Page 1

Quality Refrigeration

OWNER’S MANUAL

TB SERIES GLYCOL PIZZA/SALAD/SANDWICH PREP TABLES

4401 Blue Mound Road Fort Worth, Texas 76106 (USA)

Phone: 800.825.8220 | Service Fax: 817.740.6757 | E-mail: service@traulsen.com | Website: traulsen.com

Hours Of Operation: Monday - Friday 7:30 a.m. - 4:30 p.m.

(CST)

Page 2

TABLE OF CONTENTS

1. THE SERIAL TAG Page 1

A) Serial Tag & Location Page 1

B) Reading The Serial Tag Page 1

2. RECEIPT INSPECTION Page 2

3. INSTALLATION Page 2

4. PRESTART CHECKS Page 3

5. OPERATION Page 3

A) Operation Page 3

B) Pan Chiller Page 3

C) Lower Storage Cabinet Page 4

D) Shutdown For Extended Period Page 4

E) Removing Food Product At Night Page 4

F) Leaving Food Product In The Unit

Throughout The Night Page 4

6. CONTROL BASICS Page 4

A) Control Basics Page 4

B) Control Panel Diagram Page 4

C) Enter The Customer Access Page 5

6. CONTROL BASICS (continued)

D) Adjusting The Thermostat Set Point Page 5

E) Adjusting The Thermostat Set Point Differential Page 5

F) Changing the Themperature Scale Page 5

G) Adjusting The Room Temperature Offset Page 5

H) Starting A Manual Defrost Cycle Page 6

I) Viewing Sensor Temperatures Page 6

J) Remote Applications Page 6

7. GENERAL CARE Page 6

A) General Care Page 6

B) Adjusting The Shelves Page 6

C) Cleaning The Condenser Page 6

D) Cleaning The Lower Storage Cabinet Page 7

E) Cleaning The Pan Chiller Page 7

8. TROUBLE SHOOTING Page 7

A) Trouble Shooting Page 8

9. SERVICE/WARRANTY INFORMATION Page 9

A) Service Information Page 9

B) Service Support Information Page 9

C) Warranty Registration Page 9

10. WARRANTIES Page 10

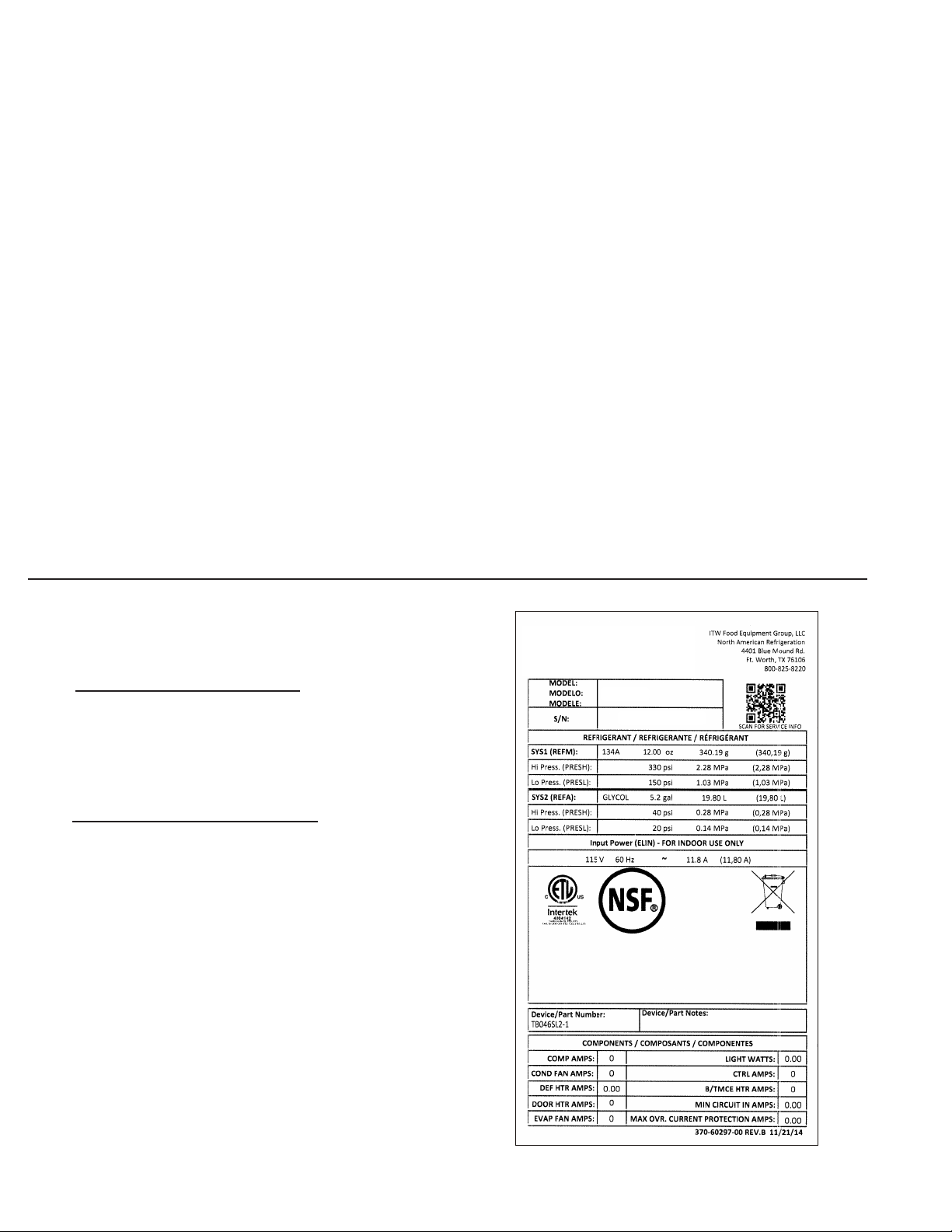

1. THE SERIAL TAG

1. A - SERIAL TAG & LOCATION:

The serial tag is a permanently afxed label on which is recorded

vital electrical and refrigeration data about your Traulsen product,

as well as the model and serial number. This tag is located in the

right interior compartment on all standard TB Series models.

