Page 1

User’s Guide

SISTF10xx-130-LR(T)

Stand-Alone Redundant Ring Industrial Switch

• Copper to Fiber

• Ethernet / Fast Ethernet

• 10Base-T / 100Base-TX to 100Base-FX

• Extended Temperature

• Hazardous Environment

Transition Networks SISTF10xx-130-LR(T) redundant

ring industrial switch connects three (3) 10Base-T /

100Base-TX twisted-pair copper cable lines to two

(2) 100Base-FX fiber-optic cable lines. The

SISTF10xx-130-LR(T) is designed for harsh industrial

environments such as hazardous locations (Class 1 Division 2 / Zone 2), includes a

relay output warning alarm, and is designed to withstand a high degree of vibration

and shock. It is also available in models that operate in either standard or extended

temperature ranges.

Part Number Ports 1, 2, & 3 - Copper

10Base-T/100Base-TX

Standard Temperature Models: 0°C to 60°C (32°F to 140°F):

SISTF1011-130-LR RJ-45

100 m (328 ft)*

SISTF1012-130-LR RJ-45

100 m (328 ft)*

SISTF1013-130-LR RJ-45

100 m (328 ft)*

SISTF1014-130-LR RJ-45

100 m (328 ft)*

Extended Temperature Models: -40°C to 75°C (-40°F to 167°F):

SISTF1011-130-LRT RJ-45

100 m (328 ft)*

SISTF1012-130-LRT RJ-45

100 m (328 ft)*

SISTF1013-130-LRT RJ-45

100 m (328 ft)*

SISTF1014-130-LRT RJ-45

100 m (328 ft)*

* Typical maximum cable distance.

Actual distance is dependent upon the

physical characteristics of the network

installation.

Ports 4 & 5 - 100Base-FX

Duplex Fiber-Optic

ST, 1300 nm multimode

2 km (1.2 miles)*

ST, 1310 nm single mode

15 km (9.3 miles)*

SC, 1300 nm multimode

2 km (1.2 miles)*

SC, 1310 nm single mode

15 km (9.3 miles)*

ST, 1300 nm multimode

2 km (1.2 miles)*

ST, 1310 nm single mode

15 km (9.3 miles)*

SC, 1300 nm multimode

2 km (1.2 miles)*

SC, 1310 nm single mode

15 km (9.3 miles)*

Installation . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . .8

Cable Specifications . . . . . . . . . .10

Technical Specifications . . . . . . .12

Troubleshooting . . . . . . . . . . . . .14

Compliance Information . . . . . . .16

Page 2

SISTF10xx-130-LR(T)

