Traulsen TE Service Manual

Traulsen Refrigeration

SERVICE MANUAL #07

Instructions For The Troubleshooting

And Repair Of All Traulsen TE-Series

Refrigerated Equipment Stand Models

-NOTICE-

This Manual is prepared for the use of trained Authorized Traulsen Service Agents and should not be used

by those not properly qualified. This manual is not intended to be all encompassing, but is written to

supplement the formal training, on-the-job experience and other product knowledge acquired by Authorized Traulsen Service Agents. Before proceeding with any work, you should read, in its entirety, the repair

procedure you wish to perform to determine if you have the necessary tools, instruments and skills required

to perform the procedure. Procedures for which you do not have the necessary tools, instruments and

skills should be performed only by a trained Authorized Traulsen Service Agent.

Reproduction or other use of this Manual, without the express written consent of Traulsen, is prohibited.

FORM NUMBER TR35896 - REVISED. 4/08

TABLE OF CONTENTS

I. THE SERIAL TAG 1

II. GENERAL INFORMATION

a. Introduction 2

b. Model Designations 2

c. Wiring Diagrams 2

d. Installation - See Owner’s Manual 2

e. Cleaning 2

f. Tools 2

g. Refrigeration System Theory Of Operation 2

h. Air Flow Requirements 2

i. The Microprocessor Control 2

j. Control Locations 3

k. Specifications 3

l. Operating Data Chart 3

III. REMOVAL & REPLACEMENT OF PARTS

a. Louver Assembly 4

b. Evaporator Housing Cover 4

c. Removing The Drawer 4

d. Removing The Drawer Frame (slides) 4

e. Drawer Gaskets 5

f. Microprocessor Control 5

g. Condensate Drain Pan 5

h. Accessing Start Components 5

IV. REPLACING THE...

a. Condenser Fan Motor and/or Blade 6

b. Condenser Coil 7

c. Evaporator Fan 8

d. Evaporator Coil 9

IV. REPLACING THE... (cont’d)

f. Compressor 10

V. WIRING DIAGRAMS

a. 115V Refrigerator Models 11

VI. SERVICE PROCEDURES & ADJUSTMENTS

a. System Access 12

b. Sweat On Piercing Valves 12

c. Refrigerant Leak Check 12

d. Evacuating System 13

e. Charging System 13

f. System Clean-Up 14

g. Heater Test/Drawer Perimeter Heater 14

VII. ELECTRICAL OPERATION

a. Sequence Of Operation/Normal Operation 14

b. Sequence Of Operation/Defrost Mode 14

c. Component Function 15

d. Installation of Sensors 15

VIII. REPLACEMENT PARTS LISTING 16

IX. TROUBLESHOOTING 17

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

I. THE SERIAL TAG

The serial tag is a permanently affixed sticker on

which is recorded vital electrical and refrigeration data

about your Traulsen product, as well as the model

and serial number. This tag is located on the upper

right interior wall of all TE-Series models.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen

• Model = The model # of your Traulsen

• Volts = Voltage

• Hz = Cycle

• PH = Phase

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit required

• Lights = Light wattage

• Heaters = Heater amperage

• Refrigerant = Refrigerant type used

• Design Pressure = High & low side operating

pressures and refrigerant charge

• Agency Labels = Designates agency listings

-1-

II. GENERAL INFORMATION

II. a - INTRODUCTION:

This manual applies to the following Traulsen

models only:

TE036HT, TE048HT, TE060HT, TE065HT, TE072HT

TE084HT, TE096HT, TE110HT, TE125HT &

TE139HT

II. b - MODEL DESIGNATIONS:

TE060HT

Position 1: TE = Traulsen Equipment Stand

Position 2: 036 = 36” Long Model

048 = 48” Long Model

060 = 60” Long Model

Position 3: HT = Refrigerator

II. c - WIRING DIAGRAM:

Refer to the wiring diagram for any service work

performed on this unit. A copy is located on the unit

when shipped. Should you require another copy, or a

wiring diagram for an older production unit, please

contact Traulsen Service at (800) 825-8220, and

provide the model and serial number of the unit

involved (this information is located on the serial

tag, see page one).

