Page 1

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation, use & care of:

TBC Series Blast Chillers

TBC5 Undercounter Model

TBC13 Reach-In Model

TBC1H/TBC1HR Roll-In Model

I. INSTALLATION CHECKLIST:

Remove the crate and wooden pallet using a 3/4” socket wrench. Do not lay

the unit on its front, side or back.

Install in a level location away from extreme heat or cold. Allow adequate

clearance for proper airflow.

Install legs or casters (TBC5 & TBC13), or seal to floor (TBC1H). The caster

bolts require a 1/2” socket wrench.

WARNING: The cabinet must be blocked and stable before installing

legs or casters.

Remove the plastic ties used to secure the interior slides on models TBC5

and TBC13 during shipping.

Select a dedicated electrical outlet of the proper amperage.

NOTE: Do not cut or remove the grounding prong from the plug or use an

extension cord.

* TBC5 includes a NEMA 5-15P cord set.

* TBC13 includes a NEMA L-14-20P cord set.

* TBC1H & TBC1HR must be hardwired.

Insure there are no obstructions blocking the louver panel. This will allow

for sufficient air flow and maintenance access.

NOTE: Model TBC13 requires 6” clearance on the left and right sides.

Insure that a floor drain or optional condensate evaporator is provided for

models TBC13 and TBC1H.

TBC1H/TBC1HR require a remote condensing unit capable of providing

18,700 BTU/hr @ -100F evaporator temp in a 900F environment.

NOTE: Proper line sizing should be determined by a qualified refrigeration

technician.

Install ramp on model TBC1H/TBC1HR after sealing to the floor.

II. PAN & APPROX. CHILL CAPACITY:

Model 18”x26”

Pan

TBC5 5 10 100

TBC13 13 26 200

TBC1H 1 Rack 1 Rack 300

NOTE: Actual weight of product that can be safely chilled within FDA

guidelines varies greatly depending upon product density and pan.

12”x20”

Pan

Product

Weight

III. CARE & MAINTENANCE:

WARNING: Disconnect electrical power supply before cleaning any parts of

of the unit.

a. CLEANING THE EXTERIOR & INTERIOR:

Exterior stainless steel should be cleaned with warm water, mild soap and a soft cloth. Apply

with a dampened cloth and wipe in the direction of the metal grain. Avoid the use of strong

detergents and gritty abrasive cleaners as they may tend to mar and scratch the surface.

Do Not use cleansers containing chlorine, this may promote corrosion of the stainless steel.

For stubborn odor spills, use baking soda and water (1 TBSP baking soda to 1 pint water ratio).

For cleaning stainless steel interiors the use of baking soda as described above is recommended. Use on breaker strips as well as door gaskets. All interior fittings are removable

without tools to facilitate cleaning.

b. CLEANING THE CONDENSER:

The self-contained condensing unit requires regularly scheduled cleaning to keep the finned

condenser clean of lint and dust accumulation.

To clean the self-contained condenser, first disconnect electrical power, then access the coil:

TBC5 & TBC13: Remove the front louver panel at bottom.

TBC1H/TBC1HR: Remove the louver assembly on the top/front of the cabinet.

Vacuum or brush any dirt, lint or dust from the finned condenser coil, the compressor and

other cooking system parts. If significant dirt is clogging the condenser fins, use compressed

air to blow this clear.

IV. CHANGING THE PRINTER PAPER:

Printer paper is available from Traulsen or your local Hobart Service office. It’s also available at most office supply outlets.

Traulsen Part Number: 400-60003-00

Office Depot Item Number: 302-224

Staples Item Number: PMF-5233

The label printer uses a special peel-off label stock:

Traulsen Part Number: 400-60004-00 (225 labels per roll)

To reload the paper, begin by opening the cover to access the printer(s). Remove the empty

paper roll and place a new roll on spindle. Position the paper such that the paper feeds

from the back of the roll. This allows the thermal sensitive side of the paper to be on the

upper surface as it feeds through the printer. The ends of the spindle are installed in the

roll holders on each side of the paper cradle.

Gently pull the feed roller tension arm slightly forward. It is located on the top of the printer

and will open about 90 degrees.

Feed paper down into the loading slot directly behind the fed roller tension arm.

