Page 1

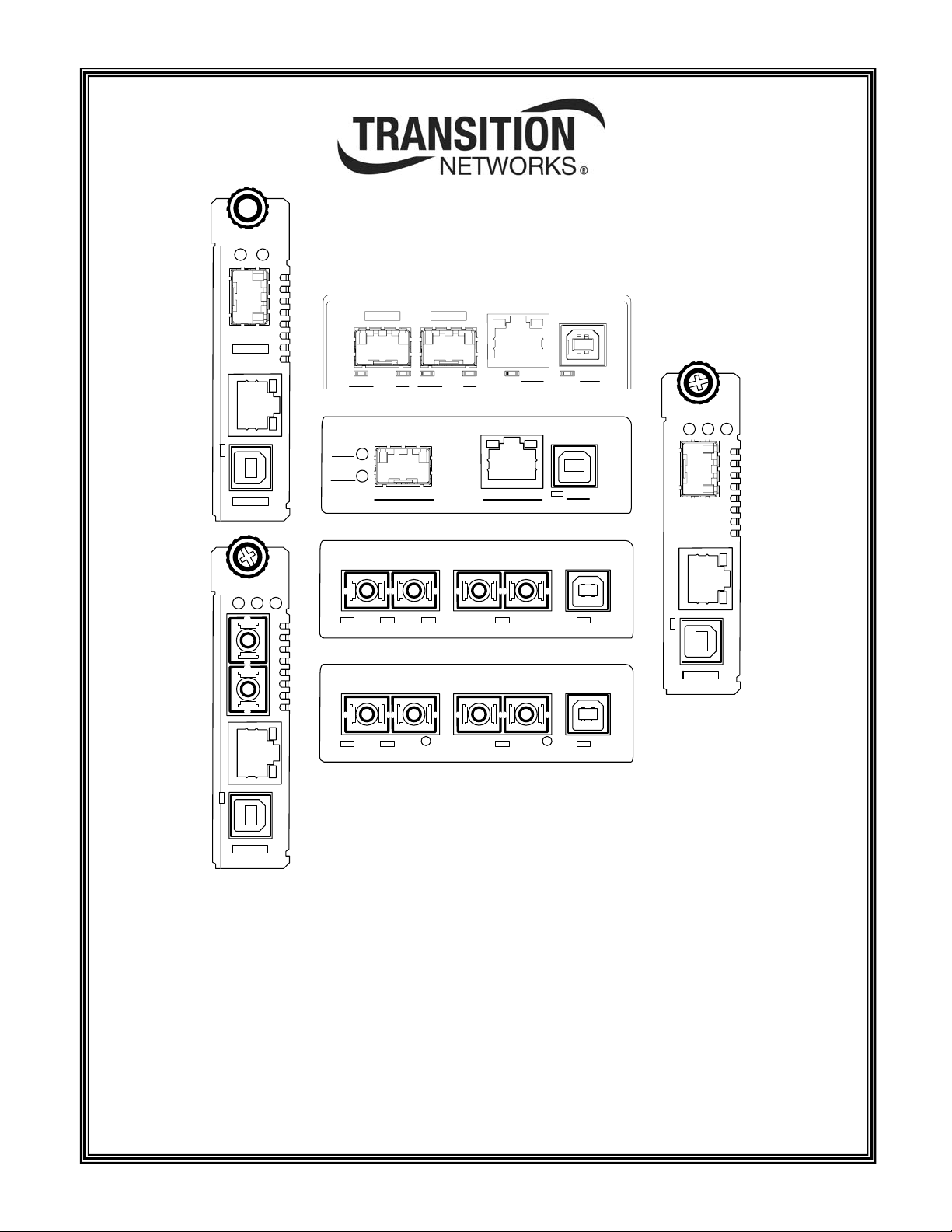

LACTPWR

10/100/10001000Base-X

USB

DPX

100Base-FX

10/100Base-TX

USB

CBFFG

LACTPWR

LACT FD LACT FD

PWR

LACT

100Base-X 1000Base-X

PWR

LNK

DPX

1000Base-X 1000Base-X

PWR

1 2

LNK

10/100/10001000Base-X

LNK

LNK

PWR USB

USB

USB

USB

USB

USB

DPX

100Base-FX

10/100Base-TX

USB

CFBRM

LACTPWR

CFBRM

FBRM1xxx-1xx & BFFG1xxx-1xx

Chassis & Stand-Alone Remotely Managed

Devices

Manual

33345, Revision D

Page 2

Page 3

Page 4

Page 5

Transition Networks

Table of contents

Section I: ..................................................................................................................................................................1

Product Description ................................................................................................................................................1

General description.......................................................................................................................................2

Product features.............................................................................................................................................3

Management methods...................................................................................................................................4

Hardware description....................................................................................................................................5

FBRM/BFFG13xx-1xx fiber-to-fiber gigabit models .................................................................................13

Redundant SFBRM1040-140 models ........................................................................................................15

Section II: ...............................................................................................................................................................17

Hardware Installation ...........................................................................................................................................17

Installing CFBRM/CBFFG cards into point system chassis ......................................................................18

Installing SFBRM/SBFFG standalone models ............................................................................................19

Installing fiber and copper cables ..............................................................................................................20

Connecting power (standalone models)...................................................................................................22

Section III: ..............................................................................................................................................................24

USB Driver Installation & COM Port Setup........................................................................................................24

Installing USB driver....................................................................................................................................25

Configuring COM port................................................................................................................................29

Section live: ...........................................................................................................................................................32

Initial Device Setup...............................................................................................................................................32

USB CLI access ............................................................................................................................................33

Initial Device setup via USB CLI ................................................................................................................35

Initial Device setup via telnet (directly to Device) ..................................................................................38

Initial Device setup via chassis agent MMU, web-based ........................................................................41

Initial Device setup IP web-based (directly to Device) ...........................................................................44

Sections V: .............................................................................................................................................................49

Device Management.............................................................................................................................................49

SNMP IP-based management.....................................................................................................................50

Device management via chassis agent (MMU) web-based.....................................................................53

Device management via IP web-base (directly to Device).....................................................................56

Section VI:..............................................................................................................................................................59

Software Features..................................................................................................................................................59

Software feature descriptions .....................................................................................................................60

Software security feature descriptions .......................................................................................................69

Section VIl:.............................................................................................................................................................71

Operations .............................................................................................................................................................71

Status LEDs...................................................................................................................................................72

OAM Device management configuration options ...................................................................................75

Firmware upgrades......................................................................................................................................76

Continued on next page

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 i

Page 6

Transition Networks

Table of contents, continued

Section Vlll: ...........................................................................................................................................................82

Troubleshooting ....................................................................................................................................................82

Troubleshooting problem and corrective action table.............................................................................83

Section lX:..............................................................................................................................................................88

Copper Cable & Fiber Optic Specifications .......................................................................................................88

Copper cables ..............................................................................................................................................89

Fiber optic cable and connector specifications........................................................................................90

Section X:.............................................................................................................................................................101

Contact Us, Warranty, & Conformity Information...........................................................................................101

Contact us...................................................................................................................................................102

Conformity declaration .............................................................................................................................103

Warranty.....................................................................................................................................................105

Compliance information...........................................................................................................................107

Appendix A:.........................................................................................................................................................109

FBRM/BFFG Part Numbers.................................................................................................................................109

FBRM copper-to-fiber part numbers........................................................................................................109

FBRM fiber-to-fiber part numbers ............................................................................................................112

BFFG copper-to-fiber part numbers.........................................................................................................115

BFFG fiber-to-fiber part numbers .............................................................................................................116

Appendix B:.........................................................................................................................................................120

FBRM/BFFG Technical Specification ................................................................................................................120

Specifications, notices, and warnings......................................................................................................120

Appendix C:.........................................................................................................................................................122

Device Commands & Descriptions...................................................................................................................122

Appendix D: ........................................................................................................................................................129

IP-Based and Chassis Management Parameters...............................................................................................129

Appendix E: .........................................................................................................................................................141

Request for Comment (RFC) Compliance.........................................................................................................141

Index.....................................................................................................................................................................143

ii

Page 7

Transition Networks

Trademark, copyright information, and about this manual

Trademark

Copyright

restrictions

About this

manual

All trademarks and registered trademarks are the property of their respective owners.

© 2008 Transition Networks: All rights reserved. No part of this work may be

reproduced or used in any form or by any means—graphic, electronic, or

mechanical—without written permission from Transition Networks.

Printed in the U.S.A.

This manual is designed to help you find the information you need quickly. It is

structured as follows:

• Table of Contents (TOC)

• Section TOC: Shows all the major topics in the section

• Side Headings: Shows all the sub topics on each page

• Index

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 iii

Page 8

Transition Networks

Caution and warnings

Definitions

Cautions

Cautions indicate that there is the possibility of poor equipment performance or

damage to the equipment. The symbol below identifies cautions

Warnings indicate that there is the possibility of injury to person.

Cautions and Warnings appear here and may appear throughout this manual where

appropriate. Failure to read and understand the information identified by the symbol

could result in poor equipment performance, damage to the equipment, or injury to

persons.

When handling chassis Devices observe electrostatic discharge precautions.

This requires proper grounding; i.e., wear a wrist strap.

Warnings

Copper based media ports, e.g., Twisted Pair (TP) Ethernet, USB, RS232,

RS422, RS485, DS1, DS3, Video Coax, etc., are intended to be connected to

intra-building (inside plant) link segments that are not subject to lightening

transients or power faults.

Copper based media ports, e.g., Twisted Pair (TP) Ethernet, USB, RS232,

RS422, RS485, DS1, DS3, Video Coax, etc., are NOT to be connected to

inter-building (outside plant) link segments that are subject to lightening.

DO NOT install the Devices in areas where strong electromagnetic fields

(EMF) exist. Failure to observe this caution could result in poor Device

performance.

Use of controls, adjustments or the performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Visible and invisible laser radiation when open. DO NOT stare into the beam

or view the beam directly with optical instruments. Failure to observe this

warning could result in an eye injury or blindness.

iv

Page 9

Transition Networks

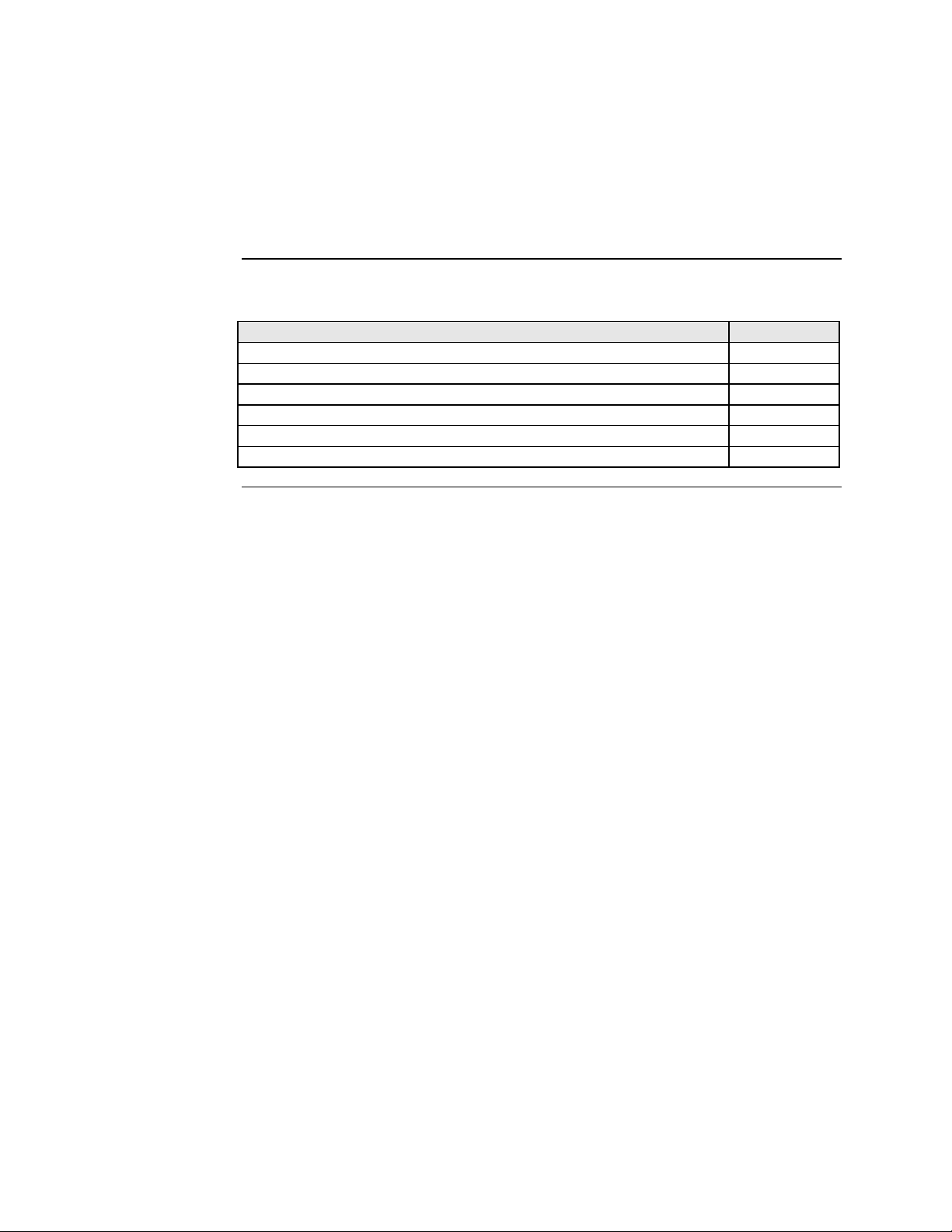

Section I:

Product Description

In this section

These are the topics:

Topic See Page

General description 2

Product features 3

Management methods 4

Hardware description 5

FBRM/BFFG13xx-1xx fiber-to-fiber gigabit models 13

Redundant SFBRM1040-140 models 15

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 1

Page 10

Section I: FBRM/BFFG Product Description Transition Networks

General description

Design and configuration

The FBRM and BFFG Devices are designed as standalone models, and also as slidein Devices for the Point System chassis. These Devices can be managed through

SNMP via the Focal Point software (free), Web-based management, Local SNMP,

and USB interfaces.

The CFBRM and CBFFG (chassis Devices), and SFBRM and SBFFG (standalone

Devices) are designed to manage Devices remotely through the copper and fiber

ports.

The FBRM or BFFG Devices installed on a network should be configured one as the

local peer and the other as a remote peer for management.

Remote management is accomplished using OAM (Operation Administration and

Maintenance) per the IEEE 802.3ah, 2004 standard. Standalone Devices can also be

managed via IP (Web-based) or Telnet.

What is OAM?

In-band management

USB interface

Point System mgmt interface

These Devices implement the IEEE 802.3ah standard or (OAM) in the Ethernet first

mile. OAM is a group of network management functions that provide network fault

indications, performance information, data, and diagnosis. These Devices implement

remote management via OAM as per the IEEE 802.3ah standard.

These Devices implement complete Real-Time Multi-Threaded Operating System

(RTOS) with a TCP/IP stack for in-band management.

The USB (Universal Serial Bus) type “B” serial port is used mainly to configure

Device-basic setup before installation and operation on a network.

Implements the current Point System management I

2

C interface. This allows

managing the Device via SNMP, using the existing Point System method.

2

Page 11

Transition Networks Section I: FBRM/BFFG Product Description

Product features

Supported features

The following is a list of the major FBRM and BFFG Device supported features:

• Remote Management via OAM (IEEE 802.3ah) and IP-based management

• AutoCross

• Transparent Link pass-through with automatic link restoration

• Far end fault detection on fiber ports

• OAM IEEE 802.3ah

• Auto-Negotiation (enable/disable)

• Force 10 Mbs or 100 Mbs speed (non-gigabit models only)

• Force half or full duplex

• Pause capability

• Automatic firmware upgrade via OAM

• Forwards all IEEE multicast frames including STP/LACP/LAMP

• Enable/disable USB port access

• Enable/disable SNMP queries

• Enable/disable system-level IP management or on a per port basis

• IEEE 802.1q VLAN (virtual local area network)

• Management VLAN for all management frames

• IEEE 802.1x port-based network access control

• Radius authentication for management

• Remote and local firmware upgrades via TFTP (Trivial File Transfer Protocol) or

Xmodem

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 3

Page 12

Section I: FBRM/BFFG Product Description Transition Networks

Management methods

Management

USB

Telnet

The FBRM and BFFG Devices support the following management methods:

• USB CLI (Command Line Interface)

• Telnet

• MMU (Management Module Unit) chassis web-based

• IP-based (web-based directly to the Device)

USB management requires a direct connection to the Device via a computer. This

method is used to set up initially or to troubleshoot Devices in the field.

Telnet management requires that the Device be connected to a network. Then from

the CPU command line type Telnet and the Device IP address as shown as follows:

Telnet nnn.nnn.nnn.nnn (represents Device IP address).

MMU

IP-based (web- based)

The MMU (Management Module Unit) is the heart of the Point System chassis’

management capability. It has the ability to monitor and manage all its installed

Devices. The MMU communicates through the CLI presented at the serial port, or

through SNMP, Telnet CLI, and Web interface available via the Ethernet port.

The switch provides complete management through IP via an SNMP interface, webbrowser, or Telnet. The Device provides an embedded web server for web-based

management. It also offers advanced management features and enables Device

management from anywhere on the network through a standard browser, such as

Microsoft Internet Explorer or Netscape.

