Page 1

50 Hz P ackage

Heat Pump Units

Product Data

Convertible Models

WCC030,040,050

30, 40, 50 MBh

IPB-99-7-EN-10-6-99

Page 2

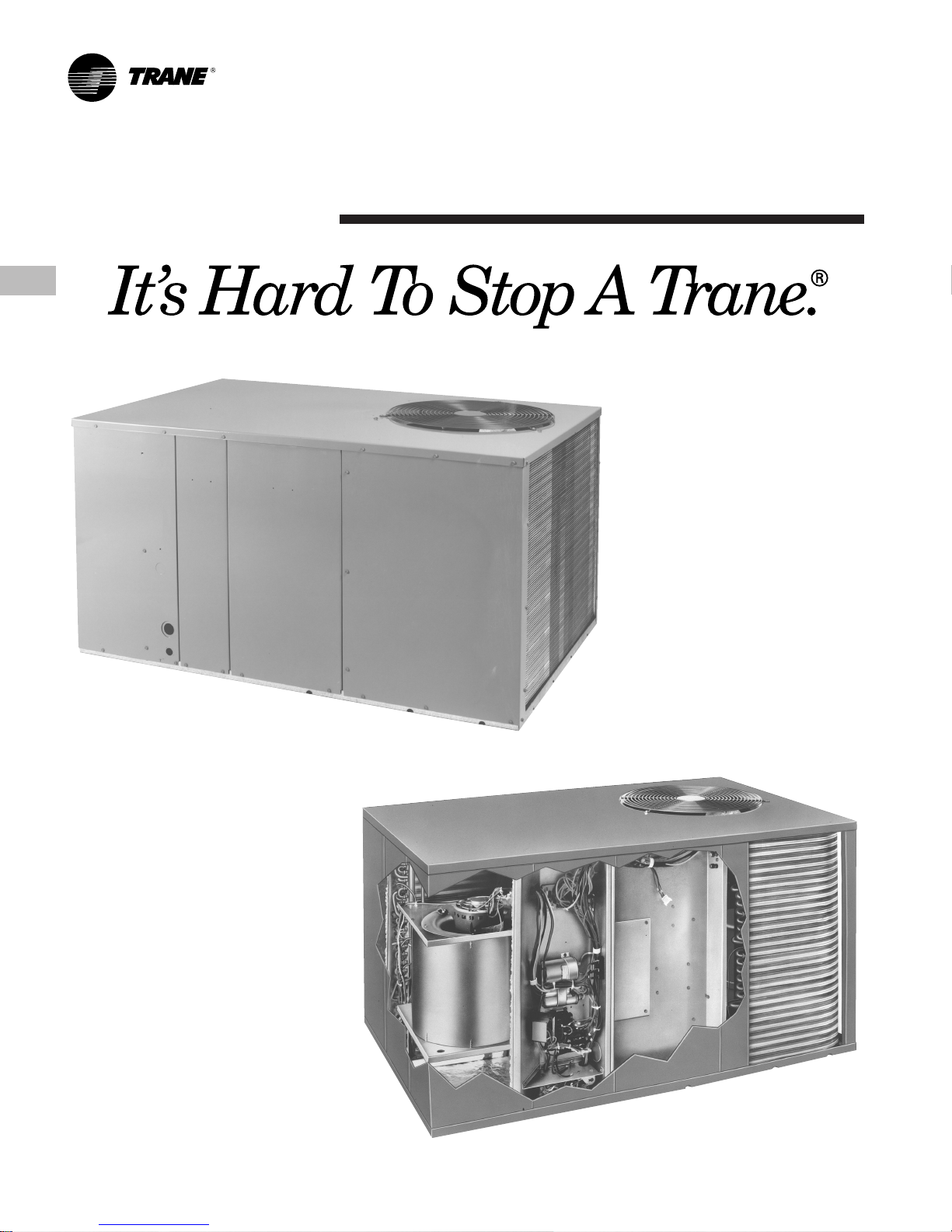

General

Features

T-Top™

Corrosion Resistant Screws

Powder Paint

Water-Shed™ Base

High Efficiency

Climatuff

DuraT uff™ Plate Fin Coil

Time Defrost Control

Sloped Drain Pan

100% Foil Faced Insulation

Easy Access

©American Standard Inc. 1999 IPB-99-7-EN-10-6-99

®

Compressor

Page 3

Contents

Feature Summary 2

Features and Benefits 4

Standard Equipment 4

Impack Accessories 5

Optional Equipment 6

Selection Procedure 7

Model Number Nomenclature 7

General Data 8

English Units

WCC030FD00B 8

WCC040FD00B 8

WCC050FD00B 8

Metric Units

WCC030FD00B 9

WCC040FD00B 9

WCC050FD00B 9

IPB-99-7-EN-10-6-99 3

Perf ormance Data 10

Cooling English Units 10

Cooling Metric Units 11

Heating English Units 12

Heating Metric Units 13

Indoor Blower Performance 14

Optional Equipment 15

Controls 16

Field Wiring 17

Dimensions 20

Mechanical Specification Options 26

Page 4

• High Efficiency

Impack performance is among the highest

in the industry.

• Climatuff® Compressor

Protection against chemical, electrical, and

mechanical stresses are built in for

efficiency and a longer life. The compressor

is backed by a 5-year limited warranty, with

an optional warranty for 5 more years.

• Time Defrost Control

This is an electronic, time initiated, temperature terminated defrost system that offers a

choice of 50, 70, or 90 minute cycles. The

time override limits the defrost cycle to 10

minutes.

• Convertibility

Impack units are easily converted from

horizontal to downflow with the removal of

one screw from each panel. Accordingly, the

need to stock both dedicated horizontal and

dedicated downflow models has been

eliminated.

• Installation

The ease of installation and application

flexibility exhibited through the design

reduce both field time and material.

• Application

The low profile horizontal duct take-offs

eliminate the need for expensive transition

ducts in crawl space applications.

• Commonality

The common cabinet among the TCC’s,

WCC’s, and YCC’s minimizes both the

training of sales and service personnel and

replacement parts inventory.

• Flexibility

A single curb fits the entire Impack line from

1.5 tons through 5 tons thereby providing

great installation flexibility on shopping

malls, factories, schools, and other

commercial buildings where a mix-match of

tonnages and utilities is desired.

Features and

Benefits

Standard Equipment

• Water-Shed™ Base

Superior water integrity is accomplished

with the Water-Shed™ base pan having

elevated downflow openings and a perimeter channel that prevents water from

draining into the ductwork.

• Easy Access

All electrical components can be diagnosed

and replaced with the removal of one panel

that is attached with two screws.

• Service

All wiring is both numbered and color coded

thereby reducing training and servicing

costs related to circuit tracing and components replacements.

• Maintenance

A plug on the outdoor fan motor allows the

top cover to be removed completely without

the hassle of cumbersome wires. The

unique service orifice ring allows the indoor

fan motor/blower to be removed as a unit.

• Plate Fin Coil

Refrigeration coils are built with internally

enhanced copper tubing for high efficiency

with less coil area.

• Shipping

Unit dimensions were carefully selected to

provide an attractive aspect ratio and for

shipping and handling considerations.

• Good Neighbor

Most units can be installed flush with the

residence or building thereby minimizing the

ground space required. Blankets of

insulation reduce blower noise and energy

losses to the outside environments.

• Rooftop Mounting

The cabinets are physically smaller than

most competitive models. This means less

intrusive installations on residential rooftops

where aesthetics are critical.

• Handling

The three-way wooden skid allows for easy

loading between the wheel wells on pickup

trucks for transporting to job sites.

• Structure

The units are lighter weight through the use

of high technology components thereby

reducing mounting structure requirements

and difficulty when handling.

• Duct Flanges

Only Impack has downflow duct flanges for

duct attachments that preserve the built-in

water integrity.

• Corrosion

The drain pan is engineered material and

eliminates the need for coatings and sealers

to prevent sweating and corrosion. The

heavy gauge, zinc-coated steel cabinet has

a weather resistant enamel finish that stays

attractive and protects your investment for

years.

• Low Ambient Control

Zero degree ambient cooling is accomplished with two kits. One for low cost

installations when full tonnage is not

needed. The other kit maintains head

pressure and full capacity at zero degrees.

• Quality and Reliability Testing

We perform a 100% coil leak test at the

factory. The evaporator and condenser

coils are leak tested at the factory. The

evaporator and condenser coils are leak

tested at 200 psig and pressure tested to

450 psig respectively. In addition the Impack

designs were rigorously rain

tested at the factory to ensure water

integrity. Shipping tests are performed to

determine packaging requirements. Factory

shake and drop tests are used as part of

the package design process to help assure

that the unit will arrive at the job site in top

condition. Additionally, all components are

inspected at the point of final assembly.

Substandard parts and components are

identified and rejected immediately. Every

unit receives a 100% run test before leaving

the production line to make sure it lives up

to rigorous Trane® requirements. We at

Trane test our designs at our factory and not

on our customers!

4 IPB-99-7-EN-10-6-99

Page 5

Impack

Accessories

• Standard Thermostats

No special thermostats are needed with

Impack units.

• Filter Frame Kit

The Impack filter frames accept standard

filters and fit inside the unit. The frame kits

function in either horizontal or downflow

duct configurations.

• Coil Guard Kit

The guards are vinyl coated 1" x 3" wire

grills. These grills will protect the coil from

hail, kids with sticks as well as normal

shipping and installation handling damage.

• UNI-CURB™

One universal curb fits all the Impack

models. It ships knocked down. The curb

design incorporates the popular locking tabs

for quick and easy assembly. Full perimeter

curbs are also available for all models.

• 25% Fresh Air Kit

The kit installs over the horizontal return air

opening with six screws for downflow requirements. It can be used on horizontal air flow

applications by cutting a hole in the return

air duct or in the unit filter access panel.

• Rectangular to Round Duct Kits

The adapter kit can be used in either

horizontal or downflow applications.

• Low Ambient Kit

An EDC provides low ambient cooling to 0° F

with some reduced capacity and protects

the system against evaporator icing during

other unusual cooling conditions.

• Fan Delay Relay Kit

This solid state kit is a time delay that keeps

the indoor blower on for about ninety

seconds and increases the SEER. It wires

into the low voltage unit pigtails.

• High Static Motor Kit

Contains a higher torque indoor fan motor.

• Lifting Lug Kit

Four reusable lugs in each kit allow units to

be easily lifted to rooftop installations. These

lugs snap (no screws required) into slots in

the unit drip lip channel.

• Start Kit

The kit mounts in the control box for those

installations with specific conditions such as

excessive voltage drop due to long wires.

(This is a capacitor and start relay kit and is

not a PTC device.) This kit can be a good

specification buster!

IPB-99-7-EN-10-6-99 5

• Economizer

The economizer fits inside the unit with only

the rain hood and barometric relief on the

outside. Cabling (with polarized plugs) is

shipped with the economizer. This cabling is

easily routed to the control box where it

terminates in low voltage pigtails. The

economizer features a fully modulating low

voltage motor eliminating the need for any

high voltage wiring. The economizer must

be used with the filter frame kit . . . no return

air filter in the economizer kit. A dr y bulb

sensor is shipped with the economizer. The

economizer was not designed for use in

horizontal applications. Heat pump applications require a relay kit.

• Enthalpy Control Kit

For those applications specifying an economizer with enthalpy control, this control can

be used in place of the dry bulb sensor or,

alternately, two enthalpy controls can be

paired to provide differential enthalpy control.

• Single Power Entry Kit

The kit minimizes installation costs by

reducing the load center circuit requirement

and reducing the number of circuit pulls

needed.

Page 6

Optional

Equipment

OPTIONAL EQUIPMENT FOR PACKAGE UNITS (Check mark [

Indoor Thermostats — 3H/2C Auto Changeover ............................................................................................................................... BAY28X153A [ ]

Roof Curb (Flat Roof) (WCC-F) 5 ................................................................................................................................................. BAYCURB030A [ ]

Roof Curb (Flat Roof) (WCC040-050F) ........................................................................................................................................ BAYCURB034A [ ]

0-25% Manual Fresh Air Damper (WCC030F) 2 ........................................................................................................................BAYDMPR040A [ ]

0-25% Manual Fresh Air Damper (WCC040,050F) 2 ................................................................................................................. BAYDMPR041A [ ]

12" Round Duct Adapter (2 per box) (WCC030F) ........................................................................................................................ BAYDUCT004A [ ]

14" Round Duct Adapter (1 per box) (WCC040,050F) ................................................................................................................. BAYDUCT005A [ ]

0-100% Mod. Economizer w/Baro. Relief (WCC030F) 12345 .............................................................................................. BAYECON054A [ ]

0-100% Mod. Economizer w/Baro. Relief (WCC040,050F) 12345 ....................................................................................... BAYECON055A [ ]

0-100% Horizontal Economizer 23 ............................................................................................................................................ BAYECON073A [ ]

Enthalpy Control (solid state) (WCC-F) 3 .....................................................................................................................................BAYENTH001A [ ]

Economizer Relay Kit (WCC-F) 1 .................................................................................................................................................BAYRLAY003A [ ]

Filter Frame (20x25x1" filter not incl.) WCC030F 2 .......................................................................................................................BAYFLTR012A [ ]

Filter Frame (3-10x25x1" filters not incl.) WCC040,050F 2 ..........................................................................................................BAYFLTR014A [ ]

Lifting Lug Kit (WCC-F) ........................................................................................................ ............................................................. BAYLlFT002A [ ]

Evaporator Defrost Control (Low Ambient Cool) Kit (WCC-F) 1 ................................................................................................. BAYLOAM011A [ ]

Condenser Coil Guard (WCC030F) .............................................................................................................................................. BAYGARD017A [ ]

Condenser Coil Guard (WCC040,050F) ....................................................................................................................................... BAYGARD022A [ ]

High Static Motor (WCC030F) (230/460) (3/4 hp) ........................................................................................................................ BAYHSMT043A [ ]

High Static Motor (WCC040,050F) (230/460) (1 hp) .................................................................................................................... BAYHSMT044A [ ]

Anti-Short Cycle Timer (WCC-F) ...................................................................................................................................................... BAYASCT001 [ ]

Indoor Fan Delay Kit (WCC-F) ............................................................................................................................................................ BAY24X045 [ ]

Notes:

1

Relay required with economizer on WCC-F models .