1. B - READING THE SERIAL TAG

• Model = The model # of your Traulsen unit

• (S/N) Serial Number = The permanent ID# of your Traulsen unit

• Refrigerant SYS1= System 1 Refrigerant type used and refrigerant

charge

• Design Pressure= System 1 High and Low Pressure

• Refrigerant SYS2= System 2 Refrigerant type used and refrigerant

charge

• Design Pressure= System 2 High and Low Pressure

• Volts = Voltage

• Hz = Cycle

• Total Current = Maximum amp draw

• Min Circuit Amps = Minimum circuit ampacity

• Agency Labels = Designates agency listings

This unit is listed to UL 471, CSA 120 and NSF 7 by an approved NRTL.

TB SERIES

Page 1

Page 3

2. RECEIPT INSPECTION

3. INSTALLATION

2. A - RECEIPT INSPECTION:

Carefully inspect your Traulsen unit for damage during

delivery. If damage is detected, you should save all crating

materials and make note on the carrier’s Bill of Lading

describing the damage. A freight claim should be led

immediately. If damage is subsequently noted during or

immediately after installation, contact the respective carrier and le a freight claim. There is a ve (5) day limit to

le freight damage with the carrier. Under no condition

may a damaged unit be returned to Traulsen without rst

obtaining written permission (return authorization). You

may contact Traulsen customer care at 800-825-8220.

Some models may use R-290 (Propane)

as a refrigerant. If ammable refrigerant is present, follow

instructions as labeled on the unit. Proper care must be

taken to avoid any damage to the refrigeration system

including refrigerant tubing, condenser, evaporator coils

during handling, moving, installation and cleaning as it

may cause risk of re or explosion. If damaged, unit must

be moved to well ventilated area away from any sources

of ignition.

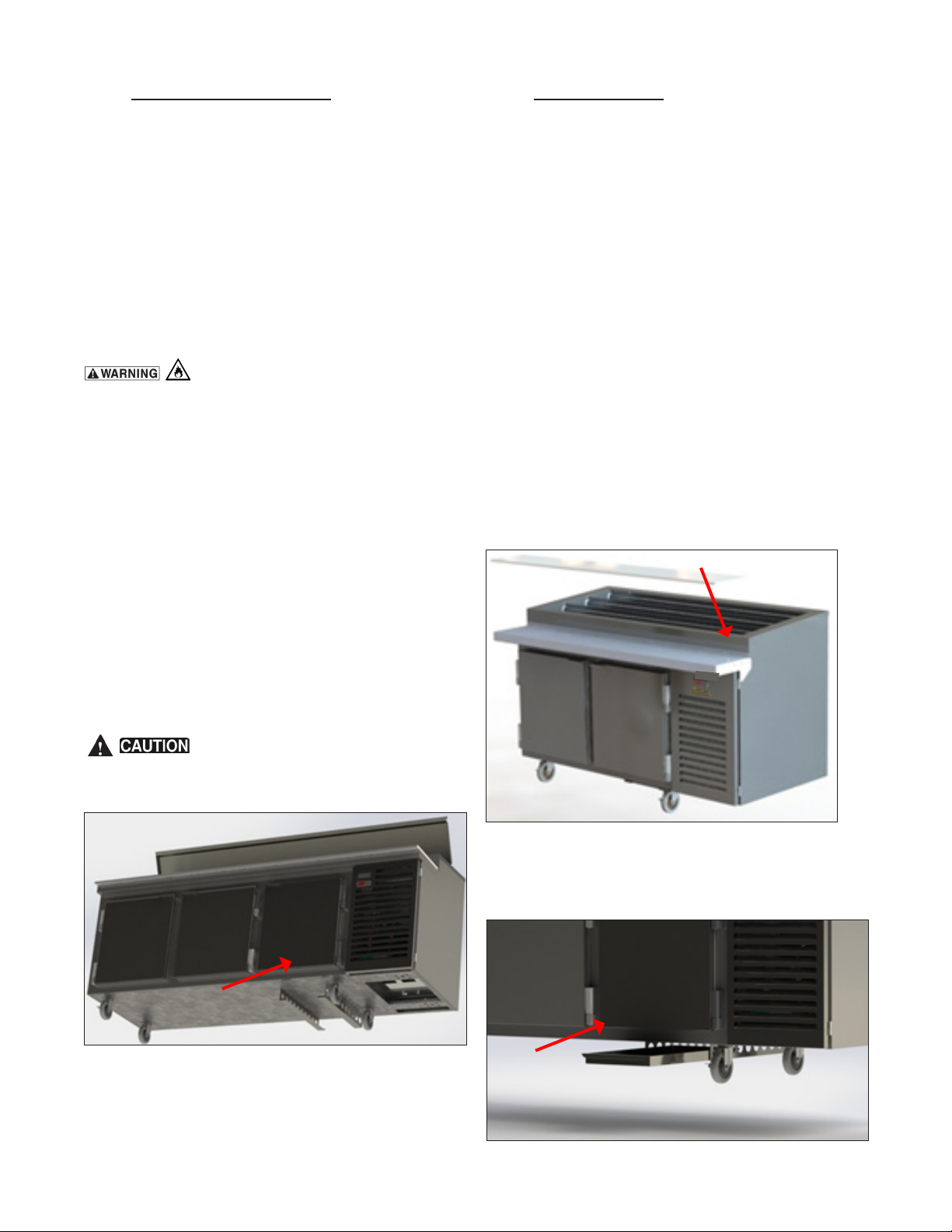

3. A - INSTALLATION:

Prep table models can be installed with no clearance at the back

and sides of the units.

