Page 1

SISTF10xx-141-LR(T)

10/100Base-TX to 100Base-FX

Industrial Unmanaged Switch

Installation Manual

Rev. A

5-July-2007

Page 2

Page 3

Transition Networks

Table of Contents

Trademark, copyright, and product classification information ......................................................................... iii

Trademark.................................................................................................................................................. iii

Copyright restrictions ................................................................................................................................. iii

FCC warning .............................................................................................................................................. iii

CE Mark ..................................................................................................................................................... iii

About this product and manual ....................................................................................................................... iv

Industrial Switch......................................................................................................................................... iv

Term/usage................................................................................................................................................ iv

About this manual ...................................................................................................................................... iv

Manual structure ........................................................................................................................................ iv

Cautions and warnings .................................................................................................................................... v

Cautions and warnings................................................................................................................................ v

Cautions......................................................................................................................................................v

Warnings.................................................................................................................................................... vi

Section I ....................................................................................................................................................................1

SISTF10xx-141 Industrial Unmanaged Switch..........................................................................................................1

In this section ..............................................................................................................................................1

General description..........................................................................................................................................2

Overview .....................................................................................................................................................2

Features......................................................................................................................................................2

SISTF10xx-141 Industrial Unmanaged Switch part numbers ..........................................................................3

Standard models.........................................................................................................................................3

Package contents ............................................................................................................................................4

Package contents........................................................................................................................................4

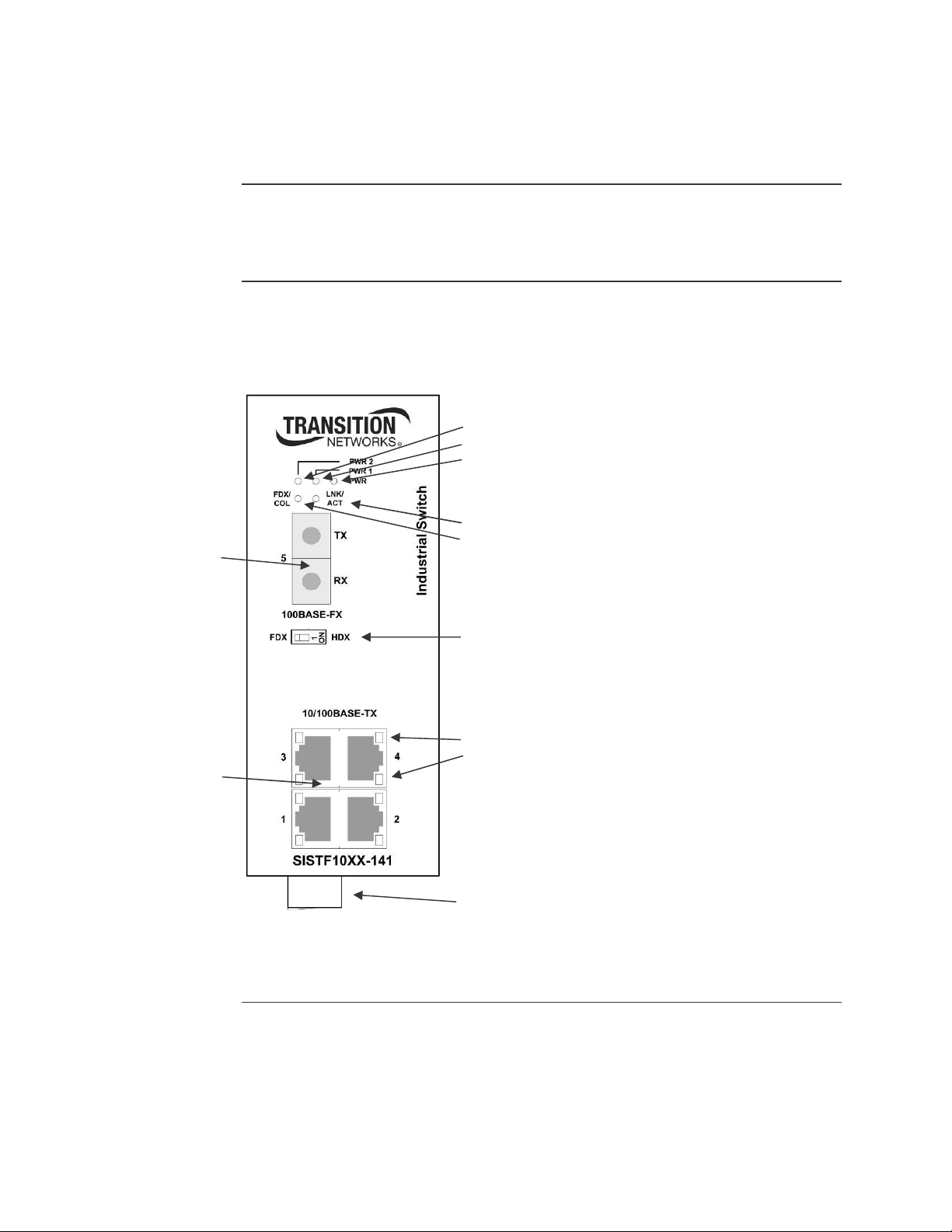

Physical description .........................................................................................................................................5

Physical dimensions....................................................................................................................................5

Front panel..................................................................................................................................................5

Bottom panel...............................................................................................................................................6

Back panel ..................................................................................................................................................6

Section II ...................................................................................................................................................................7

Installation .................................................................................................................................................................7

In this section ..............................................................................................................................................7

DIN rail mounting .............................................................................................................................................8

DIN rail clip..................................................................................................................................................8

DIN rail mounting considerations ................................................................................................................8

DIN rail mounting ........................................................................................................................................9

Wall mounting ................................................................................................................................................10

Wall mount bracket ...................................................................................................................................10

Wall mount bracket install .........................................................................................................................10

Grounding the Industrial Switch .....................................................................................................................11

Wiring considerations................................................................................................................................11

Industrial Switch grounding .......................................................................................................................11

Connecting power to the Industrial Switch.....................................................................................................12

Redundant power inputs ...........................................................................................................................12

Terminal-block wiring ................................................................................................................................13

Barrel connector interface cable ...............................................................................................................15

Connecting fiber cables .................................................................................................................................16

Fiber cable installation ..............................................................................................................................16

Connecting copper cables .............................................................................................................................17

Copper cable installation...........................................................................................................................17

Copper cable configuration .......................................................................................................................17

DIP Switches .................................................................................................................................................18

DIP switch position descriptions................................................................................................................18

Light Emitting Diodes (LEDs).........................................................................................................................19

LEDs .........................................................................................................................................................19

Section III: ...............................................................................................................................................................20

Advanced Features .................................................................................................................................................20

Introduction ...............................................................................................................................................20

In this section ............................................................................................................................................20

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 i

Page 4

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Advanced Features........................................................................................................................................21

AutoCrossTM..............................................................................................................................................21

Auto-Negotiation (IEEE 802.3u)................................................................................................................21

Pause (IEEE 802.3xy)..............................................................................................................................21