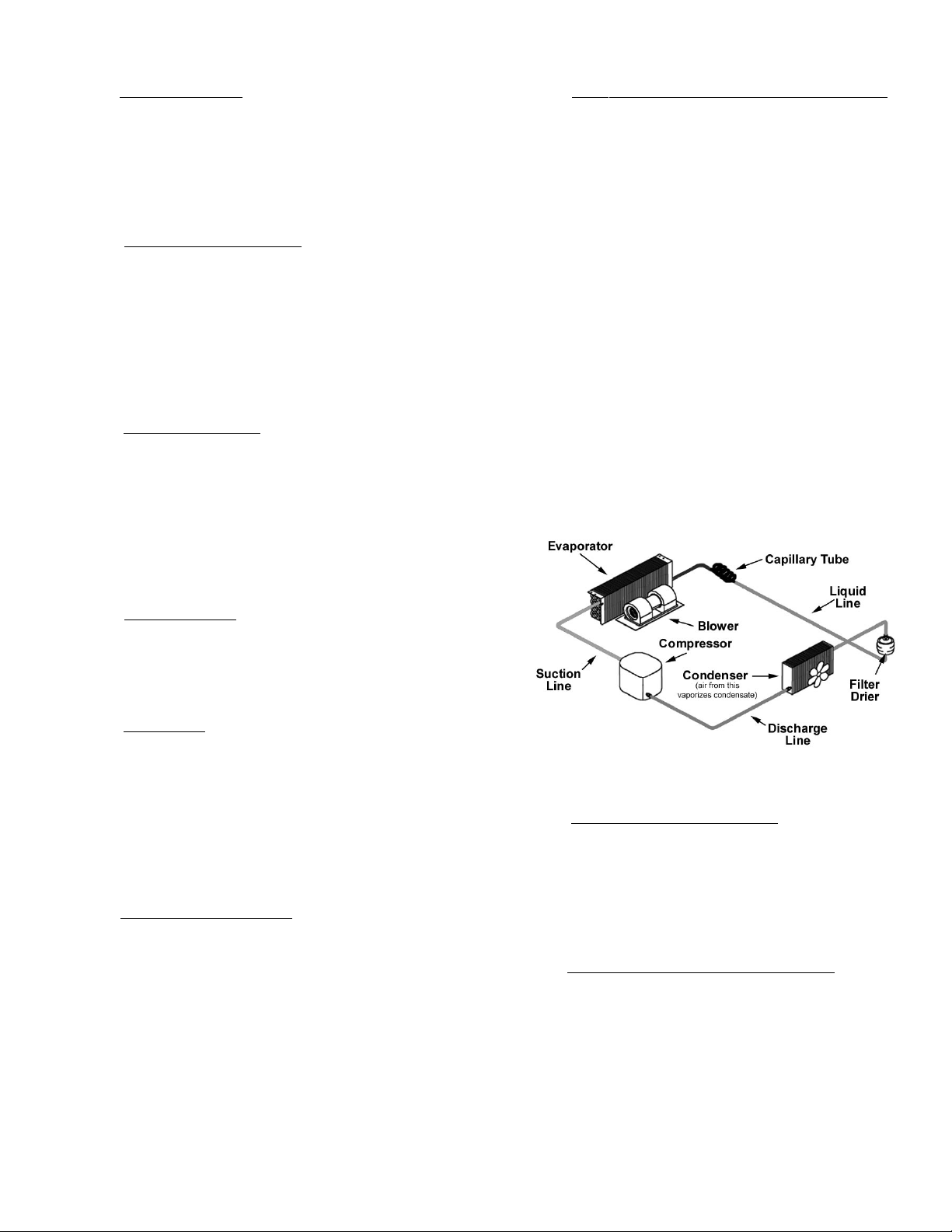

II. g - REF’N SYSTEM - THEORY OF OPERATION:

The refrigeration system is the mechanism whereby

heat is transferred from the cabinet to the outside air.