Most units are supplied with a cord and plug, which can simply be

plugged into a dedicated appropriately sized outlet.

For those requiring hard-wiring directly to the power supply, this

should be done only by a qualied electrician. A junction box

located on back of the machine near bottom is provided for electrical eld connections. See Amp Plate inside of the refrigerated

cabinet for electrical ratings.

Some components are packed and shipped inside the lower storage cabinet to avoid damage during shipment. Remove these

items from the cabinet and remove packing materials. If unit is

equipped with shelves, cut and remove the plastic ties holding

the shelves in place.

Place cutting board on rail so that holes in cutting board line up

with pins on the counter top.

Further service and repair must be performed by qualied

refrigeration technicians familiar with applicable safety

standards for ammable refrigerants. Technicians must

use appropriate personal protective equipment and follow applicable safety precautions to avoid risk of re or

explosion.

Do not damage evaporating catch pan

support brackets on the bottom of the unit when lifting the

prep table from the shipping pallet (see photo below)!

Slide evaporating catch pan over support brackets all the way

to the back of the prep table positioning it below the prep table

drain outlets.

TB SERIES

Page 2

Page 4

3. INSTALLATION (continued)

5. OPERATION

3. A - INSTALLATION: (continued):

Open the condensing compartment hinged louver door and check

the glycol level in plastic expansion tank.

A small amount of glycol may spill from tank during shipment. Prior

to startup, tank should be approximately 1/2 full. The glycol used

is a non-toxic food grade (propylene) glycol. Add 35% Propylene

Glycol if necessary.

5. A - OPERATION:

Some models may use R-290 (Propane)

as a refrigerant. Consult detailed owner’s manual available at www.traulsen.com before attempting to install or

service units with R-290 or other ammable refrigerants.

All safety precautions must be followed to avoid risk of re

or explosion. Contact Traulsen for additional information

at 800-825-8220.

Plug cordset into wall outlet (self contained models).

Open the louver door, ip the main power switch ON and

close the door. Observe the Temperature Display through

the opening in the louver door. At start-up, the readout

will ash from RHI High Glycol Temperature to CHI High

Cabinet Temperature to C35 Cabinet Air Temperature,

and to R28 Glycol Temperature this signies that the

temperatures are above normal operating range. After

the temperatures will pull down to 36°F (2°C) for the

Glycol Temperature and 41° F (5°C) for the Cabinet Air

Temperature, the readouts will stop showing RHI and

CHI error messages.

Close louver door remove rear condensing unit cover and check

if glycol ball valve is in the open position. Re-attach rear louver.

Cut zip-tie securing electrical cord and plug cord into wall socket.

GAS REFRIGERATION LINES IN CONDENSING

UNIT AREA ARE SHIPPED UNDER PRESSURE!

4. PRESTART CHECKS

4. A - PRESTART CHECKS:

Glycol Prep Tables are shipped with factory pre-set temperature

settings. Although Traulsen Glycol Prep Tables are tested at factory before shipment, there are variables that can affect cooling

performance of the unit:

• Ambient Temperature

• Humidity Level

• Air stream patterns

• Over-shelves/Heat lamps

• Product temp prior to loading into refrigerated pan chiller well.

• Surrounding equipment.

All temperature settings can be adjusted by the Customer or

Authorized Kairak Service Agent within +/- 3 °F.

Additional message power loss) will appear. Press the Alarm

Cancel Button to cancel ELE LOS message.