2

Must use filter frame when economizer/fresh air kit is used.

3

Dry bulb control standard with economizer.

2H/1C Auto ................................................................................................................................................... BAY28X138A [ ]

Prog. Setback Thermostat (WCC-F) ........................................................................................................... BAYSTAT024B [ ]

2 Stage Htg/Clg Thermostat (WCC-F) .......................................................................................................... BAYSTAT239 [ ]

Remote Sensor for Prog. Thermostat............................................................................................................ BAYSTAT021 [ ]

Fan Control Relay Kit (DPDT Relay (WCC-F) ...................................................................................... ........... BAY24X042 [ ]

5 or 7 Minute Delay Relay ............................................................................................................................. BAY41X171A [ ]

Locking Thermostat Cover (Thermostats) ....................................................................................................... BAY28X190 [ ]

Man. Prog. 2 Htg/1 Clg ................................................................................................................................... TAYSTAT500 [ ]

Man. Prog. 2 Htg/1 Clg ................................................................................................................................... TAYSTAT501 [ ]

Man. 2 Htg/1 Clg with Subbase..................................................................................................................... BAYSTAT240 [ ]

Outdoor Thermostat .................................................................................................................................... BAYSTAT033A [ ]

✓✓

✓] indicates accessories included).

✓✓

4

Ships knocked down.

5

Downflow only.

6 IPB-99-7-EN-10-6-99

Page 7

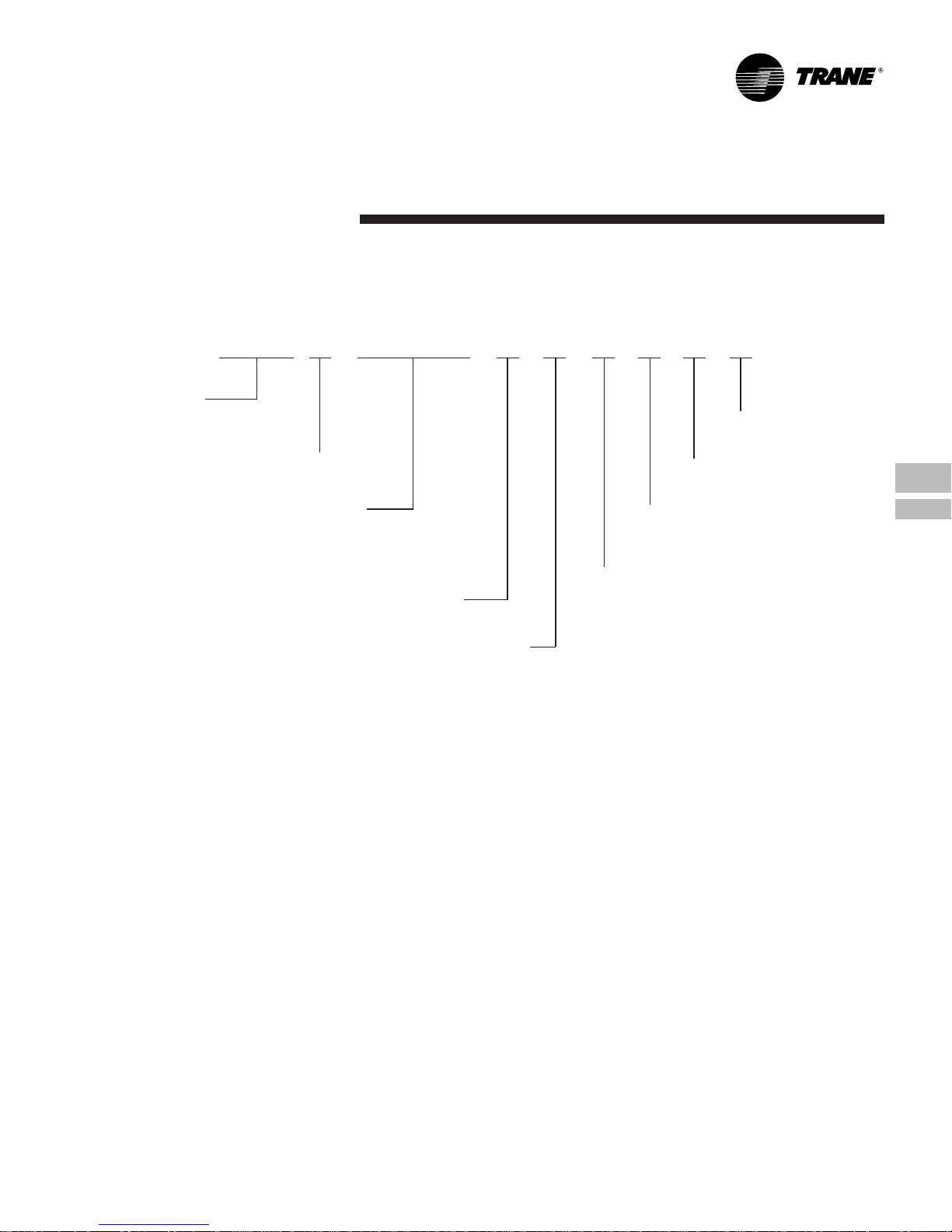

123456789101112

WCC030FD00BA

PRODUCT TYPE

TC = Package Cooling

WC = Package Heat Pumps

Selection

Procedure

Model Number Nomenclature

PRODUCT

SERVICE CHANGE

AIRFLOW CONFIGURATION

C = Convertible

NOMINAL NET COOLING

CAPACITY

030 = 30 MBh

040 = 40 MBh

050 = 50 MBh

MAJOR DESIGN MODIFICATION

F = Impack

MINOR DESIGN

MODIFICATION

FACTORY INSTALLED OPTIONS

EXAMPLES:

0 = No factory installed options

AUXILIARY HEATING CAPACITY

Ø = No Auxiliary Heat (from Factory)

ELECTRICAL CHARACTERISTICS

D = 380-415V/3/50

IPB-99-7-EN-10-6-99 7

Page 8

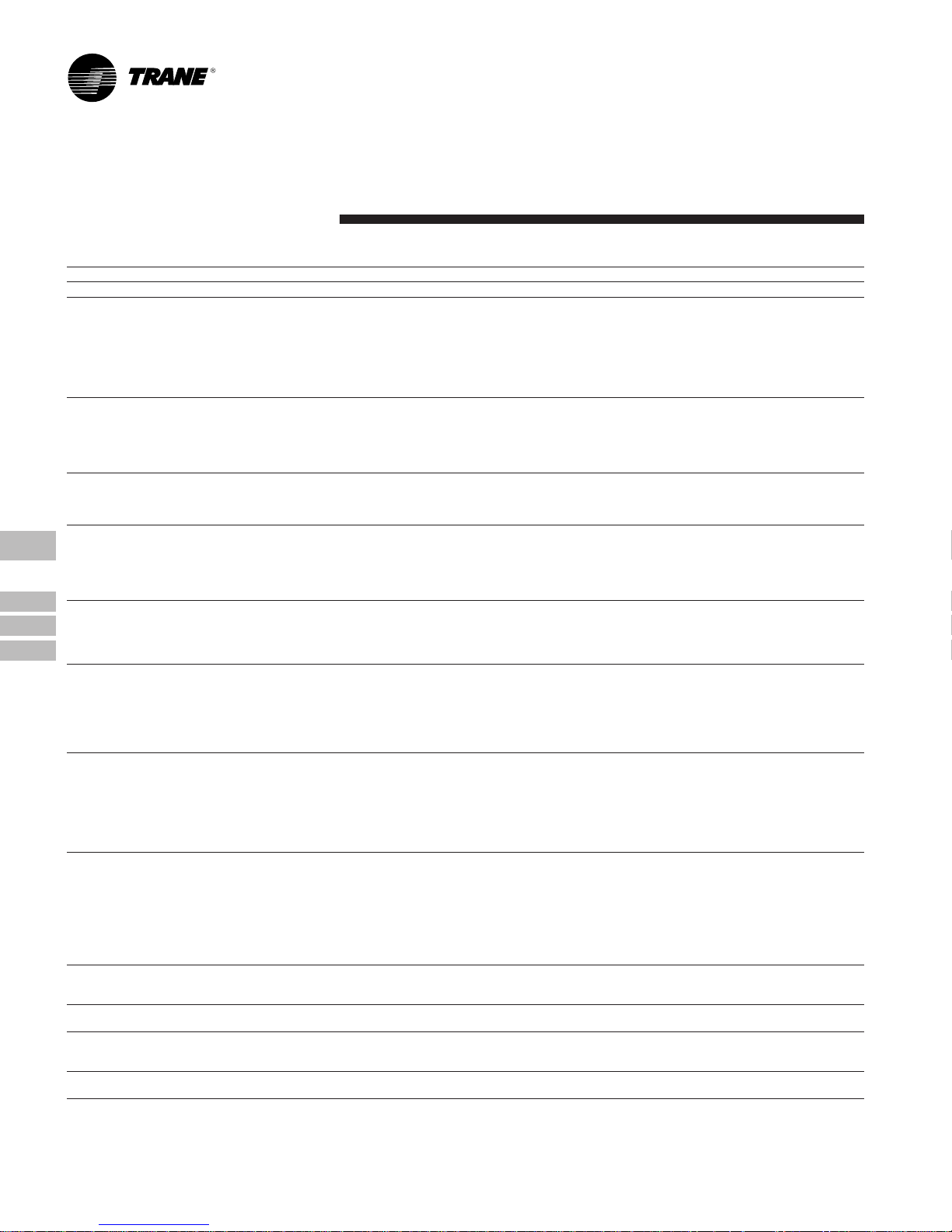

General

Data English Units

MODEL

RA TED VOL TS/PH/HZ

A.R.I. RATING

RATINGS (COOLING)

BTUH

INDOOR AIR FLOW (CFM)

POWER INPUT (kW)

EER-95 (BTU/WATT-HR.)

EER-82

NOISE RATING NO.

RATINGS (HEATING)

(HIGH TEMP.) BTUH - COP

POWER INPUT (kW)

(LOW TEMP.) BTUH - COP

POWER INPUT (kW)

HSPF (BTU/WATT-HR.)

POWER CONNS. — V/PH/HZ

MIN. BRCH. CIR. AMPACITY

FUSE SIZE - MAX.(AMPS)

FUSE SIZE - RECMD. (AMPS)

COMPRESSOR

NO. USED - NO. SPEEDS

VOLTS/PH/HZ

R.L. AMPS

L.R. AMPS

BRCH. CIR. SELEC. CUR. AMPS

OUTDOOR COIL — TYPE

ROWS / F.P.I.

F ACE AREA (SQ. FT.)

TUBE SIZE (IN.)

REFRIGERANT CONTROL

INDOOR COIL — TYPE

ROWS / F.P.I.

F ACE AREA (SQ. FT.)

TUBE SIZE (IN.)

REFRIGERANT CONTROL

DRAIN CONN. SIZE (IN.)

DUCT CONNECTIONS

OUTDOOR FAN — TYPE

NO. USED / DIA. (IN.)

TYPE DRIVE / NO. SPEEDS

CFM @ 0.0 IN. W.G.

NO. MOTORS - HP

MOTOR SPEED R.P.M.

VOLTS/PH/HZ

F.L. AMPS - L.R. AMPS

INDOOR FAN — TYPE

DIA. X WIDTH (IN.)

NO. USED

DRIVE / SPEEDS (NO.)

CFM VS. IN. W.G.

NO. MOTORS - HP

MOTOR SPEED R.P.M.

VOLTS/PH/HZ

F.L. AMPS - L.R. AMPS

FILTER — FURNISHED?

TYPE RECOMMENDED

NO. - SIZE - THICKNESS

REFRIGERANT

CHARGE (LBS. OF R-22)

DIMENSIONS

CRATED (IN.)

UNCRATED

WEIGHT

SHIPPING (LBS.) / NET (LBS.)

NOTES:

1

RATED IN ACCORDANCE WITH A.R.I. STANDARD 210/240.

2

CALCULATED IN ACCORDANCE WITH A.R.I. STANDARD 270.