Section IV:...............................................................................................................................................................22

Cable Specifications................................................................................................................................................22

Introduction ...............................................................................................................................................22

In this section ............................................................................................................................................22

Copper (RJ-45) cable specifications ..............................................................................................................23

Copper cabling..........................................................................................................................................23

Copper cable specifications ......................................................................................................................23

RJ-45 pinouts............................................................................................................................................23

Fiber cable and optic specifications ...............................................................................................................24

Fiber cable characteristics ........................................................................................................................24

Fiber optic specifications...........................................................................................................................24

Section V:................................................................................................................................................................25

Troubleshooting.......................................................................................................................................................25

Introduction ...............................................................................................................................................25

In this section ............................................................................................................................................25

Troubleshooting problem and corrective action table ....................................................................................26

Section VI:...............................................................................................................................................................27

Contact Us, Warranty, &..........................................................................................................................................27

Compliance Information ..........................................................................................................................................27

Introduction ...............................................................................................................................................27

In this section ............................................................................................................................................27

Contact us......................................................................................................................................................28

Technical support......................................................................................................................................28

Live Web chat ...........................................................................................................................................28

Web-based training...................................................................................................................................28

E-Mail........................................................................................................................................................28

Address.....................................................................................................................................................28

Warranty ........................................................................................................................................................29

Limited lifetime warranty ...........................................................................................................................29

What the warranty does not cover.............................................................................................................29

Warranty Service.......................................................................................................................................29

Who to contact for returns.........................................................................................................................29

How and where to send the returns ..........................................................................................................29

Customer pays non-compliant return costs...............................................................................................30

Non-warranty repair costs .........................................................................................................................30

Repaired non-warranty products...............................................................................................................30

This warranty is your only remedy.............................................................................................................30

Compliance information .................................................................................................................................31

Compliances .............................................................................................................................................31

UL Listed; C-UL Listed (Canada) .............................................................................................................31

FCC Regulations.......................................................................................................................................31

Canadian Regulations...............................................................................................................................31

European Regulations...............................................................................................................................31

Appendix A:.............................................................................................................................................................33

Technical Specifications..........................................................................................................................................33

SISTF10xx-141-LR(T) specifications, notices, and warnings.........................................................................33

Notices ......................................................................................................................................................34

Warnings...................................................................................................................................................34

ii

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 5

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Trademark, copyright, and product classification information

Trademark

Copyright restrictions

FCC warning

All trademarks and registered trademarks are the property of their respective owners.

© 2007 Transition Networks: All rights reserved. No part of this work may be reproduced or

used in any form or by any means—graphic, electronic, or mechanical—without written

permission from Transition Networks.

Printed in the U.S.A.

This equipment has been tested and found to comply with the limits for class A devices,

pursuant to part 15 of FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial installation. This equipment

generates, uses, and radiates radio frequency energy; therefore, if it is not installed and

used in accordance with the instructions in this document, could cause harmful

interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference; the user will be required to correct the interference

at the user’s own expense.

CE Mark

CE Marking (European Conformity): This is a Class A product. In a domestic

environment, this product could cause radio interference; as a result, the user may be

required to take adequate preventative measures.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

iii

Page 6

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

About this product and manual

Industrial Switch

Term/usage

About this manual

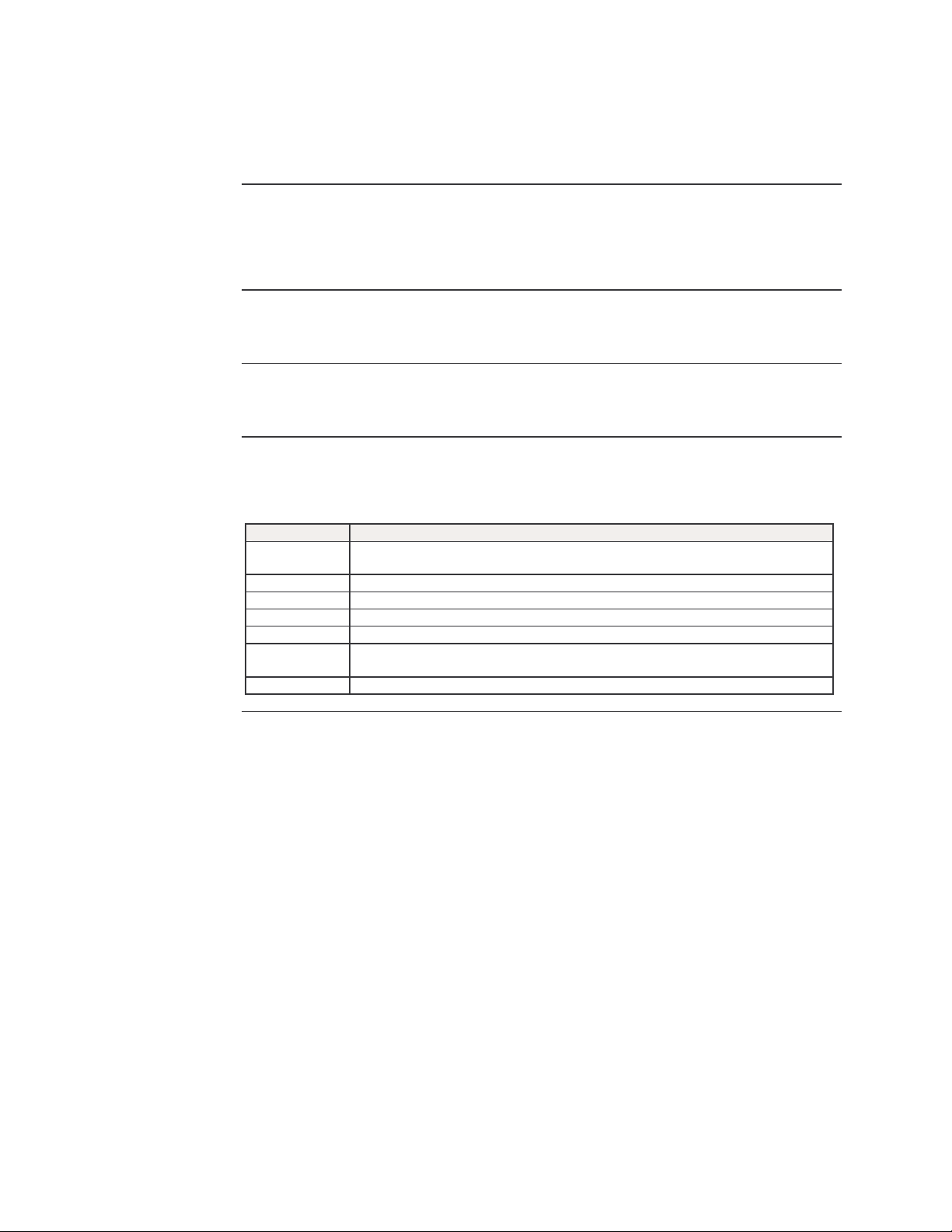

Manual structure

The SISTF10xx-141-LR(T) Industrial Unmanaged Switch provides four 10/100Base-TX (RJ-

45) copper connections and a 100Base-FX fiber connection. These switches are hardened

devices designed to reliably operate in harsh environments such as those found on factory

floors, outdoor enclosures or other hazardous environments.