4

Page 13

Transition Networks Section I: FBRM/BFFG Product Description

Hardware description

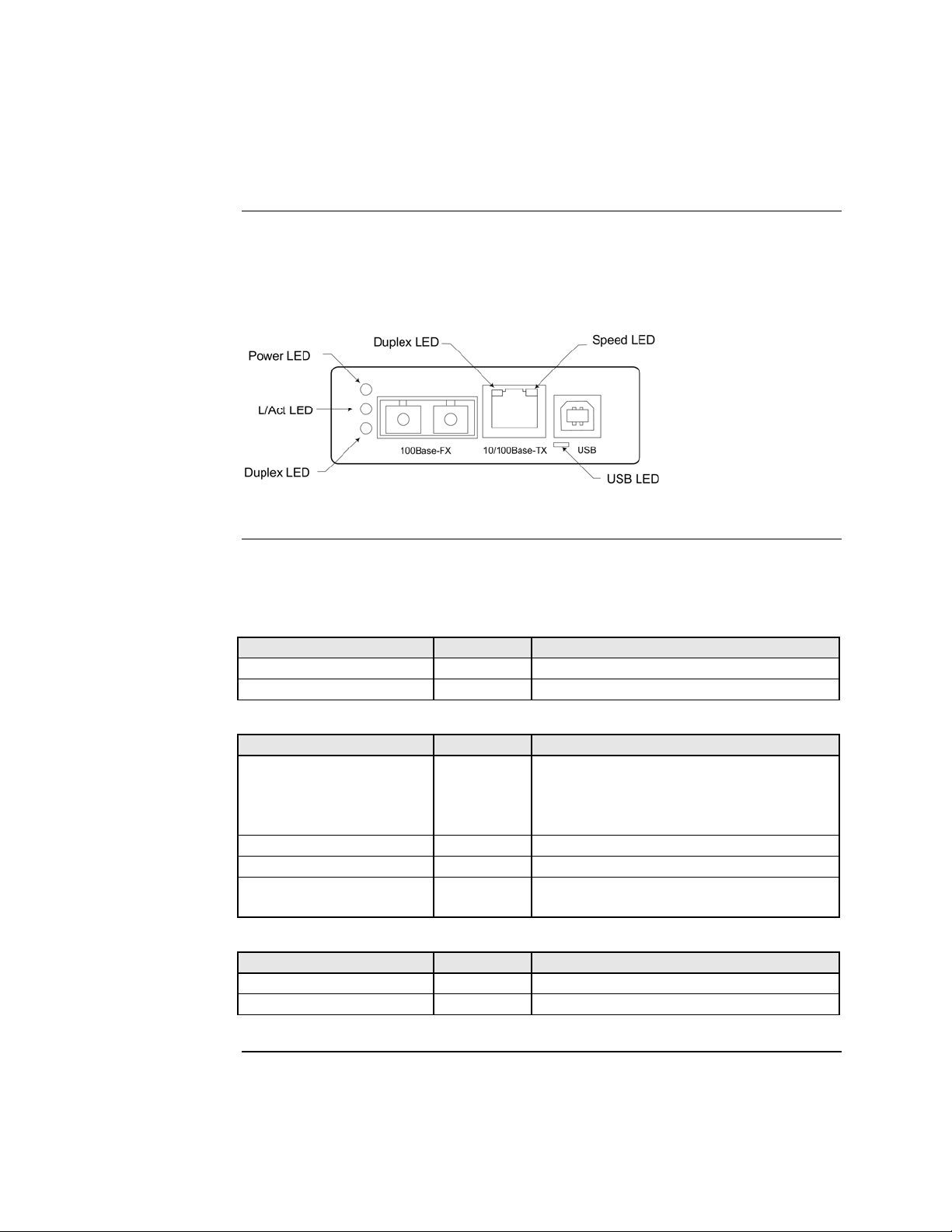

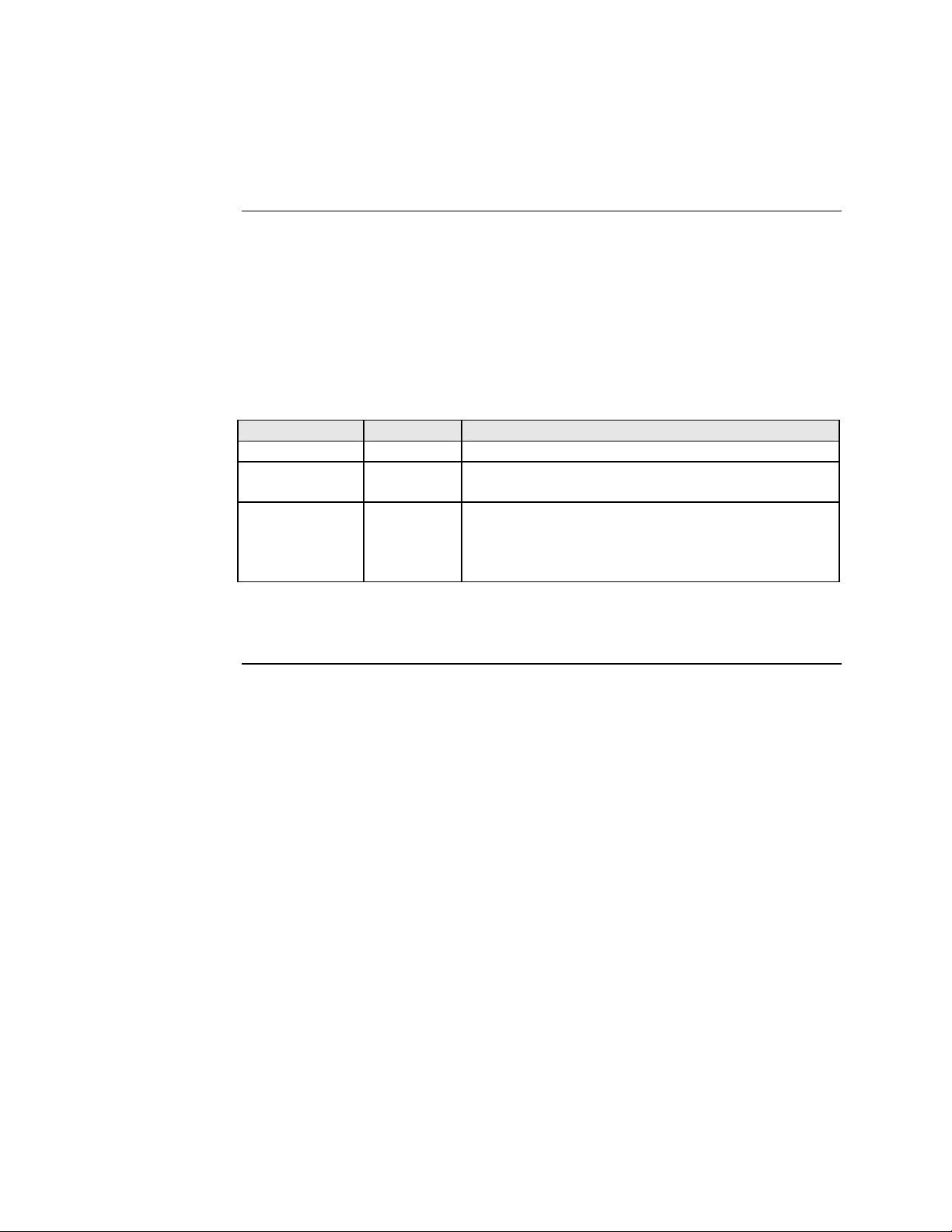

Front panel CFBRM

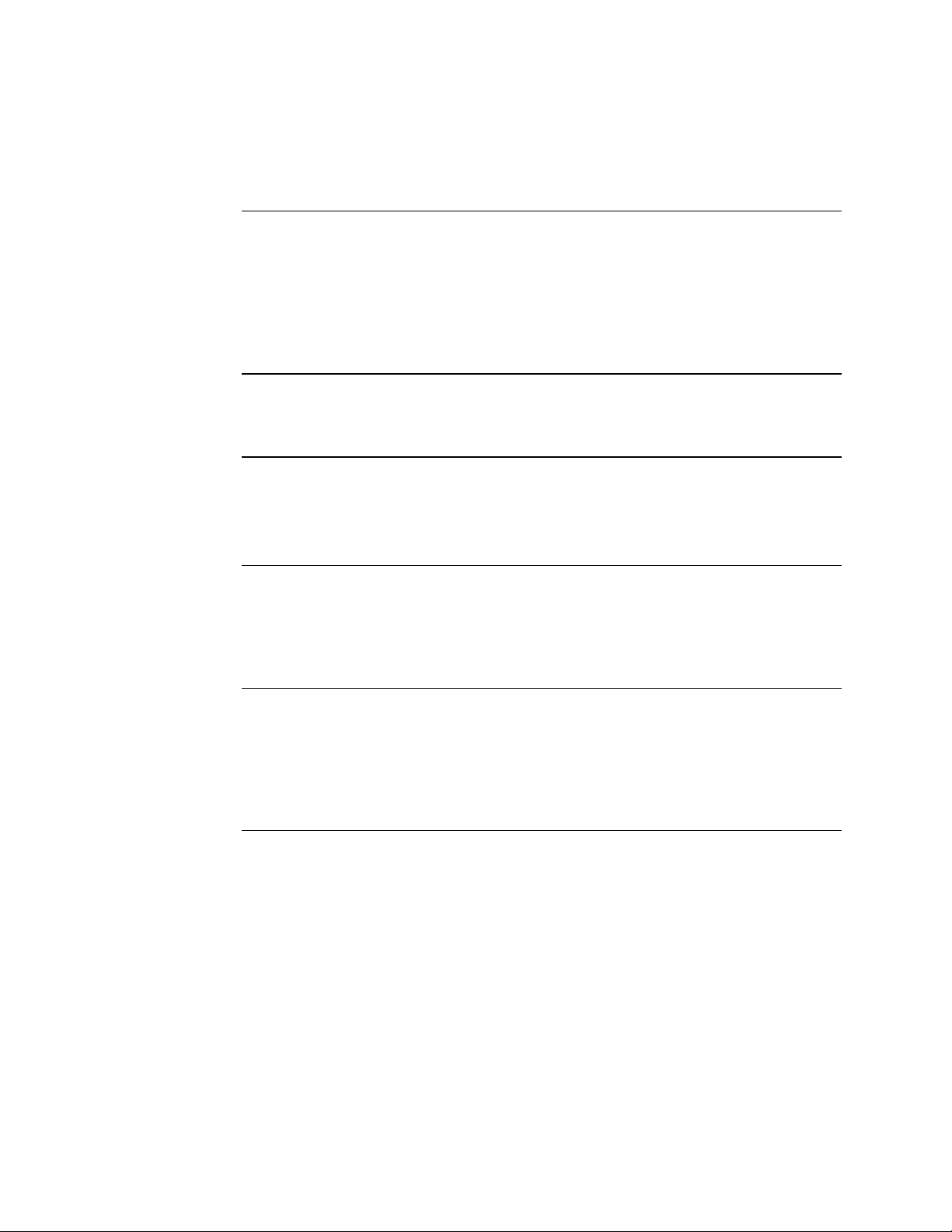

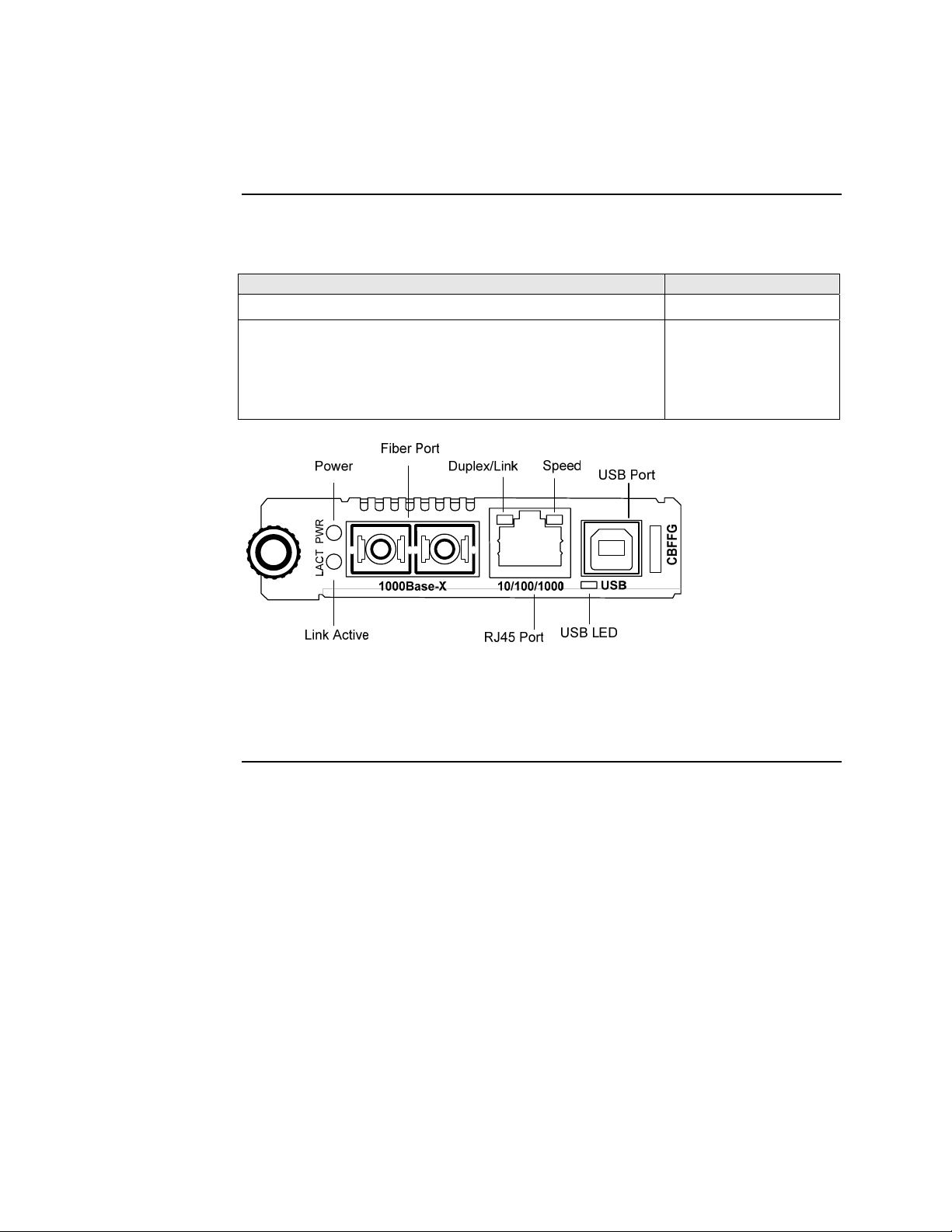

The front panel of the CFBRM10xx-1xx Devices has the following ports and LEDs:

Ports Front Panel LEDs

One RJ-45 auto-sensing of 10Base or 10/100Base-TX UTP

• Power (one)

• RJ-45 port (two)

connections

One 100Base-FX/LX/BX fiber either SC or ST connectors

• LACT (one)

• DPX (one)

One USB

• USB (one)

Figure 1: Chassis CFBRM10xx-1xx Device Front Panel

Note: The LEDs and ports are the same on the SFBRM10xx-1xx standalone

models.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 5

Page 14

Section I: FBRM/BFFG Product Description Transition Networks

Hardware description, continued

Front panel CFBRM

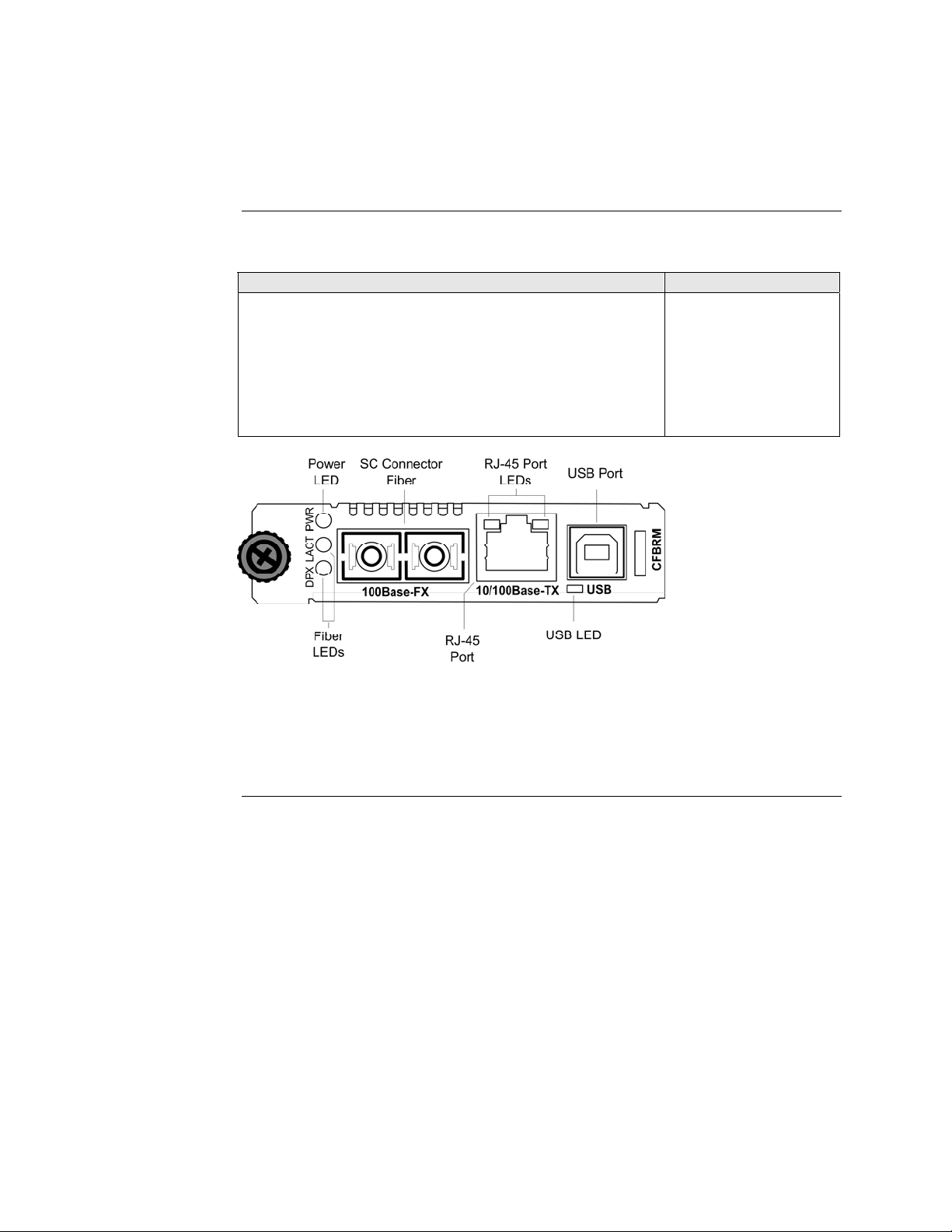

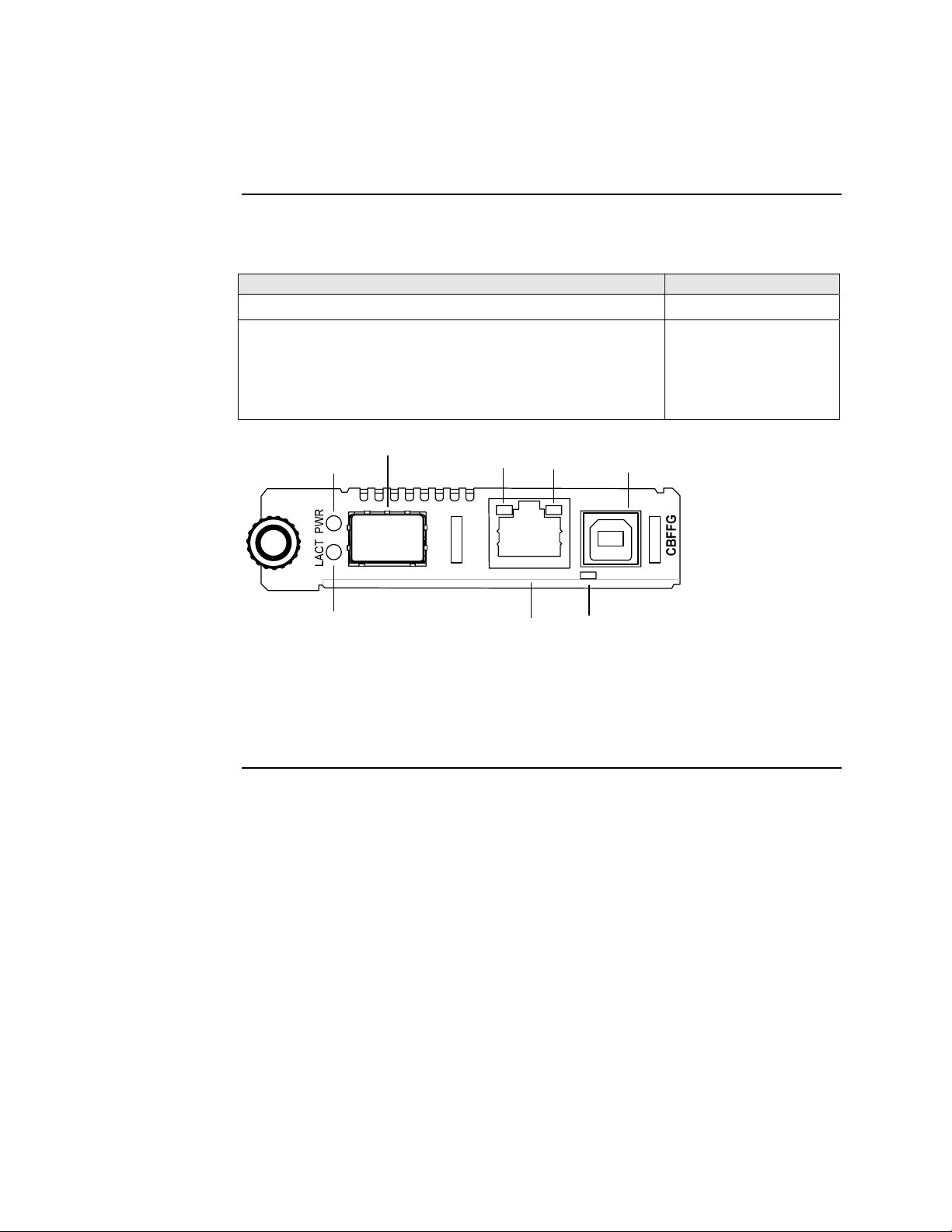

The front panel of the CFBRM 1040-140 Devices has the following ports and LEDs:

Ports Front Panel LEDs

100Base-FX SFP port

10/100 Base-T copper port

• Power (one)

• Link/Active

• Speed

• Duplex (one)

One USB

• USB (one)

Figure 2: CFBRM1040-100 Front Panel

Note: The LEDs and ports are the same on the SFBRM1040-140 standalone

models.

Continued on next page

6

Page 15

Transition Networks Section I: FBRM/BFFG Product Description

Hardware description, continued

Front panel CFBRM Gbit

The front panel of the CFBRM13xx-1xx Devices has the following ports and LEDs:

Ports Front Panel LEDs

One 100 Base-T

One 1000Base-FX/LX/BX fiber either SC or ST connectors

One USB

SC Connector

Fiber

100Base-T 1000Base-X

SC Connector

Fiber

USB Port

• Power (one)

• Fiber-Port Link (one)

• Fiber-Port Link (one)

• USB (one)

USBLNKPWR LNK

Power

LED

Fiber Link

LED

Fiber Link

LED

USB LED

Figure 3: Chassis CFBRM13xx-1xx Device Front Panel

Note: The LEDs and ports are the same on the SFBRM13xx-1xx standalone

models.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 7

Page 16

Section I: FBRM/BFFG Product Description Transition Networks

Hardware description, continued

Front panel CBFFG Gbit

The front panel of the CBFFG10xx-1xx Devices has the following ports and LEDs:

Ports Front Panel LEDs

1000Base-SX/LX/BX fiber SC port

10/100/1000Base-T copper port

• Power (one)

• Link/Active

• Speed

• Duplex (one)

One USB

• USB (one)

Figure 4: CBFFG10xx-1xx Device Front Panel

Note: The LEDs and ports are the same on the SBFFG10xx-1xx standalone

models.

Continued on next page

8

Page 17

Transition Networks Section I: FBRM/BFFG Product Description

Hardware description, continued

Front panel CBFFG Gbit

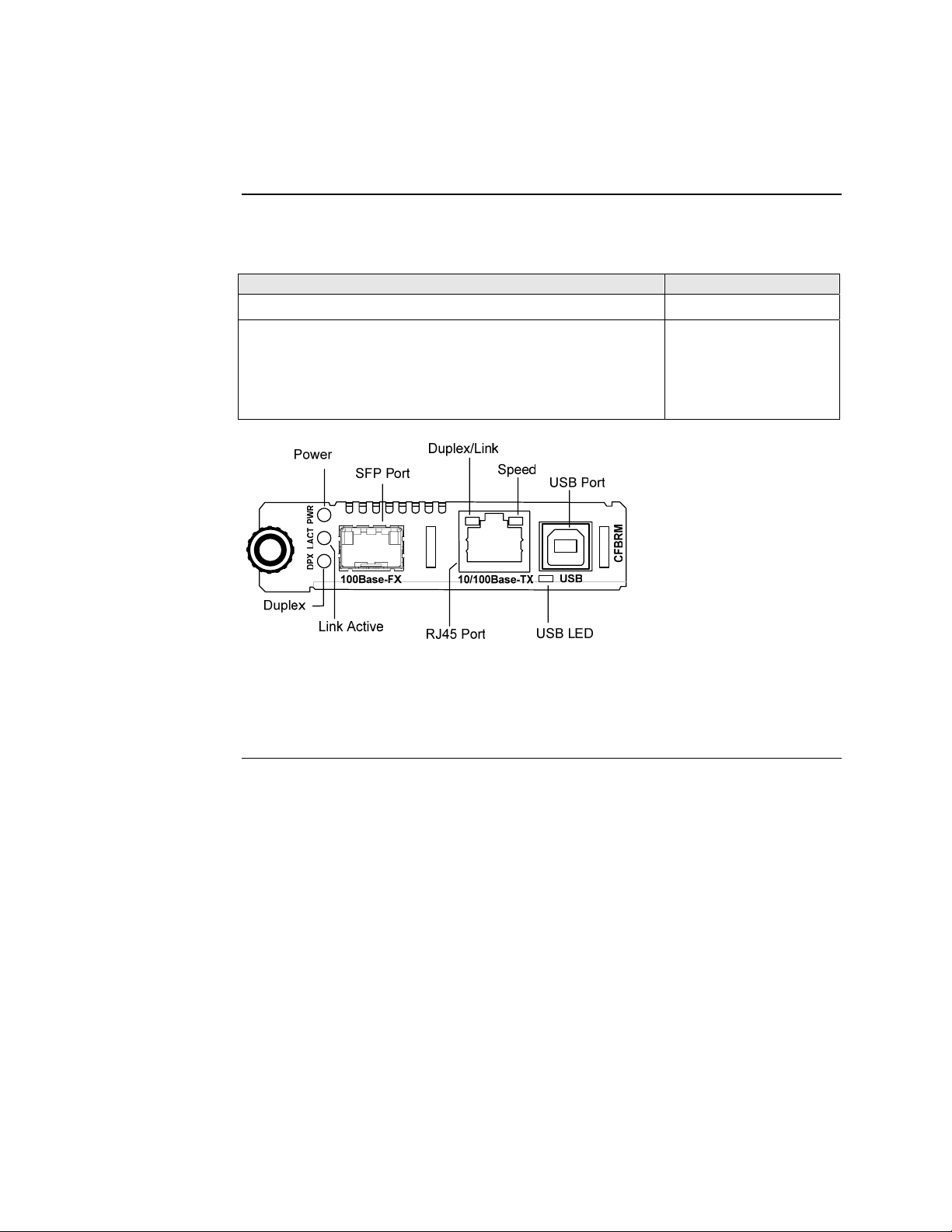

The front panel of the CBFFG1040-1xx Devices has the following ports and LEDs:

Ports Front Panel LEDs

1000Base SFP port

10/100/1000Base-T copper port

• Power (one)

• Link/Active

• Speed

• Duplex (one)

One USB

Power

SFP Port

Duplex/Link

Speed

USB Port

• USB (one)