3

CALCULATED IN ACCORDANCE WITH CURRENTLY PREVAILING NATL. ELECTRIC CODE.

4

STANDARD AIR - DRY COIL - OUTDOOR

1

6

2

1

6

3

4

5

WCC030FD00B

380-415/3/50

31000

1000

3.12

9.50

10.90

8.0

29600 - 3.12

2.78

15600 - 2.00

2.29

380-415/3/50

10.2

15

15

1 - 1

5.7

51

4.2

PLATE FIN

2 / 15

8.62

PLATE FIN

3 / 15

3.96

1 / 18

DIRECT / 1

2040

1 - 1/2

900

1.7 - 3.8

10 X 9

1

DIRECT / 2

1 - 1/3

900

1.1 - 2.6

NO

3 - 10 x 25

8.2 LBS.

406 / 366

®

CLIMATUFF

380-415/3/50

3/8 COPPER

TXV BLEED

3/8 COPPER

ORIFICE - .071

3/4 FEMALE NPT

SEE OUTLINE DRAWING

PROPELLER

380-415/1/50

CENTRIFUGAL

SEE FAN PERFORMANCE TABLE

380-415/1/50

THROW AWAY

H X W X D

35-1/4 X 38 X 57

SEE OUTLINE DRAWING

WCC040FD00B

380-415/3/50

39600

1325

4.10

9.70

10.95

8.4

39400 - 3.18

3.66

20700 - 2.06

2.96

6.80

380-415/3/50

13.8

20

20

1 -

8.0

51

7.1

PLATE FIN

2 / 15

14.0

3/8

PLATE FIN

4 / 15

5.4

3/8

1 / 22

DIRECT / 1

2830

1 - 1/2

900

1.7 - 3.8

11.0 X 11.0

1

DIRECT / 2

1 - 3/4

900

2.1 - 4.8

NO

3 - 10 x 25

13.0 LBS

561 / 521

®

SEE OUTLINE DRAWING

SEE FAN PERFORMANCE TABLE

SEE OUTLINE DRAWING

CLIMATUFF

380-415/3/50

TXV BLEED

ORIFICE- .082

3/4 FEMALE

SEE OUTLINE DRAWING

PROPELLER

380-415/1/50

CENTRIFUGAL

SEE FAN PERFORMANCE TABLE

380-415/1/50

THROWAWAY

H X W X D

39-3/8 X 47 X 66

SEE OUTLINE DRAWING

5

STANDARD AIR - WET COIL - INDOOR

6

RATED IN ACCORDANCE WITH D.O.E. TEST PROCEDURE. HSPF IS AT THE

MINIMUM DESIGN REQUIREMENT FOR REGION IV.

WCC050FD00B

380-415/3/50

51600

1675

5.53

9.35

11.15

8.4

53600 - 3.18

4.91

31300 - 2.16

4.21

6.80

380-415/3/50

16.3

25

25

1 -

9.8

71

10.0

PLATE FIN

2 / 15

14.0

3/8

PLATE FIN

4 / 15

5.4

3/8

1 / 22

DIRECT / 1

2830

1 - 1/2

900

1.7 - 3.8

11.0 X 11.0

1

DIRECT / 2

1 - 3/4

900

2.1 - 4.8

NO

3 - 10 x 25

12.0 LBS

579 / 539

®

CLIMATUFF

380-415/3/50

TXV BLEED

ORIFICE - .096

3/4 FEMALE

PROPELLER

380-415/1/50

CENTRIFUGAL

380-415/1/50

THROWAWAY

H X W X D

39-3/8 X 47 X 66

8 IPB-99-7-EN-10-6-99

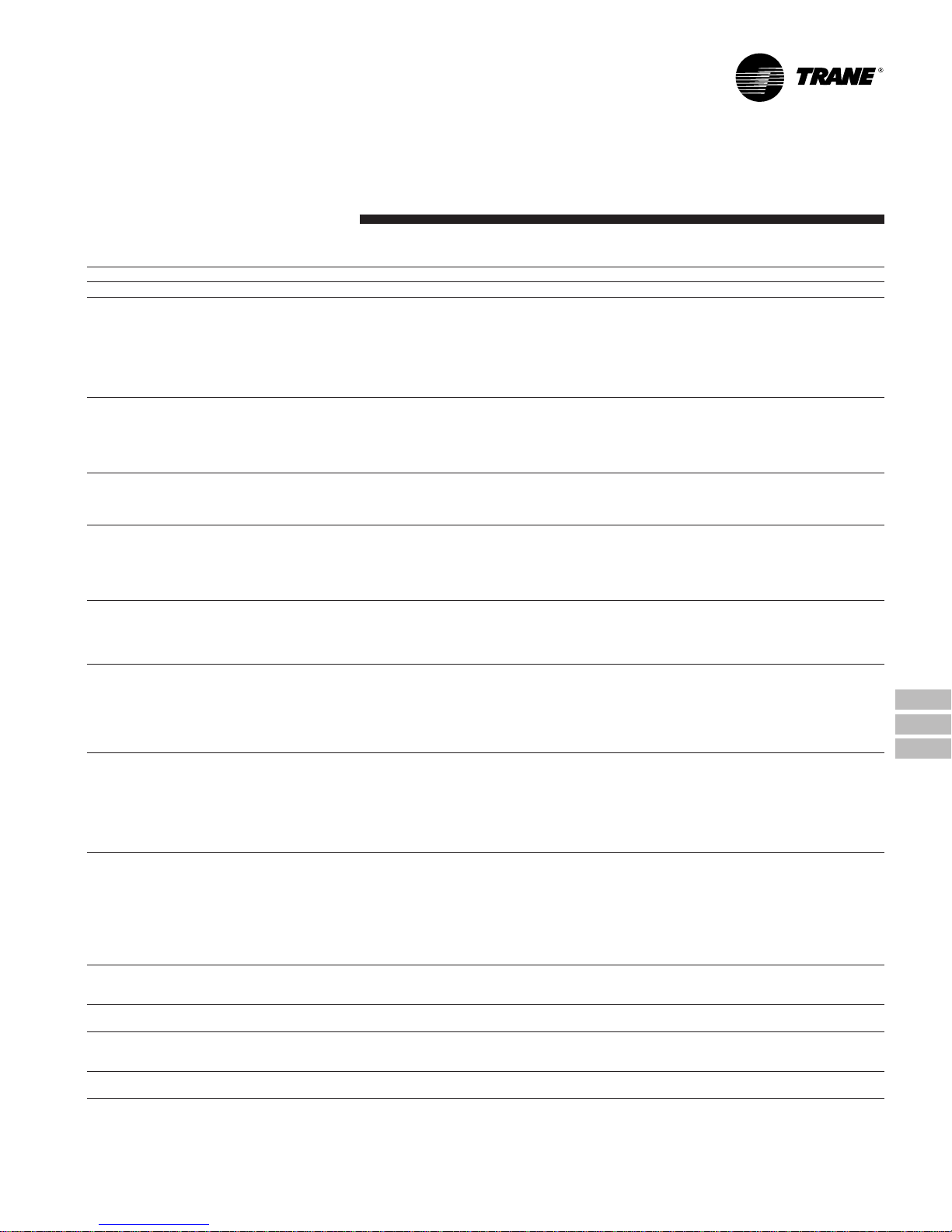

Page 9

General

Data Metric Units

MODEL

RA TED VOL TS/PH/HZ

A.R.I. RATING

RATINGS (COOLING)

BTUH

INDOOR AIR FLOW (CMH)

POWER INPUT (kW)

EER-95 (BTU/WATT-HR.)

EER-82

NOISE RATING NO.

RATINGS (HEATING)

(HIGH TEMP.) CAPACITY (WATTS) - COP

POWER INPUT (kW)

(LOW TEMP.) CAPACITY (WATTS) - COP

POWER INPUT (kW)

HSPF (BTU/WATT-HR.)

POWER CONNS. — V/PH/HZ

MIN. BRCH. CIR. AMPACITY

FUSE SIZE - MAX.(AMPS)

FUSE SIZE - RECMD. (AMPS)

COMPRESSOR

NO. USED - NO. SPEEDS

VOLTS/PH/HZ

R.L. AMPS

L.R. AMPS

BRCH. CIR. SELEC. CUR. AMPS

OUTDOOR COIL — TYPE

ROWS / FINS PER MILLIMETER

FACE AREA (SQ. M)

TUBE SIZE (IN.)

REFRIGERANT CONTROL

INDOOR COIL — TYPE

ROWS / FINS PER MILLIMETER

FACE AREA (SQ. M)

TUBE SIZE (IN.)

REFRIGERANT CONTROL

DRAIN CONN. SIZE (IN.)

DUCT CONNECTIONS

OUTDOOR FAN — TYPE

NO. USED / DIA. (MM)

TYPE DRIVE / NO. SPEEDS

CMH @ 0.0 PASCALS

NO. MOTORS - HP

MOTOR SPEED R.P.M.

VOLTS/PH/HZ

F.L. AMPS - L.R. AMPS

INDOOR FAN — TYPE

DIA. X WIDTH (MM)

NO. USED

DRIVE / SPEEDS (NO.)

CMH VS. PASCALS

NO. MOTORS - HP

MOTOR SPEED R.P.M.

VOLTS/PH/HZ

F.L. AMPS - L.R. AMPS

FILTER — FURNISHED?

TYPE RECOMMENDED

NO. - SIZE - THICKNESS

REFRIGERANT

CHARGE (KG OF R-22)

DIMENSIONS

CRATED (MM)

UNCRATED

WEIGHT

SHIPPING (KG) / NET (KG)

NOTES:

1

RATED IN ACCORDANCE WITH A.R.I. STANDARD 210/240.

2

CALCULATED IN ACCORDANCE WITH A.R.I. STANDARD 270.

3

CALCULATED IN ACCORDANCE WITH CURRENTLY PREVAILING NATL. ELECTRIC CODE.

4

STANDARD AIR - DRY COIL - OUTDOOR

1

6

2

1

6

3

4

5

WCC030FD00B

380-415/3/50

9085

1690

3.12

9.50 / 10.00

10.90

8.0

8675 - 3.12

2.78

4572 - 2.00

2.29

6.80

380-415/3/50

10.2

15

15

CLIMATUFF

380-415/3/50

3/8 COPPER

3/8 COPPER

ORIFICE - .071

3/4 FEMALE NPT

SEE OUTLINE DRAWING

PROPELLER

380-415/1/50

CENTRIFUGAL

SEE F AN PERFORMANCE TABLE

380-415/1/50

THROWAWAY

H X W X D

895 X 965 X 1448

SEE OUTLINE DRAWING

®

1 - 1

5.7

51

4.2

PLATE FIN

2 / .591

.801

TXV BLEED

PLATE FIN

3 / .591

.368

1 / 457

DIRECT / 1

3448

1 - 1/2

900

1.7 - 3.8

254 X 229

1

DIRECT / 2

1 - 1/3

900

1.1 - 2.6

NO

3 - 254 x 635

3.72 KG

184 / 166

WCC040FD00B

380-415/3/50

11606

2240

4.10

9.70 / 10.00

10.95

8.4

11547 - 3.18

3.66

6067 - 2.06

2.96

6.80

380-415/3/50

13.8

20

20

CLIMATUFF

380-415/3/50

ORIFICE- .082

3/4 FEMALE

SEE OUTLINE DRAWING

PROPELLER

380-415/1/50

CENTRIFUGAL

SEE FAN PERFORMANCE TABLE

380-415/1/50

THROW AWAY

H X W X D

1000 X 1194 X 1676

SEE OUTLINE DRAWING

5

STANDARD AIR - WET COIL - INDOOR

6

RATED IN ACCORDANCE WITH D.O.E. TEST PROCEDURE. HSPF IS AT THE

MINIMUM DESIGN REQUIREMENT FOR REGION IV.

®

1 -

8.0

51

7.1

PLATE FIN

2 / .591

1.30

3/8

TXV BLEED

PLATE FIN

4 / .591

.502

3/8

1 / 559

DIRECT / 1

4785

1 - 1/2

900

1.7 - 3.8

279 X 279

1

DIRECT / 2

1 - 3/4

900

2.1 - 4.8

NO

3 - 254 x 635

5.90 KG

254 / 236

SEE OUTLINE DRAWING

SEE FAN PERFORMANCE TABLE

1000 X 1194 X 1676

SEE OUTLINE DRAWING

WCC050FD00B

380-415/3/50

15122

2830

5.53

9.35 / 10.00

11.15

8.4

15709 - 3.18

4.91

9173 - 2.16

4.21

6.80

380-415/3/50

16.3

25

25

CLIMATUFF

380-415/3/50

ORIFICE - .096

3/4 FEMALE

PROPELLER

380-415/1/50

CENTRIFUGAL

380-415/1/50

THROWAWAY

H X W X D

®

1 -

9.8

71

10.0

PLATE FIN

2 / .591

1.30

3/8

TXV BLEED

PLATE FIN

4 / .591

.502

3/8

1 / 559

DIRECT / 1

4783

1 - 1/2

900

1.7 - 3.8

279 X 279

1

DIRECT / 2

1 - 3/4

900

2.1 - 4.8

NO

3 - 254 x 635

5.44 KG

263 / 244

IPB-99-7-EN-10-6-99 9

Page 10

Performance

Data Cooling English Units

O.D. I.D. TOTAL SENS. CAP. AT ENTERING D.B. TEMP. COMPR.