In this manual, the term “Industrial Switch” (first letter upper case) refers to the

SISTF10xx-141-LR(T) 10/100Base-TX to 100Base-FX Industrial Unmanaged Switch.

This manual provides instructions on how to install, configure, and operate the

SISTF10xx-141-LR(T) 10/100Base-TX to 100Base-FX Industrial Unmanaged Switch.

This manual has a beginning table of contents; also, at the beginning of each section there is

a table of contents. As you traverse the manual, note the side headings. These side

headings make it easier to find specific information. The manual sections are as follows:

Section Description

I Industrial Switch general description, ordering information, package

contents and physical features/description

II Installation and operation of the Industrial Switch

III Advanced features

IV Cable Specifications

V Troubleshooting

VI Contacting Transition Networks, product warranty and product compliance

information

Appendix A Presents product specifications, notices, and warnings

iv

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 7

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Cautions and warnings

Cautions and warnings

Cautions

Make sure that you read and understand all content identified by these two symbols:

Cautions and warnings appear here and throughout this manual where appropriate. Failure to

read and understand the information identified by the “caution” and “warning” symbols could

result in poor equipment performance, damage to equipment, or injury to persons.

Cautions indicate the possibility of damage to equipment.

CAUTION

Make sure that the Industrial Switch is mounted with proper space around it for ventilation

(heat dissipation). Failure to observe this caution could result in damage to the Industrial

Switch.

CAUTION

Please exercise caution when using power tools. Do not install this unit in damp or wet

locations, or in close proximity to very hot surfaces. Failure to observe this caution could

result in damage to the Industrial Switch and cables.

CAUTION

Only qualified persons should install the Industrial Switch. Failure to observe this caution

could result in poor performance or damage to the Industrial Switch.

CAUTION

Install the Industrial Switch in an environment where the temperature range will not

exceed the stated environmental specifications for the particular model being installed.

Failure to observe this caution could result in permanent damage to the Industrial Switch.

CAUTION

DO NOT install the Industrial Switch in areas where strong electromagnetic fields (EMF)

exist. Failure to observe this caution could result in poor Industrial Switch performance

and data corruption.

CAUTION

The Industrial Switch must be mounted to a well-grounded surface. Failure to observe

this caution could result in EMI problems.

CAUTION

When connecting DC power wires to the terminal-block plug, pay close attention to the

polarity markings shown near the terminal block of the Industrial Switch. Failure to

observe this caution could result in damage to the equipment.

CAUTION

This is a Class A product. In a residential environment, this product could cause radio

interference in which case the user may be required to take adequate corrective

measures.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

v

Page 8

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Cautions and warnings, continued

Warnings

Warnings indicate the possibility of injury to persons.

WARNING

Be sure to disconnect power before installing and wiring the Industrial Switch. Failure to

observe this warning could result in an electrical shock.

WARNING

Fiber optics: Visible and invisible laser radiation when open: DO NOT stare into the

beam, or directly view the beam with optical instruments. Failure to observe this warning

could result in an eye injury or blindness.

WARNING

Use of controls, adjustments or the performance of procedures other than those

specified herein may result in hazardous radiation exposure.

vi

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 9

SISTF10xx-141 Industrial Unmanaged Switch

In this section

Section I

These are the topics:

Topic See Page

General description 2

SISTF10xx-141 Industrial Unmanaged Switch model numbers 3

Package Contents 4

Physical Description 5

Page 10

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

General description

Overview

Features

The SISTF10xx-141 Industrial Unmanaged Switch can help eliminate EMI or RFI issues and

help to overcome distance limitations with copper-based cabling by providing a fiber interface

to transport data from copper-based industrial networking and communication devices over

fiber optic cabling.

Each Industrial Switch can connect to either 10Base-T or 100Base-TX copper ports and

provides a 100Base-FX fiber optic connection for links up to 20km. Multiple connector options

are offered as well as two distinct operating temperature ranges:

- Standard: 0°C to +60°C (32°F to +140°F)

- Extended: -40°C to +75°C (-40°F to +167°F)

The SISTF10xx-141 Industrial Unmanaged Switch has the following features:

• Auto-Negotiation

• AutoCrossTM

• Dual, redundant auto-sensing 12 to 48VDC inputs with reverse polarity protection

and over current protection

• IEEE 802.3x flow control support

Flow control on full-duplex

Back pressure on half-duplex

• 512KB Embedded memory

• 1K MAC address table

• DIN-Rail mounting bracket (installed)

• Wall mount bracket included

• DIP-switch to set the fiber port mode of operation – full or half-duplex

• Barrel connector interface cable included for use with external AC/DC power supply

(order separately)