g

p

Installation

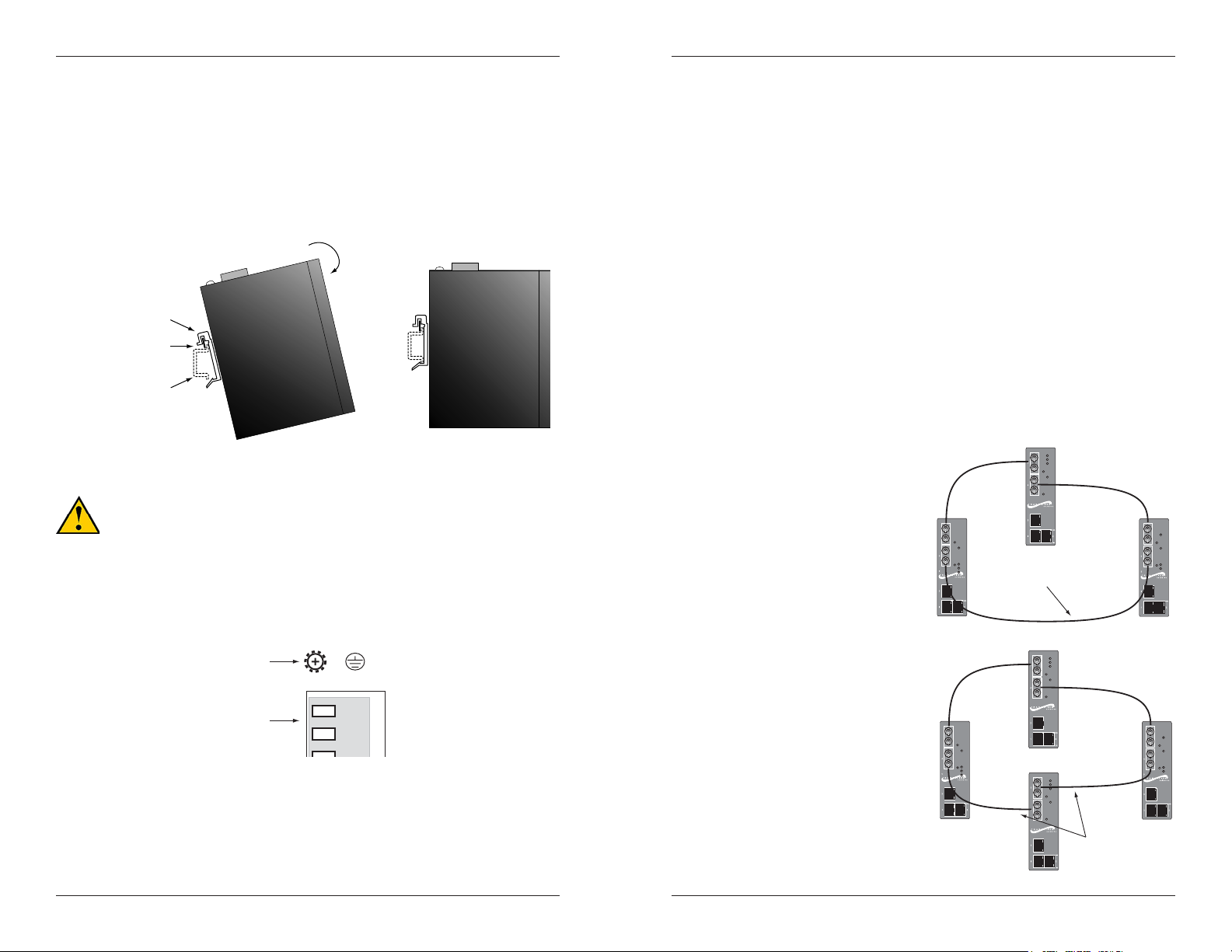

DIN-Rail Mount

The SISTF10xx-130-LR(T) Ethernet switch includes an aluminum DIN-Rail

mounting plate attached to the device’s back panel. To mount the SISTF10xx130-LR(T) onto a DIN-Rail:

1. Insert the top of the DIN-Rail into the upper slot of the mounting plate.

Installation -- Continued

The SISTF10xx-130-LR(T) is a plug-and-play unmanaged Ethernet switch with

Redundant Ring technology for better network reliability and faster recovery

time. The recovery time is less that 300 ms compared to 3 to 5 minutes for

commercial switches. Also, when one segment of the network gets

disconnected, the Redundant Ring automatically re-establishes network

connectivity.

The stiff metal spring should be positioned behind the DIN-Rail.

2. Push down and rotate the device to snap it into place on the DIN-Rail as

shown.

Step 1:

Step 2:

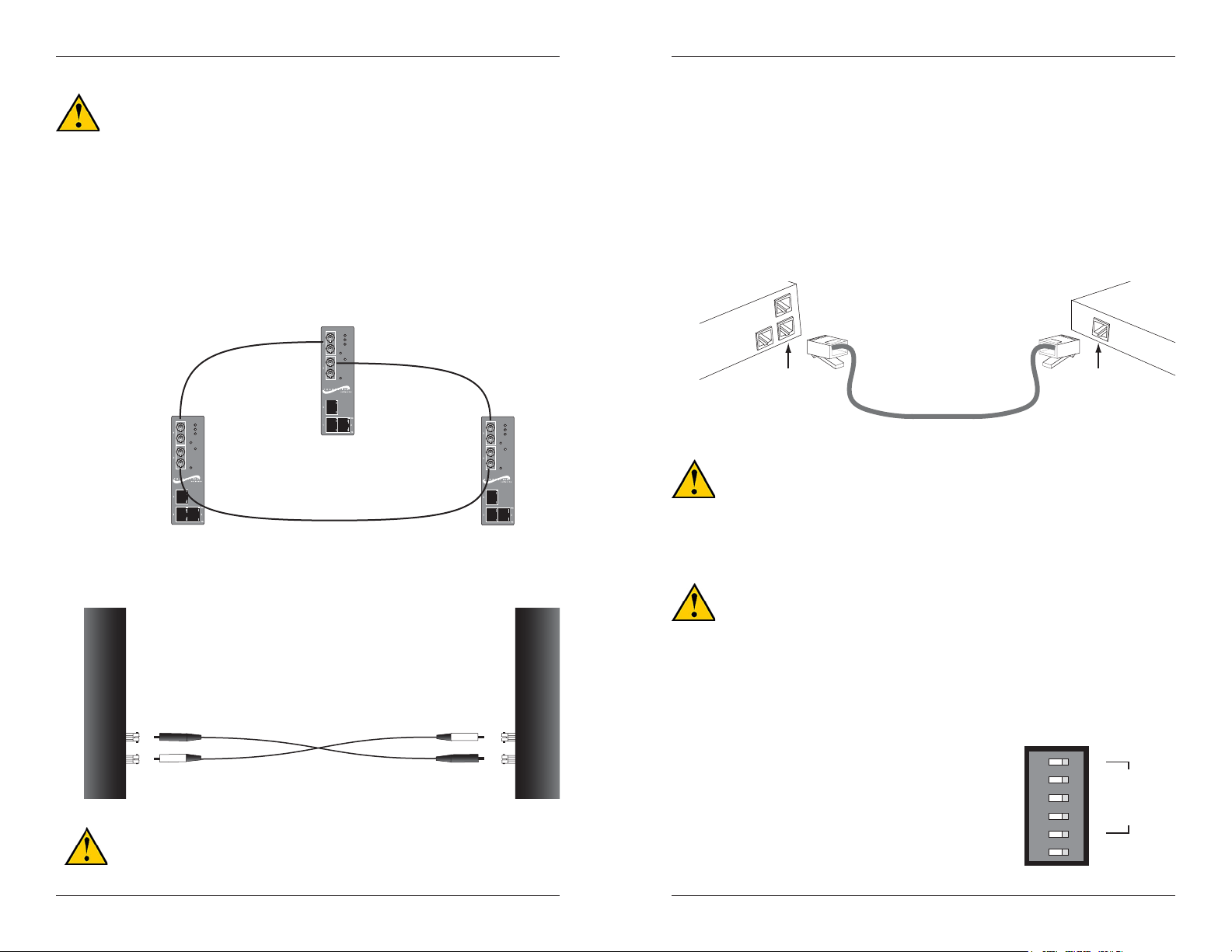

Master Device

The Redundant Ring technology identifies one switch as the Ring Master of

the network, and then automatically blocks packets from traveling through

any of the network’s redundant loops. To designate one of the SISTF10xx-

mounting

plate

spring

130-LR(T) devices to be the network’s Ring Master, set switch 6 on that device

to “ON”.