It works under the principle that the heat moves from

hot to cold as it tries to establish equilibrium.

The microprocessor control signals a need for heat to

be removed from the cabinet. The compressor begins

by compressing the refrigerant gas as it is discharged.

The high pressure refrigerant now circulates through

the condenser, removing heat from the refrigerant and

condensing it into a liquid. From there the refrigerant

flows to the filter drier which removes all traces of

moisture and particles from the system.

After the filter drier, the refrigerant passes through a

“metering device.” Traulsen uses a capillary tube to

regulate the flow of refrigerant into the evaporator

coils.

In the evaporator coil, heat is transferred from the

cabinet to the refrigerant, which changes from a cold

liquid to a warm low pressure gas. When the desired

cabinet air temperature has been reached, the

microprocessor control shuts off the compressor.

II. d - INSTALLATION:

Generally TE-Series refrigeration products are installed

by the dealer, or others contracted by the dealer or

owner. Detailed installation instructions are included

along with each unit when shipped.

II. e - CLEANING:

Detailed cleaning instructions are included with each

unit, however special care MUST be given to the

condenser coil. The condenser coil must be cleaned

at a minimum of every six months. This can be done

with a vacuum cleaner using a brush attachment, or a

stiff brush or wisk broom. For more information please

refer to

Manual.

II. f - TOOL REQUIREMENTS:

For most jobs a standard set of hand tools, a VOM and

AC current tester, along with a temperature tester or

thermometer are adequate. However in some cases

the following additional tools may be required as well:

“Section V.a” of the TE-Series Owner’s

• Refrigeration Guage Manifold

• Refrigeration Reclaiming Equipment

• Acetylene Torch

• Anti-Static Grounding Kit (TL 84919)

• Nitrogen Bottle With Gauges

• Thin 5/16” Open End Wrench

• Refrigerant Reclaim Unit

Fig. 1 - The Refrigeration System

II. h - AIR FLOW REQUIREMENTS:

To assure optimum performance, the condensing unit

of your Traulsen unit MUST have an adequate supply

of air for cooling purposes. Therefore, the operating

location must allow a minimum of 12” clearance in

front of the louvers to allow for unrestricted air flow to

the condensing unit.

II. i - THE MICROPROCESSOR CONTROL:

For detailed information on replacement, repair or

adjustment of the INTELA-TRAUL® microprocessor

control please refer to it’s service manual (form

number TR35705).