Return the feed roller tension arm to its original position. If this is not closed the printer will

not operate. Labels are loaded in the same manner. NOTE: After turning the chiller on

the label printer will automatically orient the next label for printing.

TR35941 P/N 375-60311-00 (rev. 3-13)

Page 2

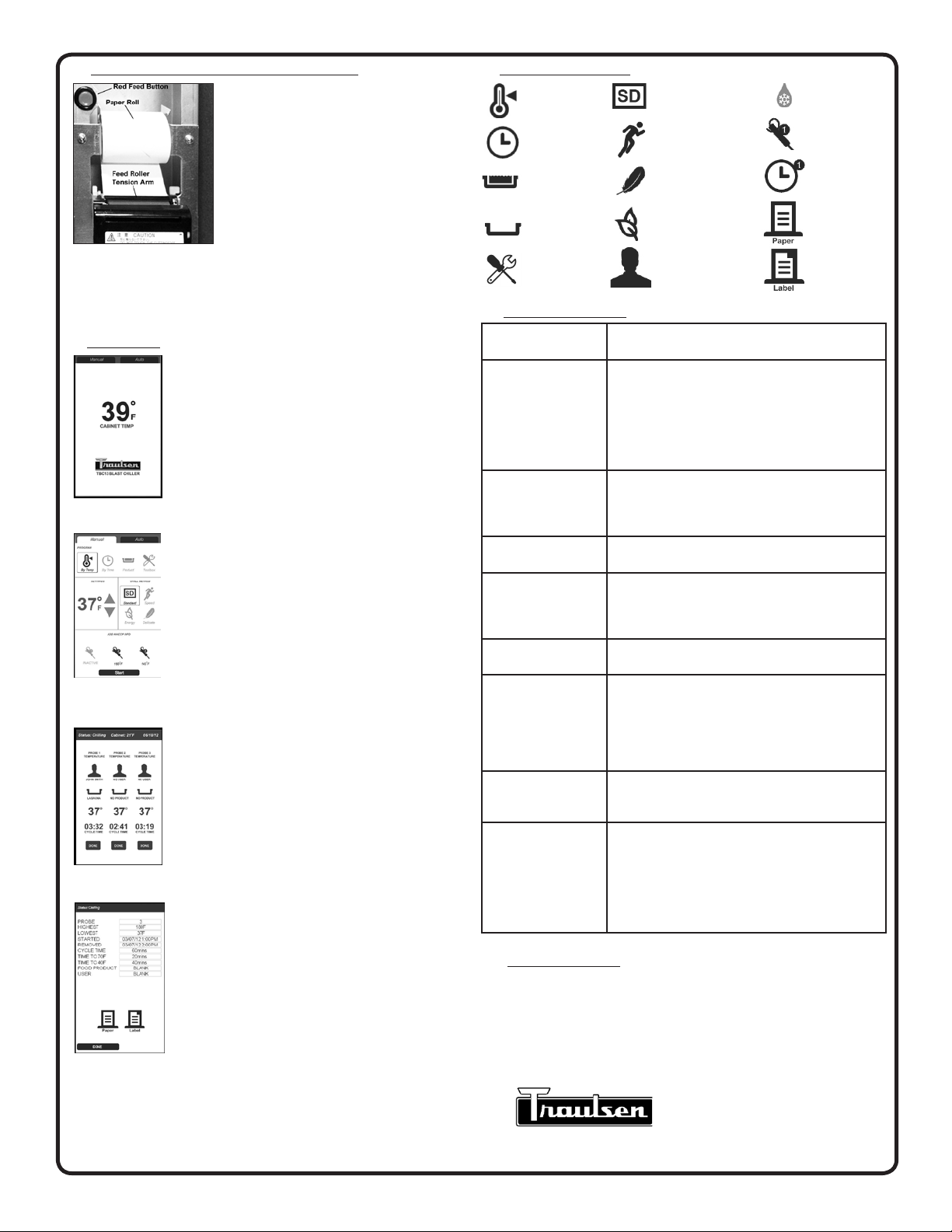

IV. CHANGING THE PRINTER PAPER:(continued)

VI. GLOSSARY OF ICONS:

Chill By Temp

Standard Chill

Defrost

Press the red feed button to feed paper through the printer.