D.B. W.B. CAP. 72 74 76 78 80 KW

59 29.3 23.6 25.4 27.2 29.1 30.0* 2.29

85 63 31.5 20.1 21.9 23.7 25.5 27.3 2.37

67 33.8 16.2 18.0 19.8 21.6 23.4 2.44

71 36.2 12.3 14.1 15.9 17.7 19.5 2.52

59 28.6 23.3 25.1 26.9 28.7* 29.4* 2.41

90 63 30.8 19.8 21.6 23.4 25.2 27.0 2.48

67 33.0 15.9 17.7 19.5 21.3 23.1 2.56

71 35.3 11.9 13.7 15.5 17.3 19.1 2.64

59 27.9 23.0 24.8 26.6 28.2* 28.8* 2.53

95 63 30.0 19.5 21.3 23.1 24.9 26.7 2.60

67 32.2 15.6 17.4 19.2 21.0 22.8 2.67

71 34.4 11.6 13.4 15.2 17.0 18.8 2.75

59 27.0 22.6 24.4 26.2 27.5* 28.1* 2.65

100 63 29.0 19.1 20.9 22.7 24.5 26.3 2.72

67 31.1 15.2 17.0 18.8 20.6 22.4 2.79

71 33.3 11.2 13.0 14.8 16.6 18.4 2.86

59 26.2 22.2 24.1 25.9 26.7* 27.4* 2.77

105 63 28.1 18.7 20.5 22.3 24.1 25.9 2.84

67 30.1 14.8 16.6 18.4 20.2 22.0 2.91

71 32.2 10.8 12.6 14.4 16.2 18.0 2.98

59 24.4 21.5 23.3 24.7* 25.3* 25.9* 3.02

115 63 26.2 17.9 19.7 21.5 23.3 25.1 3.08

67 28.1 14.0 15.8 17.6 19.4 21.2 3.14

71 30.0 10.0 11.8 13.6 15.4 17.2 3.20

WCC040FD00B AT 1325 CFM (CAPACITIES ARE GROSS IN BTUH/1000-INDOOR FAN HEAT IGNORED)

O.D. I.D. TOTAL SENS. CAP. AT ENTERING D.B. TEMP. COMPR.

D.B. W.B. CAP. 72 74 76 78 80 KW

59 37.1 30.9 33.4 35.9 37.7* 38.6* 2.60

85 63 40.0 25.9 28.5 31.0 33.5 36.1 2.68

67 42.9 20.5 23.1 25.6 28.1 30.7 2.75

71 46.0 15.0 17.6 20.1 22.6 25.1 2.84

59 36.5 30.6 33.1 35.7 37.2* 38.1* 2.73

90 63 39.3 25.7 28.2 30.7 33.3 35.8 2.81

67 42.2 20.3 22.8 25.3 27.9 30.4 2.89

71 45.2 14.8 17.3 19.8 22.4 24.9 2.97

59 35.9 30.4 32.9 35.4 36.7* 37.6* 2.87

95 63 38.6 25.4 28.0 30.5 33.0 35.5 2.95

67 41.5 20.0 22.5 25.1 27.6 30.1 3.02

71 44.5 14.5 17.0 19.6 22.1 24.6 3.10

59 34.9 29.9 32.5 35.0* 35.9* 36.8* 3.01

100 63 37.6 25.0 27.5 30.1 32.6 35.1 3.09

67 40.4 19.6 22.1 24.7 27.2 29.7 3.16

71 43.2 14.1 16.6 19.1 21.7 24.2 3.24

59 33.9 29.5 32.1 34.2* 35.1* 35.9* 3.16

105 63 36.5 24.6 27.1 29.6 32.2 34.7 3.23

67 39.2 19.2 21.7 24.2 26.8 29.3 3.30

71 42.0 13.7 16.2 18.7 21.3 23.8 3.37

59 32.0 28.7 31.3 32.6* 33.4* 34.2* 3.45

115 63 34.4 23.8 26.3 28.8 31.3 33.9 3.51

67 37.0 18.4 20.9 23.4 25.9 28.5 3.57

71 39.6 12.8 15.4 17.9 20.4 22.9 3.64

WCC030FD00B AT 1000 CFM (CAPACITIES ARE GROSS IN BTUH/1000-INDOOR FAN HEAT IGNORED)

CORRECTION FA CTORS - OTHER AIRFLOWS

AIRFLOW 875 1125

TOTAL CAP. X0.98 X1.02

SENS. CAP. X0.94 X1.05

COMPR. KW X0.99 X1.01

GROSS CAPACITY = 32200 BTUH

AIRFLOW = 1000 CFM

COMPRESSOR POWER = 2673 W ATTS

I.D. FAN POWER = 340 WATTS

O.D . FAN POWER = 250 WATTS

E.E.R. = 9.50 BTUH/WATT

NOTE: RATED WITH 25 FEET OF 7/8

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAP ACITY,COMP. KW AND APP. DEW PT. ARE VALID ONLY

FOR WET COIL

ALL TEMPERATURES IN DEGREES F.

AIRFLOW 1150 1500

TOTAL CAP. X0.98 X1.01

SENS. CAP. X0.94 X1.06

COMPR. KW X0.98 X1.02

GROSS CAPACITY = 41600 BTUH

AIRFLOW = 1325 CFM

COMPRESSOR POWER = 3022 W ATTS

I.D. FAN POWER = 560 WATTS

O.D . FAN POWER = 500 WATTS

E.E.R. = 9.70 BTUH/WATT

NOTE: RATED WITH 25 FEET OF 7/8

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAP ACITY,COMP. KW AND APP. DEW PT. ARE VALID ONLY

FOR WET COIL

ALL TEMPERATURES IN DEGREES F.

(MULTIPLY OR ADD AS INDICATED)

VALUES AT 95/80/67 RATING CONDITIONS

SUCT. AND 3/8 LIQUID LINE

CORRECTION FA CTORS - OTHER AIRFLOWS

(MULTIPLY OR ADD AS INDICATED)

VALUES AT 95/80/67 RATING CONDITIONS

SUCT. AND 3/8 LIQUID LINE

O.D. I.D. TOTAL SENS. CAP. AT ENTERING D.B. TEMP. COMPR.

WCC050FD00B AT 1675 CFM (CAPACITIES ARE GROSS IN BTUH/1000-INDOOR FAN HEAT IGNORED)

D.B. W.B. CAP. 72 74 76 78 80 KW

59 47.9 40.4 43.6 46.9 48.7* 49.9* 4.22

85 63 51.3 34.0 37.3 40.5 43.7 47.0 4.35

67 55.0 27.0 30.3 33.5 36.8 40.0 4.48

71 58.8 19.9 23.2 26.4 29.6 32.9 4.61

59 47.3 40.2 43.4 46.7 48.3* 49.4* 4.17

90 63 50.8 33.8 37.1 40.3 43.5 46.8 4.29

67 54.5 26.8 30.1 33.3 36.5 39.8 4.41

71 58.2 19.7 23.0 26.2 29.4 32.7 4.54

59 46.9 40.0 43.2 46.4 47.9* 49.0* 4.11

95 63 50.3 33.6 36.9 40.1 43.3 46.6 4.22

67 53.9 26.6 29.9 33.1 36.3 39.6 4.34

71 57.7 19.5 22.8 26.0 29.2 32.5 4.46

59 45.1 39.2 42.4 45.3* 46.5* 47.6* 4.28

100 63 48.5 32.8 36.1 39.3 42.6 45.8 4.39

67 51.9 25.9 29.1 32.3 35.6 38.8 4.51

71 55.6 18.8 22.0 25.2 28.5 31.7 4.63

59 43.4 38.4 41.7 44.0* 45.0* 46.1* 4.46

105 63 46.6 32.1 35.3 38.6 41.8 45.0 4.57

67 50.0 25.1 28.4 31.6 34.8 38.1 4.68

71 53.5 18.0 21.3 24.5 27.7 31.0 4.80

59 39.9 36.9 40.0* 41.1* 42.1* 43.1* 4.82

115 63 42.9 30.6 33.8 37.1 40.3 43.1* 4.92

67 46.0 23.6 26.9 30.1 33.3 36.6 5.03

71 49.3 16.6 19.8 23.0 26.3 29.5 5.13

CORRECTION FACTORS - OTHER AIRFLOWS

AIRFLOW 1450 1900

TOTAL CAP. X0.98 X1.01

SENS. CAP. X0.94 X1.06

COMPR. KW X0.99 X1.01

GROSS CAPACITY = 54000 BTUH

AIRFLOW = 1675 CFM

COMPRESSOR POWER = 4339 W ATTS

I.D. FAN POWER = 680 WATTS

O.D . FAN POWER = 500 WATTS

E.E.R. = 9.35 BTUH/WATT

NOTE: RATED WITH 25 FEET OF 7/8

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAP ACITY,COMP. KW AND APP. DEW PT. ARE VALID ONLY

FOR WET COIL

ALL TEMPERATURES IN DEGREES F.

(MULTIPLY OR ADD AS INDICATED)

VALUES AT 95/80/67 RATING CONDITIONS

SUCT. AND 3/8 LIQUID LINE

10 IPB-99-7-EN-10-6-99

Page 11

Performance

Data Cooling Metric Units

O.D. I.D. TOTAL SENS. CAP. AT ENTERING D.B. TEMP. COMPR.

D.B. W.B. CAP . 22.2 23.3 24.4 25.6 26.7 KW

15.0 8.6 6.9 7.4 8.0 8.5 8.8* 2.3

29.4 17.2 9.2 5.9 6.4 6.9 7.5 8.0 2.4

19.4 9.9 4.7 5.3 5.8 6.3 6.9 2.4

21.7 10.6 3.6 4.1 4.7 5.2 5.7 2.5

15.0 8.4 6.8 7.4 7.9 8.4* 8.6* 2.4

32.2 17.2 9.0 5.8 6.3 6.9 7.4 7.9 2.5

19.4 9.7 4.7 5.2 5.7 6.2 6.8 2.6

21.7 10.3 3.5 4.0 4.5 5.1 5.6 2.6

15.0 8.2 6.7 7.3 7.8 8.3* 8.4* 2.5

35.0 17.2 8.8 5.7 6.2 6.8 7.3 7.8 2.6

19.4 9.4 4.6 5.1 5.6 6.2 6.7 2.7

21.7 10.1 3.4 3.9 4.5 5.0 5.5 2.8

15.0 7.9 6.6 7.1 7.7 8.1* 8.2* 2.7

37.8 17.2 8.5 5.6 6.1 6.7 7.2 7.7 2.7

19.4 9.1 4.5 5.0 5.5 6.0 6.6 2.8

21.7 9.8 3.3 3.8 4.3 4.9 5.4 2.9

15.0 7.7 6.5 7.1 7.6 7.8* 8.0* 2.8

40.6 17.2 8.2 5.5 6.0 6.5 7.1 7.6 2.8

19.4 8.8 4.3 4.9 5.4 5.9 6.4 2.9

21.7 9.4 3.2 3.7 4.2 4.7 5.3 3.0

15.0 7.1 6.3 6.8 7.2* 7.4* 7.6* 3.0

46.1 17.2 7.7 5.2 5.8 6.3 6.8 7.4 3.1

19.4 8.2 4.1 4.6 5.2 5.7 6.2 3.1

21.7 8.8 2.9 3.5 4.0 4.5 5.0 3.2

WCC040FD00B AT 2250 CMH (GROSS CAP ACITY IN KILOWATTS)

O.D. I.D. TOTAL SENS. CAP. AT ENTERING D.B. TEMP. COMPR.

D.B. W.B. CAP . 22.2 23.3 24.4 25.6 26.7 KW

15.0 10.9 9.1 9.8 10.5 11.0* 11.3* 2.6

29.4 17.2 11.7 7.6 8.4 9.1 9.8 10.6 2.7

19.4 12.6 6.0 6.8 7.5 8.2 9.0 2.8

21.7 13.5 4.4 5.2 5.9 6.6 7.4 2.8

15.0 10.7 9.0 9.7 10.5 10.9* 11.2* 2.7

32.2 17.2 11.5 7.5 8.3 9.0 9.8 10.5 2.8

19.4 12.4 5.9 6.7 7.4 8.2 8.9 2.9

21.7 13.2 4.3 5.1 5.8 6.6 7.3 3.0

15.0 10.5 8.9 9.6 10.4 10.8* 11.0* 2.9

35.0 17.2 11.3 7.4 8.2 8.9 9.7 10.4 3.0

19.4 12.2 5.9 6.6 7.4 8.1 8.8 3.0

21.7 13.0 4.2 5.0 5.7 6.5 7.2 3.1

15.0 10.2 8.8 9.5 10.3* 10.5* 10.8* 3.0

37.8 17.2 11.0 7.3 8.1 8.8 9.6 10.3 3.1

19.4 11.8 5.7 6.5 7.2 8.0 8.7 3.2

21.7 12.7 4.1 4.9 5.6 6.4 7.1 3.2

15.0 9.9 8.6 9.4 10.0* 10.3* 10.5* 3.2

40.6 17.2 10.7 7.2 7.9 8.7 9.4 10.2 3.2

19.4 11.5 5.6 6.4 7.1 7.9 8.6 3.3

21.7 12.3 4.0 4.7 5.5 6.2 7.0 3.4

15.0 9.4 8.4 9.2 9.6* 9.8* 10.0* 3.5

46.1 17.2 10.1 7.0 7.7 8.4 9.2 9.9 3.5

19.4 10.8 5.4 6.1 6.9 7.6 8.4 3.6

21.7 11.6 3.8 4.5 5.2 6.0 6.7 3.6

WCC030FD00B AT 1698 CMH (GROSS CAP ACITY IN KILOWATTS)

CORRECTION FA CTORS - OTHER AIRFLOWS

AIRFLOW 1486 1910

TOTAL CAP. X0.98 X1.02

SENS. CAP. X0.94 X1.05

COMPR. KW X0.99 X1.01

GROSS CAP ACITY = 9435 KW

AIRFLOW = 1698 CMH

COMPRESSOR POWER = 2673 W ATTS

I.D. FAN POWER = 340 WATTS

O.D . FAN POWER = 250 WATTS

E.E.R. = 9.50 BTUH/WATT

NOTE: RATED WITH 7.62 METERS OF 7/8 IN.