If two or more devices are set to be the Ring Master, those devices with their

switch 6 set to “ON” auto-negotiate to determine which one is the Ring

DIN-Rail

Master. Also, if none of the devices are set to be the Ring Master, the

Redundant Ring technology chooses the device that has the smallest MAC

address range to be the Ring Master.

The actual topology of the Redundant Ring (i.e., which segment is blocked) is

100BASE-FX

PWR 1

TX

PWR 2

FAULT

master switch

RX

100M

in the network

TX

RING

MASTER

RX

100M

Redundant Ring Industrial Switch

10/100BASE-TX

network's backup segment

RX

TX

100BASE-FX

RX

TX

10/100BASE-TX

FAULT

100M

RING

MASTER

PWR 1

100M

PWR 2

Redundant Ring Industrial Switch

NOTE: This device is intended to be grounded to a well-grounded

mounting surface such as a metal plate. Install the grounding wire prior

to connecting any other device.

Ground the SISTF10xx-130-LR(T)

determined by the number of

devices that make up the ring:

If there is an odd number of devices

in the ring, the backup segment is

the segment directly opposite the

Ring Master:

RX

TX

100BASE-FX

RX

TX

10/100BASE-TX

FAULT

100M

RING

MASTER

PWR 1

100M

PWR 2

Redundant Ring Industrial Switch

Grounding the device helps limit the effects of noise due to electromagnetic

interference (EMI). The grounding screw is located on the top panel next to

the terminal block.

100BASE-FX

PWR 1

TX

rounding screw

terminal block

RX

TX

100BASE-FX

RX

TX

10/100BASE-TX

FAULT

100M

RING

MASTER

PWR 1

100M

PWR 2

Redundant Ring Industrial Switch

To ground the SISTF10xx-130-LR(T):

1. Connect one end of the grounding wire (not included) to the grounding

screw by looping one end of the grounding wire under the star washer.

If there is an even number of

devices in the ring, the backup

segment is one of the two segments

connected to the unit directly

opposite the Ring Master:

2. Tighten the grounding screw with a phillips-head screwdriver.

3. Connect the other end of the grounding wire to earth ground.

PWR 2

FAULT

RX

100M

TX

RING

MASTER

RX

100M

10/100BASE-TX

100BASE-FX

PWR 1

TX

PWR 2

FAULT

RX

100M

TX

RING

MASTER

RX

100M

10/100BASE-TX

master switch

in the network

Redundant Ring Industrial Switch

Redundant Ring Industrial Switch

network's backu

segments

RX

TX

100BASE-FX

RX

TX

10/100BASE-TX

FAULT

100M

RING

MASTER

PWR 1

100M

PWR 2

Redundant Ring Industrial Switch

2

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

3

Page 3

SISTF10xx-130-LR(T)

p

p

Installation -- Continued

CAUTION: Disconnect the SISTF10xx-130-LR(T) from the DC power

source BEFORE installing and/or wiring the device.

Install the Fiber Cable

To build the Redundant Ring network, connect the SISTF10xx-130-LR(T)

devices using the two fiber ports labeled “4” and “5”. The fiber links can be

connected between two adjacent devices using any of the following

combinations:

A: Port 4 of one device connected to port 4 of the adjacent device.

B: Port 4 of one device connected to port 5 of the adjacent device.

C: Port 5 of one device connected to port 5 of the adjacent device.