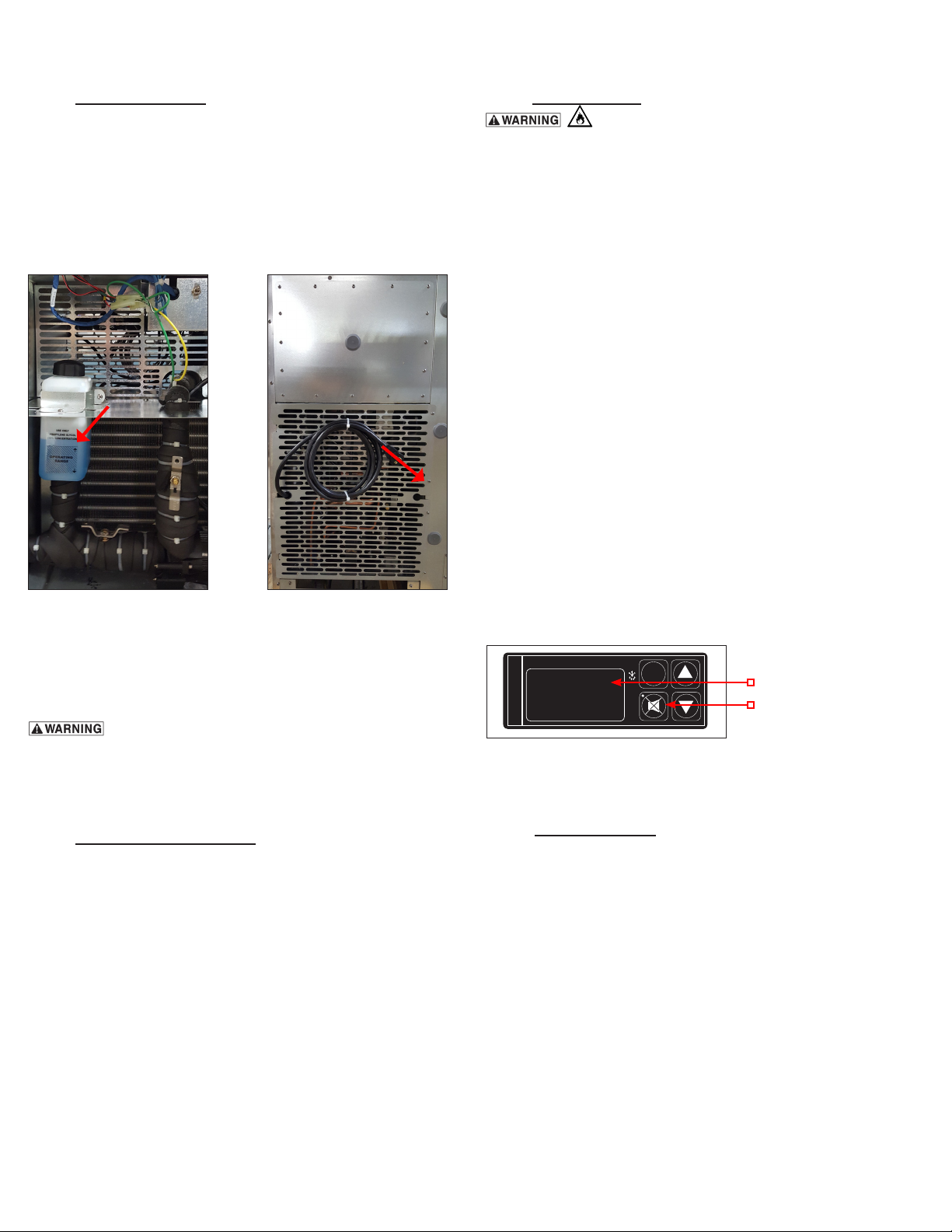

INTELA-TRAUL

°F °C

FREEZER

When the Glycol Temperature cools to 30°F (-1°C), the

unit is ready to go!

SET

1-LED Display

2-Alarm Cancel

Button

5. B - PAN CHILLER:

To ensure proper food temperatures are maintained in

exposed insert pans, the following conditions are recommended.

1. All food brought to line must be at 41°F (5°C) or below.

2. No direct air blowing on food product from other equipment in the kitchen (max air velocity 50 FPM/0.234 Meter/

second).

3. Room ambient temperatures of 86°F (30°C) or less

around working area of Pan Chiller.

4. All shelving mounted over insert pans (with heated

equipment above it) must be insulated. No line of sight

from radiant heat sources to insert pans.

5. Occasional stirring of certain foods may be required in

order to maintain consistent temperatures.

TB SERIES

Page 3

Page 5

6. CONTROL BASICS5. OPERATION (continued)

5. B - PAN CHILLER: (continued)

6. Some food products chill faster than others i.e., lettuce,

dried tomatoes, etc.

7. For remote refrigerators with pan chiller systems, it is

imperative that the existing refrigeration equipment to be

sized properly and in good working condition.

8. Traulsen recommends specied pans for optimum performance (see spec sheet for recommended suppliers).

5. C - LOWER STORAGE CABINET:

The lower storage cabinet is designed to maintain temperature between 33°F (0.55°C) and 40°F (4°C). If the

base is overloaded with warm food products, a certain

amount of time is required to remove heat from items

before operating temperatures can be maintained. The

system is only designed for storage of refrigerated product. Frequently opening the doors or drawers will increase

the temperature in the cabinet and will require a certain

amount of time to recover.

5. D - SHUTDOWN FOR EXTENDED PERIODS:

If the prep table and lower storage cabinet are not to

be used for an extended period of time, disconnect the

electrical power supply and open the doors (or drawers)

to the lower storage cabinet. As soon as the divided bars

and the cabinet have warmed to room temperature, wipe

out the pan chiller cavity and base interior.

5. E - REMOVING FOOD PRODUCT AT

NIGHT:

If you are storing product in the refrigerated storage

base and food needs to be removed from Pan Chiller at

night, simply close the night cover after removing food

pans. This will improve energy efciency during overnight

hours. If ALL food is removed from unit (pan chiller and

refrigerated base both empty), ip the ON/OFF switch to

shut down entire unit. To turn unit back on, ip switch ON.

5. F - LEAVING FOOD PRODUCT IN THE UNIT

THROUGHOUT THE NIGHT: (Recommended)

This unit is preset at factory and does not require periodic

shutdowns for the defrost cycle. This upgraded glycol

refrigeration system eliminates the operational burden

of removing food pans prior to the defrost period or for

overnight storage. No defrost cycle means that food can

be consistently cooled 100% of the time, day or night.

Plastic wrap should be placed over exposed food prior

TB SERIES

Page 4

6. A - CONTROL BASICS:

The product you received is equipped with a state-of-the-art patented microprocessor control, which precisely regulates operation

and provides alarms when problems occur. It is supplied from the

factory completely ready for use and requires no adjustments.