USB

USB LED

Link Active

10/100/10001000Base-X

RJ45 Port

Figure 5: CBFFG1040-1xx Device Front Panel

Note: The LEDs and ports are the same on the SBFFG1040-1xx standalone

models.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 9

Page 18

Section I: FBRM/BFFG Product Description Transition Networks

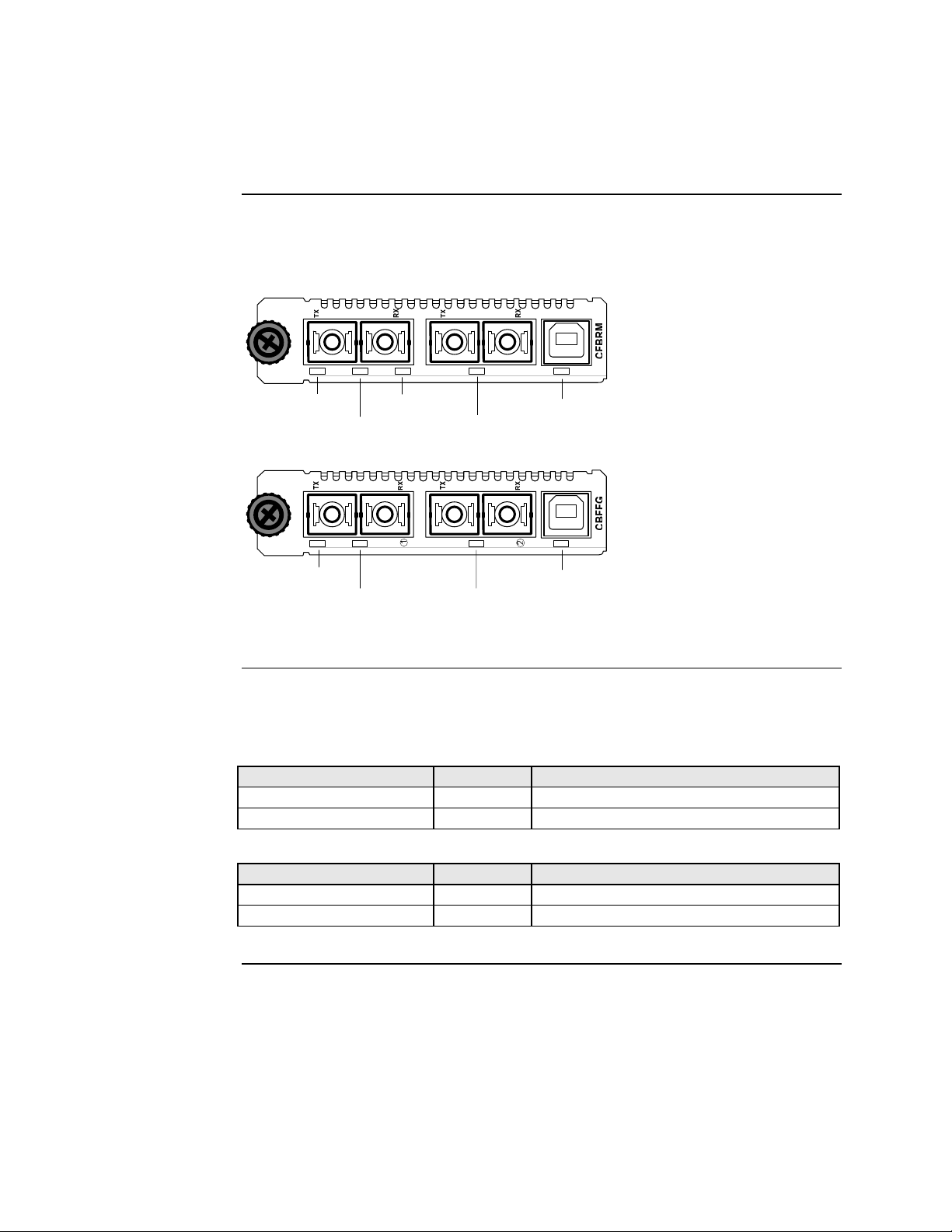

Hardware description, continued

Front panel CBFFG Gbit

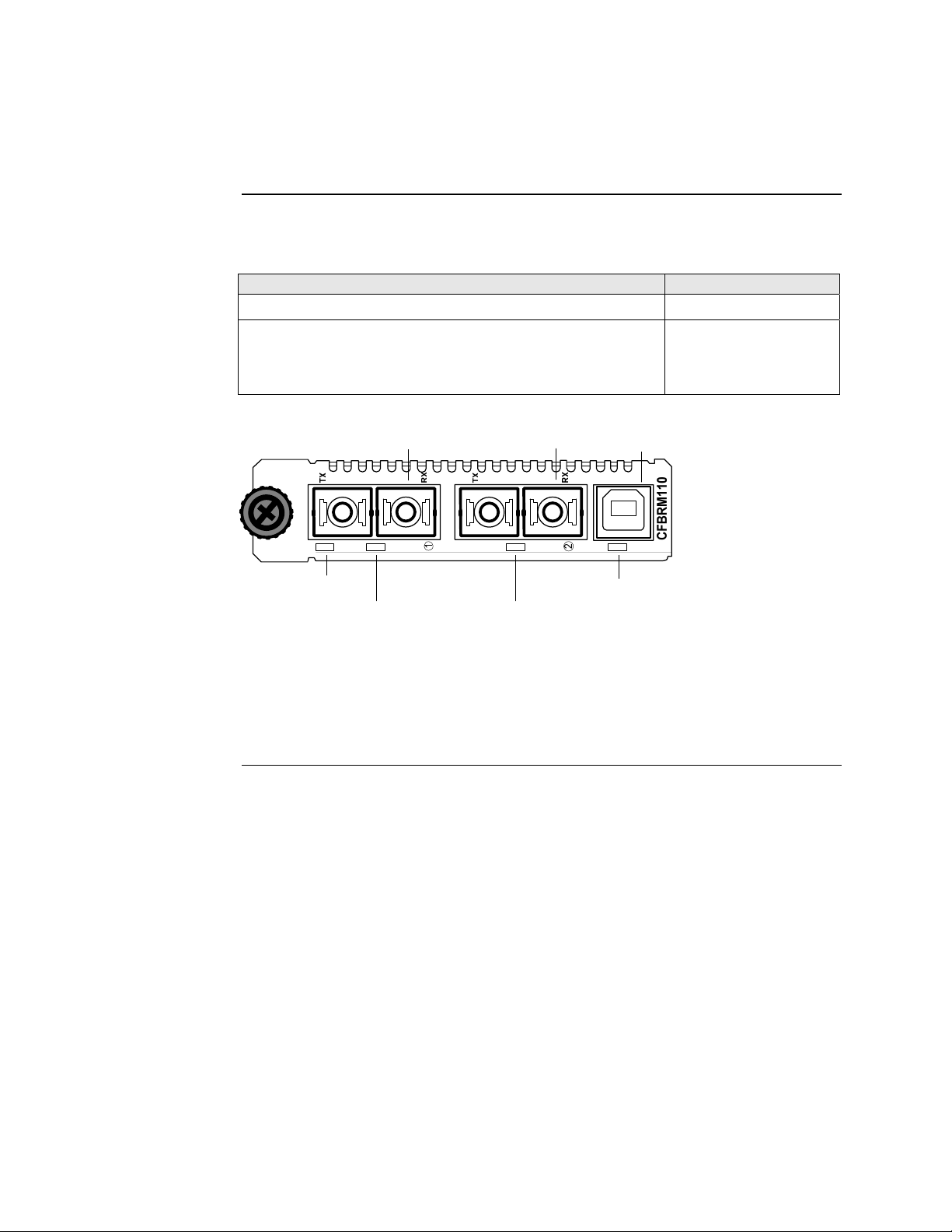

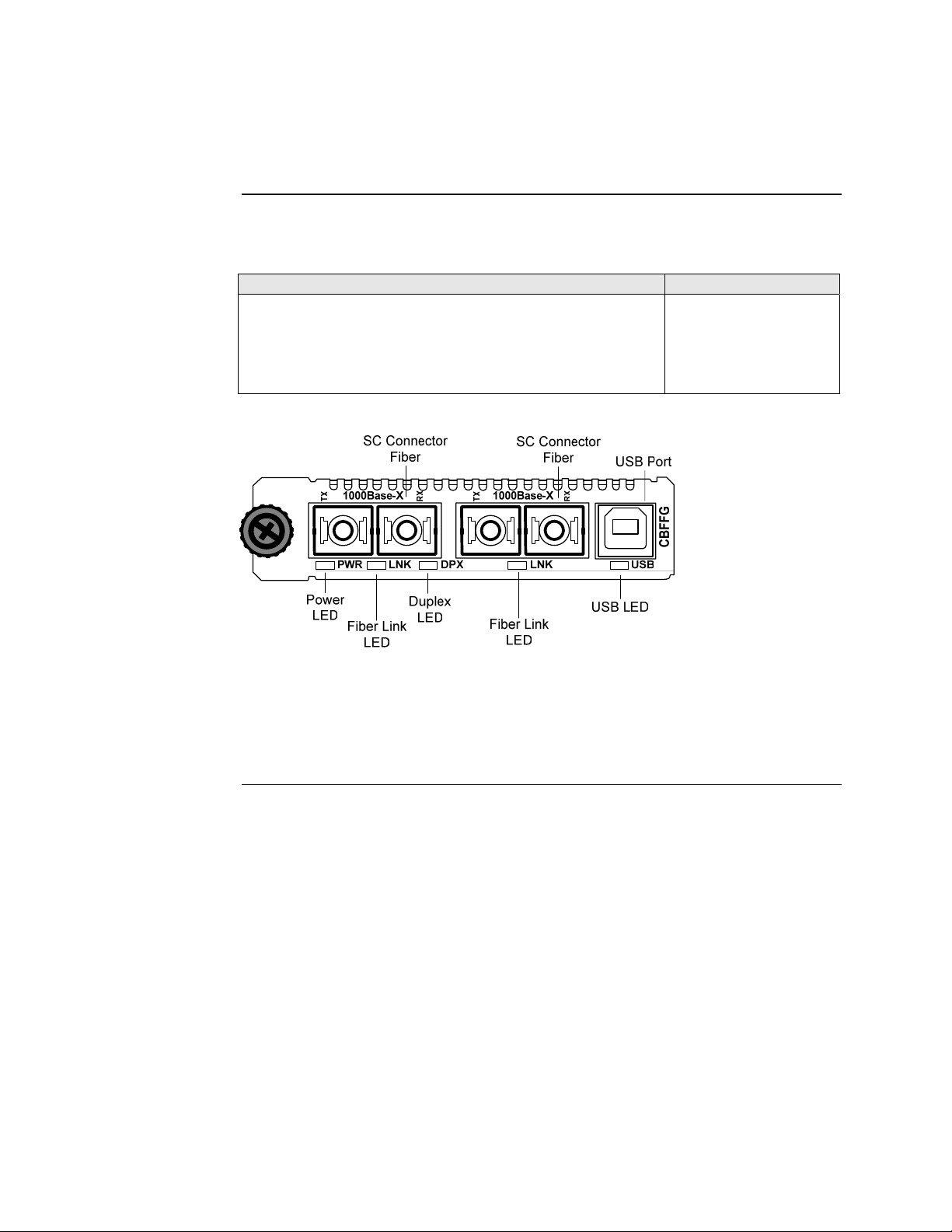

The front panel of the CBFFG13xx-1xx Devices has the following ports and LEDs:

Ports Front Panel LEDs

Two 1000Base-FX/LX/BX fiber either SC or ST connectors

• Power (one)

• Fiber-Port Link (two)

• Duplex (one)

One USB

• USB (one)

Figure 6: Chassis CBFFG13xx-1xx Device Front Panel

Note: The LEDs and ports are the same on the SBFFG13xx-1xx standalone

models.

Continued on next page

10

Page 19

Transition Networks Section I: FBRM/BFFG Product Description

Hardware description, continued

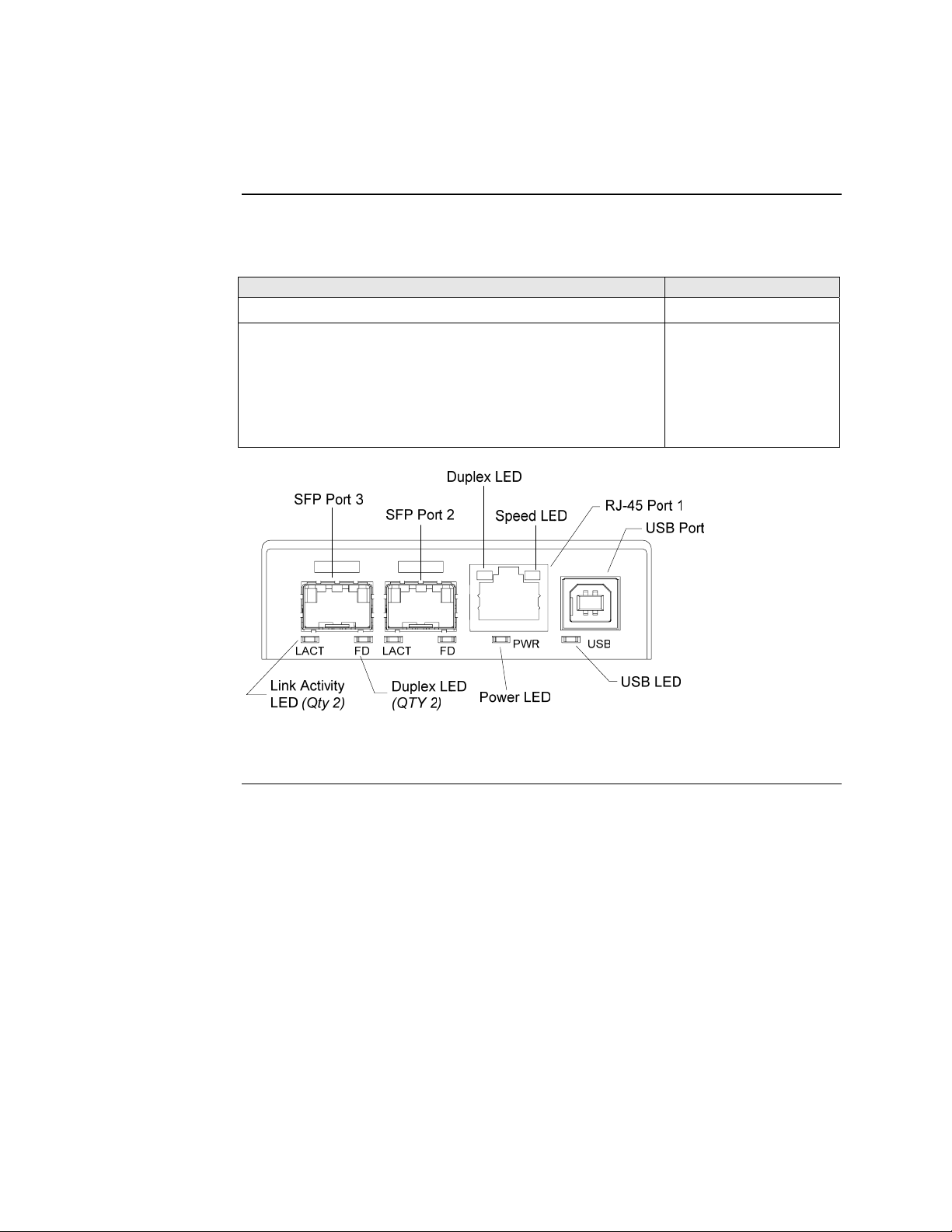

Front panel SFBRM

The front panel of the SFBRM1040-140 redundant Devices has the following ports

and LEDs:

Ports Front Panel LEDs

1000Base SX/LX SFP ports (2 and 3)

• Power (one)

• Link/Active

• Duplex

10/100/1000Base-T copper port (1)

• Speed

• Duplex (one)

One USB

• USB (one)

Figure 7: CBFFG1040-140 Device Front Panel

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 11

Page 20

Section I: FBRM/BFFG Product Description Transition Networks

Hardware description, continued

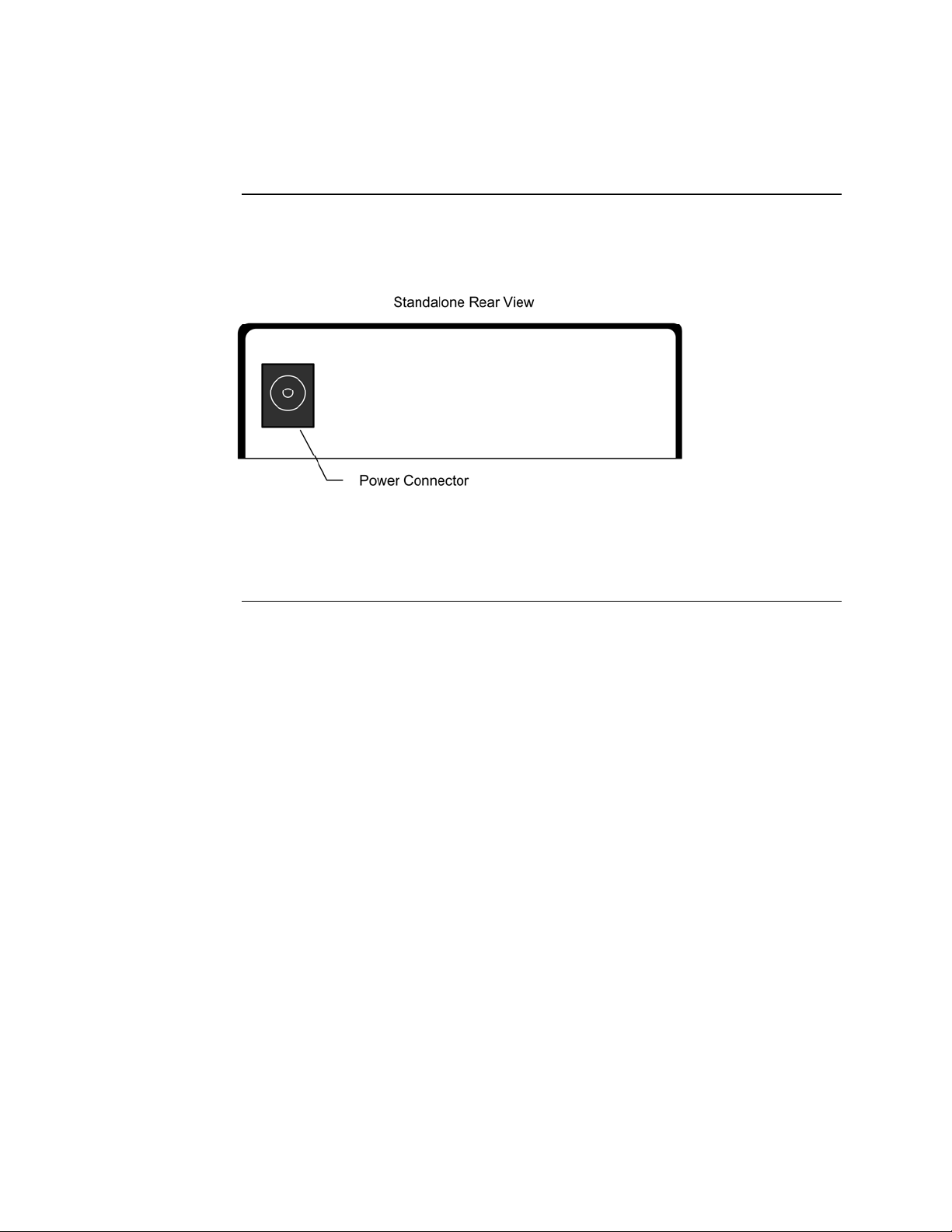

Rear panel (standalone)

On the standalone SFBRM and SBFFG Devices only, the rear panel consists of a

power-barrel connector for connecting power via a power adaptor. See Figure 8.

Figure 8: SFBRM/SBFFG 1xxx-1xx Device Real Panel (Standalone Only)

Note: The Point System chassis powers the CFBRM and CBFFG chassis Devices.

12

Page 21

Transition Networks Section I: FBRM/BFFG Product Description

FBRM/BFFG13xx-1xx fiber-to-fiber gigabit models

Gigabit (Gbit) models

The FBRM100Base-FX-to-1000Base-X and the BFFG 1000Base-X-to-1000Base-X

are the Gbit versions of the IEEE 802.3ah managed Devices. The BFFG models link

Gbit fiber connections; the FBRM models convert 100Base-Fx 100 Mbit/s to Gbit.

These Devices function generally in the same manner as copper-to-fiber FBRMs, the

difference is the way the ports are configured. See Tables 1 and 2.

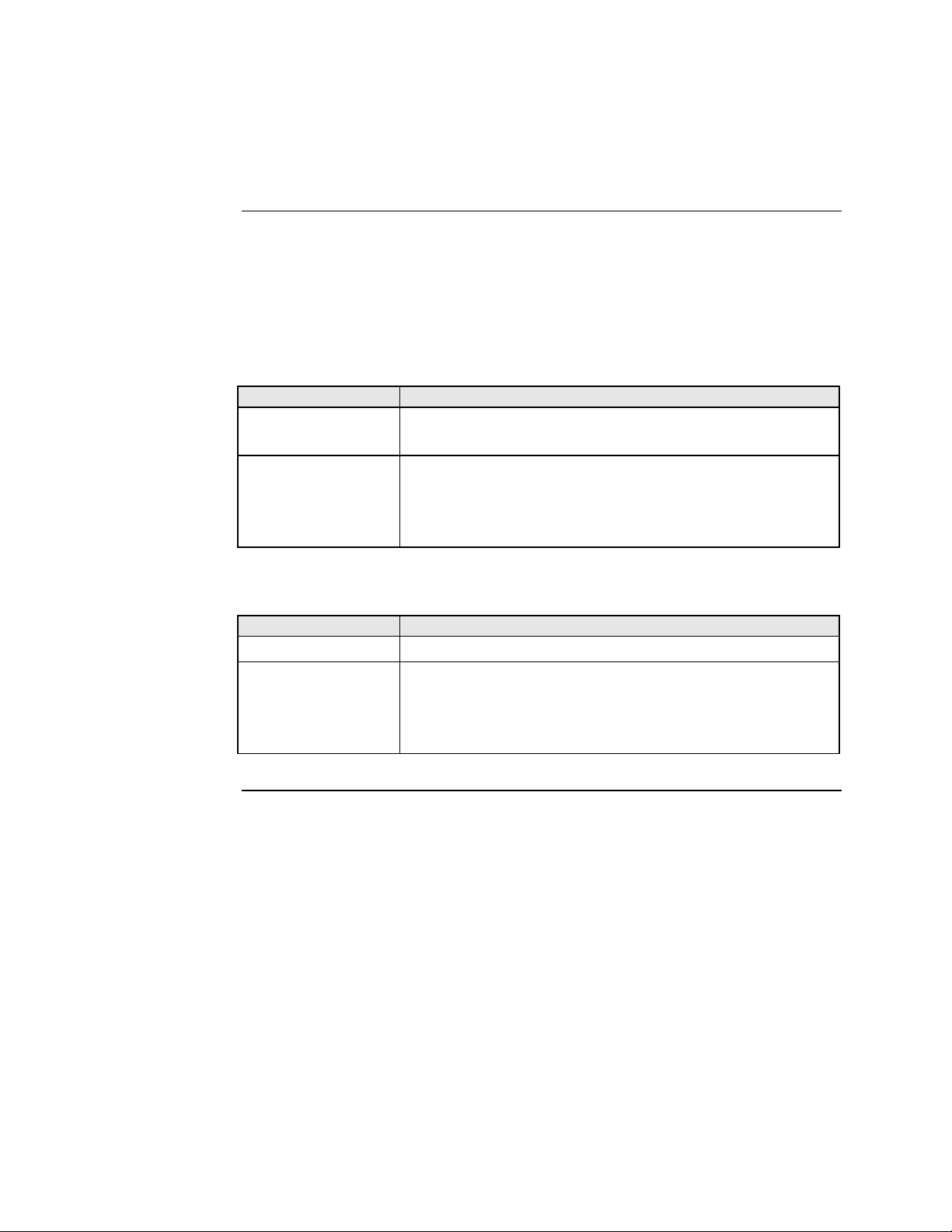

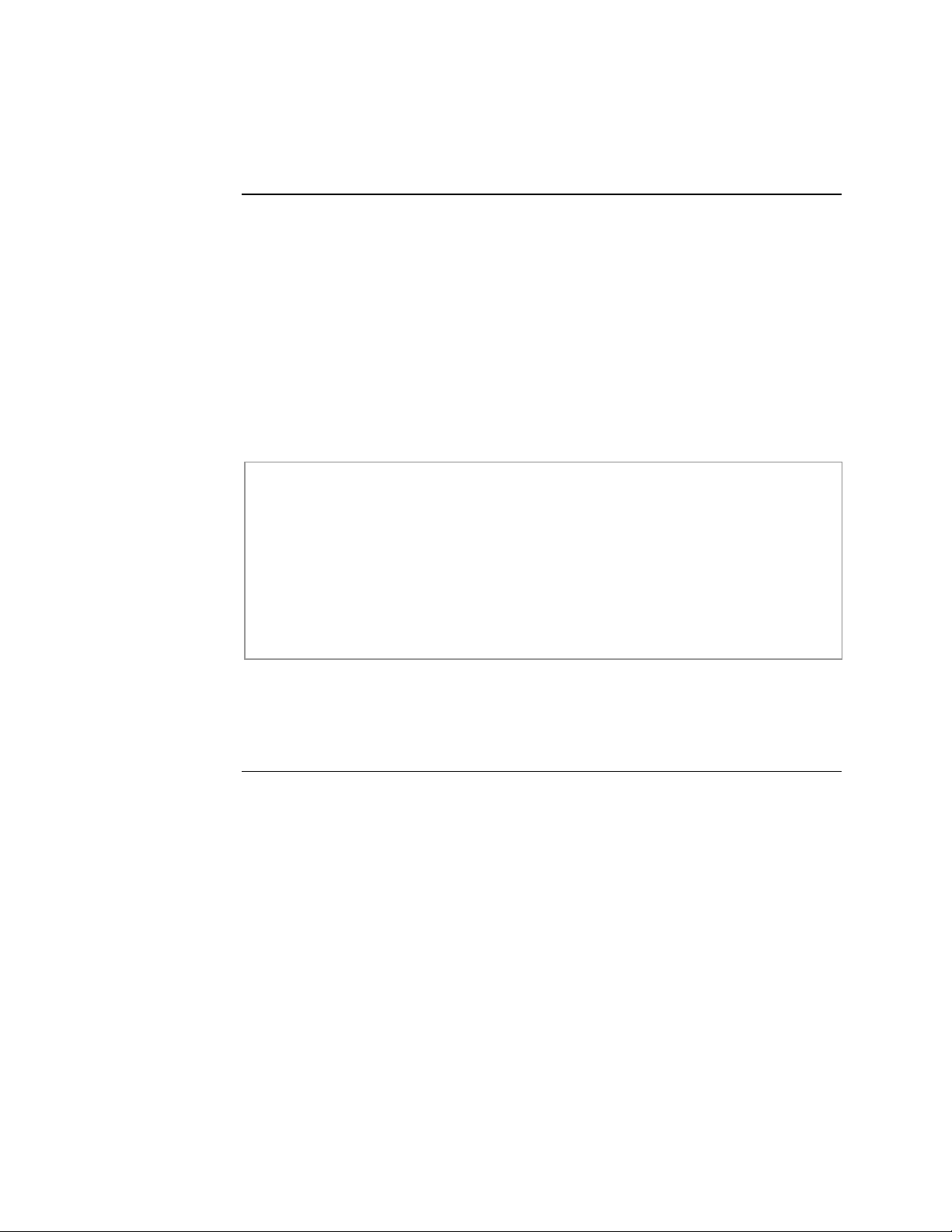

Table 1: FBRM13xx-1xx 100Base-FX-to-1000Base-X Device

Port Configuration

Port 1: 100Base-FX

• Default setting: 100Mbs and full duplex.