Replace the printer cover or close the printer door, taking care that the paper or label is

passed through the paper slot on it’s front.

V. OPERATION:

STARTING A CHILL CYCLE

AUTO:

1) Place probe in product (must be above 90 degrees F). The

chiller will automatically begin a chill cycle in 30-seconds (target

37 degrees F).

OPTIONAL: Press any active probe(s) to enter the PRODUCT and/

or USER names.

IDLE MODE

STARTING A CHILL

CYCLE

THE RUN SCREEN

DATA

MANAGEMENT

MANUAL (by temp):

1) Place probe(s) in product.

2) Select MANUAL.

3) Adjust target TEMP and CHILL METHOD (if desired, default 37

degrees F).

OPTIONAL: Press any active probe(s) to enter PRODUCT and/or

USER names.

4) Press START.

MANUAL (by time):

1) Load product in chiller.

2) Select MANUAL.

3) Adjust target TIME.

OPTIONAL: Press any time zone to enter product and or user

names.

4) Press START.

CYCLE COMPLETION & PRINTING

Upon any probe reaching the target temperature the chiller will

beep for 20-seconds and the button beneath this probe will

change from CANCEL to DONE.

1)Press DONE.

OPTIONAL: Press PRODUCT and/or USER to enter the product

and/or user names, if not done previously.

2)Press RECORD and/or LABEL (if equipped with optional label

printer) to receive a cycle data printout and/or adhesive label.

Repeat for additional copies if needed.

3)Press DONE to return to the RUN (if additional probes are active

or done) or IDLE screens.

NOTE: Cycle data can also be downloaded via the USB port by

selecting DATA MANAGEMENT in the TOOLBOX.

Many default settings can be adjusted, see full size owner’s

manual for additional details.

© 2013 Traulsen - All Rights Reserved

Chill By Time

Chill By Product

Product

Toolbox

Speed Chill

Delicate Chill

Energy Saving Chill

User

Probe

Time Zone

Print Record

Print Label

VII. TROUBLESHOOTING:

No display on control. a. Check power supply and circuit breaker.

Cycle time longer than

expected.

Auto start does not work. a. Probe n/a. Press DONE to release probe for use.

Chill cycle starts with no

product present.

Unwanted product

freezing.

Food drying out during

chilling.

Printer not printing. a. Printer is out of paper.

Condensation on exterior

surface.

Product temp appears

cooler than expected.

b. System problem. Call for service.

a. Check if door is closed.

b. Excessive volume or depth of product loaded.

c. Pan covered with a lid, plastic wrap or foil that is not in

direct contact with the product.

d. Dirty condenser coil.

e. Product is of a high density.

f. Evaporator coil iced and defrost needed.

b. Probe not placed in product.

c. Food probe placed in product below 100

d. Damaged or defective probe.

a. Probes started automatically due to their temp rising to

0

F or more.

100

a. DONE product not removed and new chill cycle started.

Remove product when Done.

b. Chill cycle By Time set for too long.

c. High water content food. Use DELICATE method.

a. Food chilled uncovered.

b. Printer paper may be installed incorrectly. Verify that the

thermal sensitive side of the paper.

c. Feed door open.

d. Paper does not feed or jams behind the paper feed slot in

the cover. Remove paper, reinstall correctly.

a. Check door alignment and gasket for proper seal.

b. Check door sweep for proper adjustment (roll-ins).

c. Electric door heater malfunction. Call for service.

a. Product temperatures within batches often vary. Verify

product temperature using a thermometer.

b. Probe placed incorrectly. Relocate probe.

c. Product has very small mass (ex. chicken tender) use chill

by time.

d. Product held at room temperature too long prior to being

placed in chiller. Verify actual product temp.

0

F.

VIII. SERVICE & PARTS:

Please visit our website @ traulsen.com for additional service and parts information.

From our home page click on the SERVICE & PARTS tab, and select one of the following:

SERVICE FINDER

SERVICE PARTS MANUALS

OPERATOR MANUALS

WARRANTY REGISTRATION

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 or (817) 625-9671

Quality Refrigeration

Parts Fax: (817) 817-740-6748

Website: traulsen.com

Loading...

Loading...