6. B - CONTROL PANEL DIAGRAM :

INTELA-TRAUL

°F °C

FREEZER

CONTROL FEATURES:

a - Water Resistant Housing

• The face of the control is water resistant to provide for protection

during cleaning.

b - Parameter/Service Levels

• See “Customer Access” on page 5.

c - Alarms (See the Troubleshooting Section for explanations)

• High/Low Cabinet Air Temperature

• High/Low Glycol Temperature

• Loss Of Power

• Sensor Failure

Defrost Error

Compressor Run Error

d - Display Features

• 3-Digit LED Display

• Fahrenheit or Celsius Temperature Scale In Use

The temperature reading will alternate every 5 seconds, displaying

SET

1-LED Display

C35 Cabinet Air Temperature and R28 Glycol Temperature.

NOTES TO THE USER:

You only have 20-30 seconds between button pushes. If you take

longer than 30 seconds, the controller will revert back to displaying

the cabinet temperature. If you enter the wrong security code, the

controller will revert back to displaying the cabinet temperature.

You can exit the parameters at any time by waiting 20-30 seconds

for the control to return to normal operation.

Page 6

6. CONTROL BASICS (continued)

6. CONTROL BASICS (continued)

6. C - ENTER THE CUSTOMER ACCESS:

Note: This is required to set any of the control parameters.

To adjust any of the control’s operating features, enter the customer access code. Use the security code 0, A, 1 combined with

the following instructions: Press the SET Button (see 3 below).

INTELA-TRAUL

°F °C

FREEZER

The display will read cus Customer Access. Press the SET But-

ton. The display will show three zeros with the left zero ashing

SET

3-SET Button

5-UP Arrow Button

4-Down Arrow Button

000. Press the SET Button. The display will show three zeros

with the center zero ashing 000. Press the ▼Arrow Button

(see 4 above) to sequence through F, E, d, C, b…etc. When you

reach “A” press the SET Button. The display will show zero, an

A, and a zero with the right zero ashing 0A0. Press the ▲

Arrow Button (see 5 above) to sequence through 1, 2, 3, 4, 5,

6, 7, 8, 9, A, b,…etc. When you reach “1” press the SET Button.

The display will read SP Thermostat Set Point. Press the SET

Button to view and again to exit. You are now ready to adjust the

control. Listed below are the available parameters in the order

they appear, using the ▼Arrow Button on the controller, you can

use either the ▲ or ▼ Arrow Button to scroll through the options.

6. D - ADJUSTING THE THERMOSTAT SET POINT:

SP Thermostat Set Point. This parameter sets the low point of

the desired pan chiller temperature range. Typically, pan chiller

will range from 27° F to 29° F (-2.7° C to -1.7° C) for this parameter setting. This parameter is preset at the factory and does not

have to be adjusted unless the customer chooses to do so. Follow the instructions to enter the Customer Access code on page

5. When the control display reads SP Thermostat Set Point,

press the SET Button. The display will then read preset 27.5

Thermostat Set Point. You can use the ▲ or ▼Arrow Button to

scroll to the next parameter or wait 30 seconds for the control to

return to normal operation.

6. E - ADJUSTING THE THERMOSTAT SET POINT

DIFFERENTIAL:

SPD Thermostat Set Point Differential. This parameter sets the

number of degrees the glycol temp will rise above set point before

the refrigeration system will cycle on. The set point differential

is set at 2.0 which will allow the glycol temperature to rise 2

degrees above Set Point setting before cycling refrigeration on.

This parameter is preset at the factory and does not have to be

adjusted unless the customer chooses to do so.

TB SERIES

Page 5

6. E - ADJUSTING THE THERMOSTAT SET

POINT DIFFERENTIAL: (continued)

Follow the instructions to enter the Customer Access code

on page 5. When the control displays SP Thermostat

Set Point, press the ▼Arrow Button until the control

display reads SPD Thermostat Set Point Differential.

Press the SET Button. Use the ▲ or ▼Arrow Button to

adjust the temperature to your desired setting. When the

display shows the temperature you want press the SET

Button. The display will then read SPDThermostat Set

Point Differential. You can use the ▲ or ▼Arrow Button

to scroll to the next parameter or wait 30 seconds for the

control to return to normal operation.

6. F - CHANGING THE TEMPERATURE

SCALE:

SCL Temperature Scale. The temperature scale deter-

mines if the temperature displayed will be in degrees

Fahrenheit

S for degrees Celsius S C. Follow the instructions to

enter the Customer Access code on page 5.

When the control displays SP Thermostat Set Point,

press the down ▼Arrow Button until the control display

reads sclTemperature Scale. Press the SET Button.

The display will start with the current setting either S f

for degrees Fahrenheit or S C for degrees Celsius. Use

the ▲ or ▼Arrow Button to toggle between the options.

When the display shows the scale you want press the

SET Button. The display will then read SCL Temperature

Scale. You can use the ▲ or ▼Arrow Button to scroll to

the next parameter or wait 30 seconds for the control to

return to normal operation.

6. G - ADJUSTING THE ROOM TEMPERATURE

OFFSET:

RO Room Temperature Offset. The room temperature

offset parameter allows a service technician or end user

the ability to have the display show a temperature that is

within three degrees of the actual temperature being read

by the Glycol Temperature sensor. This allows for continuity of reading between different temperature reading

devices. (i.e.: thermistor vs. thermocouple vs. handheld

thermometer) This parameter is preset at the factory to “0”

or no offset. Follow the instructions to enter the Customer

Access code on page 5.