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAPACITY, COMP. KW AND APP. DEW PT. ARE VALID ONLY

FOR WET COIL

ALL TEMPERATURES IN DEGREES C.

AIRFLOW 1953 2547

TOTAL CAP. X0.98 X1.01

SENS. CAP. X0.94 X1.06

COMPR. KW X0.98 X1.02

GROSS CAP ACITY =12189 KW

AIRFLOW = 2250 CMH

COMPRESSOR POWER = 3022 W ATTS

I.D. FAN POWER = 560 WATTS

O.D . FAN POWER = 500 WATTS

E.E.R. = 9.70 BTUH/WATT

NOTE: RATED WITH 7.62 METERS OF 7/8 IN.

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAPACITY, COMP. KW AND APP. DEW PT. ARE VALID ONLY

FOR WET COIL

ALL TEMPERATURES IN DEGREES C.

(MUL TIPLY OR ADD AS INDICATED)

VALUES AT ARI RATING CONDITIONS

SUCT. AND 3/8 IN. LIQUID LINES

CORRECTION FA CTORS - OTHER AIRFLOWS

(MUL TIPLY OR ADD AS INDICATED)

VALUES AT ARI RATING CONDITIONS

SUCT. AND 3/8 IN. LIQUID LINES

O.D. I.D. TOTAL SENS. CAP. A T ENTERING D.B. TEMP. COMPR.

WCC050FD00B AT 2845 CMH (GROSS CAP ACITY IN KILOWATTS)

D.B. W.B. CAP . 22.2 23.3 24.4 25.6 26.7 KW

15.0 14.0 11.8 12.8 13.7 14.3* 14.6* 4.2

29.4 17.2 15.0 10.0 10.9 11.9 12.8 13.8 4.3

19.4 16.1 7.9 8.9 9.8 10.8 11.7 4.5

21.7 17.2 5.8 6.8 7.7 8.7 9.6 4.6

15.0 13.9 11.8 12.7 13.7 14.2* 14.5* 4.2

32.2 17.2 14.9 9.9 10.9 11.8 12.7 13.7 4.3

19.4 16.0 7.9 8.8 9.8 10.7 11.7 4.4

21.7 17.1 5.8 6.7 7.7 8.6 9.6 4.5

15.0 13.7 11.7 12.7 13.6 14.0* 14.4* 4.1

35.0 17.2 14.7 9.8 10.8 11.7 12.7 13.7 4.2

19.4 15.8 7.8 8.8 9.7 10.6 11.6 4.3

21.7 16.9 5.7 6.7 7.6 8.6 9.5 4.5

15.0 13.2 11.5 12.4 13.3* 13.6* 13.9* 4.3

37.8 17.2 14.2 9.6 10.6 11.5 12.5 13.4 4.4

19.4 15.2 7.6 8.5 9.5 10.4 11.4 4.5

21.7 16.3 5.5 6.4 7.4 8.4 9.3 4.6

15.0 12.7 11.3 12.2 12.9* 13.2* 13.5* 4.5

40.6 17.2 13.7 9.4 10.3 11.3 12.2 13.2 4.6

19.4 14.6 7.4 8.3 9.3 10.2 11.2 4.7

21.7 15.7 5.3 6.2 7.2 8.1 9.1 4.8

15.0 11.7 10.8 11.7* 12.0* 12.3* 12.6* 4.8

46.1 17.2 12.6 9.0 9.9 10.9 11.8 12.6* 4.9

19.4 13.5 6.9 7.9 8.8 9.8 10.7 5.0

21.7 14.4 4.9 5.8 6.7 7.7 8.6 5.1

IPB-99-7-EN-10-6-99 11

CORRECTION FA CTORS - OTHER AIRFLOWS

AIRFLOW 2462 3227

TOTAL CAP. X0.98 X1.01

SENS. CAP. X0.94 X1.06

COMPR. KW X0.99 X1.01

GROSS CAP ACITY =15822 KW

AIRFLOW = 2845 CMH

COMPRESSOR POWER = 4339 W ATTS

I.D. FAN POWER = 680 WATTS

O.D . FAN POWER = 500 WATTS

E.E.R. = 9.35 BTUH/WATT

NOTE: RATED WITH 7.62 METERS OF 7/8 IN.

* DRY COIL CONDITION (TOTAL CAPACITY = SENSIBLE CAP ACITY)

TOTAL CAPACITY,COMP. KW AND APP. DEW PT. ARE VALID ONL Y

FOR WET COIL

ALL TEMPERATURES IN DEGREES C.

(MUL TIPLY OR ADD AS INDICATED)

VALUES AT ARI RATING CONDITIONS

SUCT. AND 3/8 IN. LIQUID LINES

Page 12

Performance

Data Heating English Units

O.D. HEA TING CAPACITY (BTUH/1000) AT TOTAL POWER IN KILOWATTS AT

TEMP . INDICATED INDOOR DRY BULB TEMP. INDICATED INDOOR DRY BULB TEMP .

F . 60 70 75 80 60 70 75 80

-18 7.94 7.70 7.57 7.45 1.62 1.69 1.72 1.75

-13 9.10 8.83 8.69 8.55 1.70 1.77 1.81 1.84

-8 10.3 9.95 9.80 9.64 1.78 1.86 1.90 1.93

-3 11.4 11.1 10.9 10.7 1.86 1.94 1.98 2.02

2 12.6 12.2 12.0 11.8 1.94 2.03 2.07 2.12

7 13.8 13.3 13.1 12.9 2.02 2.11 2.16 2.21

12 14.9 14.5 14.2 14.0 2.10 2.20 2.25 2.30

17 16.1 15.6 15.4 15.1 2.18 2.29 2.34 2.39

22 18.0 17.4 17.2 16.9 2.26 2.37 2.42 2.47

27 19.9 19.3 19.0 18.7 2.34 2.45 2.50 2.56

32 21.8 21.1 20.8 20.4 2.41 2.53 2.59 2.65

37 23.7 22.9 22.6 22.2 2.49 2.61 2.67 2.73

42 25.5 24.8 24.4 24.0 2.57 2.69 2.76 2.82

47 30.5 29.6 29.1 28.7 2.66 2.79 2.85 2.91

52 32.9 31.9 31.4 30.9 2.73 2.87 2.94 3.00

57 35.4 34.3 33.7 33.2 2.81 2.95 3.02 3.09

62 37.8 36.6 36.0 35.4 2.89 3.04 3.11 3.18

67 40.2 38.9 38.3 37.7 2.97 3.12 3.19 3.27

72 42.6 41.3 40.6 39.9 3.05 3.20 3.28 3.35

WCC040FD00B AT 1325 CFM

O.D . HEATING CAPACITY (BTUH/1000) AT TOTAL POWER IN KILOWATTS AT

TEMP. INDICATED INDOOR DRY BULB TEMP. INDICATED INDOOR DRY BULB TEMP.

F . 60 70 75 80 60 70 75 80

-18 10.5 10.2 10.1 9.97 2.27 2.36 2.40 2.45

-13 12.1 11.7 11.6 11.4 2.35 2.45 2.49 2.54

-8 13.6 13.2 13.1 12.9 2.43 2.53 2.58 2.64

-3 15.1 14.7 14.5 14.3 2.51 2.62 2.67 2.73

2 16.6 16.2 16.0 15.8 2.58 2.70 2.76 2.82

7 18.2 17.7 17.5 17.3 2.66 2.79 2.85 2.91

12 19.7 19.2 19.0 18.7 2.74 2.87 2.94 3.01

17 21.2 20.7 20.4 20.2 2.82 2.96 3.03 3.10

22 23.8 23.2 22.9 22.6 2.93 3.07 3.15 3.22

27 26.4 25.8 25.4 25.1 3.04 3.19 3.26 3.34

32 29.0 28.3 27.9 27.5 3.14 3.30 3.38 3.46

37 31.6 30.8 30.4 30.0 3.25 3.42 3.50 3.58

42 34.2 33.3 32.9 32.4 3.36 3.53 3.62 3.70

47 40.5 39.4 38.9 38.3 3.48 3.66 3.75 3.84

52 43.7 42.5 41.9 41.4 3.59 3.78 3.87 3.96

57 46.9 45.6 45.0 44.4 3.70 3.89 3.99 4.09

62 50.1 48.8 48.1 47.4 3.81 4.01 4.11 4.21

67 53.3 51.9 51.2 50.4 3.92 4.13 4.23 4.33

72 56.5 55.0 54.2 53.5 4.03 4.24 4.35 4.46

WCC030FD00B AT 1000 CFM

CORRECTION FA CTORS - OTHER AIRFLOWS

(VALUE AT 1000 CFM TIMES CORR. F A CTOR

AIRFLOW 870 1130

HEATING CAP. X0.98 X1.02

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

AIRFLOW = 1000 CFM

HEATING CAP. (HIGH TEMP.) = 29600 BTUH

HEATING CAP. (LOW TEMP.) = 15600 BTUH

COMPR. POWER (HIGH TEMP.) = 2195 WATTS

COMPR. POWER (LOW TEMP.) = 1695 WATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.12

COEFF. OF PERF. (LOW TEMP.) = 2.00

OUTDOOR FAN PO WER = 250 WATTS

INDOOR FAN PO WER = 340 WATTS

NOTE:RATED WITH 25 FEET OF 7/8

AIRFLOW 1153 1497

HEATING CAP. X0.98 X1.01

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

AIRFLOW = 1325 CFM

HEATING CAP. (HIGH TEMP.) = 39400 BTUH

HEATING CAP. (LOW TEMP.) = 20700 BTUH

COMPR. POWER (HIGH TEMP.) = 2600 WATTS

COMPR. POWER (LOW TEMP.) = 1900 WATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.18

COEFF. OF PERF. (LOW TEMP.) = 2.06

OUTDOOR FAN PO WER = 500 WATTS

INDOOR FAN PO WER = 560 WATTS

NOTE:RATED WITH 25 FEET OF 7/8

= VALUE AT NEW AIRFLOW)

70&47/43 (HIGH TEMP. POINT)

70&17/15 (LOW TEMP. POINT)

SUCTION AND 3/8 LIQUID LINE

CORRECTION FA CTORS - OTHER AIRFLOWS

(VALUE AT 1325 CFM TIMES CORR. F A CTOR

= VALUE AT NEW AIRFLOW)

70&47/43 (HIGH TEMP. POINT)

70&17/15 (LOW TEMP. POINT)

SUCTION AND 3/8 LIQUID LINE

O.D . HEATING CAPACITY (BTUH/1000) AT TOTAL POWER IN KILOWATTS AT

TEMP. INDICATED INDOOR DRY BULB TEMP. INDICATED INDOOR DRY BULB TEMP.