-2-

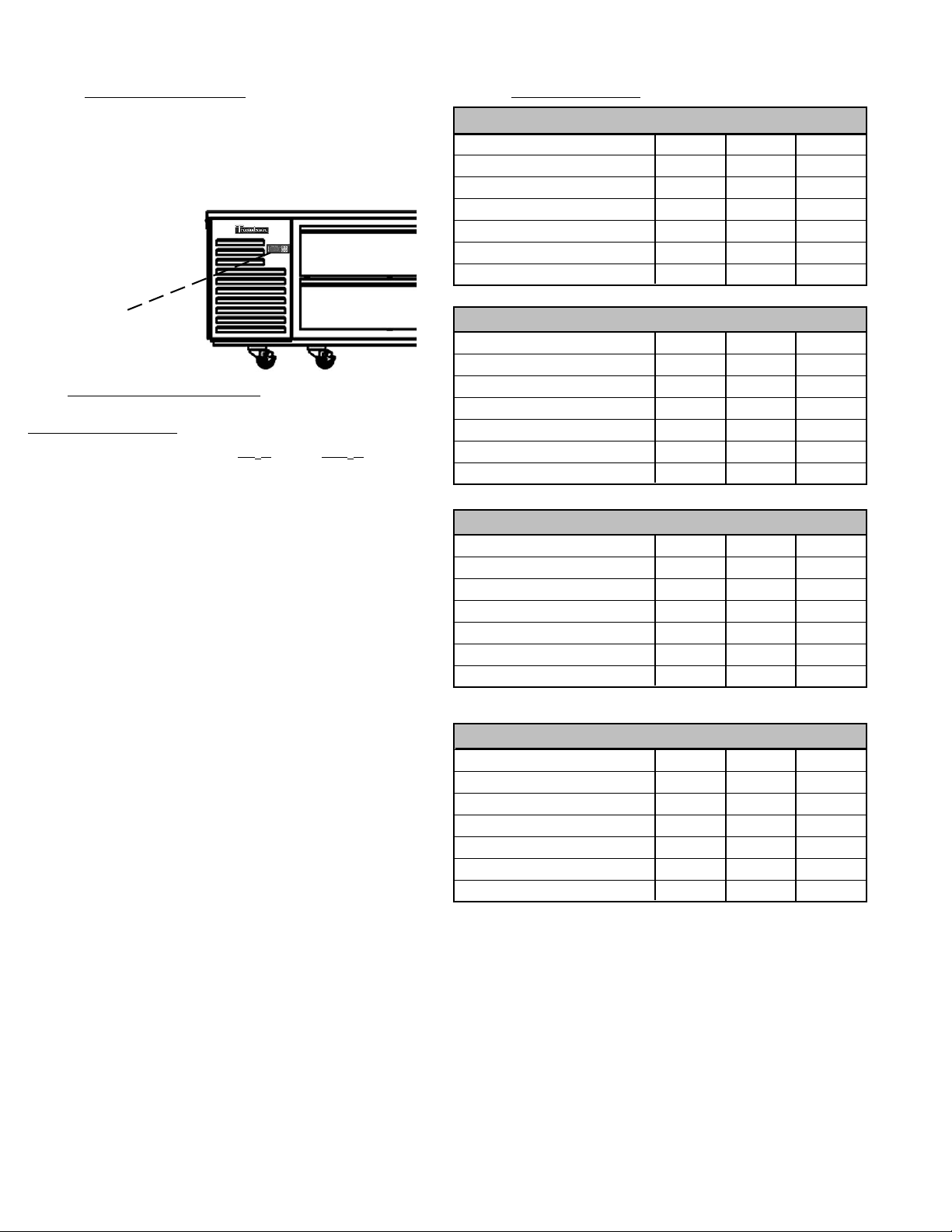

II. GENERAL INFORMATION (cont’d)

II. j - CONTROL LOCATION:

On all TE-Series refrigerator models, the microprocessor control is located on the louver assembly.

The louvers/refrigeration system are mounted standard

on the left side, but as an option are available mounted

on the right (see figure 2).

Fig. 2

Control Location

II. k -

OPERATING DATA CHART:

Refrigerated Models (cabinet temperature set at 38°F)