When the control displays SP (thermostat set point),

press the ▼Arrow Button until the control display reads

RO Room Temperature Offset. Use the ▲ or ▼Arrow

Button to toggle between the options. When the display

shows offset you want press the SET Button. The display will then read RO Room Temperature Offset. You

Page 7

6. CONTROL BASICS (continued)

7. GENERAL CARE

6. H - STARTING A MANUAL DEFROST CYCLE:

SD Start Manual Defrost. This parameter allows a service

technician to start a defrost cycle at any time. This parameter

will override any lockout settings. Follow the instructions to

enter the Customer Access code on page 5. When the control

displays SP Thermostat Set Point, press the ▼Arrow Button

until the control display reads SD Start Manual Defrost.

Press the SET Button. The display will show OFF. Press

either the ▲ or ▼Arrow Button. The display will show On.

Press the SET Button. The defrost icon will be lit when the unit

is in defrost (see 6 below).

INTELA-TRAUL

°F °C

FREEZER

Press either the ▲ or ▼Arrow Button to scroll through the parameters, or wait 30 seconds for the control to return to normal

operation.

SET

6-Defrost Icon

6. I - VIEWING SENSOR TEMPERATURES:

These parameters allow a service technician or customer to

view the temperature of all sensors within the unit. The temperatures cannot be adjusted. Follow the instructions to enter the

Customer Access code on page 5. When the control displays

SP Thermostat Set Point, press the ▼Arrow Button until the

control display reads CB Rail Sensor or EL Cabinet Sensor

or LL Liquid Line Sensor. Press the SET Button to view the

current sensor value. Press the SET Button when done. Press

either ▲ or ▼Arrow Button to scroll through the parameters, or

wait 30 seconds for the control to return to normal operation.

FOR ALARM EXPLANATIONS SEE TROUBLE SHOOTING

PAGE 8.

6. J - REMOTE APPLICATIONS:

For remote applications consult factory. For proper operation

of remote equipment, Traulsen recommends all remote glycol

racks to provide a constant supply of 20°F (-6.7°C) glycol without any interruption in prescribed ow or capacity. The glycol

supply temperature should operate +-2° differential. Every

three (3) hours, the glycol temperature must elevate to +35°F

(1.7°C) for thirty (30) minutes to shed frost from the chiller plate

surface. After the thirty minute duration, the glycol temperature

should resume 20°F (1.7°C)+-2° operation. Flow rates for all

Traulsen equipment are noted in their respective specication

documents. Temperature and ow rate values may need to be

adjusted depending on site conditions. Contact factory before

making any adjustments.

7. A - GENERAL CARE:

Disconnect electrical power supply

before cleaning any parts of the unit. All Traulsen

gylcol equipment should be cleaned only with

warm water, mild soap and a soft cloth. Apply with

a dampened cloth and wipe in the direction of the

metal grain.

Avoid the use of strong detergents and gritty, abrasive

cleaners as they may tend to mar and scratch the

surface. Do not use cleansers containing chlorine, this

may promote metal corrosion.

Care should also be taken to avoid splashing the unit

with water, containing chlorinated cleansers, when

mopping the oor around the unit.

For stubborn odor spills, use baking soda and water

(mixed to a 1 TBSP baking soda to 1 pint water ratio).

7. B - ADJUSTING THE SHELVES:

Shelves and shelf clips are shipped with the unit. For

each shelf, insert four (4) shelf clips into the pilaster

slots at the same height. The shelf clips have a small

projection on top which holds the shelf in position and

prevents it from slipping forward. After installing shelf

clips on pilasters, place shelves on clips.

7. C - CLEANING THE CONDENSER:

Disconnect electrical power supply

before cleaning any parts of the unit.

The condensing unit coil and lter must be cleaned

regularly on self-contained models for optimal performance. The operating environment will affect the

required frequency of cleaning. However, both should

be cleaned a minimum of once every three months. Air

must be able to freely circulate through the condenser.

Unit performance and operating efciency are signicantly affected by the amount of air passing through the

condenser. Condenser ns that are clogged with dirt

and debris greatly reduce airow and removal of heat.

Failure to keep the coil ns and the air lter clean may

cause premature compressor failure, which will not be

covered by warranty. (On models that contain lters,

operating unit without lter will void warranty).

Evaporator coils should be cleaned every six (6)

months for optimal performance.

TB SERIES

Page 6

Page 8

7. GENERAL CARE (continued)

7. GENERAL CARE (continued)

7. C - CLEANING THE CONDENSER:

The evaporator coils are located in the storage cabinet

behind the coil can cover. With a Phillips head screwdriver, remove four screws and take off cover. Clean

evaporator coils with a vacuum cleaner or soft brush,

do not use a wire brush. Replace coil can cover. Reconnect electrical supply.

The air lter in all the prep tables is located in the interior rear louver door and does not require any tools for

removal (see below).

7. E - CLEANING THE PAN CHILLER:

Use water, a mild detergent and a soft cloth or sponge to clean the

pan chiller. There is one drain located in the pan chiller, provided

for condensate run-off. Drain must be cleared/cleaned regularly

for proper operation. Drains should be cleaned at a minimum of

once a month.

The drain in the plan chiller compartment is typically located above

the louvered compressor compartment. A removable screen has

been provided to prevent the drain from clogging. Clear drain of

dirt and debris so that condensate can ow freely.

7. D - CLEANING LOWER STORAGE CABINET:

Use warm, soapy water to clean lower storage cabinet and doors. NEVER use cleaners containing grit,

abrasive materials, bleach or harsh chemicals. Rinse

thoroughly and dry with a clean soft cloth. Always rub in

the same direction as the grain pattern on the stainless

steel.