• FEFI (Far-end fault indication) is configurable.

Port 2: 1000Base-X

Default:

• Auto-Negotiation enabled.

• OAM enabled and in Active Mode if chassis Device

(passive if standalone).

Table 2: BFFG13xx-1xx 1000Base-X-to-1000Base-X Device

Port Configuration

Port 1: 1000Base-X

Port 2: 1000Base-X

Default: Auto-Negotiation enabled.

Default:

• Auto-Negotiation enabled.

• OAM is enabled and in Active Mode if chassis Device

(passive if standalone).

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 13

Page 22

Section I: FBRM/BFFG Product Description Transition Networks

FBRM/BFFG13xx-1xx fiber-to-fiber gigabit models, continued

Connectivity

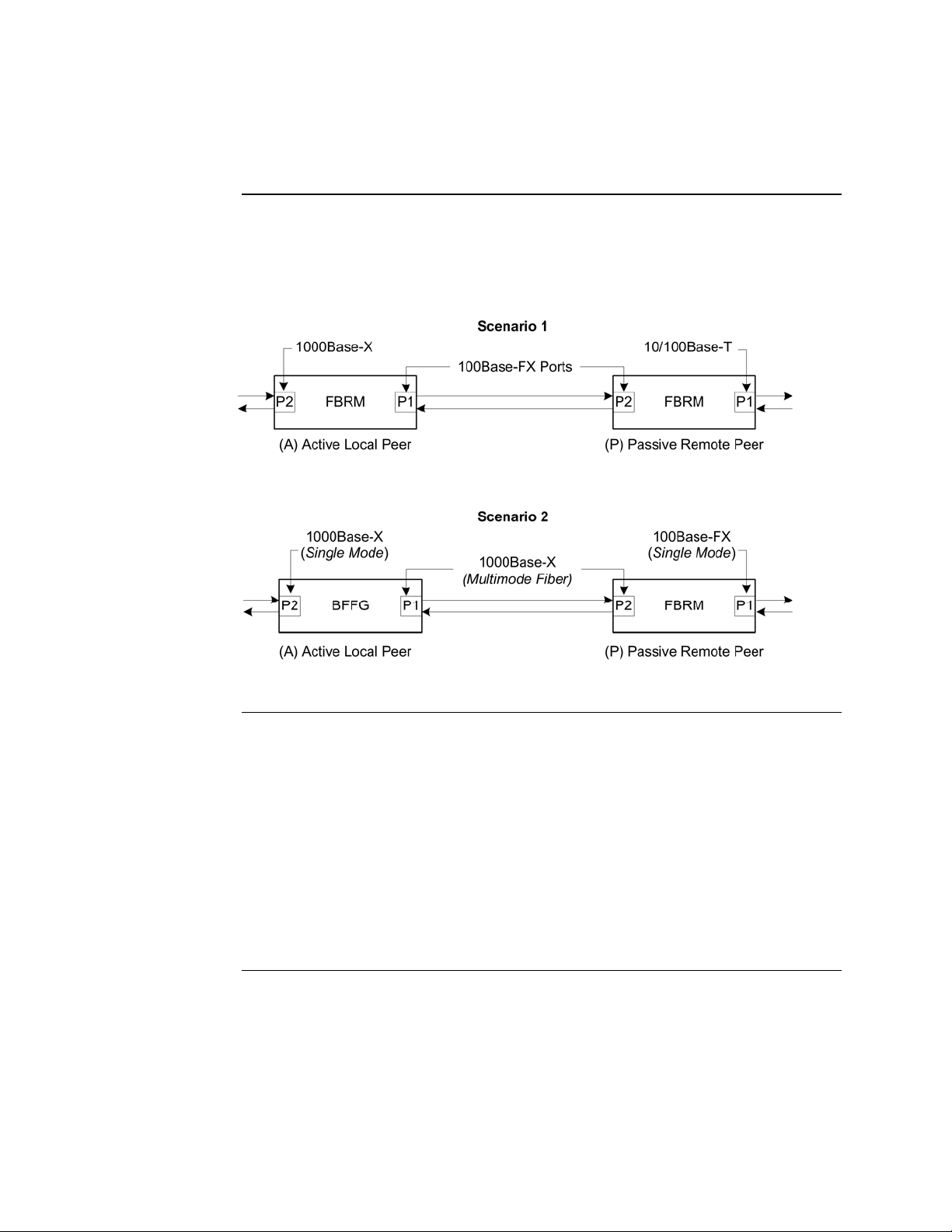

The different versions of the FBRM and BFFG can be connected and set up to

manage a remote peer completely. In a mixed setup with other FBRM or BFFG

Devices, consider the connectivity scenarios in Figure 9, and the explanation that

follows:

Connection scenario explanation

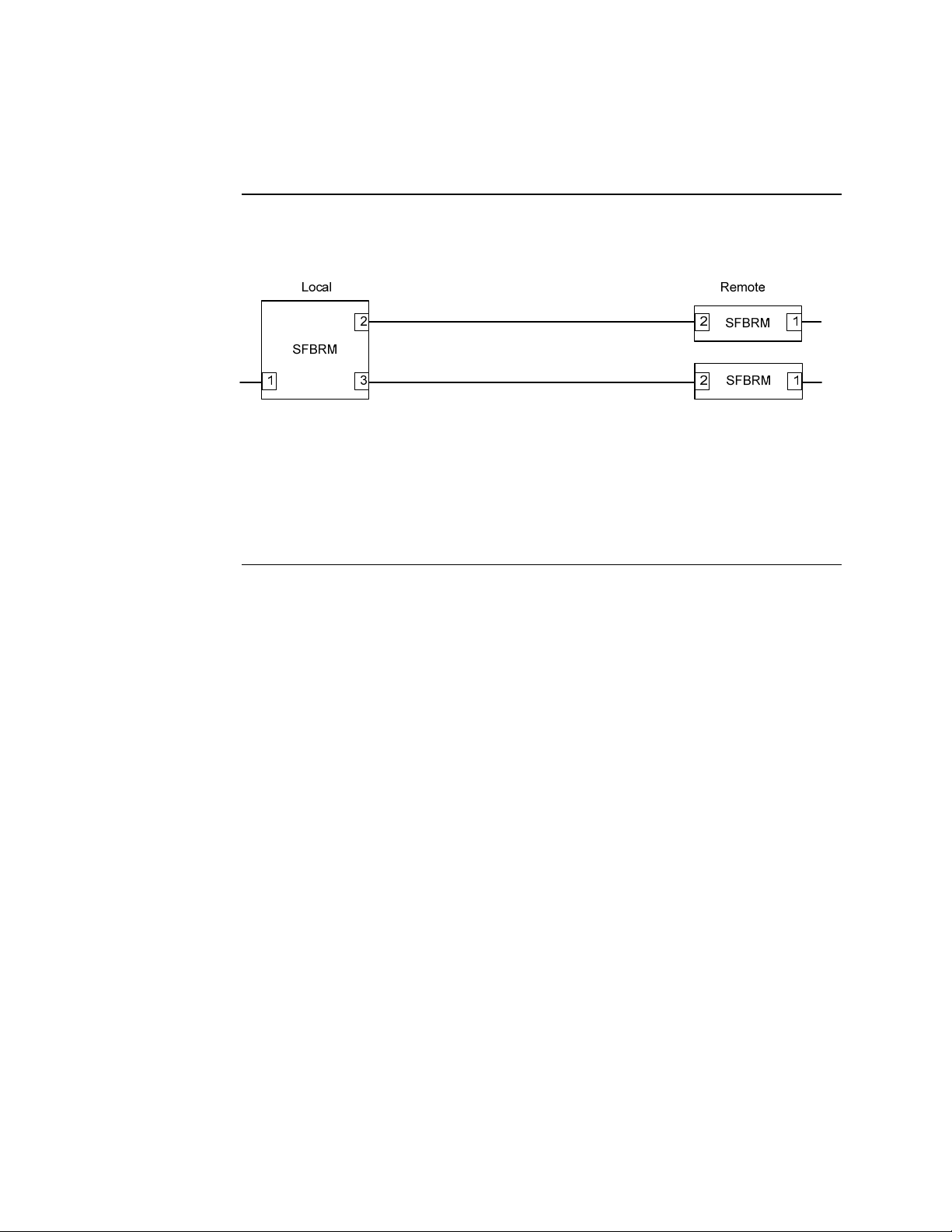

Figure 9: Connectivity Scenarios

In Figure 9, P2 of the active local peer in both scenarios is “OAM enabled” and

“Active” by default. To manage the remote passive peer via OAM, configure P1 of

the active local peer as follows:

• Enable OAM

• Select Active mode

If the connection to the passive remote peer is made thru P2 of the active local peer,

OAM occurs without human intervention.

Note: Automatic firmware upgrades will not occur with different types of FBRM

or BFFG Device configurations.

14

Page 23

Transition Networks Section I: FBRM/BFFG Product Description

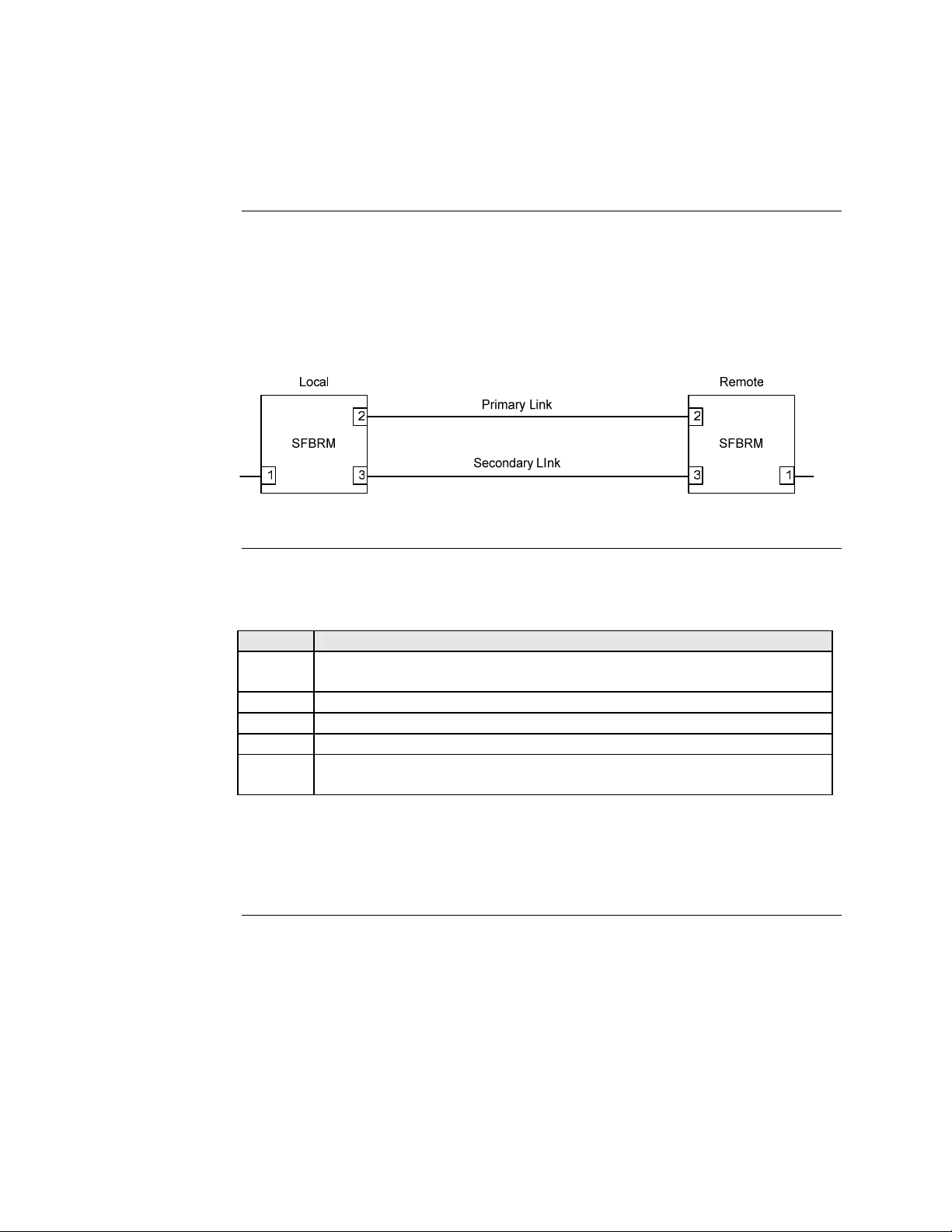

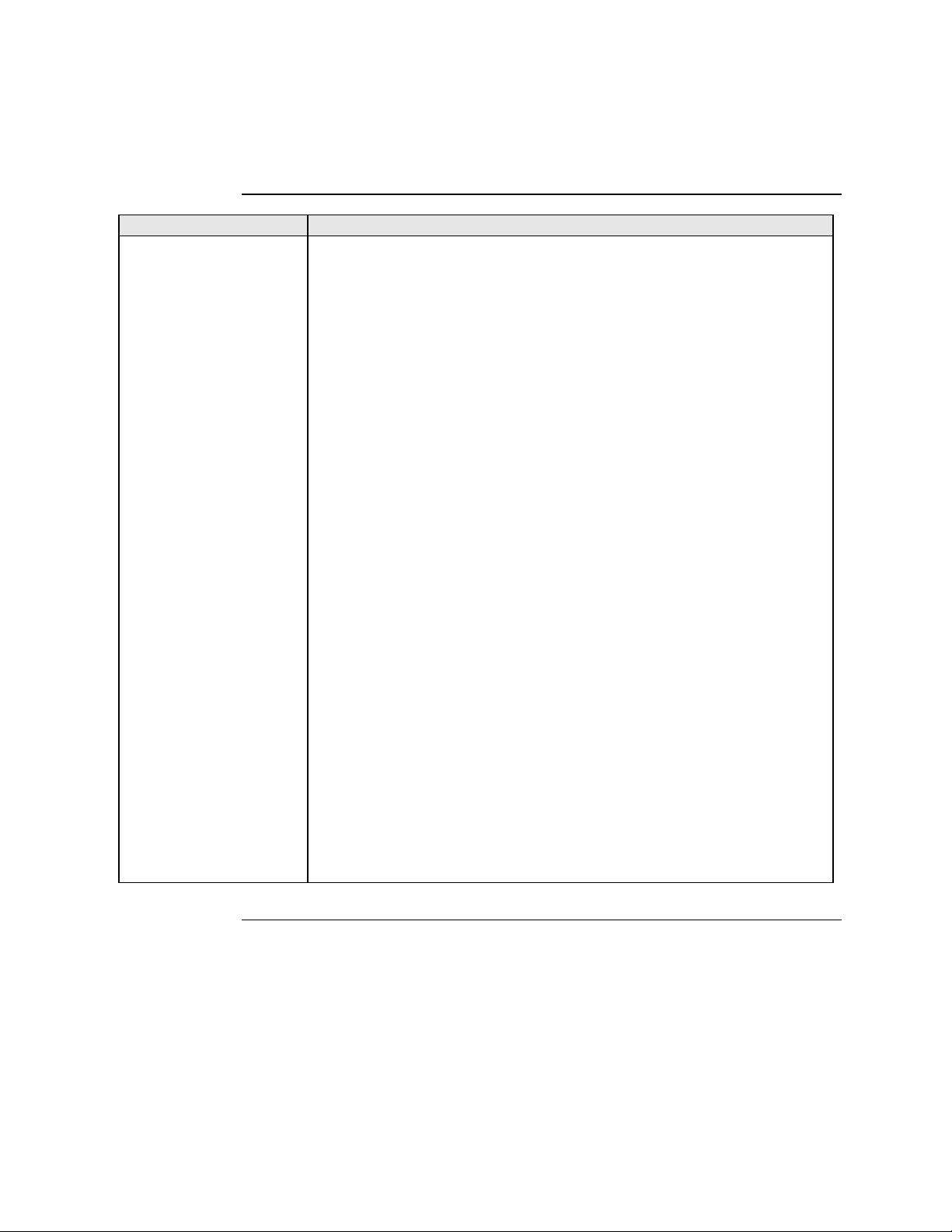

Redundant SFBRM1040-140 models

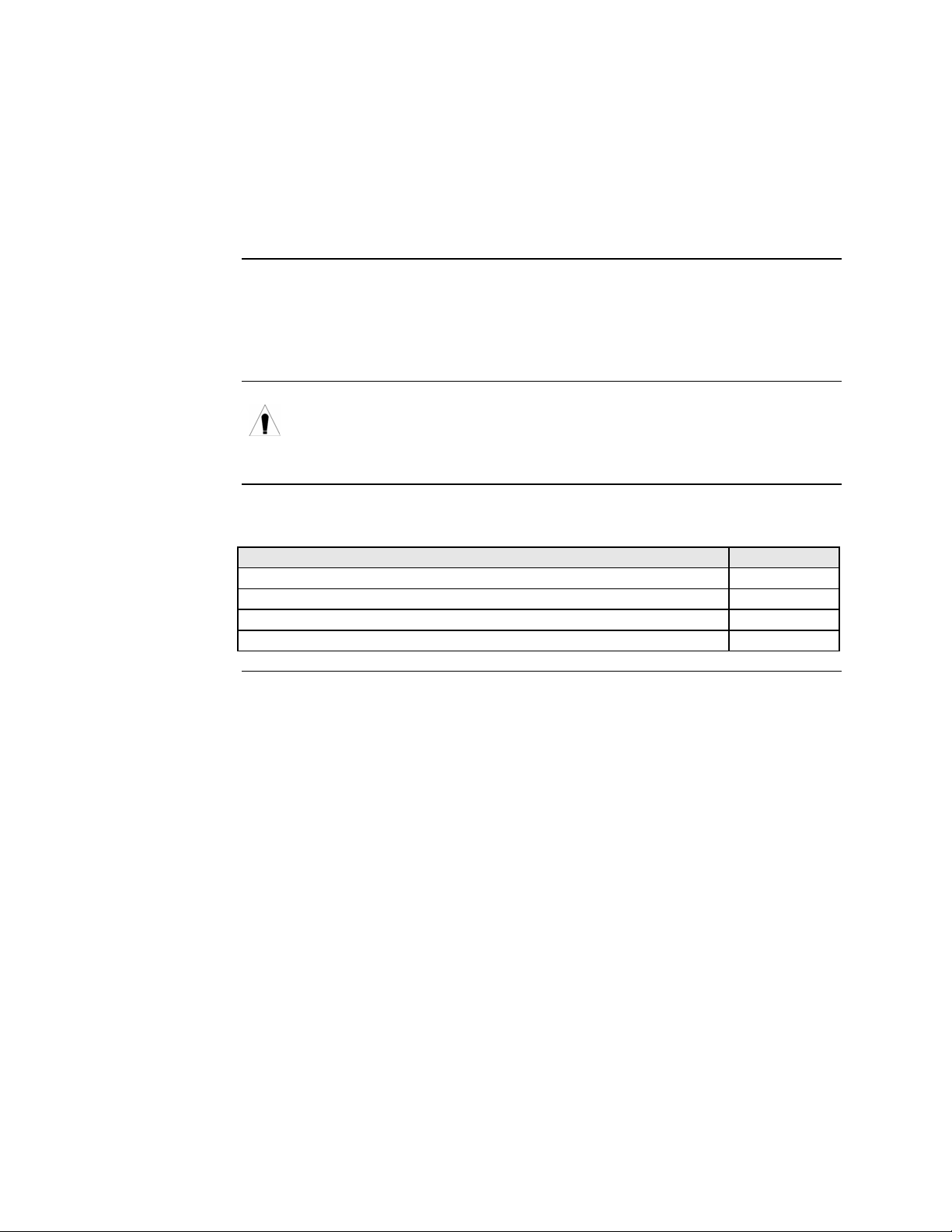

Redundant models

These SFBRM SFP Devices support fiber redundancy. They have two (2) fiber SFP

ports and one (1) copper port. When you tag the fiber ports as primary and secondary

with redundancy enabled, any fault on the primary port results in the secondary port

becoming operational. There is an option for reverting back to the primary once it

has been restored, or you can continue using the secondary port—these are user

selectable features. See Figure 10.

Figure 10: SFBRMs in Redundant Mode

Explanation

With Port 3 as the secondary port in Redundancy Mode and Port 2, the primary goes

down, the following will happen:

Stage Description

A. All Physical layer and OAM configurations of Port 2 will be applied to

Port 3.

B. Port 2 is disabled, and Port 3 initialized to take over.

C. An SNMP trap is sent indicating that the ports have switched.

D. OAM reinitializes (resets all OAM counters and event logs).

E. All the dynamic MAC entries in the ATU are flushed and the active port

has to relearn the entries.

