page 18

IX. TROUBLESHOOTING

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL AND REFRIGERA-

TION SYSTEM TEST OR MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

Compressor will not run, compressor has no current draw. 1. Main circuit breaker open.

Compressor will not run, current draw and trips overload. 1. Low voltage.

Compressor short cycles on overload. 1. Low voltage.

Compressor short cycles. 1. Improper air flow over evaporator coil.

Continuous unit operation. 1. Loss of refrigerant.

Compressor run time lengthy. 1. Partial loss of refrigerant.

Low suction pressure. 1. Capillary tube restricted.

High head pressure. 1. Improper air flow across condenser.

Will not defrost or inadequate defrost. 1. Defrost heater malfunction.

Coil icing. 1. Number of defrost cycles too few.

The cabinet & coil sensors show high temperature. 1. Sensor needs rreplacing (place sensor tip and

2. Compressor overload tripped.

3. Cabinet temperature satisfied.

4. Wired wrong or faulty connection.

5. INTELA-TRAUL

6. Start component malfunction.

7. Compressor motor windings open.

2. Start component malfunction.

3. Compressor windings shorted.

4. Locked rotor.

5. Excessive discharge pressure.

2. Low refrigerant charge.

3. Dirty condenser coil and/or filter.

4. Wired wrong or faulty connection.

5. Condenser fan inoperative.

6. Run capacitor malfunction.

7. Start component malfunction.

8. INTELA-TRAUL® control malfunction1.

9. High head pressure.

2. Low ambient conditions.

3. INTELA-TRAUL® control malfunction1.

4. Bad sensors.

5. Temp differential set too close.

2. Excessive drawer openings.

3. INTELA-TRAUL® control malfunction1.

4. Broken compressor valves.

5. Very dirty condenser and/or filter.

6. Check the “DL,” if higher than 160F

2. High ambient conditions.

3. Dirty condenser coil or improper air flow over

condenser coil.

4. Excessive product load.

5. Excessive drawer openings.

6. Drawer gasket requires replacement.

7. INTELA-TRAUL® control malfunction1.

8. Contaminates in refrigeration system.

9. Compressor valve leakage.

10. Inadequate defrost cycle.

2. Drier plugged.

3. Loss of refrigerant.

4. Poor air flow.

5. Iced evaporator coil.

2. High ambient conditions.

3. Overcharge of refrigerant.

4. Air in system.

5. Dirty condenser coil.

2. Wired wrong or faulty connection.

3. Cabinet air leak.

4. Coil sensor failure.

5. INTELA-TRAUL® control malfunction1.

2. Defrost duration too short.

3. Cabinet air leak.

4. Drain tube plugged.

5. Defrost heater not working.

6. Non-frozen product put into cabinet.

7. Coil sensor failure.

thermometer in ice water. Change sensor ir readings

differ, or if sensor displays -40 02 266).

®

control malfunction1.

-17-

Page 19

-18-

Page 20

For More Information On The Proper Installation, Use and Maintenance Of Traulsen

Refrigerated Equipment Stand Models, Please Refer To The Following Materials Available From

Your Local Hobart/Traulsen Sales & Service Location:

• INTELA-TRAUL Master Service Manual - Form Number TR35705

For Questions Regarding Repair or Warranty Service, Please Contact Traulsen Service At:

(800) 825-8220, ext. 6509

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

Loading...

Loading...