To clean the inside of the lower storage cabinet,

remove wire shelves. All wire shelves are adjustable

and can be easily removed. Clean shelving in a sink. If

the shelf clips have been removed, make sure the four

clips per shelf are at same height in pilaster.

7. D - CLEANING LOWER STORAGE

CABINET: (continued)

The shelf clips have a small projection on top which

holds the shelf in position and prevents it from slip-

If drain is piped to oor sink, pan chiller may be ushed with clean

water & mild detergents. Do not leave standing water in pan chiller.

8. TROUBLE SHOOTING

8. A - TROUBLE SHOOTING:

Some models may use R-290 (Propane) as a

refrigerant. Service and repair must be performed by qualied

refrigeration technicians familiar with applicable safety standards

for ammable refrigerants. Technicians must use appropriate

personal protective equipment and follow applicable safely precautions to avoid risk of re or explosion.

Service and repair must be performed in well ventilated and

unconned area, away from any ignition sources. All system

components must be replaced with like components. Factory

recommends to use exact make and models to assure the consistent performance and to minimize the risk of possible ignition

due to incorrect parts. In case of uncertainty or parts unavailability,

contact Traulsen technical assistance at 800-825-8220.

TB SERIES

Page 7

Page 9

8. TROUBLE SHOOTING (continued)

8. A - TROUBLE SHOOTING: (continued)

SYMPTOM AND CONTROL

POSSIBLE CAUSE RECOMMENDED ACTION

ALARM

1. Unit doesn’t run? a) No power to unit.

2. Cabinet not maintaining temp.

(base cabinet warmer than 41°F/5°C)

CHI High Cabinet Air Temperature

CL N fin Condenser coil requires

cleaning

3. Cabinet not maintaining temp (base

cabinet is colder than 35°F/1.6°C)

b)Main power switch is in OFF position.

a) Base cabinet overloaded with warm

food product (food temperature above

41°F/5°C)

b) Doors open for extended periods of

time.

c) Door gasket not sealing properly

d) Air lter dirty

e) Condenser coil dirty

f) Inadequate air circulation due to product loading

g) Circulation fan faulty

h) Low refrigerant

a) No product in unit.

b) Failed sensors.

c) Stuck Evaporator Relay.

Clo Low Cabinet Temperature

4. Prep top not maintaining temp

(Chiller Rail temp warmer than

35°F/1.6°C)

a) Prep top overloaded with warm

food product (food temperature above

41°F/5°C)

Low refrigerant

RHI Glycol temperature is too high

5. Prep top not maintaining temp

(Chiller Rail temp colder than 27°F/-

2.8°C Set Point) Clo Glycol tem-

perature is too low

a) Glycol Temp. Sensor malfunction.

b) Control system components malfunc-

tioning

a) Plug in unit and check circuit breaker.

b) Remove louver panel, reach inside compressor compartment

and ip switch to ON position.

a) Remove warm food product and replace with properly chilled

product (food must be colder than 41°F/5°C before placement

into base cabinet)

b) Replace door gasket

c) Clean or replace air lter

d) Clean condenser coil

e) Shift pans/boxes to create clearance for air circulation

f) Check fan connections and replace fan if necessary

g) Call Service

h) Call Service

a) Check and replace sensor if necessary.

b) Replace evaporator relay.

a) Remove warm food product and replace with properly chilled

product (food must be colder than 41°F/5°C before placement

into prep top) Check for leaks, recharge the system

a) Check and replace sensor if necessary.

b) Check and replace control system components.

6. Compressor run time exceeds 24

hours.

7. Sensor Failures:

a) Glycol Temp. Sensor malfunction.

b) Low in refrigerant.

a) Check and replace sensor if necessary.

b) Check for leaks, recharge the system

a) Replace sensors.

sN1 Glycol temp. sensor (green)

sN2Defrost cycle termination sensor

(blue)

sN3Cabinet Air Temp.(yellow)

8. Chiller plates are coated in water

and/or ice (thin layer).

9. Defrost cycle time exceeds 120

min.

10. Chiller plates develop thick (1/8”

or more) layer of ice.

11. Pans don’t t in prep top. a) Incorrect pan model. a) Check model specs for a list of compatible pans

12. Clear water is dripping from unit. b) Catch pan is overowing or missing. a) Clean and replace catch pan in channel located underneath

13. Loss Of Power error message

ELE LOS.

a) Normal operation a) No action required. Condensation on the chiller plates will

a) Sensor malfunctioning.

b) Hot ambient environment in the

kitchen.

a) Control set below standard factory

settings.

b) Excessive compressor runtime.

a) Unit regains power after an outage or

plugged in the rst time.

occur

in most kitchen environments. Occasionally, a thin layer of ice

may develop for a short period of time.

a) Replace the sensor.

b) Block prep table from the heat source.

a) Adjust control to factory settings.

b) Clean lter and clean condenser coil if necessary.

the prep table base, ensuring that the pan reaches the drain

lines in the back of the cabinet.

a) To clear the visual text, press the Alarm Cancel Button (see

page 3 for button location).

TB SERIES

Page 8

Page 10

9. SERVICE/WARRANTY INFORMATION

9. A - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the electrical cord plugged in?

Is the fuse OK or circuit breaker on?

Clean condenser coil

Is the power switch on?

If after checking the above items and the unit is still not operating properly, please contact an authorized Traulsen at:

4401 Blue Mound Road Fort Worth, TX 76106 (800) 825-8220.

Traulsen reserves the right to change specications or discontinue models without notice.