Ambient 70°F 100°F

Suction Pressure 35 PSIG 50 PSIG

Suction Temperature 3°F16°F

Discharge Pressure 200 PSIG 295 PSIG

Discharge Temperature 88°F115°F

II. l - SPECIFICATIONS:

TE-Series Refrigerated Equipment Stands

TE036 TE048 TE060

Horsepower 1/3 HP 1/3 HP 1/3 HP

Condensing Unit - BTU/HR 2440 2440 2440

Condensing Unit Amp Draw 4.5 4.5 4.9

Fan, Lights, Etc. Amp Draw 0.6 0.6 1.1

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 14.0 14.5 16.0

TE-Series Refrigerated Equipment Stands

TE065 TE072 TE084

Horsepower 1/3 HP 1/3 HP 1/3 HP

Condensing Unit - BTU/HR 2440 2440 2440

Condensing Unit Amp Draw 4.9 4.9 4.9

Fan, Lights, Etc. Amp Draw 1.1 1.1 1.1

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 16.5 16.5 17.0

TE-Series Refrigerated Equipment Stands

TE096 TE110 TE125

Horsepower 1/2 HP 1/2 HP 1/2 HP

Condensing Unit - BTU/HR 4090 4090 4090

Condensing Unit Amp Draw 9.6 9.6 9.6

Fan, Lights, Etc. Amp Draw 1.5 1.5 1.5

Refrigerant R-404A R-404A R-404A

Refrigerant Charge (oz.) 20.0 20.0 20.0

TE-Series Refrigerated Equipment Stands

TE139

Horsepower 1/2 HP

Condensing Unit - BTU/HR 4090

Condensing Unit Amp Draw 9.6

Fan, Lights, Etc. Amp Draw 1.9

Refrigerant R-404A

Refrigerant Charge (oz.) 21.0

-3-

III. REMOVAL & REPLACEMENT OF BASIC PARTS

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE

AND FOLLOW LOCKOUT/TAGOUT PROCEDURES.

III. a - LOUVER ASSEMBLY/SYSTEM ACCESS:

To remove the louver assembly first place your hands

under the louver panel and lift this up off the bracket

and then away from the cabinet face (see figure 3).