Note: If the configuration option “revert” is set, when the primary port link is

restored the session will revert back to the primary port. If the “revert’ option

is NOT SET and the primary link is restored, the secondary port remains in

operation until the user intervenes.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 15

Page 24

Section I: FBRM/BFFG Product Description Transition Networks

Redundant SFBRM1040-140 models, continued

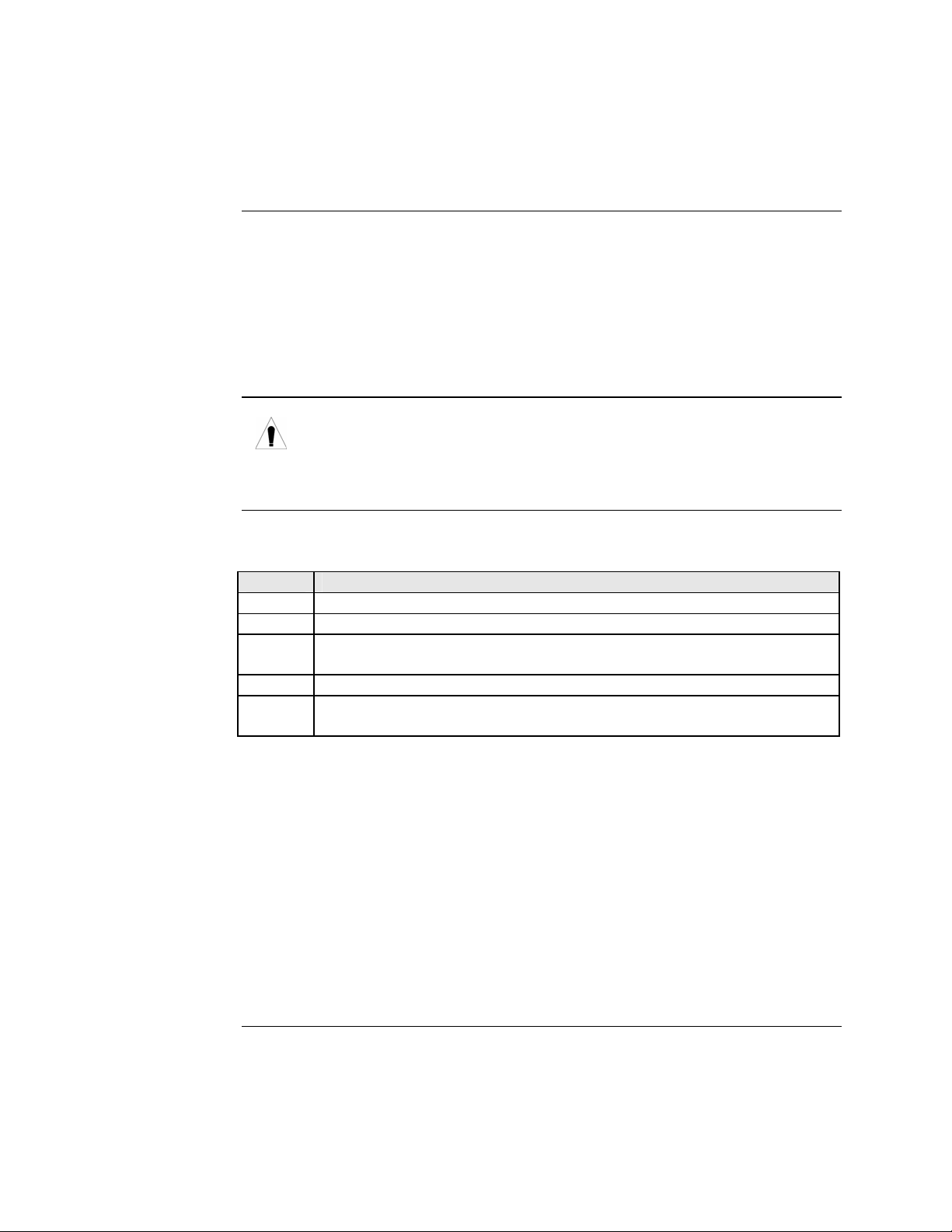

3-port switch mode

In this mode, the Device acts as a 3-port switch with the fiber port connected to 2

remote Devices. See Figure 11.

Figure 11: 3-Port Switch Mode

Note: In 3-port switch mode:

• Only one OAM session can be active at anytime.

• Transparent Link pass through is not applicable in this scenario. The port

link status from the Devices is received only as SNMP traps.

16

Page 25

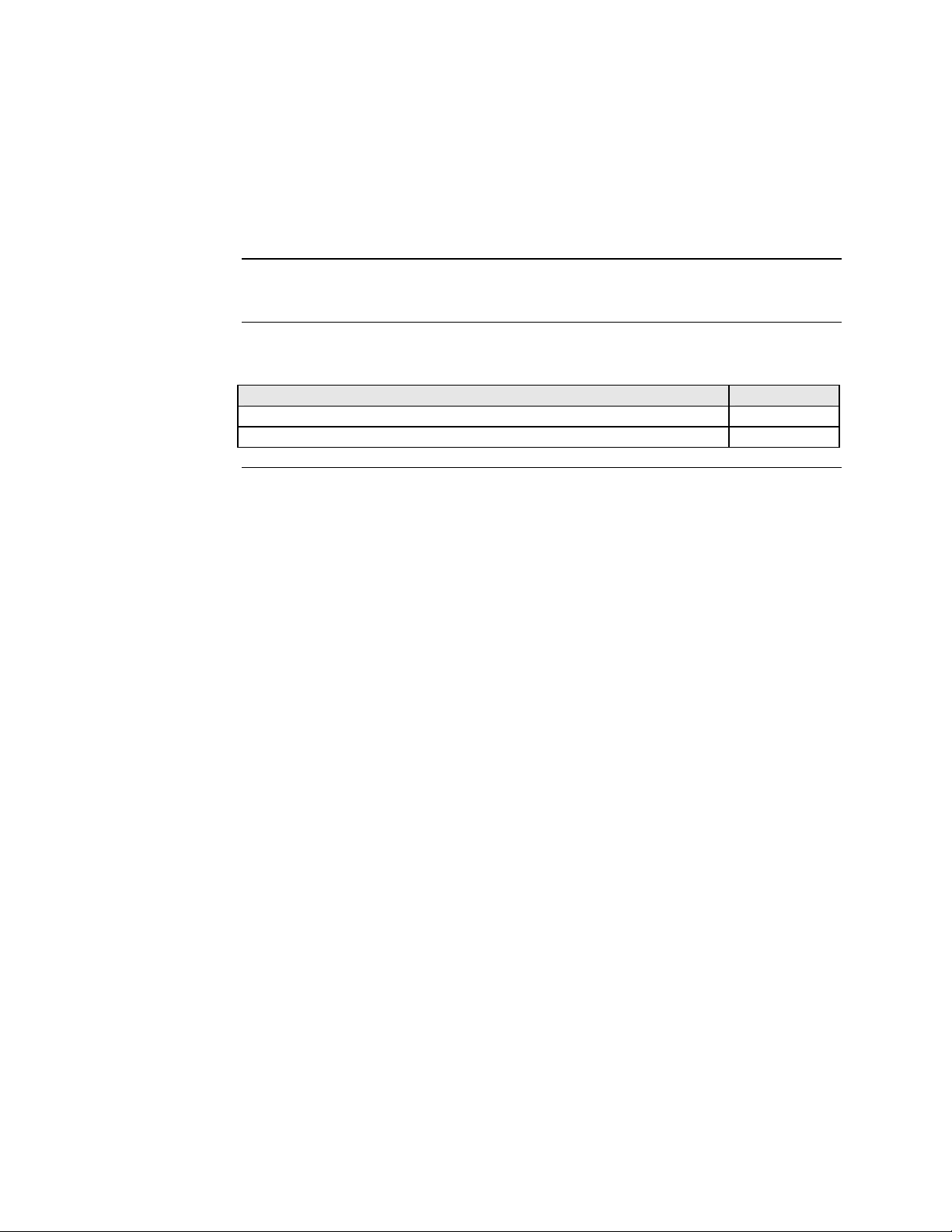

Introduction

Caution

In this section

Transition Networks

Section II:

Hardware Installation

This section describes how to install the CFBRM and CBFFG Devices into a Point

System chassis with a remotely managed SFBRM or CFBRM standalone Device.

Also, shows how to install two SFBRM Devices or two SBFFG standalone Devices

on a network, one as a local Device and the other as a remotely managed Device.

When handling chassis Devices observe electrostatic discharge precautions.

This requires proper grounding; i.e., wear a wrist strap. Failure to observe this

caution could result in damage to the chassis Device.

These are the topics:

Topic See Page

Installing CFBRM/CBFFG Devices into a point system chassis 18

Installing SFBRM/SBFFG standalone models 19

Installing copper and fiber cables 20

Connecting power (standalone models) 22

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 17

Page 26

Section ll: FBRM/BFFG Hardware Installation Transition Networks

Installing CFBRM/CBFFG Devices into point system chassis

IMPORTANT

Caution

The CFBRM/CBFFG Device product family IS NOT compatible with the CPSMM200 and CPSMM-210 MGMT modules when used in a cascaded application. The

CFBRM/CBFFG can be installed in the “master” chassis with the CPSMM-200

MGMT module, but they can not be installed in a cascaded chassis using the

CPSMM-210 MGMT module.

Alternatively, the CFBRM/CBFFG can be used with the CPSMM120 MGMT

module, which does not support chassis cascading.

Wear a grounding strap and observe electrostatic discharge precautions when

installing the CFBRM/CBFFG Device into the Point System chassis. Failure

to observe this caution could result in damage to the Device.

Chassis Device installation

To install the chassis Device into the Point System chassis, do the following:

Step Action

1. Locate an empty slot in the Point System chassis.

2. Grasp the edges of the Device by its front panel.

3. Align the Device with the slot guides and carefully insert the Device into

the installation slot.

4. Firmly seat the Device against the chassis back panel.

5. Push IN and ROTATE clockwise the panel-fastener screw to secure the

Device to the chassis. See Figure 12.

18

Figure 12: CFBRM/CBFFG Device Chassis Installation

Page 27

Transition Networks Section ll: FBRM/BFFG Hardware Installation

Installing SFBRM/SBFFG standalone models

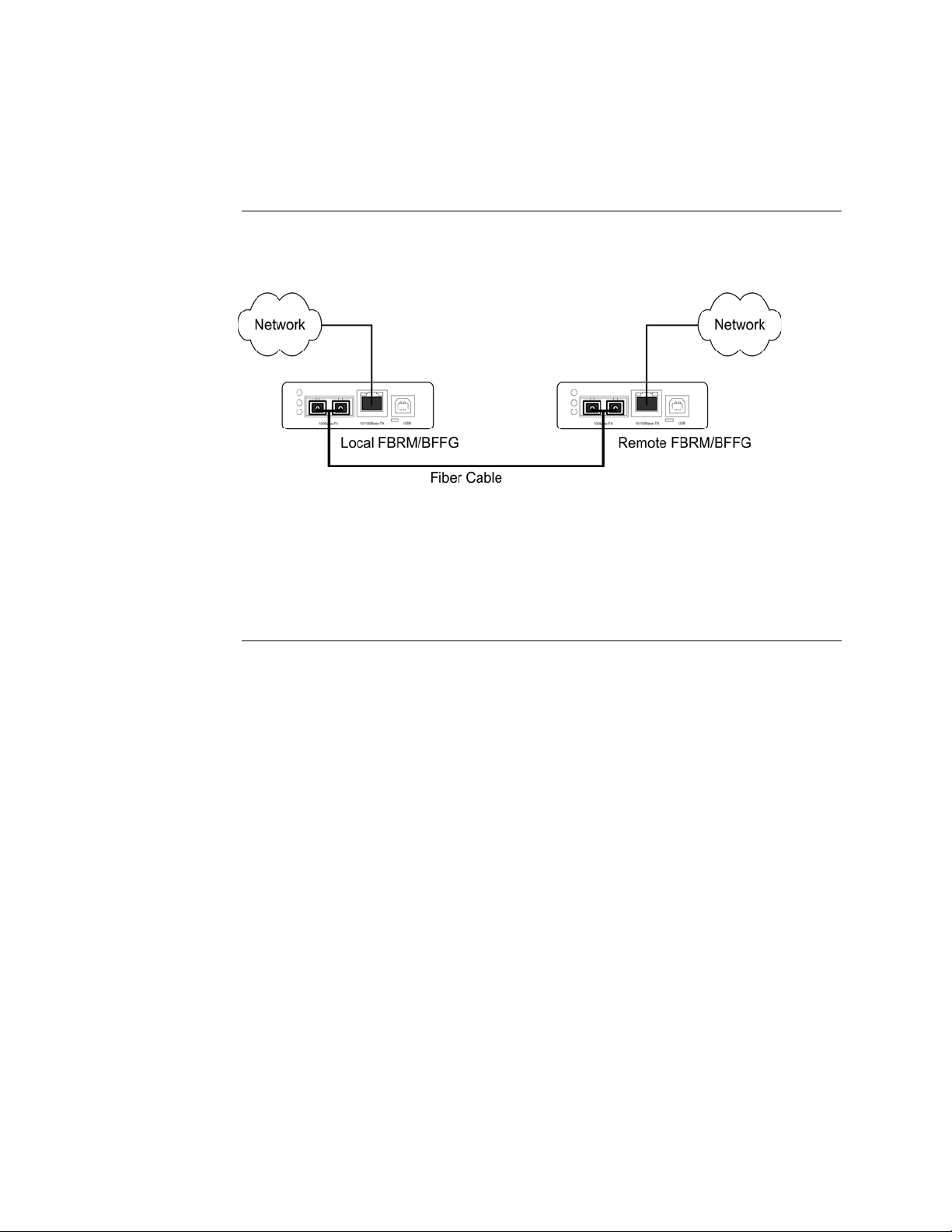

Standalone installation

Figure 13 shows a typical installation involving two (2) SFBRM/SBFFG standalone

Devices on a network.

Figure 13: Installation with Two SFBRM/SBFFG Standalone Devices

Note: With the local active standalone Device connected to a remote standalone

passive Device and with “Mode Control” set to “Auto,” the local (active)

Device will manage the remote (passive) Device. This relationship is

established automatically.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 19

Page 28

Section ll: FBRM/BFFG Hardware Installation Transition Networks

Installing fiber and copper cables

Warning

Fiber cable

Use of controls, any adjustments, or the performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Visible and invisible laser radiation when open: DO NOT stare into the laser-

light beam or view the beam directly with optical instruments. Failure to

observe this warning could result in an eye injury or blindness.

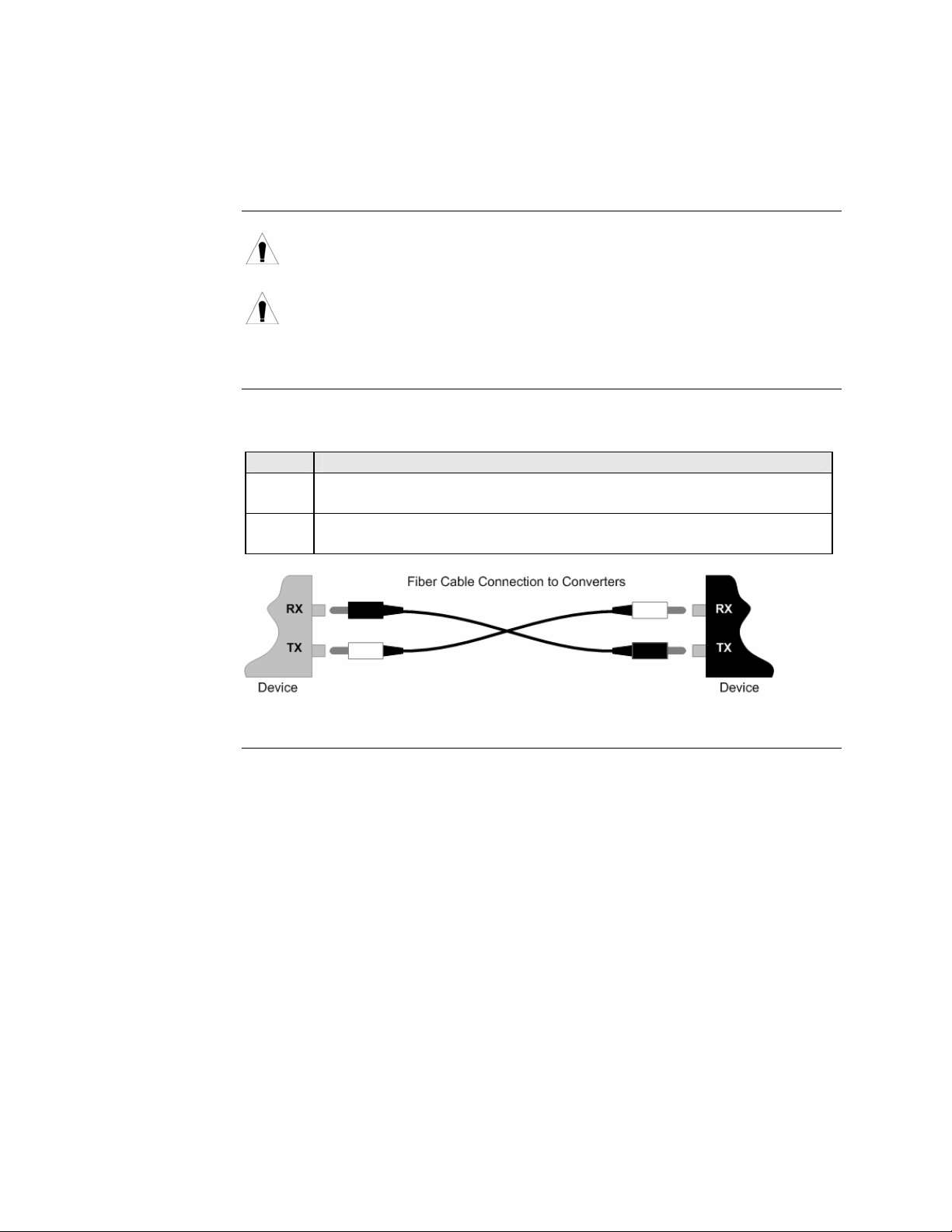

To install the fiber cable, do the following:

Step Action

1. Locate a 100/1000Base-FX/SX/LX compliant fiber cable with male,

two-stranded connectors installed at both ends. See Figure 14.

2. Connect the fiber cables to the FBRM or BFFG Devices as shown in

Figure 14.

Figure 14: Fiber Cable Installation

Continued on next page

20

Page 29

Transition Networks Section ll: FBRM/BFFG Hardware Installation

Installing fiber and copper cables, continued

Caution

Copper cable

Copper based media ports, e.g., Twisted Pair (TP) Ethernet, USB, RS232,

RS422, RS485, DS1, DS3, Video Coax, etc. are intended to be connected to

intra-building (inside building) link segments that are not subject to lightening

transients or power faults. Failure to observe this caution could result in

damage to equipment.

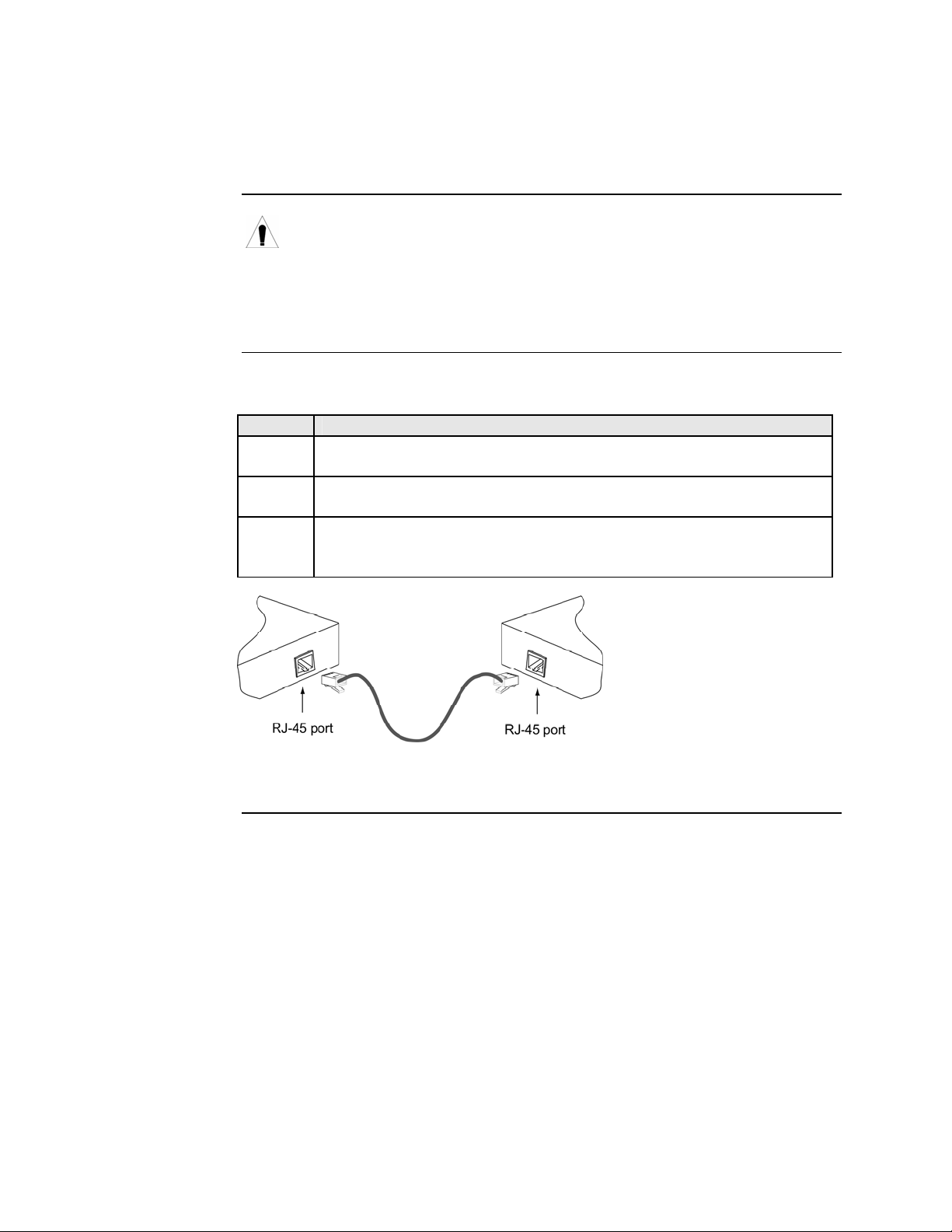

To install the copper cable, do the following:

Step Action

1. Locate a 10/100 or 10/100/1000Base-T compliant copper cable with

male, RJ-45 connectors installed at both ends.

2. Connect the RJ-45 connector at one end of the cable to the Device’s RJ-

45 ports.

3. Connect the RJ-45 connector at the other end of the cable to the 10/100

or 10/100/1000Base-T RJ-45 port on the other Device (switch,

workstation, etc.). See Figure 15.