9. B - SERVICE SUPPORT INFORMATION:

To purchase replacement parts or to speak to service support for Traulsen units please contact our Ft. Worth facility by phone

at 800-825-8220 or fax to 817-740-6748 (parts) or 817-740-6757 (service).

Note: When calling for spare parts or service support, please make sure you have model and serial number of unit

available.

Model Number

Serial Number

]

9. C - WARRANTY REGISTRATION:

The warranties for your new Traulsen unit may be registered with us by contacting our Ft. Worth facility directly by phone

at 800-825-8220.

Both three year parts and labor warranty and a ve year compressor warranty are provided standard.

TB SERIES

Page 9

Page 11

10. WARRANTIES

TRAULSEN EQUIPMENT WARRANTY

v. 100215

U.S. Domestic Warranty

For sales of Traulsen refrigeration equipment (“Equipment”) within the United States, Traulsen warrants to the original

purchaser of the Equipment (“Purchaser”) that Traulsen will convey the Equipment free and clear of all liens, security

interests, and encumbrances created by, through, or under Traulsen. Traulsen further warrants that for a period of three (3)

years from the later of either (a) the date of delivery to the common carrier or (b) the date of installation (the “Domestic

Warranty Period”) but in no event, shall the Domestic Warranty Period commence later than 18 months from the date of

delivery to the common carrier unless otherwise agreed upon by the parties in writing, under normal use and given proper

installation and maintenance as determined by Traulsen, the Equipment: (a) will conform to the specifications as provided

by Traulsen (“Specifications”) and (b) will be free from substantial defects in material and workmanship.

The warranty period for compressors shall extend for an additional two (2) years beyond the Domestic Warranty Period. In

the case of a nonconforming compressor, Traulsen shall provide a replacement compressor; however all installation,

recharging, and repair costs shall be the responsibility of Purchaser. In the case of a nonconforming part, Purchaser must

return the part to Traulsen within 30 days from the date of repair. Failure to return a claimed defective part to Traulsen

within the 30 days will waive the right to the warranty claim.

Additionally, Traulsen provides a lifetime warranty on the housing of cam-lift hinges and the workflow handles. In the case

of a non-conforming housing for cam-lift hinge or workflow handle, Traulsen shall provide a replacement part; however

Purchaser shall be responsible for any other replacement costs, including but not limited to installation and labor.

The Domestic Warranty does not apply to: (a) consumable components or ordinary wear items; (b) components that are

removable without the use of tools including but not limited to gaskets, shelf pins, and light bulbs; (c) use of the Equipment

components or parts not supplied by Traulsen or specified by Traulsen in the Operator’s Manual as set forth on Traulsen’s

website; or (d) damage resulting from fire, water, burglary, accident, abuse, misuse, transit, acts of God, terrorism, power

surges, improper installation, or repairs or installation by unauthorized third parties.

For Traulsen units purchased for use with a condenser provided by a third-party, this standard warranty will apply only to

those components contained within the unit to the point of connection of the refrigeration lines leading to the third-party

condenser.

In the event of a breach of the warranties set forth above (the “Domestic Warranty”), Traulsen will, at Traulsen’s option and

as Purchaser’s sole remedy, repair or replace, including labor costs, any nonconforming Equipment, provided that (a) during

the Warranty Period Traulsen is promptly notified in writing upon discovery of the nonconformance with a detailed

explanation of any alleged deficiencies; (b) Traulsen is given a reasonable opportunity to investigate all claims; and (c)

Traulsen’s examination of any alleged defective part confirms such alleged deficiencies and that the deficiencies were not

caused by misuse, neglect, improper installation, unauthorized alteration or repair or improper testing. Traulsen reserves the

right to, at its request, require Purchaser shall ship the alleged defective part to Traulsen for inspection and confirmation of

defect. No Equipment may be returned without Traulsen’s approval.

Purchaser is solely responsible for determining if Equipment is fit for a particular purpose and suitable for Purchaser’s

application. Accordingly and due to the nature and manner of Traulsen’s Equipment, Traulsen is not responsible for the

results or consequences of use, misuse, or application of its Equipment.

THIS DOMESTIC WARRANTY SETS FORTH THE EXTENT OF TRAULSEN’S LIABILITY FOR SALES WITHIN

THE UNITED STATES. EXCEPT AS SET FORTH ABOVE, TRAULSEN MAKES NO WARRANTY OR

REPRESENTATION OF ANY KIND, EXPRESS OR IMPLIED (INCLUDING NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE). IN NO EVENT WILL TRAULSEN’S

LIABILITY IN CONNECTION WITH THE AGREEMENT OR SALE OF THE EQUIPMENT EXCEED THE

PURCHASE PRICE OF THE EQUIPMENT AS TO WHICH THE CLAIM IS MADE. IN NO EVENT SHALL

TRAULSEN BE LIABLE FOR ANY LOSS OF USE, LOSS OF PRODUCT, LOSS OF PROFIT, OR ANY OTHER

INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES RESULTING FROM THIS WARRANTY

EVEN IF TRAULSEN HAS BEEN NOTIFIED OF THE POSSIBILITY OF SUCH DAMAGES.

TB SERIES

Page 10

Page 12

Quality Refrigeration

4401 Blue Mound Road Fort Worth, Texas 76106 (USA)

Phone: 800.825.8220 | Service Fax: 817.740.6757 | E-mail: service@traulsen.com | Website: traulsen.com

Form Number: TR36009 | Part Number: 375-60347-00 | Revision Date: 10-31-17

Traulsen © All Rights Reserved

Loading...

Loading...