100BASE-FX

PWR 1

TX

ort 5

ort 4

100BASE-FX

TX

RX

TX

RX

10/100BASE-TX

C

PWR 1

PWR 2

FAULT

100M

RING

MASTER

100M

port 5

port 4

Redundant Ring Industrial Switch

RX

TX

RX

10/100BASE-TX

PWR 2

FAULT

100M

RING

MASTER

100M

Redundant Ring Industrial Switch

port 5

port 4

B

100BASE-FX

TX

RX

TX

RX

10/100BASE-TX

PWR 1

PWR 2

FAULT

100M

RING

MASTER

100M

Redundant Ring Industrial Switch

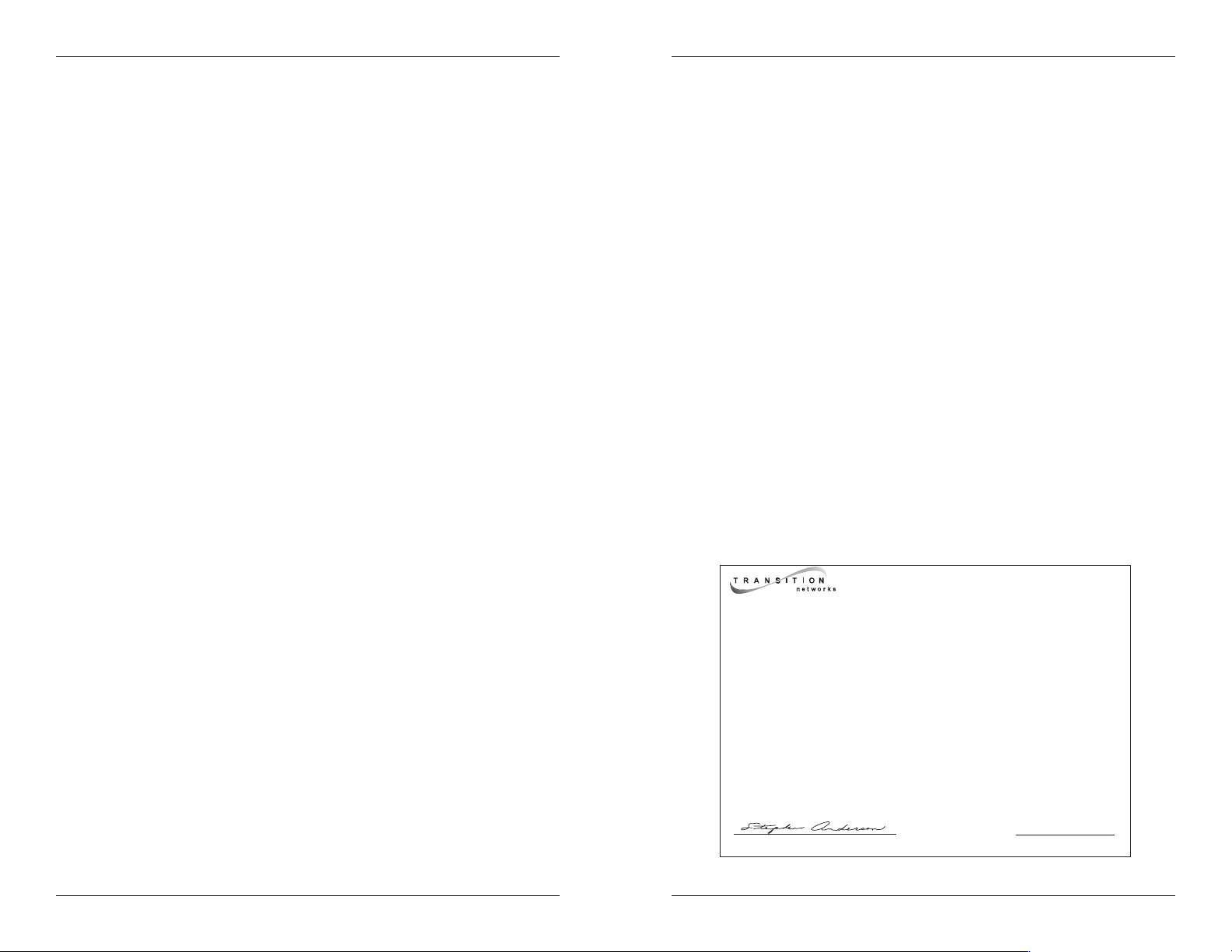

Installation -- Continued

Install the Copper Cable

The AutoCross feature allows either straight-through (MDI) or crossover (MDIX) copper cable to be used when connecting devices via the RJ-45 port.

1. Locate or build 10Base-T or 100Base-TX copper cables with male, RJ-45

connectors installed at both ends.

2. Connect the RJ-45 connector at one end of the cable to the RJ-45 port on

the SISTF10xx-130-LR(T).

3. Connect the RJ-45 connector at the other end of the cable to the RJ-45

port on the other device (PLC, workstation, etc.).

RJ-45 ports on the

SISTF10xx-130-LR(T)

CAUTION: Wear a grounding device and observe electrostatic discharge

precautions when setting the dip switches. Failure to observe this caution

could result in damage to, and failure of, the SISTF10xx-130-LR(T).

RJ-45 port

on the other device

(PLC, work station, etc.)

A

Set the Dip Switches

• The dip switches are located on the top panel of the device.

When connecting the fiber links, make sure the transmit (TX) port on one

device is connected to the receive (RX) port on the adjacent device as shown:

• Use a small flat blade screwdriver or a similar device to set the switches.

NOTE: To activate the updated switch setting, cycle the power to the

SISTF10xx-130-LR(T) by turning off the power, then turning it back on.

Switches 1 - 5: Port Alarm

Connect the fiber

cable to the

SISTF10xx-130-LR(T)

as shown.

RX

TX

NOTE: Calculate the maximum possible current in each power wire and

signal wire. Observe all electrical codes for maximum current allowed.

If the current goes above the maximum ratings, the wiring would

overheat, causing serious damage to the network equipment.

4

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

Connect the fiber

cable to the adjacent

SISTF10xx-130-LR(T)

as shown

RX

TX

The port alarm feature is used to determine faults at the copper or fiber ports.

• Switches 1, 2, and 3 correspond to copper ports 1, 2, and 3, respectively.

• Switches 4 and 5 correspond to fiber ports 4 and 5, respectively.

on: Enables the corresponding port alarm.

If the link for that port fails (or if a

power supply input fails), the internal

relay forms an open circuit and the

FAULT LED lights up.

off: Disables the corresponding port

alarm. The internal relay forms a

closed circuit and the FAULT LED

RM

P1

P2

P3

P4

P5

1

2

3

4

DIPON

5

6

remains off.

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

PORT

ALARM

RING

MASTER

5

Page 4

V2-

V1-

V1+

V2+

PWR2

FAULT

PWR1

The screws to secure

the wires are located

on the side of the

terminal block.

fault contacts

SISTF10xx-130-LR(T)

p

Installation -- Continued

Switch 6: Ring Master

on: Enables the device to be the Ring Master in a Redundant Ring topology.

This setting also enables the Redundant Ring break alarm. If a link in the

Redundant Ring breaks (and if the SISTF10xx-130-LR(T) is the Ring

Master in the Redundant Ring topology), then the internal relay forms an

open circuit and the FAULT LED lights up.

off: Disables the device from being the Ring Master.