Figure 15: Copper Cable Installation

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 21

Page 30

Section ll: FBRM/BFFG Hardware Installation Transition Networks

Connecting power (standalone models)

Chassis powers slide-in Device

Adapter powers standalone

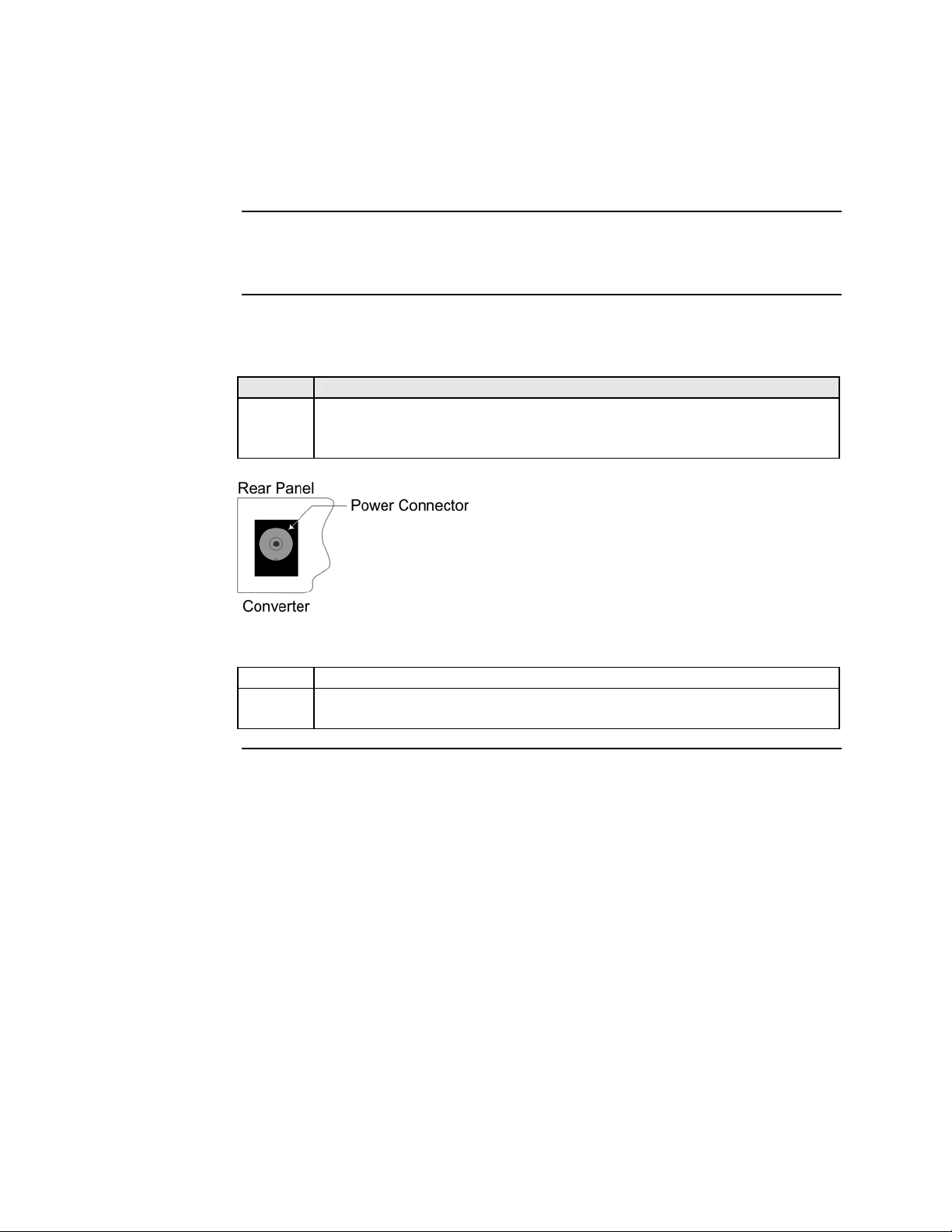

Transition Networks’ Point System chassis powers the CFBRM/CBFFG chassis

Devices.

Use an AC power adaptor to power the SFBRM/SBFFG standalone Device. To

connect power to the Device, do the following:

Step Action

1. Connect the barrel connector on the power adapter cord to the power

connector on the Device (located on the rear of the Device).

See Figure 16.

Figure 16: Standalone Device Power Connector

2. Connect the power adapter plug into AC power.

3. Verify that the Device has powered UP—the power indicator LED will be

lit.

22

Page 31

Transition Networks Section ll: FBRM/BFFG Hardware Installation

Intentionally Blank

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 23

Page 32

Transition Networks

Section III:

USB Driver Installation & COM Port Setup

Introduction

In this section

This section shows how to install the USB driver and configure COM ports.

These are the topics:

Topic See Page

Installing USB driver 25

Configuring COM ports 29

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 24

Page 33

Transition Networks Section lll: FBRM/BFFG1 Driver Installation & COM Port Setup

Installing USB driver

USB driver

Installing USB driver

The driver installation instructions are for Windows XP only. Installing the USB

driver using Windows 2000 is similar, but not necessarily identical to the following

Windows XP driver-installation procedure.

Note: The following USB drivers are provided with the product on a CD, also

available at

www.ftdichip.com (click on drivers): WinXP64, Win Server

2003, Win 2002, Win ME/98, Mac OS X, 9, 8, and Linux.

To install the USB driver on a computer with a Windows XP OS, do the following:

Step Action

1. Extract the driver (provided CD or from website) and place it in an

accessible folder on the local drive.

2. Plug the Device into the USB port on the PC to bring up the “found new

hardware” wizard dialog box, shown in Figure 17.

3. Select RADIO button, “No, not this time” as shown in Figure 17.

Figure 17: Found New Hardware Wizard Dialog Box

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 25

Page 34

Section lll: FBRM/BFFG USB Driver Installation & COM Port Setup Transition Networks

Installing USB driver, continued

Installing USB driver (continued)

Step Action

4. Click the NEXT button to launch the “installation options” dialog box.

5. Select RADIO button “Install from a list or specific location

(Advanced)” as shown in Figure 18.

Figure 18: Installation Options Dialog Box

6. Click the NEXT button to bring up the “driver search installation

options” dialog boxes shown in Figure 19.

Figure 19: Driver Search Installation Options Dialog Box

Continued on next page

26

Page 35

Transition Networks Section lll: FBRM/BFFG1 Driver Installation & COM Port Setup

Installing USB driver, continued

Step Action

7. Use the BROWSE button to locate the USB driver, as shown in

Figure 20.

C:\FBRM/BFFG1xx

Figure 20: Driver Location

8. Click the NEXT button to start installing the driver and the driver-install

screen will appear as XP copies the Device driver. See Figure 21.

FBRM/BFFG1xx Driver

Figure 21: Windows XP Installing Driver Box

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 27

Page 36

Section lll: FBRM/BFFG USB Driver Installation & COM Port Setup Transition Networks

Installing USB driver, continued

Step Action

9. After the driver installation is successful, the “finished installing” dialog

box will appear, as shown in Figure 22.

Figure 22: Finish Installing Driver Dialog Box

10. Click the FINISH button and a “found new hardware” message will

appear on the lower right side of the screen, as shown in Figure 23.

Figure 23: New Hardware Installed and Ready to Use

28

Page 37

Transition Networks Section lll: FBRM/BFFG1 Driver Installation & COM Port Setup

Configuring COM port

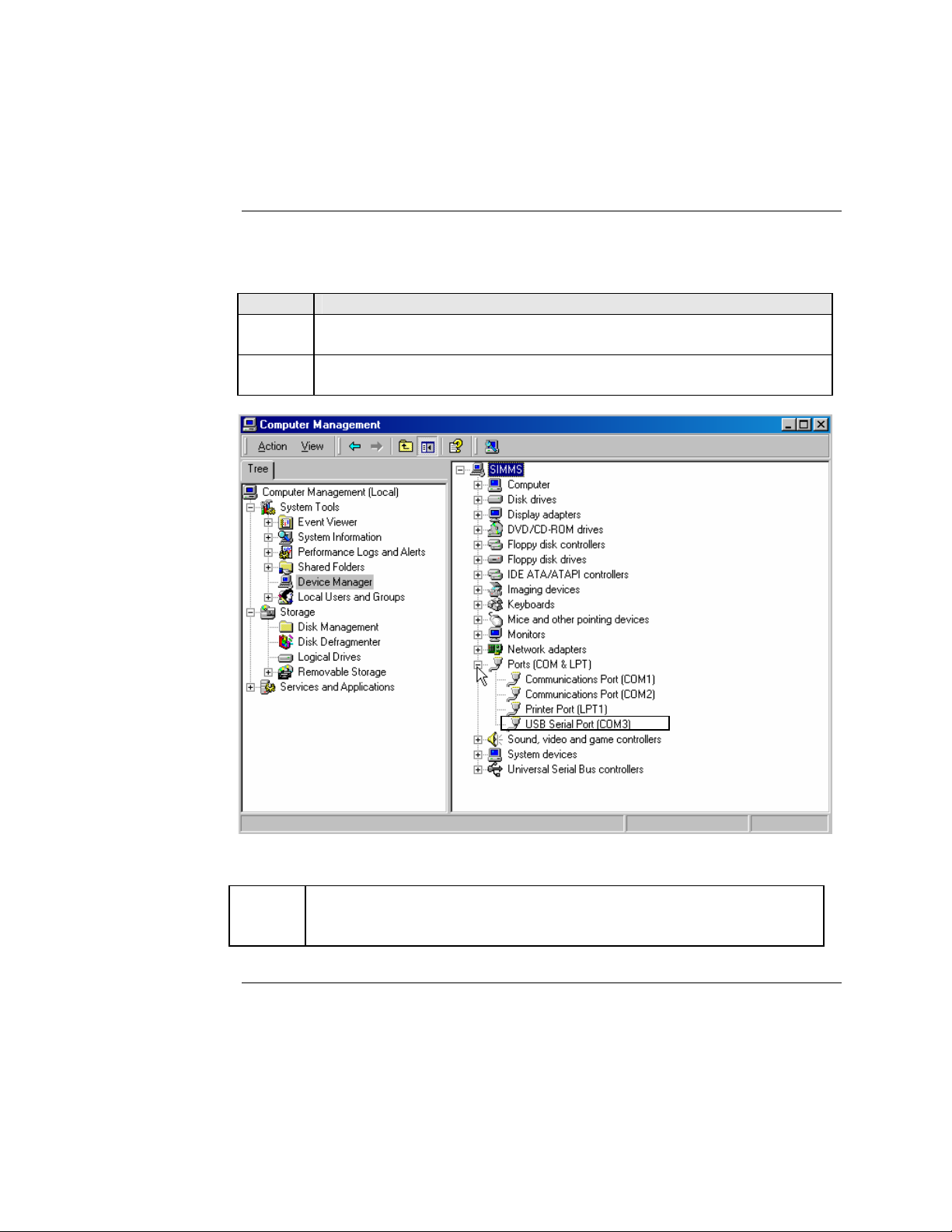

Getting COM port number

You need the COM port number to configure the terminal emulator. To get the COM

port number, do the following:

Step Action

1. On the desktop, right click on the “my computer” icon and select

“Device manager” to open the “computer management” window.

2. Click on “Device manager” to open the Device manager’s panel (screen

right panel) shown in Figure 24.

Figure 24: Computer Management Window

3.

Expand the Ports (COM & LPT) in the right column and write down the

USB COM port number for configuring the terminal emulator software

used for the USB Device.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 29

Page 38

Section lll: FBRM/BFFG USB Driver Installation & COM Port Setup Transition Networks

Configuring COM port, continued

Terminal emulator setup

To set up the terminal emulator software, e.g., HyperTerminal to use the USB COM

port, do the following:

Step Action

1. Activate the “HyperTerminal” software to bring up the “connection

description” dialog box, shown in Figure 25.

Figure 25: Connexion Description Diallo Box

2. Type in a name and select an icon.

3. Click the OK button to launch the “connect to” dialog box, shown in

Figure 26.

Figure 26: Connect To Dialog Box

Continued on next page

30

Page 39

Transition Networks Section lll: FBRM/BFFG1 Driver Installation & COM Port Setup

Configuring COM port, continued

Terminal emulator setup (continued)

Step Action

4. Select the COM port identified for the USB Device shown in the Device

manager.

5. Click the OK button to bring up the “port settings” dialog box, shown in

Figure 27.

Figure 27: COM Port Settings Dialog Box

6. Set the COM port properties as follows:

• Baud: 57600

• Data length: 8

• Parity: None

• Stop bit: 1

• Flow Control: None

7. Click the OK button and the Device login prompt will appear.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 31

Page 40

Introduction

Transition Networks

Section live:

Initial Device Setup

There are four ways to set up the FBRM/BFFG 1xxx-1xx Devices before the Device

can be operated and managed:

• USB CLI

• Telnet

• Chassis MMU (chassis model)

• IP-based (directly to FBRM/BFFG)

The factory default IP configuration is the following:

• IP address: 192.168.1.1

• Subnet Mask: 255.255.255.0

• Gateway: 192.168.1.2

In this section

These are the topics:

Topic See Page

USB CLI access 33

Initial Device setup via USB CLI 35

Initial Device setup via Telnet (directly to Device) 38

Initial Device setup via chassis agent (MMU) web-based 41

Initial Device setup via IP web-based (directly to Device) 44

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 32

Page 41

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

USB CLI access

Accessing the USB CLI

To access the USB CLI, do the following:

Step Action

1. Connect the Device to a computer via the USB port.

2. Activate the terminal emulator software to launch the emulator screen.

3. Press the ENTER key to bring up the “password” prompt.

4. Enter the password and then the login (default is “root” in both cases) to

bring up the Device console> prompt, shown in Figure 28.

Password :

Login : root

Password :

Console:/>_

Figure 28: Device Console Prompt

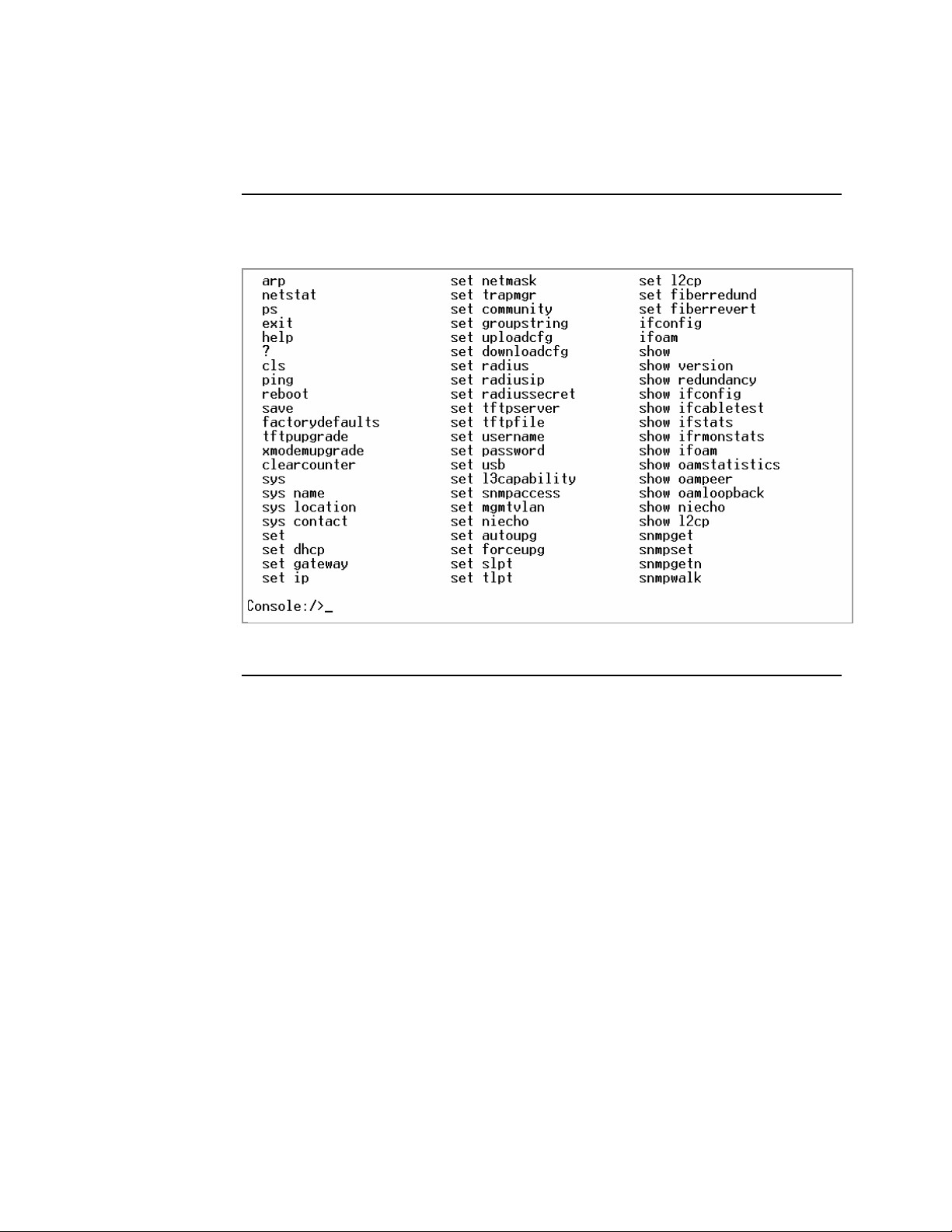

5.

To access the commands list, at the console> prompt type help or “?”

6. Press the ENTER key to launch the “commands” screen, shown in

Figure 29.

Figure 29: Commands for FBRM/BFFGs Models

Note: See Appendix C for a complete list of the configuration commands and

definitions. All CLI commands are case sensitive.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 33

Page 42

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

USB CLI access, continued

Redundant

The following is the screen of commands for the redundant SFP Devices.

Figure 30: Commands for Redundant SFP Models

34

Page 43

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup via USB CLI

IP configuration

Factory default IP config

Use the ‘set’ commands to set the IP configuration through the USB port. Configure

the Device with a network IP address, subnet mask, and default gateway. Set the IP

address via USB CLI (Command Line Interface), or via DHCP (Dynamic Host

Configuration Protocol), which is disabled by default.

The factory default IP configuration shipped with the Device is as follows:

• IP address: 192.168.1.1

• Subnet Mask: 255.255.255.0

• Gateway: 192.168.1.2

Note: Type “help set <command>” to display the format used to set the commands.

Set IP config via USB CLI

To set the IP via the USB CLI, do the following:

Step Action

At the console> prompt type set ip=nnn.nnn.nnn.nnn

1.

2. Press the ENTER key to set the IP address.

At the console> prompt type set netmask=nnn.nnn.nnn.nnn

3.

4. Press the ENTER key to set the netmask.

At the console> prompt type set gateway=nnn.nnn.nnn.nnn

5.

At the console> prompt type save

6.

7. Press the ENTER key to save the new IP configuration.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 35

Page 44

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup via USB CLI, continued

DHCP method

To set the IP configuration via the DHCP in console mode, do the following:

Note: A DHCP server must be on the network and accessible before using this

method.

Step Action

At the console> prompt type set dhcp=enable

1.

2. Press the ENTER key and the screen will appear as shown in Figure 31.

Figure 31: Enable DHCP

Type reboot

3.

4. Press the ENTER key to reboot the Device and start the DHCP process.

Note: DHCP “successful” will appear on the screen when completed, or “failed” if

not successful.

Continued on next page

36

Page 45

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup via USB CLI, continued

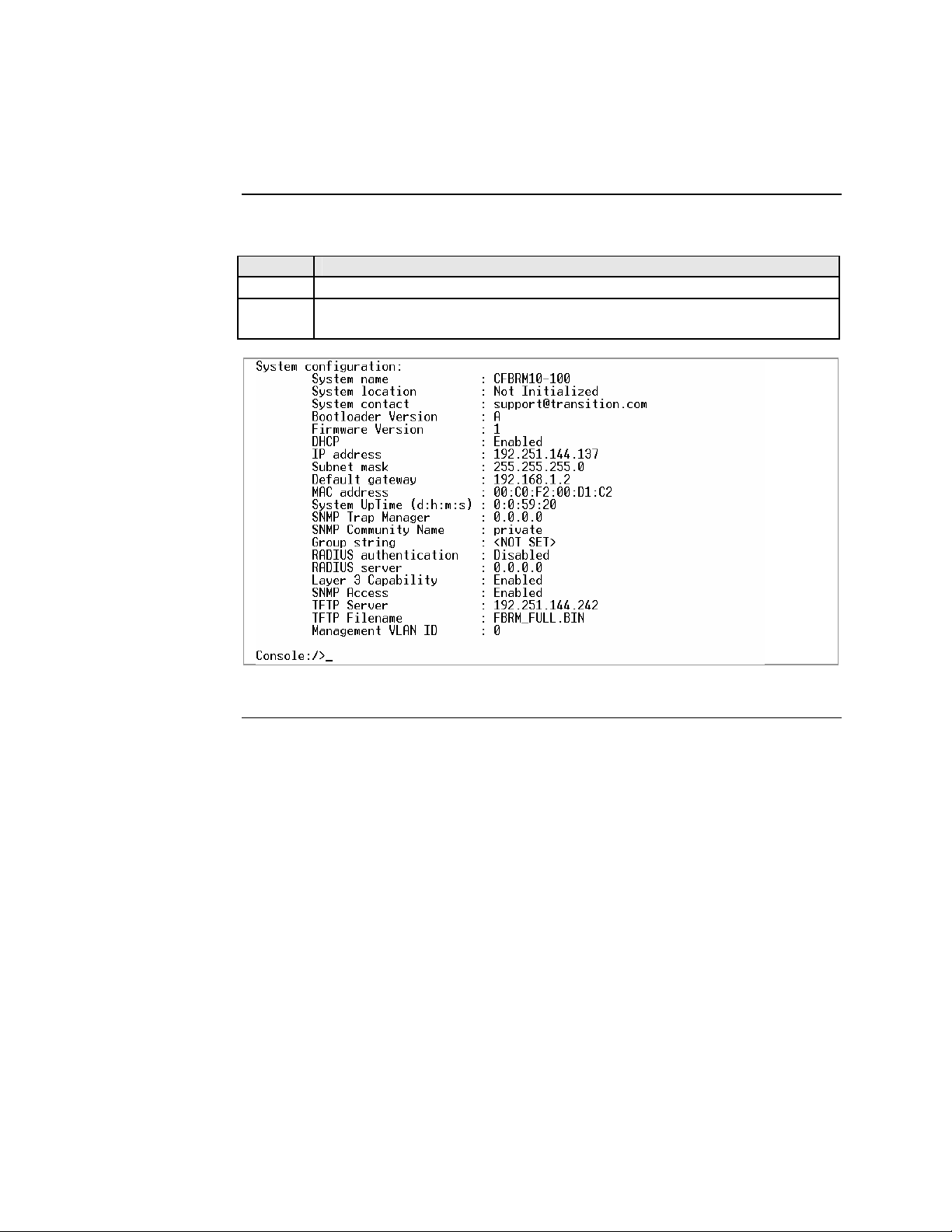

Show system configuration

To show the Device system configuration, do the following:

Step Action

1.

At the console> prompt type show

2. Press the ENTER key to bring up the Device system configuration screen,

shown in Figure 32.