F . 60 70 75 80 60 70 75 80

-18 14.3 13.9 13.8 13.6 2.94 3.06 3.12 3.18

-13 16.8 16.4 16.2 16.0 3.09 3.23 3.30 3.36

-8 19.4 18.9 18.7 18.4 3.25 3.40 3.47 3.55

-3 21.9 21.4 21.1 20.8 3.41 3.57 3.65 3.73

2 24.5 23.9 23.6 23.3 3.57 3.74 3.82 3.91

7 27.0 26.3 26.0 25.7 3.72 3.91 4.00 4.09

12 29.5 28.8 28.5 28.1 3.88 4.08 4.17 4.27

17 32.1 31.3 30.9 30.5 4.04 4.25 4.35 4.45

22 33.9 33.1 32.7 32.3 4.08 4.29 4.39 4.50

27 35.8 34.9 34.5 34.0 4.12 4.33 4.44 4.54

32 37.7 36.7 36.2 35.8 4.16 4.37 4.48 4.59

37 39.5 38.5 38.0 37.5 4.20 4.42 4.53 4.63

42 41.4 40.3 39.8 39.3 4.24 4.46 4.57 4.68

47 55.0 53.6 52.9 52.2 4.69 4.94 5.06 5.19

52 58.8 57.3 56.6 55.8 4.80 5.06 5.18 5.31

57 62.6 61.0 60.2 59.4 4.91 5.17 5.30 5.43

62 66.5 64.8 63.9 63.0 5.02 5.29 5.42 5.55

67 70.3 68.5 67.6 66.7 5.13 5.40 5.54 5.68

72 74.1 72.2 71.2 70.3 5.24 5.52 5.66 5.80

WCC050FD00B AT 1675 CFM

12 IPB-99-7-EN-10-6-99

CORRECTION FA CTORS - OTHER AIRFLOWS

(VALUE AT 1675 CFM TIMES CORR. F A CTOR

AIRFLOW 1457 1893

HEATING CAP. X0.99 X1.01

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

AIRFLOW = 1675 CFM

HEATING CAP. (HIGH TEMP.) = 53600 BTUH

HEATING CAP. (LOW TEMP.) = 31300 BTUH

COMPR. POWER (HIGH TEMP.) = 3760 WATTS

COMPR. POWER (LOW TEMP.) = 3065 WATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.18

COEFF. OF PERF. (LOW TEMP.) = 2.16

OUTDOOR FAN PO WER = 500 WATTS

INDOOR FAN PO WER = 680 WATTS

NOTE:RATED WITH 25 FEET OF 7/8

= VALUE AT NEW AIRFLOW)

70&47/43 (HIGH TEMP. POINT)

70&17/15 (LOW TEMP. POINT)

SUCTION AND 3/8 LIQUID LINE

Page 13

Performance

Data Heating Metric Units

O.D . HEATING CAP A CITY IN KILOWATTS AT TOTAL POWER IN KILOWATTS AT

TEMP. INDICATED INDOOR DRY BULB TEMP. INDICATED INDOOR DR Y B ULB TEMP.

C. 23.3 31.7 35.8 40.0 23.3 31.7 35.8 40.0

-27.8 2.33 2.26 2.22 2.18 1.62 1.69 1.72 1.75

-25.0 2.67 2.59 2.55 2.51 1.70 1.77 1.81 1.84

-22.2 3.02 2.92 2.87 2.82 1.78 1.86 1.90 1.93

-19.4 3.34 3.25 3.19 3.14 1.86 1.94 1.98 2.02

-16.7 3.69 3.57 3.52 3.46 1.94 2.03 2.07 2.12

-13.9 4.04 3.90 3.84 3.78 2.02 2.11 2.16 2.21

-11.1 4.37 4.25 4.16 4.10 2.10 2.20 2.25 2.30

-8.3 4.72 4.57 4.51 4.42 2.18 2.29 2.34 2.39

-5.6 5.27 5.10 5.04 4.95 2.26 2.37 2.42 2.47

-2.8 5.83 5.65 5.57 5.48 2.34 2.45 2.50 2.56

0.0 6.39 6.18 6.09 5.98 2.41 2.53 2.59 2.65

2.8 6.94 6.71 6.62 6.50 2.49 2.61 2.67 2.73

5.6 7.47 7.27 7.15 7.03 2.57 2.69 2.76 2.82

8.3 8.94 8.67 8.53 8.41 2.66 2.79 2.85 2.91

11.1 9.64 9.35 9.20 9.05 2.73 2.87 2.94 3.00

13.9 10.37 10.05 9.87 9.73 2.81 2.95 3.02 3.09

16.7 11.08 10.72 10.55 10.37 2.89 3.04 3.11 3.18

19.4 11.78 11.40 11.22 11.05 2.97 3.12 3.19 3.27

22.2 12.48 12.10 11.90 11.69 3.05 3.20 3.28 3.35

WCC040FD00B AT 0.63 CUBIC METERS/SEC

O.D. HEATING CAP A CITY IN KILOWATTS AT TOTAL POWER IN KILOWATTS AT

TEMP . INDICATED INDOOR DRY BULB TEMP. INDICATED INDOOR DRY BULB TEMP .

C. 23.3 31.7 35.8 40.0 23.3 31.7 35.8 40.0

-27.8 3.08 2.99 2.96 2.92 2.27 2.36 2.40 2.45

-25.0 3.55 3.43 3.40 3.34 2.35 2.45 2.49 2.54

-22.2 3.98 3.87 3.84 3.78 2.43 2.53 2.58 2.64

-19.4 4.42 4.31 4.25 4.19 2.51 2.62 2.67 2.73

-16.7 4.86 4.75 4.69 4.63 2.58 2.70 2.76 2.82

-13.9 5.33 5.19 5.13 5.07 2.66 2.79 2.85 2.91

-11.1 5.77 5.63 5.57 5.48 2.74 2.87 2.94 3.01

-8.3 6.21 6.07 5.98 5.92 2.82 2.96 3.03 3.10

-5.6 6.97 6.80 6.71 6.62 2.93 3.07 3.15 3.22

-2.8 7.74 7.56 7.44 7.35 3.04 3.19 3.26 3.34

0.0 8.50 8.29 8.17 8.06 3.14 3.30 3.38 3.46

2.8 9.26 9.02 8.91 8.79 3.25 3.42 3.50 3.58

5.6 10.02 9.76 9.64 9.49 3.36 3.53 3.62 3.70

8.3 11.87 11.54 11.40 11.22 3.48 3.66 3.75 3.84

11.1 12.80 12.45 12.28 12.13 3.59 3.78 3.87 3.96

13.9 13.74 13.36 13.18 13.01 3.70 3.89 3.99 4.09

16.7 14.68 14.30 14.09 13.89 3.81 4.01 4.11 4.21

19.4 15.62 15.21 15.00 14.77 3.92 4.13 4.23 4.33

22.2 16.55 16.11 15.88 15.68 4.03 4.24 4.35 4.46

WCC030FD00B AT 0.47 CUBIC METERS/SEC

CORRECTION FA CTORS - OTHER AIRFLOWS

(VALUE AT 0.47 CMS TIMES CORR. F A CTOR

AIRFLOW 0.41 0.53

HEATING CAP. X0.98 X1.02

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

AIRFLOW = 0.47 CMS

HEATING CAP. (HIGH TEMP.) = 8.67 KILOWATTS

HEATING CAP. (LOW TEMP.) = 4.57 KILOWA TTS

COMPR. POWER (HIGH TEMP.) = 2195 WATTS

COMPR. POWER (LO W TEMP.) = 1695 W ATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.12

COEFF. OF PERF. (LOW TEMP.) = 2.00

OUTDOOR FAN PO WER = 250 WATTS

INDOOR FAN PO WER = 340 WATTS

NOTE:RATED WITH 7.62 METERS OF 7/8

AIRFLOW 0.54 0.71

HEATING CAP. X0.98 X1.01

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

AIRFLOW = 0.63 CMS

HEA TING CAP . (HIGH TEMP .) = 11.55 KILO WA TTS

HEA TING CAP . (LO W TEMP.) = 6.07 KILOWA TTS

COMPR. POWER (HIGH TEMP.) = 2600 WATTS

COMPR. POWER (LO W TEMP.) = 1900 W ATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.18

COEFF. OF PERF. (LOW TEMP.) = 2.06

OUTDOOR FAN PO WER = 500 WATTS

INDOOR FAN PO WER = 560 WATTS

NOTE:RATED WITH 7.62 METERS OF 7/8

= VALUE AT NEW AIRFLOW)

21&8/6 (HIGH TEMP. POINT)

21&(-8)/(-9) (LOW TEMP. POINT)

SUCTION AND 3/8 LIQUID LINE

CORRECTION FA CTORS - OTHER AIRFLOWS

(VALUE AT 0.63 CMS TIMES CORR. F A CTOR

= VALUE AT NEW AIRFLOW)

21&8/6 (HIGH TEMP. POINT)

21&(-8)/(-9) (LOW TEMP. POINT)

SUCTION AND 3/8 LIQUID LINE

O.D. HEA TING CAP A CITY IN KILOW A TTS A T TOTAL PO WER IN KILOW A TTS A T

TEMP . INDICA TED INDOOR DR Y BULB TEMP . INDICATED INDOOR DRY BULB TEMP .

C. 23.3 31.7 35.8 40.0 23.3 31.7 35.8 40.0

-27.8 4.19 4.07 4.04 3.98 2.94 3.06 3.12 3.18

-25.0 4.92 4.81 4.75 4.69 3.09 3.23 3.30 3.36

-22.2 5.68 5.54 5.48 5.39 3.25 3.40 3.47 3.55

-19.4 6.42 6.27 6.18 6.09 3.41 3.57 3.65 3.73

-16.7 7.18 7.00 6.91 6.83 3.57 3.74 3.82 3.91

-13.9 7.91 7.71 7.62 7.53 3.72 3.91 4.00 4.09

-11.1 8.64 8.44 8.35 8.23 3.88 4.08 4.17 4.27

-8.3 9.41 9.17 9.05 8.94 4.04 4.25 4.35 4.45

-5.6 9.93 9.70 9.58 9.46 4.08 4.29 4.39 4.50

-2.8 10.49 10.23 10.11 9.96 4.12 4.33 4.44 4.54

0.0 11.05 10.75 10.61 10.49 4.16 4.37 4.48 4.59

2.8 11.57 11.28 11.13 10.99 4.20 4.42 4.53 4.63

5.6 12.13 11.81 11.66 11.51 4.24 4.46 4.57 4.68

8.3 16.11 15.70 15.50 15.29 4.69 4.94 5.06 5.19

11.1 17.23 16.79 16.58 16.35 4.80 5.06 5.18 5.31

13.9 18.34 17.87 17.64 17.40 4.91 5.17 5.30 5.43

16.7 19.48 18.99 18.72 18.46 5.02 5.29 5.42 5.55

19.4 20.60 20.07 19.81 19.54 5.13 5.40 5.54 5.68

22.2 21.71 21.15 20.86 20.60 5.24 5.52 5.66 5.80

IPB-99-7-EN-10-6-99 13

WCC050FD00B A T 0.79 CUBIC METERS/SEC

CORRECTION FA CTORS - O THER AIRFLOWS

(VALUE AT 0.79 CMS TIMES CORR. F ACT OR

AIRFLOW 0.69 0.89

HEATING CAP. X0.99 X1.01

COMPR. KW X1.02 X0.98

VALUES AT ARI RATING CONDITIONS OF:

21&8/6 (HIGH TEMP. POINT)

21&(-8)/(-9) (LOW TEMP. POINT)

AIRFLOW = 0.79 CMS

HEA TING CAP . (HIGH TEMP .) = 15.71 KILO WA TTS

HEA TING CAP . (LO W TEMP.) = 9.17 KILOWA TTS

COMPR. POWER (HIGH TEMP.) = 3760 WATTS

COMPR. POWER (LO W TEMP.) = 3065 W ATTS

COEFF. OF PERF. (HIGH TEMP.) = 3.18

COEFF. OF PERF. (LOW TEMP.) = 2.16

OUTDOOR FAN PO WER = 500 WATTS

INDOOR FAN PO WER = 680 WATTS

NOTE:RATED WITH 7.62 METERS OF 7/8

= V ALUE A T NEW AIRFLO W)

SUCTION AND 3/8 LIQUID LINE

Page 14

Performance

Data

Indoor Blower Performances WCC030FD

Air Flow

CFM (CMH)

[2]

750 (1270) 0.58 (145) 220 0.17 0.43 (107) 218 0.17

790 (1335) 0.56 (140) 227 0.17 0.39 (97) 225 0.18

830 (1400) 0.53 (132) 234 0.18 0.34 (85) 231 0. 19

880 (1490) 0.50 (125) 241 0.1 9 0.28 (70) 239 0.20

920 (1554) 0.47 (117) 247 0.20 0.20 (50) 247 0.21

960 (1622) 0.44 (110) 254 0.20 0.10 (25) 254 —

1000 (1690) 0.40 (100) 260 0.21 — — —

1040 (1757) 0.36 ( 90) 267 0.21 — — —

1080 (1825) 0.32 (80) 274 0.22 — — —

1130 (1910) 0.26 (65) 281 0.23 — — —

1170 (1977) 0.21 (52) 287 0.24 — — —

1210 (2045) 0.13 (32) 293 0.24 — — —

1250 (2112) 0.05 (12) 300 0.25 — — —

High Speed [1] Low Speed

Press IN.

W.G.

(PA)

PWR

Watts

BHP

Press IN.