If none of the devices are set to be the Ring Master, the Redundant Ring

technology chooses the device that has the smallest MAC address range

to be the Ring Master. However, if the Redundant Ring is broken, the

internal relay remains closed and the FAULT LED remains off.

Internal Relay

The internal relay that activates the alarm feature is connected to the two

middle contacts on the 6-contact terminal block. A user-supplied fault alarm

device can be connected to these fault contacts. An example would be to

connect the fault circuit to a warning light located in the control room. The

light can be set up to turn on when a fault is detected (see below).

Install the Port Alarm Device

A user-supplied port alarm device can be connected to the SISTF10xx-130-LR

to alert the user whenever a power fault or a port fault occurs. At least one

port alarm switch or the Ring Master switch (see page 5) must be “ON” to

enable the port alarm feature.

Installation -- Continued

Power the SISTF10xx-130-LR(T)

This device is suitable for use in Class I, Division 2, Groups A, B, C and D or

non-hazardous locations only.

WARNING: EXPLOSION HAZARD - Do not disconnect equipment

unless power has been removed or the area is known to be nonhazardous.

WARNING: EXPLOSION HAZARD - Substitution of components may

impair suitability for Class I, Division 2.

The SISTF10xx-130-LR(T) is designed for both a primary and a backup power

supply via the 6-contact terminal block, located on the top panel of the

device. Both power inputs can be connected simultaneously to live DC

power sources. If one power source fails, the other live source acts as a

backup, and automatically supplies the device with power.

6-contact terminal block

backup power

contacts

rimary power

contacts

V2+

V2-

V1+

V1-

V1, V2 INPUTS

12-48 VDC

PWR2

FAULT

PWR1

The screws to secure

the wire are located

on the side of the

terminal block.

6

The contacts for the fault alarm are on the 6-contact terminal block, located

on the top panel of the SISTF10xx-130-LR(T). To install a port alarm device:

1. Insert the two wires from the user-supplied port alarm device into the two

terminals marked “FAULT” on the 6-contact terminal block.

2. Secure the wire by tightening the corresponding screw on the side of the

terminal block.

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

CAUTION: Before connecting the SISTF10xx-130-LR(T) to the 12-48

VDC power source, ensure the power source voltage is stable.

To provide PRIMARY (PWR1) power to the SISTF10xx-130-LR(T):

1. Insert the positive (+) DC wire from the 12-48VDC power source into the

terminal marked “V1+”.

2. Insert the negative (-) DC wire into the terminal marked “V1-”.

3. Secure the wires by tightening the corresponding screws on the side of

the terminal block.

To provide BACKUP (PWR2) power to the SISTF10xx-130-LR(T):

1. Insert the positive (+) DC wire from the 12-48VDC power source into the

terminal marked “V2+”.

2. Insert the negative (-) DC wire into the terminal marked “V2-”.

3. Secure the wires by tightening the corresponding screws on the side of

the terminal block.

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

7

Page 5

SISTF10xx-130-LR(T)

Operation

Status LEDs

Use the status LEDs to monitor the SISTF10xx-130-LR(T) in the network.

The three LEDs near the top indicate the power and fault status:

PWR1 (amber) on = Primary power is connected to device.

PWR2 (amber) on = Backup power is connected to the device.

FAULT (red) on = If any of the five (5) port

alarm switches are “on“ and

the link on the corresponding

port is inactive (ex: switch 3

is “on” and port 3 is inactive);

or if there is a loss of primary

or backup power

The “100M” LEDs indicate the link status of the

corresponding fiber port (100Base-FX):

100M (green) on = Fiber link is active.

flashing = Data is being

transmitted over the fiber link.

The “RING MASTER” LED indicates whether or not

the SISTF10xx-130-LR(T) is the current Ring Master

of the Redundant Ring network:

RING (green) on = The device is the Ring

MASTER Master of the Redundant Ring

Network.

flashing = A link in the

Redundant Ring is broken.

The LEDs embedded in each of the RJ-45 ports

indicate the status of the corresponding copper link

(10/100Base-T/TX):

10M (green) on = Copper link is active at 10 Mb/s.

flashing = Data is being transmitted over the copper link

at 10 Mb/s.

100M (green) on = Copper link is active at 100 Mb/s.

flashing = Data is being transmitted over the copper link

at 100 Mb/s.

8

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

100BASE-FX

TX

RX

TX

RX

10/100BASE-TX

PWR 1

PWR 2

FAULT

100M

100M

RING

MASTER

Operation -- Continued

Features

Auto-Negotiation

With the Auto-Negotiation feature, the SISTF10xx-130-LR(T) automatically

configures itself to achieve the best possible mode of operation over the

copper link. The device broadcasts its speed (10 Mb/s or 100 Mb/s) and

duplex capabilities (either full- or half-duplex) and negotiates the best mode of

operation between the two linked devices.

If the device is connected to a non-negotiating device over the copper link, it

will default to 10 Mb/s speed, half-duplex mode.

AutoCross

The AutoCross feature allows either straight-through (MDI) or crossover (MDIX) cables to be used when connecting the SISTF10xx-130-LR(T) to devices

such as PLCs or workstations. AutoCross determines the characteristics of the

cable connection and automatically configures the unit to link up, regardless

of the cable configuration. (Requires no operator intervention.)

Plug-and-Play

The SISTF10xx-130-LR(T) models are plug-and-play devices, so that software

configuration is not required at installation or during maintenance.