Figure 32: Example System Configuration Screen

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 37

Page 46

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

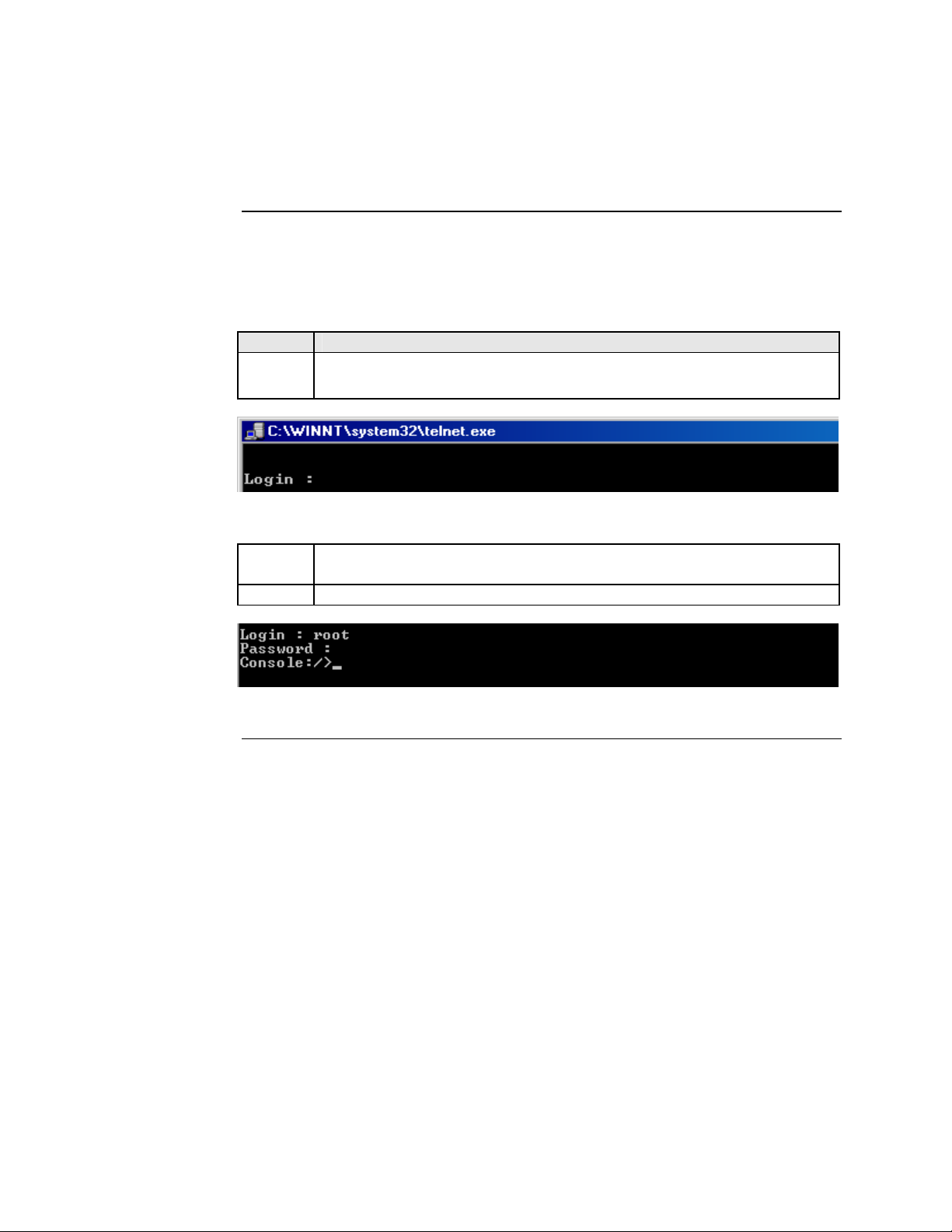

Initial Device setup via telnet (directly to Device)

To set up the Device initially via telnet directly to the Device, do the following:

Initial setup via Telnet to Device

Step Action

1.

At the command line type: Telnet nnn.nnn.nnn.nnn (IP address of the Device) to

bring up the password prompt, shown in Figure 33.

Figure 33: Password Prompt

Type the case-sensitive username and password (default is ‘root’ for

2.

both).

3. Press the ENTER key to launch the console prompt, shown in Figure 34.

Figure 34: Console Prompt

Continued on next page

38

Page 47

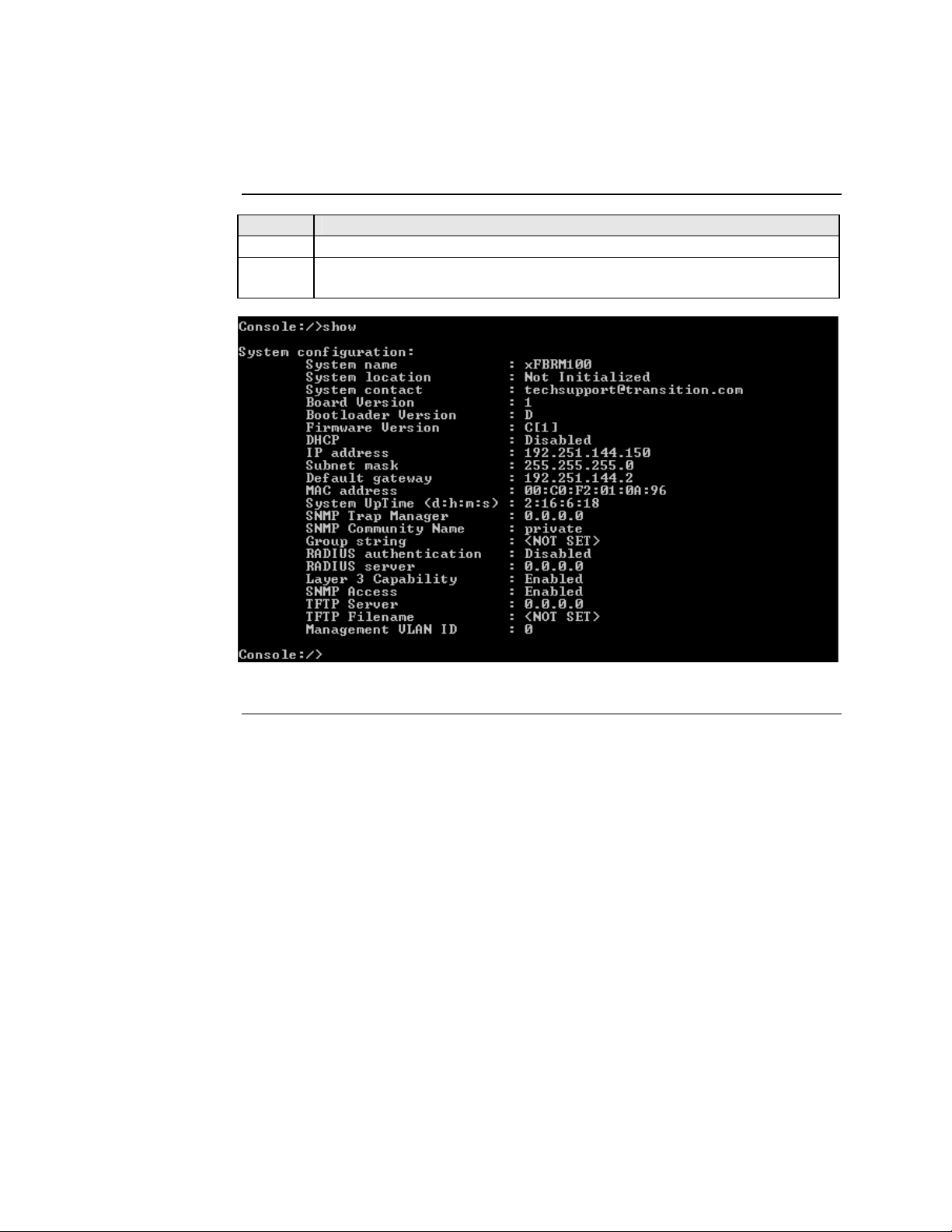

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup via telnet (directly to Device), continued

Step Action

At the console:/> prompt type show

4.

5. Press the ENTER key to display the system configuration, as shown in

Figure 35.

Figure 35: System Configuration Screen

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 39

Page 48

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup via telnet (directly to Device), continued

Step Action

6.

At the console prompt type: help

7.

Press the ENTER key to show the commands, shown in Figure 36.

Terminating

telnet

Figure 36: Device Command Screen

Note: The CLI and Telnet interface commands are structured in the same manner.

To disconnect the Telnet client from the management module server, press the

CTRL-D keys, or at the console prompt type: exit or logoff

40

Page 49

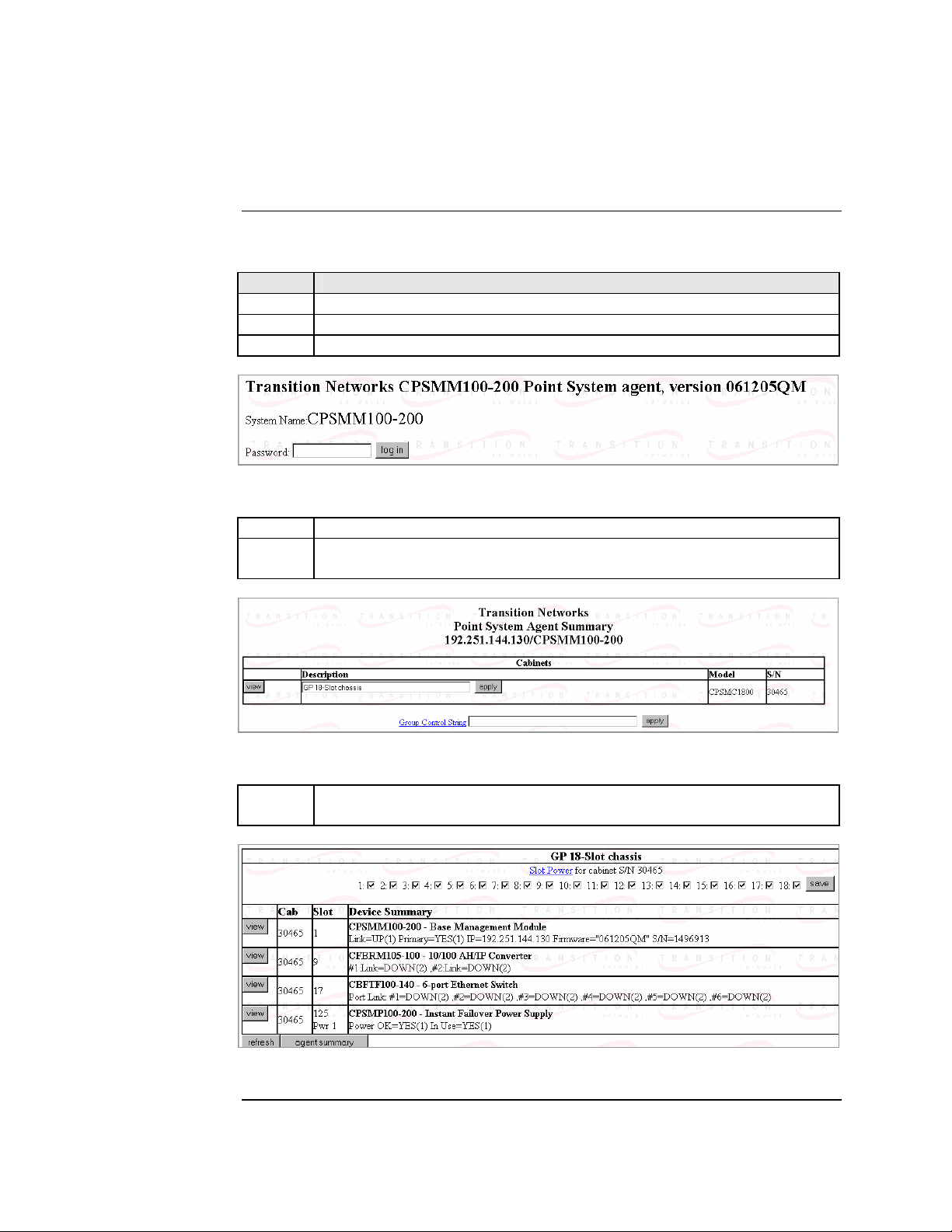

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

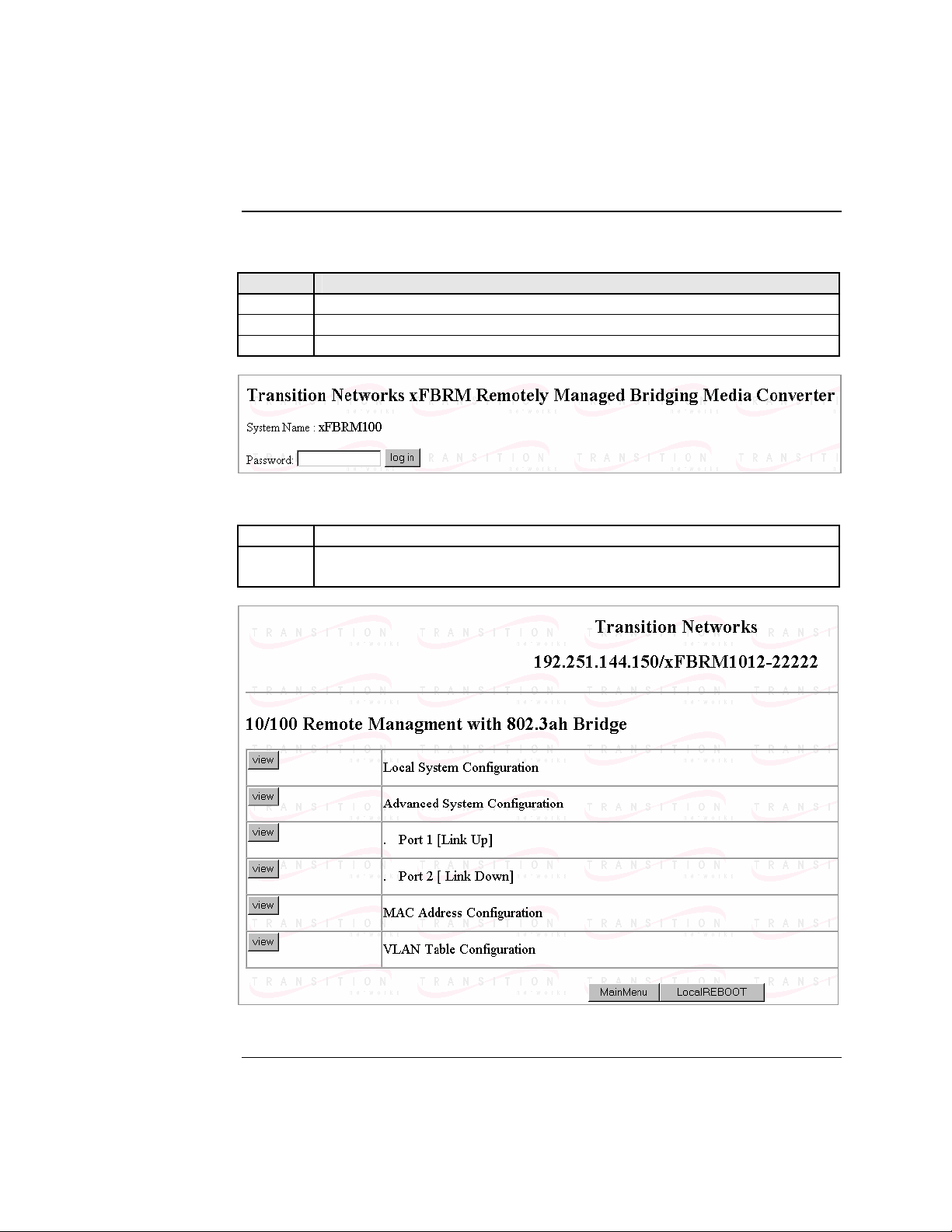

Initial Device setup via chassis agent MMU, web-based

Setup via Web to MMU

To set up the Device initially via the MMU web-based, do the following:

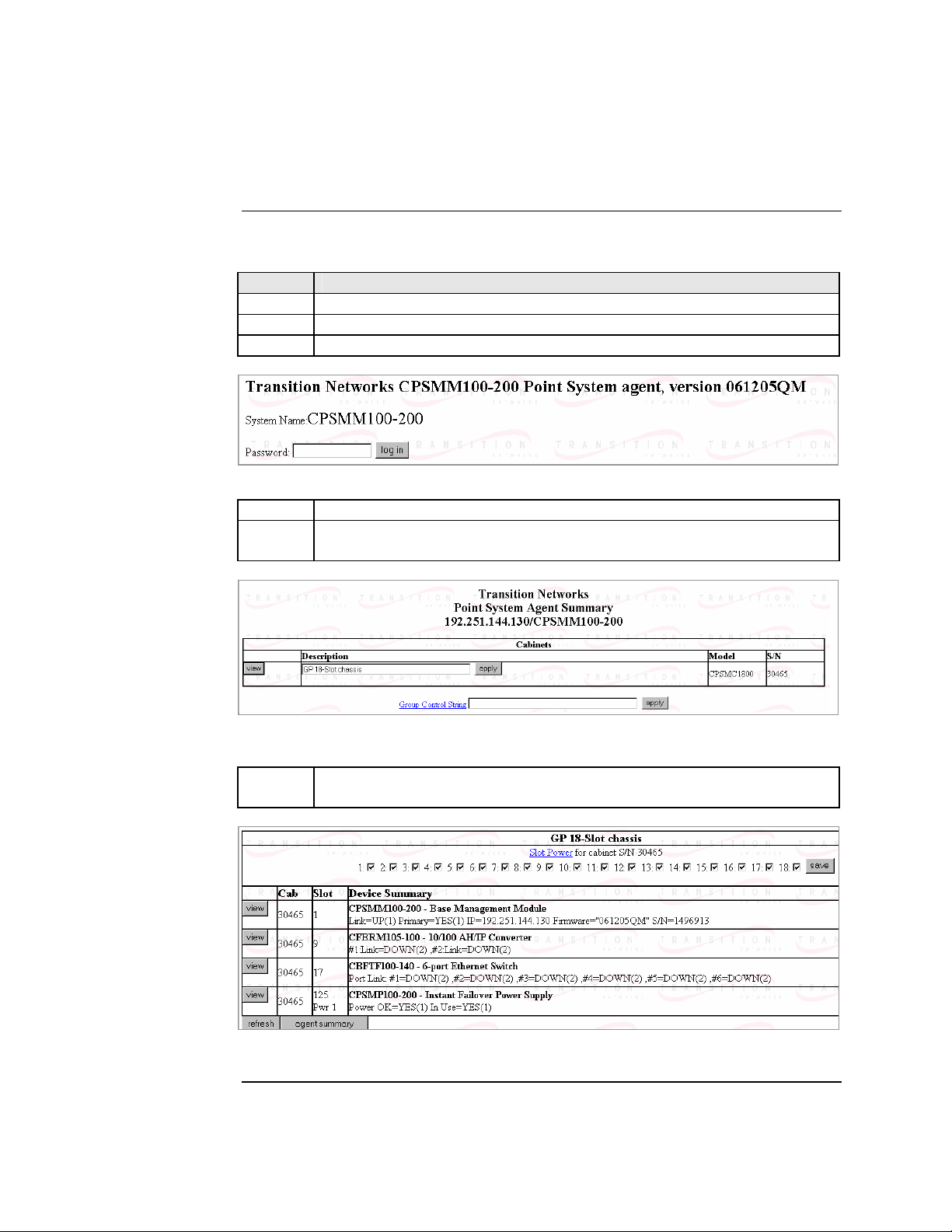

Step Action

1. Open a web browser.

2. At the URL type the IP address of the chassis (MMU).

3. Click the GO button to bring up the password screen, shown in Figure 37.

Figure 37: Chassis Agent (MMU) Log In Screen

Type the password (default is private). 4.

5. Press the ENTER key to launch the chassis agent’s main menu, shown in

Figure 38.

Figure 38: Chassis Agent (MMU) Main Menu

6. Click the VIEW button to show the Devices in the chassis and the screen

will appear, as shown in Figure 39.

Figure 39: Point System Chassis Main Menu

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 41

Page 50

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup via chassis agent MMU, web-based, continued

Step Action

7. Click the VIEW button of the CFBRM/CBFFG Device in slot 9 to show

the local configuration screen for the Device. See Figure 40.

Note: You can configure the IP along with other Device parameters on this screen.

42

Figure 40: Local Switch FBRM/BFFG Configuration Screen

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

Continued on next page

Page 51

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup via chassis agent MMU, web-based, continued

IP config via DHCP

To configure the IP via DHCP, do the following:

Step Action

1. A DHCP server must be on the network and accessible.

2. On the local switch configuration screen, enable DHCP.

3. On the local switch configuration screen set item Reset Switch to “Yes.”

4. Click the SAVE/EXECUTE button to start the DHCP process.

Note: To verify that the DHCP IP configuration was successful, check the IP

configuration for the Device on the local switch screen and note the changes

to the IP configuration.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 43

Page 52

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup IP web-based (directly to Device)

Initial setup via IP to Device

To set up the Device initially via a IP web-based, do the following:

Step Action

1. Open a web browser.

2. At the URL type in the FBRM/BFFG default IP address.

3. Click the GO button to launch the password screen shown in Figure 41.

Figure 41: Login Screen

Type the password (default is private). 4.

5. Press the ENTER key to launch the FBRM/BFFG main menu, as shown

in Figure 42.

44

Figure 42: FBRM/BFFG Main Menu

Continued on next page

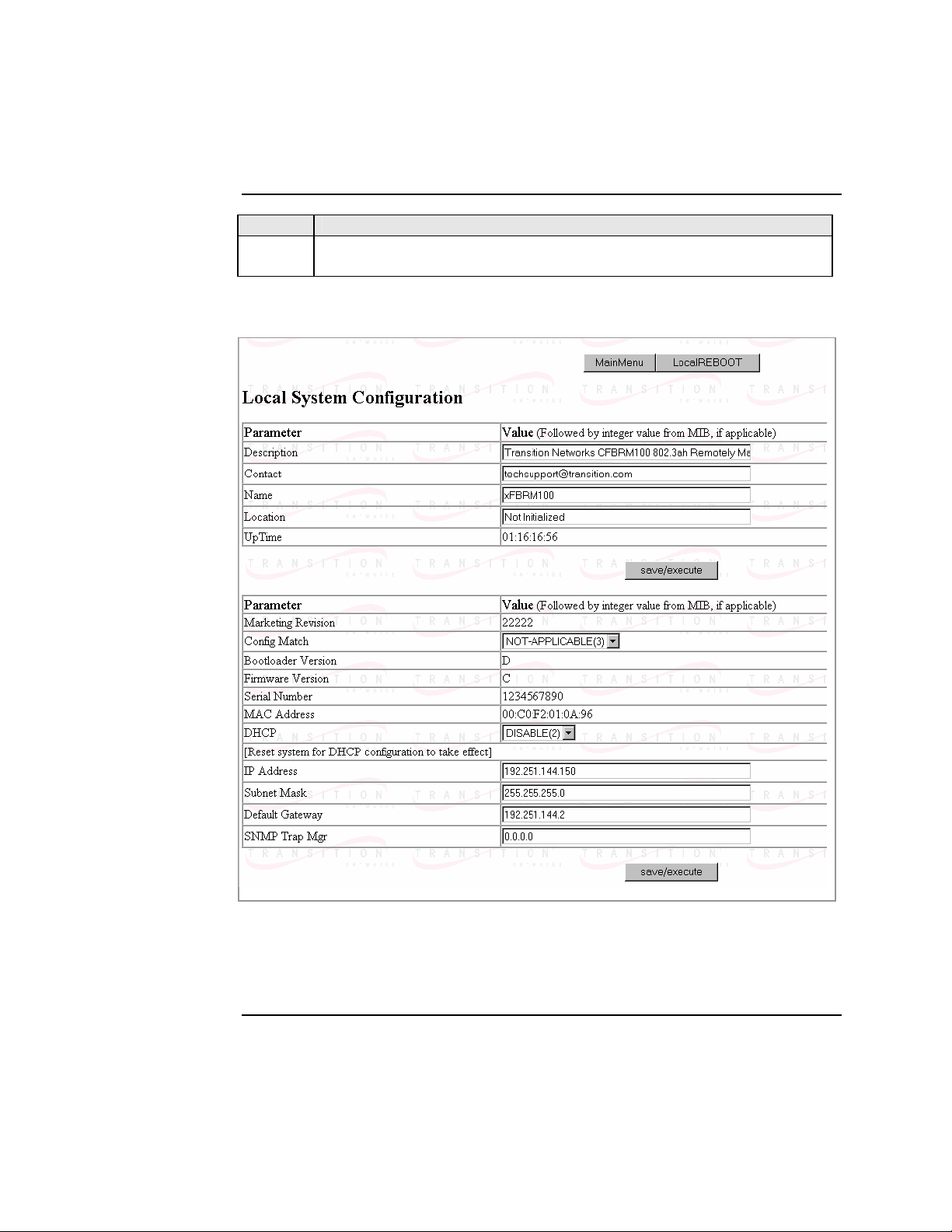

Page 53

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup IP web-based (directly to Device), continued

Step Action

6. Click the local system configuration VIEW button to show the local

system configuration menu, shown in Figure 43.