• IP31 protection metal enclosure

• Lifetime Warranty

2

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 11

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

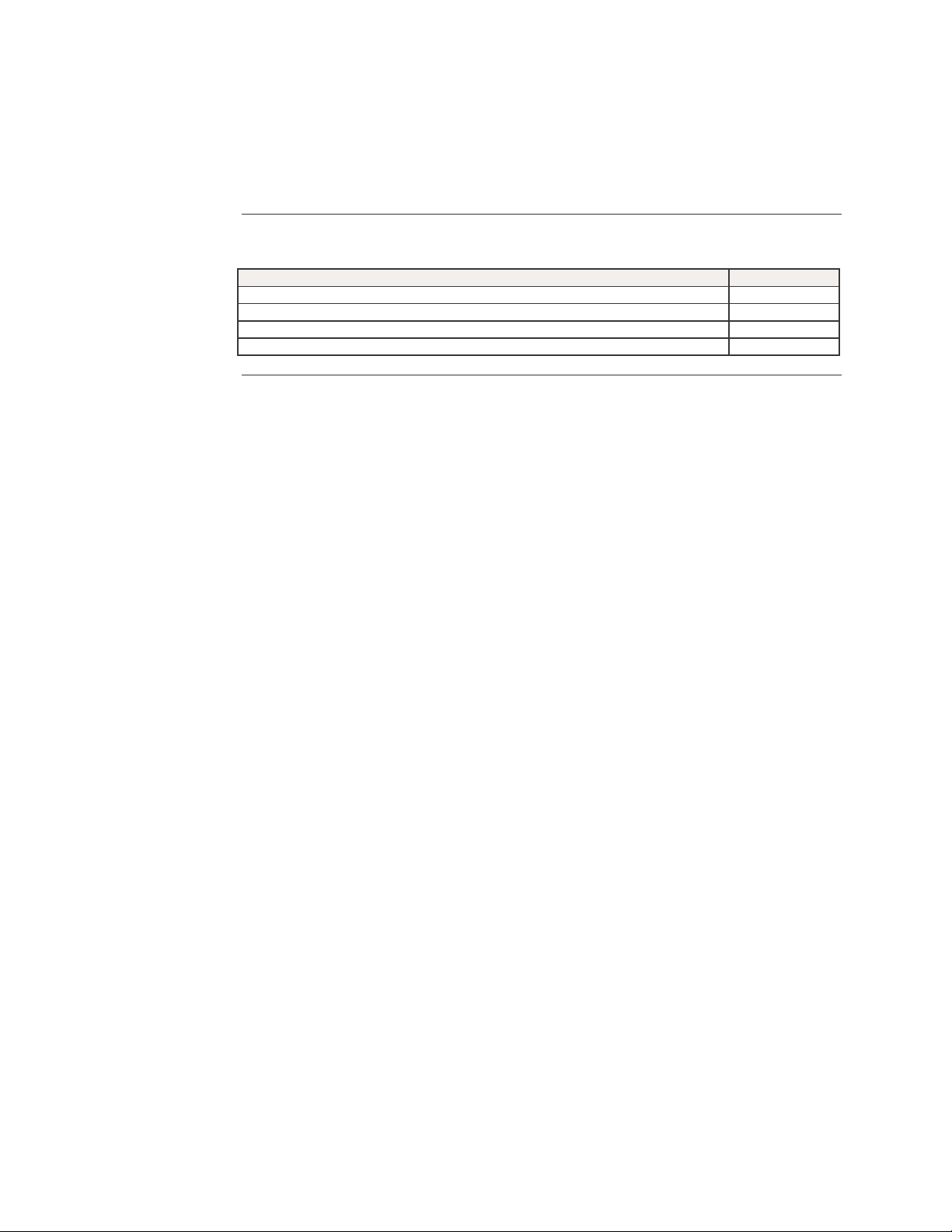

SISTF10xx-141 Industrial Unmanaged Switch part numbers

Standard models

The part numbers shown in Tables 1 and 2 perform as described in this manual.

Table 1: Industrial Unmanaged Switch Part Numbers

Standard Operating Temperature (0°C to +60°C)

Part Number Ports 1-4: 10/100Base-TX Port 5: 100Base-FX

SISTF1011-141-LR RJ-45

100 m (328ft)

SISTF1013-141-LR RJ-45

100 m (328ft)

SISTF1014-141-LR RJ-45

100 m (328ft)

Table 2: Industrial Unmanaged Switch Part Numbers

Extended Operating Temperature (-40°C to +75°C)

Part Number Ports 1-4: 10/100Base-TX Port 5: 100Base-FX

SISTF1011-141-LRT RJ-45

100 m (328ft)

SISTF1013-141-LRT RJ-45

100 m (328ft)

SISTF1014-141-LRT RJ-45

100 m (328ft)

Note: The distances for ports 1 and 2 listed in Tables 1 and 2 are typical maximum

distances; the physical characteristics of the network will affect the actual distances.

ST, 1300 nm multimode

2 km (1.2 miles)

SC, 1300 nm multimode

2 km (1.2 miles)

SC, 1310 nm single mode

20 km (12.4 miles)

ST, 1300 nm multimode

2 km (1.2 miles)

SC, 1300 nm multimode

2 km (1.2 miles)

SC, 1310 nm single mode

20 km (12.4 miles)

Table 3: Optional Accessories (sold separately)

Part Number Description

SPS-UA12DHT-xx External power supply includes:

(1) AC/DC power supply, 100-240VAC input, 50-60Hz,

12VDC, 1.5A ouput, -25°C to +70°C operating temp.

(1) Regional specific power cord

(1) Barrel connector interface cable

Note: Replace the xx in the part number above with one of the following identifiers to match

the region where the Industrial Switch will be installed:

NA = North America JP = Japan OZ = Australia/New Zealand

UK = United Kingdom EU = Europe SA = South Africa

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

3

Page 12

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Package contents

Package contents

Quantity Description

1 10/100BaseTX to 100BaseFX Industrial Unmanaged Switch

1 DIN-Rail mounting bracket (installed)

1 One wall mount plate

6 Screws (for attaching wall-mount bracket)

1 Installation manual CD

1 Barrel connector interface cable

- For external AC/DC power supply (sold separately)

Compare the package contents of your industrial Switch with the standard checklist above. If

any item is damaged or missing, please contact Transition Networks Technical Support.

4

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 13

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Physical description

Physical dimensions

Front panel

Width: 2.1” [54mm]

Height: 5.3” [135mm]

Depth: 4.1” [105mm]

The front panel of the Industrial Switch is shown in Figure 1 with corresponding descriptions

listed below:

Secondary power input 2 LED

Primary power input 1 LED

Power LED

100Base-FX

fiber port

10/100Base-TX

UTP ports (RJ-45)

Link / Activity Fiber Port 5 LED

Full Duplex / Collision Fiber Port 5 LED

Full-duplex / Half-duplex Fiber Port 5

DIP switch

Link / Activity Copper Port 1-4 LED

Full Duplex / Collision Copper Port 1-4 LED

Terminal block - power inputs

Figure 1: SISTF10xx-141-LR(T) Industrial Switch (Front View)

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

5

Page 14

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Physical description, continued

Bottom panel

The bottom view of the Industrial Switch is shown in Figure 2 with corresponding descriptions

listed below:

Grounding Screw

6-position terminal block

Primary power input terminals (2)

Secondary power input terminals (2)

Back panel

Figure 2: SISTF10xx-141-LR(T) Industrial Switch (Bottom View)

The back view of the Industrial Switch is shown in Figure 3 with corresponding descriptions

listed below:

DIN Rail Clip

(installed)

Metal spring

Screws (3)

Figure 3: SISTF10xx-141-LR(T) Industrial Switch (Back View)

6

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 15

In this section

Section II

Installation

These are the topics:

Topic See Page

DIN rail mounting 8

Wall mounting 10

Grounding the Industrial Switch 11

Connecting power to the Industrial Switch 12

Connecting fiber cable 16

Connecting copper cable 17

DIP switches 18

Light Emitting Diodes (LEDs) 19

Page 16

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

DIN rail mounting

DIN rail clip

The Industrial Switch includes an aluminum DIN Rail Clip attached to the rear panel. Verify

the clip is attached and oriented as pictured in Figure 4 below.

DIN Rail Clip

(installed)

Metal spring

Screws (3)

DIN rail mounting considerations

Figure 4: Mounted DIN Rail Clip

Consider the following before mounting the DIN rail to a surface and attaching the Industrial

Switch:

• The surface must support at least 635g (1.4 lbs) for the Industrial Switch.

• Do not place heavy objects on the Industrial Switch.

CAUTION

Mount the Industrial Switch with proper spacing around it for ventilation (heat

dissipation). Failure to observe this caution could result in damage to the Industrial

Switch.

CAUTION

Please exercise caution when using power tools. Do not install this unit in damp or wet

locations, or in close proximity to very hot surfaces. Failure to observe this caution could

result in damage to the Industrial Switch and cables.