Redundant Ring Industrial Switch

Switching, Filtering, and Forwarding

Packets are either filtered or forwarded when they arrive at one of the

switched ports.

• Packets with source and destination addresses belonging to the same port

segment are filtered and constrained to one port (relieving the rest of the

network from the need to process them).

• Packets with a destination address to another port segment are forwarded

to the appropriate port, and are not sent to the other ports where it is not

needed.

• Packets that are used in maintaining the operation of the network (such as

the occasional multi-cast packet) are forwarded to all ports.

The Ethernet switch operates in the store-and-forward switching mode, which

eliminates bad packets and enables peak performance to be achieved when

there is heavy traffic on the network.

Switching and Address Learning

The Ethernet switch address table holds up to 1K node addresses, making it

suitable for use with large networks. The address tables are self-learning, so

that as nodes are added, removed, or moved from one segment to another, the

Ethernet switch automatically keeps up with new node locations. An addressaging algorithm deletes the least-used addresses in favor of newer, more

frequently used addresses. To reset the address buffer, power down the unit

and then power it back up.

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

9

Page 6

SISTF10xx-130-LR(T)

Cable Specifications -- Continued

Copper Cable

Category 5: (minimum requirement)

Gauge: 24 to 22 AWG

Attenuation: 22.0 dB /100m @ 100 MHz

Maximum Cable Distance: 100 meters

• Straight-through OR crossover cable may be used.

• Shielded twisted-pair (STP) OR unshielded twisted-pair (UTP) may be used

• Pins 1&2 and 3&6 are the two active pairs in an Ethernet network .

• RJ-45 Pin-out: Pin 1 = TD+, Pin 2 = TD-, Pin 3 = RD+, Pin 6 = RD-

• Use only dedicated wire pairs for the active pins:

(e.g., blue/white & white/blue, orange/white & white/orange, etc.)

• Do not use flat or silver satin wire.

Straight-Through Cable

Twisted Pair #1

Twisted Pair #2

1

2

3

6

1

2

3

6

Twisted Pair #1

Twisted Pair #2

Please note the following when wiring the network:

• Signal lines must not be directly connected to outdoor wiring.

• Use separate paths to route the power wiring and the signal wiring. If

power wiring and signal wiring paths must cross, make sure the wires are

perpendicular at the intersection point.

• Do not run signal wiring and power wiring in the same wire conduit. To

avoid interference, wires with different signal characteristics should also

be routed separately.

• Use the type of signal transmitted through a wire to determine which

wires should be kept separate. The rule of thumb is that wiring with

similar electrical characteristics can be bundled together.

• Keep input wiring and output wiring separate.

• Where necessary, label the wiring to all devices in the network.

NOTE: This device has been evaluated as EEx nC IIC T4 equipment

under DEMKO Certificate No. 03 ATEX 0324537U. Each module is

suitable for use in Zone 2 Explosive Atmospheres. The device must be

installed in a minimum IP 54 enclosure as defined in IEC 60529 and EN

60529.

NOTE: This unit is a building-in type. The installation into a certain end

equipment shall comply with fire enclosure request of IEC

60950/EN60950 or similar sentence.

Crossover Cable

1

2

3

6

Cable Specifications

The physical characteristics must meet or exceed IEEE 802.3™ specifications.

Fiber Cable

Bit Error Rate: <10-9

Single mode fiber (recommended): 9 µm

Multimode fiber (recommended): 62.5/125 µm

Multimode fiber (optional): 100/140, 85/140, 50/125 µm

Standard Models

SISTF1011-130-LR 1300 nm multimode

Fiber Optic Transmitter Power: min: -20.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -36.0 dBm max: -32.0 dBm

Link Budget: 16.0 dB

SISTF1012-130-LR 1310 nm single mode

1

2

3

6

Fiber Optic Transmitter Power: min: -15.0 dBm max: -6.0 dBm

Fiber Optic Receiver Sensitivity: min: -34.0 dBm max: -32.0 dBm

Link Budget: 19.0 dB

SISTF1013-130-LR 1300 nm multimode

Fiber Optic Transmitter Power: min: -20.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -36.0 dBm max: -32.0 dBm

Link Budget: 16.0 dB

SISTF1014-130-LR 1310 nm single mode

Fiber Optic Transmitter Power: min: -15.0 dBm max: -6.0 dBm

Fiber Optic Receiver Sensitivity: min: -34.0 dBm max: -32.0 dBm

Link Budget: 19.0 dB

Extended Temperature Models

SISTF1011-130-LRT 1300 nm multimode

Fiber Optic Transmitter Power: min: -20.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -36.0 dBm max: -32.0 dBm

Link Budget: 16.0 dB

SISTF1012-130-LRT 1310 nm single mode

Fiber Optic Transmitter Power: min: -15.0 dBm max: -6.0 dBm

Fiber Optic Receiver Sensitivity: min: -34.0 dBm max: -32.0 dBm

Link Budget: 19.0 dB

SISTF1013-130-LRT 1300 nm multimode

Fiber Optic Transmitter Power: min: -20.0 dBm max: -14.0 dBm

Fiber Optic Receiver Sensitivity: min: -36.0 dBm max: -32.0 dBm

Link Budget: 16.0 dB

SISTF1014-130-LRT 1310 nm single mode

Fiber Optic Transmitter Power: min: -15.0 dBm max: -6.0 dBm

Fiber Optic Receiver Sensitivity: min: -34.0 dBm max: -32.0 dBm

Link Budget: 19.0 dB

NOTE: The fiber optic transmitters on this device meet Class I Laser

safety requirements per IEC-825/CDRH standards and comply with 21

CFR1040.10 and 21CFR1040.11.