W.G. (PA)

PWR

Watts

BHP

———————

———————

———————

———————

———————

———————

[1] Factory setting at HI speed [2] Wet coil, no filter, no heater

Indoor Blower Performances WCC050FD

Air Flow

CFM (CMH)

[2]

1170 (1980) 0.73 (184) 431 0. 33 0.60 (150) 414 0.29

1210 (2050) 0.70 (175) 440 0.34 0. 55 ( 137) 423 0.29

1250 (2120) 0.67 (167) 450 0.35 0. 51 ( 127) 432 0.29

1290 (2180) 0.65 (163) 459 0.36 0. 47 ( 117) 442 0.28

1330 (2250) 0.63 (157) 469 0.38 0. 42 ( 105) 451 0.28

1380 (2340) 0.59 (148) 478 0.39 0.39 (97) 460 0.27

1420 (2400) 0.56 (140) 488 0.40 0.35 (87) 469 0.27

1460 (2470) 0.53 (132) 498 0.41 0.31 (77) 479 0.27

1500 (2540) 0.51 (127) 508 0.42 0.28 (70) 488 0.2 6

1540 (2600) 0.48 (120) 519 0.43 0.24 (60) 497 0.2 5

1580 (2670) 0.44 (110) 530 0.44 0.21 (52) 506 0.2 5

1630 (2760) 0.40 (100) 541 0.45 0.17 (42) 516 0.24

1670 (2830) 0.37 (92) 552 0.46 0.14 (35) 525 0.23

1710 (2890) 0.33 (83) 563 0.47 0.10 (25) 534 0.23

1750 (2960) 0.28 (70) 575 0.47 0.07 (17) 544 0.23

1790 (3025) 0.24 (60) 588 0.48 — — —

1830 (3090) 0.19 (45) 601 0.49 — — —

1880 (3180) 0.15 (37) 608 0.49 — — —

1920 (3250) 0.11 (27) 620 0.50 — — —

1960 (3315) 0.07 (17) 631 0.52 — — —

[1] Factory setting at HI speed [2] Wet coil, no filter, no heater

High Speed [1] Low Speed

Press IN.

W.G. (PA)

PWR

Watts

BHP

Press IN.

W.G. (PA)

PWR

Watts

BHP

Indoor Blower Performances WCC040FD

Air Flow

CFM (CMH)

[3]

1000 (1690) — — — 0.69 (172) 356 0.27

1040 (1757) — — — 0.67 (167) 365 0.27

1080 (1825) — — — 0.64 (160) 373 0.28

1130 (1910) — — — 0.60 (150) 381 0.28

1170 (1977) 0.73 (183) 431 0.3 3 0. 57 ( 142) 389 0.29

1210 (2045) 0.70 (175) 440 0.34 0.5 3 (1 32) 398 0.29

1250 (2112) 0.67 (167) 450 0.35 0.4 9 (1 22) 40 7 0.29

1290 (2180) 0.65 (162) 459 0.36 0.4 5 (1 12) 41 7 0.29

1330 (2247) 0.63 (157) 469 0.38 0.4 0 (1 00) 42 7 0.29

1380 (2332) 0.59 (147) 478 0.39 0.35 (87) 437 0.28

1420 (2400) 0.56 (140) 488 0.40 0.28 (70) 448 0.28

1460 (2467) 0.53 (132) 498 0.41 0.19 (47) 463 0.26

1500 (2535) 0.50 (125) 508 0.42 0.10 (25) 479 0.24

1540 (2602) 0.47 (117) 518 0.43 0.01 (2.5) 49 5 0.23

1580 (2670) 0.44 (110) 528 0.44 — — —

1630 (2755) 0.41 (102) 537 0.45 — — —

1670 (2825) 0.38 (95) 547 0.46 — — —

1710 (2890) 0.35 (87) 557 0.47 — — —

1750 (2958) [2] 0.31 (77) 567 0.48 — — —

[1] Factory setting at LO speed

[2] Water Blow Off Unit

High Speed Low Speed [1]

Press IN.

W.G.

(PA)

PWR

BHP

Watts

[3] Wet coil, no filter, no heater

Press IN.

W.G. (PA )

PWR

Watts

BHP

14 IPB-99-7-EN-10-6-99

Page 15

Optional

Equipment

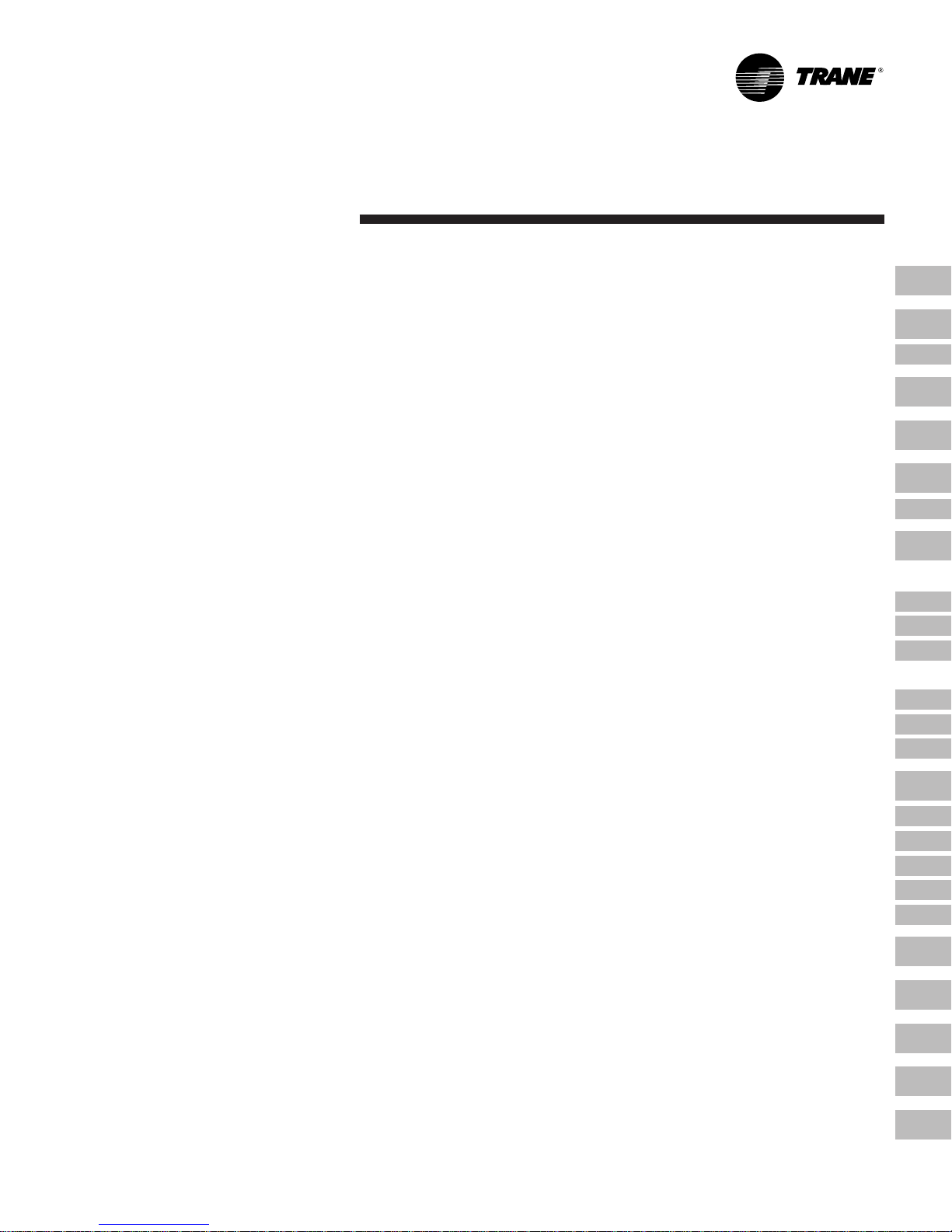

25% Manual Fresh Air Kit

T ypical Filter Frame

IPB-99-7-EN-10-6-99 15

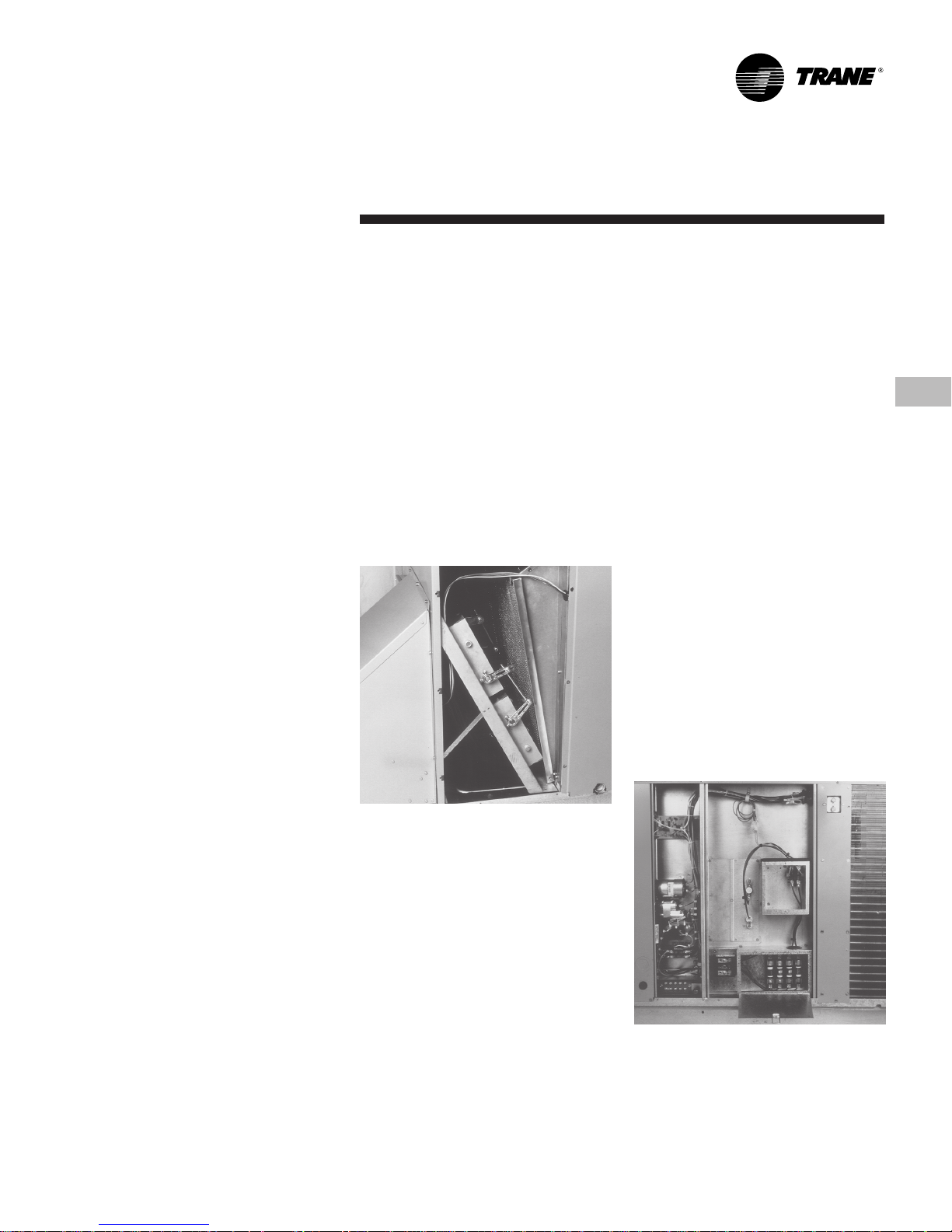

Page 16

Optional

Equipment

Economizer and Rain Hood

(Downflow Applications)

ALL DIMENSIONS ARE IN INCHES (MM)

Thermostats

Two stages heating/cooling or one stage

heating/cooling thermostats are available in

either manual or automatic changeover.

Programmable Electronic

Night Setback Thermostat

Heating setback and cooling setup with 7-day,

5-1-1 programming capability. Available in

2 heating/cooling or 1 heating/cooling

versions with automatic changeover.

ECONOMIZER

MODEL

BA YEC ON054B WCC030F

BA YEC ON055B

APPLICATION

MODELS

WCC040F

WCC050F20(500)21(533)26(660)

ABC D E FGH

20

16-5/8

(500)

(420)

Controls

Field Installed Control Options

Economizer Controls

The standard equipment offering is a fixed dry

bulb changeover control. In addition to the

standard offering, there are two other field

installed control accessories.

Enthalpy Control

Replaces the dry bulb control with a solid

state dry bulb and wet bulb changeover

controller which has a fully adjustable set

point. Enthalpy control offers a higher level of

23-1/2

22-9/16

(600)

energy savings potential than the standard

dry bulb control due to the additional wet bulb

sensing capability.

Differential Enthalpy

Replaces the standard dry bulb control with

two enthalpy sensors that compare total heat

content of the indoor air and outdoor air to

determine the most efficient entering air

source. This control option offers the highest

level of energy efficiency available.

(575)

OMIT

8-5/8

22-1/4

(565)

26-1/8

(670)

25-1/8

(640)

32-1/8

(820)

(220)

12-1/8

(315)

From Dwg. 21D662389 Rev.1

1-1/2

(38)

1-3/4

(45)

16 IPB-99-7-EN-10-6-99

Page 17

Field

Wiring

WCC-F Heat Pump Models

NOTES:

1. FUSED DISCONNECT SIZE, POWER WIRING AND

GROUNDING OF EQUIPMENT MUST COMPLY

WITH CODES.

2. BE SURE POWER SUPPLY AGREES WITH

EQUIPMENT AND HEATER NAMEPLATE.

3. LOW VOLTAGE WIRING TO BE 18 AWG MINIMUM

CONDUCTOR.

4. SEE HEATER NAMEPLATE FOR CURRENT

RATING OF HEATER USED.

5. SEE UNIT AND HEATER DIAGRAM FOR

ELECTRICAL CONNECTION DETAILS.