Continued on next page

8

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 17

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

DIN rail mounting, continued

DIN rail mounting

To mount the Industrial Switch to the DIN rail, see Figure 5 and do the following:

Step Action

1. Align and then position DIN-Rail-clip spring to the top of the DIN rail as shown in

Figure 5, step (a).

2. Press DOWN on the Industrial Switch and then IN to snap it into place on the DIN

Rail. See Figure 5, step (b).

Figure 5: Industrial Switch Mounting to DIN Rail

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

9

Page 18

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Wall mounting

Wall mount bracket

Wall mount bracket install

Locate wall mount

brackets and screws

The Industrial Switch includes a wall mount bracket and screws in the contents of the shipping

package. The wall mount bracket can be attached to the rear panel of the Industrial Switch to

enable mounting to a vertical surface such as the wall of an enclosure. Locate the bracket (1)

and screws (6) and follow the steps below to install the bracket on the Industrial Switch.

To install the wall mount bracket to the Industrial Switch, see Figure 6 and do the following:

Step Action

1. Remove existing screws (3) and DIN-Rail bracket from rear of Industrial Switch.

2. Locate wall mount bracket and screws (6) from Industrial Switch packaging.

3. Place bracket in correct orientation as shown and insert and tighten screws to

secure bracket to rear of Industrial Switch.

4. Mount assembled device to a wall per locally accepted practices for anchoring

and securing. (Wall mount screws not included.)

Screw bracket onto rear

2

3

of Industrial Switch

Figure 6: Installing wall mount bracket to Industrial Switch

Remove screws and

1

DIN rail bracket

10

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 19

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Grounding the Industrial Switch

CAUTION

Be sure to disconnect the Industrial Switch from the DC power source before installing

and wiring the device.

Wiring considerations

The following wiring considerations are recommended:

• Signal lines must not be directly connector to outdoor wiring.

• Use separate paths or conduits to route wiring for power and device data cables. To avoid

interference, wires with different signal characteristics route separately. If power wiring and

device data cables must cross make sure that the wires are perpendicular at the

intersection point.

• Use the type of signal transmitted through a wire to determine which wires should be kept

separate. The rule of thumb is wiring that shares similar electrical characteristics can be

bundled together.

• Keep input and output wiring separated.

CAUTION

The Industrial Switch is intended to be grounded to a well-grounded mounting surface

such as a metal plate. Install the grounding wire prior to connecting any other device to

the Industrial Switch.

Industrial Switch grounding

Grounding the Industrial Switch helps limit the effects of noise due to electromagnetic

interference (EMI) via proper grounding. Always run the ground connection from the ground

screw to a grounding surface before connecting the Industrial Switch to a DC power source.

See Figure 7.

Figure 7: Industrial Switch Ground Screw (Bottom Panel)

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

11

Page 20

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Power Input 1

Power Input 2

Connecting power to the Industrial Switch

Redundant power inputs

The Industrial Switch has dual (redundant) power inputs capable of auto-sensing the input

voltage, while providing over current protection and reverse polarity protection.

The dual power inputs can be connected simultaneously to live DC power sources. See Figure

8. If one power source fails, the other live source acts as a backup, and automatically supplies

the Industrial Switch with power.

12

Figure 8: Redundant Power Connections

IMPORTANT

• Power is supplied through an external 12-48 VDC power source. Check the Technical

Specification section for details about the DC power input voltage.

• The Industrial Switch does not include a power switch; therefore, plugging a wired and

active terminal-block plug into its terminal block will immediately power ON the unit.

CAUTION

Before connecting the Industrial Switch to a DC power source, ensure the power source

is stable.

CAUTION

This device is intended to be supplied by a listed power source marked LPS or Limited

Power Source, provided with a connector for field wiring terminal.

CAUTION

This device is designed for operation with a safety extra-low voltage (SELV) in

compliance with IEC950 / EN60950 / VDE0805 and in compliance with the low voltage

directive 73/23/EEC and 93/68/EEC.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 21

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Connecting power to the Industrial Switch, continued

Note: The terminal block can accept 12 – 24 AWG wire for power and alarm relay inputs.

Terminal-block wiring

To wire the 6-position terminal block for redundant power, do the following:

Note: The 6-position terminal-block plug is constructed (keyed) to mate with the Industrial

Switch terminal block. When wiring the plug for power, use the polarity markings next

to the terminal block and on top of the plug to ensure proper connection.

Step Action

1. Turn the external power source OFF.

2. Strip the power wires as required.

3. Insert one stripped power wire into the terminal block plug. Observe polarity.

See Figure 9.

4. Secure the wire using a flathead screwdriver by tightening the contact screw.

See Figure 9.

5. Repeat Steps 3 and 4 until all wires are installed and secured.

Figure 9: 6-Position Terminal-Block (Primary/Redundant Power Wiring)

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

13

Page 22

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Connecting power to the Industrial Switch, continued

Terminal-block wiring (continued)

Step Action

6.

Insert the terminal block plug into the Industrial Switch’s terminal block, as shown

in Figure 10.

Figure 10: Wired Terminal Block Plug Inserted Into Industrial Switch

7.

8.

Make sure that the DC power source is stable and clean.

Turn ON the power source and the PWR LED should turn ON along with PWR 1

LED and/or PWR 2 LED, depending on whether one or both power supplies are

connected and turned ON.

14

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 23

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Connecting power to the Industrial Switch, continued

Barrel connector interface cable

A barrel connector interface cable is included with the Industrial Switch and can be used to

convert the barrel connector output of an external AC/DC power supply over to a wire interface

that can then be inserted into the terminal block following the instructions and figure 9, both

located on page 13 of this manual.

Note: An external AC/DC power supply is not included with the Industrial Switch. Transition

Networks offers an accessory power supply that can be purchased separately, if

required. Please see optional accessories in the general information section of this

manual for ordering information.

CAUTION

The operating temperature of the Industrial Switch, when used in conjunction with an

AC/DC power supply will be limited to the lesser operating temperature range of either

device.

For example: SISTF10xx-141-LRT (-40ºC to +75ºC operating temp) used

with SPS-UA12DHT-xx (-25ºC to +70ºC operating temp)

Operating temp for combination is -25ºC to +70ºC

Step Action

1. Locate the barrel interface cable included in the Industrial Switch packaging.

2. Strip the power wires as required.

3. Insert one stripped power wire into the terminal block plug, Observe polarity. See

Figure 9 on page 13.

4. Secure the wire using a flathead screwdriver by tightening the contact screw.

See Figure 9 on page 13.

5. Repeat Steps 3 and 4 until all wires are installed and secured.

6. Locate an external AC/DC power supply with barrel connector interface and

make sure the power supply is not plugged into any power source.

7. Insert barrel connector into the receptacle on the interface cable. See Figure 11.

External AC/DC

power supply with

barrel connector

Figure 11: Barrel Connector Interface Cable with external power supply

Step Action

8. Plug external AC/DC power supply into an external power source.

9. Turn ON or plug in the external power supply and the PWR LED should turn ON

along with PWR 1 LED and/or PWR 2 LED, depending on whether one or both

power supplies are connected and turned ON.