Note: You can configure the IP along with other Device parameters on this screen.

Figure 43: FBRM/BFFG Local System Configuration Screen

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 45

Page 54

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup IP web-based (directly to Device), continued

IP config via DHCP

To set up the IP configuration via DHCP, do the following:

Step Action

1. A DHCP server must be on the network and accessible.

2. On the local switch configuration screen, enable DHCP as shown in Figure

44.

46

Figure 44: IP-based Local System Configuration Screen

3. Click the Local REBOOT button at the top of the screen to start the DHCP

process.

Note: To verify that the DHCP IP configuration was successful, check the IP

configuration for the Device on the local system configuration screen and

note the changes to the IP configuration.

Continued on next page

Page 55

Transition Networks Section lV: FBRM/BFFG Initial Device Setup

Initial Device setup IP web-based (directly to Device), continued

Redundant Devices

To set up the redundant feature for the stand-alone 3-port FBRM SFP Device via IP

web-based, do the following:

Step Action

1. Open a web browser.

2. At the URL type in the SFBRM default IP address.

3. Click the GO button to launch the password screen shown in Figure 45.

Figure 45: Login Screen

Type the password (default is private). 4.

5. Press the ENTER key to launch the SFBRM main menu, as shown in

Figure 46.

Figure 46: Redundant Device Main Menu

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 47

Page 56

Section IV: FBRM/BFFG Initial Device Setup Transition Networks

Initial Device setup IP web-based (directly to Device), continued

Step Action

6. Click the advance system configuration VIEW button to show the

redundancy configuration parameters, shown in Figure 47.

48

Figure 47: Redundancy Configuration Screen

Note: The redundancy features are specific to the 3-port SFBRM SFP Device

only.

Page 57

In this section

Transition Networks

Sections V:

Device Management

These are the topics:

Topic See Page

SNMP IP-based management 50

Device management via chassis MMU web-based 53

Device management via IP (directly to Device) 56

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 49

Page 58

Section V: FBRM/BFFG Device Management Transition Networks

SNMP IP-based management

SNMP

The FBRM/BFFG Device provides complete management through the SNMP

interface. It supports the following standard MIBs for management, using SNMPv1:

• RFC 1213 (MIB- II)

• RFC 2819 (RMON – statistics group)

• RFC 2863 (IF MIB counters)

• RFC 3635 (Ether-like MIB counters)

• RFC 1493 (Bridge MIB objects counters)

• RFC 2674 (Bridge extension counters)

I-D: draft-ietf-hubmib-efm-mib (EFM OAM mib – the EFM hub mib is added to the

TN private tree since it has not been added to the ISO tree.) Use the provide version

shipped on the CD with your Device.

See Figure 48.

EFM-Hub MIBs

Figure 48: EFM Hub MIBs Added to Private Tree

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

50

Page 59

Transition Networks Section V: FBRM/BFFG Device Management

SNMP IP-based management, continued

TN private MIBs

The TN private MIBs for SNMP IP-based management feature extensive

management options. Some of the features are the following:

• Copper and fiber link status

• Copper and fiber port duplex

• Administratively enable/disable port

• Copper port speed

• Enable/disable Auto-Negotiation (copper)

• Enable/disable Pause

• Enable/disable capability advertisement for speed and duplex

• RMON statistics

• AutoCross on copper port

• Remote fault detect

• Enable/disable far-end fault on fiber

• Transparent link-pass through

• 802.3ah OAM enable/disable on all ports

• OAM channel statistics

• OAM remote loopback

• Rate limiting/band width allocation using fixed rate sets

• IP traffic class priority

• 802.1q VLAN support

• Virtual cable test

The remote Device can be managed completely through OAM. Figure 49 shows an

example of a private MIB objects tree.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 51

Page 60

Section V: FBRM/BFFG Device Management Transition Networks

SNMP IP-based management, continued

MIB objects

Figure 49 shows the placement of the MIB objects on the private tree.

Private MIB Objects

Figure 49: Private MIB Objects

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

52

Page 61

Transition Networks Section V: FBRM/BFFG Device Management

Device management via chassis agent (MMU) web-based

Management via MMU

To set up the FBRM/BFFG initially via the MMU, do the following:

Step Action

1. Open a web browser.

2. At the URL type the IP address of the chassis (MMU).

3. Click the GO button to launch the password screen. See Figure 50.

Figure 50: Chassis Agent (MMU) Login Screen

Type the password (default is private). 4.

5. Press the ENTER key to launch the chassis agent’s main menu, as shown

in Figure 51.

Figure 51: Chassis Agent (MMU) Main Menu

6. Click the VIEW button to show the Devices in the cabinet slots, as shown

in Figure 52.

Figure 52: Devices in Chassis Slots

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 53

Page 62

Section V: FBRM/BFFG Device Management Transition Networks

Device management via chassis agent (MMU) web-based, continued

Step Action

7. Click the VIEW button of the CFBRM/CBFFG Device to bring up the

local switch management screen. See Figure 53.

Figure 53: Local Switch Configuration Screen

8. Scroll down to the LOCAL PORT buttons, shown in Figure 54.

Figure 54: Local System Configuration Local Port Buttons

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

54

Page 63

Transition Networks Section V: FBRM/BFFG Device Management

Device management via chassis agent (MMU) web-based, continued

Step Action

9. Click a PORT BUTTON to bring up the local port switch configuration

screen, shown in Figure 55.

10. Scroll down the screen to see the remaining parameters.

Note: You can set OAM and other parameters on this screen.

Figure 55: Port 1 Local Switch

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 55

Page 64

Section V: FBRM/BFFG Device Management Transition Networks

Device management via IP web-base (directly to Device)

Introduction

IP web-based management

The FBRM/BFFG Device supports complete Web-based management for viewing

statistics and configuring the Device. See the help file on Transition Networks

website for more details about different configuration variables.

To manage the Device via the IP web-based, do the following:

Step Action

1. Open a web browser.

2. At the URL type the IP address of the Device.

3. Click the GO button to bring up the password screen, shown in Figure 56.

Enter the password (default password is “private”). 4.

Figure 56: Device Password Screen

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

56

Page 65

Transition Networks Section V: FBRM/BFFG Device Management

Device management via IP web-base (directly to Device), continued

IP web-based management (continued)

Step Action

5. Click the LOG IN button to bring up the main menu of the Device. See

Figure 57.

Note: Any Transition Networks FBRM/BFFG remote peer can be completely

managed by an FBRM/BFFG local peer through OAM.

Figure 57: FBRM/BFFG Main Menu

Note: DO NOT use the browser BACK button to navigate the screens. This will

cause the connection to drop.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 57

Page 66

Section V: FBRM/BFFG Device Management Transition Networks

Device management via IP web-base (directly to Device), continued

OAM configuration

The OAM configuration screen allows enabling or disabling OAM by setting the

mode to “active” or “passive.” If the remote Device is a Transition Networks

FBRM/BFFG Device, the main menu (PORT button with the remote Device

connected) will show the options for managing the remote OAM peer.

The Devices are interoperable with other IEEE 802.3ah compliant Devices. Standard

OAM discovery, loopback, dying gasp, link and other critical events are supported.

The OAM configuration screen for that port will show the following:

• OAM state

• MAC address

• OUI (unique identifier)

Note: On the SFBRM1040-1xx redundant models, there can be only one (1) OAM

session at a time—the OAM enabled port is user selected. Port 2 fiber is the

default port.

OAM config screen

To view the OAM configuration screen for non-transition networks IEEE 802.3ah

compliant Devices, do the following:

Step Action

1. Click any port VIEW button on the CFBRM/CBFFG main menu to bring

up configure screen of that port.

2. Click the OAM Config button and the screen will appear, as shown in

Figure 58.

3. You can set up OAM parameters on this screen.

Figure 58: OAM Configuration and Status Screen (OAM Config Button)

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

58

Page 67

Introduction

In this section

Transition Networks

Section VI:

Software Features

This section explains the operational status LEDs and what they indicate, along with

product features, and the three (3) methods used to upgrade the software.

These are the topics:

Topic See Page

Software feature descriptions 60

Software security feature descriptions 69

24-Hour Technical Support: 1-800-260-1312 Intern ational: 00-1-952-941-7600 59

Page 68

Section Vl: FBRM/BFFG Software Features Transition Networks

Software feature descriptions

Note: The FBRM/BFFG Devices does not have configuration switches.

Firmware activated features

The FBRM/BFFG series Devices features can be configured via USB, MMU, or IP.

Table 3 explains the configurable parameters of the Devices.

Table 3: Device Software Configurable Features

Feature Description

AutoCross When the AutoCross feature is active, it allows the use

(10/100Base-T or

10/100/1000Base-T)

of a straight-through (MDI) or crossover (MDI-X)

copper cable when connecting to 10/100Base-T or

10/100/1000Base-T Devices. AutoCross determines the

characteristics of the connection and configures the

Devices to link up automatically. This occurs regardless

of the cable configuration: MDI or MDI-X. (Transition

networks recommends leaving AutoCross in default

mode, “enabled.”)

Automatic Firmware

Upgrades

The Device has an automatic firmware upgrade feature.

This feature applies to a communication link between a

local peer and its remote peer Devices connected via a

fiber optic cable. If the remote passive peer Device is not

in Active Mode and a local active peer Device detects a

different firmware revision on its remote passive peer

Device, the local active Device will force a bootload

condition and download its firmware revision to its

remote passive peer Device.

Note The local Device could have a different firmware

revision (newer or older) than its remote peer. In

either case, the firmware revision on the local

Device will replace that of its remote passive

peer.

Note: The firmware of the local active peer Device

should be upgraded before the remote passive

peer Device to ensure that the correct firmware

version is on both Devices.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

60

Page 69

Transition Networks Section Vl: FBRM/BFFG Software Features

Software feature descriptions, continued

Table 3: Device Software Configurable Features (continued)

Feature Description

Auto-Negotiation This feature allows the two Devices to configure

themselves to achieve the best possible mode of

operation over a link, automatically. The Device

broadcasts its speed and duplex (full or half) capabilities

to the other Device and negotiates the best mode of

operation. Auto-Negotiation allows quick connections

because the optimal link between the Devices is

established automatically.

In a scenario where the Device links to a nonnegotiating Device, disable Auto-Negotiations. In this

instance, the mode of operation will drop to the lowest

common denominator between the two Devices; e.g., 10

Mb/s at half-duplex.

Disabling this feature allows forcing the connection to

the desired speed and duplex mode of operation.

Backup Configuration The firmware uses TFTP to upload its present

configuration onto a TFTP server, and can also

download the configuration from the TFTP server and

update its settings. This is useful when you want to

program more than one unit to the same configuration.

One unit can be programmed and that configuration can

be used to populate the other units. Care should be taken

on some settings such as IP address and VLAN settings.

This feature can be used with ‘ingress/egress’ frames. Bandwidth Allocation by

priority (ingress/egress)

It allows setting the bandwidth in varied increments,

starting at 64kps to full bandwidth.

Rate Limiting based on frame priorities can also be

configured. Each higher priority frame can be

configured to get twice the bandwidth of lower priority

frames; e.g., priority “3” frame configurations can get

twice the bandwidth of priority “2” frames.

Egress bandwidth allocation

in 64Kbits/sec increments:

• Rate limit all frames

Ingress bandwidth allocation

in 64Kbits/sec increments

with four filter selections:

• Rate limit all frames

• Rate limit multicast, flooded unicast, and broadcast

• Rate limit multicast and broadcast

• Rate limit broadcast

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 61

Page 70

Section Vl: FBRM/BFFG Software Features Transition Networks

Software feature descriptions, continued

Table 3: Device Software Configurable Features (continued)

Feature Description

Congestion Reduction The FBRM and BFFG Devices do not forward collision

signals or error packets between collision domains,

which improves baseline network performance.

In addition, the Devices filter packets destined for local

Devices, which reduces network congestion.

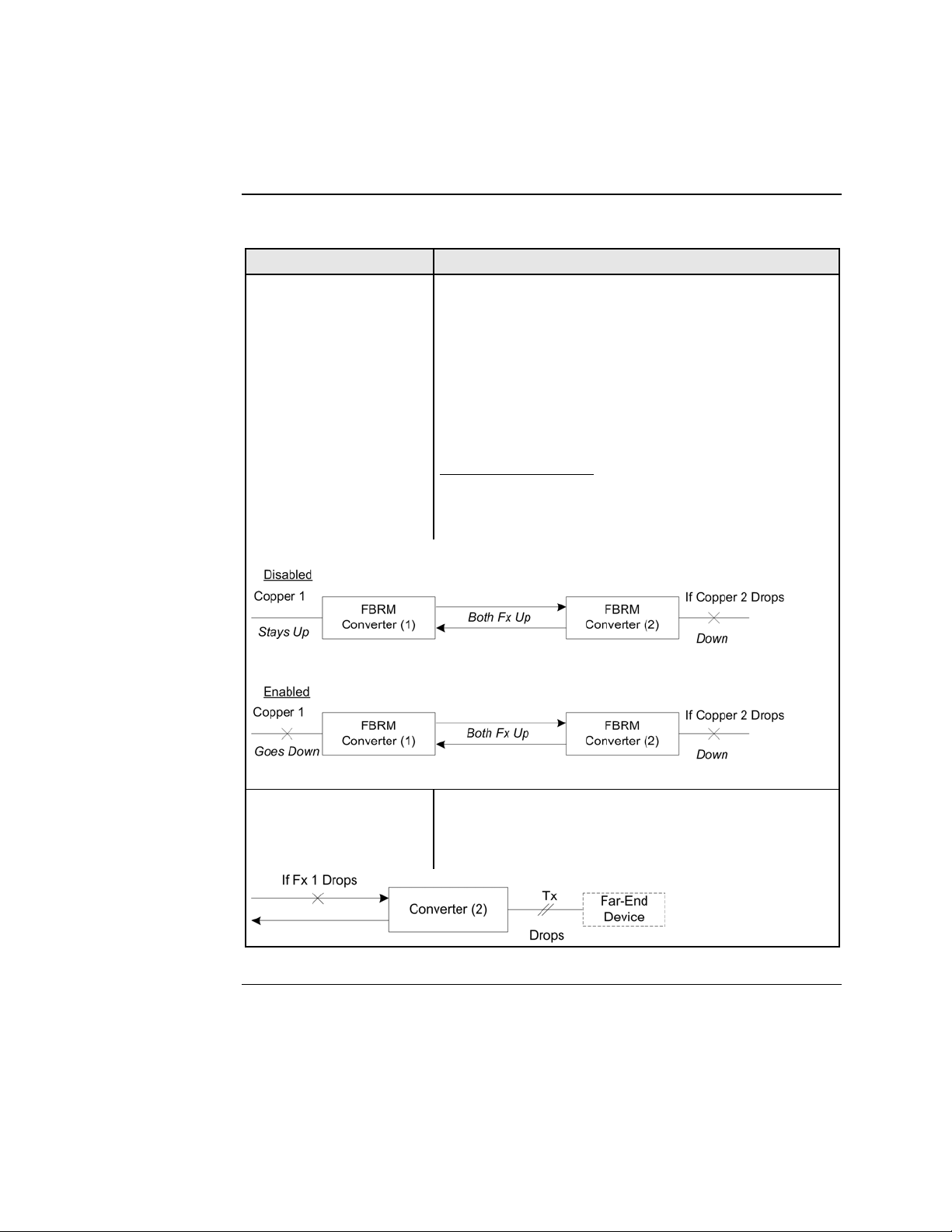

Far-End Fault (FEF)

FEF is a troubleshooting feature. With FEF enabled, if

the receiver on the fiber port goes “down” on one

Device, a FEF idle pattern is sent to the other Device to

terminate data transmission. Then an SNMP trap is sent

to the administrator, identifying the fiber link loss.

If FEF is disabled, a “down” Rx link on one Device

does not transmit to its peer, the down link notification

will not be passed on.

For FEF enabled and disabled scenarios, see illustration

below.

Far-End Fault Detection

(FEFD) Fiber Ports

If FEFD is enabled when the receiver on the fiber port

goes down on one Device, it sends a far-end-fault

pattern to the other side to bring down the fiber port on

both ends. An SNMP trap will be sent to the

administrator, indicating the fiber link loss.

If FEFD is disabled, a “down” Rx link on one Device is

not transmitted to the other Device; the link down signal

will not be passed over the link.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

62

Page 71

Transition Networks Section Vl: FBRM/BFFG Software Features

Software feature descriptions, continued

Table 3: Device Software Configurable Feature (continued)

Feature Description

Full Duplex In a full-duplex network, maximum cable lengths are

determined by the cable type. See the Cable

Specifications section for the different FBRM and BFFG

models.

The 512-Bit Rule does not apply in a full-duplex

network.

Firmware upgrades

(bootloader)

Half Duplex In a half-duplex network, the maximum cable lengths are

Auto firmware upgrade enable/disable:

In some cases, there may not be a requirement for

automatic firmware upgrades. For example, one might

connect a remote peer Device with the latest firmware

version before upgrading the local peer Device.

Typically, the local peer Device would detect a different

firmware version and will downgrade the firmware on

the remote peer Device. To prevent this, disable

automatic upgrade on the remote peer Device. The

remote peer Device will reject all upgrade requests from

the local peer Device—you can then upgrade the local

Device.

Force upgrade:

This is used to force a firmware upgrade on the remote

peer Device when the auto-upgrade feature is disabled on

the remote peer Device. This gives the local peer Device

authority to override the auto-upgrade feature of its

remote peer Device.

determined by the round trip delay limitations of each

Fast Ethernet collision domain. (A collision domain is

the longest path between any two terminal Devices, e.g.,

terminal, switch, or router.)

The 512-Bit Rule determines the maximum length of

cable permitted by calculating the round-trip delay in bit-

times (BT) of a particular collision domain. If the result

is less than or equal to 512 BT, the path is good.

For more information on the 512-Bit Rule, see the white

paper titled “Collision Domains” on Transition

Networks’ website at: www.transition.com

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 63

Page 72

Section Vl: FBRM/BFFG Software Features Transition Networks

Software feature descriptions, continued

Table 3: Device Software Configurable Features (continued)

Feature Description

Operation

Administration and

Maintenance (OAM,

IEEE 802.3ah-2004

standard)

Critical Event (OAM, When the link on the other port fails, the Device sends an

IEEE 802.3ah-2004

standard)

Discovery (OAM,

IEEE 802.3ah-2004

standard)

Event Notification with

Log In (OAM,

IEEE 802.3ah-2004

standard)

Note: On the SFBRM1040-1xx redundant models, there

can be only one (1) OAM session at a time—the

OAM enabled port is user selected. Port 2 fiber is

the default port.

The Device implements the IEEE OAM 802.3ah

standard for troubleshooting and remote management.

This product implements OAM on both the fiber and

twisted pair interfaces. It implements the following

OAM features:

• Discovery

• Remote Loop Back

• Exchange of configuration information and remote

firmware upgrades with organization specific PDUs

• Link status failure indication

The Device implements the draft-ietf-hubmib-efm-mib

(EFM OAM MIB). Use the version provided on the CD.

OAM critical event signal to its peer, indicating the fault

condition.

An active-state Device initiates OAM communications

by sending PDUs across the link connected to an OAM

enabled port. The Device at the other end (if OAM

capable) responds to the request from the active Device

by establishing an OAM communications channel.

An OAM link event notifies its OAM peer of any symbol

or frame errors that occurred on its link. The window

used for error monitoring, along with the threshold value

are configurable. At the end of the window, if the errors

are greater than or equal to the threshold value, an OAM

event notification is sent to its peer. If the threshold is set

to zero, then at the end of each window an event

notification is sent—this acts more like an asynchronous

update of the link statistics.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

64

Page 73

Transition Networks Section Vl: FBRM/BFFG Software Features

Software feature descriptions, continued

Table 3: Device Software Configurable Features (continued)

Feature

Last Gasp/Dying

Gasp(OAM, IEEE

802.3ah-2004 standard)

Remote Loop Back

(OAM, IEEE 802.3ah2004 standard)

Description

All FBRM/BFFG Devices come equipped with a Last

Gasp/OAM Dying Gasp feature. This feature enables

the Device to store a small amount of power to enable

sending an SNMP trap to alert the management console

of a power failure. Feature benefits are the following:

• Notification of an impending power loss before it

happens

• Allows for quicker resolution of the power loss

The default action for last gasp/OAM dying gasp is to

send an SNMP Trap. If the desire is to send a dying

gasp through OAM, it must be configured through the

SNMP/Web interface. It requires choosing the port on

which to send the Dying Gasp command since both

ports are OAM capable. This feature helps

communicate with OAM peers that are not TN Devices.

OAM remote loop back can be used to test link health

by sending a loop back request from the active peer

Device to the remote passive peer Device. Once the

remote passive peer enters loop back mode, all frames

coming into that port are looped back, yet not forwarded

to other ports.

The OAM frames are still exchanged between the local

and remote peer Devices—only OAM frames get

through. The active peer Device discards the frames

coming out of its remote peer Device to prevent

flooding the network. See the illustration below.

Alternate Loop back

This feature can be used to verify end-to-end

connectivity.

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600 65

Page 74

Section Vl: FBRM/BFFG Software Features Transition Networks

Software feature descriptions, continued

Table 3: Device Software Configurable Feature (continued)

Feature

OAM Exchange of

configuration

information and remote

upgrades with

organizational specific

PDUs ( IEEE 802.3ah-

2004 standard)

Link Status Failure

Indications

Standard MIB Counters

Description

The remote peer Device (only if a TN

FBRM/BFFGDevice) set to passive mode can be

completely managed through the SNMP/Web

management by its active peer Device when set to

Active Mode. This is done using organizational specific

PDUs. When the active peer upgrades to a new revision

of firmware, it detects the firmware configuration of its

remote peer Device and upgrades it automatically.

If the active peer is in a chassis, the remote peer can be

managed through Point System management by the

management module unit (MMU).

Link status failure indication with OAM PDU flags

fielded and sent as an OAM critical event (refer to

57.4.2.1 of the standard).

The Device provides complete management through the

SNMP interface. It supports the following standard

MIBs for management using SNMPv1:

• RFC 1213 (MIB-II)

• RFC 2819 (RMON – statistics group)

• RFC 2863 (IF MIB counters)

• RFC 3635 (Ether-like MIB counters)

• RFC 1493 (Bridge MIB object counters)

• RFC 2674 (Bridge extensions counters)

Continued on next page

24-Hour Technical Support: 1-800-260-1312 International: 00-1-952-941-7600

66

Page 75

Transition Networks Section Vl: FBRM/BFFG Software Features

Software feature descriptions, continued

Table 3: Device Software configurable Features (continued)

Feature

Pause (flow control) and

Back Pressure

Point System

Management

Description

Pause is used to suspend data transmission temporarily

to relieve buffer congestion. If a Device needs sometime

to clear network congestion, it will send a pause signal

to the Device at the other end, then that Device will wait

a predetermined amount of time before re-transmitting

its data.

This feature reduces data bottlenecks and allows

efficient use of network Devices, preventing data losses.

The pause feature is set in Firmware mode, using the

SNMP interface. It can be set to one of four settings:

• Disable (no pause)

• Symmetrical pause

• Asymmetric TX (transmit) pause

• Asymmetric RX (receive) pause

Note: Enable the “pause feature” if available on ALL

network Devices attached to the media

Device(s), otherwise disable this feature.

Back pressure is used in half duplex mode. Back

pressure ensures the retransmission of incoming packets