10

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

11

Page 7

SISTF10xx-130-LR(T)

Technical Specifications

For use with Transition Networks Model SISTF10xx-130-LR(T) or equivalent

Standards: IEEE 802.3™, 802.3u™; 802.3x™

Data Rate: 10 Mb/s, 100 Mb/s (copper); 100 Mb/s (fiber)

Processing Type: Store and Forward

w/ IEEE802.3x™ full-duplex, non-blocking flow control

Dimensions: 1.8" x 5.3" x 4.1" (46 mm x 135 mm x 105 mm)

Weight: 1.4 lb. (0.65 kg) (approximate)

Input Power: 12-48VDC, 0.2-0.7A, 24W (minimum), (redundant inputs)

with overload and reverse polarity protection

Address Table Size: 1,000 Unicast Mac addresses

Alarm Relay: 1 Amp @ 24 VDC

Mechanical: Ingress Protection: IP30

Environment: Tmra* (standard temp): 0 to 60°C (32 to 140°F)

Tmra* (extended temp): -40 to 75°C (-40 to 167°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Humidity: 5 to 95%, non condensing

Warranty: Lifetime

*Manufacturer’s rated ambient temperature.

The information contained in this user’s guide is subject to change. For the most

up-to-date information see the user’s guide on line at: www.transition.com.

CAUTION: This device is intended to be supplied by a listed power unit

marked LPS or Limited Power Source, provided with a connector for field

wiring terminal, and output rated 12-48VDC, 0.2-0.7 A, 24 W minimum.

CAUTION: This device is designed for operation with a safety extra-low

voltage (SELV) in compliance with IEC950 / EN60950 / VDE0805 and in

compliance with the low voltage directive 73/23/EEC and 93/68/EEC.

Technical Specifications -- Continued

EMS Type Tests

Test Description Test Levels Severity

IEC61000-4-2 ESD Air discharge +/- 8 KV 3

Contact discharge +/- 6 KV 3

ESD contact discharge +/- 6 KV 3

IEC61000-4-3 Radiated RFI Housing 10V/m, 80 MHz - 1 GHz

IEC61000-4-4 Burst

(Fast Transient)

IEC61000-4-5 Surge Power supply lines +/- 2 KV, 12 Ω, CM

IEC61000-4-6 Induced

(Conducted RFI)

Power supply lines +/- 2 KV 3

Communication lines +/- 1 KV 3

Relay +/- 1 KV 3

Relay +/- 2 KV, 12 Ω, CM

Power supply lines 10 Vrms, 150-80 MHz

Communication lines 10 Vrms, 150-80 MHz

Relay 10 Vrms, 150-80 MHz

AM 1 KHz, 80% mod

10 V/m, 0.9 - 1.8 GHz

FM 200 Hz 50% square

+/- 1 KV, 2 Ω, DM

+/- 1 KV, 2 Ω, DM

AM 1 KHz, 80% mod

AM 1 KHz, 80% mod

AM 1 KHz, 80% mod

Environmental Type Tests

Test Description Test Levels

IEC 60068-2-6 Vibration 10 - 500 - 10 Hz, 0.5 oct./min, 4g, X, Y, Z (3 axes)

IEC 60068-2-27 Shock 50 g, 11 ms, +/-X, +/-Y, +/- Z (6 direction)

IEC 60068-2-32 Free fall 75 cm, 1 corner, 3 edges, 6 faces (total 10 drops)

3

3

3

3

3

3

This device is certified by the manufacturer to comply with DHHS Rule 21/CFR,

Subchapter J applicable at the date of manufacture.

CAUTION: Visible and invisible laser radiation when open. Do not

stare into beam or view directly with optical instruments.

CAUTION: Use of controls, adjustments or the performance of

procedures other than those specified herein may result in hazardous

radiation exposure

12

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

13

Page 8

SISTF10xx-130-LR(T)

Troubleshooting

If the device fails, isolate and correct the fault by determining the answers to the

following questions and then taking the indicated action:

1. Is the PWR1 LED illuminated?

NO

• Ensure the power source is the proper voltage (12 - 48 VDC).

• Ensure the (+) and (-) wires from the power source are inserted

properly in the terminal block contacts labeled “PWR1”.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

YES

• Proceed to step 2.

2. Is the PWR2 LED illuminated?

NO

• Ensure the power source is the proper voltage (12 - 48 VDC).

• Ensure the (+) and (-) wires from the power source are inserted

properly in the terminal block contacts labeled “PWR2”.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

YES

• Proceed to step 3.

3. Is the FAULT LED illuminated?

YES

• If one or more port alarm switches (1 - 5) is ON

corresponding fiber or copper link; or primary or backup power.

• Ensure the problem copper or fiber link is properly connected.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

NO

• Proceed to step 4.

4. Is the Ring Master LED flashing?

YES

• A link in the Redundant Ring is broken. Inspect the fiber links in the

ring for proper connection.

• Verify that the TX and RX cables on one device are connected to the

RX and TX ports, respectively, on the adjacent device.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

NO

• Proceed to step 5.

5. Are either 100M LEDs (near the fiber links) illuminated?

NO

• Check the corresponding fiber cables for proper connection.

• Verify that the TX and RX cables on the device are connected to the

RX and TX ports, respectively, on the other device.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

YES

• Proceed to step 6.