Barrel Connector

Interface Cable

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

15

Page 24

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Connecting fiber cables

Fiber cable installation

When connecting fiber cables to the 100BASE-FX port on the Industrial Switch, make sure the

correct type is used: ST or SC.

To install the fiber cables, do the following:

Step Action

1. Remove and keep the fiber-port protective dust cover(s).

Note: When not connected to a fiber cable, keep the protective cover(s) on the optical ports

to protect the optics and keep dust and debris from entering the optical interface.

2. Check that the fiber connectors on the fiber-optic cabling are clean. If necessary,

clean the fiber connectors using locally accepted cleaning procedures.

Note: Dirty fiber connectors on fiber optic cables will impair light transmission quality

through the cable and lead to degraded performance on the port.

3. Connect the fiber cable as shown in Figure 12.

Figure 12: Fiber Cable Connections

4. Check the corresponding fiber port LED on the Industrial Switch to verify the

connection—LNK/ACT LED should be lit.

Warning

• Visible and invisible laser radiation when open: DO NOT stare into the beam, or

directly view the beam with optical instruments. Failure to observe this warning could

result in an eye injury.

• Use of controls, adjustments or the performance of procedures other than those

specified herein may result in hazardous radiation exposure.

16

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 25

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Connecting copper cables

Copper cable installation

To connect the copper cable to the Industrial Switch and other equipment, do the following:

Step Action

1. Locate or build 10Base-T or 100Base-TX copper cables with male, RJ-45

connectors installed at both ends.

2. Connect the RJ-45 connector at one end of the cable to the RJ-45 port on

the Industrial Switch. See Figure 13 below.

3. Connect the RJ-45 connector at the other end of the cable to the RJ-45

port on the other device (switch, workstation, PLC, etc.).

4. Check the copper port LED on the Industrial Switch to verify the connection—

LNK/ACT LED should be lit.

Copper cable configuration

Figure 13: Copper Cable Installation

Either a straight-through or cross-over cable may be used. See Figure 14.

Figure 14: Straight-Through and Crossover Cables

Note: The AutoCrossTM feature determines the characteristics of the cable connection and

automatically configures the unit to link up, regardless of the cable configuration,

allowing either straight-through (MDI) or crossover (MDI-X) cables to be used.

(Requires no operator intervention.). See Advanced Features section for more

information.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

17

Page 26

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

ON

DIP Switches

DIP switch position descriptions

The Industrial Switch features one DIP switch on the front panel used to configure the fiber

port for use in a particular network setting. Figure 15 shows the DIP switch and a chart that

explains each setting.

No Description Default

1

Half-duplex / Full-duplex Fiber Port 5

(Half-duplex ON, Full-duplex OFF)

Figure 15: Dip Switch Setting and Explanation

CAUTION

DIP switch changes will not become active until the Industrial Switch is power cycled

(turned OFF then ON).

OFF

18

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 27

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Light Emitting Diodes (LEDs)

LEDs

The Industrial Switch has LED indicators located on its front panel. The LEDs present at-aglance network status, and provide real-time connectivity information. Figure 16 shows the

LEDs and a chart that explains the function of each.

LED Description

PWR Green = input power present on either

of the power inputs

PWR1 Green = input power present on PWR1

input

PWR2 Green = input power present on PWR2

input

LNK/ACT

(Fiber port)

FDX/COL

(Fiber port 5)

LNK/ACT

(UTP ports 1-4)

FDX

(UTP ports 1-4)

Green = fiber link

Green (blinking) = fiber port is receiving

link pulses or data from a

100Base-FX compliant port

Orange = Full duplex

Off = Half duplex or no device attached

Orange (blinking) = Collisions occurring

Green = UTP link

Green (blinking) = UTP port is receiving

link pulses or data from a

10/100Base-TX compliant port

Off = No device attached

Orange = Full duplex

Off = Half duplex or no device attached

Orange (blinking) = Collisions occurring

Figure 16: LEDs and Description Chart

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

19

Page 28

Introduction

In this section

Section III:

Advanced Features

This section provides an explanation of the advanced features on the Industrial Switch.

These are the topics:

Topic See Page

AutoCrossTM 21

Auto-Negotiation 21

Pause 21

Page 29

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Advanced Features

AutoCrossTM

AutoCrossTM automatically detects and configures the twisted pair port on the converter to the

correct MDI or MDI-X configuration allowing either straight-through (MDI) or crossover (MDI-X)

cables to be used – see figure 17. No user intervention is required.

* Eliminates an entire category of troubleshooting

* No need to identify cable type; straight-through or crossover

* No user intervention required to determine correct button / switch settings

Figure 17: Straight-Through and Crossover Cables

Auto-Negotiation

(IEEE 802.3u)

Pause (IEEE 802.3xy)

Auto-Negotiation allows devices to perform automatic configuration to achieve the best

possible mode of operation over a link. The Industrial Switch will broadcast its speed

(10Mbps, 100Mbps) and duplex (half/full) capabilities to other devices and negotiate the best

mode of operation between the two devices.

* No user intervention required to determine best mode of operation

* Optimal link established automatically

* Quick and easy installation

Note: If the Industrial Switch is connected to a non-negotiating device over the copper link,

it will default to 10Mb/s speed, half duplex mode.

PAUSE signaling is an IEEE feature that is used to temporarily suspend data transmission

between two devices in the event that one of the devices becomes overwhelmed. In the event

that a device needs some time to clear network congestion, it will send out a PAUSE signal to

the other end device, which will then wait a pre-determined amount of time before retransmitting the data. Transition's converters will pass PAUSE signaling unhindered; ensuring

that the message is delivered to the end device.

* PAUSE enabled devices allowed to work properly

* Prevents loss of valuable data transmission

* Reduces bottlenecks and allows for efficient use of network devices

Note: PAUSE signaling is not standardized over fiber media. Transition's Industrial Switchs

will communicate this signaling over fiber between the converters to pass this

signaling on to the other end device.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

21

Page 30

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Section IV:

Cable Specifications

Introduction

In this section

This section provides copper and fiber cable specifications.

These are the topics:

Topic See Page

UTP cable specifications 23

Fiber cable and optic specifications 24

22

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 31

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Copper (RJ-45) cable specifications

Copper cabling

Shielded twisted-pair (STP) or unshielded twisted-pair (UTP) cabling may be used and can be

configured as either Straight-through or crossover – see figure 18.

Figure 18: Straight-Through and Crossover Cables

Note: The AutoCrossTM feature determines the characteristics of the cable connection and

automatically configures the unit to link up, regardless of the cable configuration,

allowing either straight-through (MDI) or crossover (MDI-X) cables to be used.

(Requires no operator intervention.). See Advanced Features section for more

information.

Copper cable specifications

RJ-45 pinouts

Wire category: Category 5 (minimum)

Attenuation: 22.0 dB /100m @ 100 MHz

Gauge: 24 to 22 AWG

Maximum cable distance: 100 meters (328 ft)

Figure 19 shows the RJ-45 connector pin assignment chart.