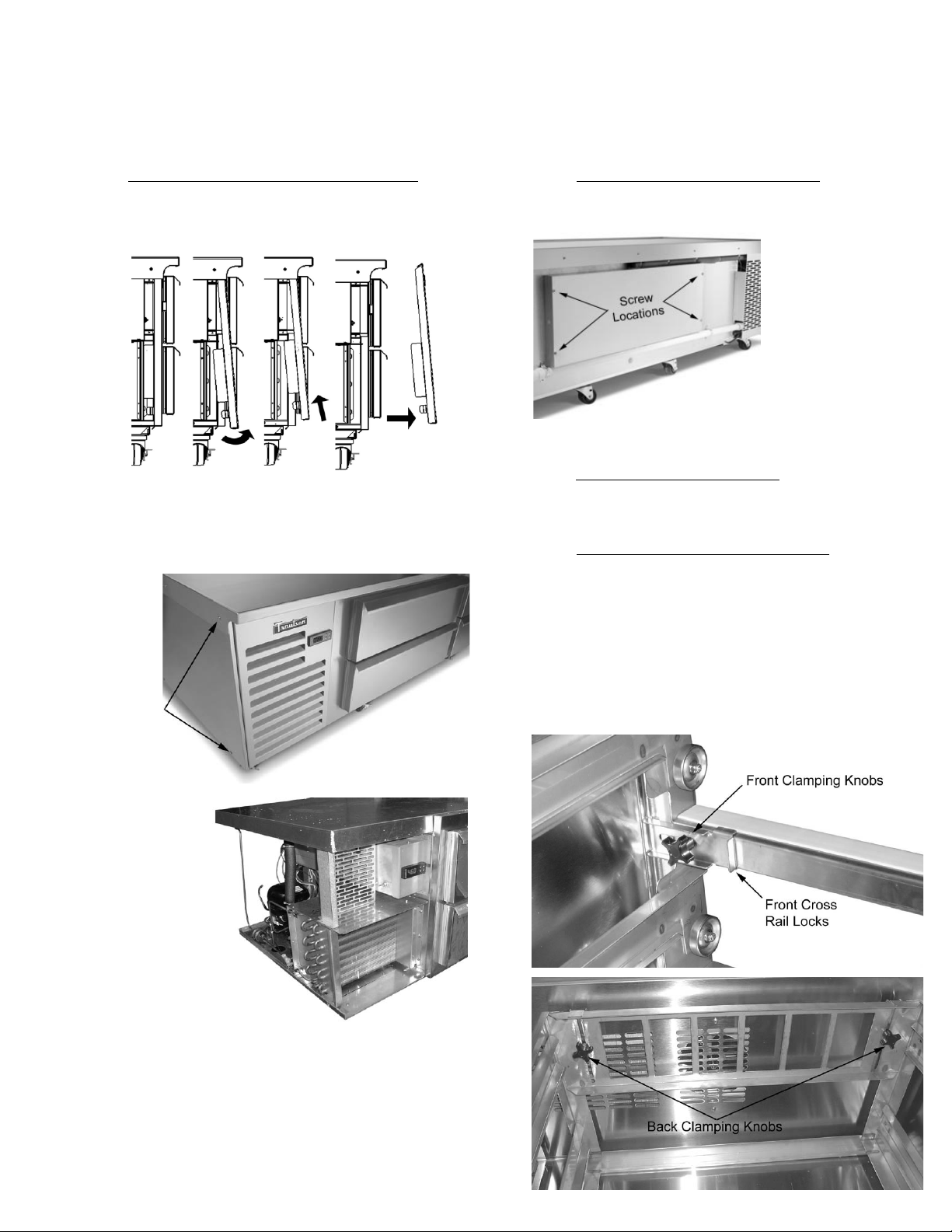

Fig. 3

To gain full access to the refrigeration system from

the side, remove the cover by removing the bottom

screws (see figures 4 & 5).

Fig. 4

Screw

Locations

EVAPORATOR HOUSING COVER:

III. b Remove the back cover by removing the four screws

which secure this to the cabinet (see figure 6).

Fig. 6

Reverse the procedure when done to reinstall.

III. c -

REMOVING THE DRAWERS:

Remove the drawer(s) from the drawer frame by lifting

up on the drawer, and then pulling out.

III. d - REMOVING THE DRAWER FRAME:

Once the drawer(s) have been removed, the drawer

frame module can also be removed by loosening the

front and back clamping knobs (2 of each), located on

the cross-rail and liner locks (see figures 7 & 8). Slide

the front cross-rail locks towards the center of the

drawer frame module and allow the liner locks to drop

down from the top of the liner.Pull the drawer frame

module forward, tip forward and pull out. The entire

frame assembly is now free to slide out of the cabinet.

Fig. 5

Side System

Access

When finished, lower the louver assembly into

position and replace the side panel. Secure these in

place using the previously removed screws.

Fig. 7

Fig. 8

-4-

III. REMOVAL & REPLACEMENT OF BASIC PARTS (cont’d)

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE

AND FOLLOW LOCKOUT/TAGOUT PROCEDURES.