14

24-hour Technical Support: 1-800-260-1312 -- International: 00-1-952-941-7600

, the device lost the

Troubleshooting -- Continued

6. Are either 100M LEDs (near the fiber links) flashing?

NO

• If there is activity on the corresponding fiber port, disconnect and

reconnect the fiber cable to restart the initialization process.

• If there is no activity on the corresponding fiber port, contact Tech

Support: 800-260-1312, Int’l: 00-1-952-941-7600.

YES

• Proceed to step 7.

7. Are any of the 10M LEDs (on the RJ-45 port) illuminated?

YES

• The device has selected 10 Mb/s for the twisted-pair link.

• If the speed is not correct, disconnect and reconnect the twisted-pair

cable to restart the initialization process.

• Proceed to step 8.

NO

• Proceed to step 8.

8. Are any of the 100M LEDs (on the RJ-45 port) illuminated?

YES

• The device has selected 100 Mb/s for the twisted-pair link.

• If the speed is not correct, disconnect and reconnect the twisted-pair

cable to restart the initialization process.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

NO

• Check the twisted-pair cables for proper connection.

• Contact Tech Support: 800-260-1312, Int’l: 00-1-952-941-7600.

Declaration of Conformity

Name of Mfg: Transition Networks

Model: SISTF10xx-130-LR(T) Series Redundant Ring Industrial Switches

Part Number(s): SISTF1011-130-LR, SISTF1012-130-LR, SISTF1013-130-LR,

Regulation: EMC Directive 89/336/EEC

Purpose: To declare that the

is in conformity with the following standards.

EN 55022:1998 Class A; FCC Part 15 Subpart B; 21CFR subpart J;

UL 60950; UL 508; CSA C22.2 no 60950; EN 60950;

UL/cUL Class 1, Div 2, Groups A, B, C, D; ATEX Class 1, Zone 2, EExnC IIC;

EN61000-4-2, -4-3, -4-4, -4-5, -4-6; IEC 60068-2-6, -2-27, -2-32

I, the undersigned, hereby declare that the equipment specified above conforms to the above

Directive(s) and Standard(s).

Stephen Anderson, Vice-President of Engineering Date

NOTE: The following part numbers are UL listed: SISTF1013-130-LR, SISTF1013-130LRT, SISTF1014-130-LR, SISTF1014-130-LRT

techsupport@transition.com -- Click the “Transition Now” link for a live Web chat.

6475 City West Parkway, Minneapolis MN 55344, USA

SISTF1014-130-LR, SISTF1011-130-LRT, SISTF1012-130-LRT,

SISTF1013-130-LRT, SISTF1014-130-LRT

SISTF10xx-130-LR(T)

to which this declaration refers

_December 3, 2004_____

15

Page 9

Compliance Information

UL Listed; C-UL Listed (Canada)

NOTE: The following part numbers are UL listed: SISTF1013-130-LR, SISTF1013-130-LRT,

SISTF1014-130-LR, SISTF1014-130-LRT.

CISPR22/EN55022 Class A CE Mark

FCC Regulations This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at the user's own expense.

Canadian Regulations This digital apparatus does not exceed the Class A limits for radio

noise for digital apparatus set out on the radio interference regulations of the Canadian

Department of Communications. Le présent appareil numérique n'émet pas de bruits

radioélectriques dépassant les limites applicables aux appareils numériques de la Class A

prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

European Regulations

Warning:

radio interference in which case the user may be required to take adequate measures.

Achtung ! Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können

bei Betrieb dieses Gerätes Rundfunkstörungen auftreten. In diesem Fäll ist der Benutzer für

Gegenmaßnahmen verantwortlich.

Attention ! Ceci est un produit de Classe A. Dans un environment domestique, ce produit

risque de créer des interférences radioélectriques, il appartiendra alors à l'utilsateur de

prende les measures spécifiques appropriées.

This is a Class A product. In a domestic environment this product may cause

CAUTION: RJ connectors are NOT INTENDED FOR CONNECTION TO THE

PUBLIC TELEPHONE NETWORK. Failure to observe this caution could result in

öffentlickes Telekommunikationsnetz in den EG-Mitgliedstaaten verstösst gegen die

jeweligen einzelstaatlichen Gesetze zur Anwendung der Richtlinie 91/263/EWG zur

Angleichung der Rechtsvorschriften der Mitgliedstaaten über Telekommunikationsendeinrichtungen einschliesslich der gegenseitigen Anerkennung ihrer Konformität.

damage to the public telephone network. Der Anschluss dieses Gerätes an ein

Contact Transition Networks

Technical support is available 24 hours a day.

US and Canada: 1-800-260-1312 International: 00-1-952-941-7600

Chat live via the Web with Transition Networks Technical Support.

Log onto www.transition.com and click the Transition Now link.

Transition Networks provides seminars via live web-based training.

Log onto www.transition.com and click the Learning Center link.

Send an e-mail anytime to our technical support staff at: techsupport@transition.com

Transition Networks, 6475 City West Pkwy, Minneapolis, MN 55344, USA

telephone: 952-941-7600, toll free: 800-526-9267, fax: 952-941-2322

Trademark Notice

All trademarks and registered trademarks are the property of their respective owners.

Copyright Restrictions © 2004 Transition Networks. All rights reserved. No part of this

work may be reproduced or used in any form or means (graphic, electronic, mechanical)

without written permission from Transition Networks. Printed in the U.S.A.

33310.A

Loading...

Loading...