No MDI Signal Name MDI-X Signal Name

1 Receive Data + (RD+) Transmit Data + (TD+)

2 Receive Data - (RD-) Transmit Data - (TD-)

3 Transmit Data + (TD+) Receive Data + (RD+)

6 Transmit Data - (TD-) Receive Data - (RD-)

Figure 19: RJ-45 Connector Pin Assignment Chart

Note: The Industrial Switch is configured as a MDI-X device.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

23

Page 32

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Fiber cable and optic specifications

Fiber cable characteristics

Fiber optic specifications

Cable physical characteristics must meet or exceed IEEE 802.3™ specifications.

Parameter Specification

Bit Error Rate: <10-9

Single mode fiber: 9 µm

Multimode fiber: 62.5/125 µm

Multimode fiber: 100/140, 85/140, 50/125 µm

The following shows the fiber optic specification:

Fiber Cable Specifications

SISTF1011-141-LR(T)

Fiber-optic transmitter power:

Fiber-optic receiver sensitivity:

Link budget:

SISTF1013-141-LR(T)

Fiber-optic transmitter power:

Fiber-optic receiver sensitivity:

Link budget:

SISTF1014-141-LR(T)

Fiber-optic transmitter power:

Fiber-optic receiver sensitivity:

Link budget:

1300 nm multimode

min: -20.0 dBm max: -14.0 dBm

min: -31.0 dBm max: 0.0 dBm

11.0dB

1300 nm multimode

min: -20.0 dBm max: -14.0 dBm

min: -30.0 dBm max: 0.0 dBm

11.0dB

1310 nm single mode

min: -15.0 dBm max: -8.0 dBm

min: -34.0 dBm max: 0.0 dBm

19.0 dB

Note: The fiber optic transmitters on this device meet Class I Laser safety requirements per

IEC-825/CDRH standards and comply with 21CFR1040.10 and 21CFR1040.11.

24

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 33

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Section V:

Troubleshooting

Introduction

In this section

This section provides basic troubleshooting information for the Industrial Switch via a problem

and corrective action table. The problems are stated in the problem column and the action(s)

to take for the problem is stated in the corrective action column. If the corrective measures

listed do not correct the problem, contact our 24-Hour Technical Support department at 1-800260-1312, International: 00-1-952-941-7600.

These are the topics:

Topic See Page

Troubleshooting problem and corrective action table 26

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

25

Page 34

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Troubleshooting problem and corrective action table

Problem Potential Cause Potential Solution

Industrial Switch does not

power up

No link or activity on the

UTP port

No link or activity on the

Fiber port

• Is the wired terminal-block plug fully

inserted into the Industrial Switch?

• Is the power LED lit?

• Is the power LED lit?

• Is the UTP cable properly installed

at both ends?

• Is the power LED lit?

• Is the Fiber cable properly installed

at both ends?

• Wire and insert the terminal-block plug

into the Industrial Switch’s terminal

block – See pages 12-16

• Check that DC power is at the

recommended levels.

• Contact Technical Support.

US/Canada: 1-800-260-1312,

International: 00-1-952-941-7600

• Check that the power is turned ON.

• Verify that the cable at both ends is

properly inserted into the UTP port

• Contact Technical Support.

US/Canada: 1-800-260-1312,

International: 00-1-952-941-7600

• Check that the power is turned ON.

• Verify that the cable at both ends is

properly inserted into the fiber port

• Contact Technical Support.

US/Canada: 1-800-260-1312,

International: 00-1-952-941-7600

26

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 35

Introduction

In this section

Section VI:

Contact Us, Warranty, &

Compliance Information

This section explains how to contact Transition Networks via Phone, fax, email, and direct

mail. It also explains:

• What the warranty covers

• Who to contact to return product

• How and where to return the product

• Industry standards compliance

These are the topics:

Topic See Page

Contact us 28

Warranty 29

Compliance information 31

Page 36

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Contact us

Technical support

Live Web chat

Web-based training

Technical Support is available 24 hours a day.

United States: 1-800-260-1312

International: 00-1-952-941-7600

Chat live via the Web with a Transition Networks Technical Support Specialist.

Log onto www.transition.com and click the Transition Now link.

Transition Networks provides 8-10 seminars per month via live web-based training.

Log onto www.transition.com and click the Learning Center link.

Ask a question anytime by sending an e-mail message to our technical support staff at:

techsupport@transition.com

Address

Transition Networks

6475 City West Parkway

Minneapolis, MN 55344, U.S.A.

Telephone: 952-941-7600

Toll free U.S.A & Canada: 800-526-9267

Fax: 952-941-2322

28

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 37

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Warranty

Limited lifetime warranty

What the warranty does not cover

Warranty Service

Effective for products shipped May 1, 1999 and after, every Transition Networks’ labeled

product will be free from defects in material and workmanship for its lifetime. This warranty

covers the original user only and is not transferable.

This warranty does not cover damage from accident, acts of God, neglect, contamination,

misuse or abnormal conditions of operation or handling, including over-voltage failures caused

by use outside the product’s specified rating, or normal wear and tear of mechanical

components. If the user is unsure of the proper means of installing or using the equipment,

contact Transition Networks’ free technical support services.

Transition Networks will at its option:

• Repair the defective product to functional specification at no charge

• Replace the product with an equivalent functional product

• Refund the purchase price of a defective product

Who to contact for returns

How and where to send the returns

To return a defective product for warranty coverage, contact Transition Networks’ technical

support department for a return authorization number (RAN). Transition’s technical support

department can be reached through any of the following means:

Technical Support is available 24 hours a day:

• Tel: 800-260-1312 x 200 or 952-941-7600 x 200

• Fax: 952-941-2322

• Email: techsupport@transition.com

• Live web chat: Transition Now

• Voicemail: 800-260-1312 x 579 or 952-941-7600 x 579

• All messages will be answered within one hour

Send the defective product postage and insurance prepaid to the following address:

CSI Material Management Center

c/o Transition Networks

6103 Blue Circle Drive

Minnetonka, MN 55343 U.S.A.

Attn: RETURNS DEPT: Credit Return Authorization (CRA)# or Return Material Authorization

(RMA) # ___________

Failure to protect the product during shipping may void this warranty. The return authorization

number must be written on the outside of the carton to ensure its acceptance. We cannot

accept delivery of any equipment sent to us without a CRA or RMA number.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

29

Page 38

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

Warranty, continued

Customer pays non-compliant return costs

Non-warranty repair costs

Repaired nonwarranty

products

The customer must pay the non-compliant product(s) return transportation cost to Transition

Networks for evaluation of said product(s) for repair or replacement. Transition Networks will

pay for shipping the repaired or replaced in-warranty product(s) back to the customer (any and

all customs charges, tariffs, or/and taxes are the customer’s responsibility).