6. IF ELECTRIC HEATER ACCESSORY IS NOT

INSTALLED OMIT THE ELECTRIC HEATER,

ASSOCIATED POWER WIRES AND THE ‘W’ AND

‘X2’ THERMOSTAT WIRES.

7. FIG. 3 DEMONSTRATES CONNECTION OF THE

OUTDOOR THERMOSTAT ACCESSORY ONLY.

FOR FURTHER UNIT CONNECTION DETAILS

REFER TO THE OTHER FIGURES.

8. THE 41A(BR) WIRE IS FIRST STAGE ELECTRIC

HEAT. IF THE ELECTRIC HEATER ACCESSORY

HAS TWO HEATING STAGES THE 41C(BR) WIRE

IS SECOND STAGE ELECTRIC HEAT.

9. WHEN THE BAYECON054A OR –055A

ECONOMIZER IS INSTALLED THE BAYRLAY003

RELAY ACCESSORY KIT IS REQUIRED TO

INTERFACE THE ECONOMIZER TO THE HEAT

PUMP FOR PROPER SYSTEM OPERATION.

WHEN THE BAYECON054B OR –055B OR 073A

ECONOMIZER IS INSTALLED, THE BAYRLAY004A

RELAY ACCESSORY KIT IS REQUIRED TO

INTERFACE THE ECONOMIZER TO THE HEAT

PUMP FOR PROPER SYSTEM OPERATION.

10. THE BAYSTAT033A OUTDOOR THERMOSTAT

ACCESSORY KIT CONTAINS A THERMOSTAT

AND A RELAY. THE RELAY IS NOT REQUIRED

TO BE USED IN THIS APPLICATION.

IPB-99-7-EN-10-6-99 17

From Dwg. 21D756978

Page 18

Field

Wiring

Wiring Diagram for WCC030,040,050FD00B Units

continued on next page

18 IPB-99-7-EN-10-6-99

From Dwg. 21D756914 P03

Page 19

Field

Wiring

Wiring Diagram for WCC030,040,050FD00B Units

IPB-99-7-EN-10-6-99 19

From Dwg. 21D756914 P03

Page 20

Dimensions

BAYCURB030A Roof Curb Outline With WCC030F Units

ALL DIMENSIONS ARE IN INCHES (MM)

MODEL NO.

WCC030F

WCC040F

WCC050F

All dimensions are in inches (mm).

AIR DUCT

OPENINGS

SUPPLY 21 (533) 16-3/4 ( 425) — —

RETURN — — 21 (533) 21-1/8 (540)

SUPPLY 21 (533) 19 (483) — —

RETURN — — 21 (533) 22-1/8 (565)

Required Clearance for Unit Installation and Roof Penetration Hole Size Required

INSULATED DECK PANS

ARE INCLUDED WITH THE

BAYCURB038A ONLY.

34

(865)

21

(533)

1

(38)

1

/

(790)

2

31

1

(38)

1

(38)

1

/

2

1

/

2

ABCD

ALL DIMENSIONS ARE IN INCHES (MM)

A

SUPPLY

1

/

4

(108)

1

53

/

(1350)

1

/

8

50

(1275)

B

D

RETURN

2

1

1

(38)

C

/

2

1

/

1

(38)

8

(38)

2

1

1

/

2

This member used

on WCC030F

models only

8

(200)

1

/

2

1

(38)

34

(865)

8

(222)

13

/16

(2.1)

14

3

/4

(355)

11/4

(32)

From Dwg. 21C729942

SERVICE CLEARANCE & PENETRATION DIMENSIONS

MODEL NO. A B C D E F

42"

30"

*12"

30"

WCC030F

WCC040F

WCC050F

* 18" (457) WITH 25% FRESH AIR ACCESSORY

30" (762) WITH ECONOMIZER

(1067)

42"

(1067)

(762)

30"

(762)

(305)

*12"

(305)

(762)

36"

(915)

44"

(1117)

50"

(1270)

25"

(635)

25"

(635)

From Dwg. 21C662039

20 IPB-99-7-EN-10-6-99

Page 21

BAYCURB034A Roof Curb Outline With WCC040,050F Units

MODEL NO.

WCC040F

WCC050F

All dimensions are in inches (mm).

AIR DUCT

OPENINGS

SUPPLY

RETURN

ABC

21

(533)19(482)

21

(533)

—

—

22-1/8

(565)

Dimensions

ALL DIMENSIONS ARE IN INCHES (MM)

1

1

/

11/

(38)

2

(32)

A

SUPPLY

4

43

(1090)

12

(305)

1

62

/

16

(1575)

11/

2

(38)

1

/2 (114)

A

RETURN

13

/

16

(21)

4

C

B

11/

2

(38)

7

17

(450)

40

(1015)

/

8

1

/

1

(38)

1

(38)

From Dwg. 21C662034

14

(355)

2

1

/

2

Required Clearance for Unit Installation and Roof Penetration Hole Size Required

SERVICE CLEARANCE DIMENSIONS

MODEL NO. A B C D

WCC040F

WCC050F

* 18" (457) WITH 25% FRESH AIR ACCESSORY

30" (762) WITH ECONOMIZER

42"

(1070)

30"

(815)

*6"

(150)

36"

(915)

ALL DIMENSIONS ARE IN INCHES (MM)

50"

(1270)

25"

(635)

From Dwg. 21C662039

IPB-99-7-EN-10-6-99 21

Page 22

Dimensions

Field Fabricated (Side X Side) Ducts — WCC030-050F Units

Installed from Above Mounting Curb

ALL DIMENSIONS ARE IN INCHES (MM)

P.V .C. Rubber Gasket Position on B AYCURB030A for Unit Placement — WCC030-050F Units

NOTES:

1. OVERLAP AND POSITION JOINTS IN P.V.C. RUBBER

GASKET.

2. AIR SEALS – APPLY P.V.C. RUBBER LAST TO INSURE

THERE IS ADEQUATE P.V.C. FOR THE WATER SEAL.

3. USE TYPICAL SEALING METHODS TO PREVENT AIR

DUCT LEAKAGE AT CURB-DUCT JOINT.

ALL DIMENSIONS ARE IN INCHES (MM)

22 IPB-99-7-EN-10-6-99

Page 23

Dimensions

WCC030-050F OUTLINE DRA WING — Fr ont

ALL DIMENSIONS ARE IN INCHES (MM)

CABINET

SIZE

"B"

"D"

"D"

IPB-99-7-EN-10-6-99 23

MODEL BAYCURB "A" "B" "C" "D" "E" "F" "G" "H"

WCC030F 030A

WCC040F

WCC050F

WCC040F

WCC050F

030A

034A

14-1/8

(360)

14-13/16

(380)

14-13/16

(380)

16-5/8

(425)36(915)34(865)

21

(535)45(1145)34(865)

21

(533)45(1145)43(1092)

29-3/16

(740)

33-3/8

(850)

33-3/8

(850)

13-3/4

(350)

13-3/4

(350)

13-3/4

(350)

——

10-1/8

(261)

——

From Dwg. 21D661772

9-7/8

(251)

Page 24

Dimensions

WCC030-050F OUTLINE DRA WING — Fr ont

ALL DIMENSIONS ARE IN INCHES (MM)

MODELABCDE F

WCC030F

WCC040F

WCC050F

55-1/4

(1405)

64-5/16

(1634)45(1145)

36

(915)

29-3/16

(740)

33-3/8

(850)

12-15/16

(330)

14-13/16

(375)

4-7/8

(122)

4-7/8

(122)

24 IPB-99-7-EN-10-6-99

KNOCKOUTS FOR 3/4" (20) AND 1-1/4" (32 ) CONDUI T

KNOCKOUTS FOR 3/4" (20) AND 1-1/2" (38 ) CONDUI T

From Dwg. 21D729945 Rev. 5

Page 25

13/8

(35)

Dimensions

WCC030-050F OUTLINE DRAWING — Rear

ALL DIMENSIONS ARE IN INCHES (MM)

MODEL

WCC030F

WCC040F

WCC050F

1

/4 (6)

1

/2 (12)

CORNER WEIGHT LBS (KG)

W1 W2 W3 W4

94

(43)73(33)80(36)

126

104

(57)

(47)

131

108

(59)

(49)

127

(58)

132

(60)

104

(47)

153

(70)

159

(72)

UNIT

WEIGHT

LBS (KG)

318

(144)

486

(220)

504

(229)

11/8

(30)

CONDENSATE DRAIN

FOR 3/4" (19) FEMALE NPT

3 (75)

3

/4 (19)

5

(16)

/8

3

(19)

/4

ABC D E F G H J K LMNP

55-1/4

(1400)36(915)

64-5/16

(1634)45(1145)

29-3/16

(750)

33-3/8

(846)

18-9/16

(470)

21-1/16

(535)

11-1/16

(280)

15-1/16

(385)

6-9/16

(170)

4-15/16

(120)

6-13/16

(170)17(430)

9-1/8

21-15/16

(230)

(550)

18-13/16

(465)24(610)

24-3/4

(628)29(736)

24-3/4

(628)29(736)

17-1/2

(445)10(250)3(75)

20

(500)14(350)

3-1/2

(90)

4-7/16

(115)

8-5/16

(210)

From Dwg. 21D729988 Rev. 10

IPB-99-7-EN-10-6-99 25

Page 26

Mechanical

Specification Options

General

The units shall be horizontal airflow as

shipped and convertible to downflow. All units

shall be factory assembled, piped, internally

wired and fully charged with R-22. Units shall

be UL listed and carry a UL label. All units

shall be factory run tested to check cooling

operation, fan and blower rotation and control

sequence. Units shall be designed to operate

at ambient temperatures between 115°F and

55°F in cooling as manufactured. Cooling

performance shall be rated in accordance

with ARI standards.

Unit Casing

All components shall be mounted in a

weather-resistant steel cabinet with an

enamel finish. Access panels shall be

provided for unit controls and indoor coil and

fans. Indoor air section compartment shall be

completely insulated with fireproof, permanent, odorless glass fiber material. Knockouts

shall be provided for utility and control

connections. Drain connections shall be

provided to accommodate indoor water runoff.

Compressor

The compressor shall be a hermetically

sealed, high efficiency Climatuff® compressor.

Internal overcurrent and over temperature

protection, internal pressure relief shall be

standard. Crankcase heaters shall be

standard on all three phase models.

Refrigeration System

All units shall have capillary tube refrigerant

control. Service pressure tap ports, and a

refrigerant line filter dryer shall be standard.

Indoor and Outdoor Coils

Coils shall be internally finned or smooth bore

3/8" copper tubes mechanically bonded to

configured aluminum plate fin as standard.

Evaporator coil leak and pressure tested to

200 psig; condenser coil tested to 450 psig.

Indoor Fan

The indoor fan shall be a forward curved,

centrifugal-type fan with a multiple-speed,

direct drive motor. Motor is permanently

lubricated and shall have built-in overload

protection.

Outdoor Fan

One, direct-drive, statically and dynamically

balanced propeller fan shall be used in a

draw-through vertical discharge configuration.

Permanently lubricated weather proof motor

shall have built-in thermal overload protection.

System Controls

System controls include condenser fan,

evaporator fan and compressor contactors.

Accessories

Roof Curb — The roof curb shall be designed

to mate with the unit and provide support and

complete weathertight installation when

properly installed. Adhesive back polyurethane sealing strips shall be provided to

ensure an airtight seal between supply and

return openings of the curb and unit. The roof

curb design allows field fabricated ductwork to

be connected directly to the curb. Curb ships

knocked down for field assembly, and includes

factory-installed wood nailer strips.

Fully Modulating Economizer — This

accessory shall be field installed and be

composed of the following items: 0-100%

fresh air damper, damper drive motor, fixed

dry bulb enthalpy control, and low voltage

pigtails for electrical connections. Solid state

enthalpy or differential enthalpy control is

optional. Economizer operations shall be

controlled by the preset position of the

enthalpy control. A barometric relief damper

shall be standard with the economizer and

provide a pressure operated damper that shall

be gravity closing and prohibit entrance of

outside air on equipment “off” cycle.

Manual Outside Air Dampers — Rain hood

and screen shall be field installed. Suitable for

up to 25% outside air.

Anti-Short Cycle Timer — Timed off device

that ensures a minimum of five minutes off

between compressor cycles.

Control Options

Standard Indoor Thermostats — T wo stage

heating/cooling or one stage heating/cooling

thermostats shall be available in either manual

or automatic changeover.

Programmable Electronic Night Setback

Thermostat — Programmable electronic

thermostat shall provide heating setback and

cooling setup with 7-day, programming

capability. 1H/1C or 2H/2C models available.

26 IPB-99-7-EN-10-6-99

Page 27

Notes

IPB-99-7-EN-10-6-99 27

Page 28

The Trane Company

Trane International Unitary Systems

1789 Chaussée de Wa vre

1160 Brussels

Belgium

www.trane.com

An American Standard Company

File Number P.I.

Supersedes

Stocking Location

Since The Trane Company has a policy of continuous product improvement, it reserves the right to change

design and specifications without notice.

IPB-99-7-EN-10-6-99

IPB-92-6

P.I.-L

Loading...

Loading...