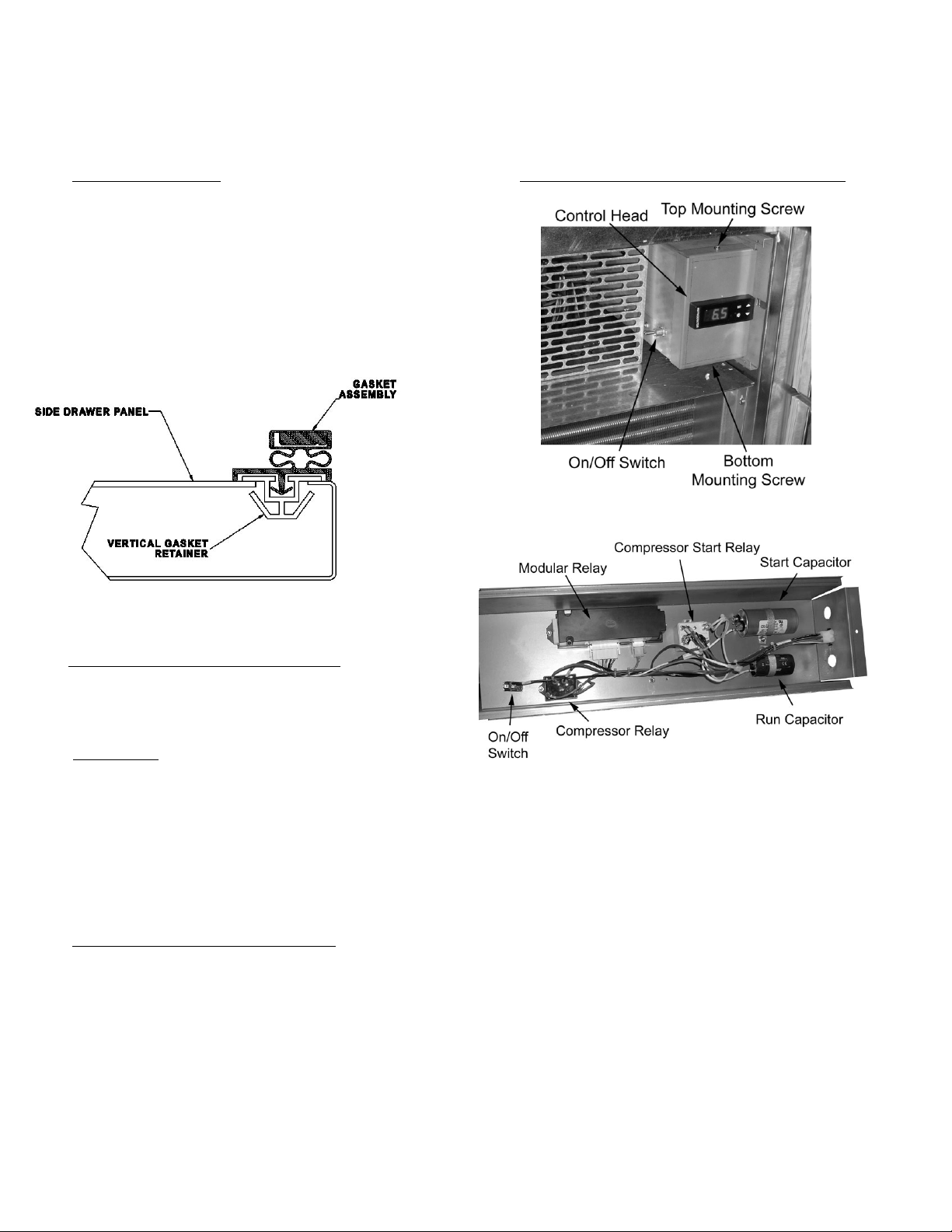

III. e - DRAWER GASKETS:

To remove the gasket to be replaced, grasp it firmly by

one corner and pull it out. Before attempting to install

a new gasket, both the unit and the gasket itself must

be at room temperature. Insert the four corners first

by using a rubber mallet (or hammer with a block of

wood). After the corners are properly inserted, work

your way towards the center from both ends by gently

hitting with a mallet until the gasket is completely

seated in place (see figure 9 for gasket cross section).

Fig. 9

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

III. h - ACCESSING START COMPONENTS (cont’d):

Fig. 10

III. f - THE MICROPROCESSOR CONTROL:

To remove the microprocessor controller from the unit

in which it was installed, please refer to section “V” of

your INTELA-TRAUL® Master Service Manual.

III. g - DRAIN PAN:

To remove the drain pan, begin by removing the

evaporator housing cover as outlined in section “III.

c.” Next, remove the screws and brackets which

secure the drain pan, and remove the drain tube from

the drain pan. Finish by sliding the drain pan out from

under the coil.

Reverse the procedure to install.

III. h - ACCESSING START COMPONENTS:

The start components are located behind the front

louver, inside a metal tray.

To access the start components, first remove the

louver assembly as shown in section III. a. Next loosen

the top set screw (see figure 10). and remove the molex

connection in the back of the box to gain access to

the back set screw. Slide the electrical box out the

font on its tracks.

Fig. 11

See figure 11 for component detail.

-5-

Loading...

Loading...