Before making any non-warranty repair, Transition Networks requires a $200 charge, plus

actual shipping costs to and from the customer. If the repair is greater than $200, an estimate

is issued to the customer for authorization of repair. If no authorization is obtained, or the

product is deemed not repairable, Transition Networks will retain the $200 service charge and

return the product to the customer not repaired.

Non-warranted products repaired by Transition Networks for a fee will carry a 180-day limited

warranty. All warranty claims are subject to the restrictions and conventions set forth by this

document.

Transition Networks reserves the right to charge for all testing and shipping incurred, if after

testing, a return is classified as “No Problem Found.”

This warranty is your only remedy

This warranty is your only remedy. No other warranties, such as fitness for a particular

purpose, are expressed or implied. Transition Networks is not liable for any special, indirect,

incidental or consequential damages or losses, including loss of data, arising from any cause

or theory. Authorized resellers are not authorized to extend any different warranty on

Transition Networks’ behalf.

30

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 39

SISTF10xx-141-LR(T) Industrial Unmanaged Switch Transition Networks

Compliance information

Compliances

UL Listed;

C-UL Listed

(Canada)

FCC Regulations

Canadian Regulations

CISPR22/EN5022 Class A + EN55024; EN60950 Class A; FCC Class A; CE Mark

The following part numbers are UL Listed: SISTF1011-141-LR, SISTF1011-141-LRT,

SISTF1013-141-LR, SISTF1013-141-LRT, SISTF1014-141-LR, SISTF1014-141-LRT.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the

interference at the user’s own expense.

This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus

set out on the radio interference regulations of the Canadian Department of Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la Class A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

European Regulations

CUATION:

This is a Class A product. In a domestic environment, this product could cause radio

interference in which case the user may be required to take adequate corrective measures.

Achtung !

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb

dieses Gerätes Rundfunkstörungen auftreten. In diesem Fäll ist der Benutzer für

Gegenmaßnahmen verantwortlich.

Attention !

Ceci est un produit de Classe A. Dans un environment domestique, ce produit risque de créer

des interférences radioélectriques, il appartiendra alors à l'utilsateur de prende les measures

spécifiques appropriées.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

31

Page 40

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

European

Regulations,

(continued)

In accordance with European Union Directive 2002/96/EC of the European Parliament and of

the Council of 27 January 2003, Transition Networks will accept post usage returns

of this product for proper disposal. The contact information for this activity can be

found in the ‘Contact Us’ portion of this document.

CAUTION: RJ connectors are NOT INTENDED FOR CONNECTION TO THE

PUBLIC TELEPHONE NETWORK. Failure to observe this caution could result in

damage to the public telephone network.

Der Anschluss dieses Gerätes an ein öffentlickes Telekommunikationsnetz in den EGMitgliedstaaten verstösst gegen die jeweligen einzelstaatlichen Gesetze zur Anwendung der

Richtlinie 91/263/EWG zur Angleichung der Rechtsvorschriften der Mitgliedstaaten über

Telekommunikationsendeinrichtungen einschliesslich der gegenseitigen Anerkennung ihrer

Konformität.

32

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Page 41

Appendix A:

Technical Specifications

SISTF10xx-141-LR(T) specifications, notices, and warnings

Parameter Description

Standards IEEE 802.3TM, 802.3uTM, 802.3xTM

Regulatory Compliance for Emissions CISPR/EN55022 Class A; FCC Class A; CE Mark

Safety Compliance UL 60950; cUL; CSA C22.2 no 60950

EMI Compliance EN61000-4-2; EN61000-4-3; EN61000-4-4;

EN61000-4-5; EN61000-4-6

Environmental Compliance IEC60068-2-32 (Free fall)

IEC60068-2-27 (Shock)

IEC60068-2-6 (Vibration)

Ports (1) fiber port single mode/multi-mode

(4) RJ-45 port

Fiber Optic Specifications

Max Distance

Max Data Rate Fiber: 100 Mb/s

Signals TxD, RxD, CTS, RTS, DTR, DSR, RI, DCD, GND

MAC Addresses 1K MAC address table

Memory Buffer 512KB

Transfer Rate 14,880 pps [10Mb] or 148,800 pps [100Mb]

Packet Throughput 0.74Mpps @64bytes (4TX + 100FX)

Backplane 1.0 Gbps

Power Consumption 3.3 watts

Ingress Protection IP31

MTBF 380,973 hours (MIL-HDBK-217F)

Input Power 12 to 48 VDC, 0.2A-0.7A; dual, redundant auto-

Dimensions

Weight

Shipping weight

Standard Operating Temperature

(-LR models only)

Extended Operating Temperature

(-LRT models only)

Storage Temperature

Operating Humidity

Warranty Lifetime

1300 nm Multimode

TX power: min: -20.0 dBm max: -14.0 dBm

RX power: min: -31.0 dBm max: 0.0 dBm

Link budget: 11.0dB

1310 nm Single mode

TX power: min: -15.0 dBm max: -8.0 dBm

RX power: min: -32.0 dBm max: 0.0 dBm

Link budget: 19.0dB

Fiber (multimode): up to 2km (1.2 miles)

Fiber (single mode): up to 20km (12.4 miles)

Copper: up to 100 meters (328 ft.)

Copper: 10Mb/s or 100Mb/s

sensing inputs with reverse polarity and overload

current protection

Width: 2.1" [54 mm]

Depth: 4.1" [105 mm]

Height: 5.3" [135 mm]

0.64 kg (1.4 lbs)

0.90 kg (2 lbs)

0ºC to +60ºC (32 ºF to 140ºF)

-40ºC to +75ºC (-40 ºF to 167ºF)

-40ºC to +85ºC (-40 ºF to 185ºF)

5% to 90% (non-condensing)

Page 42

Transition Networks SISTF10xx-141-LR(T) Industrial Unmanaged Switch

SISTF10xx-141-LR(T) specifications, notices, and warnings, continued

Notices

Warnings

• The information in this user’s guide is subject to change. For the most up-to-date

information on the SISTF10xx-141-LR(T) Industrial Unmanaged Switch, please refer to the

user’s guide on-line at: www.transition.com.

• Product is certified by the manufacturer to comply with DHHS Rule 21/CFR, Subchapter J

applicable at the date of manufacture.

• IMPORTANT Copper based media ports: e.g., Twisted Pair (TP) Ethernet, USB, RS-232,

RS422, RS485, DS1, DS3, Video Coax, etc., are intended to be connected to intra-building

(inside plant) link segments that are not subject to lightening transients or power faults.

Copper based media ports: e.g., Twisted Pair (TP) Ethernet, USB, RS-232, RS-422, RS485, DS1, DS3, Video Coax, etc., are NOT to be connected to inter-building (outside plant)

link segments that are subject to lightening transients or power faults. Failure to observe

this caution could result in damage to equipment.

WARNING: Visible and invisible laser radiation when open: Do not stare into the beam

or view the beam directly with optical instruments. Failure to observe this warning could

result in an eye injury or blindness.

WARNING: Use of controls, adjustments or the performance of procedures other than

those specified herein may result in hazardous radiation exposure.

34

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

Loading...

Loading...